Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

81results about How to "Lower water contact angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

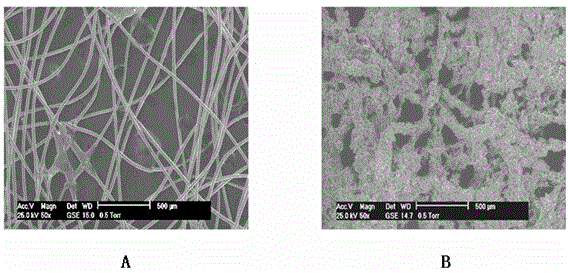

Polyvinylidene fluoride hollow fiber film and preparation method thereof

ActiveCN101590374AProper temperature regulationExtraction is easy and fastMembranesSemi-permeable membranesFiberPolyvinylidene difluoride

The invention discloses a polyvinylidene fluoride hollow fiber film and a preparation method thereof. The polyvinylidene fluoride hollow fiber film comprises the following components by weight percent: 20-60% of polyvinylidene fluoride resin, 10-50% of organic pore-forming agent, 1-30% of inorganic pore-forming agent and 5-30% of solvent. The preparation method comprises the following steps: mixing, squeezing, cooling, stretching, extracting the organic pore-forming agent and the inorganic pore-forming agent, and thermally shaping. The obtained polyvinylidene fluoride hollow fiber film has the advantages of high strength, good performance, better hydrophilicity, simple preparation process and energy saving.

