Epoxy/silicone polymer composite material, and preparation method and application thereof

A composite material and organosilicon technology, applied in the field of materials, can solve the problems of difficult large-scale use, high price, and limited application, and achieve the effects of improved adhesion, low cost, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Preparation of aralkylmethyl hydrogen-containing polysiloxane and aralkylmethylpolysiloxane

[0041] Mix 100g of industrial high hydrogen-containing silicone oil (1.55wt% active hydrogen content) and 104g of styrene at room temperature, and add Kasted catalyst (platinum divinyldisiloxane double head complex solution, 1800ppm) 0.3g, heated up to 50°C for 12 hours, and distilled under reduced pressure at 80°C for 2 hours to obtain phenethylmethylhydrogenpolysiloxane A; the obtained phenethylmethylhydrogenpolysiloxane A The content of active hydrogen is 0.21wt%, and the content of phenethyl is 50wt%;

[0042] After mixing 100g of industrial hydrogen-containing silicone oil (active hydrogen content of 0.75wt%) and 50g of styrene at room temperature, add Kasted catalyst (platinum divinyldisiloxane double head complex solution, 1800ppm) 0.3g, heated up to 50°C for 12 hours, and distilled under reduced pressure at 80°C for 2 hours to obtain phenethylmethylhydrogenpolysilo...

Embodiment 2

[0050] 0.5 g of phenylethylmethyl hydrogen-containing polysiloxane B (30wt% phenylethyl, 0.10wt% active hydrogen) prepared in Example 1, methyl MQ silicone resin (M / Q=0.55, Shandong Dayi Chemical Industry Co., Ltd. Co., Ltd.) 1.0g, E-51 bisphenol A type epoxy resin 9g, dicyclopentadiene dioxide 1g, stannous octoate 0.05g, methyltetrahydrophthalic anhydride 10g and mix uniformly to obtain a mixture; mix the mixture After standing for 10 minutes, it will defoam, and it will remain stable for 1 day at room temperature without delamination;

