Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Dryness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fully-automatic immunofluorescence quantitative analysis apparatus and detection method

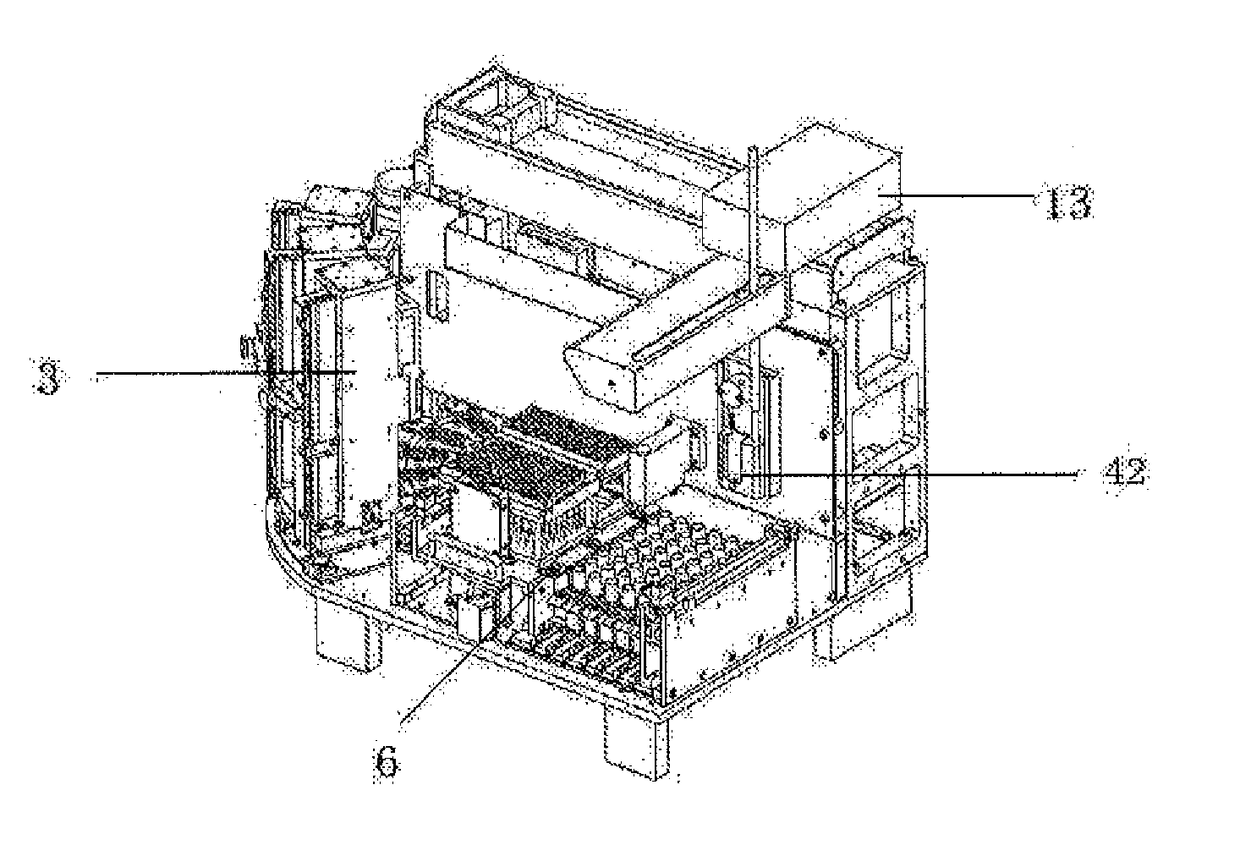

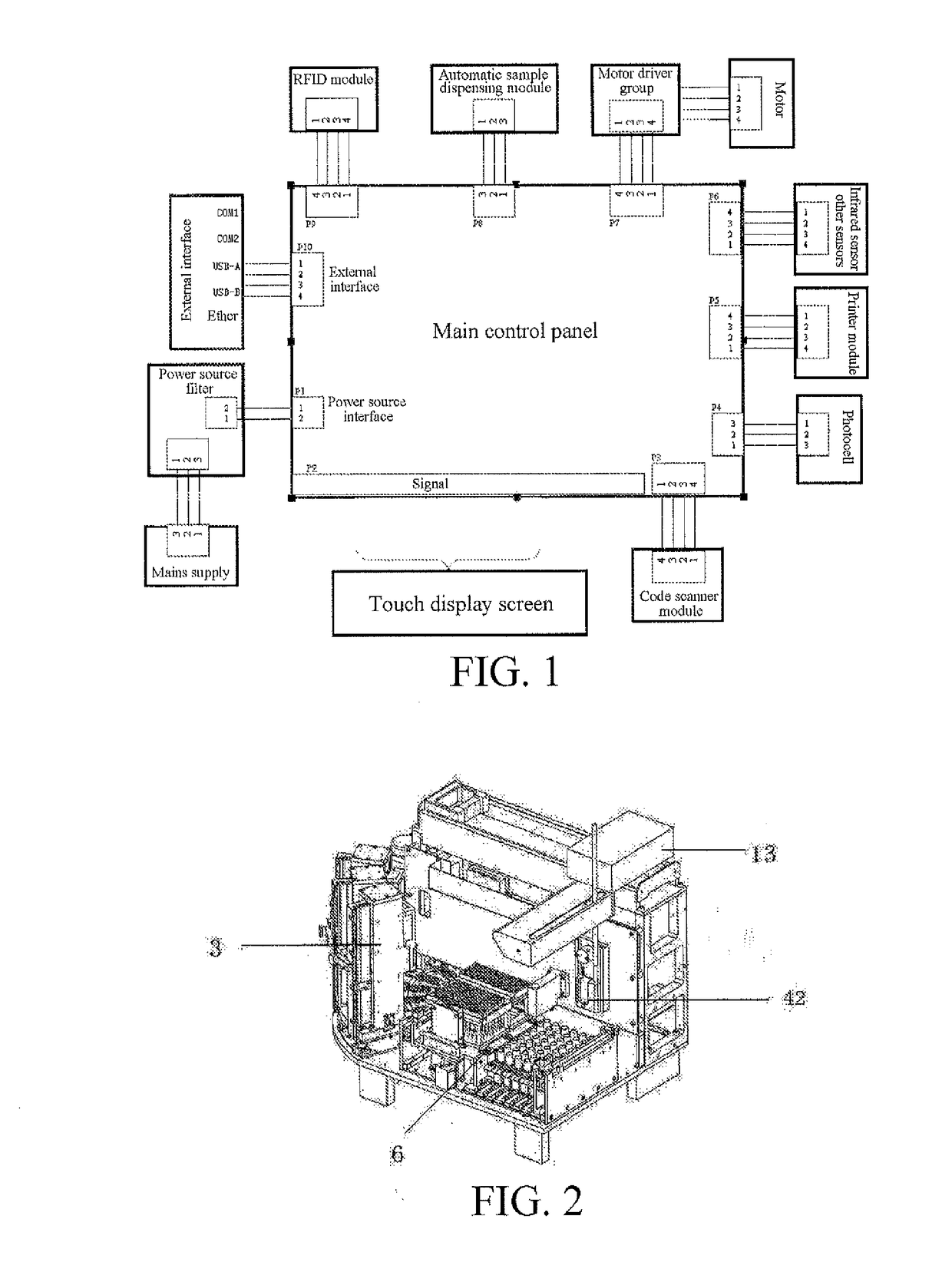

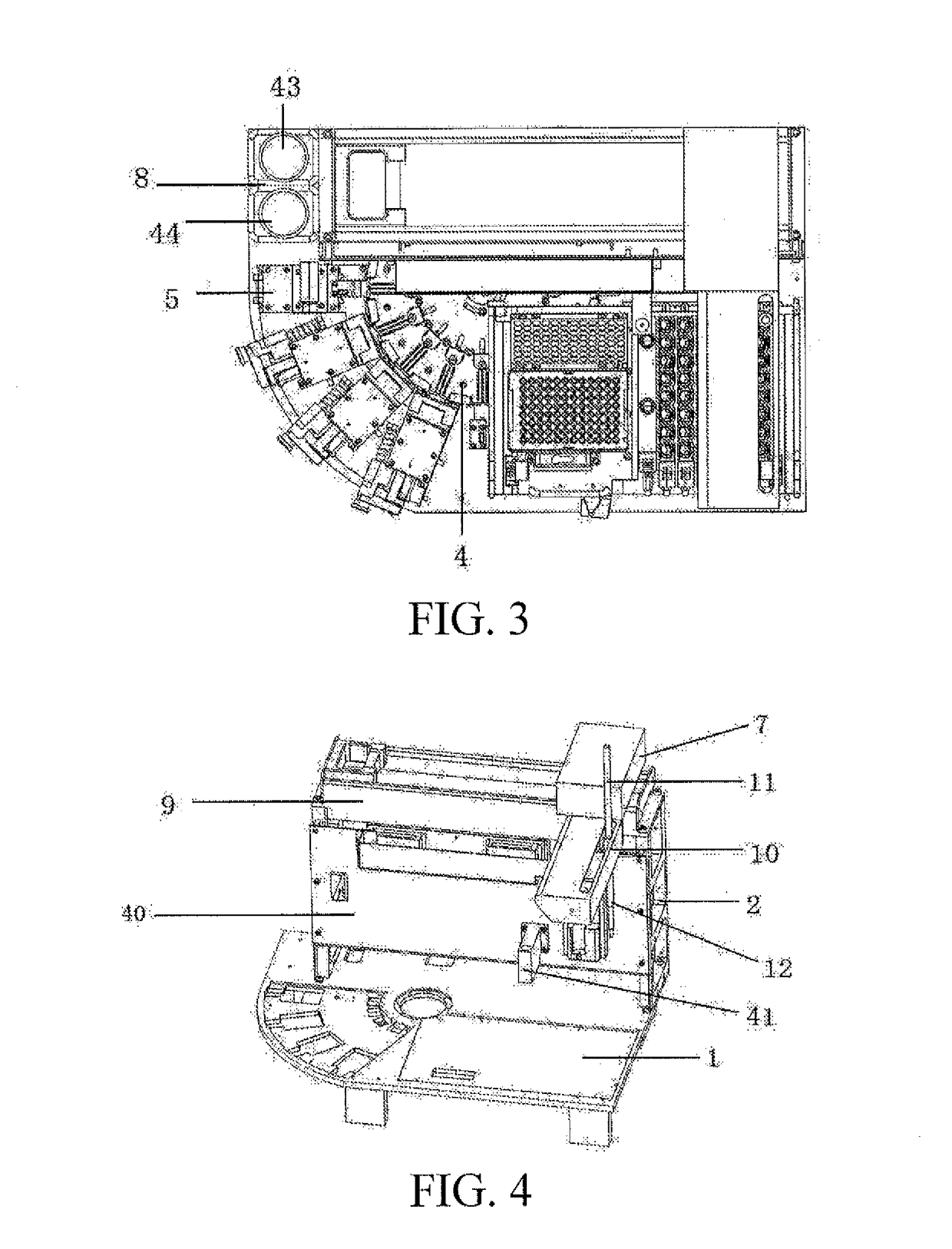

A fully-automatic immunofluorescence quantitative analyzing apparatus and detection method belong to the field of quantitative immunofluorescence analysis and detection. The immunity quantitative analyzing apparatus includes a support baseplate, a reagent strip storage and automatic loading module, a cuvette ring module, a detection module, a sample module, a sample dispensing module, a washing module and a control system, the reagent strip storage and automatic loading module, the cuvette ring module, the detection module, the sample module, the sample dispensing module, the washing module being sequentially arranged on the support baseplate. The reagent strip storage and automatic loading module provides a reagent strip for the cuvette ring module, and the sample dispensing module dispenses the sample on the sample module to the cuvette ring module and performs a reaction, and the sample enters the detection module to complete the detection after the reaction is complete.

