Preparation method of direct methanol fuel cell anode catalyst

A methanol fuel cell and catalyst technology, applied in battery electrodes, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of scarce resources, high price, high cost, etc., and achieve self-agglomeration, improve utilization, and improve catalytic performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

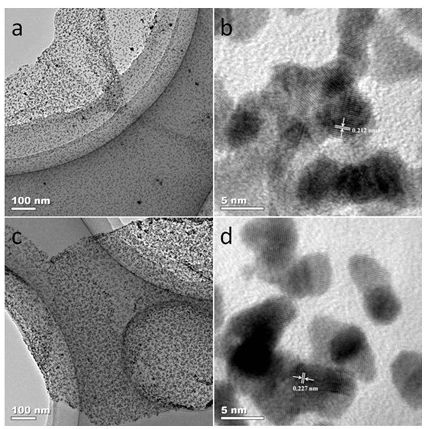

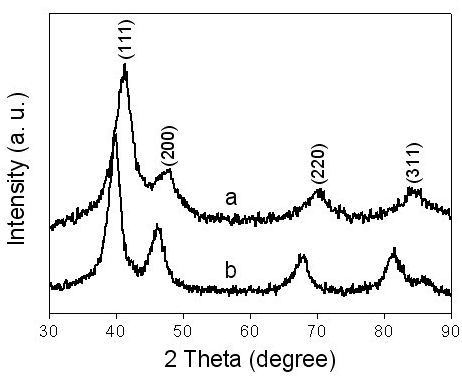

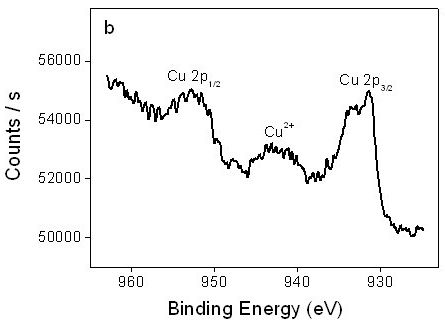

Image

Examples

Embodiment 1

[0028] (1) Preparation of graphene: 1.0 g graphite and 1.0 g NaNO 3 Add to 46 mL of 98% H 2 SO 4 The solution was mechanically stirred in an ice bath for 20 minutes, then slowly added 6.0 g KMnO 4 and 80 mL of secondary water, the temperature was controlled at 90 ± 5 °C; after stirring for 30 minutes, 200 mL of secondary water was added to the reaction system and 6 mL of 30% H 2 o 2 The solution was filtered while it was hot, and washed with secondary water until the filtrate was neutral; the obtained product was dispersed in 500 mL of secondary water, and ultrasonicated for 2 hours to obtain uniformly dispersed single-sheet graphene.

[0029] (2) Preparation of PEI-functionalized graphene: ultrasonically disperse 20 mg of graphene in 50 mL of 1 mol / L NaCl solution, then add 1.08 g of PEI, continue ultrasonication for 4.5 hours; then centrifuge the reaction solution and wash it with secondary water , the product was vacuum-dried at 40 °C for 48 hours, and the product was ...

Embodiment 2

[0032] (1) Preparation of graphene: 1.0 g graphite and 1.0 g NaNO 3 Add to 46 mL of 98% H 2 SO 4 The solution was mechanically stirred in an ice bath for 20 minutes, then slowly added 6.0 g KMnO 4 and 80 mL of secondary water, the temperature was controlled at 90 ± 5 °C; after stirring for 30 minutes, 200 mL of secondary water was added to the reaction system and 6 mL of 30% H 2 o 2 The solution was filtered while it was hot, and washed with secondary water until the filtrate was neutral; the obtained product was dispersed in 500 mL of secondary water, and ultrasonicated for 2 hours to obtain uniformly dispersed single-sheet graphene.

[0033] (2) Preparation of PEI-functionalized graphene: Disperse 20 mg graphene in 50 mL 1 mol / L NaCl solution, add 1.08 g PEI after ultrasonication for 1 hour, and continue ultrasonication for 4.5 hours; After washing with water, the product was vacuum-dried at 40 °C for 48 hours, and the product was labeled as PEI-graphene.

[0034] (3) P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com