Producing well sleeve interior anti-corrosion method

A technology for internal anti-corrosion and oil production wells, which is applied in the direction of casing, drill pipe, drilling equipment, etc., can solve the problems of high labor cost, large amount of corrosion inhibitor, high cost, etc., and achieve the goal of improving anti-corrosion effect, reducing consumption and personnel cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In order to overcome the defects of the existing anti-corrosion technology, this embodiment provides an anti-corrosion method in the casing of the oil production well, which extends the pump liner to the upper end of the perforation section 5 by 1-2m, so that the moving liquid level is between the end of the pump liner. The oil-water mixture in the annular space between the casing 2 and the tubing 1 becomes a dead volume and increases the oil-water ratio, and the oil-water mixture in the annular space between the casing 2 and the tubing 1 is filled with a corrosion inhibitor.

[0024] Principle of the present invention:

[0025] When the pump liner is extended, the liquid from the dynamic liquid surface to the annulus of the pump liner oil sleeve will become a dead volume. Due to the difference in density of oil and water in the produced fluid, oil-water separation will gradually occur under the action of gravity, and the crude oil will occupy the In the upper space, th...

Embodiment 2

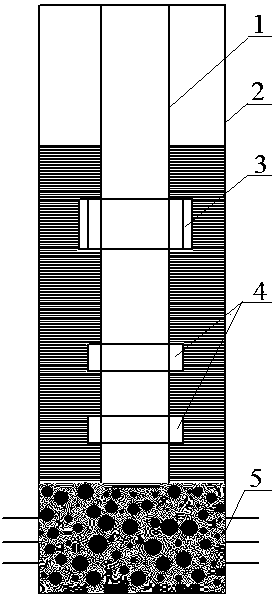

[0029] On the basis of embodiment 1, this embodiment provides a kind of figure 1 In the anti-corrosion method in the casing of the oil production well shown, after the oil-water mixture becomes dead volume, the crude oil in the oil-water mixture under the pump tailpipe moves upward, and the water in the dead volume moves downward to realize the oil-water ratio of the dead volume. increase.

[0030] In this embodiment, the pump tailpipe is a metal oil pipe 1 , and a sacrificial anode 4 is externally hung on the metal oil pipe 1 .

[0031] Such as figure 1 As shown, the fluid surface of the oil-water mixture is between the casing 2 and the annular space of the tubing 1, and the pump tailpipe of the oil well pump 3 is at the upper end of the perforation section 5 at 1-2m. The metal oil pipe 1 is used as the field oil pipe 1, and the sacrificial anode 4 is an aluminum anode, zinc anode or other type anode suitable for the well temperature, and the number and distribution of the ...

Embodiment 3

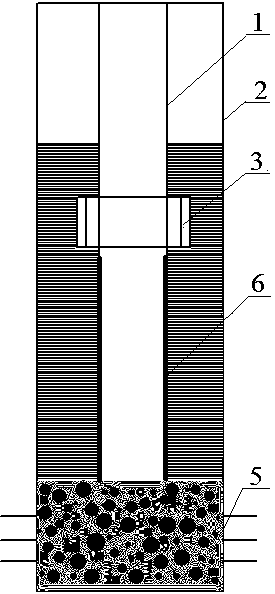

[0033] On the basis of embodiment 1, this embodiment provides a kind of figure 2 In the shown anti-corrosion method for the casing of the production well, the pump tailpipe is a non-metallic pipe 6 .

[0034] The non-metallic pipe 6 can be made of glass steel pipe, flexible composite pipe, etc., and the tensile strength of the coupling joint must meet the site requirements. The use of non-metallic pipe 6 can reduce the hanging weight of the pump while avoiding corrosion.

[0035] No matter which method of embodiment 2 or embodiment 3 is adopted, because the liquid from the moving liquid surface to the tailpipe is a dead volume and is crude oil with low water content, the long-term anti-corrosion purpose can be achieved by adding the corrosion inhibitor once, which can be greatly improved. Significantly reduce the amount of corrosion inhibitors and personnel costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com