Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

79results about How to "Improve anti-corrosion effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Marine anticorrosive powdered paint and preparation method thereof

InactiveCN103031024AImprove anti-corrosion effectAcid resistantAnti-corrosive paintsPowdery paintsZincPowder coating

The invention provides marine anticorrosive powdered paint and a preparation method thereof. The formula of the paint comprises polyethylene, glass flakes and zinc powder, wherein the polyethylene is one or a combination of low-density polyethylene (LDPE), medium-density polyethylene (MDPE) and high-density polyethylene (HDPE); the glass flakes are scalelike glass flakes which are 40-3000 meshes; and the glass flakes are made of alkali glass or neutral glass. According to the invention, the glass flakes and the flaky zinc powder are added in the polyethylene (PE) base, so that glass layers and zinc layers having good barrier effect are distributed in the PE powder, wherein the glass layers can resist acid, alkali, salt and water, and the scalelike glass flakes can form multiple barrier layers in the PE layer. Thus, corrosive small molecules pass through the barrier layers as if passing through a maze and need to travel on a long and tortuous road, thereby improving the anticorrosive effect.

Owner:杭州五源科技实业有限公司

Auto-rust converting rust-containing corrosion resistant emulsion and preparation method thereof

ActiveCN102408507AWith autorotation functionReduce work intensityAnti-corrosive paintsMethacrylateGlycidyl methacrylate

The invention relates to the field of materials and discloses an auto-rust converting rust-containing corrosion resistant emulsion and preparation method thereof. The auto-rust converting rust-covering corrosion resistant emulsion is prepared as follows: a mixture of at least one from metacrylic acid ester or acrylic ester and styrene is selected as an allyl monomer; methacrylic acid phosphate, methacrylic acid glycidyl ester and vinyl tri-methoxysilane are selected as functional monomers; a mixture diester of at least one from acrylic acid, or methacrylic acid and acrylamide is selected as a functional monomer; poly (ethylene glycol) phosphate, allyl alkylphenol polyoxyethylene ammonium sulfate, and the like, are selected as emulsifying agents. The emulsion prepared has the auto-rust converting function, does not a huge amount of manual work to eliminate rusts during coating and can be coated by containing rust. Moreover, the emulsion has good corrosion resistant capacity, is safe and environmental friendly, is innocuous, can not cause fire, and reduces the working intensity and harmfulness of constructors.

Owner:佛山保立佳化工有限公司

Water-based metal rust inhibitor and preparation method thereof

The invention provides a water-based metal rust inhibitor and a preparation method thereof. The rust inhibitor comprises sorbitan monooleate, inositol hexaphosphate, zinc dihydrogen phosphate, acrylamide, glutamic acid, dinonyl-naphthalenesulfonate, dicyclohexylamine, octadecylamine oleyl sarcosinate, oxidized barium petrotate, sodium ethylenediamine teramethylene phosphonate, 1-hydroxyethylidene, dimethylaminoethyl acrylate, sulfomethylated polyacrylamide, a film forming agent and deionized water. The preparation method comprises the steps of firstly, mixing sorbitan monooleate, inositol hexaphosphate, zinc dihydrogen phosphate and water, and adding octadecylamine oleyl sarcosinate; then, adding acrylamide, glutamic acid, dinonyl-naphthalenesulfonate, dicyclohexylamine and oxidized barium petrotate into the deionized water, and adding 1-hydroxyethylidene; and mixing a mixture I and a mixture II, and adding the left components to obtain the water-based metal rust inhibitor. The rust inhibitor can be attached to the surface of metal, so that the metal has better wear resistance and corrosion resistance.

Owner:NINGBO SHEN XIN ELECTRONICS CO LTD

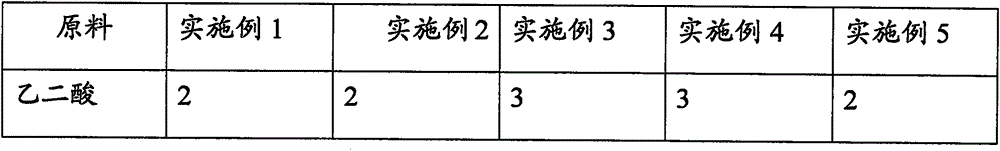

Water-soluble antirust agent

The invention provides a water-soluble antirust agent. The water-soluble antirust agent is prepared from fatty acid, specific amine, an additive, ethyl alcohol and water. The mass ratio of the fatty acid to the alcohol amine to the additive to the ethyl alcohol to the water is (2-3):(1-15):(5-10):(10-15):(80-100). The fatty acid is selected from one or more of oxalic acid, valeric acid, naphthenic acid, citric acid, benzoic acid, lauric acid, adipic acid, oleic acid and sebacic acid, the apecific amine is selected from one or more of octanoic acid dicyclohexylamine, triethanolamine, diethanol amine and ethanol amine, and the additive is an antioxidant. The antirust valid period of the water-soluble antirust agent is long and can reach 3-6 months; an antirust film is thin and is only tens of microns thick, a follow-up process cannot be influenced even though the antirust film is not removed, and the film can be removed with warm water due to the good film removability of the water-soluble antirust agent; and the water-soluble antirust agent is low in production cost, free of foreign smells and beneficial to environmental protection.

Owner:彭国泉

Water-soluble metal antirusting agent and preparation method thereof

ActiveCN102776052ASimple preparation processImprove wear resistanceBase-materialsAlcoholFilm-forming agent

The invention discloses a water-soluble metal antirusting agent and a preparation method thereof. The water-soluble metal antirusting agent contains a film-forming agent, wherein the film-forming agent is formed by fatty acid with C4-C20, alcohol amine and phosphate ester with C8-C18. According to the water-soluble metal antirusting agent disclosed by the embodiment of the invention, no harm is caused to a human body, energy is saved, the environmentally-friendly requirement is met, the preparation process is simple, and the water-soluble metal antirusting agent disclosed by invention contains the film-forming agent and can be adhered onto a metal surface, so that the water-soluble metal antirusting agent disclosed by the invention has the advantages of better abrasion resistance and antirusting performance.

Owner:TSINGHUA UNIV

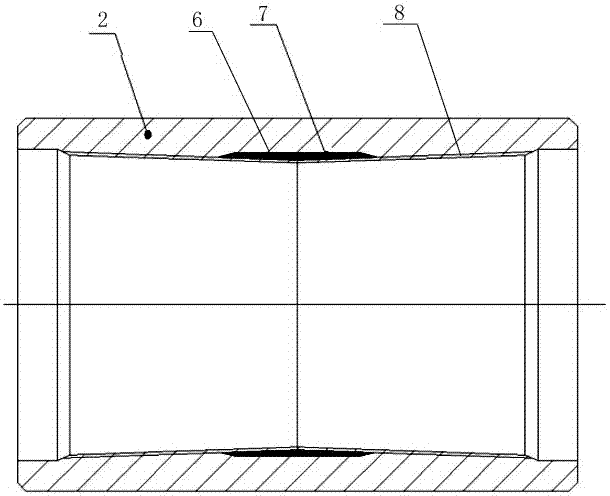

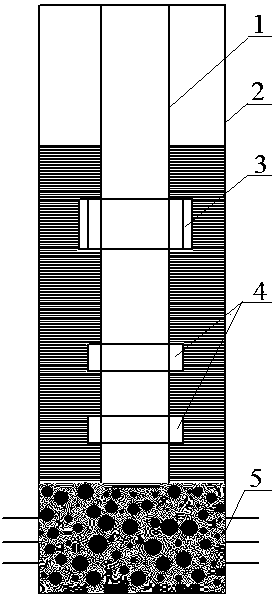

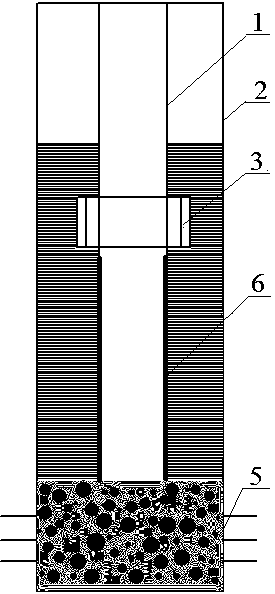

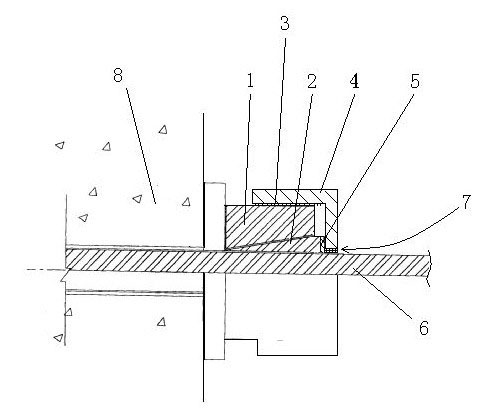

Inner spray welding anticorrosive wear resistant oil pipe and machining method and machining device

The invention discloses an inner spray welding anticorrosive wear resistant oil pipe and a machining method and a machining device. The inner spray welding anticorrosive wear resistant oil pipe comprises a preheating sensing heating ring and a remelting sensing heating ring which are arranged on the outer surface of a pipe body in sequence; a sprayer, a nozzle and supports are arranged in the pipe body, each support is provided with two support rods, the bottoms of the support rods are provided with steel balls capable of freely rolling, and the steel balls are in contact with an inner hole surface of the pipe body; the outer surface of the pipe body is further provided with power idler wheels for pushing the pipe body to rotate and move forwards, the outer end of the pipe body is provided with a spray gun, the spray gun and the sprayer are connected by a powder feeding pipe, a mixed gas pipe and an outer pipe, a cooling water pipe is further arranged in the outer pipe, the outer pipe is filled with cooling water, a cooling water returning pipe is further arranged on the outer pipe, and the spray gun is provided with a hopper, an oxygen pipe, an acetylene pipe and a water inlet. The inner spray welding anticorrosive wear resistant oil pipe is simple in structure, not only the inner surface of an oil pipe but also the end surface and threads of the oil pipe can be subjected to corrosion prevention, a tensile strength of the threads is not affected, the corrosion prevention effect and a connecting strength of a joint are improved, and the corrosion prevention effect is good.