Owner:GETEIN BIOTECH

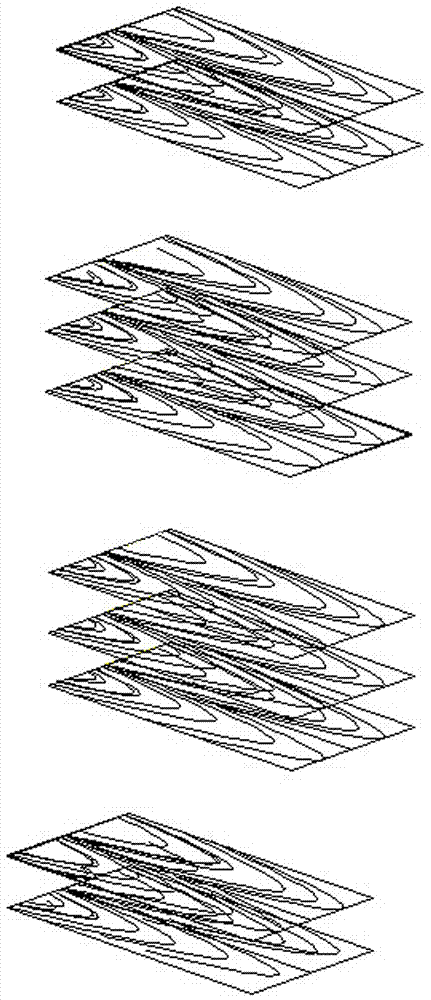

Method for manufacturing environment-friendly high-strength anti-deformation solid wood composite door

InactiveCN103128823AReduce moisture contentOvercoming high moisture content and poor flatnessWood veneer joiningAdhesive application devicesSanderSolid wood

The invention discloses a method for manufacturing an environment-friendly high-strength anti-deformation solid wood composite door. The method includes steps of softening and miniaturizing log to obtain wood sheets; classifying the wood sheets into a panel and core materials and drying the panel and core materials; splicing the thin sheets into integral plates, classifying the integral plates into a panel and core materials, selecting integral plates with transverse textures in the core materials to be used as balance tension plates, arranging the balance tension plates into multiple layers and gluing the multiple layers of balance tension plates; performing press fit for the multiple layers of glued balance tension plates into a multilayer plate by the aid of a hot press, preserving the multilayer plate, cutting off four edges of the multilayer plate and sanding the multilayer plate by a sander so as to set the thickness of the multilayer plate; cutting the multilayer plate into fixed-width battens, manufacturing an anti-deformation core material, and setting the thickness of the anti-deformation core material; and manufacturing a medium-density plate and the anti-deformation core material into a structural plate, preserving the structural plate, cutting four edges of the structural plate, sanding the structural plate to set the thickness of the structural plate, carving the structural plate, milling the profile of the structural plate, milling lines of the structural plate and finishing the structural plate to obtain the high-strength anti-deformation solid wood composite door. The method has the advantages that common wood resources are sufficiently utilized to replace valuable wood resources, accordingly, materials are saved, waste materials are recycled, forest resources are powerfully protected, the cost is lowered, composite materials are replaced, and the method has an excellent application prospect.

Owner:HARBIN SHENGSHI HUALIN TECH

Water-based metal rust inhibitor and preparation method thereof

The invention provides a water-based metal rust inhibitor and a preparation method thereof. The rust inhibitor comprises sorbitan monooleate, inositol hexaphosphate, zinc dihydrogen phosphate, acrylamide, glutamic acid, dinonyl-naphthalenesulfonate, dicyclohexylamine, octadecylamine oleyl sarcosinate, oxidized barium petrotate, sodium ethylenediamine teramethylene phosphonate, 1-hydroxyethylidene, dimethylaminoethyl acrylate, sulfomethylated polyacrylamide, a film forming agent and deionized water. The preparation method comprises the steps of firstly, mixing sorbitan monooleate, inositol hexaphosphate, zinc dihydrogen phosphate and water, and adding octadecylamine oleyl sarcosinate; then, adding acrylamide, glutamic acid, dinonyl-naphthalenesulfonate, dicyclohexylamine and oxidized barium petrotate into the deionized water, and adding 1-hydroxyethylidene; and mixing a mixture I and a mixture II, and adding the left components to obtain the water-based metal rust inhibitor. The rust inhibitor can be attached to the surface of metal, so that the metal has better wear resistance and corrosion resistance.

Owner:NINGBO SHEN XIN ELECTRONICS CO LTD

Green pawpaw mastication tablet and producing method thereof

The invention relates to a green papaya chewing tablet made from natural plant fruit papaya, which mainly contains the materials of green papaya powder, sweetener and adhesives; the preparation method comprises following steps: making green papaya powder first; mixing the green papaya powder with other materials; making the mixture into particle materials; drying the particle materials with low temperature; squashing the particle materials into tablets; finally packing the tablets to obtain the product. The green papaya chewing tablet has the advantages of strengthening spleen and stomach, helping digestion, relieving constipation, detoxicating and deswelling, improving lactation, preserving continence, preventing tooth decay, anti-tumor, reducing weight, enlarging breast, and being suitable for general population, more particularly for the female friends.

Owner:广西科学院生物研究所有限责任公司

Medical nursing pad for preventing bedsore

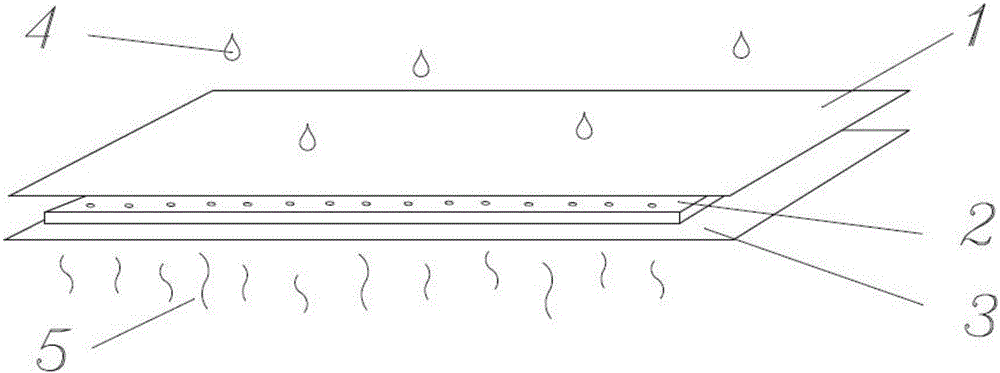

ActiveCN106038073AImprove drynessImprove comfortUpholstery manufactureNursing bedsSpecific functionReverse osmosis

The invention provides a medical nursing pad for preventing bedsore. The medical nursing pad comprises a surface layer, a core layer and a bottom layer, wherein the core layer comprises fluff pulp and a super absorbent polymer (SAP) material, and is wrapped with toilet paper; pointy SAPs are distributed on the core layer; an infiltrating liquid is absorbed and locked by the SAPs in an inverted funnel-shaped SAP region of the core layer, so that the reverse osmosis quantity of the nursing pad after liquid absorption is minimized; and meanwhile, water moisture separated from the liquid reaches the bottom layer through a longitudinal moisture channel formed by gaps among fluff pulp fibers in the core layer and determined by a density range, and diffuses out of the medical nursing pad through nanoscale breathable micropores in the bottom layer. The medical nursing pad can quickly absorb and firmly lock the moisture and the reverse osmosis quantity of the nursing pad is minimized, so that the nursing pad is kept dry and comfortable; and meanwhile, the moisture channel can be provided, so that the medical nursing pad can keep a specific function of moisture osmosis, and the purpose of preventing the bedsore is achieved after the medical nursing pad is combined with the specific function.

Owner:BEIJING BEISHUTE MATERNITY & CHILD ARTICLES

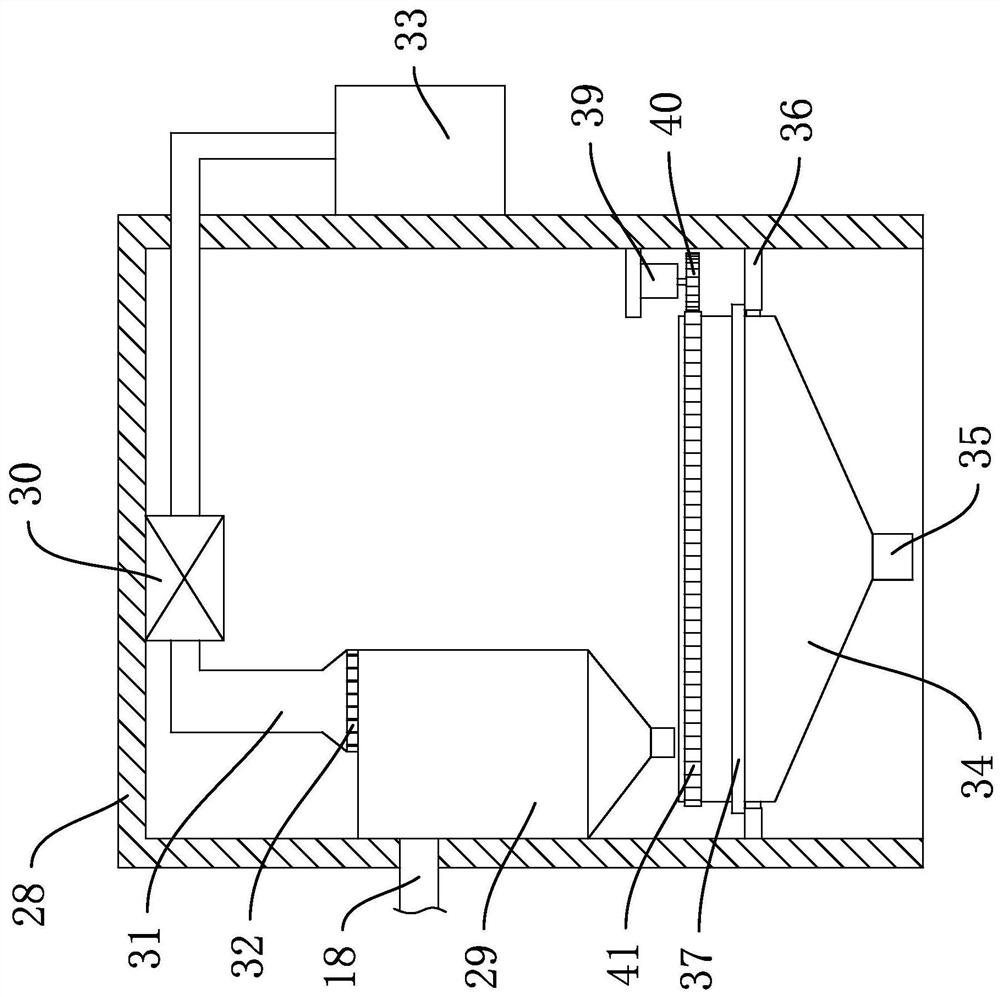

Special treatment vehicle for endoscopic diagnosis and treatment operation

InactiveCN108992175AQuick washImprove scrubbing effectSurgical furnitureDiagnosticsDisinfectantElectric machinery

The invention discloses a special treatment vehicle for endoscopic diagnosis and treatment operation, comprising a main body box. A lower surface of the main body is fixedly connected with supportinglegs. Universal wheels are fixedly installed at lower ends of the plurality of supporting legs. One side surface of the main body box is fixedly connected with push rods. One end of each of the two push rods is fixedly connected with a handle. One side surface of the main body box is provided with an operation port. An inner wall of the operation port penetrates and extends to an inner side wall of the main body box. According to the special treatment vehicle for endoscopic diagnosis and treatment operation, during the actual use process, an appropriate amount of disinfectant liquid is added in a liquid medicine tank, an endoscope hose that needs to be cleaned is held, the partial hose and the end lens that need to be cleaned are put into a cleaning cylinder, the length of the cleaning cylinder can be determined due to the fact that the length of the hose entering the human body during the routine stomach examination is relatively fixed, meanwhile a motor and a submersible pump are enabled, and the submersible pump enables the disinfectant liquid to successively enter an infusion tube and an annular tube and finally to be ejected from a nozzle, thereby spraying the disinfectant liquid on the surface of the endoscope hose.

Owner:THE FIRST PEOPLES HOSPITAL OF NANTONG

Polysaccharide-containing moisturizing and oil-controlling composition and application thereof in cosmetics

InactiveCN111568801AEnhanced barrier functionHave immunityCosmetic preparationsToilet preparationsMetaboliteNormal skin

The invention discloses a polysaccharide-containing moisturizing and oil-controlling composition and an application thereof in cosmetics. The composition is prepared from the following components in percentage by mass of 0.05 to 20% of polysaccharide moisturizing composition, 0.01%-20% of an oil control composition, 0.5%-20% of an emollient, 0.05%-10% of an emulsion stabilizer, 0.1 to 3.0% of preservative and the balance of auxiliary materials and water. The key technology of the polysaccharide-containing moisturizing and oil controlling composition is that moisturizing and oil controlling areconducted at the same time, the normal skin barrier function is restored, and the polysaccharide moisturizing composition has a good moisturizing effect; the oil control composition efficiently inhibits the activity of 5 alpha-reductase and efficiently inhibits grease and metabolites secreted by sebaceous glands, hair follicles and sweat glands of facial skin, the oil control composition not onlyinhibits the activity of the 5 alpha-reductase, but also shrinks the pore diameter and reduces the channel for grease to be secreted out of epidermis, and the oil control effect is synergistically enhanced through a physical method; and the cosmetic prepared by the invention has relatively low irritation and allergy.

