Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

139results about How to "High water contact angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

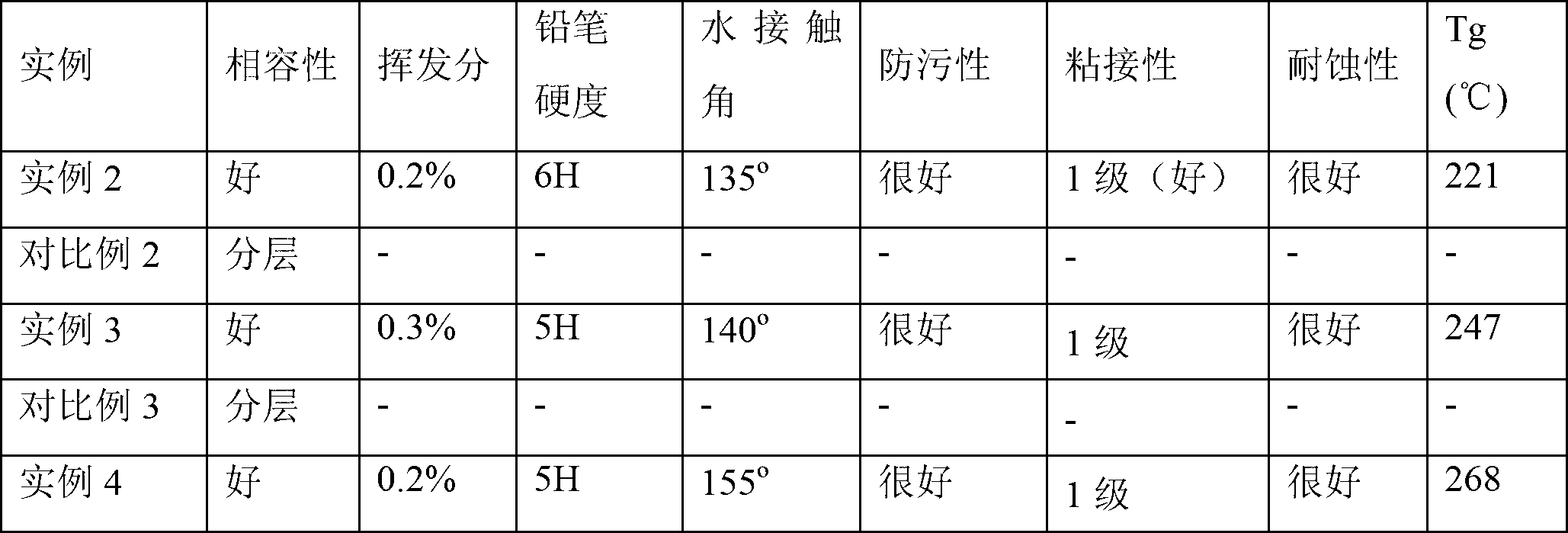

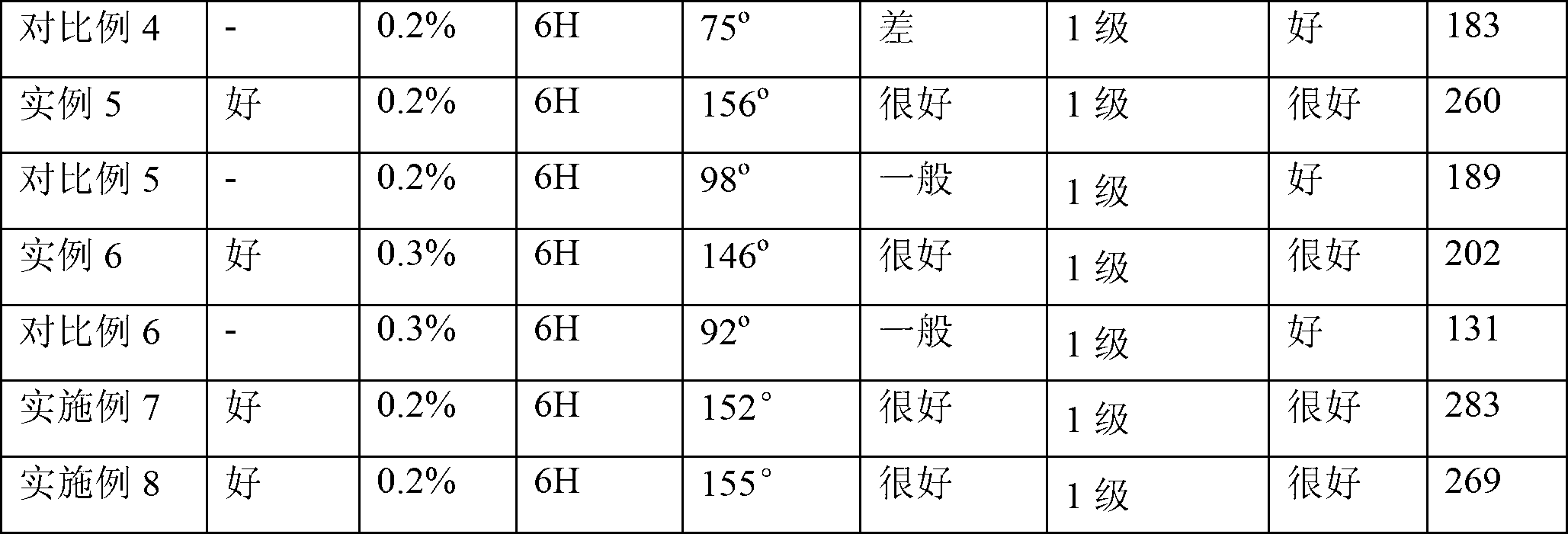

Epoxy/silicone polymer composite material, and preparation method and application thereof

The present invention discloses an epoxy / silicone polymer composite material and a preparation method and application thereof. The present invention includes mixing 100 parts by weight of epoxy resin, 5-500 parts by weight of alkyl methylpolysiloxane and 10-200 parts by weight of MQ silicon resin for curing processing at 20-180 DEG C to obtain the epoxy / silicone polymer composite material. The epoxy resin not only self-crosslinks, but also occurs curing crosslinking with the MQ silicon resin through the alkyl methylpolysiloxane or forms interpenetrating network with high strength and glass transition temperature to achieve improvement of adhesiveness of epoxy / silicone polymer composite material. The MQ silicon resin makes the film surface roughness of the epoxy / silicone polymer composite material significantly increase by forming a multi-structure, and the water contact angle be greatly improved. The epoxy / silicone polymer composite material is available in raw materials, low in cost, and simple in preparation process. The prepared epoxy / silicone polymer composite material has excellent water resistance and stain resistance, mechanical strength, adhesion, corrosion resistance and high-temperature resistance performances.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

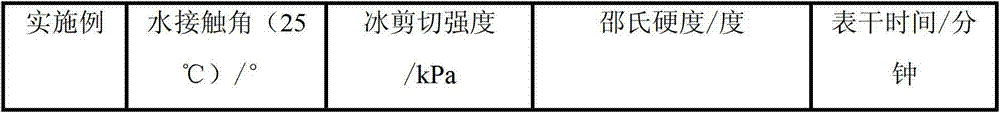

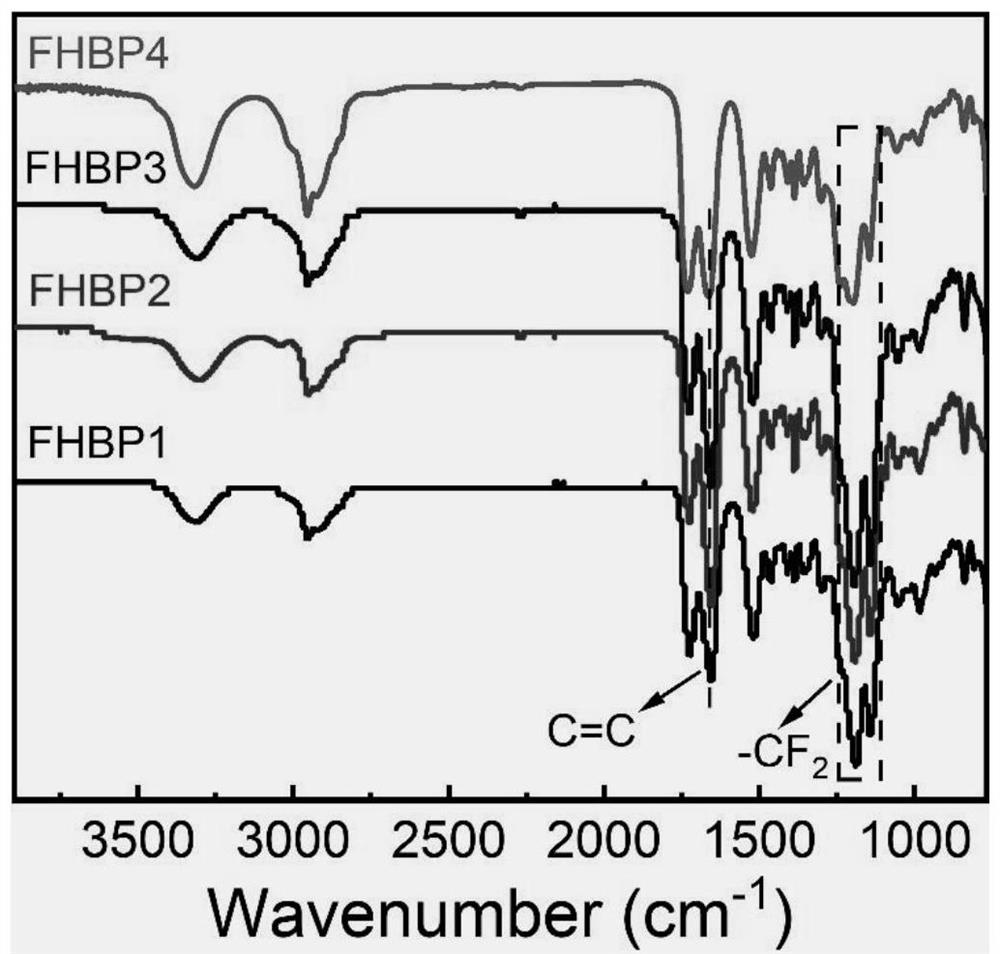

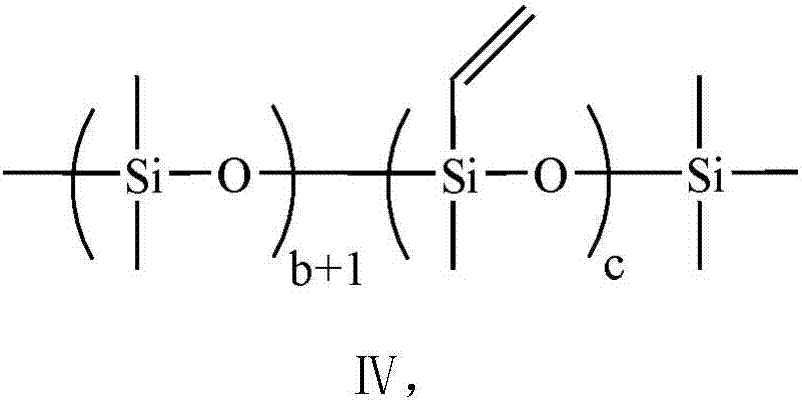

Double-component fluorosilicone rubber ice-covering-proof coating material and preparation method thereof

The invention discloses a double-component fluorosilicone rubber ice-covering-proof coating material and a preparation method thereof. The preparation method comprises the following steps: dissolving fluorine-containing acrylate in solvent, adding a platinum catalyst, uniformly stirring, and pouring into a four-neck flask; starting an electromagnetic stirrer, introducing inert gas, heating in water bath, adding hydrogen-containing silicone oil, and reacting to generate fluorine modified silicone oil; placing vinyl terminated polydimethylsiloxane in a beaker, adding 5-40 parts by mass of white carbon black used as reinforcement filler, evenly stirring, then adding 0.5-5 parts by mass of whitener TiO2, and evenly stirring; weighing 1-5 parts by mass of hydrogen-containing silicone oil and 1-5 parts by mass of fluorine modified silicone oil, placing in the beaker, evenly stirring, adding 10-50mu L of platinum catalyst, and finally adding the solvent; and evenly coating through a spin coater, and curing in a baking oven for 1-4 hours, thus obtaining the double-component fluorosilicone rubber coating. The invention overcomes the defects in the prior art, uses polyorganosiloxane as the raw material, can achieve satisfactory ice-covering-proof effect and is used in the fields of paint and the like.

Owner:TIANJIN UNIV

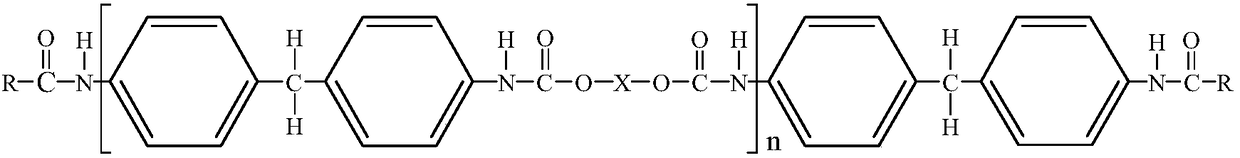

Method for preparing organic silicon graft modified polyurethane resin for synthetic leather

The invention discloses a method for preparing an organic silicon graft modified polyurethane resin for synthetic leather. The method comprises the following step: polymerizing a chain extender, diisocyanate, a polymer polyhydric alcohol, micromolecule polyhydric alcohol and an organic metal catalyst in an organic solvent at 50-100 DEG C, wherein organic silicon of which one end contains two hydroxide radicals and the other end contains no active hydroxide radical is adopted as the chain extender. In the process that the grafted organic silicon modified resin is filmed, organic silicon chain segments are connected with a polyurethane structure through covalent bonds, the organic silicon chain segments are enriched on the surface of a coating, the water contact angle of the surface of the obtained coating is improved, the surface of the coating is smooth in hand feeling and bright in gloss, the properties of the surface of the coating are long-lasting and are hard to damage by mechanical and washing action, and thus the resin is an excellent and long-lasting synthetic leather surface treatment material.

Owner:WENZHOU KELAIEN SCI & TECH

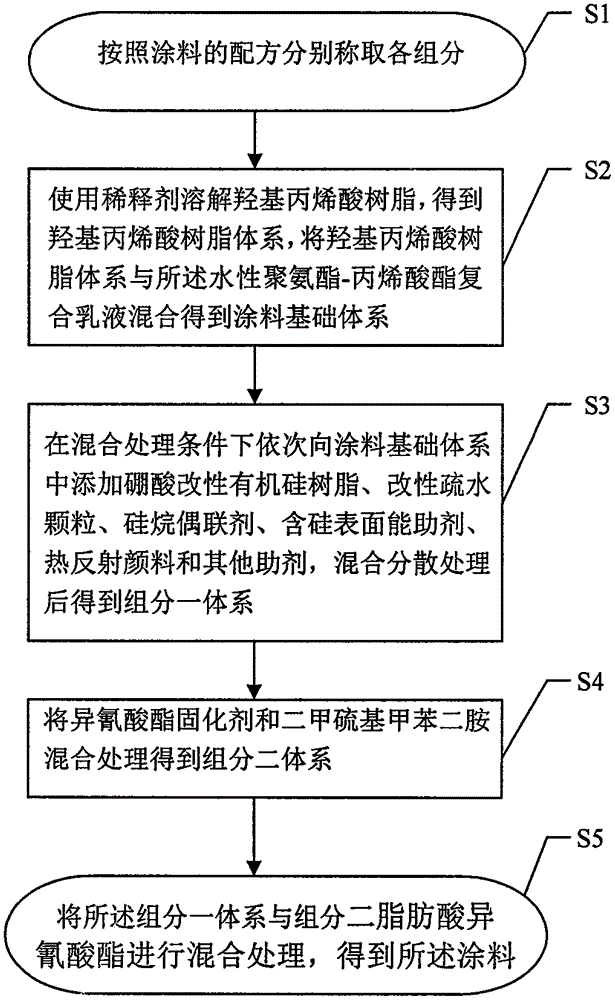

Building facade coating and preparation method thereof

InactiveCN105273603AStrong adhesionImprove impact resistancePolyurea/polyurethane coatingsAcrylic resinBoronic acid

The present invention aims to provide a building exterior facade coating and a preparation method thereof, the coating comprises a component I and a component II, wherein the component I comprises the following components by mass: 45-50 parts of waterborne polyurethane-acrylate ester composite emulsion; 10-25 parts of hydroxyl acrylic resin; 2-10 parts of boronic acid-modified silicone resin; 5-10 parts of modified hydrophobic particles, 1-3 parts of a silane coupling agent; 0.5-4 parts of a silicon-containing surface energy aid; 6-8 parts of a heat reflective pigment; and 1-5 parts of other additives; the component II comprises the following components by mass: 17-25 parts of an isocyanate curing agent; and 3-4 parts of dimethythiotoluene diamine. The building exterior facade coating also has good corrosion resistance, high temperature resistance, good flame retardance, good coating and substrate adhesion, strong hydrophobicity and good environmental performance and other advantages.