Owner:江苏美能膜材料科技有限公司

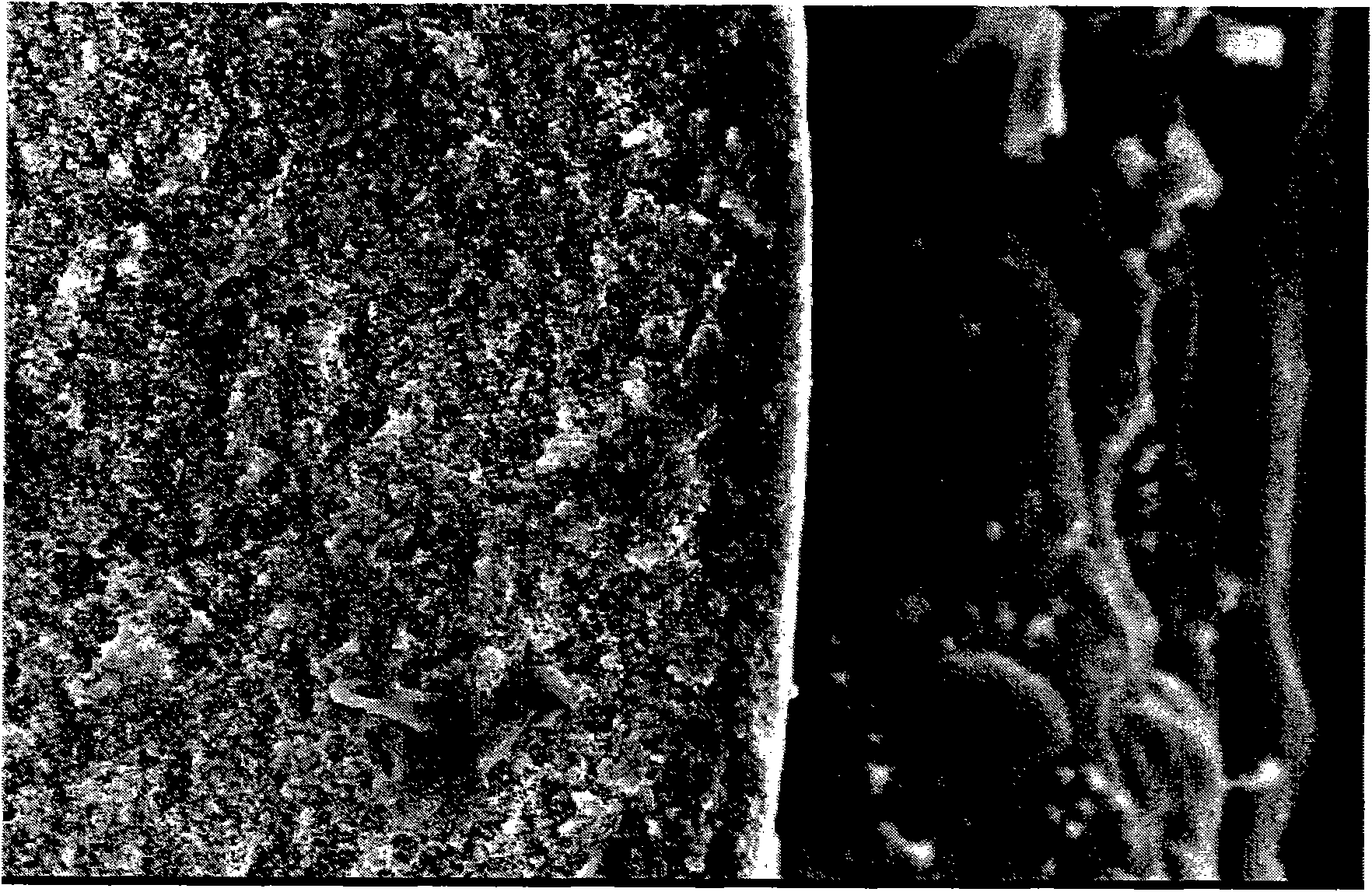

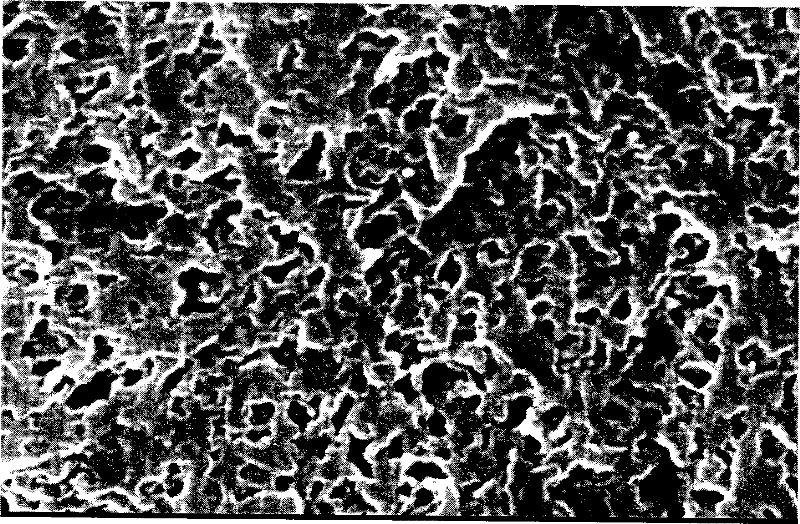

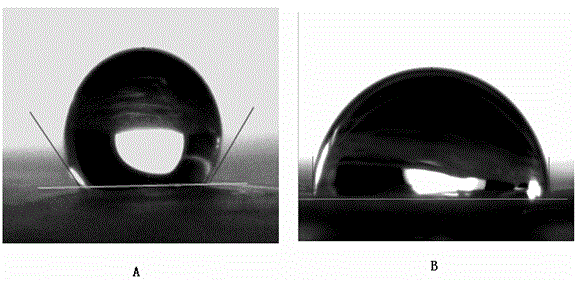

Method for preparing micro-nanostructure on surface of titanium implant

ActiveCN102912357ALower water contact angleRich structureSurface reaction electrolytic coatingAnodic oxidationBonding strength

The invention discloses a method for preparing a micro-nanostructure on the surface of a titanium implant and relates to a titanium implant. According to the provided method for preparing the micro-nanostructure on the surface of the titanium implant, the surface of the titanium implant is subjected to sand blasting and large-grit etching to form micron morphology; and on the basis of retaining the micron morphology, the nanoscale morphology is constructed by anodic oxidation and two morphologies are compounded and overlapped. The method comprises the following steps of: feeding medical pure titanium into a sand blasting machine for carrying out sand blasting treatment; carrying out ultrasonic treatment on the sample subjected to sand blasting treatment; feeding the sample subjected to ultrasonic treatment in a mixed solution of sulfuric acid, hydrochloric acid, nitric acid and water for carrying out acid etching treatment; and taking the sample subjected to acid etching treatment as an anode, feeding the sample in an anodic oxidation liquid for carrying out anodic oxidation treatment, flushing, drying and cooling to constant weight to obtain the titanium implant of which the surface is of a micro-nanostructure. The method has the advantages of abundant and uniform morphologies, favorable bonding strength of a film layer and a matrix, simple process equipment, short reaction time and facilitation for industrial production.

Owner:百齿泰(厦门)医疗科技有限公司

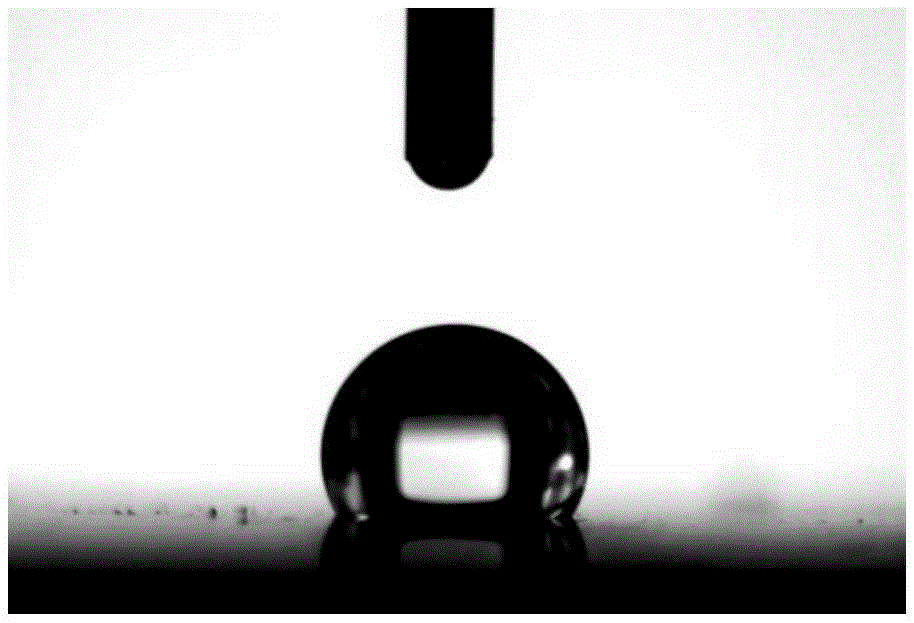

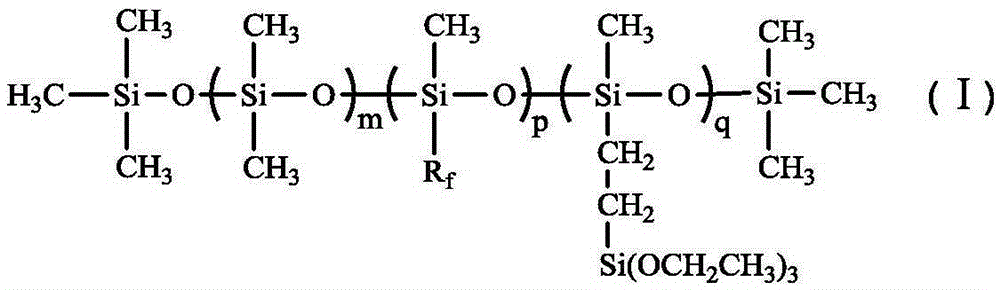

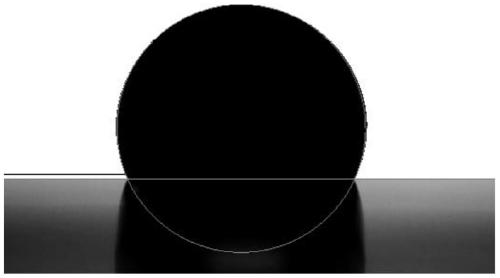

Room-temperature-cured fluorine-silicone coating containing fluorinated cage-shaped silsesquioxane and preparation method and application