Owner:广州蛋壳网络科技有限公司

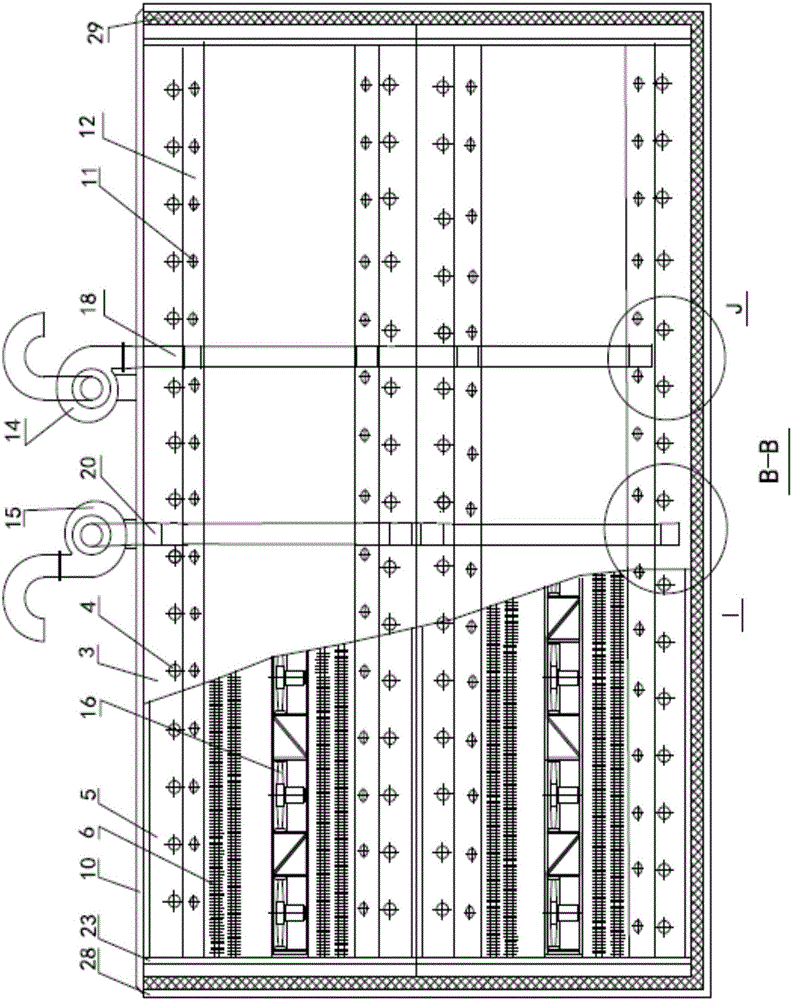

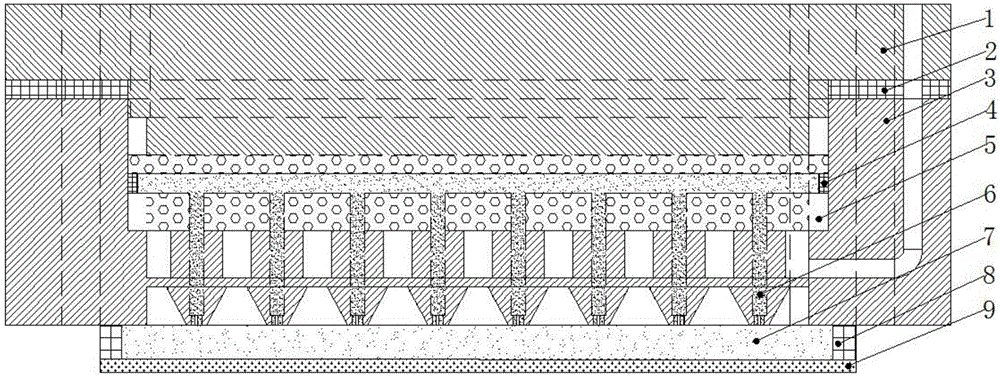

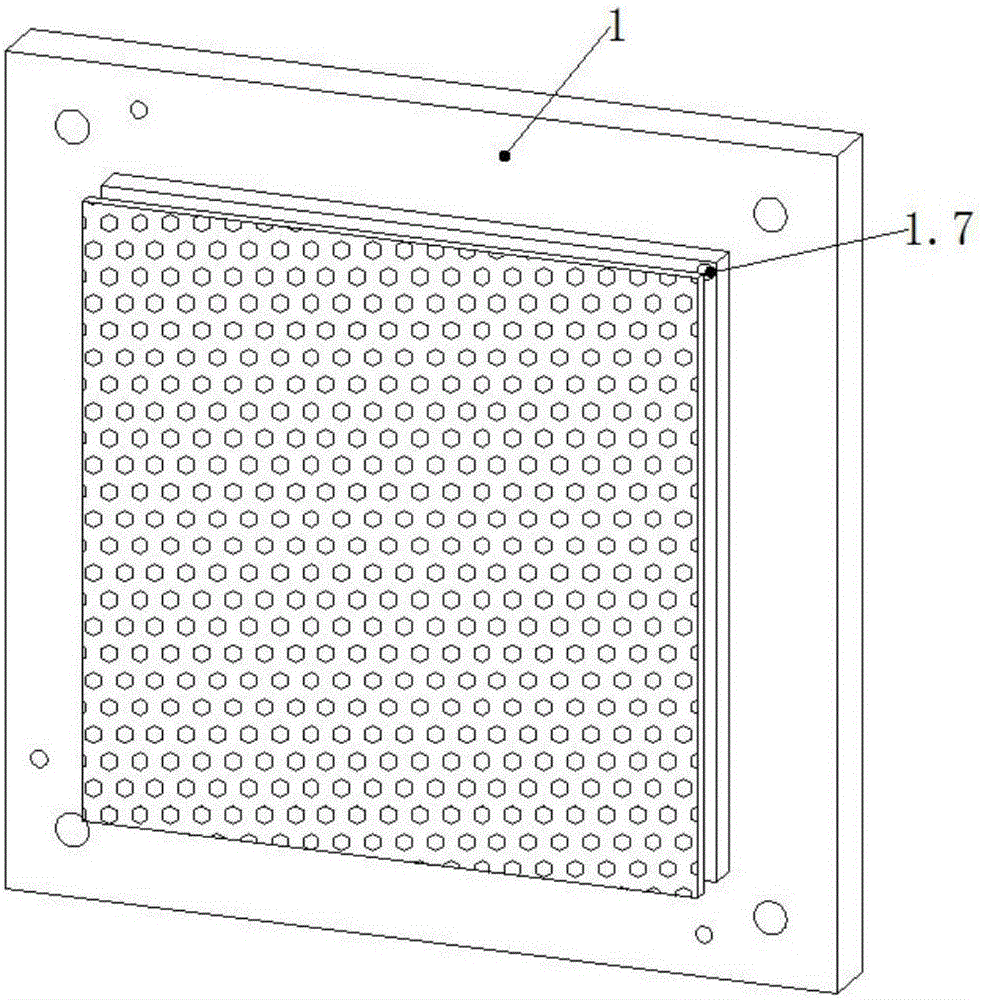

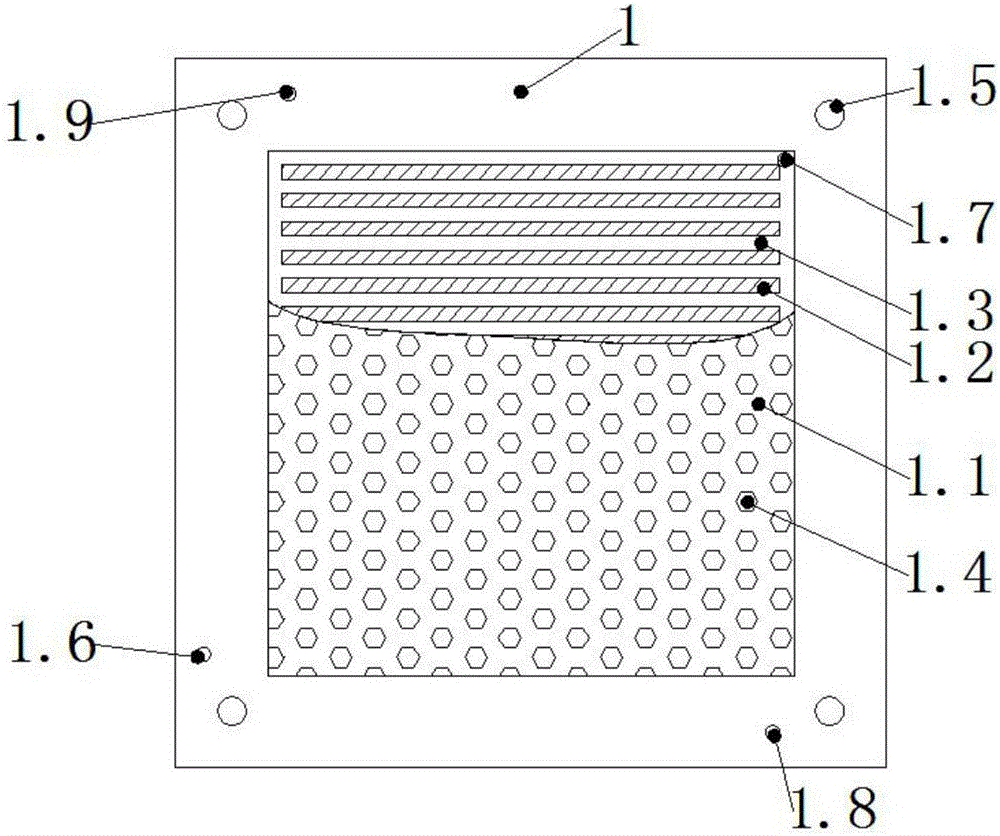

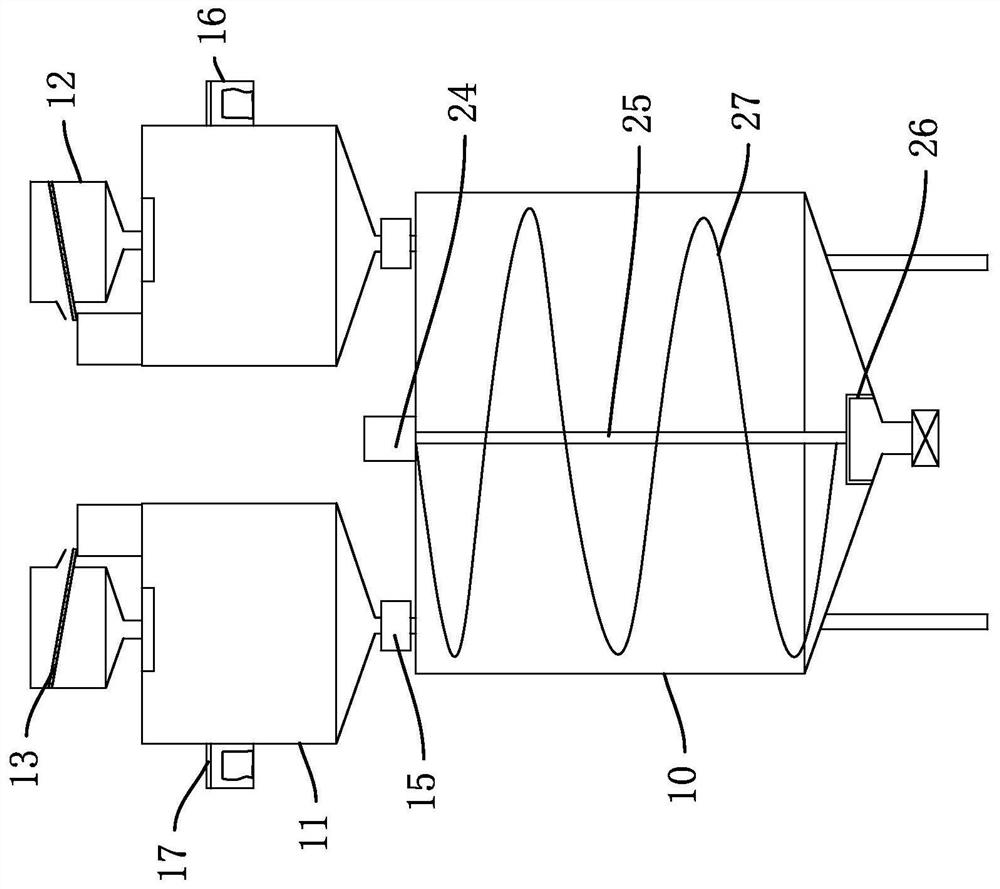

Side draught fan type cabin wood drying device and drying method

ActiveCN106288671AMeet the needs of dry productionPollution compensationDrying solid materials with heatAuxillariesWood productionMachining

The invention relates to a wood drying device and drying method, in particular to a side draught fan type cabin wood drying device and drying method. In order to solve the problems that an existing wood drying production device and method waste energy, pollute environment and prolong the wood production machining period, imported wood has the large medical inspection and insect removing workloads, and an existing wood transportation ship cannot achieve the function of wood drying in the remote transportation way, the device comprises a cabin, a cabin-interior equipment bearing frame, a drying device humidity adjusting air exchange system, a wood drying medium forced circulating system, a heat exchanger system, a drying medium state monitoring sensor system and a dried wood water containing rate monitoring sensor system. The method comprises the steps of wood stacking, cabin cover closing, wood drying, drying degree detection of the wood, and drying medium state adjusting according to a detection result. The device and method are used for drying and insect removal treatment in the wood transportation process.