Owner:杭州蓝筹企业管理有限公司

Preparation method for core-shell fluorinated polyurethane-acrylate latex

InactiveCN102924664AImprove grafting efficiencyFast polymerization rateCoatingsPolymer scienceFunctional monomer

The invention relates to a preparation method for core-shell fluorinated polyurethane-acrylate latex. The method comprises the following steps: placing polyether glycol and toluene diisocynate into a stirrer to prepare polyurethane; and emulsifying an emulsifier, butyl acrylate, methyl methacrylate, a functional monomer and a proper amount of water at high speed to prepare the core-shell fluorinated polyurethane-acrylate latex. By the method, the defects that the fluorinated acrylate in the prior art is independent of oil and water phases due to hydrophobicity and lipophobicity, effective micelle is difficult to form by the general surfactant and the grafting ratio is low are overcome. The core-shell fluorinated polyurethane-acrylate latex has a core-shell structure and the fluorinated acrylate is enriched in the shell, so a latex film has a large water contact angle. The using amount of the fluorinated acrylate monomer (G04) is 1 to 2 percent of the weight of the monomer and the using amount of polyurethane (PU) is 10 percent of the weight of a composite latex solid, so the preparation cost is low. The emulsifier does not need a fluorine-containing surfactant, so the polymerization rate is high, the grafting efficiency of the fluorinated acrylate monomer is high and the latex is stored stably.

Owner:江苏日出化工有限公司 +1

Anti-icing single-component fluorosilicone rubber coating material and preparation method thereof

The invention discloses an anti-icing single-component fluorosilicone rubber coating material and a preparation method thereof. The preparation method comprises the steps of taking alpha, omega-dyhydroxyl polydimethyl siloxane as basic rubber, and preparing an anti-icing single-component fluorosilicone rubber coating by changing the relative content of a cross-linking agent and a fluorine-containing cross-linking agent. The anti-icing single-component fluorosilicone rubber coating material and the preparation method thereof aim at overcoming the defects in the prior art and used for the fields of paint and the like, organopolysiloxane is taken as a raw material, and a better anti-icing effect can be achieved.