ActiveCN105315888AImprove hydrophobicity and oleophobicityImprove hydrophobicitySilicon organic compoundsCoatingsPolymer scienceSilicone coating

The invention discloses a room-temperature-cured fluorine-silicone coating containing fluorinated cage-shaped silsesquioxane and a preparation method and application. The coating is prepared from, by mass, 69%-95% of condensed type fluorine-silicone resin, 5%-30% of the fluorinated cage-shaped silsesquioxane and 0.5% of dibutyltin dilaurate. The fluorine-silicone resin and the fluorinated cage-shaped silsesquioxane are hydrolyzed through oxethyl functional groups contained by the fluorine-silicone resin and the fluorinated cage-shaped silsesquioxane, and dealcoholization condensation is performed under the action of a catalyst to form the coating; the fluorine-containing groups can be gathered on the surface of the coating in the film forming process, therefore, the surface energy of the coating can be reduced, and the hydrophobic and oleophobic properties are improved; the synergistic effect of fluorine and silicone in the coating is beneficial for lowering the adhesive strength of ice on the surface of the coating, the contact angle of coating water reaches 124.5 degrees, and the minimum shearing strength of the ice is 82 kPa; adding of the fluorinated cage-shaped silsesquioxane is beneficial for improving the hydrophobic property and anti-icing property of the coating. The coating can be applied to the field of anti-icing coating materials.

Owner:天津绿缘环保工程股份有限公司

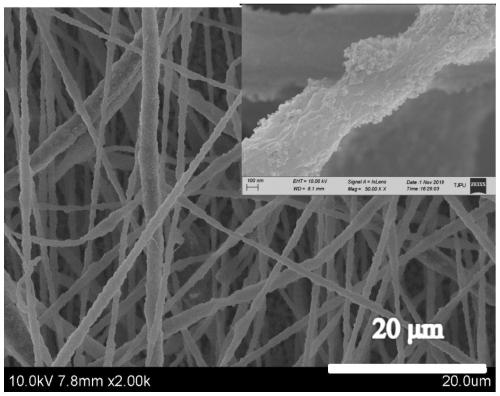

Single-sided super-hydrophobic polymer fiber membrane and preparation method and application thereof

ActiveCN111389245APrevent wettingReduce mass transfer resistanceSemi-permeable membranesMembranesFiberSuperhydrophobe

The invention provides a single-sided super-hydrophobic polymer fiber membrane and a preparation method and application thereof, and belongs to the technical field of flue gas desulfurization by a membrane method. Hydrophobic nanoparticles are introduced into a spinning solution; meanwhile, sub-micron bulges are constructed on the surface of the fiber by utilizing different boiling points and different volatilization rates of double solvents; the submicron bulges and the nano hydrophobic particles play a synergistic role to construct a lotus leaf-like hydrophobic fiber layer with a micro-nanodual coarse structure, and one side of the prepared single-sided super-hydrophobic polymer fiber membrane, which is provided with the super-hydrophobic fiber layer, has excellent hydrophobicity. In the long-term desulfurization process, the single-sided super-hydrophobic polymer fiber membrane has relatively high desulfurization performance, and particularly, compared with an original membrane, the single-sided super-hydrophobic polymer fiber membrane is relatively good in desulfurization performance and relatively good in stability.