Owner:DONGYING XINJIA ENVIRONMENTAL PROTECTION TECH DEV CO LTD

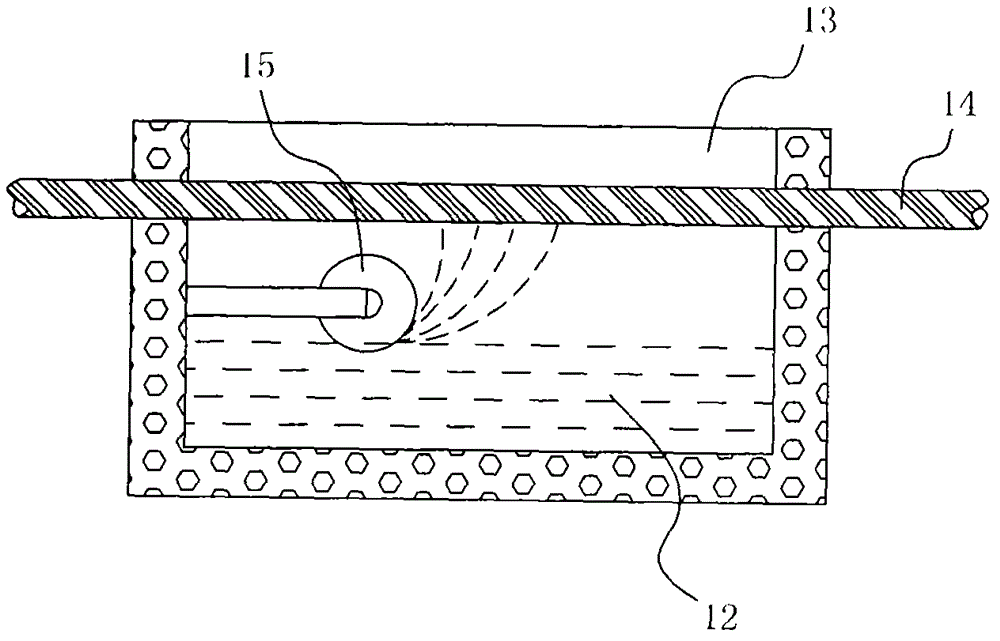

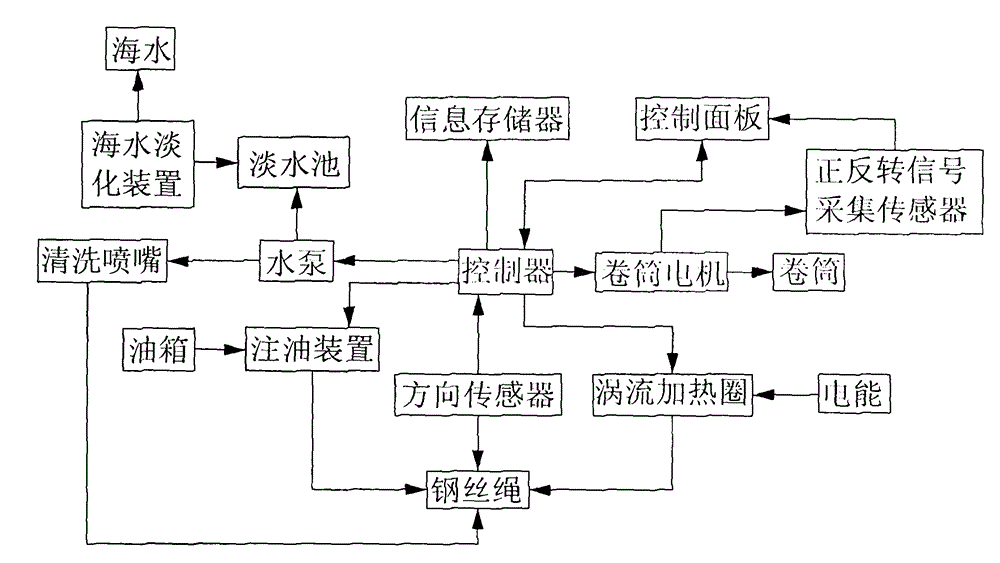

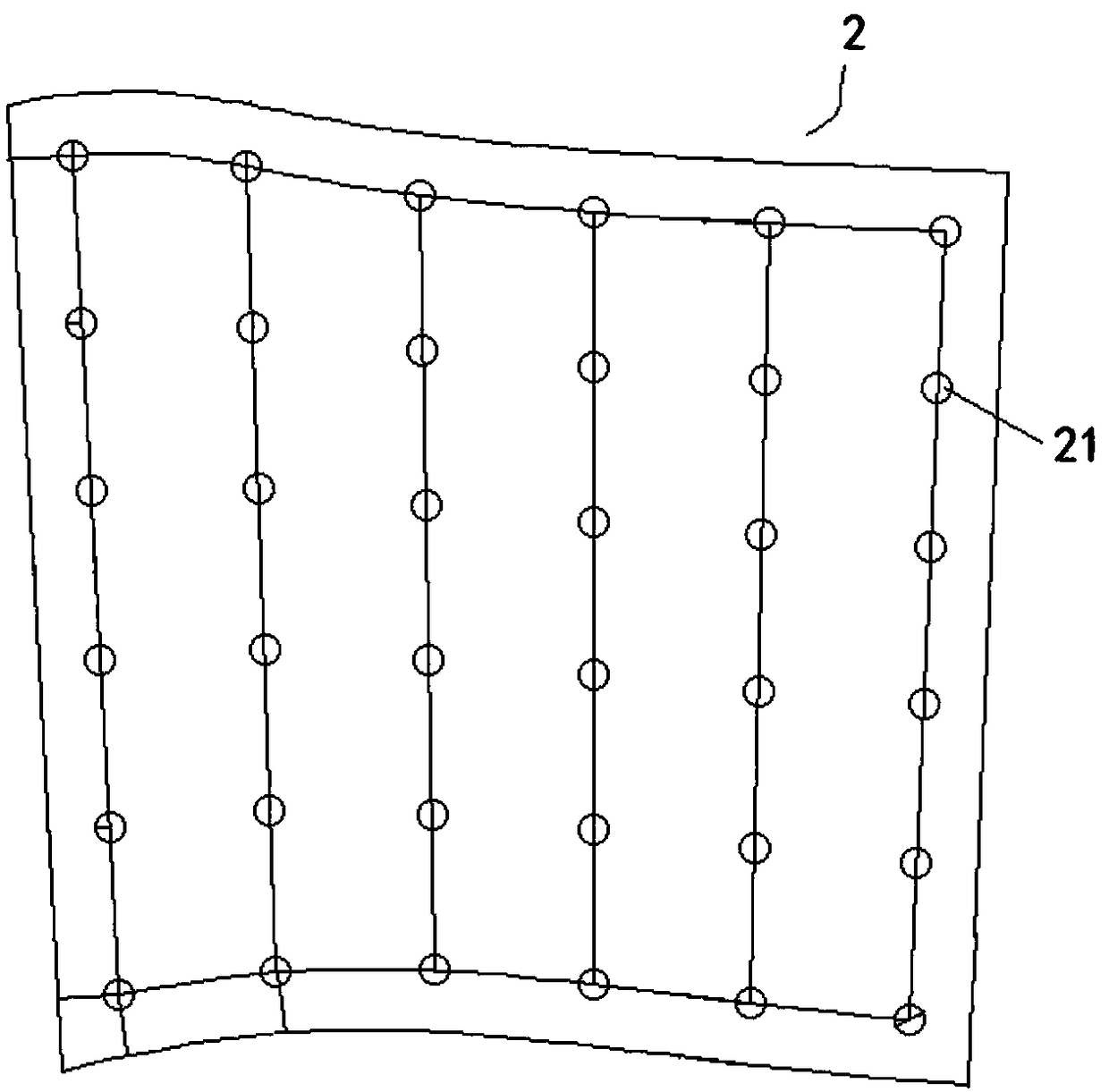

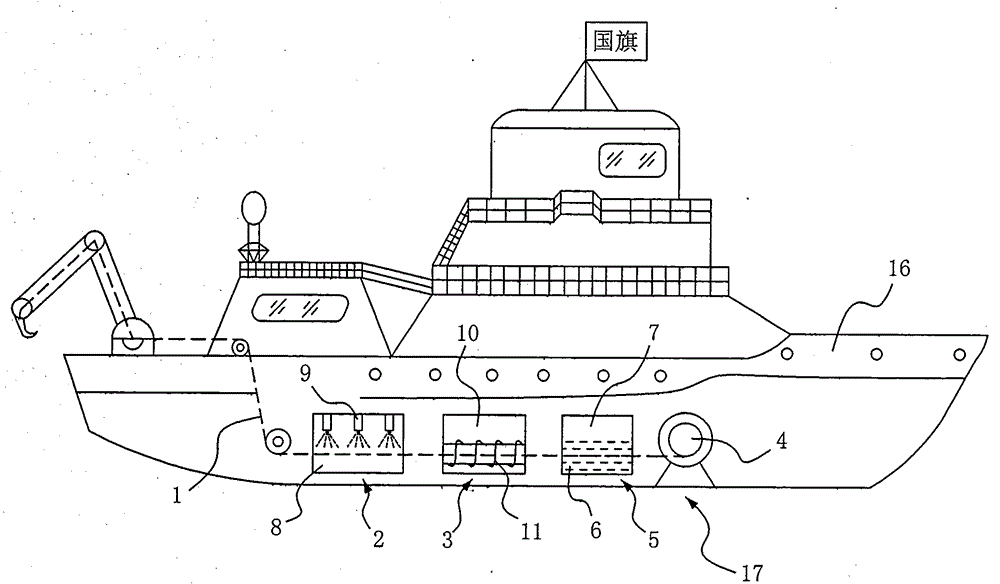

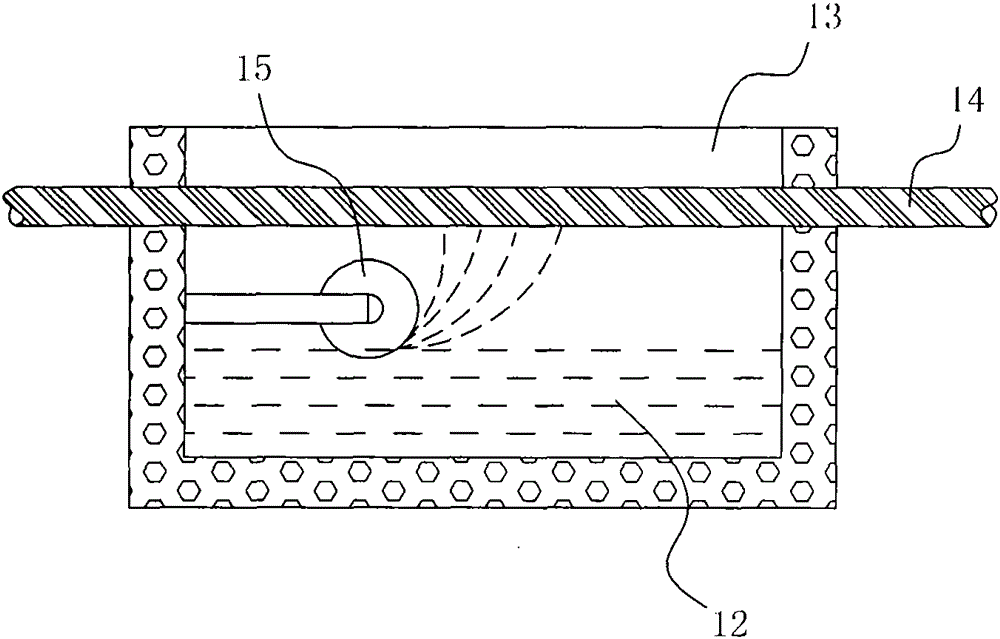

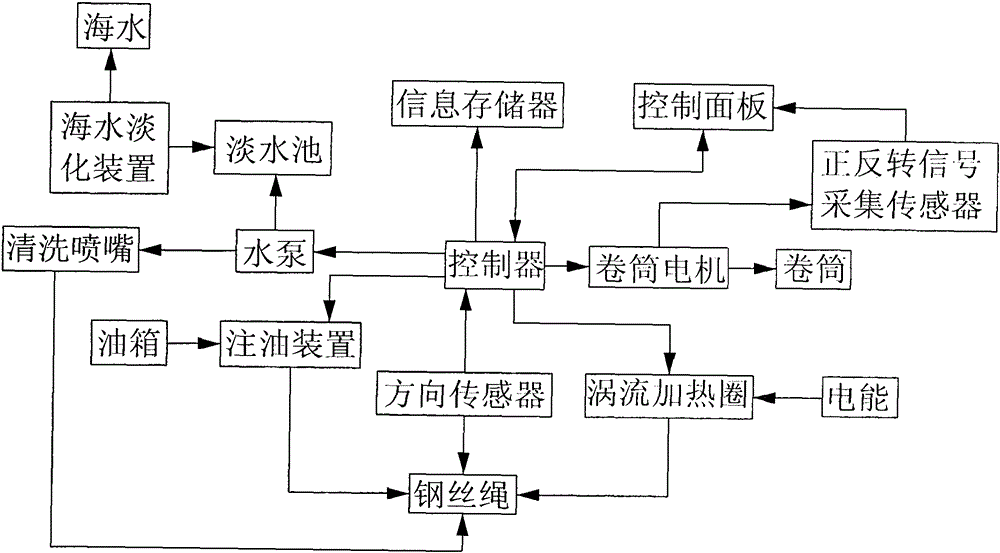

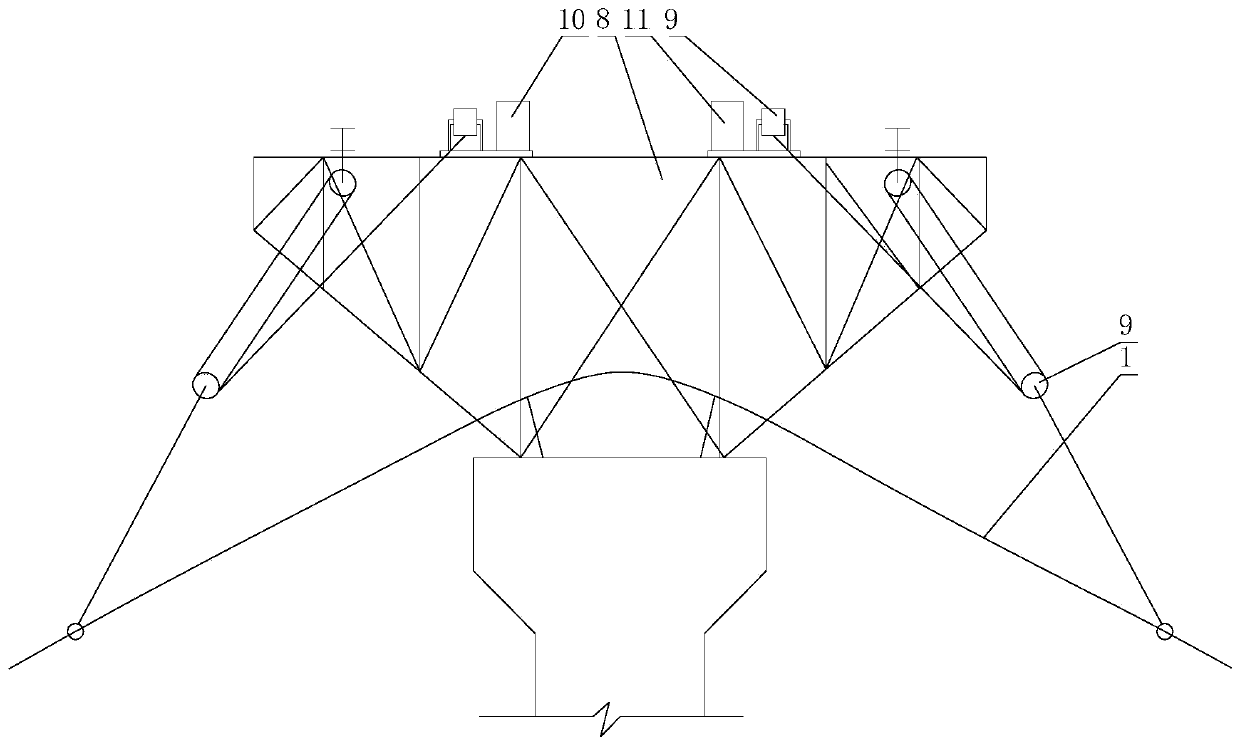

Rustproof maintaining device for steel wire rope specially for scientific expedition ship and maintenance method thereof

ActiveCN104988778ATime saving refueling processRefueling Process SafetyPretreated surfacesRope making machinesEngineeringSeawater

The invention discloses a rustproof maintaining device for a steel wire rope specially for a scientific expedition ship. The device comprises a cleaning device used for cleaning the steel wire rope with seawater, a drying device used for drying the cleaned steel wire rope, a winding device used for driving the telescoping of the steel wire rope, and a controller. The invention also discloses a rustproof maintenance method for the steel wire rope specially for the scientific expedition ship. The method includes: after a direction sensor detects the winding direction of the steel wire rope, detection signals are sent to the controller, the controller receives the detection signals and sends starting signals used for driving the cleaning device, the drying device, and a rustproof fluid adding device to maintain the steel wire rope to the cleaning device, the drying device, and the rustproof fluid adding device, and the cleaning device, the drying device, and the rustproof fluid adding device start to operate and maintain the wound steel wire rope. According to the maintaining device and the maintenance method, the steel wire rope can be recovered and automatically cleaned, dried, and oiled, and the automation degree is high.

Owner:THE FIRST INST OF OCEANOGRAPHY SOA

Martensite stainless steel for manufacture of scalpel blade and manufacturing method of martensite stainless steel

InactiveCN108300945AMeet process requirementsReduce adverse effectsFurnace typesHeat treatment furnacesMetallurgyMartensitic stainless steel