Owner:TIANJIN UNIV

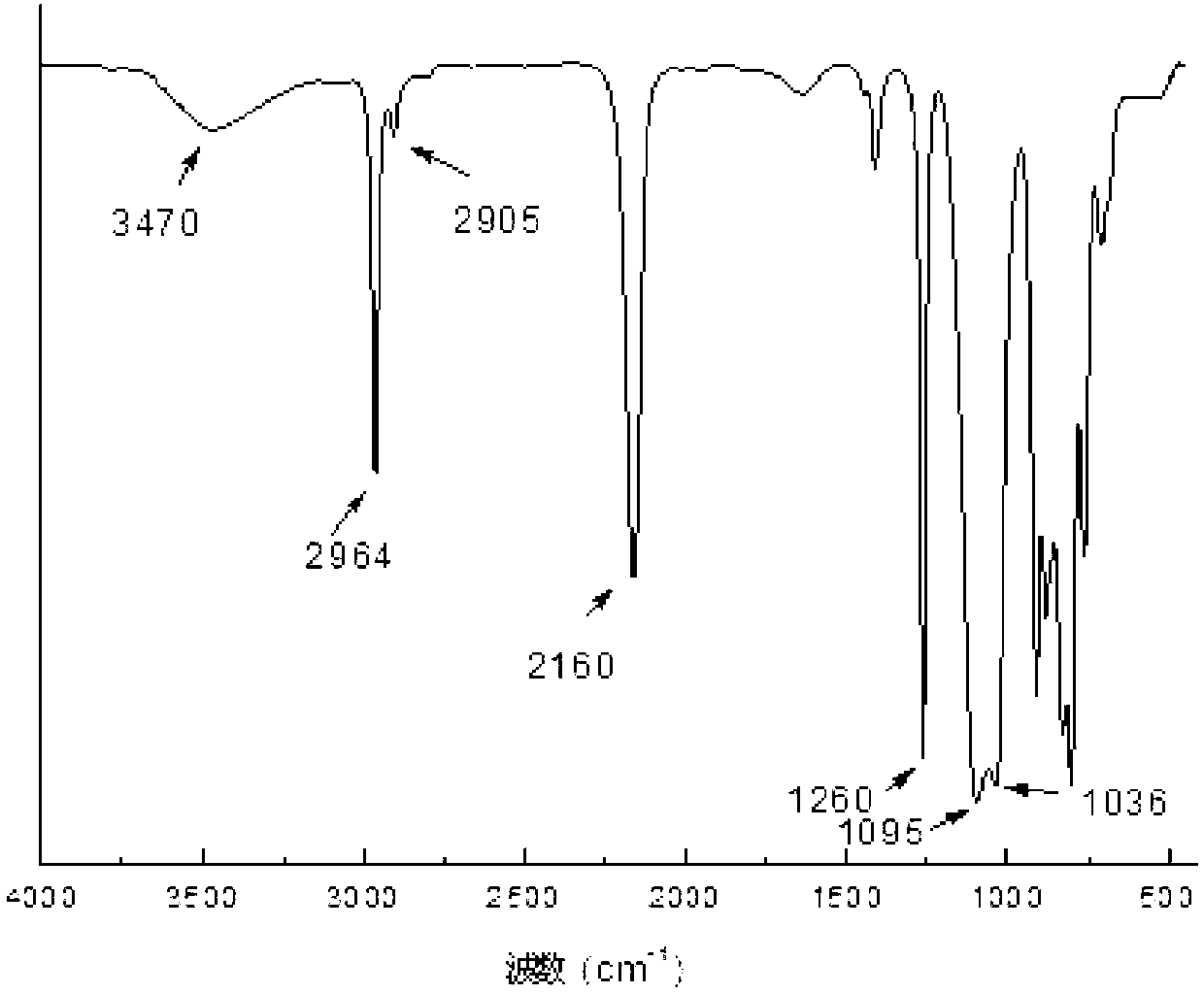

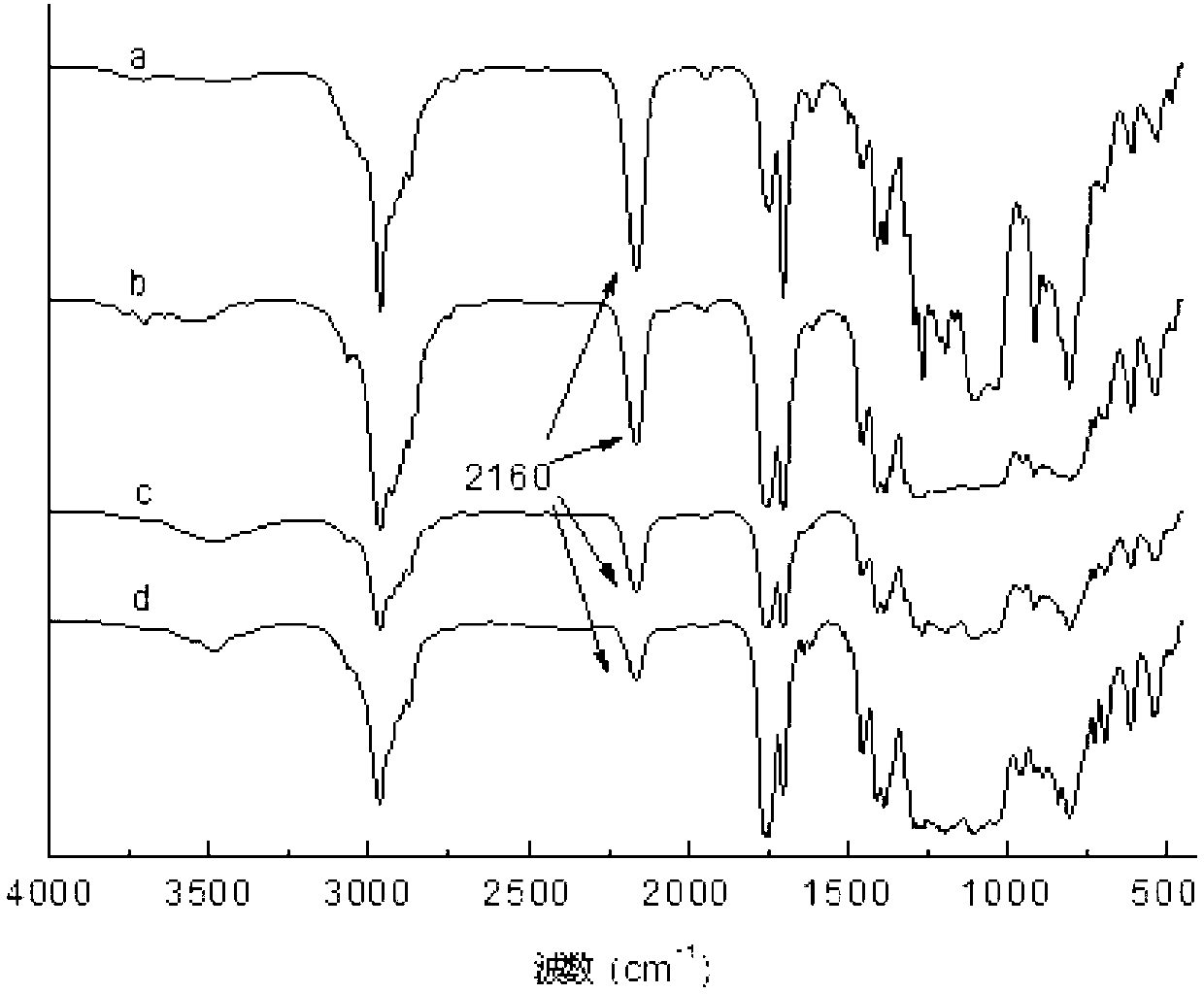

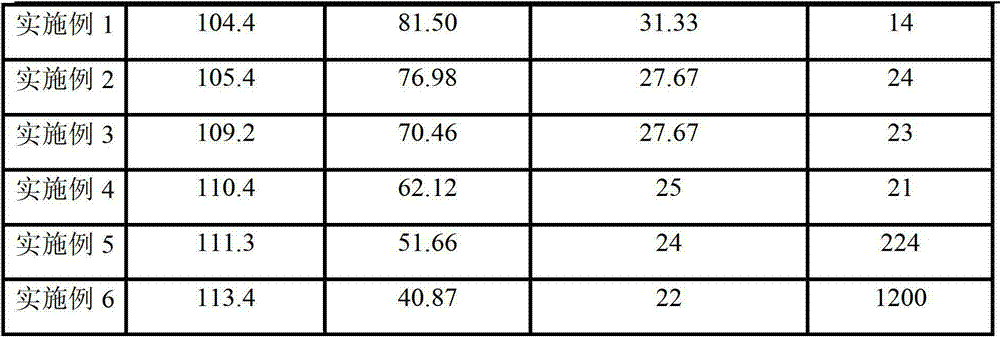

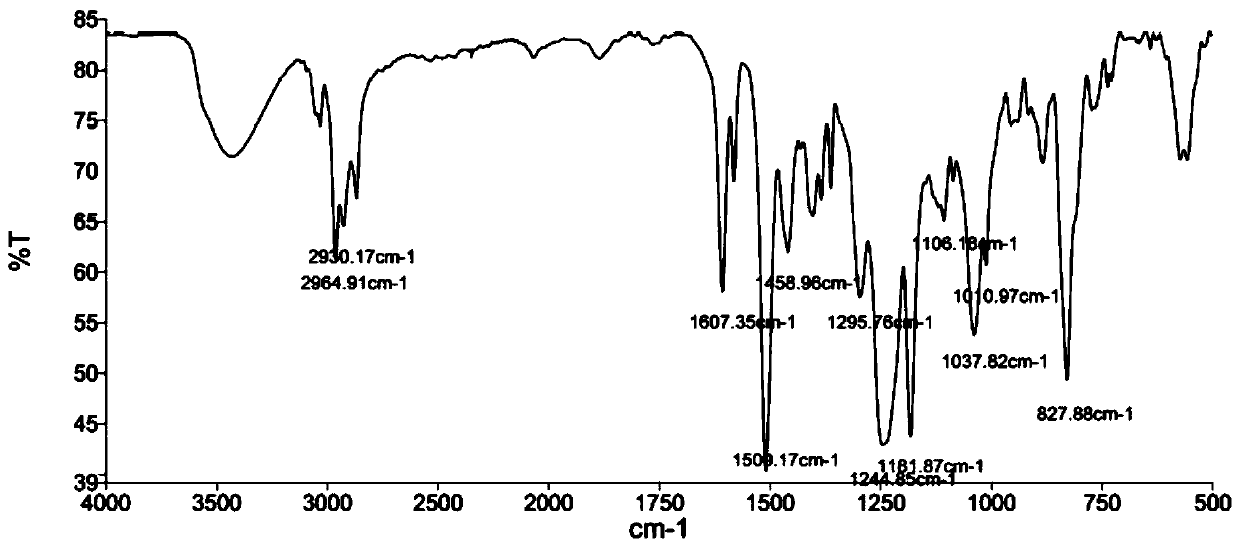

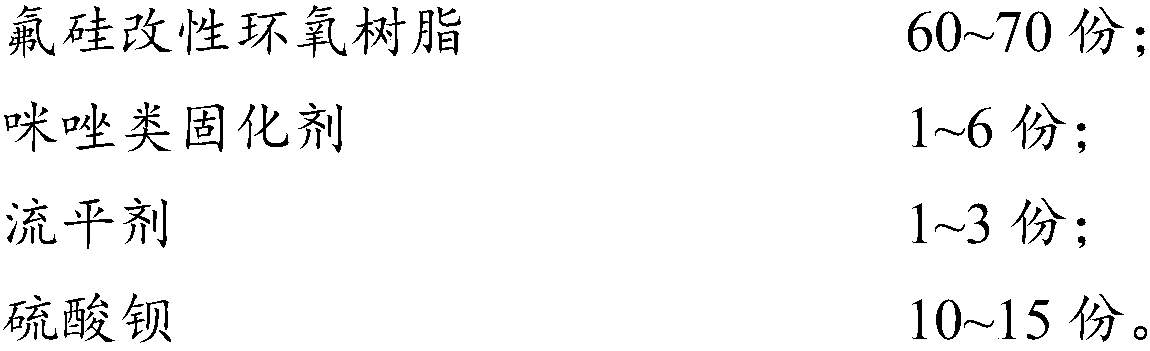

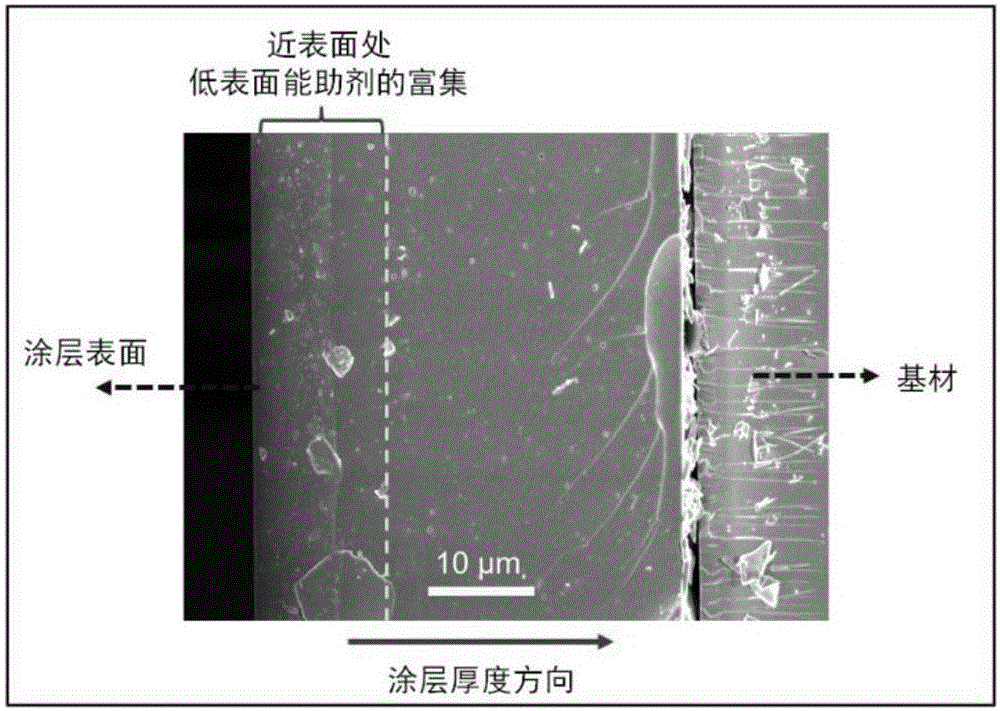

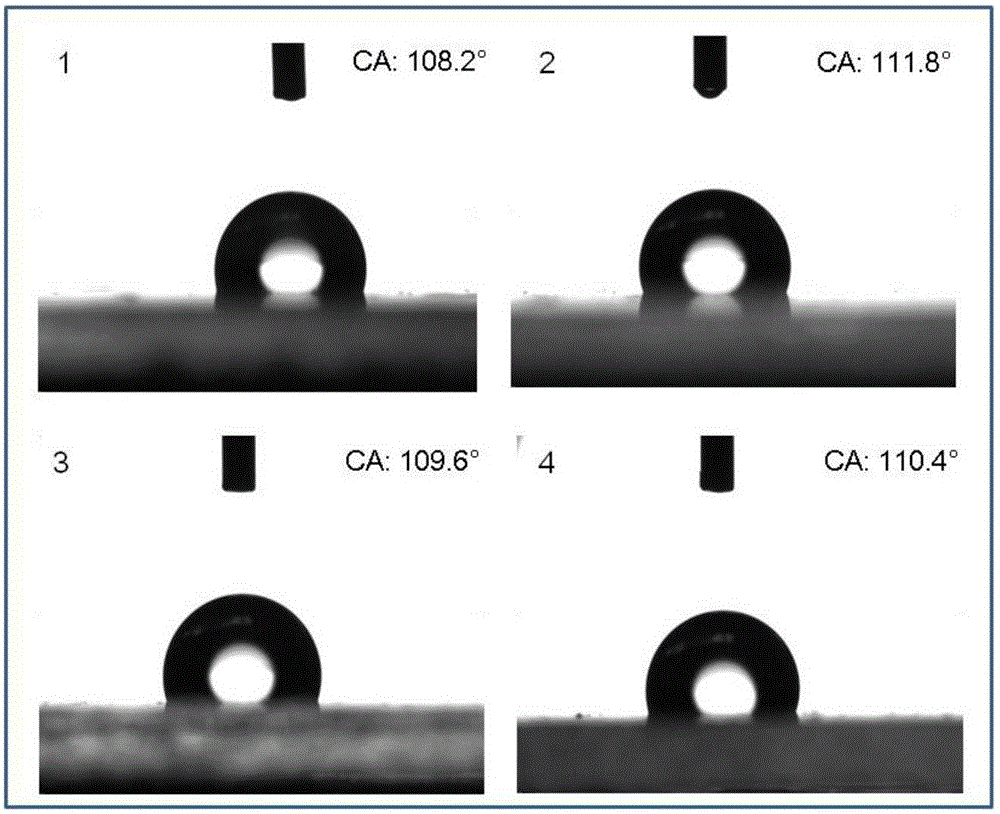

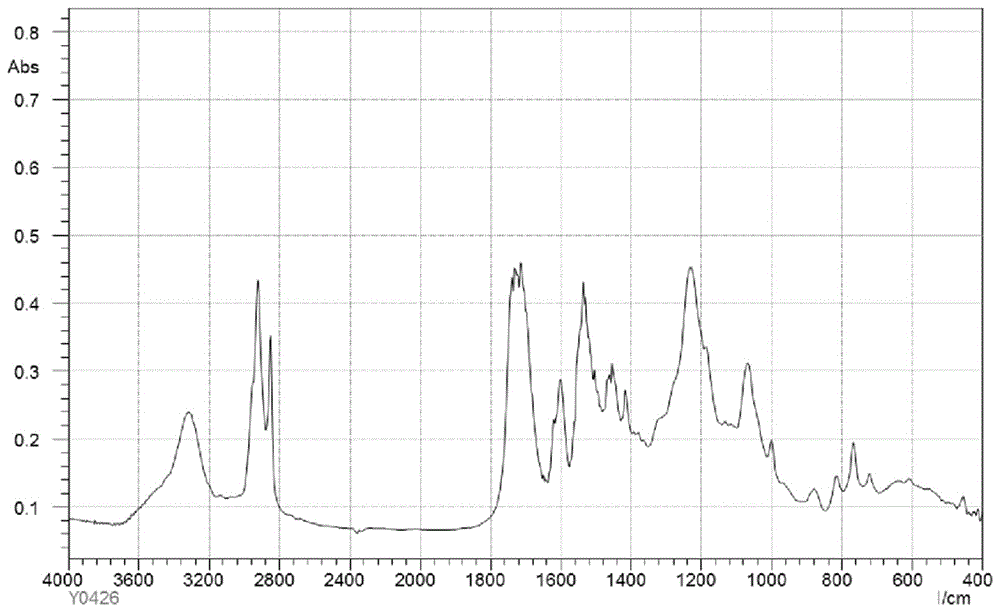

Fluorosilicon modified epoxy resin and preparation method thereof and powder coating

ActiveCN107936764AHigh water contact angleLow priceAnti-corrosive paintsPowdery paintsSide chainSodium hydroxide

The invention provides a preparation method of fluorosilicon modified epoxy resin. The preparation method comprises the following steps: firstly, pre-polymerizing fluorine-containing acrylate and gamma-(methacryloxy)propyltrimethoxysilane, wherein the fluorine-silicon ratio and the branch chain length can be adjusted; dividing an epoxy resin synthesizing process into two steps, namely firstly grafting a fluorosilicon prepolymer, and then performing chain extension by using bisphenol A, so that a fluorosilicon structure can be uniformly distributed in a molecular structure of epoxy resin. The fluorosilicon modified epoxy resin provided by the invention comprises fluorosilicon polymer grafted side chains, and can significantly improve the surface properties of powder coating, so that the powder coating has the characteristics of hydrophobicity, oleophobicity and low surface energy. The invention further provides the powder coating. Experimental results of the embodiment show that the powder coating has the water contact angle being higher than 140 degrees, and can maintain unchanged for 30 days under corrosion of hydrochloric acid with the concentration of 10%, sodium hydroxide withthe concentration of 20% and sodium chloride with the concentration of 3.5%.

Owner:ANHUI SHANFU NEW MATERIAL TECH

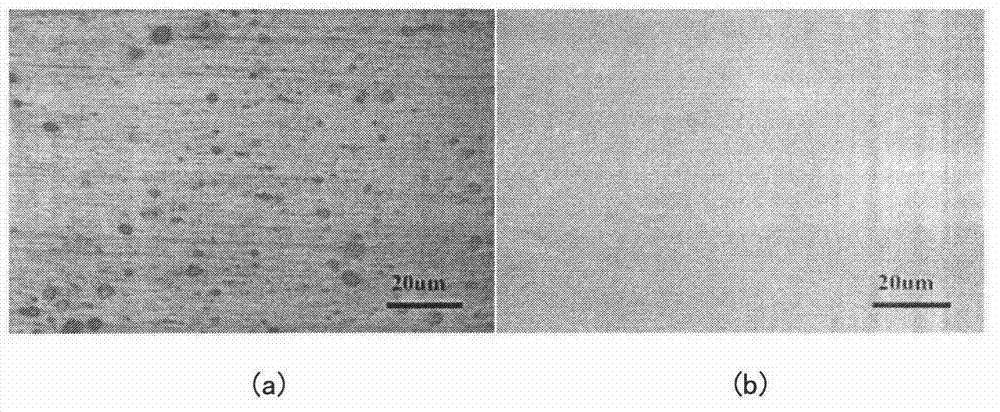

Ice-coating-resistant coating and preparation method and application thereof

ActiveCN105315870AStrong anti-icing durabilityIncreased durabilityPolyurea/polyurethane coatingsAcrylic resinDiluent

The invention is applicable to the field of coatings and provides an ice-coating-resistant coating and a preparation method and application thereof. The ice-coating-resistant coating comprises a component A and a component B, wherein the component A comprises hydroxy acrylic resin, a silane coupling agent, low-surface energy auxiliaries containing silicon, surface modification auxiliaries, diluents and other auxiliaries, and the component B is fatty acids isocyanate. The ice-coating-resistant coating is good in ice-coating-resistant durability, the water contact angle of the coating is large, the adhesive force between the coating and a substrate is good, mechanical performance is excellent, and the process is simple.

Owner:安徽足迹新材料科技有限公司

Preparation method of waterborne polyurethane with hyperbranched structure silicone oil side chain

The invention provides a hyperbranched silicone oil side chain modified waterborne polyurethane polymer and a preparation method thereof. The preparation method of the polymer comprises the following steps: making 100 parts of polyether polyol and 10 parts of hyperbranched amino silicone oil react with 20 to 80 parts of diisocyanate to obtain a polyurethane prepolymer which contains a hyperbranched silicone oil side chain and is blocked by an isocyanate group; adding 2 to 19 parts of small molecular polyol chain extender into the prepolymer and 0.1 to 10 parts of amino-containing small molecular dihydric alcohol for chain extension, and performing quaternization and further emulsification to obtain hyperbranched silicone oil side chain modified polyurethane polymer emulsion. In the hyperbranched silicone oil side chain modified waterborne polyurethane emulsion, a hyperbranched siloxane chain segment is adopted, so that the water contact angle is increased, and the water absorption of polyurethane is lowered; the emulsion can be used as a fluorine-free waterproof agent to be applied to chemical fiber cloth or cotton; the preparation method is simple in process, the reaction speed is moderate and the operating conditions are easy to control; the product belongs to a water-based emulsion, and conforms to the development direction of environmental friendliness.

Owner:WACKER DYMATIC SILICONES SHUNDE CO LTD FOSHAN

Organosilicon modified carbonyl epoxy composite material

InactiveCN1847309ASmall hydrophobic and anti-fouling propertiesGood hydrophobic and antifouling propertiesEpoxyWeather resistance

The present invention relates to one kind of organosilicon modified carbonyl epoxy composite material. Organosilicon with relatively low surface tension, high hydrophobicity, excellent contamination resistance and high weather resistance is used in modifying epoxy resin. The composite material may also contains certain amount of aldehyde, polybasic amine, ketone, tertiary amino compound and / or quaternary ammonium base as well as inorganic stuffing, such as cement, sand, etc. The organosilicon modified carbonyl epoxy composite material may have relatively stuffing adding amount, good flowability, low cost, good mechanical performance, high strength and other advantages, and may be used as paint and cementing material.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