Owner:TIANJIN POLYTECHNIC UNIV

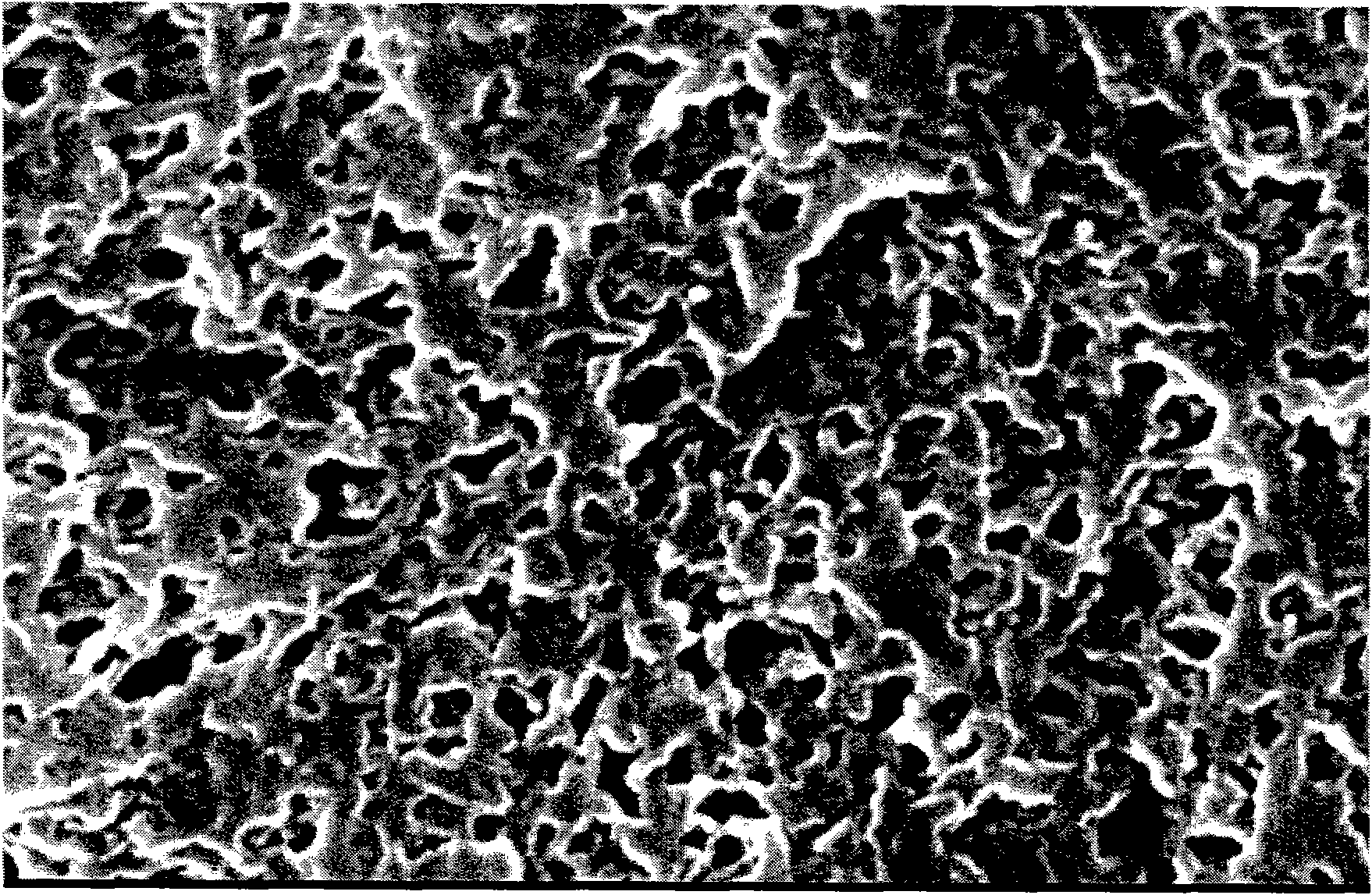

Amphipathic three-block polymer PS(x)MAA(y)-g-fPEG(z) modified PVDF ultrafiltration membrane and preparation method thereof

ActiveCN105289331AControllable structureImprove stabilitySemi-permeable membranesPolymer scienceUltrafiltration

The invention provides an amphipathic three-block polymer PS(x)MAA(y)-g-fPEG(z) modified PVDF ultrafiltration membrane and a preparation method thereof. PS(x)MAA(y)-g-fPEG(z) is used as an additive for modifying PVDF to obtain the amphipathic three-block polymer PS(x)MAA(y)-g-fPEG(z) modified PVDF ultrafiltration membrane. The amphipathic three-block polymer PS(x)MAA(y)-g-fPEG(z) modified PVDF ultrafiltration membrane is prepared by adopting an immersion precipitation phase inversion method, the modified membrane can keep long-time stability. According to the method, the adopted additive is prepared by simple free radical polymerization and normal temperature esterification reaction, the operation is simple, the use rang is wide, and compared with the prior art, the method is few in operation steps, simple and convenient to operate, low in cost and easy to implement in commercial production; as a PS chain section in the additive-PS(x)MAA(y)-g-fPEG(z) has good compatibility with PVDF, the modified membrane is relatively stable in the using process and not liable to disappear; an MAA(y) chain section in the additive-PS(x)MAA(y)-g-fPEG(z) is enriched on the surface of the PVDF, so that the hydrophily of the modified PVDF membrane is good, the contact angle of the membrane with water is small, the water drop seepage velocity is high, and tight contact of pollutants on the surface of the membrane is prevented.