The invention relates to martensite stainless steel for manufacture of a scalpel blade and a manufacturing method of the martensite stainless steel. The martensite stainless steel is prepared from, byweight, 0.65-0.70% of C, smaller than or equal to 0.5% of Si, 0.4-0.7% of Mn, smaller than or equal to 0.03% of P, smaller than or equal to 0.025% of S, smaller than or equal to 0.5% of Ni, 13.0-13.5% of Cr, 0.8-1.2% of Mo, 0.08-0.12% of V and the balance Fe and other inevitable impurities. The hardness reaches HV700 or above after quenching and tempering are completed, meanwhile, the carbon content of the martensite stainless steel is controlled within a reasonable range in order to avoid adverse influences caused by increase of the carbon content in the prior art, and the anti-corrosion effect is good.

Owner:江苏延汉材料科技有限公司

Peel-off type mung bean acne-removing mask and preparation method thereof

ActiveCN103385826AImprove anti-corrosion effectExtended shelf lifeCosmetic preparationsToilet preparationsChemistryCarboxylate

The invention discloses a mung bean acne-removing mask and a preparation method thereof. The peel-off type mung bean acne-removing mask is prepared by using a conventional method from the following raw materials by weight: 10 to 14 parts of polyvinyl alcohol, 8 to 12 parts of glycerin, 0.8 to 1.2 parts of hydrolyzed sericin, 4 to 6 parts of ethanol, 6 to 8 parts of C11-15 alcohol polyether-7 sodium carboxylate, 0.8 to 2 parts of a mung bean extract, 0.03 to 0.08 part of a composite antiseptic and 100 parts of deionized water, wherein the composite antiseptic is composed of, by weight, 1 to 3 parts of carnosic acid, 3 to 5 parts of a bamboo leaf antioxidant, 1 to 3 parts of nisin and 1 to 3 parts of 3-iodo-2-propynyl butyl carbamate. The peel-off type mung bean acne-removing mask provided by the invention can purify pores in depth, remove unnecessary grease and promote water-oil balance of the skin, enables the skin to be fresh, comfortable and vital, reduces acne traces, whitens the skin, eliminates dullness of the skin, allows the skin to be uniform, bright and white and is capable of removing acne and clearing heat.

