Injectable reinforcement material used for masonry structure reinforcement and preparation method thereof

A masonry structure and raw material technology, which is applied in the field of sprayable reinforcement materials for masonry structure reinforcement and its preparation, can solve the problems of physical and mechanical compatibility between reinforcement materials and masonry structure materials, long-term effectiveness, and reinforcement systems. Compatibility and durability issues have not yet attracted enough attention to achieve the effects of high structural compactness, good pumping performance, and good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

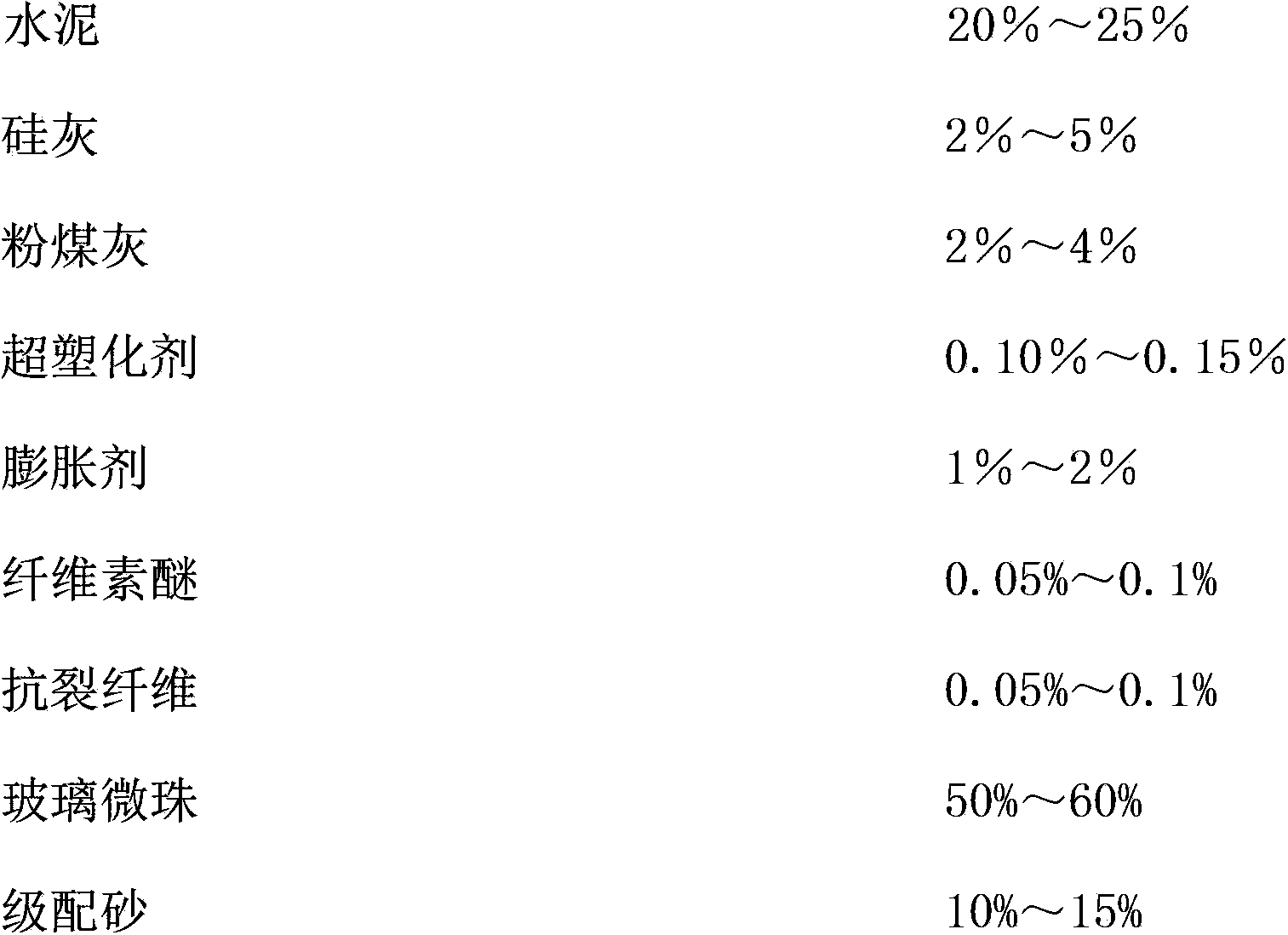

[0030] The mass ratio of each component of the sprayable reinforcement is as follows:

[0031]

[0032]

[0033] The specific steps for preparing the sprayable reinforcement in this example are as follows: first, pre-mix the additives in the formula except cement, glass beads, and graded sand according to the proportion to form an additive mixture, and then mix the additive mixture with cement, glass The microbeads and graded sand are fully mixed and packaged. After transported to the construction site, 12% of the dry powder mass is added with water and fully stirred. The screw jetting machine is used for construction. The thickness of a single spraying construction can reach 3cm.

Embodiment 2

[0035] The mass ratio of each component of the sprayable reinforcement is as follows:

[0036]

[0037]

[0038] The specific steps for preparing the sprayable reinforcement in this example are as follows: first, pre-mix the additives in the formula except cement, glass beads, and graded sand according to the proportion to form an additive mixture, and then mix the additive mixture with cement, glass The microbeads and graded sand are fully mixed and packaged. After transported to the construction site, 13% of the dry powder mass is added with water and fully stirred. The screw jetting machine is used for construction. The thickness of a single spraying construction can reach 3.5cm.

[0039] According to the methods of the above two embodiments, and select the representative modified cement mortar product for masonry reinforcement on the market as a typical comparison sample, under the same conditions of construction, maintenance and testing methods, the performance data ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com