Anti-slipping anchor for foundation of split mounting type tower crane

An assembled and anti-slip technology, which is applied in the direction of infrastructure engineering, construction, sheet pile walls, etc., can solve problems such as not being able to be immersed in water or soil for a long time, high requirements for the use environment, and threats to the safe use of tower cranes. Low cost, good anti-corrosion effect, simple production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

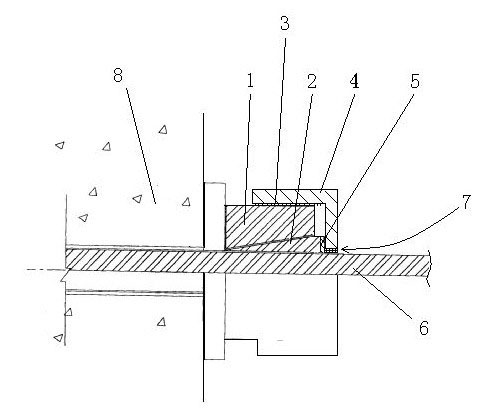

[0012] Such as figure 1 As shown, the anti-slip anchor used for the foundation of the assembled tower crane includes an anchor ring 1 and a clip 2 inside the anchor ring 1. The outer circumference of the clamping end of the anchor ring 1 is provided with a thread 3, and the inner circumference of the clamping cap 4 is Matching threads are provided on the surface, and the clamping cap 4 is threadedly connected to the clamping end of the anchor ring 1.

[0013] still as figure 1 As shown, an elastic object 5 is provided between the top of the clamping cap 4 and the end of the clip 2. In this embodiment, the elastic object 5 is an elastic gasket (such as a rubber gasket).

[0014] still as figure 1 As shown, the top of the clamping cap is provided with a connecting object 6 piercing hole, and the piercing hole is set concentrically with the anchor ring, and the inner periphery of the hole is provided with a sealing ring 7 . In this embodiment, after the connector 6 passes thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com