Owner:广州美姿生物科技有限公司

Antistatic vapor phase rust inhibitor and preparation method thereof

InactiveCN104532251AGood anti-rust performance and anti-static performanceLong durationMaltitolPEG 400

The invention discloses an antistatic vapor phase rust inhibitor. The antistatic vapor phase rust inhibitor is prepared from the following raw materials, by weight, 0.5-1 part of monoethaneamine benzoate, 1-2 parts of dicyclohexylamine benzoate, 1-2 parts of benzyl salicylate, 2-4 parts of flaxseed oil, 0.3-0.5 parts of quaternary ammonium bis-imidazoline, 6-8 parts of chitosan, 1-2 parts of sodium caseinate, 1-2 parts of pentaerythrite oleate, 1-2 parts of polyethylene glycol 400 monooleate, 1-2 parts of maltitol, 6-8 parts of sodium tripolyphosphate, 1-2 parts of disodium ethylene diamine tetraacetate, 4-6 parts of a modification assistant and 40-50 parts of water. The rust inhibitor simultaneously has contact rust inhibition and vapor phase rust inhibition efficacies, has the advantages of good rust resistance and antistatic property, long rust inhibition lasting time and high safety, and is suitable for the rust inhibition of steel workpieces.

Owner:ANHUI PROVINCE SUZHOU CITY LONGHUA MACHINERY MFG

Metal surface silane treating agent containing acrylic acid and preparation method of metal surface silane treating agent

InactiveCN103102724AImprove corrosion resistanceImprove anti-corrosion effectAnti-corrosive paintsTriethanolamineIsothiazolinone

The invention discloses metal surface silane treating agent containing acrylic acid and a preparation method of the metal surface silane treating agent. The metal surface silane treating agent containing acrylic acid is a mixed solution which is prepared from the following components: ethenyl tri-(beta-methoxyethyoxyl) silane, film-forming resin, acrylic acid, triethanolamine, oxalic acid, propylene glycol, 2-n-octyl-4-isothiazolin-3-acetone, polydimethylsiloxane, antioxidant 1010, sodium bicarbonate and ethylene glycol dimethyl ether. According to the metal surface silane treating agent and the preparation method of the metal surface silane treating agent disclosed by the invention, the ethenyl tri-(beta-methoxyethyoxyl) silane is adopted as the main material, glycol dimethyl ether is adopted as a solvent, and the cost is low; meanwhile, acrylic acid and various different auxiliary materials are added to the materials, and the treatment time and the treatment temperature of the treating agent are improved. When the silane treating agent disclosed by the invention is used to treat a metal workpiece, a polyacid film layer is formed on the surface of the metal workpiece; the film layer has the characteristics of being strong in adhesive force, free of holes and cracks, compact and uniform and small in polar current density; moreover, the production process is environment-friendly and pollution-free.

Owner:江苏金科环境工程科技有限公司

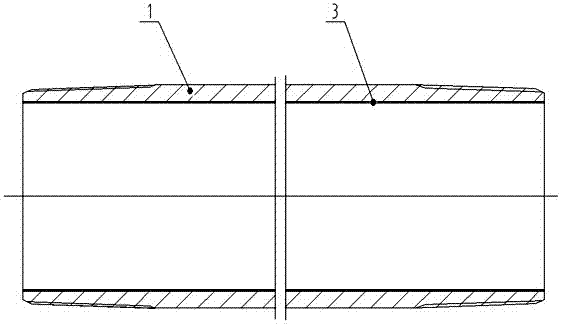

Centrifugal compressor welding case and centrifugal compressor

InactiveCN109441882AImprove anti-corrosion effectAvoid reworkPump componentsPumpsSteel platesCentrifugal compressor

The invention discloses a centrifugal compressor welding case and a centrifugal compressor, and relates to the technical field of compressors. The main purpose is to improve the anticorrosion effect of the welding case and lower the manufacturing cost. According to the main technical scheme, the centrifugal compressor welding case comprises a case body and a lining plate, the case body is internally provided with a supporting ring, a flow guiding plate and a flow dividing plate; the supporting ring, the flow guiding plate and the flow dividing plate are all stainless steel forgings, and the case body is a low-alloy steel body; and the lining plate comprises a plurality of plate blocks, each plate block is a stainless steel plate block, the multiple plate blocks comprise a plurality of planar plate block bodies and a plurality of curved plate block bodies, the multiple plate blocks are welded and connected to the corresponding positions of the inner surfaces of the case body in a matched mode correspondingly, and every two adjacent plate blocks are in gap welded connection and are in smooth transition. The centrifugal compressor welding case and the centrifugal compressor are mainlyused for improving the anticorrosion effect of the welding case.

Owner:SHENYANG TURBO MASCH CORP

Quenching method for deformed steel bars

InactiveCN103484616AImprove anti-corrosion effectImprove performanceQuenching agentsDistilled waterPotassium sulfate

The invention provides a quenching method for deformed steel bars. The method comprises the following steps: after heating the deformed steel bars to 960-980 DEG C, preserving the heat for 1-2 h; and immerging into a quenching agent for quenching, wherein the quenching time is 3-5 s, and the quenching agent is composed of the following components by mass: 5-7% of industrial sodium chloride, 1-2% of sodium nitrate, 1-2% of potassium sulfate, and the rest of distilled water. Through the application of the quenching method for deformed steel bars to quench, the obtained deformed steel bars have excellent rust-proof performance, the performance of an oxide skin is improved, and the quenching method is simple and convenient to use.

Owner:WUXI YANGGONG MACHINERY MFG

Low-temperature quick-drying anticorrosive paint

InactiveCN102417788AImprove anti-corrosion effectImprove adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsZinc phosphateN-Butanol

The invention discloses a low-temperature quick-drying anticorrosive paint prepared from stirred raw materials of, by weight: 60-65 parts of polyurethane, 10-12 parts of polytetrafluoroethylene, 10-11 parts of zinc phosphate, 20-24 parts of n-butanol, 5 parts of strontium sulfate, 10 parts of sodium hexametaphosphate, 4 parts of an antifoaming agent, and 3 parts of a dispersant. As a result of industrial experiments, the paint provided by the invention has advantages of good corrosion resistance and high adhesion. With the pant, phenomena of peeling and shelling are prevented. The paint can be dried within tens of minutes under a normal temperature.

Owner:WUJIANG TIANYUAN PLASTIC

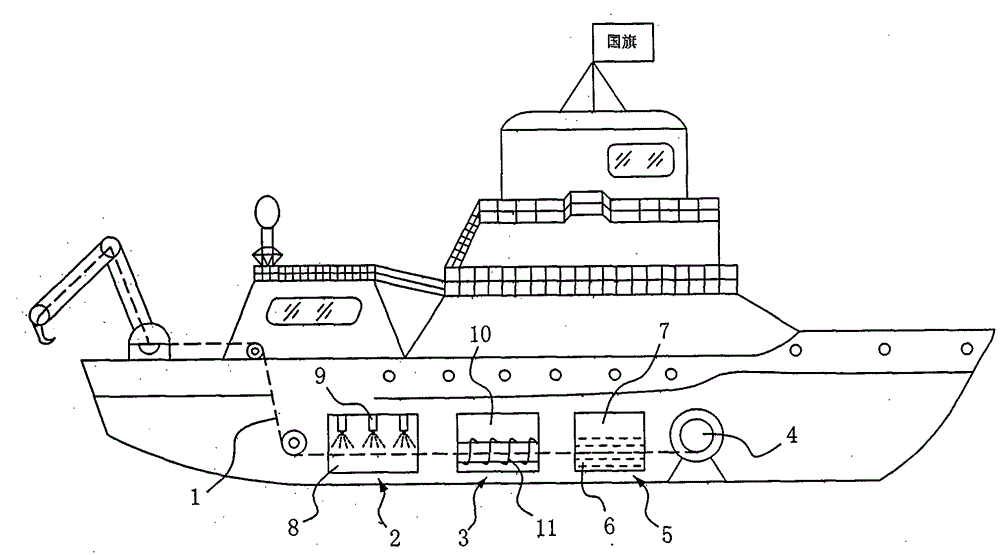

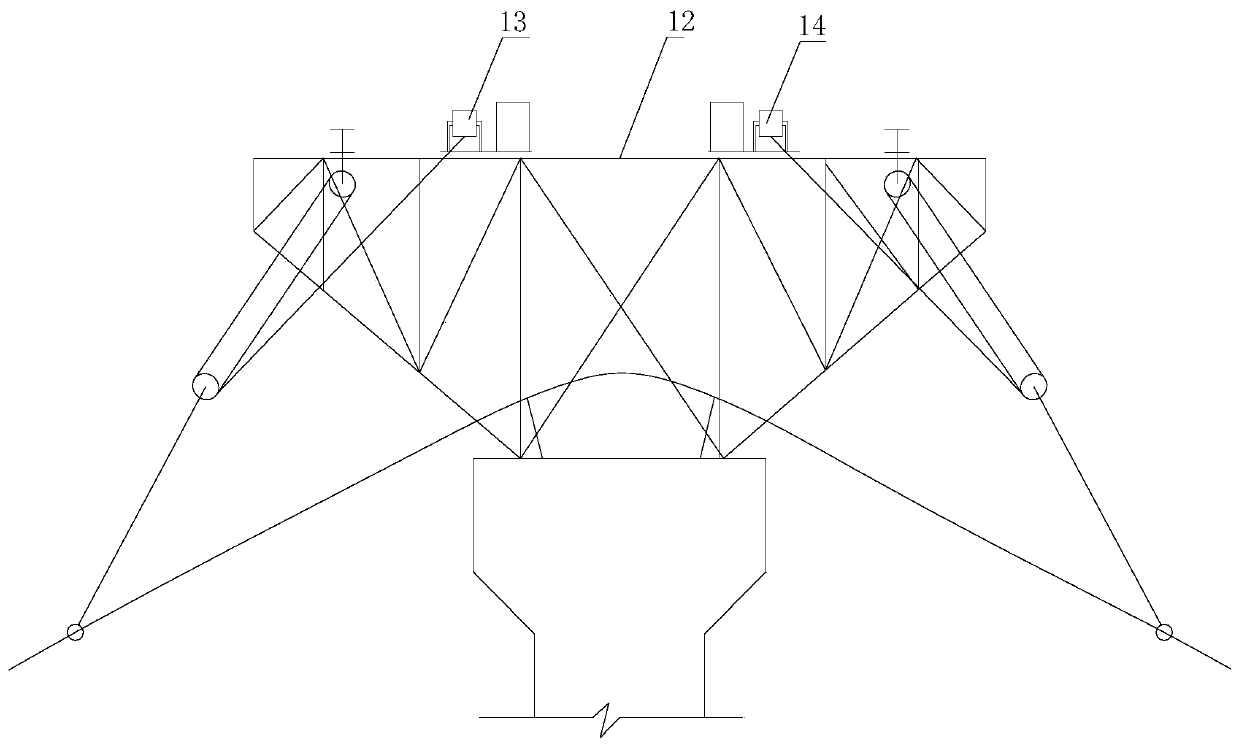

Scientific expedition ship with steel wire rope rust-proof maintaining device

InactiveCN104988777ATime saving refueling processRefueling Process SafetyRope making machinesCleaning using liquidsEngineeringSeawater