Owner:BEIJING WUZHOUMU INT IND CO LTD

Method for continuously drying polycarbonate

InactiveCN102645085ADry evenlyShort stayDrying solid materials with heatHearth type furnacesSolventPolycarbonate

The invention belongs to the technical field of drying, and relates to a method for continuously drying polycarbonate, polycarbonate powdery materials are firstly fed into a pneumatic drying accelerator, superheat steam is simultaneously fed, in a pneumatic drying bushing, the polycarbonate powdery materials and the superheat steam concurrently flow forwards, are subjected to heat and mass transfer, and most solvent and water removal to complete the flow drying; then, the materials are mixed up with the steam flow to enter a cyclone drier, the materials and the steam do rotational motion along the inner wall to be subjected to fierce mass and heat transfer, then enter a cyclone separator to realize gas-solid separation for completing the cyclone drying; and the gas which is separated by the cyclone separator enters a solvent recovery system after being filtered by a bag-type dust collector, and the materials enter a primary fluidized bed to be mixed with high-temperature dry air, are subjected to full fluidization and heat transfer to remove the water content, enter a secondary fluidized bed to be cooled to normal temperature, and then enter the next process. The method has a simple technology, is easy to control in operation, has high thermal efficiency, saves energy sources, is environment-friendly, and has a good drying effect, large solvent recovery amount and obvious benefits.

Owner:QINGDAO UNIV OF SCI & TECH +2

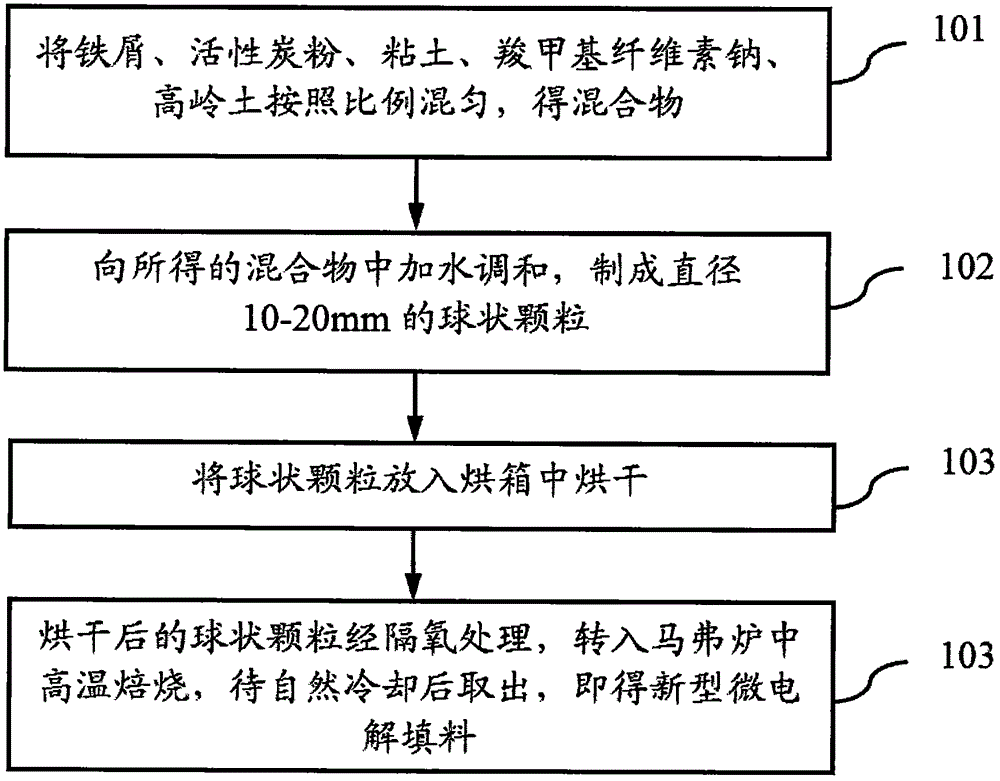

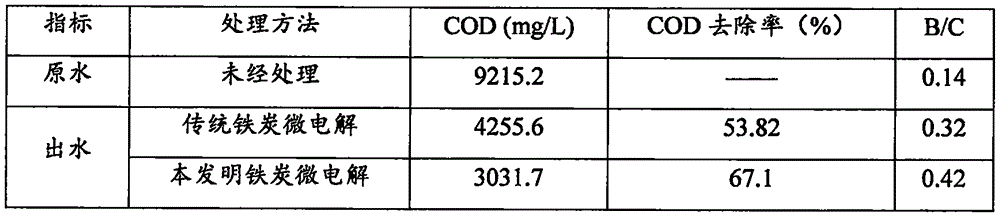

Micro-electrolysis filler for treatment of hardly degraded waste water and preparation method of micro-electrolysis filler

The invention discloses a micro-electrolysis filler for treatment of hardly degraded waste water. The micro-electrolysis filler consists of the following raw materials in percentage by weight: 30-40% of scrap iron, 30-40% of activated carbon powder, 20-40% of clay, 0.2-0.6% of carboxymethylcellulose sodium, and 1.0-1.5% of kaolin. A preparation method of the micro-electrolysis filler comprises the steps of: (1) performing mixing: uniformly mixing the scrap iron, the activated carbon powder, the clay, the carboxymethylcellulose sodium, and the kaolin in proportion to obtain a mixture; (2) performing granulation: adding water into the obtained mixture, and performing blending to prepare spherical granules; (3) performing drying: drying the spherical granules in a drying oven; and (4) performing oxygen-free calcination: performing oxygen-isolated treatment on the spherical granules, transferring the spherical granules into a muffle furnace, performing high-temperature calcination, and taking the spherical granules after natural cooling to obtain the micro-electrolysis filler. The micro-electrolysis filler disclosed by the invention can keep the characters of the scrap iron and the activated carbon powder very well, and can have relatively high porosity and specific area while the strength of the filler is ensured, so that the COD of waste water can be greatly reduced, and the biodegradability of the waste water is improved.

Owner:SHENYANG ACAD OF ENVIRONMENTAL SCI

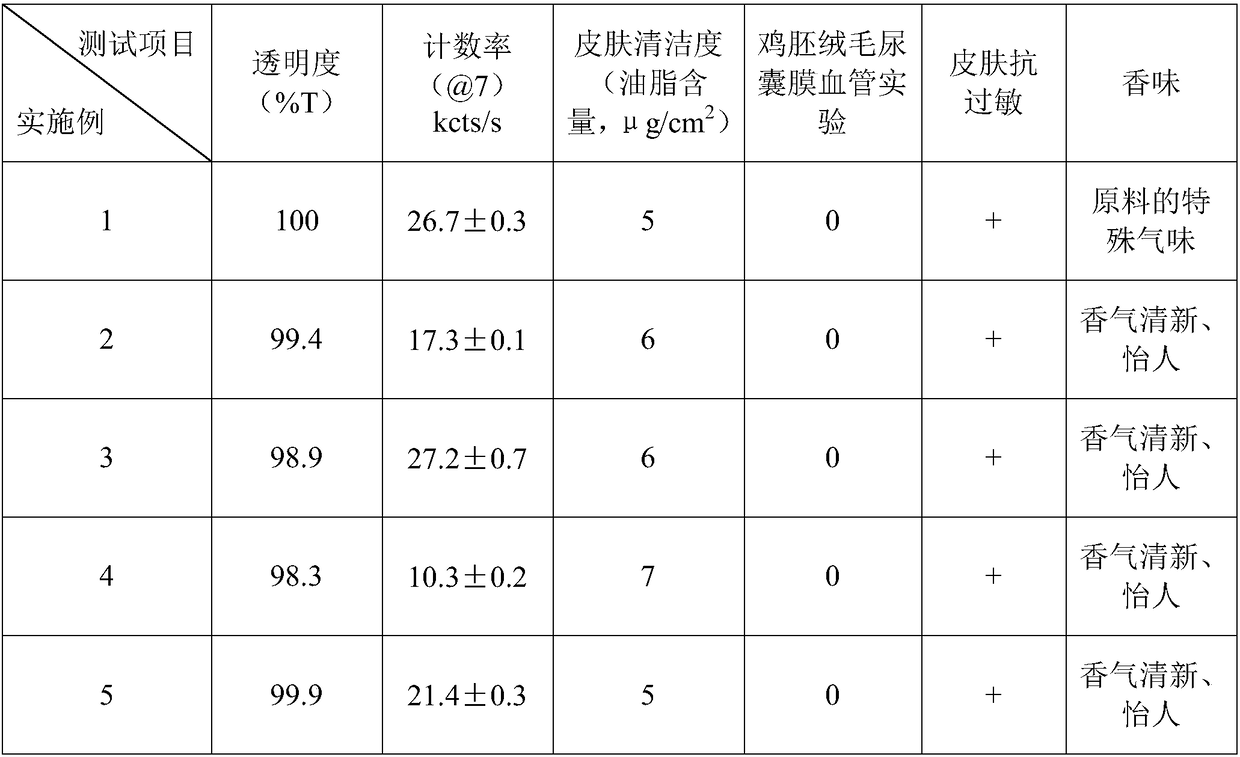

Anti-allergy soothing composition, cleansing agent comprising same and preparation method

InactiveCN108066216AHigh purityReduce sensitivityCosmetic preparationsToilet preparationsPurslane extractOfficinalis

The invention provides an anti-allergy soothing composition, a cleansing agent comprising the same and a preparation method. The anti-allergy soothing composition takes a purslane extract and a cortexmagnoliae officinalis bark extract as main raw materials, and adding PEG / PPG-25 / 30 copolymer and olive oil PEG-8 esters, wherein the purslane extract has anti-irritating, anti-allergy and soothing effects; the cortex magnoliae officinalis bark extract has anti-bacterial, anti-inflammation, anti-oxidant and anti-allergy soothing active effects; and by cooperation of the purslane extract and the cortex magnoliae officinalis extract, the anti-allergy effect can be improved. The anti-allergy soothing cleansing agent takes the anti-allergy soothing composition as a main material, and is added witha moisturizer, a softener, a cleanser and other auxiliary agents, the purslane extract and the cortex magnoliae officinalis bark extract are fused, in a using process, the cleanser can clean dirt inthe deep layer of skin, the micromolecular purslane extract and cortex magnoliae officinalis bark extract can rapidly enter the deep layer of the skin, and therefore, effects of moisturizing and relieving skin allergy are achieved.

Owner:国东启

Low-irritation cleaning composition and preparation method thereof

InactiveCN108379148ACheerful and optimisticCheerful spiritCosmetic preparationsToilet preparationsCounting ratePreservative

The invention belongs to the technical field of cosmetics and provides a low-irritation cleaning composition and a preparation method thereof. The low-irritation cleaning composition comprises the following components in parts by weight: 5 to 15 parts of a wetting agent, 0.1 to 0.5 part of a foam stabilizer, 5 to 20 parts of a surfactant, 0.5 to 1.2 parts of a preservative, 0.5 to 2.0 parts of ananti-allergic agent, 0.01 to 0.1 part of a pH value regulator, 0.001 to 0.1 part of sodium hyaluronate, 0.001 to 0.1 part of a leontopodium alpinum extract, 0.001 to 0.1 part of a sunflower extract, 0to 0.03 part of an aromatic and 60 to 80 parts of water. The low-irritation cleaning composition has high transparency and relatively low counting rate (relatively high counting rate indicates that acleaning agent has more or larger aggregates capable of scattering more light); and besides, the prepared composition has higher skin cleanliness and does not has irritation to skin.

