Micro-electrolysis filler for treatment of hardly degraded waste water and preparation method of micro-electrolysis filler

A wastewater treatment and micro-electrolysis technology, which is applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as heavy workload, micro-electrolysis failure, and waste water for a long time. High porosity and specific surface area, improve the biodegradability of wastewater, and reduce the effect of wastewater COD

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

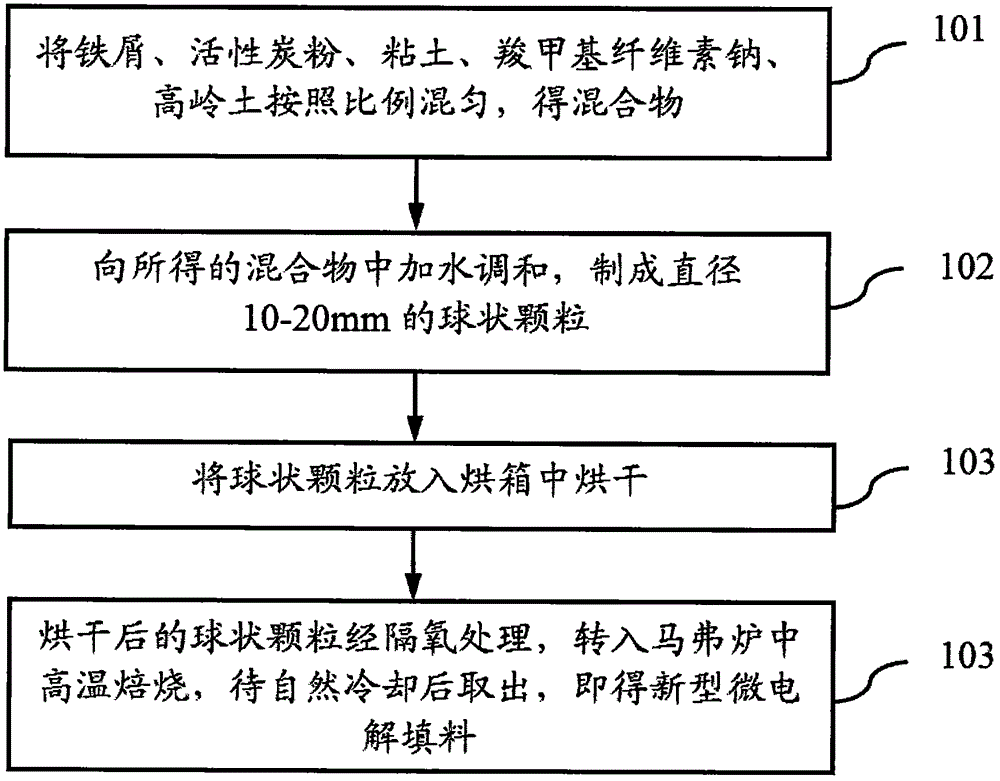

[0023] Such as figure 1 As shown, a method for preparing micro-electrolytic fillers for refractory wastewater treatment provided by the embodiments of the present invention comprises the following steps:

[0024] Step 101 mixing materials: mixing iron filings, activated carbon powder, clay, sodium carboxymethyl cellulose, and kaolin according to the proportion to obtain a mixture;

[0025] Step 102 granulation: adding water to the obtained mixture to make spherical particles with a diameter of 10-20 mm; wherein the water content is controlled between 9% and 11% when adding water to adjust;

[0026] Step 103 drying: put the spherical particles into an oven for drying, the drying temperature is 100-120°, and the drying time is 20-40 minutes;

[0027] Step 104 Anaerobic roasting: The dried spherical particles are subjected to an oxygen barrier treatment, transferred to a muffle furnace for high-temperature roasting, and taken out after natural cooling to obtain a new type of mic...

Embodiment 1

[0033] The embodiment of the present invention provides a micro-electrolytic filler for refractory wastewater treatment, which is composed of the following raw materials in weight percentage: 40% of iron filings, 30% of activated carbon powder, 28.8% of clay, 0.2% of sodium carboxymethylcellulose, and 1.0% of kaolin . Its preparation method is carried out according to the following steps:

[0034] (1) Pass the iron filings through a 100-mesh sieve, so that the particle size of the iron filings is less than 0.15mm, and select activated carbon powder with an average pore size of 15-25A and a specific surface area of 600-2500m 2 / g, clay is crushed with a crusher, crosses a 100-mesh sieve, and the particle size is less than 0.15mm, then iron filings, activated carbon powder, clay, sodium carboxymethyl cellulose, and kaolin are mixed according to the above ratio to obtain a mixture;

[0035] (2) Granulation: add water to the resulting mixture to make a spherical granule with a ...

Embodiment 2

[0039] The embodiment of the present invention provides a micro-electrolytic filler for refractory wastewater treatment, which is composed of the following raw materials in weight percentage: 30% of iron filings, 40% of activated carbon powder, 27.9% of clay, 0.6% of sodium carboxymethyl cellulose, and 1.5% of kaolin . Its preparation method is carried out according to the following steps:

[0040] (1) Pass the iron filings through a 100-mesh sieve, so that the particle size of the iron filings is less than 0.15mm, and select activated carbon powder with an average pore size of 15-25A and a specific surface area of 600-2500m 2 / g, clay is crushed with a crusher, crosses a 100-mesh sieve, and the particle size is less than 0.15mm, then iron filings, activated carbon powder, clay, sodium carboxymethyl cellulose, and kaolin are mixed according to the above ratio to obtain a mixture;

[0041](2) Granulation: add water to the resulting mixture to make a spherical granule with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com