Owner:SUZHOU UNIV OF SCI & TECH

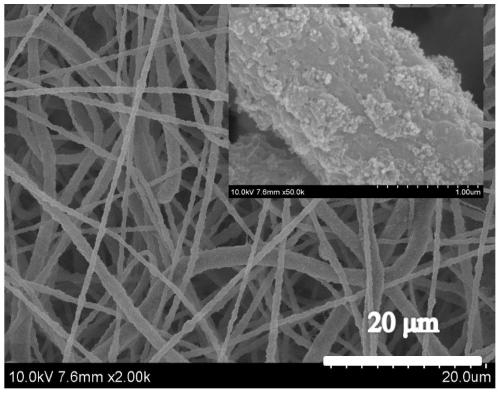

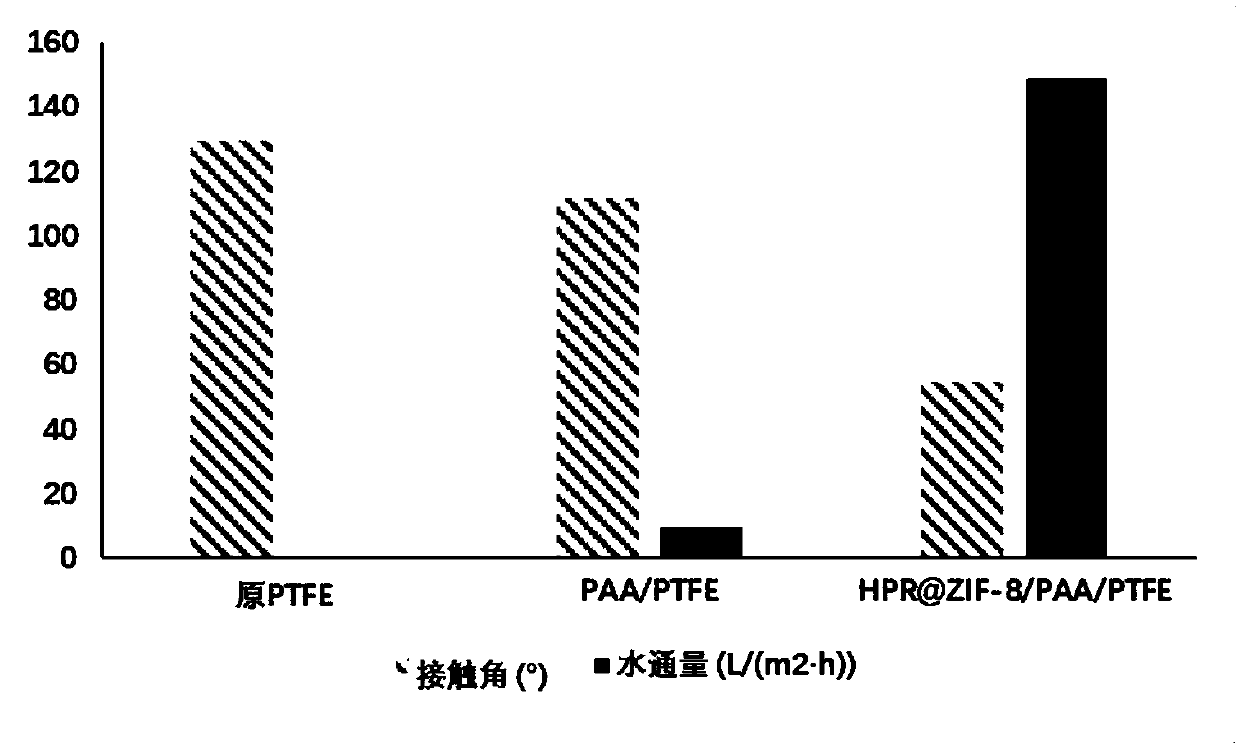

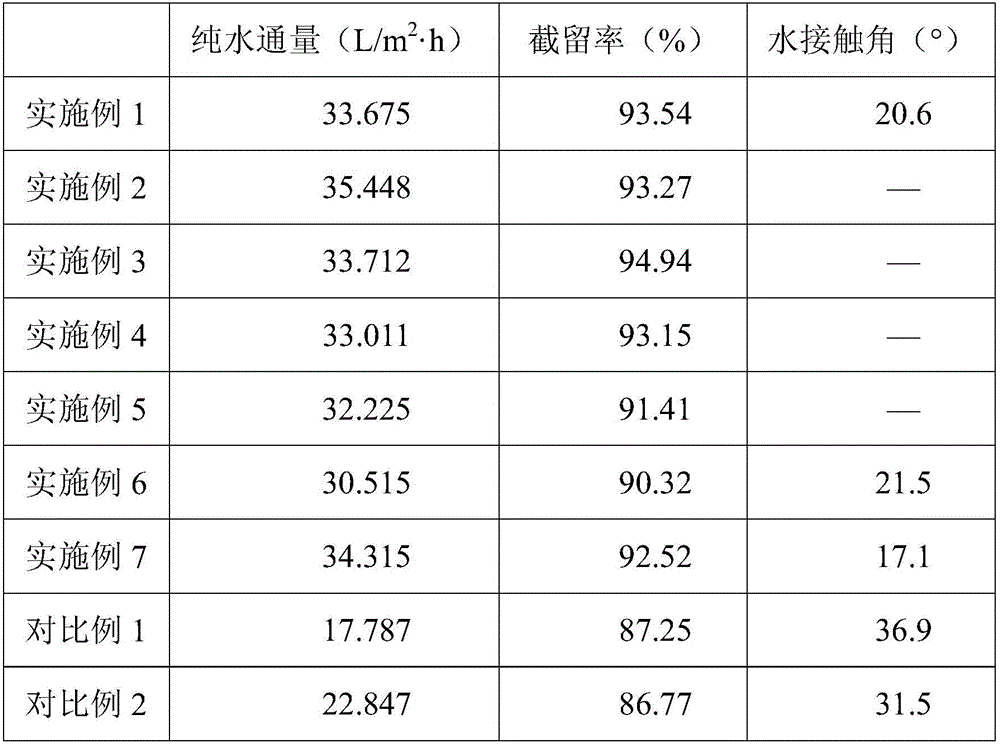

Method for in-situ preparation of nano-enzyme membrane

ActiveCN107723284AImprove hydrophilicityIn situ growthOxidoreductasesOn/in organic carrierEnzyme membranePhotocatalytic degradation

The invention provides a method for in-situ preparation of a nano-enzyme membrane. The method comprises pretreating an original membrane, carrying out grafting polymerization on the membrane surface,carrying out coordination self-assembling and in-situ growth on the nano-enzyme on the membrane surface, immersing the membrane grafted with polyacrylic acid in a MOFs precursor solution for some timeso that metal ions in the precursor solution and the carboxyl group of polyacrylic acid are assembled to the membrane surface through coordination, adding an organic ligand solution and an enzyme liquid into the precursor solution so that the enzyme is wrapped by the MOFs skeleton structure and the in-situ growth of the nano-enzyme on the membrane surface is realized, and carrying out after-treatment on the nano-enzyme membrane so that the nano-enzyme membrane with the nano-enzyme is obtained. The method greatly improves enzyme activity and stability, improves the loading rate of the enzyme on the membrane, reduces the water contact angle of the original membrane, realizes high water flux and provides the polymer membrane with pollution resistance, biocatalysis, photocatalytic degradationof pollutants and other functions.