The invention discloses a scientific expedition ship with a steel wire rope rustproof maintaining device. The scientific expedition ship comprises a ship body and the steel wire rope rustproof maintaining device, the steel wire rope rustproof maintaining device comprises a cleaning device used for cleaning a steel wire rope with seawater, a drying device used for drying the cleaned steel wire rope, and a winding device used for driving the telescoping of the steel wire rope, and the steel wire rope rustproof maintaining device also comprises a controller. The invention also discloses a steel wire rope rustproof maintenance method specially for the scientific expedition ship. The method includes: after a direction sensor detects the winding direction of the steel wire rope, detection signals are sent to the controller, the controller receives the detection signals and sends starting signals used for driving the cleaning device, the drying device, and a rustproof fluid adding device to maintain the steel wire rope to the cleaning device, the drying device, and the rustproof fluid adding device, and the cleaning device, the drying device, and the rustproof fluid adding device start to operate and maintain the wound steel wire rope. The steel wire rope can be recovered and automatically cleaned, dried, and oiled, and the automation degree is high.

Owner:THE FIRST INST OF OCEANOGRAPHY SOA

Producing well sleeve interior anti-corrosion method

ActiveCN108179994AImprove anti-corrosion effectReduce usage and personnel costsDrilling rodsDrilling casingsWater contentDead volume

The invention provides a producing well sleeve interior anti-corrosion method. A pump hanging tail pipe is extended to the position, 1-2m from the upper end, of a perforation segment, thereby enablingoil water mixture of a sleeve and the space of an oil pipe ring between the flow liquid level and the tail end of the pump hanging tail pipe to become dead volume and oil water ratio to be increased,and a corrosion inhibitor is additionally filled in the oil water mixture of the sleeve and the space of the oil pipe ring. According to the producing well sleeve interior anti-corrosion method, liquid of the space of the flow liquid level and the tail pipe of the oil pipe ring becomes the dead volume by extending the pump hanging tail pipe, because the densities of oil and water of output liquidare different and the gravity theory exists, the oil and water are gradually separated, and crude oil occupies the upper space; output water moves downward, the part of dead volume from the flow liquid level to the space of the tail pipe of the oil pipe ring is occupied by the crude oil, the water content is greatly decreased, thereby greatly reducing corrosion for the interior of the sleeve; thecorrosion inhibitor is added in the space of the oil sleeve ring at the same time, since the part of the liquid is the dead volume, once the added corrosion inhibitor is dispersed in the part of theliquid, and the corrosion inhibitor can exist for a longtime without replenishing; and the dosage of the corrosion inhibitor and the personal cost can be greatly reduced.

Owner:PETROCHINA CO LTD

Deformed steel bar quenching technique

InactiveCN103484611AImprove anti-corrosion effectQuenching process is simpleQuenching agentsPhosphateDistilled water

The invention provides a deformed steel bar quenching technique which is characterized in that after a deformed steel bar is heated to 800-950 DEG C, the temperature is kept for 30-50 minutes, then the deformed steel bar is immersed into a quenching agent for quenching, and the quenching time lasts for 2-4 s; the quenching agent comprises the following components in percent by mass: 4-6 percent of potassium dihydrogen phosphate, 1-2 percent of sodium nitrate, 10-15 percent of sodium carbonate, 6-8 percent of industrial sodium chloride and distilled water as the rest. By using the deformed steel bar quenching technique for quenching, the deformed steel bar obtained is excellent in rust protection performance, and the quenching technique provided by the invention is simple and convenient to use.

Owner:WUXI YANGGONG MACHINERY MFG

Composition of electronic sewing machine driving mechanism lubricating grease and preparation method

InactiveCN110157524AImprove adhesionImprove load resistanceLubricant compositionEngineeringWater soluble

The invention relates to the technical field of lubricating greases and discloses a composition of an electronic sewing machine driving mechanism lubricating grease. The composition comprises the following components in percentage by mass: 75-80% of basic oil and 20-25% of a thickening agent, and the following additives in percentage by mass are put into the composition according to the total amount of the two components: 2% of a dispersant, 3% of an extreme pressure anti-wear reagent, 2% of an antirusting agent, 1% of an antioxidant and 5% of a solid lubricant. The preparation method of the composition of the electronic sewing machine driving mechanism lubricating grease comprises the following steps: respectively putting 75-80% of water-soluble polyether, 20-25% of a composite lithium soap and 2.5-3.5% of dialkyl molybdenum dithiocarbamate into a reaction kettle, starting stirring, heating to 95-100 DEG C, stirring for 60 minutes, increasing the temperature to 130-140 DEG C, and stirring for 40-60 minutes. The obtained electronic sewing machine driving mechanism lubricating grease has excellent adhesiveness, load resistance, shearing resistance, wearing reduction and rusting erosion resistance, and is applicable to contact friction of metals within a temperature range of minus 30 DEG C to 180 DEG C and plastics or metals and metals.

Owner:安徽和欣润滑科技有限公司

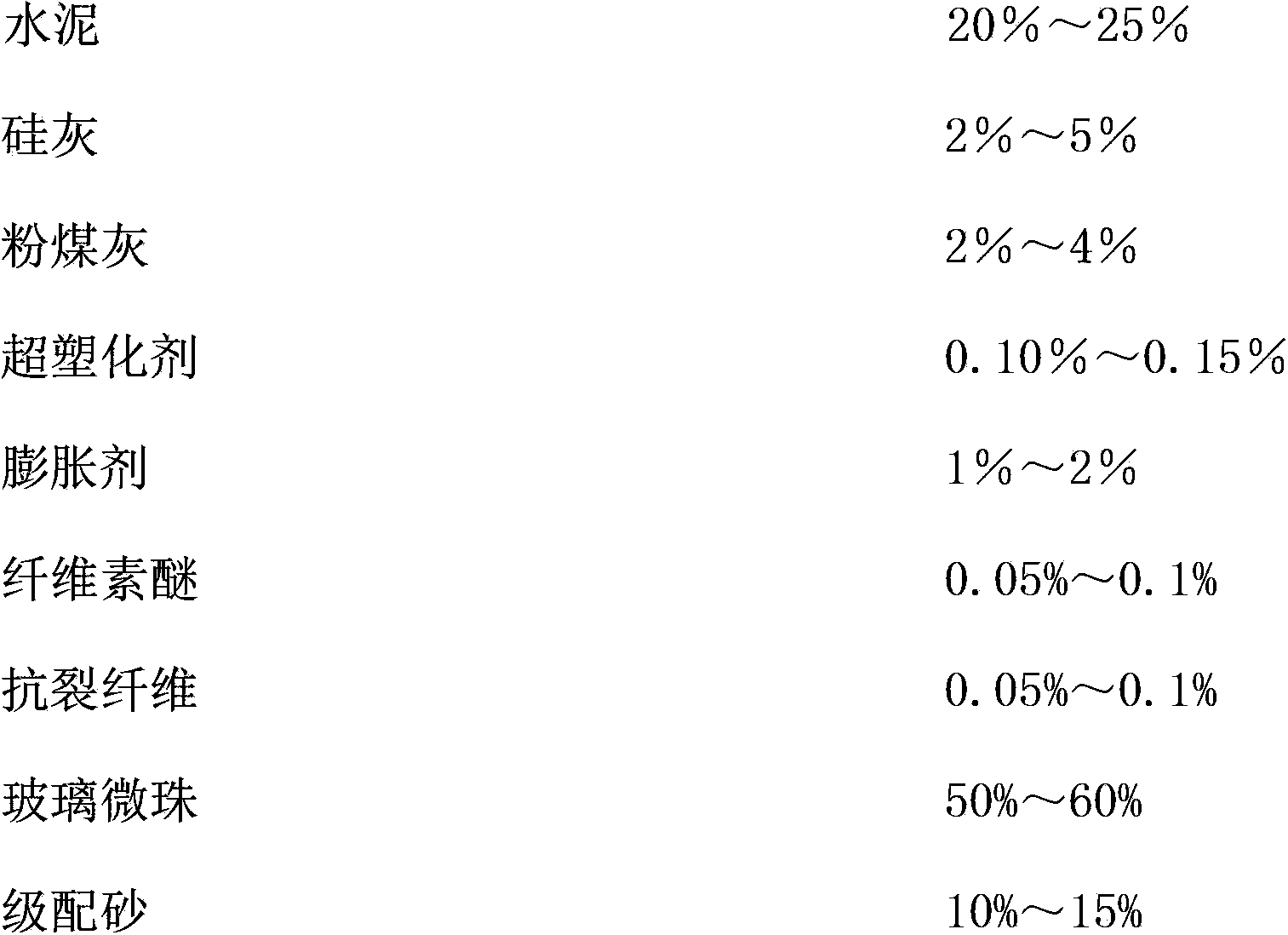

Injectable reinforcement material used for masonry structure reinforcement and preparation method thereof

The invention discloses an injectable reinforcement material used for masonry structure reinforcement, which is prepared from the following raw materials by mass: 20%-25% of cement, 2%-5% of silica fume, 2%-4% of fly ash, 0.10%-0.15% of a super plasticizer, 1%-2% of an expansive agent, 0.05%-0.1% of cellulose ether, 0.05%-0.1% of anti-cracking fiber, 50%-60% of glass beads and 10%-15% of graded sand. The cement is 42.5 ordinary Portland cement, the silica fume is active silica fume with effective SiO2 content greater than 90%, and the fly ash is first-grade low calcium fly ash. The formula design of the injectable reinforcement material not only considers properties of a material its own, and also gives consideration to the matching performance of a masonry structure material and the material, and the compatibility and durability of a reinforcement system are obviously better than those of a conventional modified cement mortar reinforcement system; the injectable reinforcement material has good pumping performance, and is suitable for mechanized injecting construction.