Owner:GUANGZHOU SOYAWA BIO TECH CO LTD

Pneumatic rebounce type livestock feed crushing and drying device

ActiveCN110976007ADrynessBlow actionFeeding-stuffDrying gas arrangementsTemperature controlAnimal science

The invention relates to the field of animal husbandry equipment, in particular to a pneumatic rebound type livestock feed crushing and drying device. The device comprises a machine body, a storage cavity is formed in the upper part of the machine body, and a machining cavity is formed in the lower part of the machine body; a material conveying cylinder is installed in the middle of the top of themachining cavity, and a spiral blade is installed on a material conveying shaft on the inner side of the material conveying cylinder; a filter screen cylinder is arranged on the outer side of the material conveying cylinder, and the lower end of the filter screen cylinder is connected with a material blocking cylinder in a matched mode; the inner side of the material blocking cylinder is providedwith a rotating disc, the upper side of the rotating disc is fixedly provided with a plurality of crushing cutters in a circumferential distribution manner, and the lower side of the rotating disc isfixedly provided with a center pipe; and the center pipe is further provided with a plurality of exhaust pipes in a circumferential distribution manner, the lower end of the center pipe is connectedwith an air conveying pipe through a rotating joint, the other end of the air conveying pipe is connected with a temperature control fan, and a plurality of crushing rods are further installed on thecenter pipe on the lower side of the exhaust pipes. The livestock feed crushing and drying device is novel in structure and convenient to control, and has the effects of better efficiency and effect on livestock feed crushing and drying.

Owner:山东天聚安普瑞农牧发展有限公司

Novel solid-wood splice plate manufacturing method

InactiveCN104118019ATo overcome the problem of severe warpage, deformation and cracking, which makes it difficult to guarantee qualityImprove flatnessLaminationLamination apparatusSolid woodSander

The invention discloses a novel solid-wood splice plate manufacturing method. The method includes the following steps that softening physical treatment is conducted on raw woods; miniaturization treatment is conducted, and veneers are made; the veneers are dried through a special technology; a whole plate is formed through splicing, face plates and core materials are separated, a fully-longitudinal multi-layer plate structure is formed, and gluing is conducted; a fully-longitudinal multi-layer plate is formed through pressing of a hot press, and the wood is optimized through scientific pressure, compression ratio and compressed time; maintenance is conducted; four edges are cut off, and sanding and thickness calibrating are conducted through a sander; the longitudinal solid-wood multi-layer plate is cut into multiple layers of boards with a saw, and the boards are the same as a deformation prevention solid-wood multi-layer stacking plate in thickness; natural texture faces of the multiple layers of boards are glued, both the boards and a work table facet are put into an automatic felt-board machine, pressurization, high frequency and automatic heating are conducted, and the deformation prevention solid-wood multi-layer stacking plate is manufactured at one time, the four edges are cut off with the saw, sanding and thickness calibrating are conducted, the whole face of the spliced deformation prevention solid-wood multi-layer stacking plate is a multi-layer plate section, and the double faces are pasted with one layer or two layers of transverse signal plates. According to the novel solid-wood splice plate manufacturing method, the deformation prevention deepening treatment is further conducted based on the deformation prevention solid-wood multi-layer stacking plate; the internal stress of the wood is eliminated to the maximum degree, and wood deformation, cracking and warping are truly solved.

Owner:HARBIN SHENGSHI HUALIN TECH

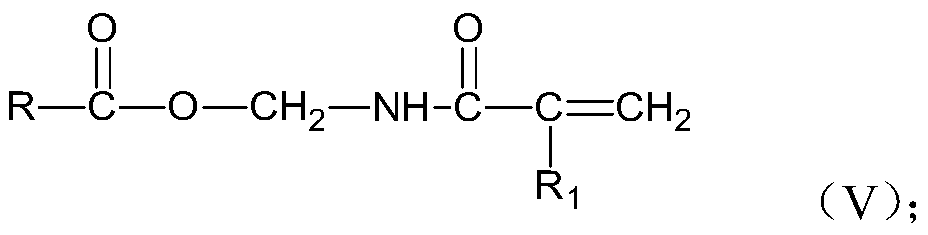

Preparation method of acrylic resin with branched chain containing polyester chain

The invention belongs to the technical field of acrylic resin, and particularly relates to a preparation method of acrylic resin with a branched chain containing a polyester chain. The preparation method comprises the steps: preparing a polyester intermediate with a polyester resin tail end and an unsaturated double bond; and carrying out free radical polymerization reaction on the polyester intermediate and an acrylic monomer to prepare the acrylic resin with the branched chain containing the polyester chain. With adopting of the preparation method of the acrylic resin with the branched chaincontaining the polyester chain, the prepared acrylic resin has the advantages of good adhesiveness, solvent resistance, gloss, softness and impact resistance of polyester resin, also has excellent physical properties such as weather resistance, hardness, chemical resistance and dryness of the acrylic resin, and the polyester resin and the acrylic resin complement each other to finally form perfect physical properties, so that the acrylic resin can be applied to two-liquid polyurethane coatings in automobile repair coatings and finish paints.

Owner:山东凯威尔新材料有限公司

Solar light cultivated illumination introducing apparatus for buildings

The invention relates to a sunlight shining introduction device applied to buildings, wherein the light-condensing aluminum mirrors mounted at the top of the building are kept basically synchronized with the sun movement track. A light-transporting main pipe is installed along the building outer frame and the sunlight can be introduced by an adjustable double-sided reflector which is mounted in the nozzle; the light-transporting branch pipes are mounted in each floor and the light-transporting side pipes are mounted in each room, and the inner walls of all the light-transporting pipes are coated with aluminum mirror coating; and the single-side reflectors are mounted in the bending angles of the light-transporting main pipe and the nozzles of the branch pipes and the side pipes. The control valves are mounted in the light-transporting side pipes, and a reflecting cover of convex mirror is installed at the light-introducing end. The sunlight introduced by the light-condensing mirrors enter the light-transporting main pipe, branch pipes and the side pipes to each room through the reflection of reflectors; the light-exiting port of each user can adjust or close the luminous flux through the control valves; and the reflecting cover can enlarge the sunlight shining area. Through the invention, people can enjoy the natural sunlight directionally and make full use of the sunlight resource to improve to living condition quality.

