Graphene-based catalyst as well as preparation method and application thereof

An alkene-based catalyst and graphene-based technology, applied in electrochemical generators, fuel cells, electrical components, etc., can solve the problems of agglomeration growth, Pt catalyst failure, migration and merger, etc., and achieve simple catalytic activity and anti-poisoning ability High, avoid the effect of migration and merger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

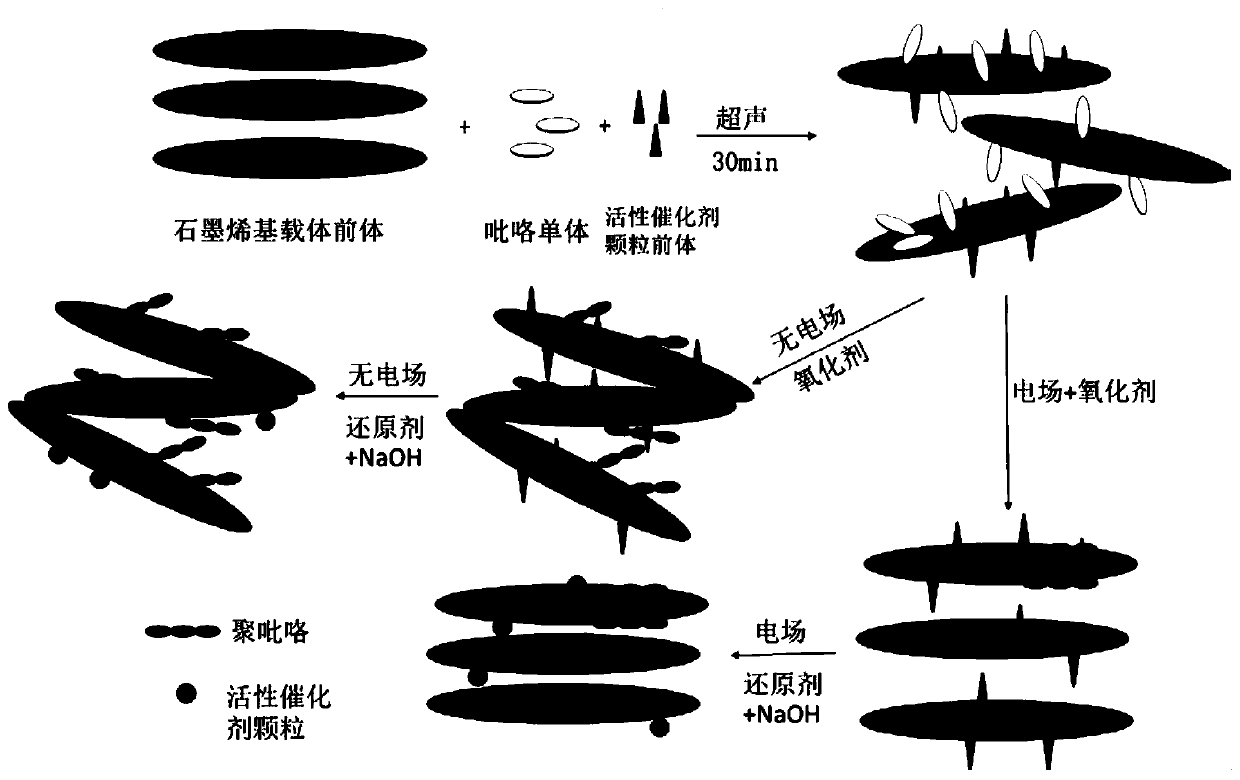

[0066] Two of object of the present invention is to provide a kind of preparation method of above-mentioned graphene-based catalyst, with reference to figure 1 , including the following procedures:

[0067] 1) Provide graphene-based carrier precursor, active catalyst particle precursor and pyrrole.

[0068] The graphene-based carrier precursor can be at least one of graphene, graphene oxide and nitrogen-doped graphene, preferably, the graphene-based carrier precursor is graphene oxide or nitrogen-doped graphene, which has higher activity , can provide greater adsorption and make the catalyst more stable.

[0069] When the active catalyst particle is a platinum group noble metal active catalyst particle, the precursor of the active catalyst particle may be a salt or an acid containing a platinum group noble metal.

[0070] When the active catalyst particles are platinum group noble metal alloy active catalyst particles, the precursor of the active catalyst particles includes ...

Embodiment 1

[0091] 1) Weigh 3.78g of graphene oxide, dissolve it in 50mL of water, ultrasonically disperse for 30min, and the ultrasonic frequency is 20KHZ, to obtain an aqueous solution of graphene oxide;

[0092] 2) Weigh 0.4g of pyrrole, disperse it in 30mL mixture of water and ethanol with a volume ratio of 1:1, mix evenly to obtain a pyrrole solution, add the pyrrole solution to the aqueous solution of graphene oxide, stir ultrasonically for 30min, and ultrasonically The frequency is 20KHZ;

[0093] 3) Measure 3mL of 0.37M H 2 PtCl 6 Add the aqueous solution to the mixed solution obtained in step 2), and ultrasonically stir for 30 minutes at an ultrasonic frequency of 20KHZ to obtain the first mixed solution; in the first mixed solution, the mass of Pt is 0.22g, accounting for 5% of the total mass of the catalyst;

[0094] 4) Insert electrodes with a spacing of 10 mm into the first mixed solution, apply an alternating current with a frequency of 100 Hz and a voltage gradient of 100...

Embodiment 2

[0101] 1) Weigh 3g of graphene oxide, dissolve it in 50mL of water, ultrasonically disperse for 30min, and the ultrasonic frequency is 50KHZ, to obtain an aqueous solution of graphene oxide;

[0102] 2) Weigh 0.3g of pyrrole, disperse in 30mL mixed solution of water and ethanol with a volume ratio of 1:1, mix evenly to obtain a pyrrole solution, add the pyrrole solution to the aqueous solution of graphene oxide, stir ultrasonically for 30min, and ultrasonically The frequency is 50KHZ;

[0103] 3) Measure 15mL of 0.37M H 2 PtCl 6 Add the aqueous solution to the mixed solution obtained in step 2), and ultrasonically stir for 30 minutes at an ultrasonic frequency of 50KHZ to obtain the first mixed solution; in the first mixed solution, the mass of Pt is 1.1g, accounting for 25% of the total mass of the catalyst;

[0104] 4) Insert electrodes with a spacing of 10 mm into the first mixed solution, apply an alternating current with a frequency of 100 Hz and a voltage gradient of 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com