Owner:上海泛欧建筑材料有限公司 +1

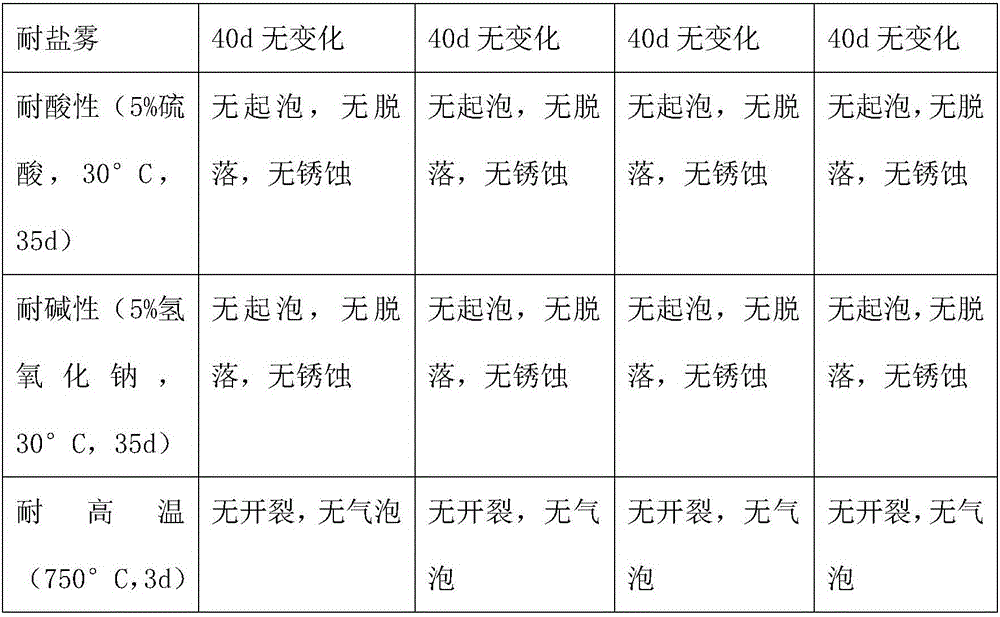

Anticorrosive paint for electric system and preparing method thereof

InactiveCN105969176ASimple preparation processEasy to industrializeFireproof paintsUnspecified rubber coatingsElectric power systemHazardous substance

The invention discloses anticorrosive paint for an electric system. The anticorrosive paint is prepared from, by weight, 23-35 parts of organic fluorosilicon resin, 18-31 parts of vulcanized rubber, 13-27 parts of carbon nano-tube, 26-46 parts of composite conductive filler, 1-7 parts of ammonium polyphosphate, 6-32 parts of propyl alcohol, 3-8 parts of butyl glycidyl ether, 2-7 parts of zinc stearate, 2-6 parts of silane coupling agent and 1-4 parts of bentonite. The invention further discloses a method for preparing the anticorrosive paint. The preparing process is simple, industrialization can be achieved easily, controllability is high, production cost is low, raw materials are widely available, water corrosion resistance, acid resistance, alkali resistance and high temperature resistance are high, service life is long, maintenance is not needed in use, comprehensive performance is excellent while in service, cost performance is high, no toxic or harmful substance exists, using is safe, and environment pollution is avoided.

Owner:许婷

Anti-slipping anchor for foundation of split mounting type tower crane

The invention discloses an anti-slipping anchor for a foundation of a split mounting type tower crane, which comprises an anchor ring and a clamp plate in the anchor ring. Threads are arranged on the periphery of a clamping end of the anchor ring, matching threads are arranged on an inner peripheral surface of a clamping cap, the clamping cap is connected to the clamping end of the anchor ring in a threaded manner, and a connecting object piercing hole is arranged at the top of the clamping cap. The anti-slipping anchor has a good anti-slipping effect, furthermore, the structure of an existing anchor does not need to be changed, only the threads are arranged on the periphery of the clamping end of the anchor ring, the clamping cap is connected to the clamping end of the anchor ring to tightly jack the clamp plate, and accordingly the anti-slipping anchor is simple in manufacture and low in cost. A sealing ring is arranged on the inner periphery of the connecting object piercing hole at the top of the clamping cap, rainwater can be effectively prevented from entering the connecting object piercing hole, and a corrosion prevention effect is good.

Owner:从卫民 +1

Suspension bridge main cable strand pre-forming and erection construction method

InactiveCN110318331AEasy to observeEasy to twistSuspension bridgeBridge structural detailsEngineeringStructural stability

The invention relates to a suspension bridge main cable strand pre-forming and erection construction method. The method comprises a parallel steel wire rope strand, a steel wire, a front anchor cup, arear anchor cup, a positioning steel wire and a zinc-copper alloy block. The main cable strand preforming comprises the following steps of S1, manufacturing a marking steel wire; S2, manufacturing astandard length steel wire; S3, forming the parallel steel wire rope strand; and S4, pouring the steel wire rope strand anchor cup. The suspension bridge main cable strand pre-forming and erection construction method has a good structural stability, the two ends of a main cable strand are firmly connected with the front anchor cup and the rear anchor cup, the corrosion resistance is good, and theadvantages of protruding wires and scattered wires can be effectively eliminated.