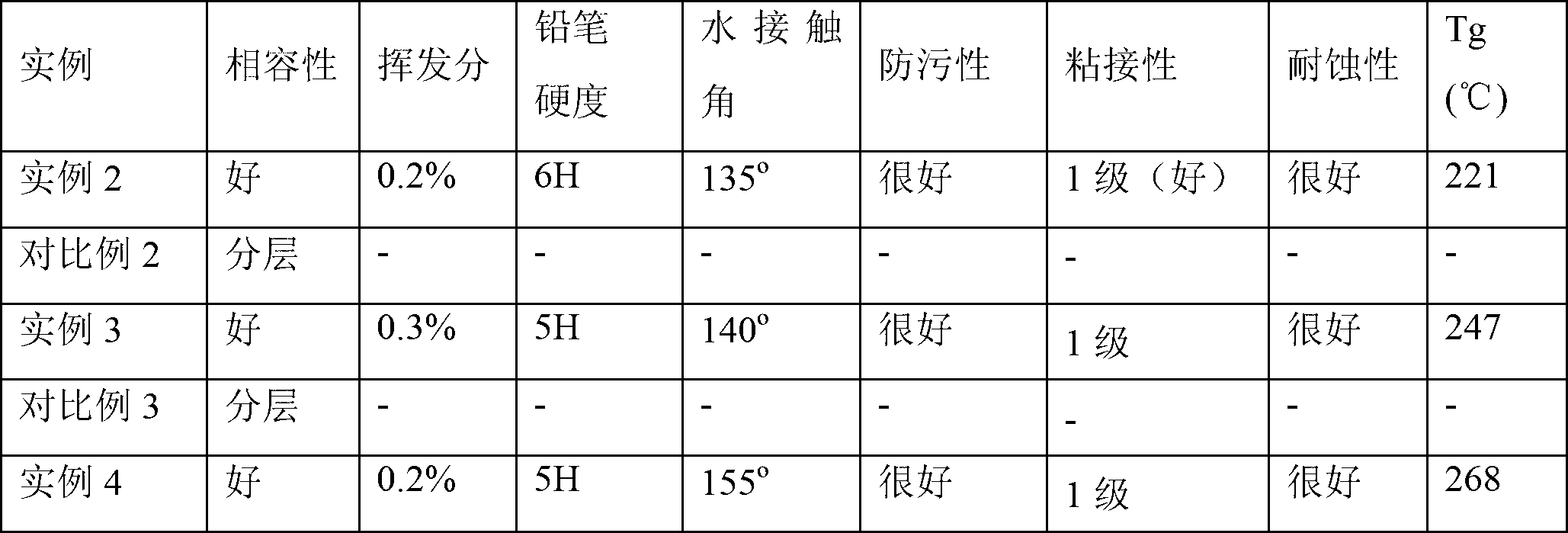

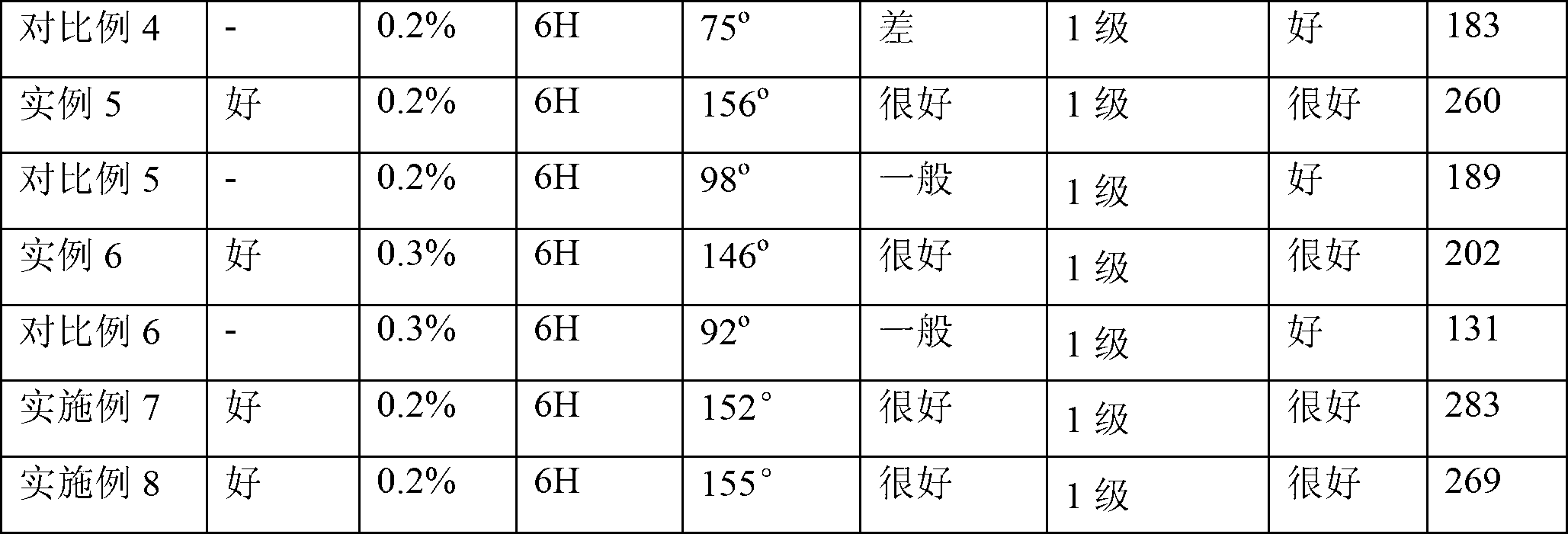

[0051] The above mixture is coated on the corresponding substrate, and then placed in an oven and heated to 80°C, kept for 1 hour and then kept at 150°C for 2 hours to obtain an epoxy / organic silicon polymer composite material; the epoxy / organic The results of performance tests (volatile matter, pencil hardness of the film, water contact angle, adhesion, corrosion resistance and glass transition temperature Tg) of the silicon polymer composit...

Embodiment 3

[0055] 10 g of phenylethylmethyl hydrogen-containing polysiloxane A (50wt% phenethyl, 0.21wt% active hydrogen) prepared in Example 1, vinylmethyl MQ silicone resin (M / Q=1.4, vinyl The content is 3.5wt%, Zhongshan Jianli Silicone Development Co., Ltd.) 10g, E-44 bisphenol A epoxy resin 8g, 4-vinyl epoxycyclohexane 2g, chloroplatinic acid 0.3g, tetrahydro phthalate Diformic anhydride (MHHPA) 6g and zinc acetylacetonate 0.2g were evenly mixed to obtain a mixture; the mixture was allowed to stand for 10 minutes to defoam, and it was still stable at room temperature for 1 day without delamination;

[0056] Coat the above mixture on the corresponding base material, then place it in an oven and raise the temperature to 80°C, keep it warm for 1 hour, and then keep it at 180°C for 2 hours to obtain an epoxy / organosilicon polymer composite material. The performance test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com