Owner:顾忠兴

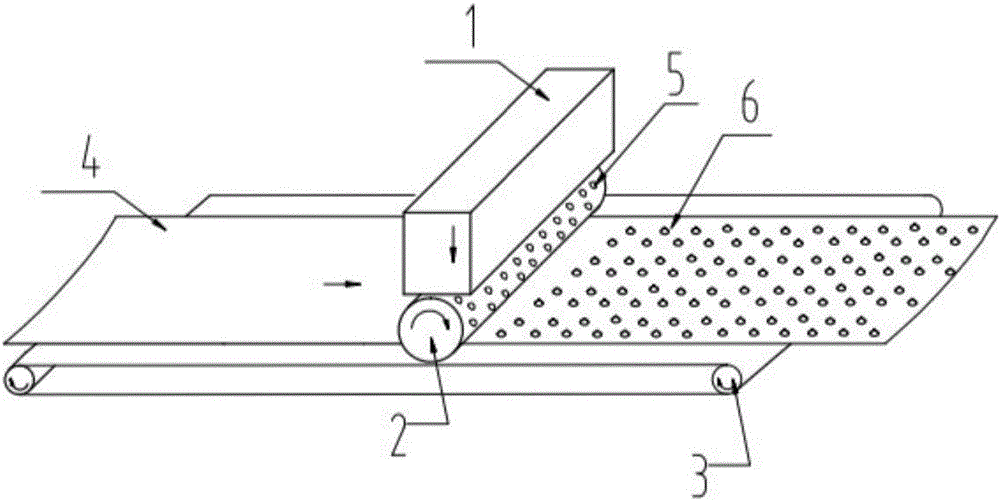

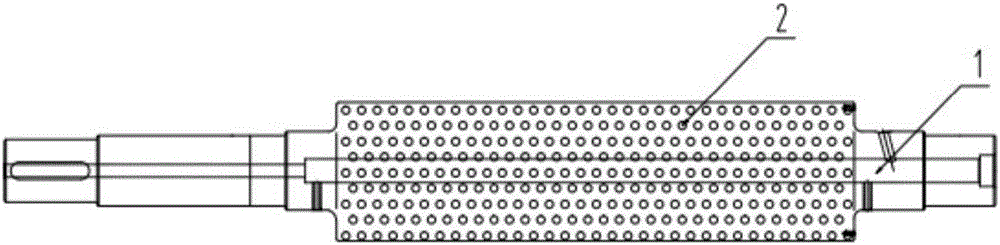

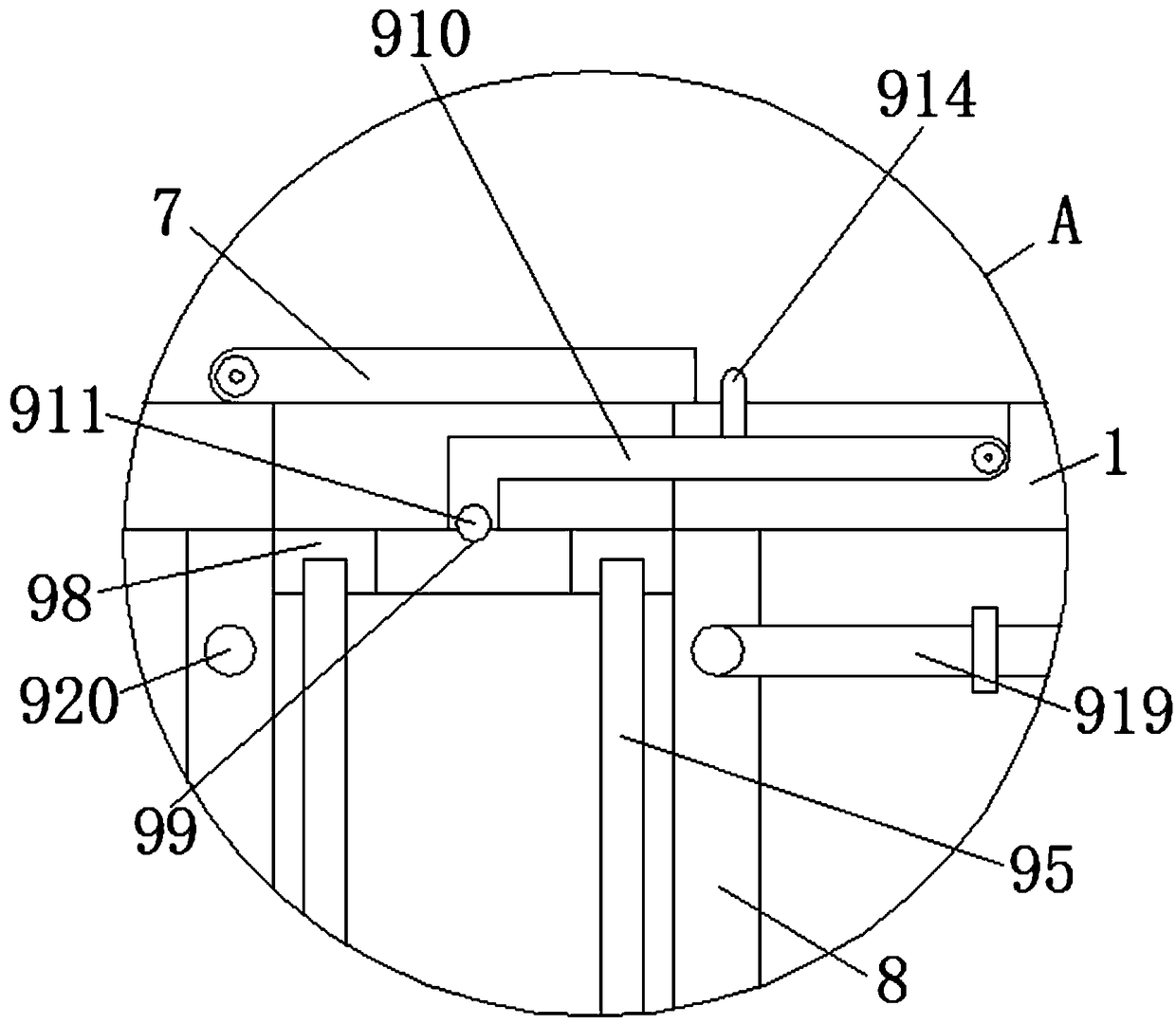

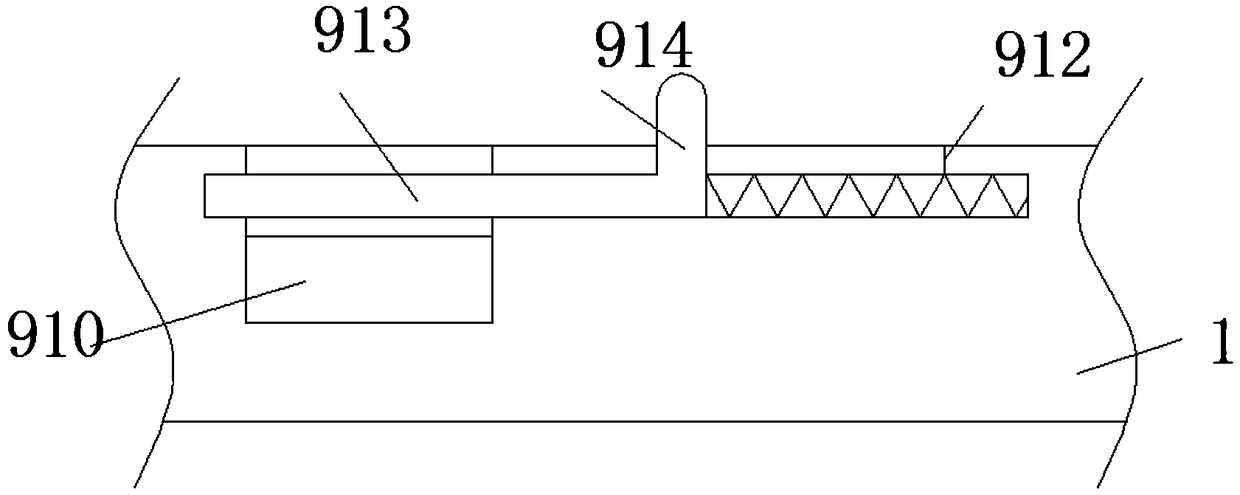

Microwave and electromagnetic heat source convection combined belt drying machine

InactiveCN103644720AIncrease temperatureQuick dehydration and dryingDrying using combination processesDrying gas arrangementsMicrowaveEngineering

The invention discloses a microwave and electromagnetic heat source convection combined belt drying machine. The microwave and electromagnetic heat source convection combined belt drying machine comprises a feed hopper, an even material distributing device, a high-power electromagnetic heater, an exhaust fan, microwave bins, magnetron microwave generators, a machine body, low-power electromagnetic heaters, a driving belt, a discharge transmission roller wheel, a motor, a transmission, a discharge power bin section, a speed reduction drying cavity section, an air inlet, a microwave convection drying cavity section, an electromagnetic constant speed drying cavity section, machine legs, a conveyer belt and a feed transmission roller wheel. The machine body is formed by connecting and combining the electromagnetic constant speed drying cavity section, the microwave convection drying cavity section, the speed reduction drying cavity section and the discharge power bin section. The microwave and electromagnetic heat source convection combination is adopted, complementary advantages are achieved, the advantages of convection drying and microwave drying are achieved, respective shortcomings are overcome, and the efficiency and economy in the drying process are improved greatly.

Owner:刘芳圃

Flow field plate structure for increasing drainage performance of fuel cell

The invention provides a flow field plate structure for increasing drainage performance of a fuel cell, wherein the flow field plate structure comprises a flow field plate, an upper support layer, a liquid absorbing material, a gas diffusion layer and a catalytic layer; the top of the flow field plate is provided with the upper support layer, and the edge of the bottom face of the upper support layer is connected with the edge of the top face of the flow field plate; the middle of the bottom face of the upper support layer is provided with a hollow-out layer; the bottom of the flow field plate is provided with the gas diffusion layer and the catalytic layer from top to bottom; the liquid absorbing material is arranged vertically, the lower part of the liquid absorbing material makes contact with the gas diffusion layer, and the upper part of the liquid absorbing material passes through the flow field plate and is connected with the upper support layer; the upper support layer and the flow field plate are respectively provided with dry gas inlets, reaction gas inlets and reaction gas outlets which communicate correspondingly, the upper support layer is provided with a dry gas outlet, and the dry gas inlets communicate with the liquid absorbing material. The flow field plate structure has the advantages that the flow field plate structure is provided with dry gas flow channels alone, dry gas is used for achieving transpiration of the liquid absorbing material, and flow of the dry gas of the fuel cell and flow of reaction gas of the fuel cell are not interfered with each other.

Owner:WUHAN UNIV OF TECH

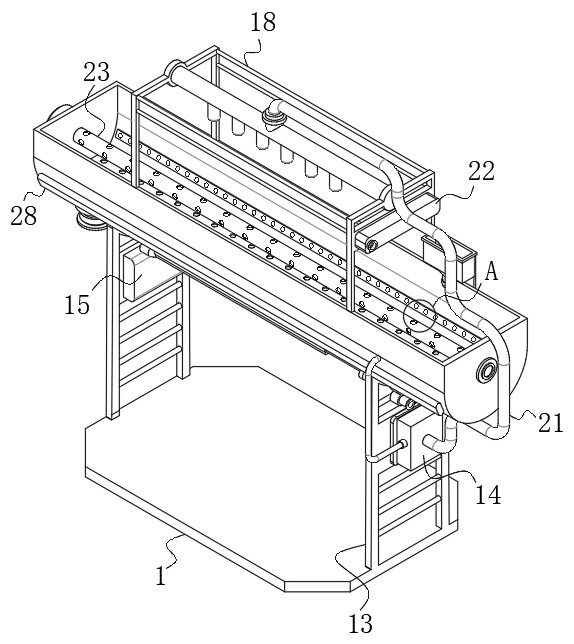

PE pipe three-section metering high-speed single-screw extruder

The invention provides a PE pipe three-section metering high-speed single-screw extruder, and belongs to the technical field of machinery. The PE pipe three-section metering high-speed single-screw extruder solves the technical problems that an existing screw extruder is troublesome in feeding and the like. The PE pipe three-section metering high-speed single-screw extruder comprises a base, and is characterized in that a working barrel and a blending device are arranged on the base, a machining barrel is arranged on the working barrel, a screw is rotationally arranged in the machining barrel,a first power motor is further arranged on the base, the screw is connected with an output shaft of the first power motor through a reduction gearbox, a first feeding port is formed in one end of themachining barrel, the other end of the machining barrel is connected with a discharging nozzle, a feeding device is further arranged on the machining barrel, the feeding device communicates with thefirst feeding port through a drying box, the feeding device communicates with the blending device, a heating device is further arranged on the working barrel, the heating device is connected with a moving structure, and a heat circulation mechanism is further arranged on the base. The PE pipe three-section metering high-speed single-screw extruder has the advantage of high working efficiency.

