Hydrogen maker by direct alcohol electrolyzation and its integrated unit

A direct, electrolytic cell technology, applied in the electrolysis process, electrolysis components, etc., can solve the problem of high power consumption for hydrogen production by electrolysis of water, achieve the effect of improving activity and anti-poisoning ability, and increasing output rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

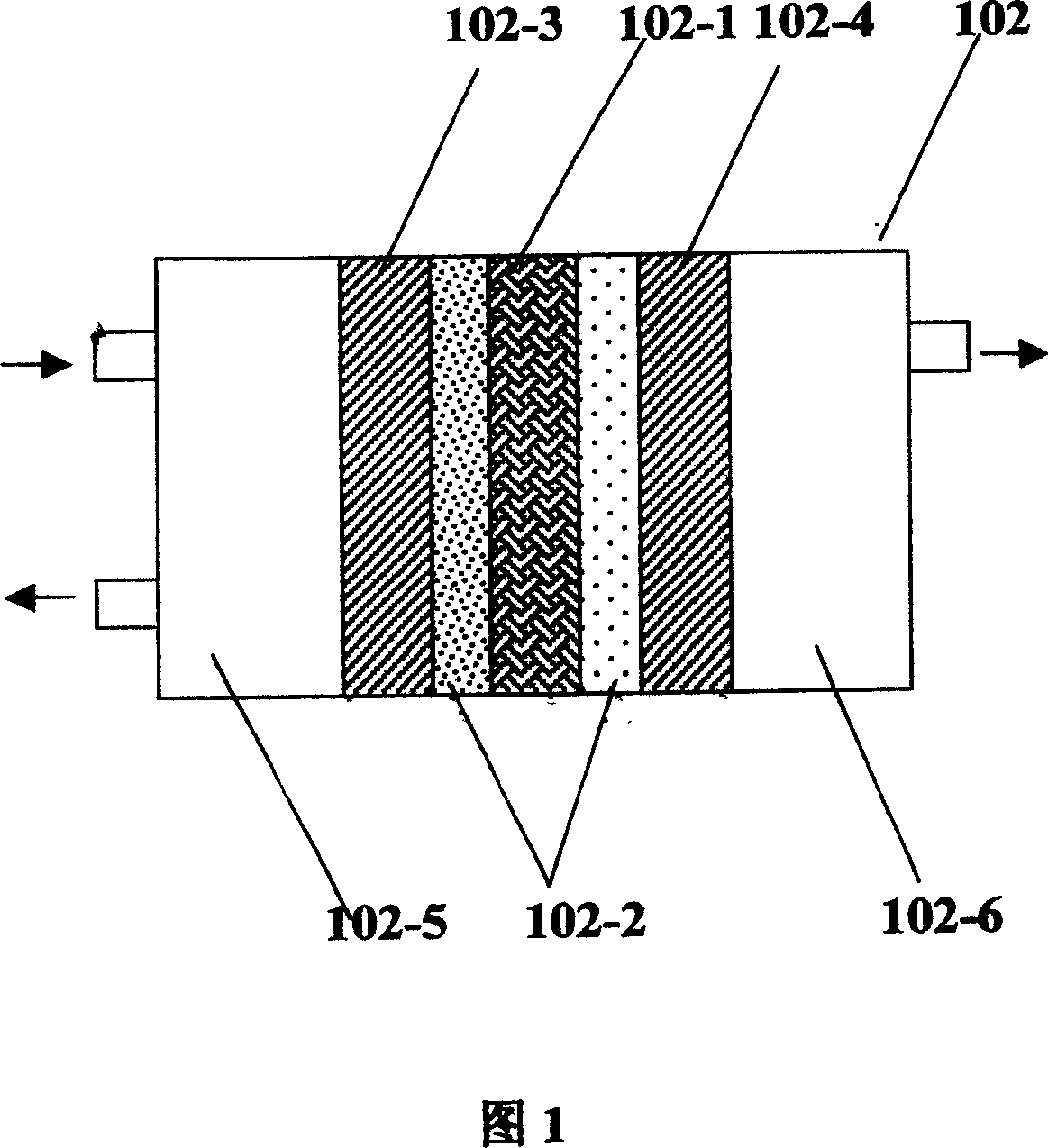

Method used

Image

Examples

Embodiment 1

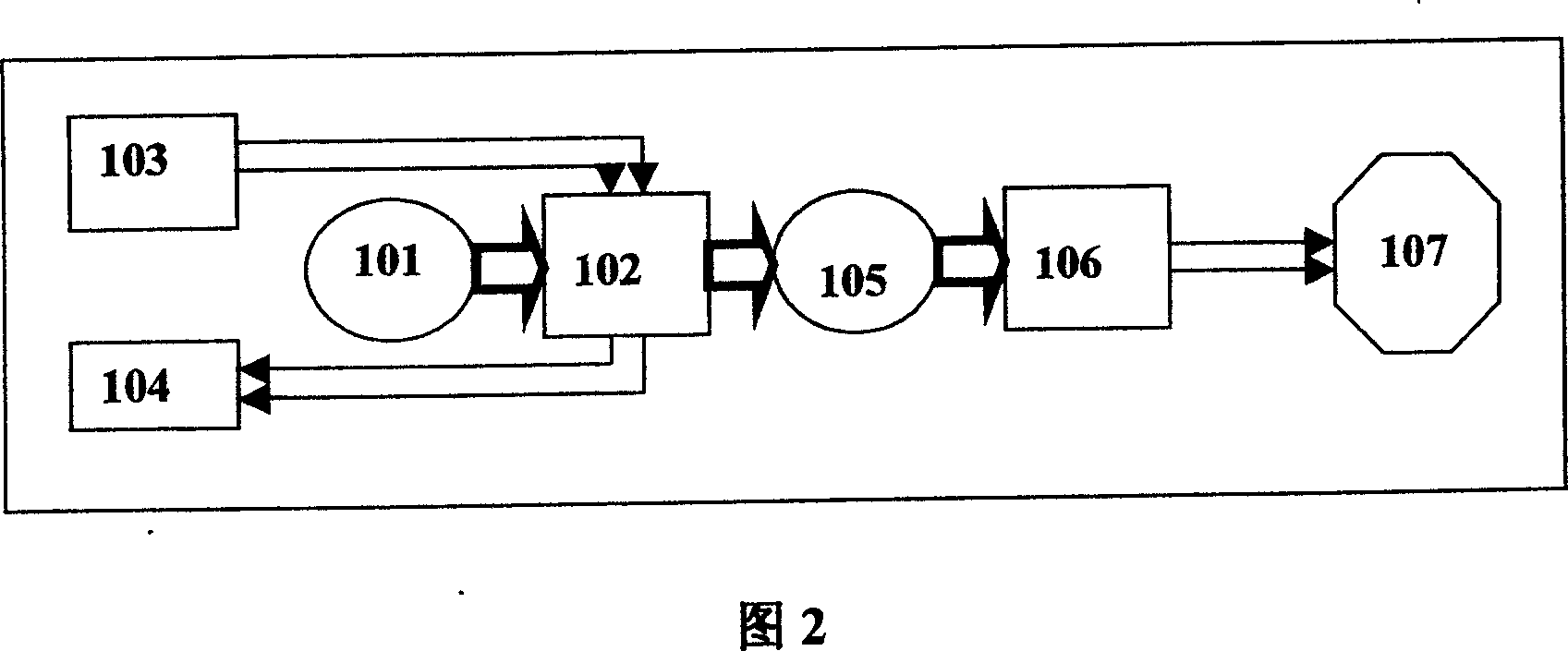

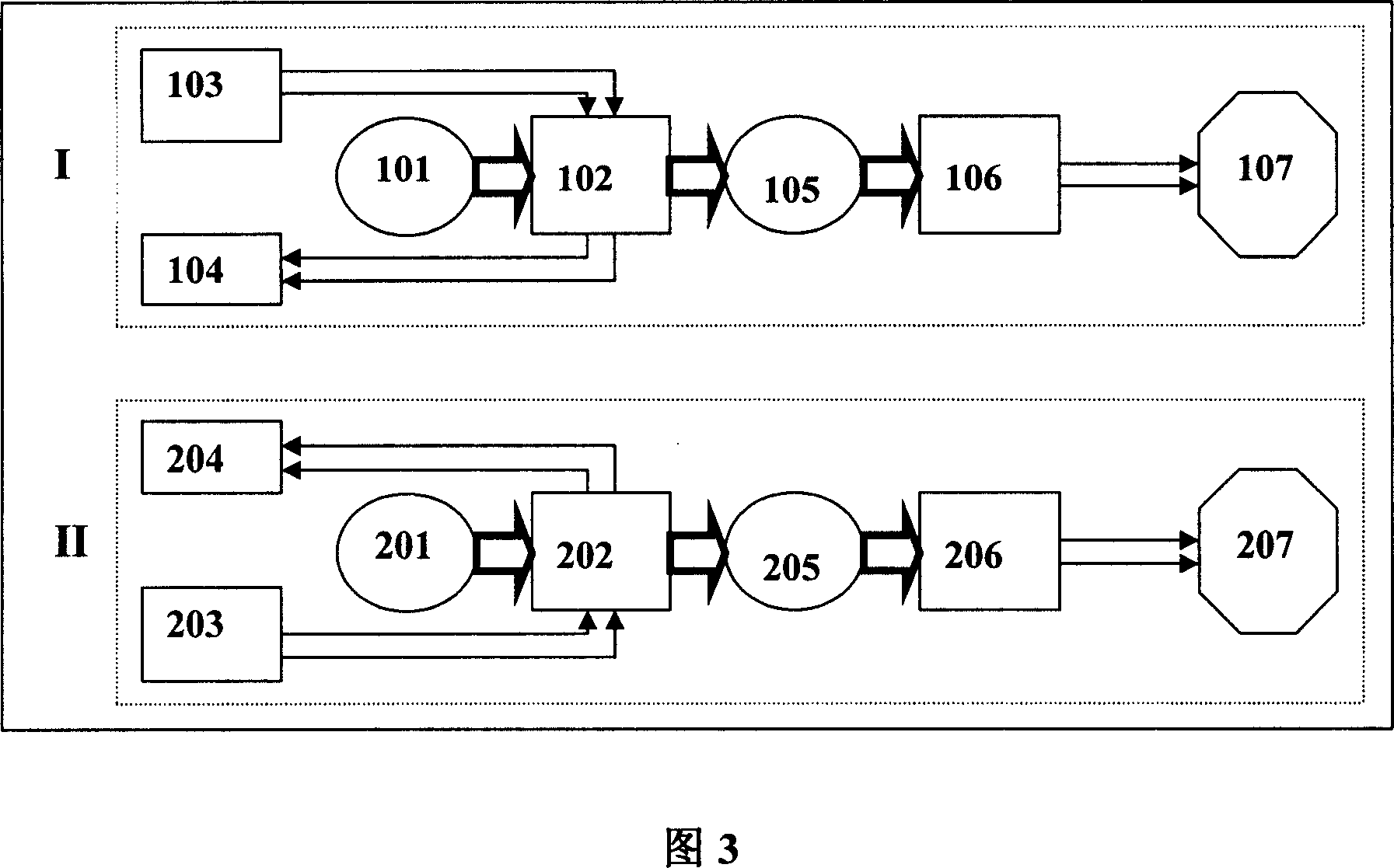

[0042] The integrated device is composed of alcohol or water container 101,201, hydrogen generator 102,202, hydrogen gas collecting device 105,205, DC regulated power supply 103,203 and test and control system 104,204. The material used in 101 is glass, and the material used in 201 is plexiglass. The hydrogen collecting device 105, 205 is made of plexiglass. 103 and 203 are DC power supplies for AC transformation, and test and control systems 104 and 204 are digital voltage display meters and electronic circuits.

Embodiment 2

[0044] The integrated device is composed of alcohol or water container 101,201, hydrogen generator 102,202, hydrogen gas collecting device 105,205, DC regulated power supply 103,203 and test and control system 104,204. The material used in 101,201 is polytetrafluoroethylene. The hydrogen collecting device 105, 205 is made of glass. 103 and 203 are DC power supplies for AC transformation, and test and control systems 104 and 204 are digital voltage display meters and electronic circuits.

Embodiment 3

[0046] The integrated device is composed of alcohol or water container 101,201, hydrogen generator 102,202, hydrogen gas collecting device 105,205, DC regulated power supply 103,203 and test and control system 104,204. The material used in 101 is glass, and the material used in 201 is plexiglass. The hydrogen collecting device 105, 205 is made of glass. The DC power sources 103 and 203 are solar cells, and the test and control systems 104 and 204 are digital voltage display meters and electronic circuits.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com