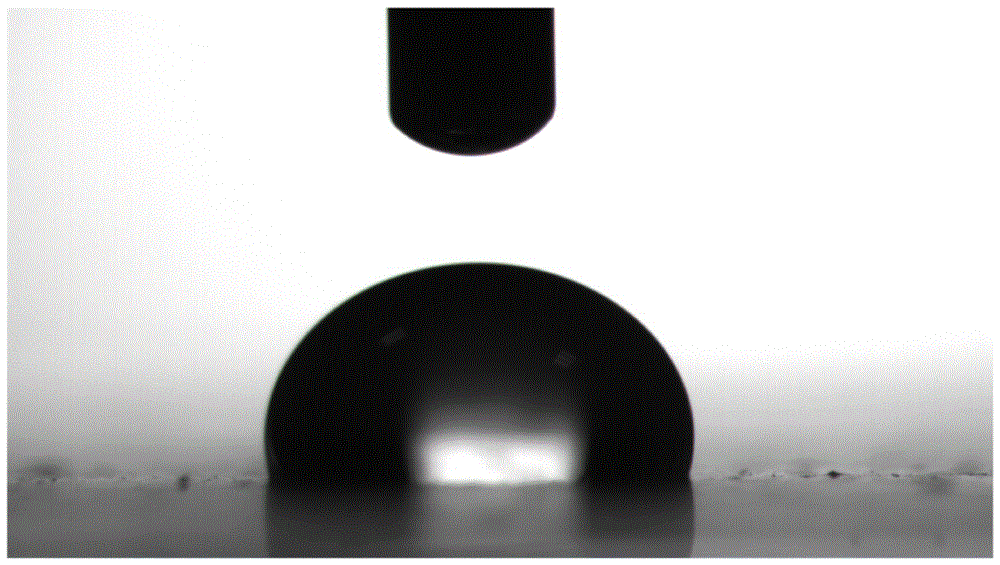

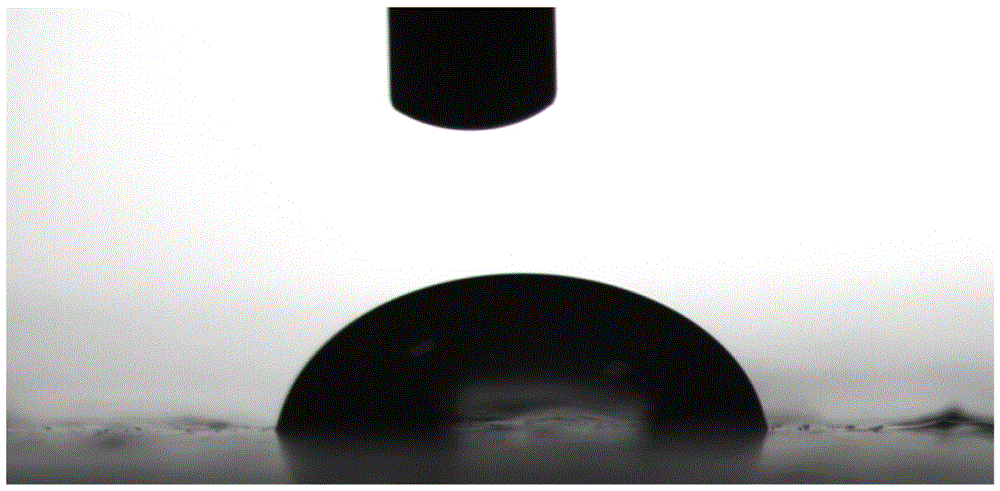

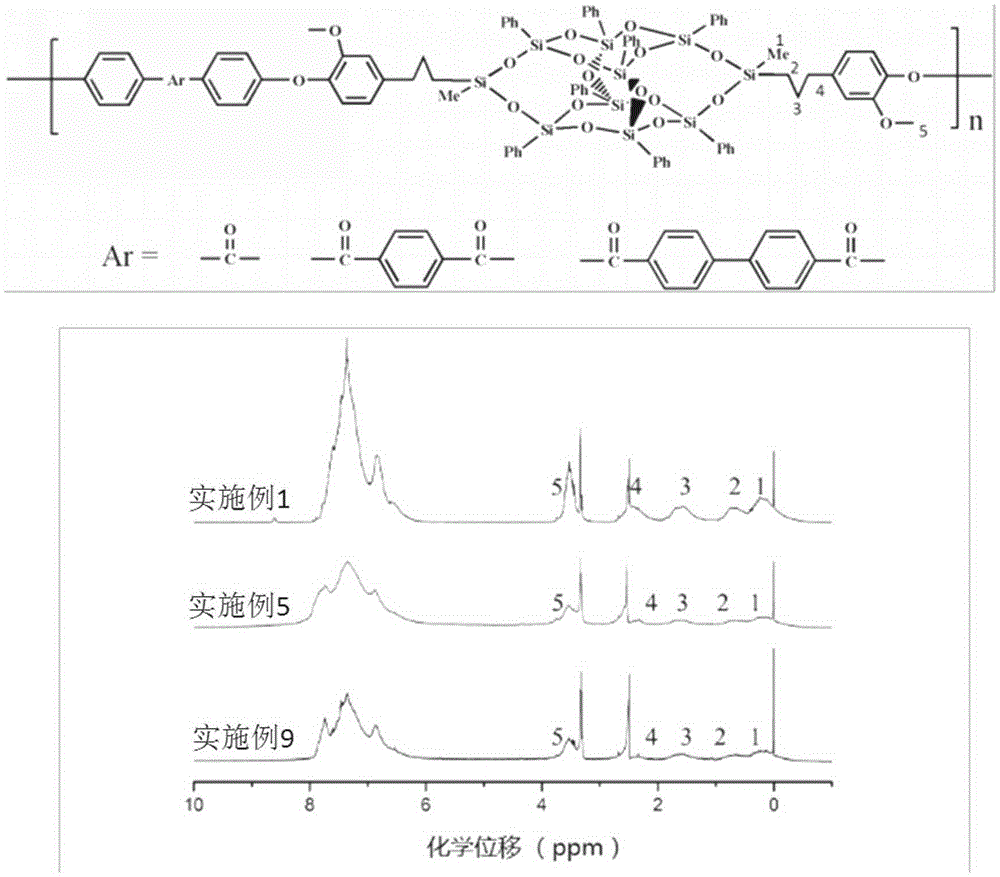

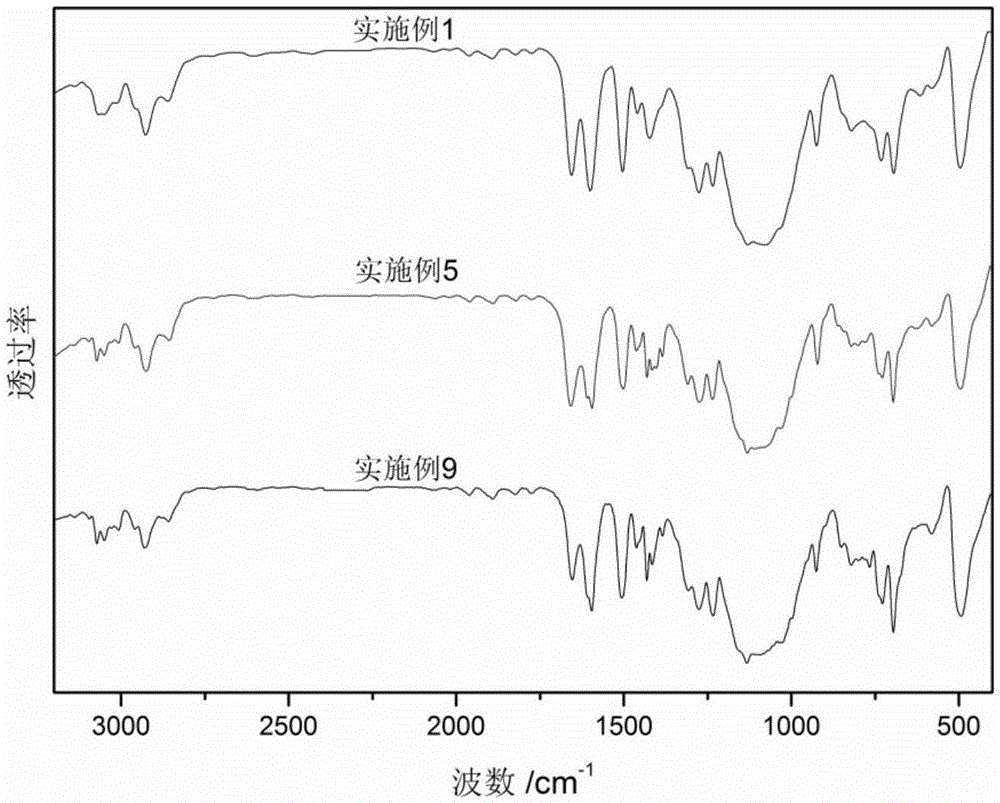

Poly(aryl ether ketone) resin with main chain containing polyhedral oligomeric silsesquioxane double-deck structure, and preparation method thereof

The invention discloses a poly(aryl ether ketone) resin with a main chain containing a polyhedral oligomeric silsesquioxane double-deck structure, and a preparation method thereof, and belongs to the technical field of high molecular material. According to the invention, 3,13-di(2-methoxy-4-propylphenol) octaphenyl polyhedral oligomeric silsesquioxane is taken as a raw material, and is reacted with difluoroketone monomers such as 4,4'-difluoro diphenylmethanone, 1,4-(4-fluoro-benzoyl)-phenyl or 4,4'-(4-fluoro-benzoyl)-1,1'-biphenyl so as to prepare the low-dielectric constant hydrophobic poly(aryl ether ketone) resin with a main chain containing a polyhedral oligomeric silsesquioxane double-deck structure. Compared with conventional poly(aryl ether ketone), the poly(aryl ether ketone) resin with a main chain containing a polyhedral oligomeric silsesquioxane double-deck structure possesses following characteristics because of introduction of polyhedral oligomeric silsesquioxane that water contact angle is increased obviously, and the largest water contact angle can be 100 DEG, dielectric constant is reduced obviously, and the smallest dielectric constant can be 1.95. The synthetic route of the preparation method is simple; and the poly(aryl ether ketone) resin with a main chain containing a polyhedral oligomeric silsesquioxane double-deck structure possesses excellent hydrophobic performance and low dielectric constant, and is a high-molecular material with excellent comprehensive properties and a promising application prospect.

Owner:重庆沃特智华新材料科技有限公司

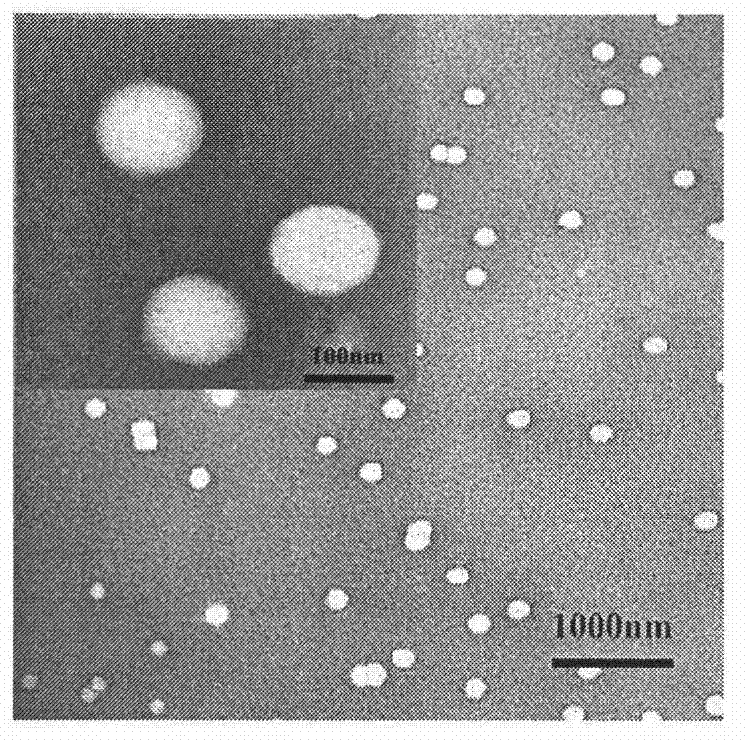

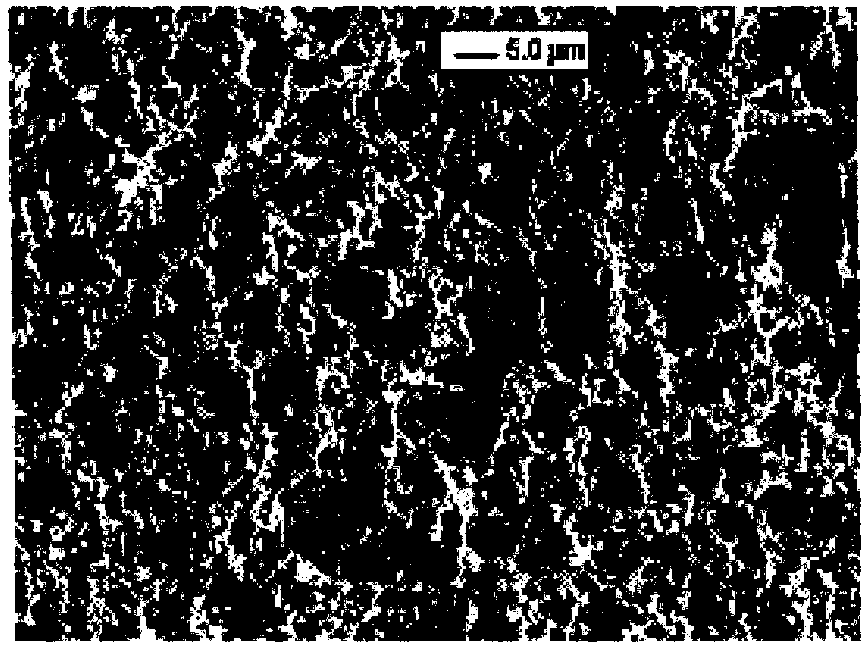

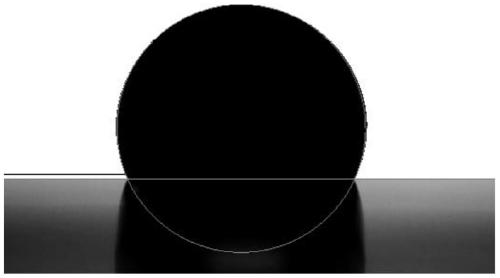

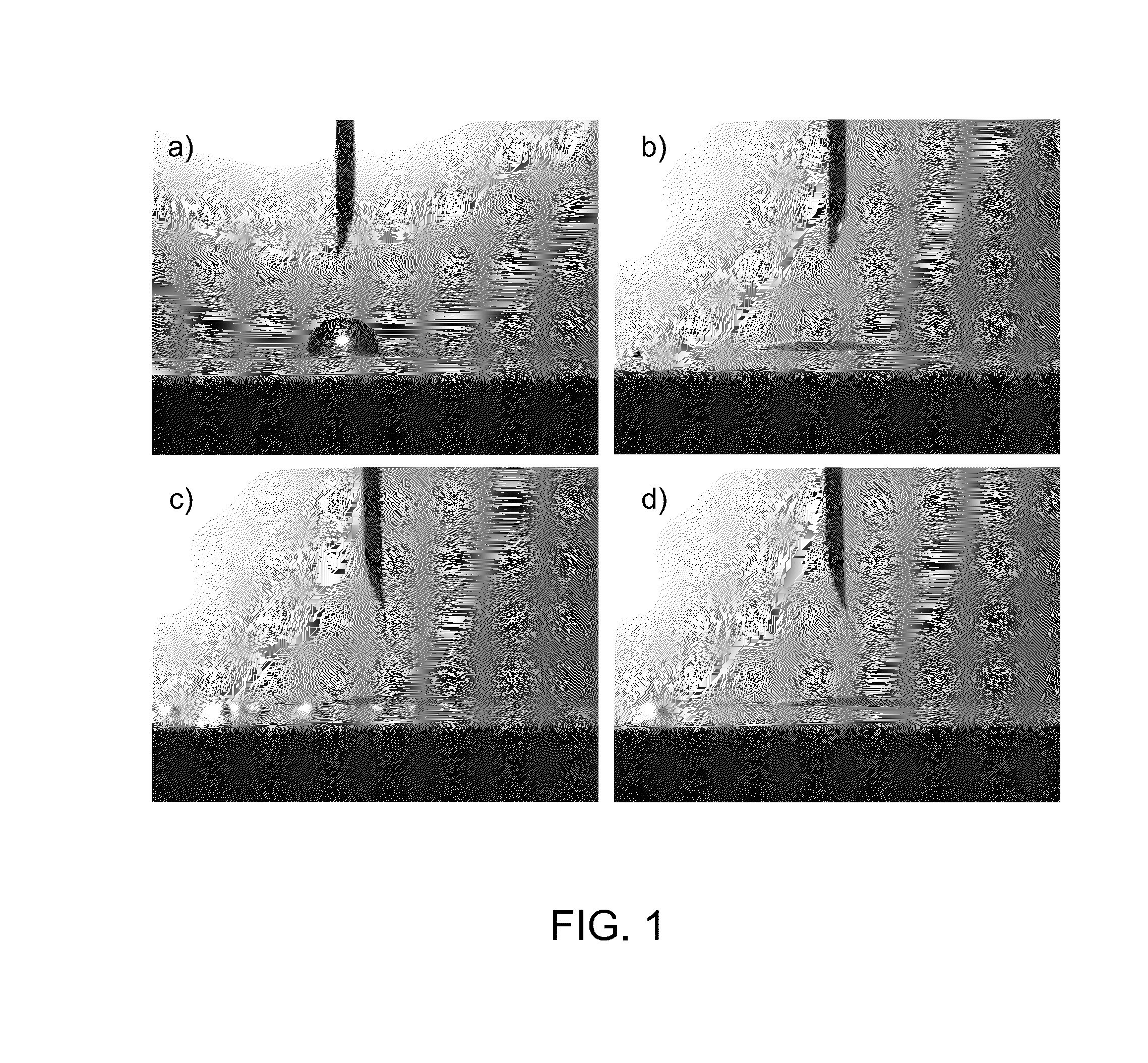

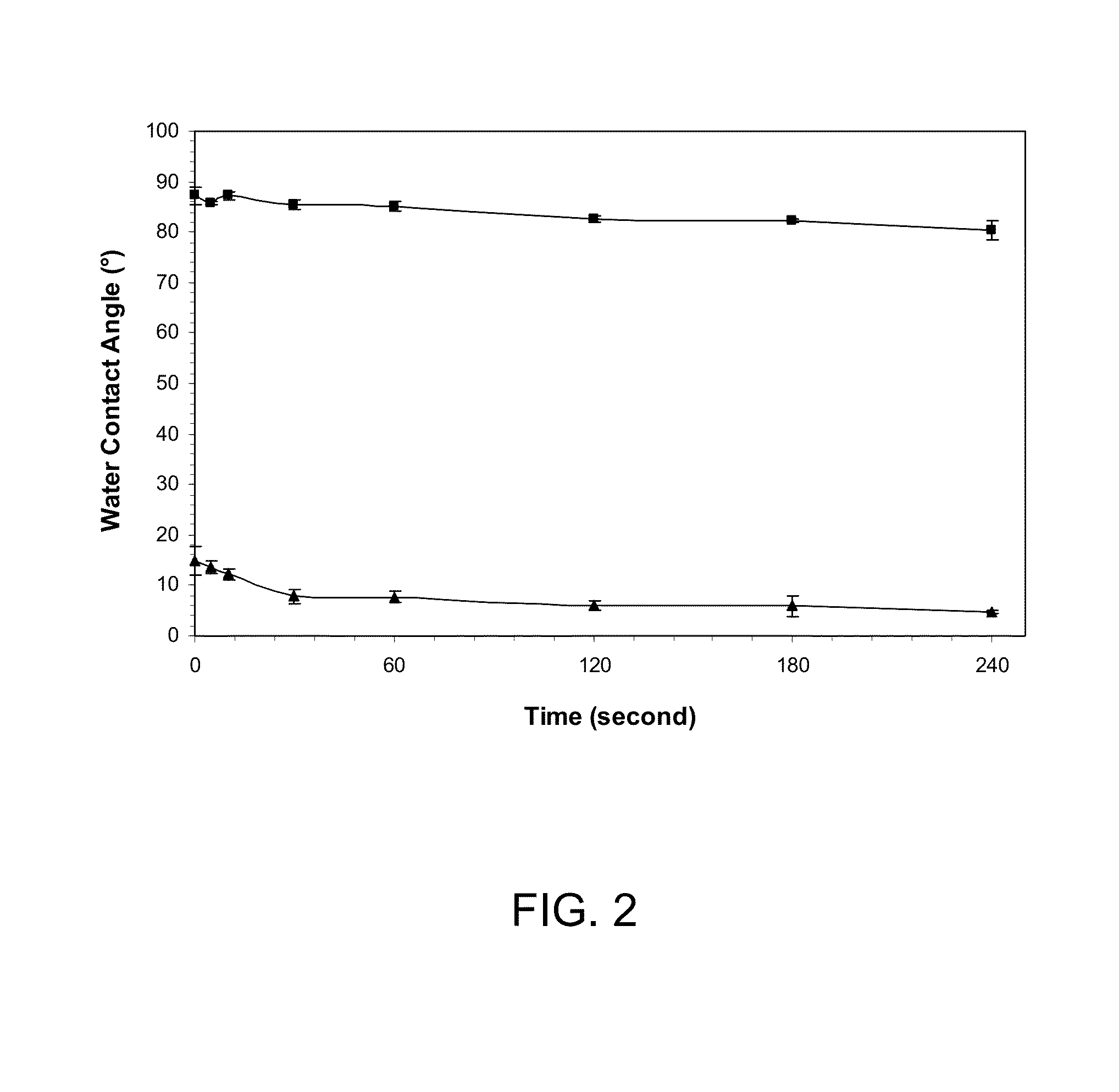

Nano-structured surface and an in situ method for forming the same

InactiveUS20100009188A1Improve hydrophobicityHigh water contact angleLotus effect fibresSynthetic resin layered productsNanoparticleWater contact