Owner:浙江振飞塑业有限公司

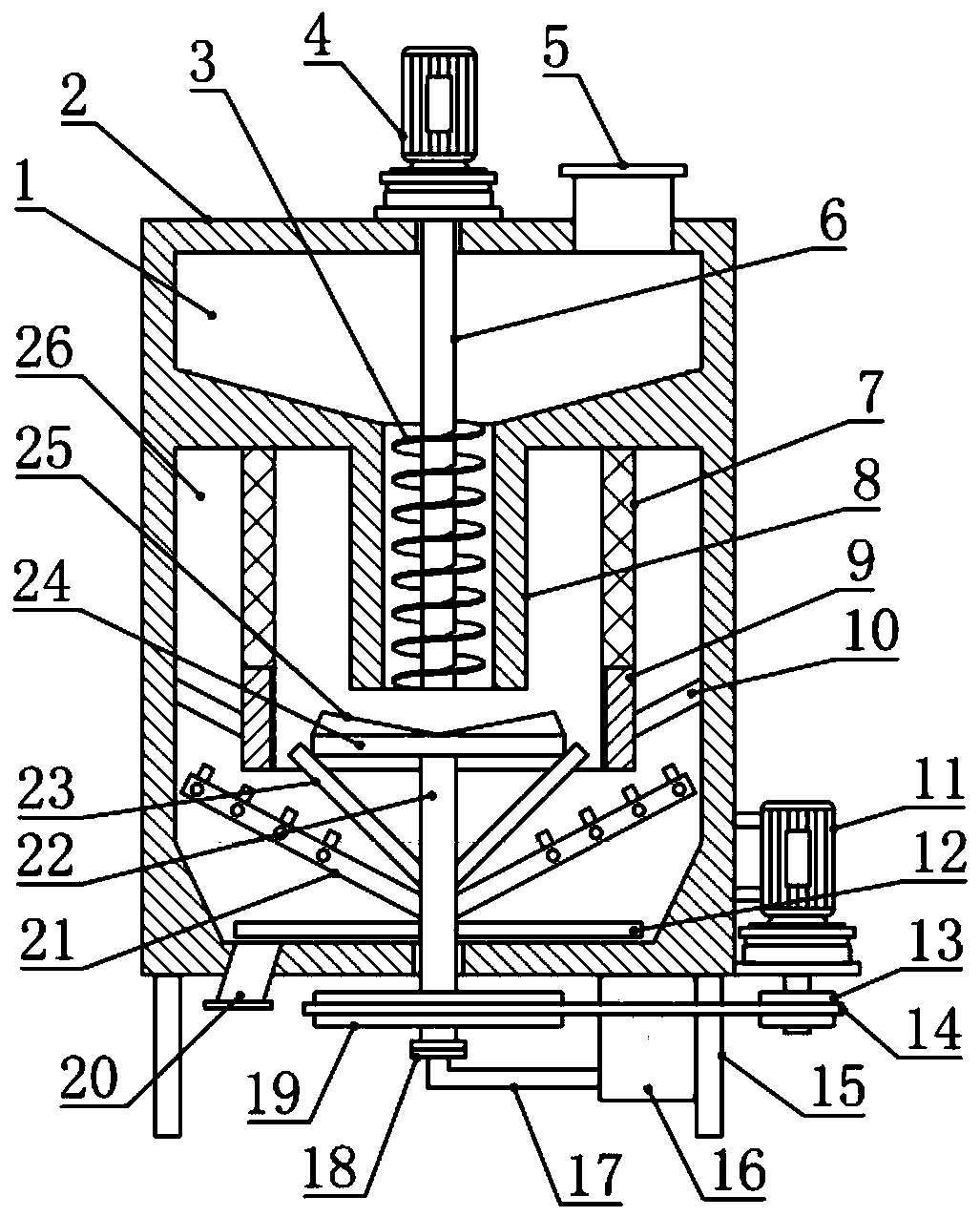

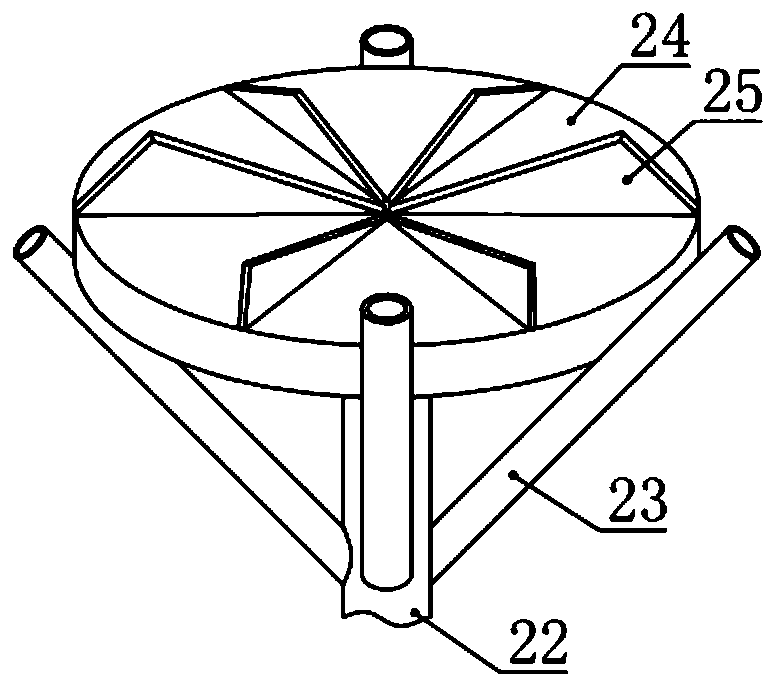

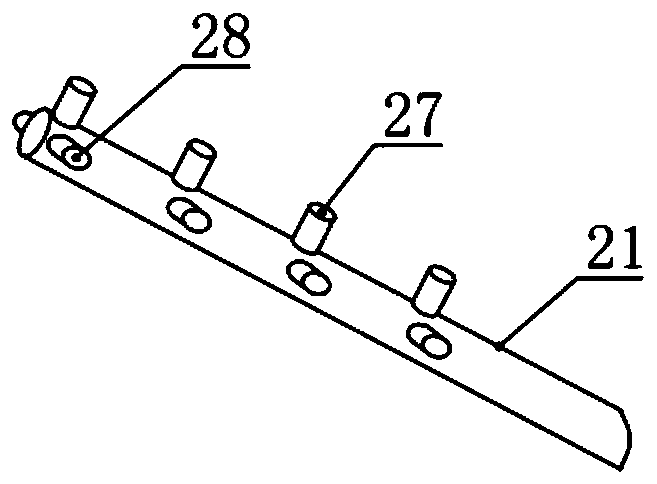

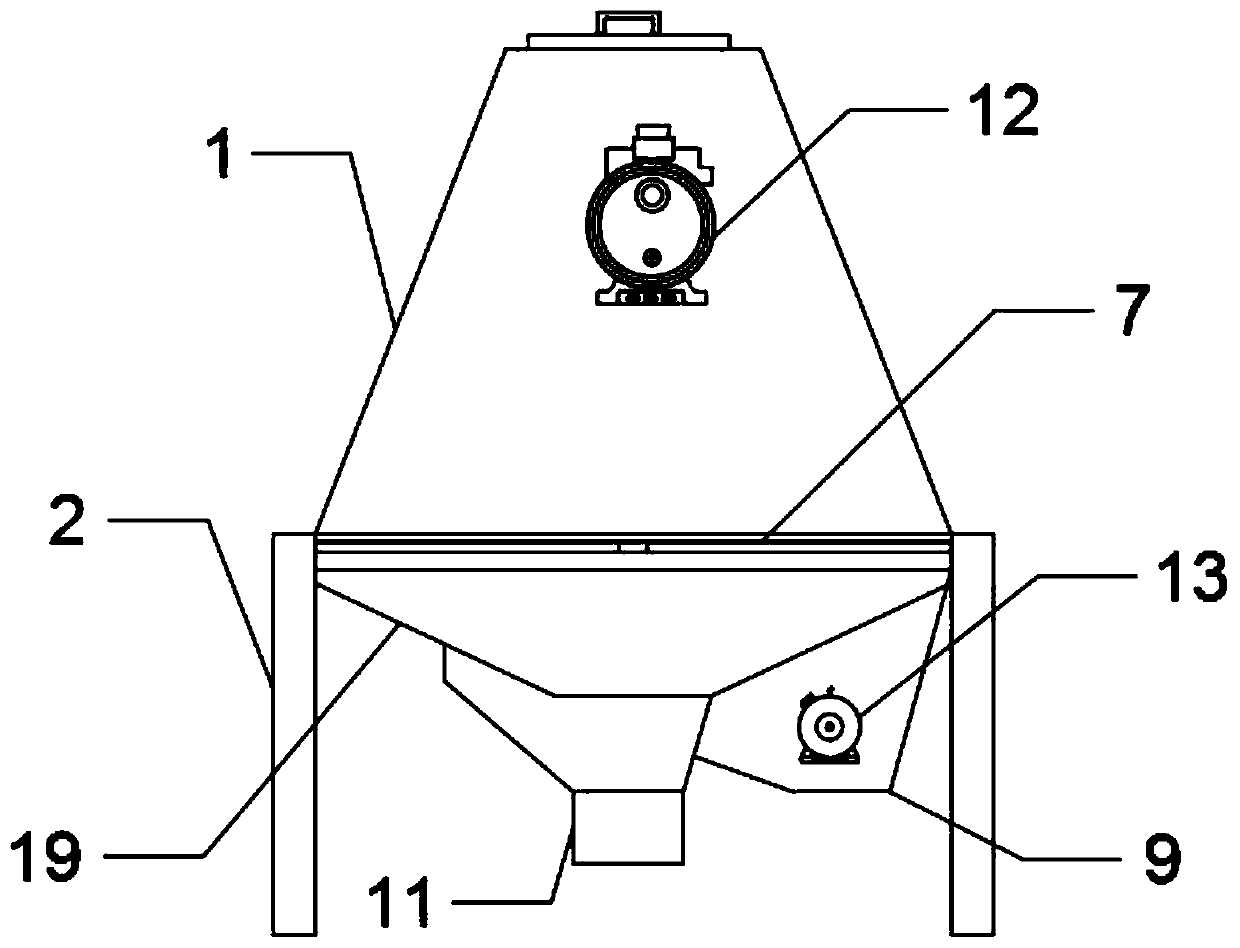

Environment-friendly flocculation treatment equipment and flocculation treatment process for domestic sewage

InactiveCN112266122AGuaranteed flocculation treatment effectIncrease speedWater/sewage treatment with mechanical oscillationsTreatment involving filtrationFlocculationMotor vibration

The invention discloses environment-friendly flocculation treatment equipment for domestic sewage, which belongs to the technical field of sewage treatment. The equipment comprises a base; two sets ofsymmetrically-arranged damping buffer pieces are fixedly connected to the top face of the base, a vibration frame is fixedly connected to the top ends of the two sets of damping buffer pieces, two symmetrically-arranged vibration motors are fixedly connected to the top face of the vibration frame, a draining pool is fixedly connected between the inner surfaces of the vibration frame, a draining filter plate is clamped to the inner wall of the draining pool, draining holes distributed in a rectangular array are formed in the surface of the draining filter plate, and a circulating filter mechanism is fixedly mounted on the top surface of the vibration frame; the circulating filter mechanism comprises an outer shell, and the peripheral side face of the outer shell is fixedly connected with the vibration frame. Through the design of a flocculation tank, the circulating filter mechanism and the draining pool, the flocculation process in the sewage treatment process can be efficiently completed, and during flocculation of the device, solid flocs flocculated from sewage can be continuously filtered out through the filter mechanism.

Owner:南京荧河谷科技有限公司

Ink jet treatment liquid, ink jet recording method, and recorded matter

ActiveCN101537748AWith bleeding inhibitionHas storage stabilityOrganic chemistryDuplicating/marking methodsAdhesion forceBond properties

The aim of the invention is to provide an ink jet treatment liquid which can be jetted and has adhesion force, bonding property, transparent property and drying property after jet relatively to the non-absorptive printing medium of ink and simultaneously has storing stability. The ink jet treatment liquid contains a cationic polyurethane, a polyamine and / or a polyamine derivative.

Owner:SEIKO EPSON CORP

Worms expelling and fungus-proof drying agent

InactiveCN1546220ASlow down sublimationModerate concentration and long-actingBiocideOther chemical processesAdditive ingredientDesiccant

The invention discloses a kind of anthelminthic and mould proofing drier, whose primary ingredients include 'high efficiency sorption mineral drier' and anthelminthic material, the high efficiency sorption mineral drier uses large specific area clay mine as material, adds in some Cacl2. The anthelminthic is made up of with volatile insect killer such as camphor, the invention combines the mould proofing function and anthelminthic function, at the same time, the wet absorbing process of the drier may decrease the speed.

Owner:杜建中

Moisture-absorbing and environment-protection type fabric

InactiveCN105919198AGood hygroscopicityMoisture absorptionProtective garmentSpecial outerwear garmentsSurface layerIsolation layer

The invention discloses a moisture-absorbing and environment-protection type fabric. The moisture-absorbing and environment-protection type fabric is characterized by comprising the following raw materials in percentage by mass: 12 to 20% of hemp fiber, 10 to 26% of chinlon, 2 to 5% of fluon, and 6 to 14% of copper ammonia fiber, wherein color cotton and the chinlon are blended to form an inner layer of the moisture-absorbing and environment-protection type fabric; the hemp fiber and wool fiber are blended to form an isolation layer of the moisture-absorbing and environment-protection type fabric; the copper ammonia fiber and the fluon are blended to form a surface layer of the moisture-absorbing and environment-protection type fabric. The moisture-absorbing and environment-protection type fabric has the advantages that the fabric is light, thin and comfortable, the moisture-absorbing effect is good, and the moisture-absorbing, drying and heat-insulation effects are realized by utilizing different raw materials in different positions; if the moisture-absorbing and environment-protection type fabric is not worn after use, the moisture-absorbing and environment-protection type fabric can be automatically degraded after a period of time, so that the time and labor are saved, and the environment-protection effect is realized; the production cost is lower, the production technology is simple, any additional technological step is not needed, and the production efficiency is improved.

Owner:南通中兴多元复合钢管有限公司

Water removal device for active carbon fibers

InactiveCN111550991AQuality improvementGuaranteed drynessGas current separationDrying gas arrangementsFiberCarbon fibers

The invention discloses a water removal device for active carbon fibers, and belongs to the technical field of active carbon fiber water removal. The device comprises a shell, multiple ventilation plates of different sizes are mounted in the shell, a space formed through spaced arrangement of the ventilation plates is a water removal partition layer, the bottom of the shell is provided with a sealbottom plate, the upper end of the seal bottom plate is provided with a water removal drying bin mounted on the inner sides of the ventilation plates in a sleeved manner, multiple seal rings are mounted on the outer side of the seal bottom plate, connecting strips are connected among the seal rings, the seal bottom plate is connected with the seal rings through the connecting strips, the lower portion of the seal bottom plate is provided with a guide bin fixedly connected with the lower end of a supporting frame body, a discharging opening is formed in the lower end of the guide bin, pure drying air output by the water removal drying bin carries out air drying on active carbon fiber particles in the water removal partition layer, a dust removal box removes fine particles in the active carbon fibers, and the aims of removing the water in the active carbon fibers and improving the quality of the active carbon fibers can be achieved.

Owner:安徽欣冉碳纤维环保科技有限公司

Codonopsis pilosula medicinal diet and formula

InactiveCN1589672AIncrease lossSolve freshUnknown materialsFood preparationCodonopsis pilosulaHorticulture

A medical food is prepared from fresh pilose asiabell root, fresh root of anothe plant and gynostemma pentaphyllum. Its advantages are less loss of nutrient and agreeable taste.