Owner:深圳市新纳捷科技有限公司

Preparation method of polystyrene-based mesoporous silica film

InactiveCN102050955AFacilitate depositionIncrease the molar ratioElectrophoretic coatingsPolystyreneMesoporous silica

The invention relates to a preparation method of a polystyrene-based mesoporous silica film. The preparation method comprises the following steps: carrying out surface sulfonation modification on a polystyrene slice; mixing and stirring water (H2O), ammonia water (NH3) and tetraethoxysilane (TEOS) in a mole proportion of 1:0.008:0.012 to prepare a sol solution, wherein the ammonia water serves as a catalyst, and the tetraethoxysilane serves as a silicon source; putting two electrode pads in the sole solution, deviating a polystyrene matrix to an anode plate, applying an electric field at two ends of the electrode pads, and applying an electric field at the two ends of the electrode pads for 4 hours-7 hours by using a voltage of 2.8V-4.0V; and obtaining a polystyrene-based mesoporous silica deposition film, drying and then obtaining the polystyrene-based mesoporous silica film. The film is even in thickness, the surface is smooth and has no crack, and vermicule-like mesoporous pore canals are formed and have a certain order. The preparation method in the invention is low in cost, simple to operate and easy to control, the required equipment is simple, and the large-scale production can be achieved.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of CNT-modified nanofiltration membrane

ActiveCN105817146AEasy to separateImprove hydrophilicityMembranesSemi-permeable membranesSurface layerNanofiltration

The invention provides a preparation method of a CNT-modified nanofiltration membrane. The preparation method comprises the following steps: covering the surface of one side of a porous support membrane with a CNT-containing aqueous phase solution, an organic phase solution and the CNT-containing aqueous phase solution in sequence; taking out and drying the membrane after reaction for a period of time; heat-treating and soaking the membrane in water to obtain the CNT-modified nanofiltration membrane. Compared with a conventional interfacial polymerization process, the preparation method provided by the invention has the characteristics that a polymer surface layer is formed on one side of the porous support membrane, which is conducive to better play a separation role of the nanofiltration membrane; an appropriate amount of CNT is dispersed in the aqueous phase solution, while a step of secondary infiltration of an aqueous phase is added, to not only optimize the mechanical properties of the nanofiltration membrane, more importantly, significantly enhance the hydrophilicity, water flux and retention rate of the nanofiltration membrane, so that the nanofiltration membrane prepared according to the preparation method has an excellent industrial production basis and a broad application prospect.

Owner:JIANGXI UNIV OF SCI & TECH

Composite barrier films and method

InactiveCN1745197AImprove clarityLow hazeLayered productsVacuum evaporation coatingSputteringComposite film

In one embodiment, the invention relates to composite films having barrier properties, and more particularly, to composite films which comprise a silicon nitride based coating on a flexible plastic substrate wherein the silicon nitride based coating has a thickness of less than about 220 nm and is deposited on the plastic substrate by sputtering of a silicon target in an atmosphere comprising at least 75% by volume of nitrogen. The composite barrier film has a visible light transmittance of at least about 75%. In another embodiment, the invention relates to a barrier method of depositing a silicon nitride based coating on a plastic substrate to form a composite barrier film which comprises depositing a silicon nitride based coating on the substrate by sputtering of a silicon target in an atmosphere comprising at least about 75% by volume nitrogen.

Owner:STREAMING SALES

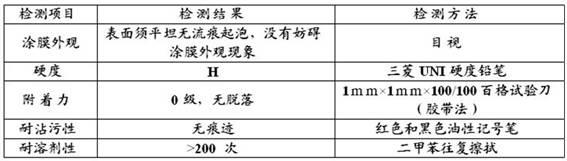

A kind of topcoat for building curtain wall aluminum veneer and preparation method thereof

The invention relates to a finish for a building curtain wall aluminum veneer, and a preparation method thereof. The finish comprises 60 to 70% of FEVE fluorocarbon resin, 5 to 10% of an organic silicon resin, 0.05 to 0.1% of an acrylic acid levelling agent, 0.1 to 0.3% of an organosilicon levelling agent, 0.3 to 0.8% of benzotriazole ultraviolet absorbent, 0.3 to 0.8% of hindered amine light stabilizer, 0.1 to 0.3% of an organotin catalyst, 10 to 15% of butyl acetate, 10 to 15% of dimethylbenzene and 9 to 13% of an aliphatic isocyanate curing agent, wherein the aliphatic isocyanate curing agent needs to be individually packaged and stored and is added into a formula prior to construction for use. The FEVE fluorocarbon resin and the organic silicon resin are utilized as film-forming substances of the finish and the finish can be cured at normal temperature, and thus energy and labor are saved. Through a fluorine-silicon interpenetrating network structure, film surface tension is reduced and a water contact angle is reduced, and thus film anti-contamination properties are improved greatly. Through introduction of silicon atoms, film toughness is improved, and thus a film surface isnot easy to craze and temperature tolerance and endurance are further improved. In addition, the finish has the advantages of simple preparation method and low cost.

Owner:苏州金近幕墙有限公司

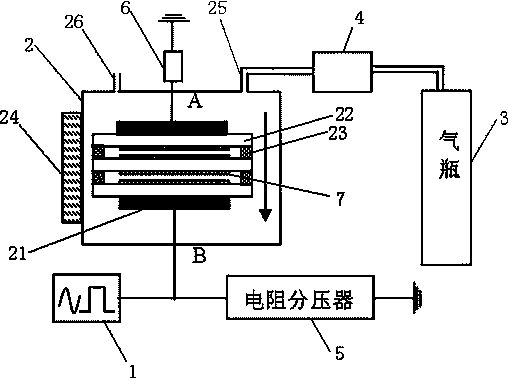

DBD (Dielectric Barrier Discharge) low temperature plasma generating device and polymer film surface treatment method

ActiveCN104202897AIncrease the number ofIncrease the areaPlasma techniquePolymer sciencePolymer thin films

The invention relates to the technical field of material surface treatment and particularly discloses a DBD (Dielectric Barrier Discharge) low temperature plasma generating device and a polymer film surface treatment method. The DBD low temperature plasma generating device comprises a power source and a DBD plasma reactor; at least three layers of dielectric slabs are arranged in a reaction chamber of the DBD plasma reactor; a gap is formed between every two adjacent layers of dielectric slabs. The polymer film surface treatment method comprises performing treatment through the DBD low temperature plasma generating device. Discharge can be formed between every two layers of dielectric slabs to form uniform good low temperature plasma, the polymer film treatment can be performed on the bilateral sides of every layer of dielectric slab which is located in the middle, the treatment of one layer of polymer film can be performed through the dielectric slab which cover two electrodes, and accordingly the number and the area of the single treatment polymer films can be improved. The single treatment rate of the polymer films is increased and the treatment efficiency is high by the polymer film surface treatment method.