A nano-structured surface includes a substrate layer, and a plurality of immobilized nanoparticles on the substrate layer. The surface has a water contact angle of greater than 145 degrees. An in situ method of fabricating a nano-structured surface includes treating a substrate layer with a mixture that includes a silica precursor, a water-soluble catalyst, and a low-surface-energy compound to form a treated substrate layer, and curing said treated substrate layer in the atmosphere of ammonia to form a nano-structured surface on the substrate layer.

Owner:THE HONG KONG POLYTECHNIC UNIV

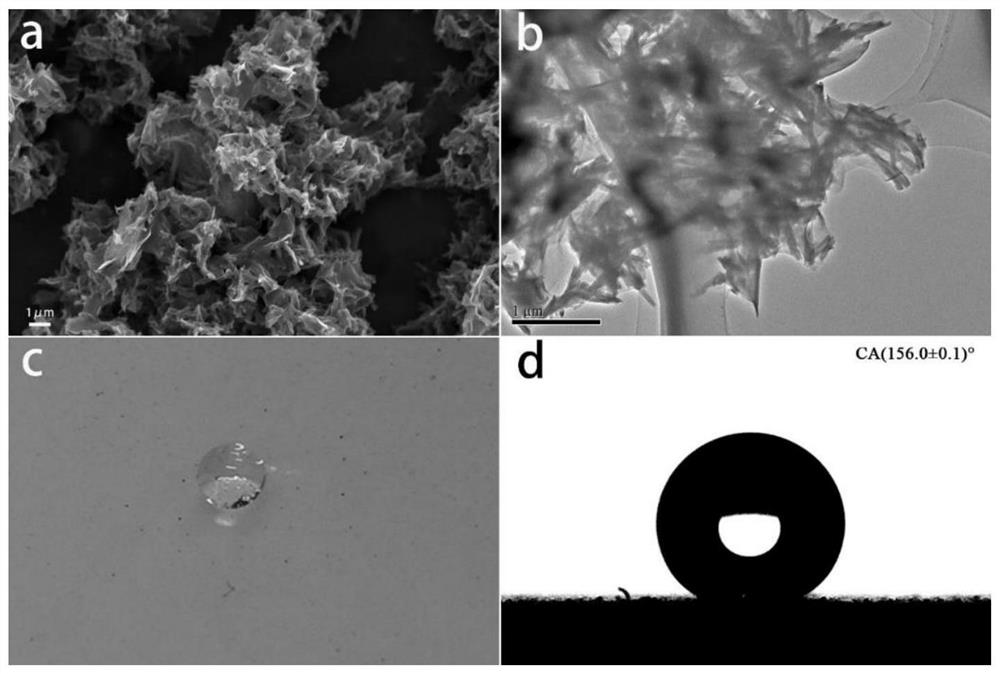

Preparation of multi-stage structure polycaprolactone super hydrophobic electrostatic spinning film by using one-step forming method

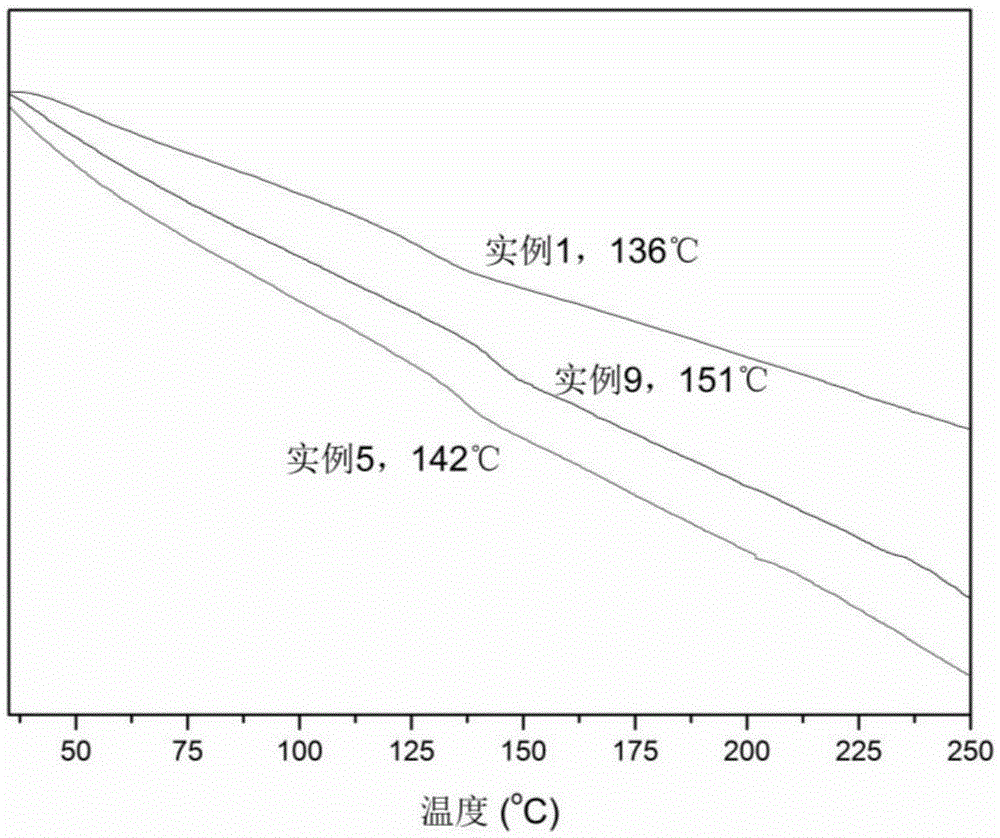

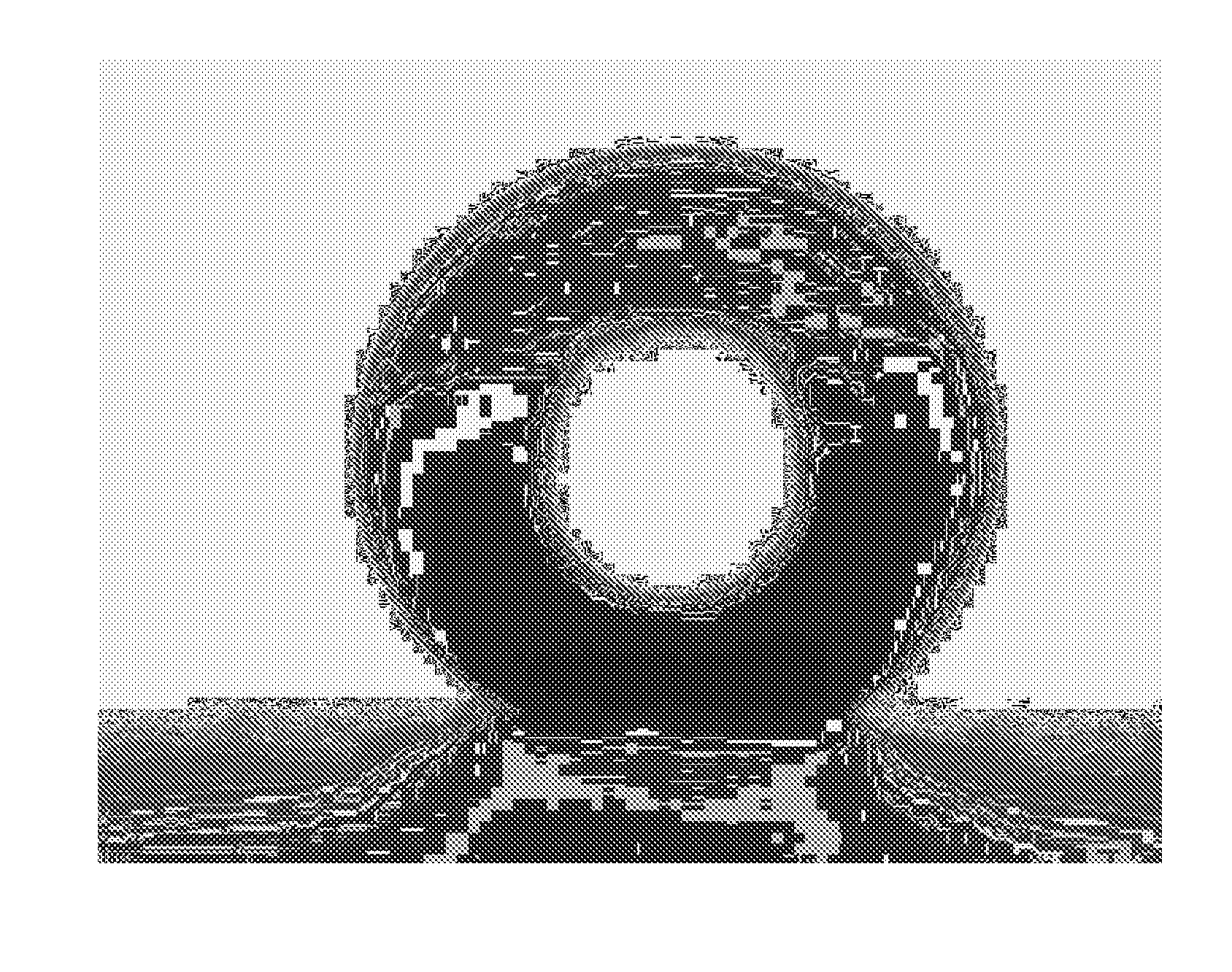

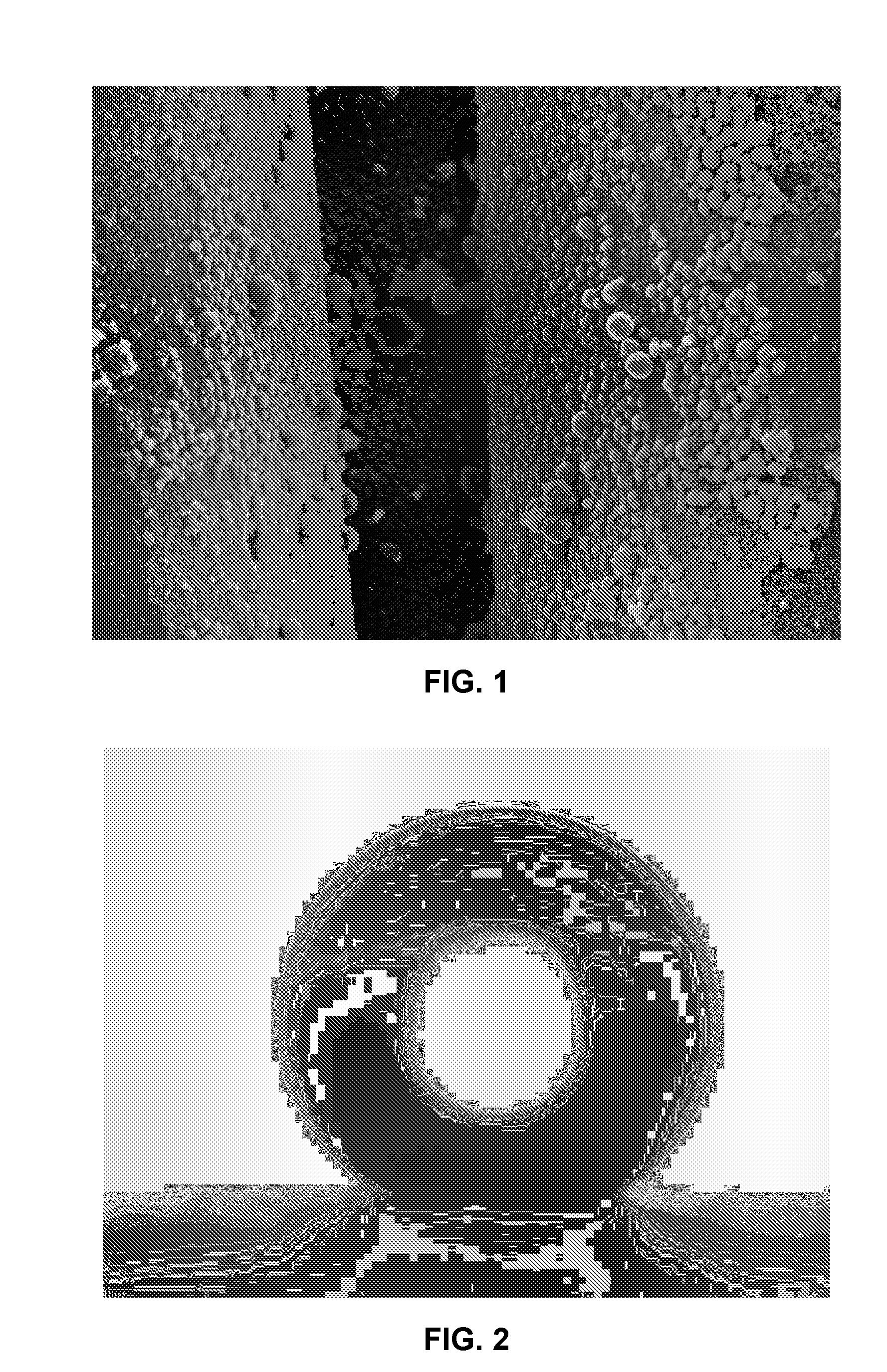

The invention relates to preparation of multi-stage structure polycaprolactone super hydrophobic electrostatic spinning film by using a one-step forming method, belongs to the field of preparation ofelectrostatic spinning nano fiber and super hydrophobic. The method comprises the preparation of an electrostatic spinning polycaprolactone / methyl silicone oil precursor solution and adding hydrophobic silica dioxide nanoparticles to the precursor solution and stirring by ultrasound for 0.5 hour; the polycaprolactone film is prepared through electrostatic spinning. Usually, the water contact angleof the polycaprolactone / methyl silicone oil fiber film is 136 degrees and around. The water contact angle of the polycaprolactone / methyl silicone oil / nano silica dioxide bead structural film can reach 151 degrees and around. The film has strong oil adsorption ability and oil-water separation ability. The preparation process is simple and the energy consumption is low. Polycaprolactone is a natural degradable and environment-friendly polymer, does not pollute the environment and has a great prospect in the field of oil-water separation.