Owner:崔应朝

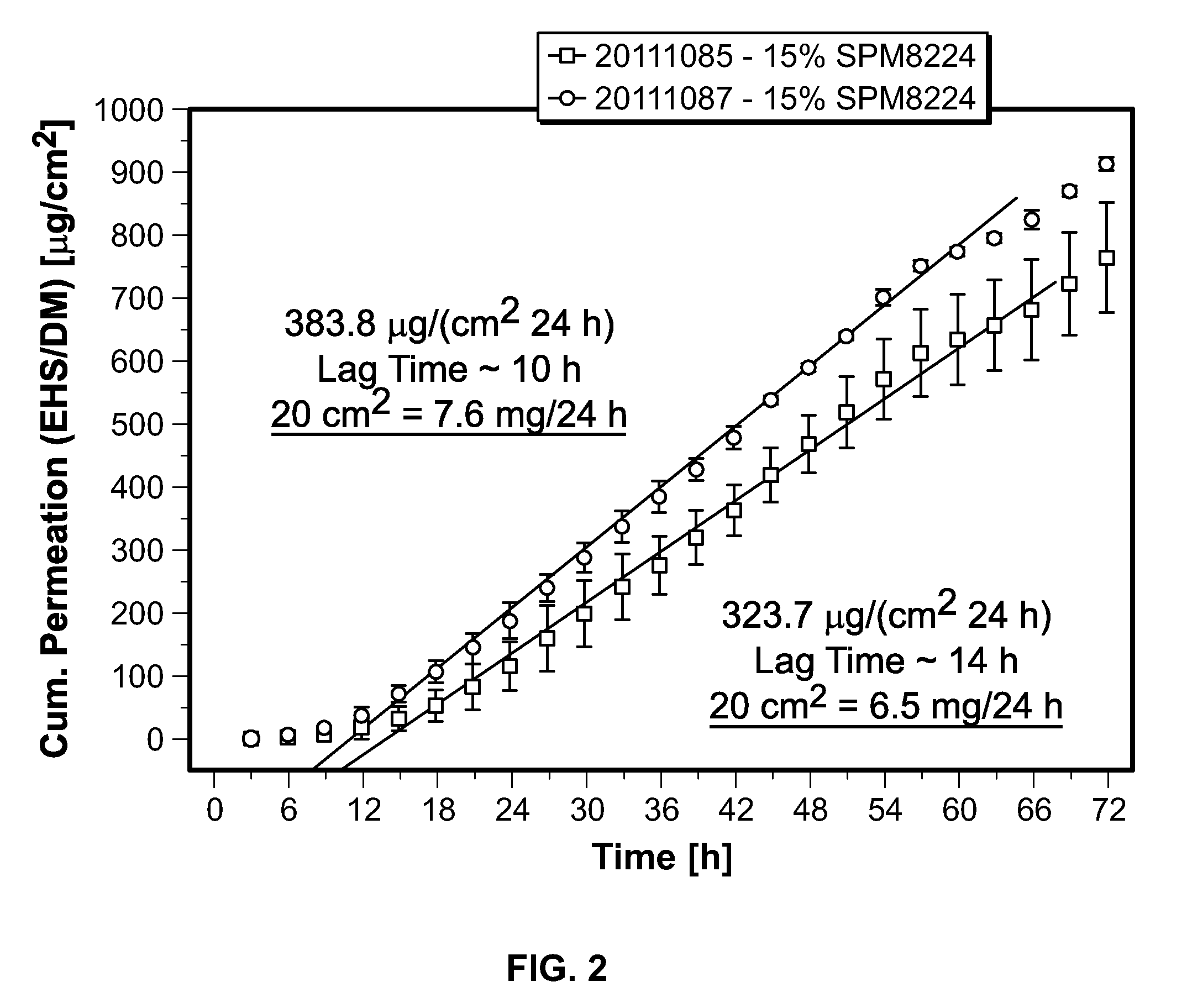

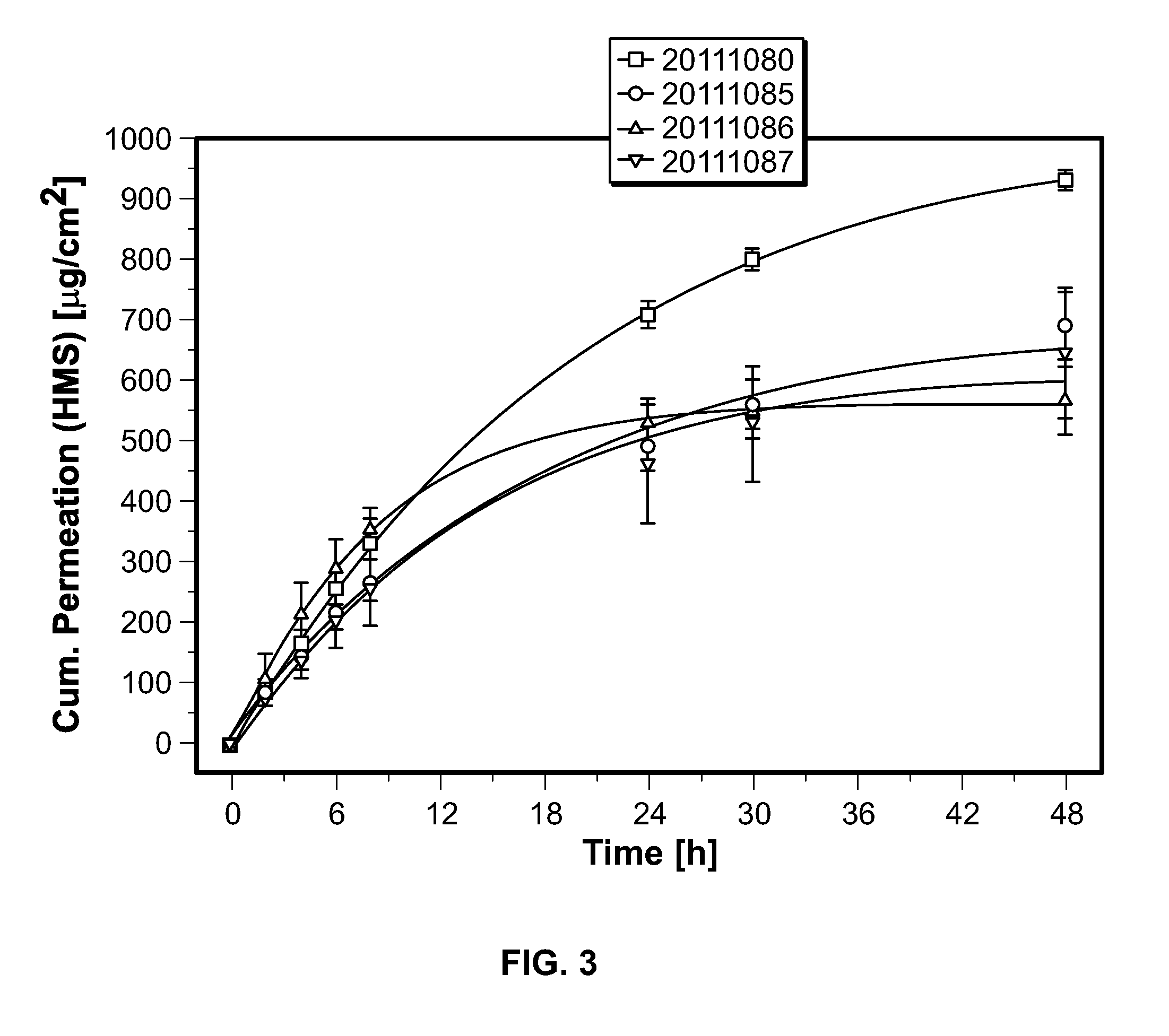

Transdermal delivery of (r)-3,3-diphenylpropylamin-monoestern

The invention relates to a device for transdermally administering a compound of formula (I), wherein A represents hydrogen or deuterium, R represents a group selected among C1-4alkyl, C3-10cycloalkyl, or phenyl, each of which can be substituted by C1-3alkoxy, fluoride, chlorine, bromine, iodine, nitro, amino, hydroxy, oxo, mercapto, or deuterium, the C atom marked by * (asterisk) being provided in the R configuration. The invention is characterized in that the compound of general formula (I) is provided in a polymer matrix and is released at a dose of 0.5 to 20 mg per day through human skin. The invention further relates to the use of said compounds of formula (I) for producing transdermal medicaments.

Owner:UCB SA

Method and apparatus for producing gypsum hollow block

InactiveCN1178775CHas qualityReduce moisture contentDischarging arrangementMaterials preparationAutomatic control

The production process of hollow gypsum block includes four steps of: compounding material slurry, forming, drying and packing. The forming is one automatically controlled stepped course in production units with machines corresponding to material preparation, casting to form and delivery. The control central controls the hydraulic system to drive all the machines in the production units via the gypsum solidifying data collecting control method. The present invention has high product quality, lower water consumption and short drying time.

Owner:刘勇军 +1

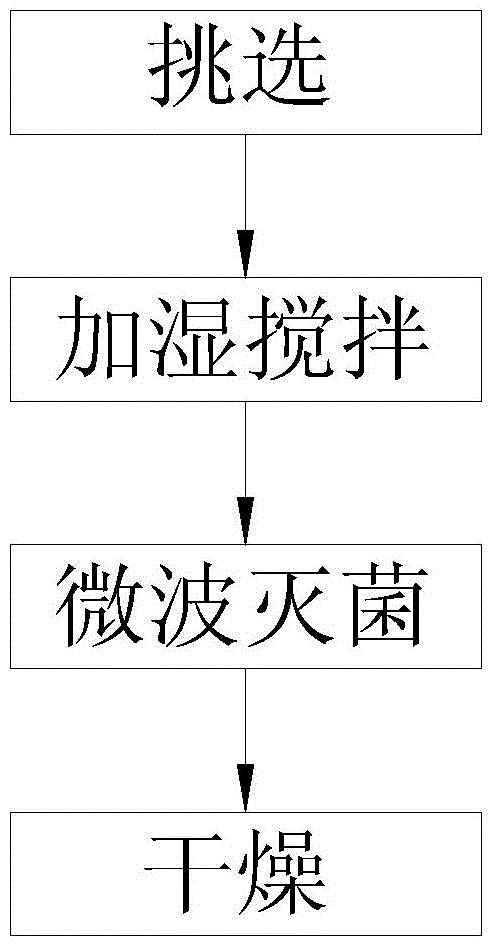

Humidifying microwave processing method for tendril-leaved fritillary bulb

InactiveCN104998037ADistinctive characteristic spotsGood effectPlant ingredientsMicrowave powerEngineering

The invention discloses a humidifying microwave processing method for tendril-leaved fritillary bulb. The method comprises the following steps: (1) selecting tendril-leaved fritillary bulb and removing mixed impurities; (2) putting the tendril-leaved fritillary bulb into a humidifying tank with a stirring function and stirring the tendril-leaved fritillary bulb while continuously adding water, where the addition amount of water is 10 to 15% of the weight of the tendril-leaved fritillary bulb; and (3) sending the tendril-leaved fritillary bulb to a microwave tunnel for disinfection, wherein disinfection conditions are that tendril-leaved fritillary bulb conveying speed is 1.5 to 2.5 m / min, microwave frequency is 2450 MHz, and microwave power is 10 to 30 KW. The tendril-leaved fritillary bulb processed by using the humidifying microwave processing method has good drug effect; and time for mixing of the processed tendril-leaved fritillary bulb with snake bile is short, and uniform mixing can be realized.

Owner:SINOPHARM GRP FENGLIAOXING FOSHAN PHARM CO LTD

Table for assisting collection of test data and operating method of table

InactiveCN107497351AAchieve the purpose of the experimentImprove aestheticsShaking/oscillating/vibrating mixersTransportation and packagingTemperature controlEngineering

The invention discloses a table for assisting collection of test data. The table comprises a box body, a rocking culture rack, a disinfecting and cleaning mechanism and a control mechanism, wherein the rocking culture rack is arranged inside the box body; the control mechanism is arranged at the periphery of the rocking culture rack and extends out of the box body via wires; and the disinfecting and cleaning mechanism is arranged on the inner surface of the box body. The invention further discloses an operating method of the table for assisting collection of test data. The experimental sample can be monitored in real time, and experimental data can be provided, so that an experimenter can collect the data in the experimental process, and the final test aim is achieved. Meanwhile, four functions of disinfecting, cleaning, temperature control and humidity control can be provided, environment variables are reduced to the greatest degree, and the experimental accuracy is ensured.

Owner:苏州培英实验设备有限公司

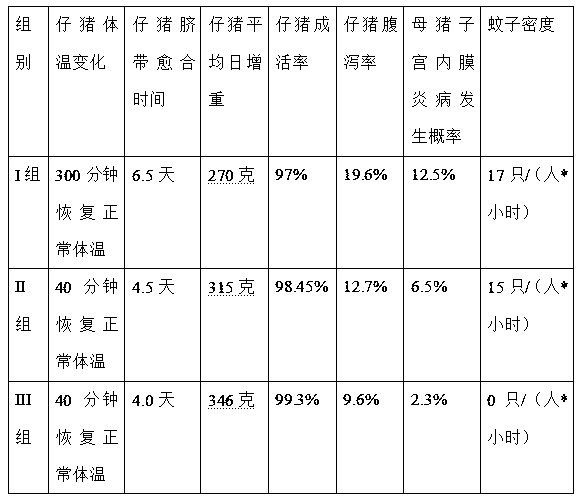

Use method of delivery powder for sow production

PendingCN111419742AMaintain body temperatureComprehensive body temperatureCosmetic preparationsToilet preparationsBiotechnologyDisease

The invention discloses delivery powder for sow parturition. The delivery powder comprises 0.3-1 part of fennel essential oil, 1-4 parts of light calcium carbonate, 1-20 parts of calamine powder, 50-90 parts of silicon dioxide and 0.1-0.5 part of deet,wherein the particle size of the silicon dioxide is less than or equal to 25 nm; and after delivery of a sow, the delivery powder is applied to thebody surfaces of piglets or the vulva of the sow. The delivery powder has an ultra-strong dry and comfortable function, the body surfaces of the piglets can be instantly dried and comfortable by applying a small amount of the powder, the body temperature of the piglets is effectively kept, the survival rate and health piglet rate of the piglets are increased, the delivery powder is applied to umbilical cord breaking, tail breaking and castration wounds of the piglets, inflammation diminishing and bleeding stopping are rapidly achieved, the probability of invasion of external bacteria is reduced, dryness of the rest position of the piglets is guaranteed, and bacterial reproduction is inhibited; and the morbidity of common diseases such as bacterial diarrhea (especially yellow, white and reddysentery) and streptococcus of the piglets is reduced, the safe mosquito repelling effect can be achieved when the powder is used in summer, mosquito bites are prevented, and the probability of diseases such as encephalitis B and African swine fever is reduced.

Owner:LIAONING AIPULUOSI FEED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com