Owner:INST OF FLUID PHYSICS CHINA ACAD OF ENG PHYSICS

Thin film with low friction coefficient and high water contact angle and preparation method thereof

InactiveCN111286061AReduce coefficient of frictionLower water contact anglePolyurea/polyurethane coatingsEpoxy resin coatingsPolymer scienceUV curing

The invention provides a thin film with a low friction coefficient and a high water contact angle and a preparation method thereof. The thin film comprises a transparent base film, a bottom coating layer and an AF layer which are sequentially attached from bottom to top. The preparation method comprises the following steps: step S001, taking materials: selecting a transparent base film made of a proper material; step S002, preparing a bottom coating solution: diluting an unsaturated functional group-containing polymer and a photoinitiator with a solvent to form a base coating solution; step S003, attaching a bottom coating layer: coating the transparent base film with the base coating solution, and carrying out heating curing, UV curing or dual curing through a drying oven to form the basecoating layer; S004, attaching an AF layer: coating the semi-finished product formed in the step S003 with an AF solution, and forming the AF layer through cross-linking curing after being heated bythe drying oven. According to the thin film with the low friction coefficient and the high water contact angle and the preparation method thereof, the defects that an existing thin film is smooth, poor in anti-fingerprint effect, complex in preparation process and not suitable for mass production are overcome.

Owner:NINGBO HUGHSTAR ADVANCED MATERIAL TECH

Preparing method and application of graphene-oxide-modified nanofiltration membrane

InactiveCN109772177AEasy to separateImprove hydrophilicitySemi-permeable membranesWater contaminantsRare earthWater contact

The invention discloses a preparing method of a graphene-oxide-modified nanofiltration membrane. The preparing method includes the steps that the surface of one side of a porous supporting membrane issubjected to an interfacial polymerization reaction in a water-phase solution, an organic phase solution and a water-phase solution in sequence, then the membrane is aired and subjected to a heat reaction to be soaked with ultra-pure water, and the graphene-oxide-modified nanofiltration membrane is prepared. The graphene-oxide-modified nanofiltration membrane is subjected to a polymerization reaction on the interface of one side of a porous support membrane, a polymer effective functional layer can be furthest generated, and the separation effect of the nanofiltration membrane is improved; meanwhile, a preparation process is simplified, and the cost is saved; a proper amount of graphene oxide (GO) is added into the water-phase solution, the hydrophilic performance, the membrane permeationperformance and the mechanical property of the nanofiltration membrane are greatly improved, the water contact angle of the nanofiltration membrane prepared with the method is reduced by 18% to 61%,the water flux is increased by 5% to 155%, and the reject rate is also increased. The graphene-oxide-modified nanofiltration membrane is simple in technology and easy to operate, and the graphene-oxide-modified nanofiltration membrane prepared with the method is applied to enrichment and recycling of water treatment and mineral-leaching tail-water ionic rare earth.

Owner:JIANGXI UNIV OF SCI & TECH

Composite barrier films and method

InactiveUS20050109606A1Desirable oxygen and water barrier characteristicImprove clarityLayered productsVacuum evaporation coatingSputteringComposite film

In one embodiment, the invention relates to a method of depositing a silicon nitride based coating on a plastic substrate to form a composite barrier film which comprises depositing a silicon nitride based coating on the substrate by sputtering of a silicon target in an atmosphere comprising at least about 75% by volume nitrogen. In another embodiment, the composite films prepared by the method of the invention comprise a silicon nitride based coating on a flexible plastic substrate wherein the silicon nitride based coating has a thickness of less than about 220 nm and a visible light transmittance of at least about 75%.

Owner:STREAMING SALES

Polyvinylidene fluoride hollow fiber film and preparation method thereof

ActiveCN101590374BExtraction is easy and fastHas a bactericidal effectMembranesSemi-permeable membranesFiberPolyvinylidene difluoride

The invention discloses a polyvinylidene fluoride hollow fiber film and a preparation method thereof. The polyvinylidene fluoride hollow fiber film comprises the following components by weight percent: 20-60% of polyvinylidene fluoride resin, 10-50% of organic pore-forming agent, 1-30% of inorganic pore-forming agent and 5-30% of solvent. The preparation method comprises the following steps: mixing, squeezing, cooling, stretching, extracting the organic pore-forming agent and the inorganic pore-forming agent, and thermally shaping. The obtained polyvinylidene fluoride hollow fiber film has the advantages of high strength, good performance, better hydrophilicity, simple preparation process and energy saving.

Owner:江苏美能膜材料科技有限公司

Hydrophilic modifying method for acrylonitrile/maleic acid copolymer separation film

InactiveCN1569318AHighlight substantiveSignificant progressSemi-permeable membranesPolyethylene glycolAcrylonitrile

The invention is a hydrophile modification method for acrylonitrile / maleic acid polymer separation film. The method eliminates water molecular to two adjoined carboxy on the film surface by the dehydrating agent and forms anhydride, using the reaction ability of the anhydride and the carboxy, the hydrophile high molecular polyethylene glycol is grafted to the surface of the film. After the graft, the hydrophile performance can be upgraded greatly, and it can be maintained muchly. For example, the contact angle of the membrane surface is decreased; it can be decreased from 48 degrees to 21 degrees, the macrophage conglutination can be decreased to 88%.

