Suspension bridge main cable strand pre-forming and erection construction method

A construction method and technology for suspension bridges, applied in suspension bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of poor fastening between the two ends of the main cable strands and the anchor cup, difficulties in erection, and scattered parallel steel wires of the main cable strands, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose, technical solution and advantages of the present invention clearer, the method for preforming and erecting the main cable strands of the suspension bridge of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

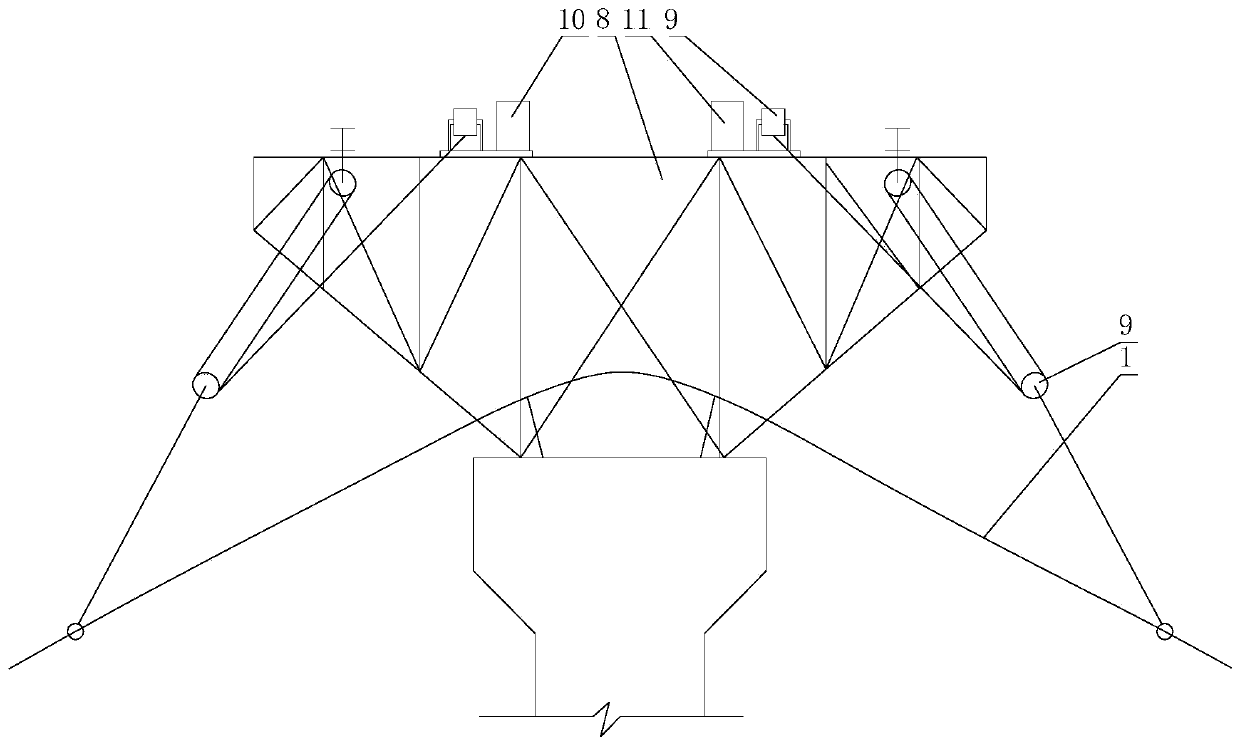

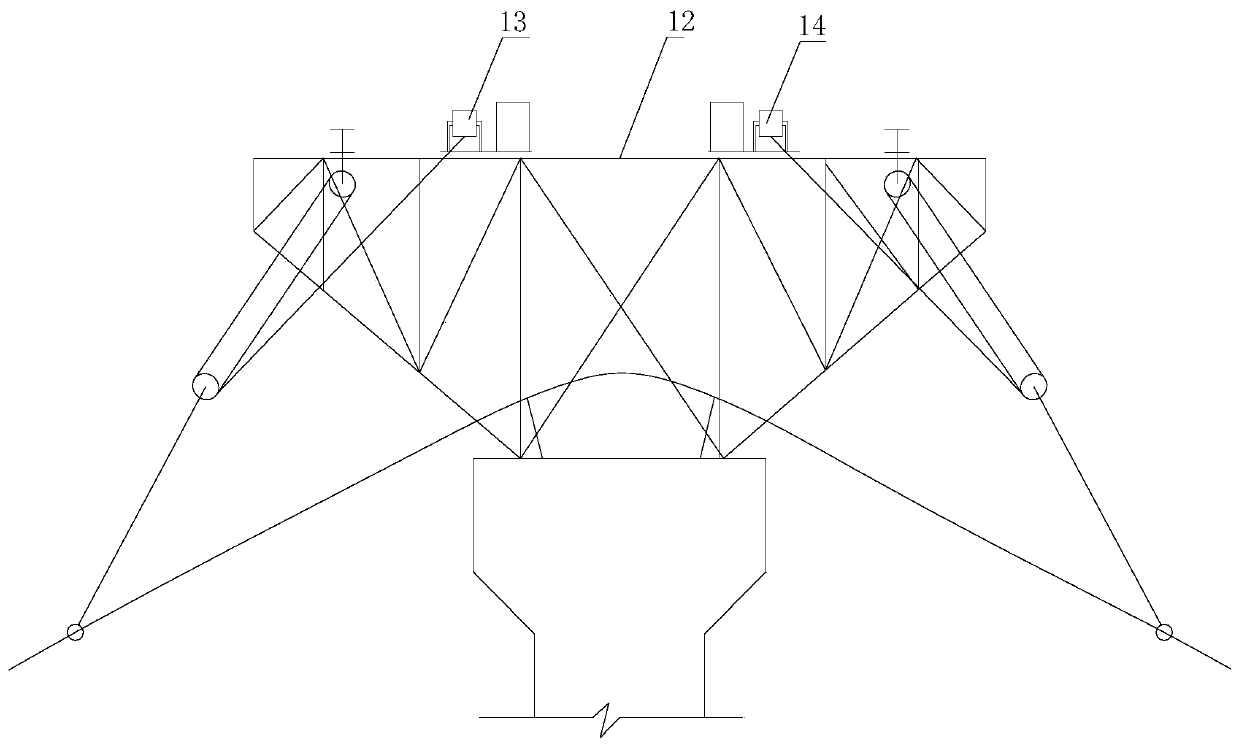

[0028] See Figure 1-6 , the preforming of the main cable strands of the suspension bridge in the embodiment of the present invention includes the following devices: parallel steel wire strands 1, steel wires 2, front anchor cups 3, rear anchor cups 4, positioning steel wires 5 and zinc-copper alloy blocks 6;

[0029] The preforming of the main strands consists of the following steps:

[0030] The first step: making the marking steel wire: select one steel wire 2, and paint the whole length of the steel wire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com