Owner:JILIN UNIV

Method for preparing porous polyvinylidene fluoride super-hydrophobic coating layer

ActiveCN110564227AStrong anti-icing abilityStrong weather resistanceCoatingsWeather resistanceTriethoxysilane

The invention discloses a method for preparing a porous polyvinylidene fluoride super-hydrophobic coating layer. The method comprises the following steps: mixing polyvinylidene fluoride and N,N-dimethyl formamide, performing stirring, mixing the obtained transparent solution with perfluordecyl triethoxy silane, performing stirring, mixing the obtained perfluordecyl triethoxy silane mixed solutionwith composite nano titanium dioxide granules, performing stirring, performing ultrasonic treatment, and smearing or spraying the obtained porous polyvinylidene fluoride super-hydrophobic coating to asubstrate, so as to obtain a porous polyvinylidene fluoride super-hydrophobic coating layer. The method disclosed by the invention has the advantages of being simple in process, convenient to operate, cheap in raw material, easy in industrial production, and the like, and the super-hydrophobic coating layer which is excellent in super-hydrophobic performance, good in ice resistance and wind resistance, good in weather resistance and good in adaptability can be prepared in a large scale, can be widely applied to anti-ice treatment on fan blades, has great significances for improving the performance and increasing the power generation capacity of a wind turbine generator, and has high use value and good application prospects.

Owner:国家能源集团龙源江永风力发电有限公司

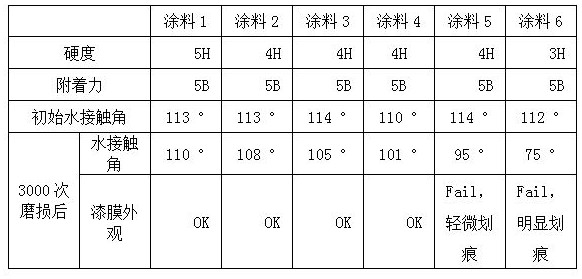

Wear-resistant and stain-resistant ultraviolet curing PVC (polyvinyl chloride) floor coating

ActiveCN113897128ASimple processLow costChemical industryPolyurea/polyurethane coatingsPolymer scienceOligomer

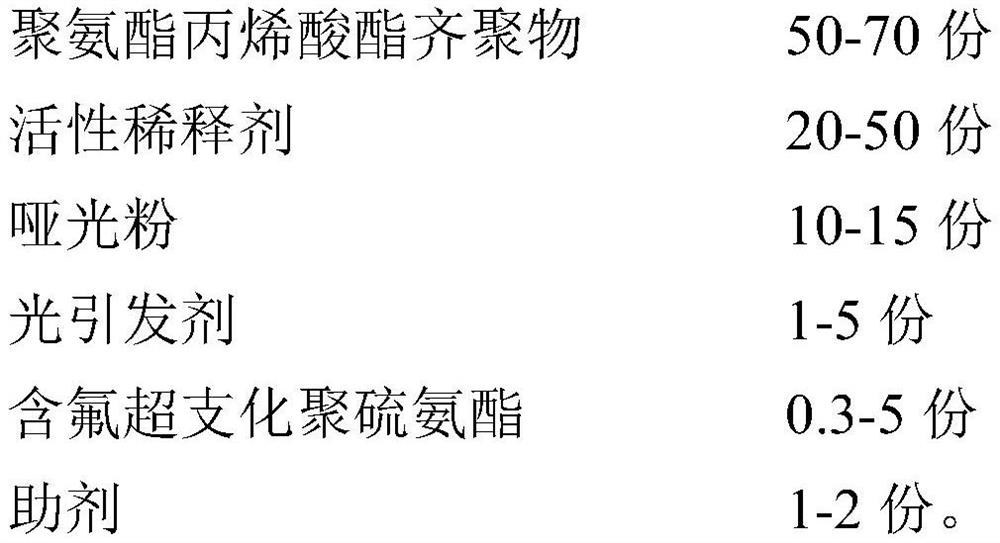

The invention discloses a wear-resistant and stain-resistant ultraviolet curing PVC (polyvinyl chloride) floor coating. The coating is prepared from the following raw materials in parts by weight: 50 to 70 parts of polyurethane acrylate oligomer, 20 to 50 parts of reactive diluent, 10 to 15 parts of matt powder, 1 to 5 parts of photoinitiator, 0.3 to 5 parts of fluorine-containing hyperbranched polythionocarbamate and 1 to 2 parts of additive. The fluorine-containing hyperbranched polythionocarbamate added in the invention not only reduces the internal stress and curing shrinkage of a system and enhances the adhesive force with a base material, but also improves the crosslinking density, hardness and wear resistance of the coating by introducing a rigid polythionocarbamate structure.

Owner:JIANGNAN UNIV +1

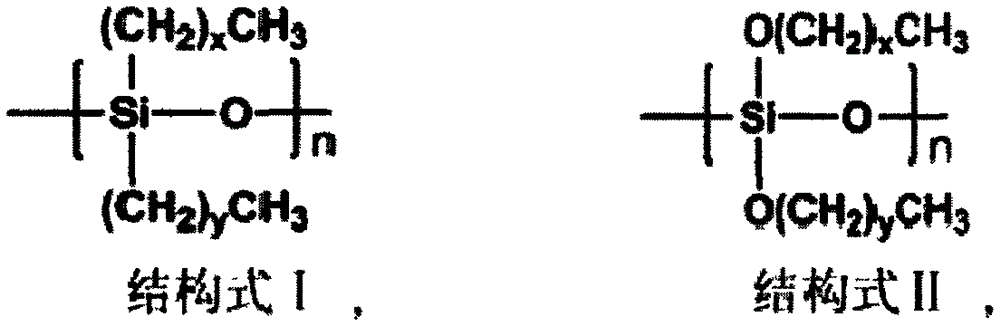

High-wear-resistance UV resin with anti-fingerprint function and preparation method thereof

ActiveCN112574390AGood anti-fingerprint and abrasion resistanceImprove wear resistanceAntifouling/underwater paintsPaints with biocidesPolyesterPolymer science

The invention relates to high-wear-resistance UV resin with an anti-fingerprint function and a preparation method of the high-wear-resistance UV resin. Raw materials of the resin comprise the following components: an isocyanate mixture, perfluoropolyether alcohol containing a hydroxyl group at one end, a mixture of single-end-carbon hydroxyl polysiloxane and double-end-carbon hydroxyl polysiloxane, linear polyester glycol free of fluorine and silicon, hydroxyl acrylate containing a polyurethane structure and a polyurethane reaction catalyst. According to the invention, perfluoropolyether and an organic silicon chain segment are introduced into a molecular chain of an UV resin polymer at the same time through reaction among the components, and the friction coefficient and the surface energyof the surface of the resin are reduced by utilizing the synergistic effect of fluorine-silicon molecules, so the prepared UV resin has good fingerprint resistance and wear resistance; and meanwhile,the hydrogen bond content of the molecular chain is increased by introducing carbamate with relatively high content into the molecular chain of the UV resin polymer, so the cohesive energy of the molecular chain is further improved, and the wear resistance of the UV resin is further improved.