Owner:河源迪奇亚工业技术有限公司

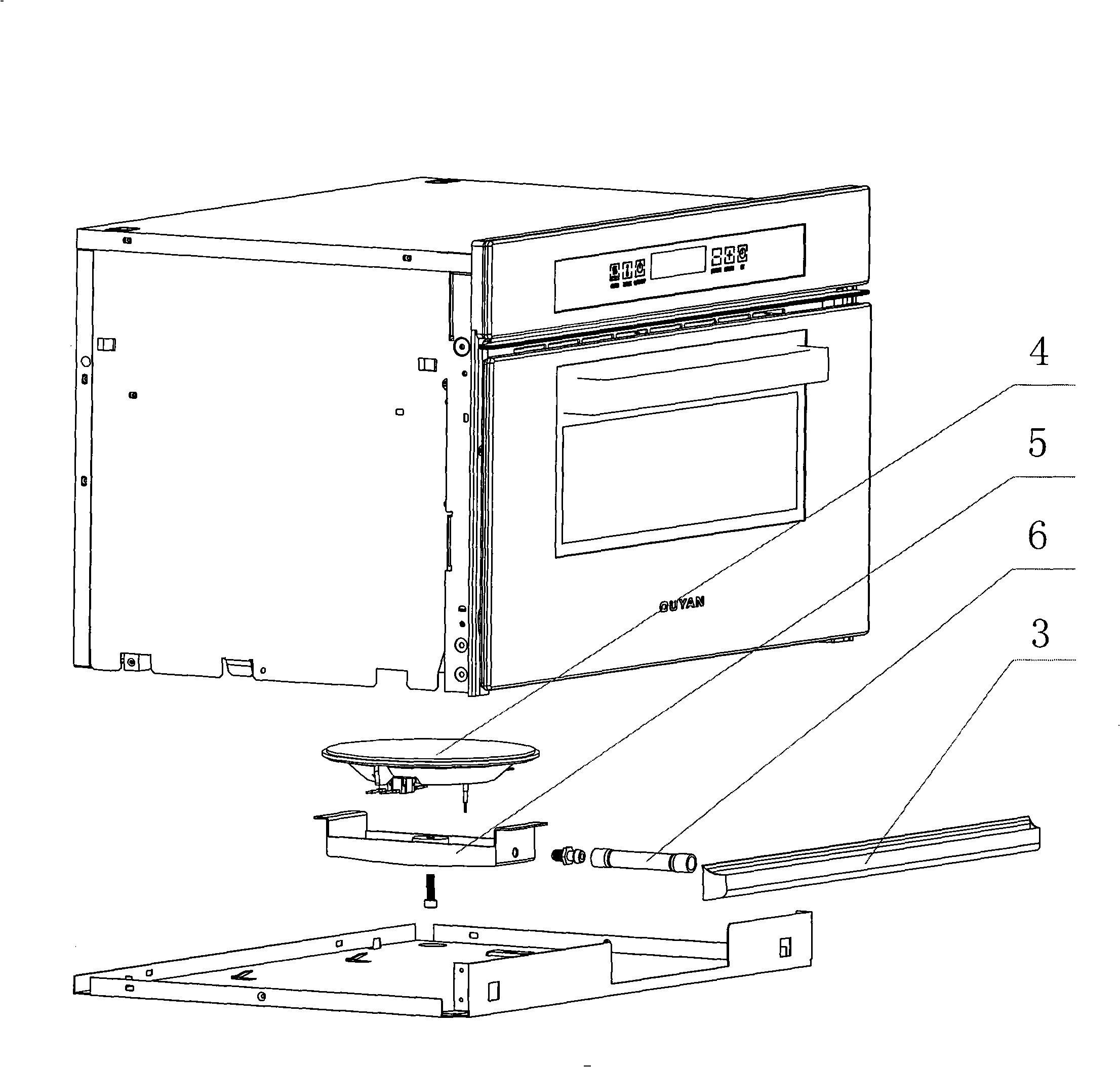

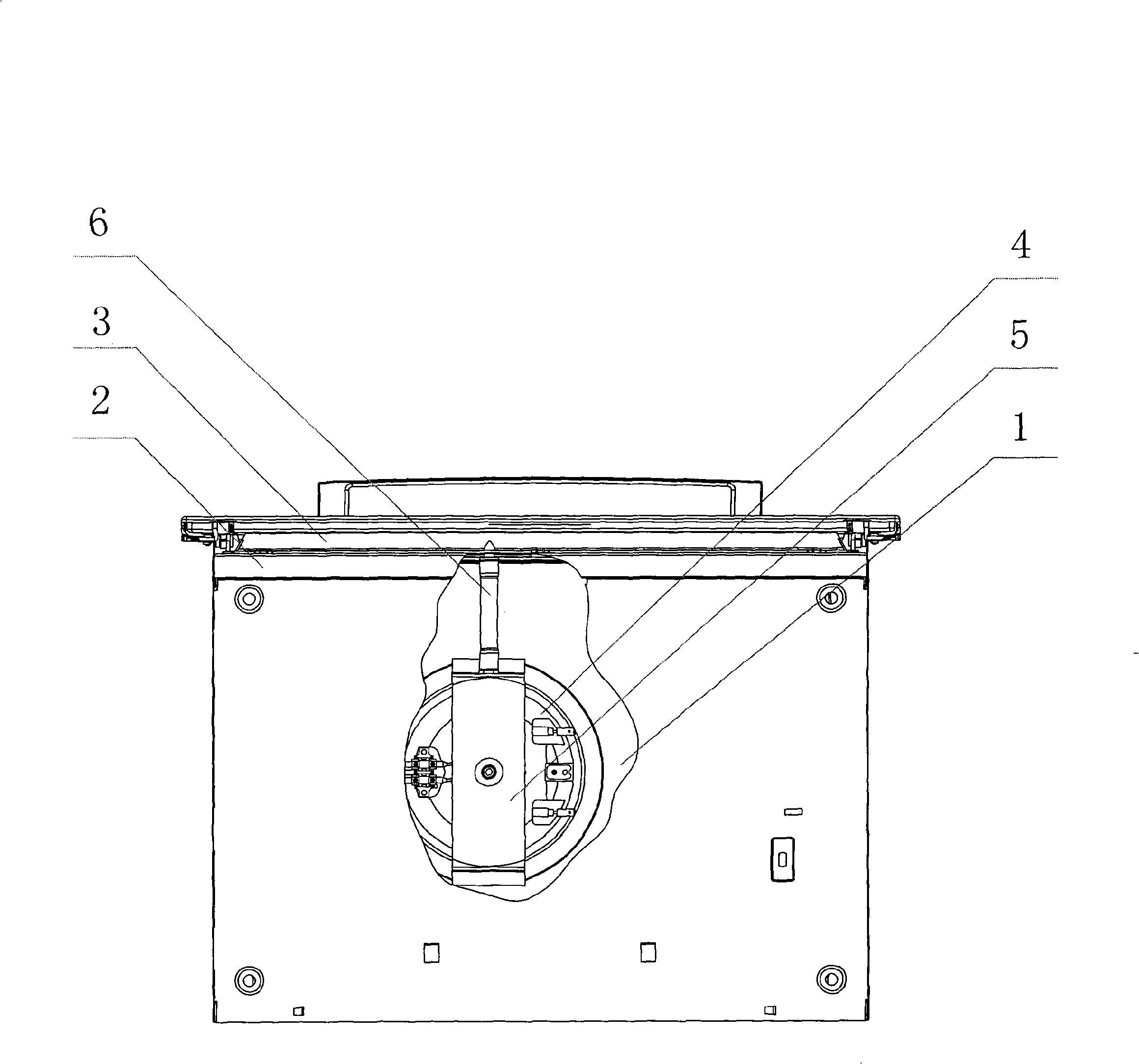

Domestic electric steaming furnace

InactiveCN101536870AThere will be no overflowEnsure food hygieneSteam cooking vesselsHeat conductingEngineering

The invention discloses a domestic electric steaming furnace which can clean water in a water containing tank without the water containing tank being dismounted, ensures the dietetic hygiene of users and successfully protects cupboards while bringing conveniences to the users. The domestic electric steaming furnace comprises a furnace body (1), a furnace body panel (2), the water containing tank (3) and a heating disk (4). The furnace is also provided with an air discharging channel and a heat conducting device (5) used for evaporating water. The heat conducting device (5) is communicated with the water containing tank (3) via a connecting pipe (6) and is also communicated with the air discharging channel. The heat conducting device (5) is arranged under the heating disk (4) and is in contact with the heating disk (4). The inner bottom surface of the heat conducting device (5) is lower than the inner bottom surface of the water containing tank (3). The connecting pipe (6) is arranged in a horizontal or inclined way. The inclined arrangement of the connecting pipe (6) indicates that the higher end of the connecting pipe (6) is connected with the water containing tank (3) and the lower end of the connecting pipe (6) is connected with the heat conducting device (5).

Owner:宁波欧燕电器有限公司

Silicon-containing organic engine coolant and applications thereof

InactiveCN109666458APrevent freezingLowering the freezing pointHeat-exchange elementsPreservativeCarboxylic salt

The invention provides a silicon-containing organic engine coolant, which comprise, by weight, 25-55 parts of ethylene glycol, 2-10 parts of a carboxylate, 0.1-5 parts of a silicate, 0.1-5 parts of asilicate stabilizer, 0.5-10 parts of a corrosion inhibitor, 0.2-2 parts of a preservative, 0.5-2 parts of an antifoaming agent, and 30-70 parts of deionized water. According to the present invention,the silicon-containing organic engine coolant can well protect the metal and non-metal materials of the engine cooling system, can effectively prevent corrosion and water scale, and has stability andlong service life within a large pH value range.

Owner:CHINA PETROLEUM & CHEM CORP

Method for composite phosphatization on metallic material surface

InactiveCN101298671AGood anti-corrosion effectStrong adhesionMetallic material coating processesCompound (substance)Corrosion

The invention relates to the field of chemical processing of material surfaces, in particular to a method for implementing composite phosphatization on the surface of metallic materials. The invention adopts the following technical proposal: firstly, common phosphatizing techniques are adopted for processing the surface of a metallic part, and a phosphatized layer of the metallic part is coated with a layer of protective resin, thus improving the corrosion resistance effect of the metallic part. Compared with currently popular techniques such as galvanization, phosphatization, color hardening and electrophoresis, etc., the method for implementing composite phosphatization on the surface of metallic materials has better corrosion resistance effect, strong adhesive attraction, is not easy to shed when being collided, and has moderate cost and simple technique. The method for implementing composite phosphatization on the surface of metallic materials is mainly used for the protective processing of metallic material surfaces.

Owner:李世奇

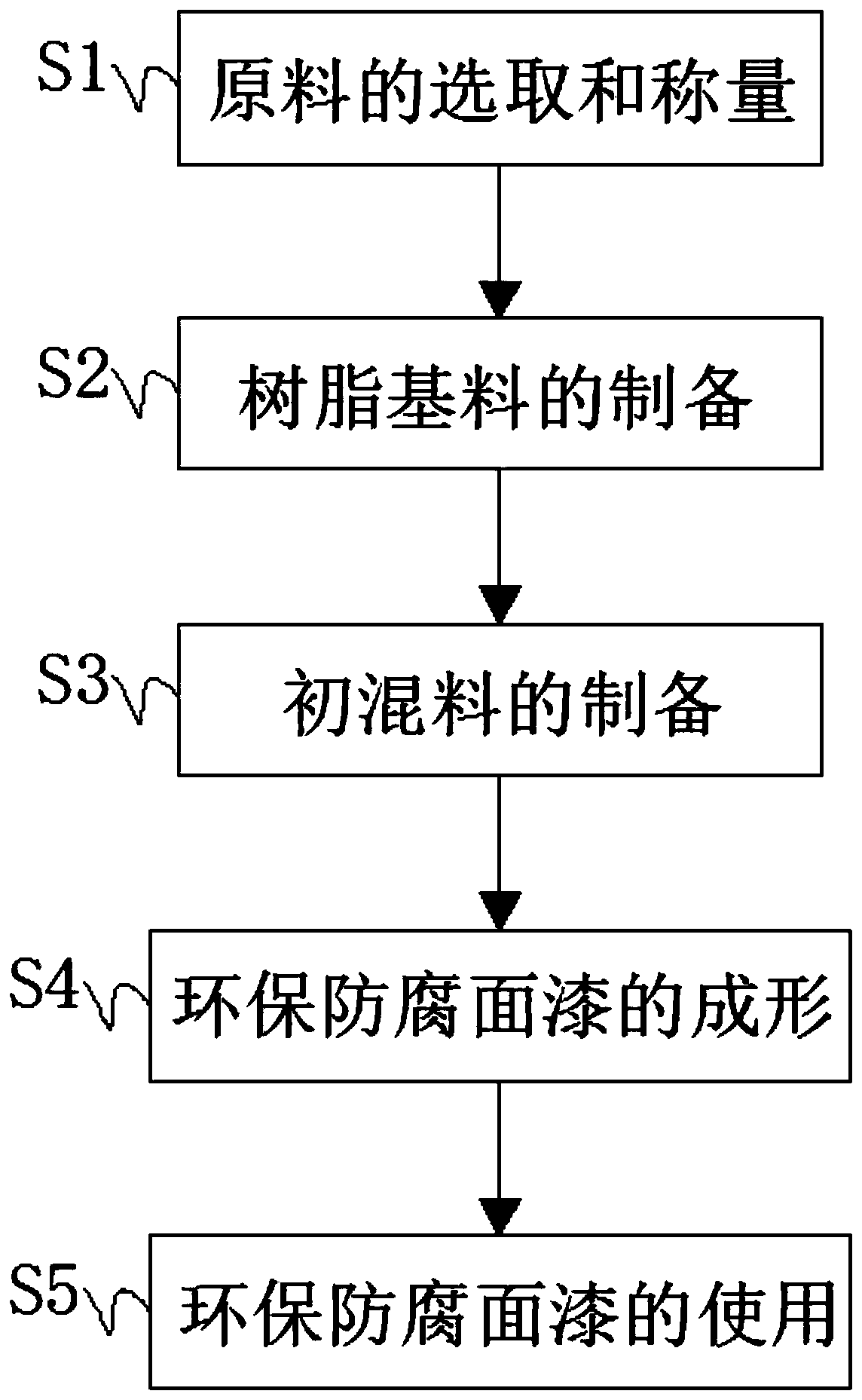

Novel environmentally-friendly anticorrosive top coat

InactiveCN110655863AImprove corrosion resistanceImprove anti-corrosion effectShellac coatingsAntifouling/underwater paintsSodium silicatePolyvinyl alcohol

