Method for preparing nanowire sheet intercalated structure supported type direct alcohol fuel cell catalyst

A fuel cell and nanowire technology, used in fuel cells, battery electrodes, nanotechnology, etc., can solve the problems of nano-scale active component Pt particle poisoning, catalyst performance degradation, and alcohol fuel transmission obstruction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

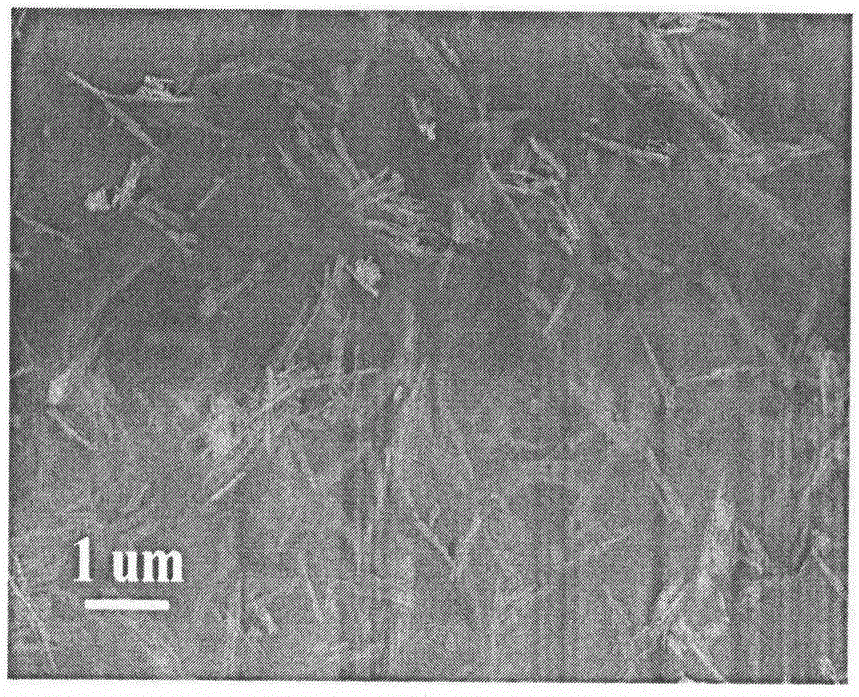

Image

Examples

specific Embodiment approach 1

[0008] Specific embodiment one: the preparation method of nanowire sheet intercalation structure loading type direct alcohol fuel cell catalyst in this embodiment is to realize according to the following steps: one, graphene (GO) is dispersed in sodium hydroxide solution, Then slowly add Cu(NO 3 ) 2 , then add EDA to sonicate for 30min, and finally add 35% N 2 h 4 To obtain the mixed solution, the copper salt can be Cu(NO 3 ) 2 , Cu(NO 3 ) 2 2.5H 2 O, Cu(NO 3 ) 2 ·5H 2 O; 2. Pour the mixed solution obtained in step 1 into a 50ml quartz dish, and heat it at 80°C for 30 minutes with MW; 3. Cool the product to room temperature, wash with water and ethanol, and finally centrifuge and dry at low temperature to obtain CuNWs / GO structure supported direct alcohol fuel cell catalyst carrier. The carrier can also be doped with N, P, S and other amorphous non-metals and Fe 3 o 4 graphite and other transition metal oxides. Methods The catalyst support CuNWs / GO was prepared ...

specific Embodiment approach 2

[0010] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the Cu(NO 3 ) 2 is Cu(NO 3 ) 2 2.5H 2 O, Cu(NO 3 ) 2 ·5H 2 O. Its steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0011] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the Cu(NO 3 ) 2 CuCl 2 . Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com