Owner:太仓中化环保化工有限公司

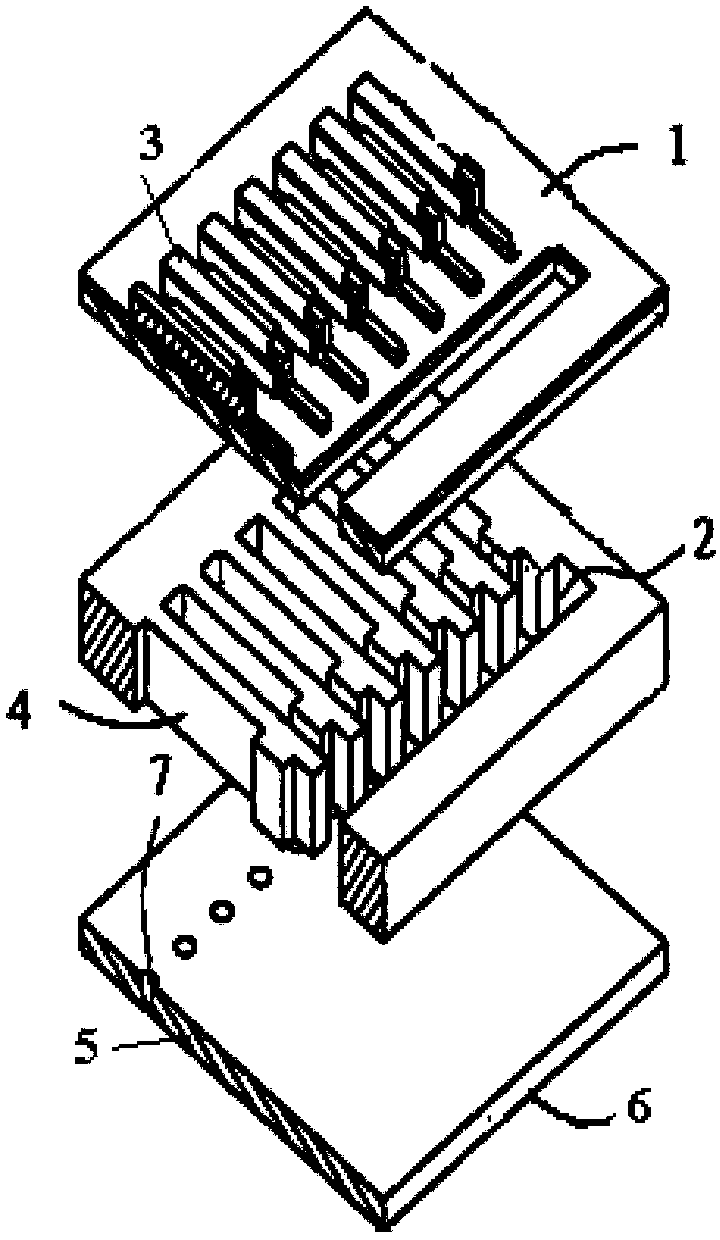

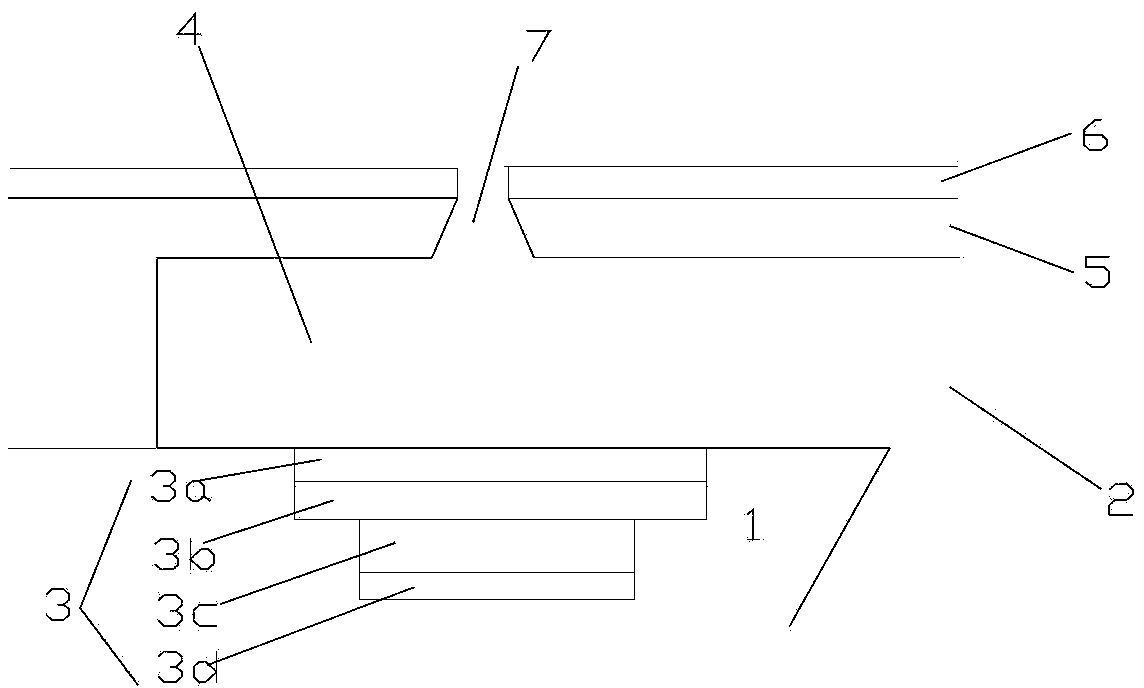

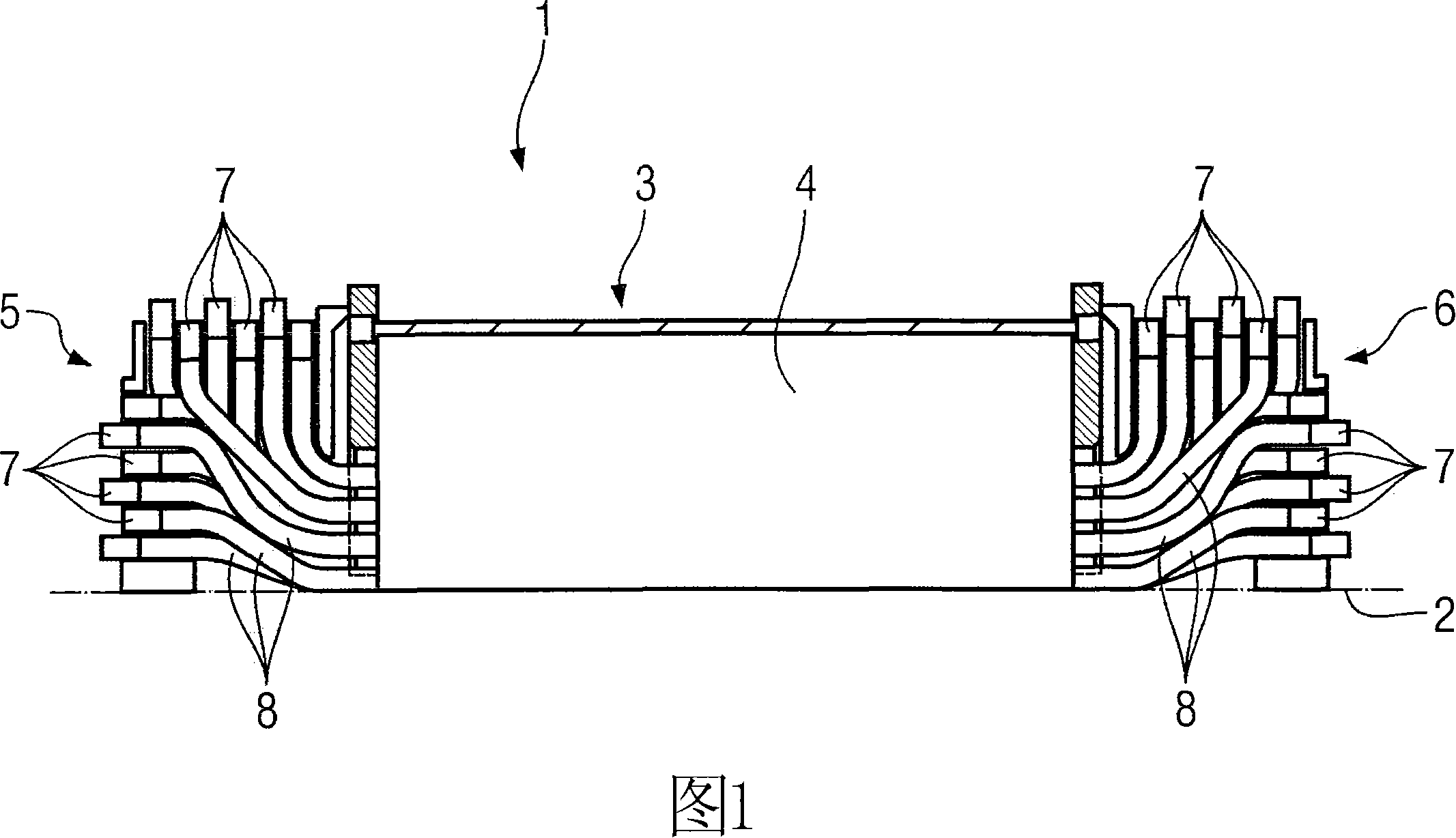

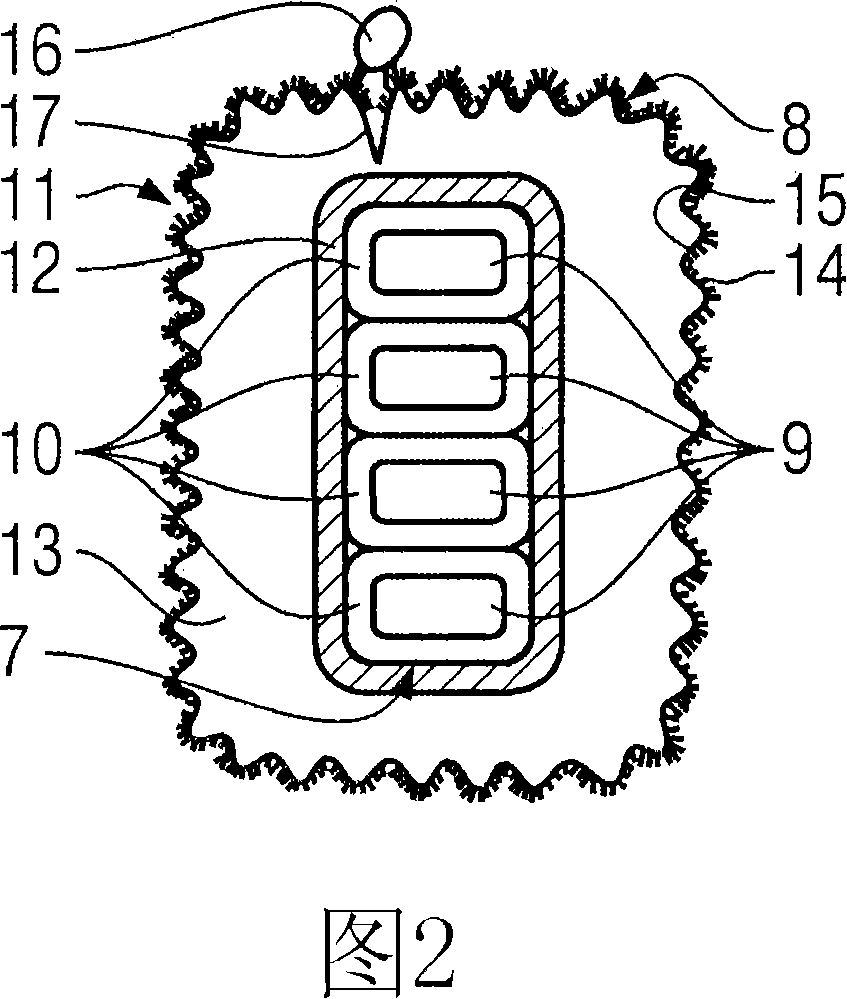

Liquid ejecting head and liquid ejecting device

The invention provides a liquid ejecting head and a liquid ejecting device. The liquid ejecting head comprises a nozzle plate and a substrate, the nozzle plate is provided with a nozzle, and a pressure cavity is formed in the space between the nozzle plate and the substrate. The pressure cavity is communicated with the outside through the nozzle on the nozzle plate. The substrate is provided with a pressure generating part which enables the pressure in the pressure cavity to be changed. A super-hydrophobic material layer is arranged on the face, deviated from the pressure cavity, of the nozzle plate, and the super-hydrophobic material layer is at least placed around the area of the nozzle. The liquid ejecting device comprises the liquid ejecting head. The liquid ejecting head is used for improving the printing quality, and the service life of the nozzle plate is prolonged.

Owner:ZHUHAI SAILNER 3D TECH CO LTD

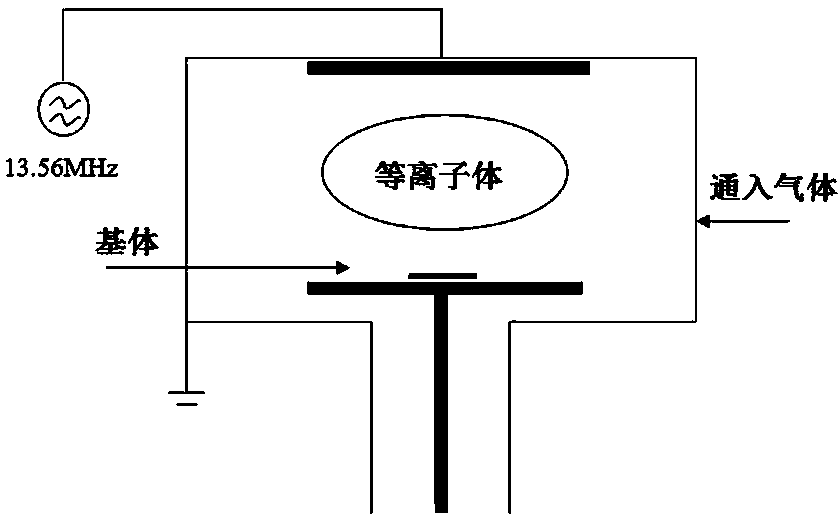

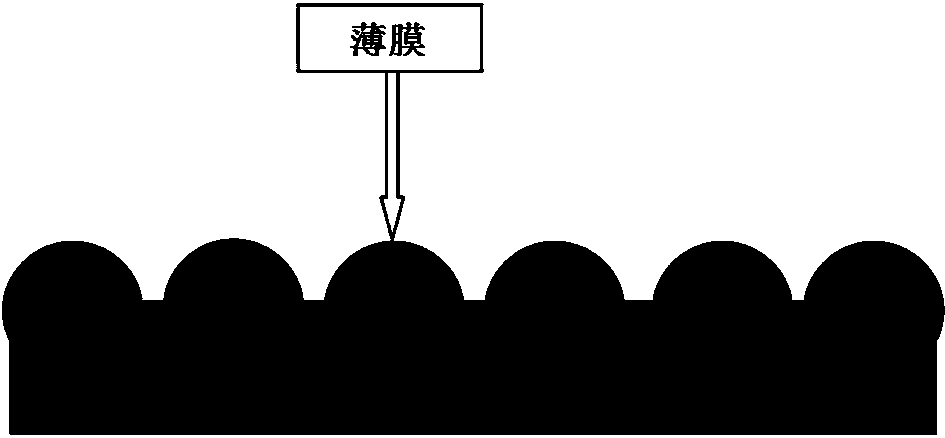

Thin film with low friction coefficient and high water contact angle and preparation method thereof

InactiveCN111286061AReduce coefficient of frictionLower water contact anglePolyurea/polyurethane coatingsEpoxy resin coatingsPolymer scienceUV curing

The invention provides a thin film with a low friction coefficient and a high water contact angle and a preparation method thereof. The thin film comprises a transparent base film, a bottom coating layer and an AF layer which are sequentially attached from bottom to top. The preparation method comprises the following steps: step S001, taking materials: selecting a transparent base film made of a proper material; step S002, preparing a bottom coating solution: diluting an unsaturated functional group-containing polymer and a photoinitiator with a solvent to form a base coating solution; step S003, attaching a bottom coating layer: coating the transparent base film with the base coating solution, and carrying out heating curing, UV curing or dual curing through a drying oven to form the basecoating layer; S004, attaching an AF layer: coating the semi-finished product formed in the step S003 with an AF solution, and forming the AF layer through cross-linking curing after being heated bythe drying oven. According to the thin film with the low friction coefficient and the high water contact angle and the preparation method thereof, the defects that an existing thin film is smooth, poor in anti-fingerprint effect, complex in preparation process and not suitable for mass production are overcome.

Owner:NINGBO HUGHSTAR ADVANCED MATERIAL TECH

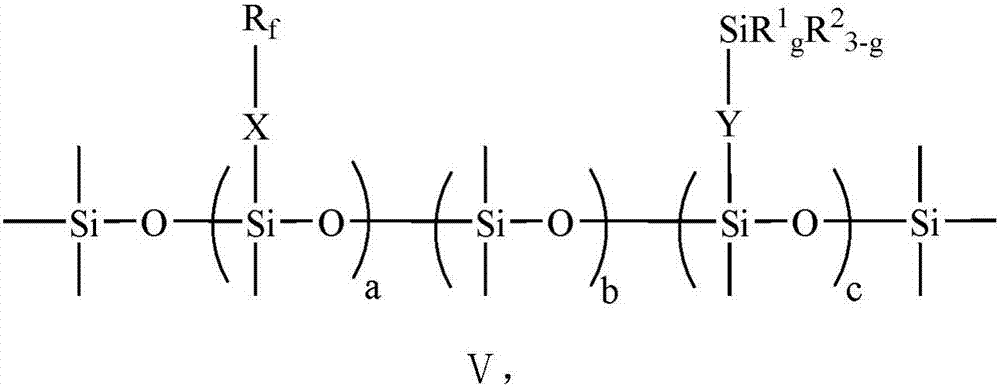

Preparation method of perfluoropolyfluoroether fluorosilane with plurality of hydrolytically-active end groups

ActiveCN107216459ARaw materials are easy to getMild process conditionsAntifouling/underwater paintsPaints with biocidesSilanesEnd-group

The invention relates to a preparation method of perfluoropolyfluoroether fluorosilane with a plurality of hydrolytically-active end groups. The preparation method comprises the following steps: performing an addition reaction of vinyl-terminated perfluoropolyether and dialkoxyfluorosilane in the presence of a fluorine-containing solvent and a catalyst to obtain perfluoropolyether fluoroalkyl silane; performing a hydrolysis reaction on the perfluoropolyether fluoroalkyl silane to obtain a perfluoropolyether fluoroalkyl silane hydrolysate; reacting the perfluoropolyether fluoroalkyl silane hydrolysate with polyvinylsilicone oil in the presence of an alkali catalyst to obtain vinyl perfluoropolyether fluorosilicone oil; performing an addition reaction of the vinyl perfluoropolyether fluorosilicone oil and trialkoxyhydrosilane in the presence of a fluorine-containing solvent and a catalyst to obtain the perfluoropolyfluoroether fluorosilane. The preparation method has the advantages of adoption of readily-available raw materials and mild and safe process conditions; the defects that raw materials are difficult to obtain and are flammable and combustible in the prior art are overcome.

Owner:太仓中化环保化工有限公司

Preparation method of waterborne polyurethane emulsion

InactiveCN107814908ALarge particle sizeWidely distributedFibre treatmentRound-bottom flaskIsophorone

The invention provides a preparation method of a waterborne polyurethane emulsion and belongs to the field of preparation of materials. The method is characterized by comprising the following steps: successively adding isophorone isocyanate, polyether 210, castor oil and double hydroxyl-terminated polysiloxane into a four-neck round-bottom flask, fully stirring and then heating, adding a catalystand reacting; adding DMPA(dimethylol propionic acid), continuously reacting, then adding BDOTMP, continuously reacting and then cooling; adding triethylamine for neutralizing, cooling, adding deionized water for emulsifying, and intensely stirring to obtain the waterborne polyurethane emulsion modified by castor oil and double hydroxyl-terminated polysiloxane. When the amount of double hydroxyl-terminated polysiloxane is increased, the particle size of the emulsion is increased; the distribution is broadened; the appearance of the emulsion is changed from transparent to milk white; the stability is reduced; the glue film water contact angle is increased; the water absorption rate is reduced; the tensile strength of the glue film is firstly increased and then reduced; the elongation at break is increased.

Owner:SHAANXI ALLIANCE LOGISTICS

Cellulose films with at least one hydrophobic or less hydrophilic surface

InactiveUS20140288296A1Low oxygen permeabilityHigh water contact angleCellulose coatingsCeramic shaping apparatusFiberCellulose

A method for the production of cellulose films with at least one hydrophobic or less hydrophilic surface, or with at least one surface with a water contact angle (θ) in a range from 55° to less than 100° is described. The method involves contacting the cellulose material with a hydrophobic solid material during the preparation of the cellulose films or with a vapour of a non-polar or polar aprotic solvent during or after the preparation of the cellulose films. Examples of the cellulose material are cellulose filaments (CF) made to have at least 50% by weight of the filaments having a filament length up to 350 μm and a filament diameter between 100 and 500 nm from multi-pass, high consistency refining of wood or plant fibers, and commercially-available sodium carboxymethyl cellulose. Examples of the hydrophobic solid material are hydrophobic polymers, poly(methylpentene) and poly(ethylene). Examples of the non-polar solvent are hexane and toluene. Examples of the polar aprotic solvent are acetone and ethyl acetate.

Owner:FPINNOVATIONS INC

Fluorine-doped diamond-like film, preparation method thereof and impressing template comprising fluorine-doped diamond-like film

InactiveCN103436853ALower surface energyImprove hydrophobicityVacuum evaporation coatingSputtering coatingFluorine containingDiamond thin film

The invention discloses a fluorine-doped diamond-like film, a preparation method thereof and an impressing template comprising the fluorine-doped diamond-like film. The fluorine-doped diamond-like film is deposited on the surface of a substrate; the mass content of fluorine contained in the fluorine-doped diamond-like film is 1%-4%; the thickness of the fluorine-doped diamond-like film is 1-10 nanometers. The fluorine-doped diamond-like film disclosed by the invention has the advantages of a diamond-like film, also has the advantages of excellent hydrophobic property and anti-sticking property and good adhesion with the substrate, protects the structural integrity of the substrate, improves the reusing ratio of the substrate, is simple in preparation process and low in cost and can be applied to the anti-sticking treatment of the nanometer impressing template.

