Preparation method and application of PdRh catalyst for fuel cell

A fuel cell and catalyst technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of anti-poisoning ability and stability to be further improved, and achieve excellent catalytic oxidation performance of methanol, good catalytic stability, and mild reaction conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Take 1.0 g of P123 and dissolve it in 10 mL of double distilled water with stirring and ultrasonic; take 10.21 mg of potassium chloropalladate and stir and ultrasonically dissolve it in 10 mL of double distilled water; then take 5.51 mg of rhodium chloride and dissolve it in 10 mL of double distilled water Finally, mix the above three solutions evenly.

[0036] (2) Transfer the mixed solution to the liner of a 50 mL polytetrafluoroethylene reactor, put it into the reactor, place it in a drying oven, and react at 180°C for 10 hours to stop the reaction.

[0037] (3) After naturally cooling to room temperature, the reaction solution was centrifuged at 10,000 r / min, washed 3 to 5 times with twice distilled water and absolute ethanol, then dispersed and stored in absolute ethanol to obtain the PdRh catalyst.

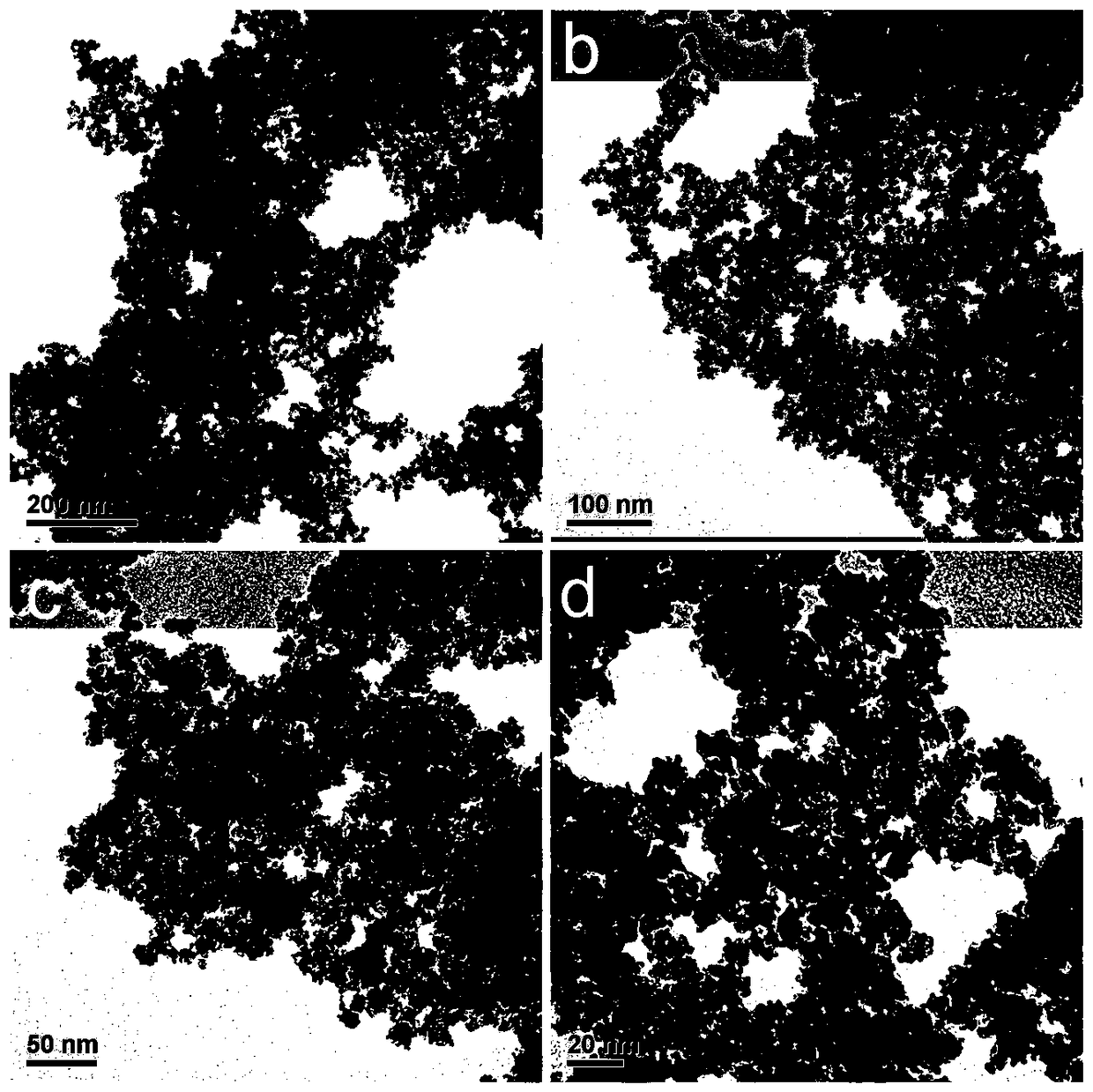

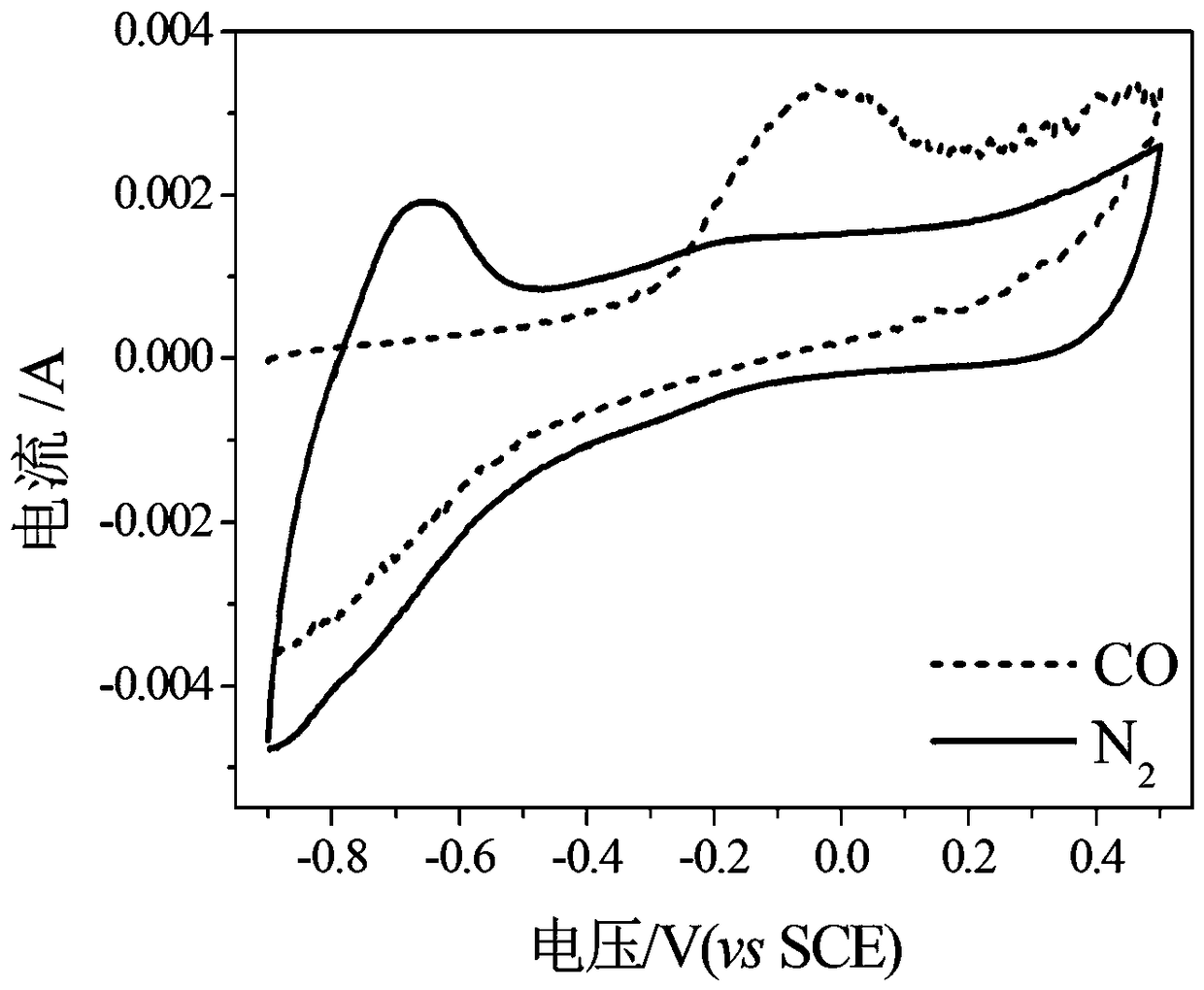

[0038] figure 1Shown is the transmission electron microscope figure of the fuel cell PdRh catalyst prepared by the present embodiment, by figure 1 It can be se...

Embodiment 2

[0042] (1) Take 1.0 g P123 and 22.10 mg KI and dissolve them in 10 mL of double distilled water with stirring and ultrasonic; take 10.23 mg of potassium chloropalladate and stir and ultrasonically dissolve them in 10 mL of double distilled water; then take 5.90 mg of rhodium chloride and dissolve them in 10 mL mL of double distilled water, and finally mix the above three solutions evenly.

[0043] (2) Transfer the mixed solution to the liner of a 50 mL polytetrafluoroethylene reactor, put it into the reactor, place it in a drying oven, and react at 180°C for 10 hours to stop the reaction.

[0044] (3) After naturally cooling to room temperature, the reaction solution was centrifuged at 10,000 r / min, washed 3 to 5 times with twice distilled water and absolute ethanol, then dispersed and stored in absolute ethanol to obtain the PdRh catalyst.