The invention discloses a novel environmentally-friendly anticorrosive top coat, which comprises the following raw materialsby weight: 60-70 parts of a natural resin, 1-3 parts of a mildew-proof bactericide, 0.5-1 part of silver chloride, 1-3 parts of a curing agent, 1-3 parts of zinc powder, 0.5-1 part of sodium silicate, 5-10 parts of a polyvinyl butyral resin, 0.5-1 part of a cross-linking agent and 0.5-1 part of a thickening agent. The invention belongs to the technical field of building coating materials. According to the invention, with the novel environmentally-friendly anticorrosive top coat, the composition of the top coat can be improved, the corrosion resistance of the top coat is improved,and the natural environmentally-friendly resin is used for replacing the synthetic resin to achieve the purposes of energy saving and environmental protection and modify the natural resin, such that the top coat base material can meet the requirements of high corrosion resistance and highimpact resistance while the environmental protection is achieved so as to well achieve the purposes of environmental protection and practicality, substantially improve the anticorrosion effect of theanticorrosive paint and achieve energy saving and environmental protection to benefit people.

Owner:HANGZHOU BAOLI SPORTS FACILITIES ENG

Powder coating having excellent antirust effect and used for pump valve

InactiveCN105440901AImprove corrosion resistanceGood weather resistanceAnti-corrosive paintsPowdery paintsEnvironmental resistanceSilanes

The invention discloses powder coating having an excellent antirust effect and used for a pump valve. The powder coating is prepared from raw materials in parts by weight as follows: 52-54 parts of polyester resin, 7-8 parts of fluorocarbon resin, 4-5 parts of triglycidyl isocyanurate, 13-15 parts of nano aluminum oxide, 0.8-0.9 parts of perfluoro octyl triethoxysilicane, 25-30 parts of an ethanol solution with the concentration being 75wt%, 0.5-0.6 parts of a silane coupling agent kh560, 0.8-1 part of polyethylene wax, 1.2-1.5 parts of a polyacrylate leveling agent, 6-8 parts of superfine zinc powder, 2-3 parts of an ethylene-chlorotrifluoroethylene copolymer, 2-3 parts of polyvinylpyrrolidone, 13-15 parts of barium sulfate, 3-4 parts of mica iron oxide and a proper amount of water. The powder coating has excellent comprehensive performance, the film forming speed is high, the antirust effect of the powder coating is further improved due to addition of the superfine zinc powder and mica iron oxide, and a coating layer is tough and firm and not prone to peeling, has a smooth surface and is free of pinholes, safe and environment-friendly.

Owner:TONGLING SIDE TECH

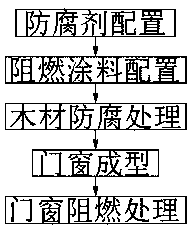

High-flame-retardancy fireproof door and window and manufacturing method thereof

InactiveCN110014489AImprove anti-corrosion effectImprove high temperature resistanceWood treatment detailsPressure impregnationRosinChemistry

The invention discloses a high-flame-retardancy fireproof door and window and a manufacturing method thereof, and belongs to the technical field of doors and windows. The high-flame-retardancy fireproof door and window comprise the following components: a rosin emulsion, an antioxidant, octanoic acid, disodium octoborate tetrahydrate, a chelating agent, polyethylene glycol, absolute ethyl alcohol,a flame retardant, pentaerythritol, phosphate, epoxy resin, silica gel powder, a refractory material, organic silicon quaternary ammonium salt and pure water. According to the invention, anticorrosive treatment is carried out on a door and window through a preservative, so that the anti-corrosion effect of the door and window is improved; flame-retardant treatment is carried out on the door and window through the flame retardant in a flame-retardant coating; high-temperature-resistant performance of the door and window is effectively improved through mixing of the epoxy resin and the silica gel powder, so that fire can be effectively prevented from spreading; the organic silicon quaternary ammonium salt is added to the flame-retardant coating, and the organic silicon quaternary ammonium salt has antibacterial and bacteriostatic effects, can resist high temperature and washing and has durability, so that the antibacterial and mildew-proof effects of the door and window are greatly enhanced, the mildew-proof effect is improved, and the service life of the door and window is greatly prolonged.

Owner:安徽百祺瑞建材科技有限公司

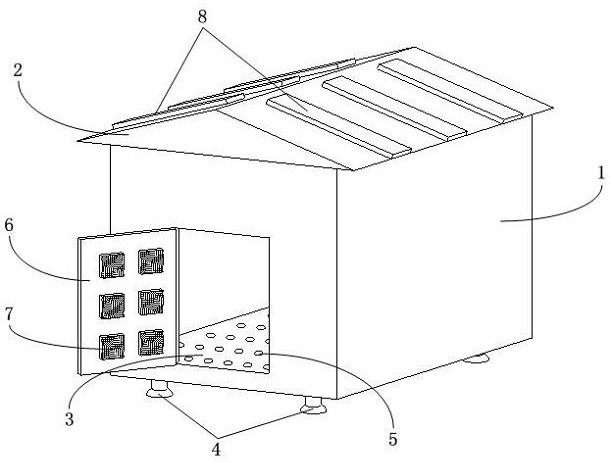

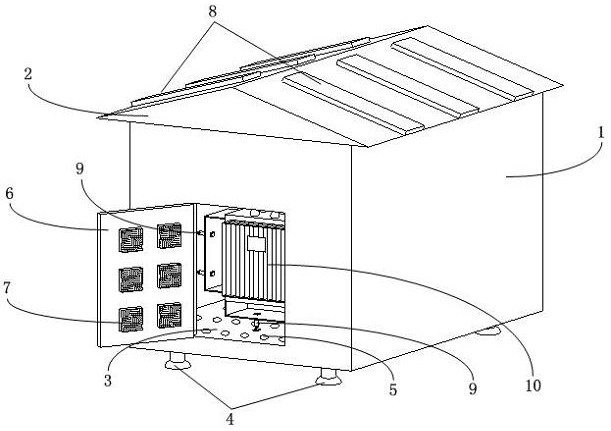

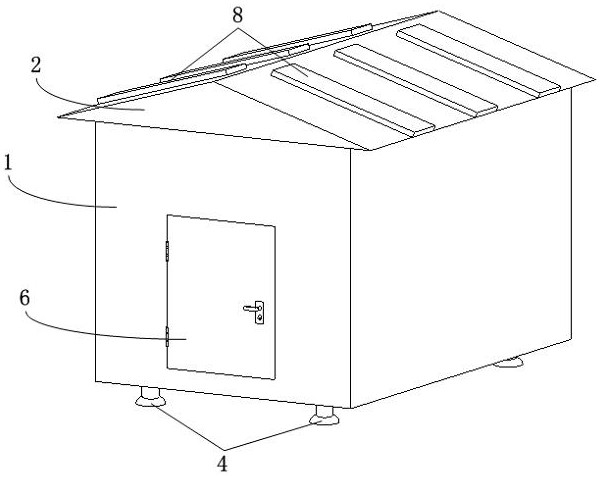

Noise reduction and elimination type box-type substation shell

PendingCN111864595ASimple structureImprove compactnessTransformer housesSubstation/switching arrangement cooling/ventilationEngineeringElectromagnetic shielding

The invention discloses a noise reduction and elimination type box-type substation shell. The shell comprises an outer shell, a top cover, a supporting base and supporting legs, the top cover is fixedto the top of the outer shell, the supporting base is fixed to the bottom of the outer shell, heat dissipation holes are formed in the supporting base, the top cover and the supporting base enclose the outer shell into a closed box-type structure, and the supporting legs are fixed to the bottom end face of the supporting base; the outer shell is formed by sequentially connecting four wallboards,a movable door is connected to any wallboard, a sound absorption patch is bonded to the movable door, each wallboard comprises a sound attenuation layer, an electromagnetic shielding layer, a vacuum layer, a heat dissipation layer and an outer protection layer which are sequentially arranged from inside to outside, and the sound absorption layers, the electromagnetic shielding layers, the vacuum layers, the heat dissipation layers and the outer protection layers are fixedly connected with one another. The noise reduction and elimination type box-type substation shell is simple in structure, reasonable in design, high in overall structure compactness, good in sound insulation and noise reduction performance, high in heat dissipation efficiency, high in use safety and good in market application prospect.

Owner:佛山市中衡电气设备有限公司

Waterborne industrial rustproof color paste and preparation method thereof

PendingCN108641490AExtended time intervalNo pollution in the processFireproof paintsAnti-corrosive paintsWater solubleDefoaming Agents

The invention relates to a waterborne industrial rustproof color paste and a preparation method thereof, wherein the rustproof color paste comprises the following raw material components in parts by mass: 45-65% of pigment, 4-7% of wetting dispersant, 5-10% of humectant, 0.05-0.1% of stabilizer, 0.01-0.5% of defoaming agent, 1-2% of acidic complexing agent, 0.05-0.3% of bactericide, 0.2-0.3% of PHregulator and 10-40% of deionized water. The rustproof color paste prepared by using the preparation method is not only suitable for rustproofness of a steel surface with a rusted and hard oxide scale layer or an old paint film, but also suitable for rustproofness of a stainless steel surface if being added into a waterborne industrial coating. In addition, the rustproof color paste prepared by using the preparation method is also environment-friendly when being used and further has good compatibility with various common waterborne industrial coatings such as an alkyd primer and an epoxy ester primer as well as water-soluble resin.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com