Owner:上海帕壳实业有限公司

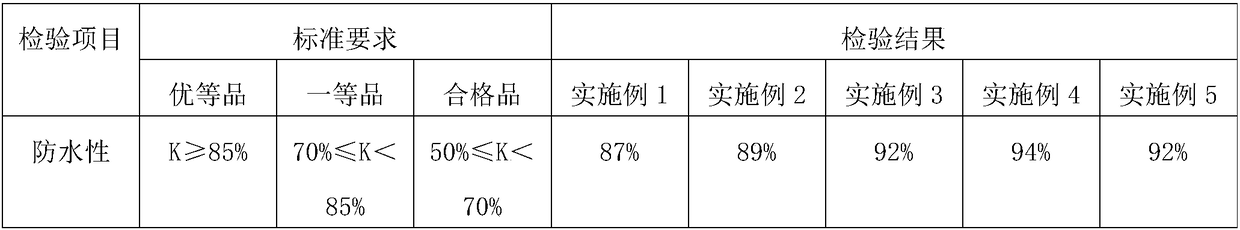

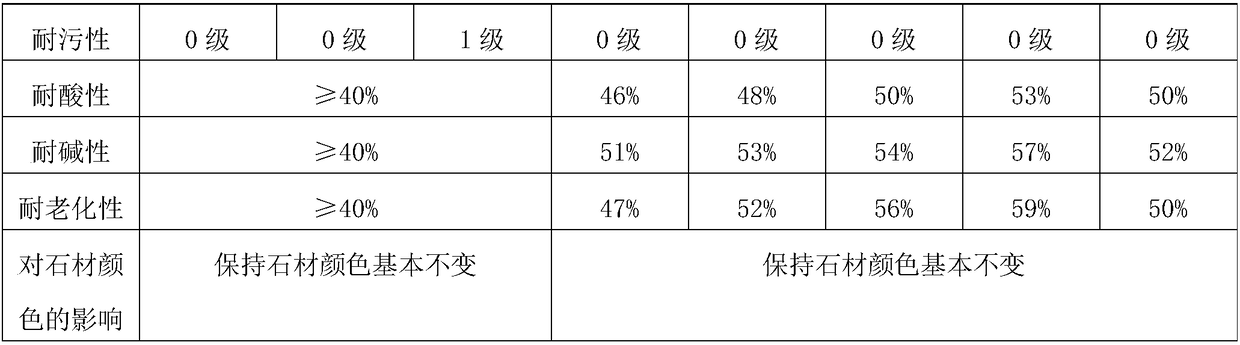

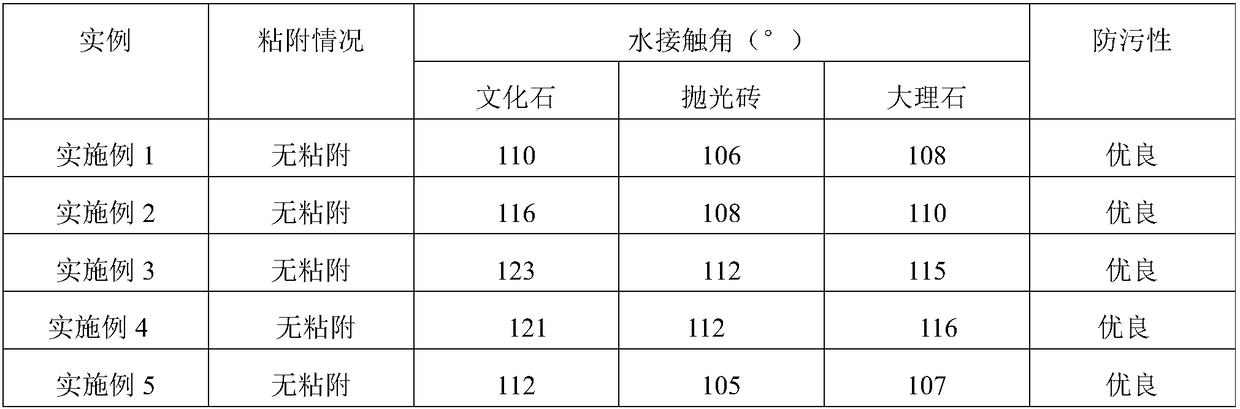

Protection treatment method of stone surfaces

InactiveCN108911787AImprove permeabilityImprove bindingAntifouling/underwater paintsPretreated surfacesHydrogenActive component

The invention discloses a protection treatment method of stone surfaces. The protection treatment method of stone surfaces comprises a step of stone surface pretreatment and a step of waterproof antifouling treatment. According to the step of waterproof antifouling treatment, a stone protective agent is adopted for waterproof antifouling treatment of stone surfaces, wherein the stone protective agent comprises a component A and a component B; the active component of the component A is hydrogen-containing silicone oil; the active component of the component B is long chain alkyl trialkoxysilane.The step of waterproof antifouling treatment comprises following steps: at an environment with a relative humidity of 90% or lower, stone surfaces are uniformly coated with the component A for 3 to 5times at time intervals of 30 to 60min; when A component surface drying is achieved, the stone surfaces are uniformly coated with the component B for 2 to 5 times, and drying curing is carried out for 8 to 24h so as to obtain finished products. The protection treatment method is simple in treatment technology; resource and energy consumption is low; processing period is short; waterproof and antifouling effect is excellent and lasts long.

Owner:沈开湘

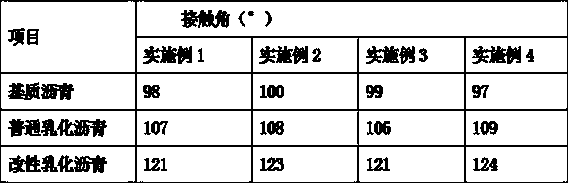

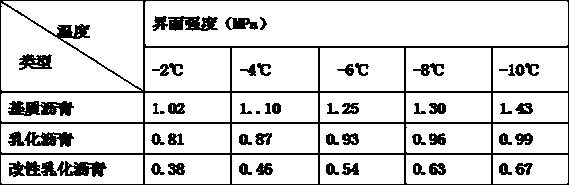

OMMT modified anticondensation ice emulsified asphalt and preparation method thereof

InactiveCN109971189AReduce formationHigh water contact angleBuilding insulationsOrganificationMontmorillonite

The invention relates to OMMT modified anticondensation ice emulsified asphalt and a preparation method thereof, and relates to the technical field of preparation of road maintenance materials. The method comprises the following steps: performing organification treatment on Na-MMT to obtain organic montmorillonite, preparing a mixed soap liquid by using OMMT and an emulsifying agent as raw materials, and adding the mixed soap liquid into matrix asphalt to prepare the modified emulsified asphalt having excellent anticondensation ice performance. The method provided by the invention has the beneficial effects that the mixed soap liquid prepared from the organic montmorillonite and the emulsifying agent is used as a modifying agent of the asphalt, the contact angle of the obtained emulsifiedasphalt is greatly improved relative to the matrix asphalt and ordinary emulsified asphalt, so that bonding strength between frozen water and a road layer is reduced, and the anticondensation ice performance of the emulsified asphalt is improved; the storage stability of the emulsified asphalt is improved, and the anti-aging property is improved; fog seal layer treatment is performed on a road surface by the emulsified asphalt, and the method has the advantages of high efficiency, no consumption, simple construction, relatively-low costs and no pollution.

Owner:青海省交通规划设计研究院有限公司 +1

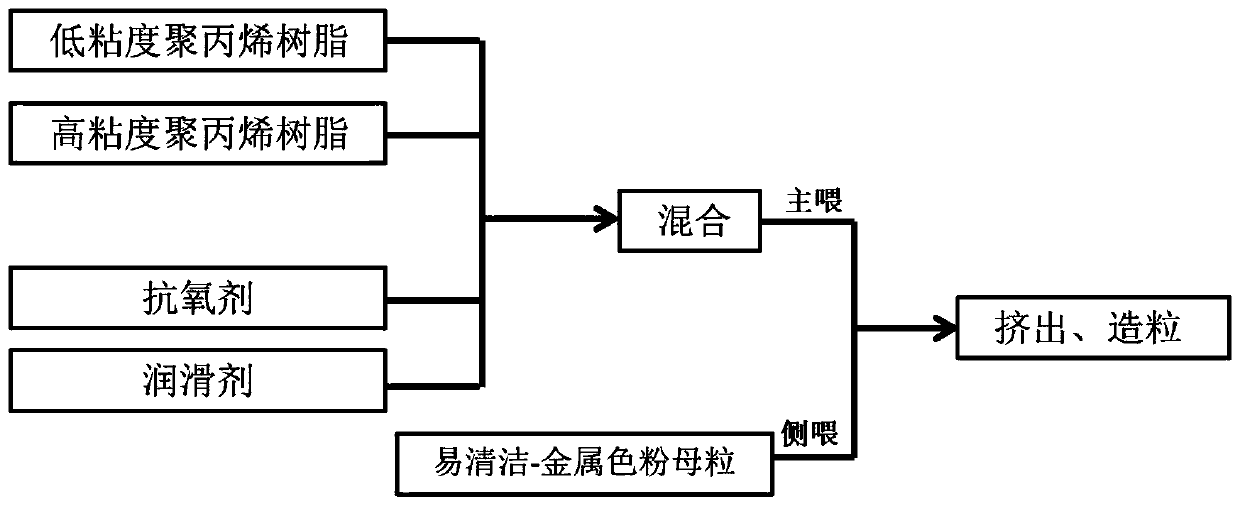

Easy-to-clean spraying-free polypropylene material and preparation method thereof

The invention provides an easy-to-clean spraying-free polypropylene material and a preparation method thereof. The easy-to-clean spraying-free polypropylene material is prepared from the following rawmaterials in parts by weight: 70-90 parts of low-viscosity polypropylene resin, 10 to 30 parts of high-viscosity polypropylene resin, wherein the weight parts of the low-viscosity polypropylene resinand the weight parts of the high-viscosity polypropylene resin sum to 100 parts, 0.5 to 1 part of an antioxidant, 0.5 to 1 part of a lubricating agent and 1-5 parts of easy-to-clean metal toner master batch. The preparation method comprises the following steps: mixing the low-viscosity polypropylene resin, the high-viscosity polypropylene resin, the antioxidant and the lubricant by using a high-speed agitator, and adding the obtained mixture into a double-screw extruder through a main feeding port; adding the easy-to-clean metal toner master batch into the double-screw extruder through a sidefeeding port; and then performing melt extrusion and granulation to obtain the material. The easy-to-clean spraying-free polypropylene material has excellent mechanical properties, processability andeasiness in cleaning, and can be applied to the fields of automobiles and household appliances such as automobile exterior trim, air conditioner decoration strips, exterior decoration structures of small household appliances and the like.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

SiN overcoat for perpendicular magnetic recording media

InactiveUS20070054153A1High densityThinner overcoatProtective coatings for layersRecord information storageHigh densityMagnetic media

A SiON overcoat for use on magnetic media for magnetic recording. The SiON overcoat is deposited by pulsed DC sputtering while applying a negative DC bias. The SiON overcoat is especially useful on perpendicular magnetic recording media because of its ability to deposit thinly and evenly on a rough, granular high coercivity recording media while maintaining excellent corrosion protection properties. A SiON overcoat can be applied less than 3 nm thick while still maintaining excellent mechanical and corrosion protection. The overcoat also has a very high density and water contact angle.

Owner:WESTERN DIGITAL TECH INC

Moisture-repellent protective layer for a winding head of an electric machine

InactiveCN101156296AExtended service lifeReduce the difficulty of cleaning workWindings insulation materialWindings insulation shape/form/constructionElectric machineWater contact

The invention relates to a protective layer (13) for a winding head of an electric machine. Said protective layer consists of a moisture-repellent material that comprises a nanostructured surface (8) once it has been applied to the winding head, resulting in a water contact angle of at least 120 DEG .

Owner:SIEMENS AG

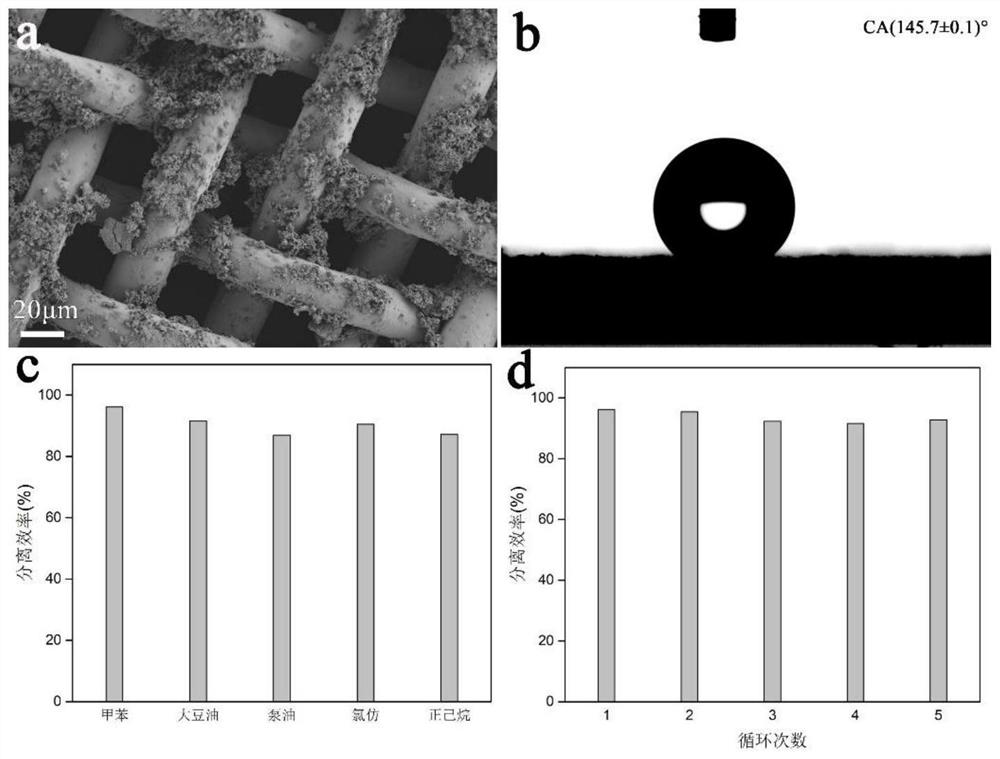

Preparation method of natural mineral-based super-hydrophobic coating and oil-water separation net

InactiveCN112827219AHigh water contact angleSimple operation processNon-miscible liquid separationHalloysiteNatural mineral

The invention discloses a natural mineral-based super-hydrophobic coating, an oil-water separation net and a preparation method of the coating and net, and belongs to the field of environment-friendly materials. The super-hydrophobic coating and oil-water separation net are composed of halloysite, a surface modifier and a substrate material. The production method mainly comprises two steps of surface modification of halloysite and preparation of the coating and oil-water separation net. The halloysite has a nanotube structure; the surface modifier has relatively low surface energy; and the preparation process is simple, the cost is low, and large-scale preparation can be realized. The hydrophobicity of the super-hydrophobic coating and oil-water separation net disclosed by the invention comes from the synergistic effect of a coarse structure constructed by surface halloysite and low-surface-energy hexadecyl trimethoxy silane. The super-hydrophobic coating disclosed by the invention has a high water contact angle and can be applied to the fields of self-cleaning and oil-water separation.

Owner:UNIV OF SCI & TECH BEIJING

Heparan modified polyurethane/polyethersulfone blended hollow fiber membrane and preparation method thereof

InactiveCN109316982AReduced compatibilityReduce the amount of adsorptionSemi-permeable membranesHollow fibre membraneHydroxypropyl Chitosan

The invention provides a heparan modified polyurethane / polyethersulfone blended hollow fiber membrane and a preparation method thereof. According to the heparan modified polyurethane / polyethersulfoneblended hollow fiber membrane, heparan modified polyurethane is sulfonated dihydroxypropyl chitosan modified polyurethane; the preparation method comprises the following steps: adding 1 to 10 percentof the sulfonated dihydroxypropyl chitosan modified polyurethane, 8 to 20 percent of polyethersulfone and 80 to 90 percent of a solvent into a dissolving kettle; controlling the temperature to be 70 to 90 DEG C and stirring for 2 to 20 h; after the components are completely dissolved, standing for 10 to 20 h to finish de-foaming, so as to obtain a membrane solution; then preparing the sulfonated dihydroxypropyl chitosan modified polyurethane / polyethersulfone blended hollow fiber membrane by adopting a dry-wet process spinning method. The blended hollow fiber membrane provided by the inventionhas good anticoagulation performance and physicochemical stability; a preparation technology is simple and conditions are moderate and controllable.

Owner:CENT SOUTH UNIV

Silver nanowire-polyperfluorinated ethylene propylene super-hydrophobic porous membrane and preparation method

ActiveCN109126479AGood neatnessIncrease roughnessSemi-permeable membranesMembranesEtchingPorous membrane

The invention provides a silver nanowire-polyperfluorinated ethylene propylene super-hydrophobic porous membrane and a preparation method. The method comprises the following steps: first, preparing acellular polystyrene porous membrane according to a breath figure method, and performing reverse repeated etching by taking the polystyrene porous membrane as a template to produce a polyperfluorinated ethylene porous membrane with micro-nanograde bulge array, and further depositing a layer of etching silver nanowire orientation film on the surface of the polyperfluorinated ethylene porous membrane, thereby producing the silver nanowire-polyperfluorinated ethylene propylene super-hydrophobic porous membrane. Compared with the traditional method, the super-hydrophobic porous membrane prepared according to the method of the invention is not only large in water contact angle, small in rolling angle, and strong in super-hydrophobic capacity and self-cleaning ability, but also has high antibacterial capability; the preparation method is simple, the membrane pore structure can be dynamically controlled or regulated, and the pollution cannot be produced.

Owner:上海优梯熙光学材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com