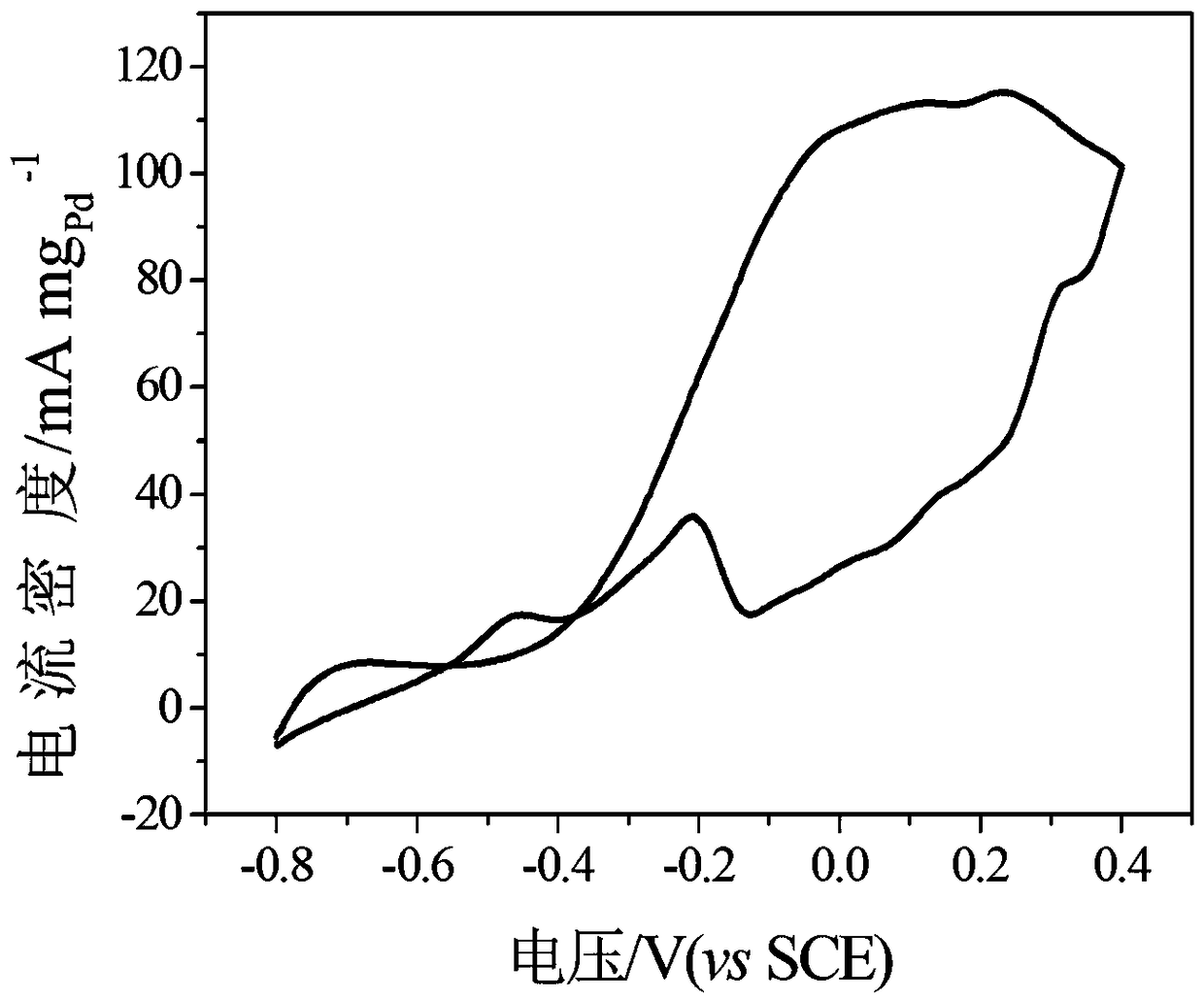

[0045] Figure 4 Shown is the transmission electron microscope figure of the fuel cell PdRh catalyst prepared by the present embodimen...

Embodiment 3

[0049] (1) Take 1.0 g P123 and 40.42 mg KI and dissolve them in 10 mL of double distilled water with stirring and ultrasonic; take 10.42 mg of potassium chloropalladate and dissolve them in 10 mL of double distilled water with stirring and ultrasonic; then take 5.84 mg of rhodium chloride and dissolve them in 10 mL mL of double distilled water, and finally mix the above three solutions evenly.

[0050] (2) Transfer the mixed solution to the liner of a 50 mL polytetrafluoroethylene reactor, put it into the reactor, place it in a drying oven, and react at 180°C for 10 hours to stop the reaction.

[0051] (3) After naturally cooling to room temperature, the reaction solution was centrifuged at 10,000 r / min, washed 3 to 5 times with twice distilled water and absolute ethanol, then dispersed and stored in absolute ethanol to obtain the PdRh catalyst.

[0052] Figure 7 Shown is the transmission electron microscope figure of the fuel cell PdRh catalyst prepared by the present embo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com