Owner:ZHEJIANG UNIV

Polyvinylidene fluoride membrane with differentiated double-sided hydrophobicity as well as preparation method and application thereof

ActiveCN111318182AIncrease roughnessImprove adhesionSemi-permeable membranesMembranesMicro nanoMass transfer resistance

The invention relates to the technical field of flue gas desulfurization, and provides a polyvinylidene fluoride membrane with differentiated double-sided hydrophobicity as well as a preparation method and an application of the polyvinylidene fluoride membrane. According to the preparation method, a super-hydrophobic layer with a micro-nano double-coarse structure is constructed on the surface ofone side of the polyvinylidene fluoride base membrane by utilizing the synergistic effect of hydrophobic nanoparticles and polymer particles, so that the polyvinylidene fluoride membrane with differentiated double-sided hydrophobicity is obtained. When the polyvinylidene fluoride membrane with the differentiated hydrophobicity on the two sides is used for removing SO2 through membrane desulfurization, membrane wetting can be effectively avoided, the mass transfer resistance of SO2 on one side of absorption liquid is reduced, the effect of long-term stable operation is achieved, and the polyvinylidene fluoride membrane has excellent desulfurization performance. The preparation method provided by the invention is simple and controllable in process and easily available in raw materials.

Owner:TIANJIN POLYTECHNIC UNIV

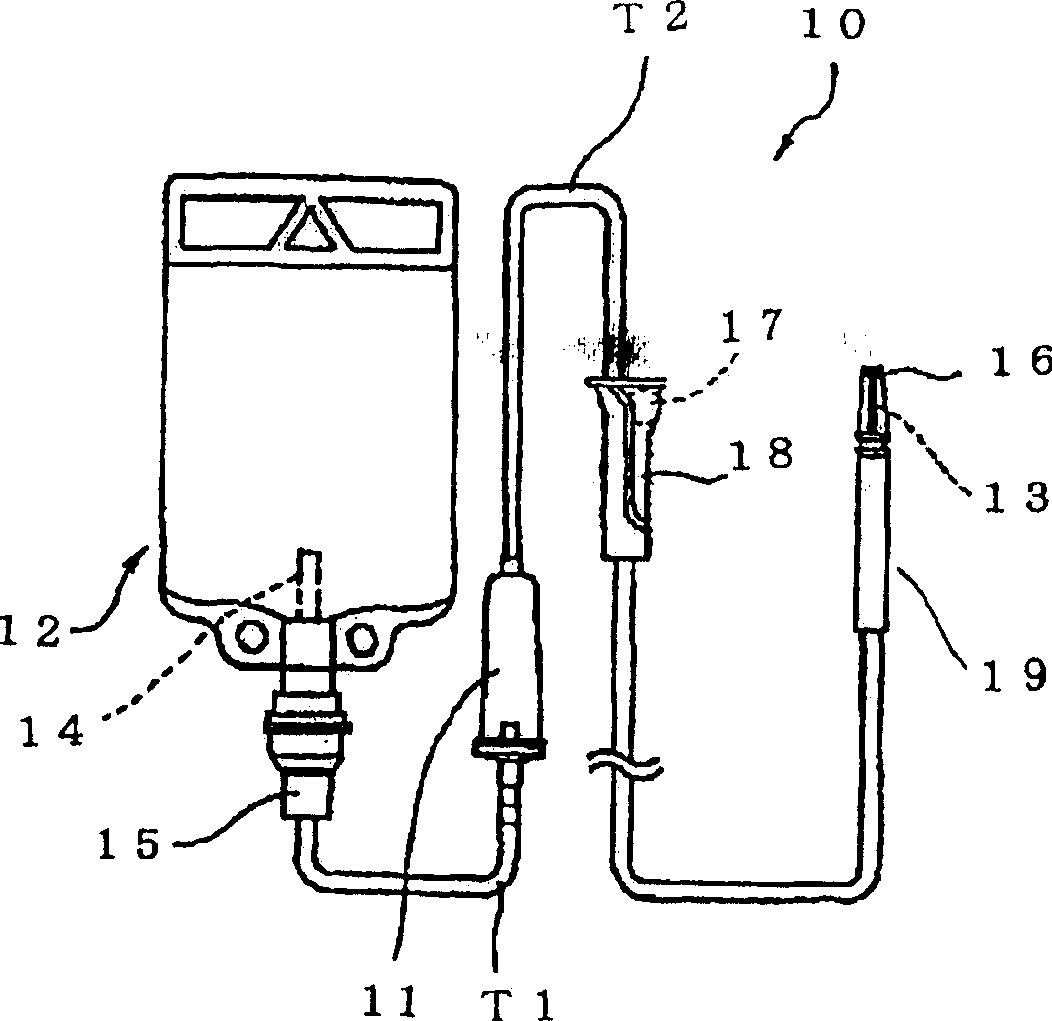

Method for adhering polybutadiene molded article, polybutadiene composite molded article manufactured thereby, medical member, and infusion fluid set

InactiveCN1898304ALower water contact angleImprove bonding (bonding) forceInfusion devicesAdhesive processes with surface pretreatmentChemical treatmentPolymer science

To improve the joining (adhesion) force of a polybutadiene formed article and a polar resin formed article, and to further improve the joining force by selecting (combining) a solvent(s) for these formed articles. A method for adhering a polybutadiene formed article, which comprises (1) the step of reducing the water contact angle of a surface of the polybutadiene formed article by ozone treatment, electron beam treatment, corona discharge treatment, plasma discharge treatment, ultraviolet laser treatment or chemical treatment, and (2) the step of adhering the polybutadiene formed article reduced in the water contact angle to a polar resin formed article.

Owner:JSR CORPORATIOON

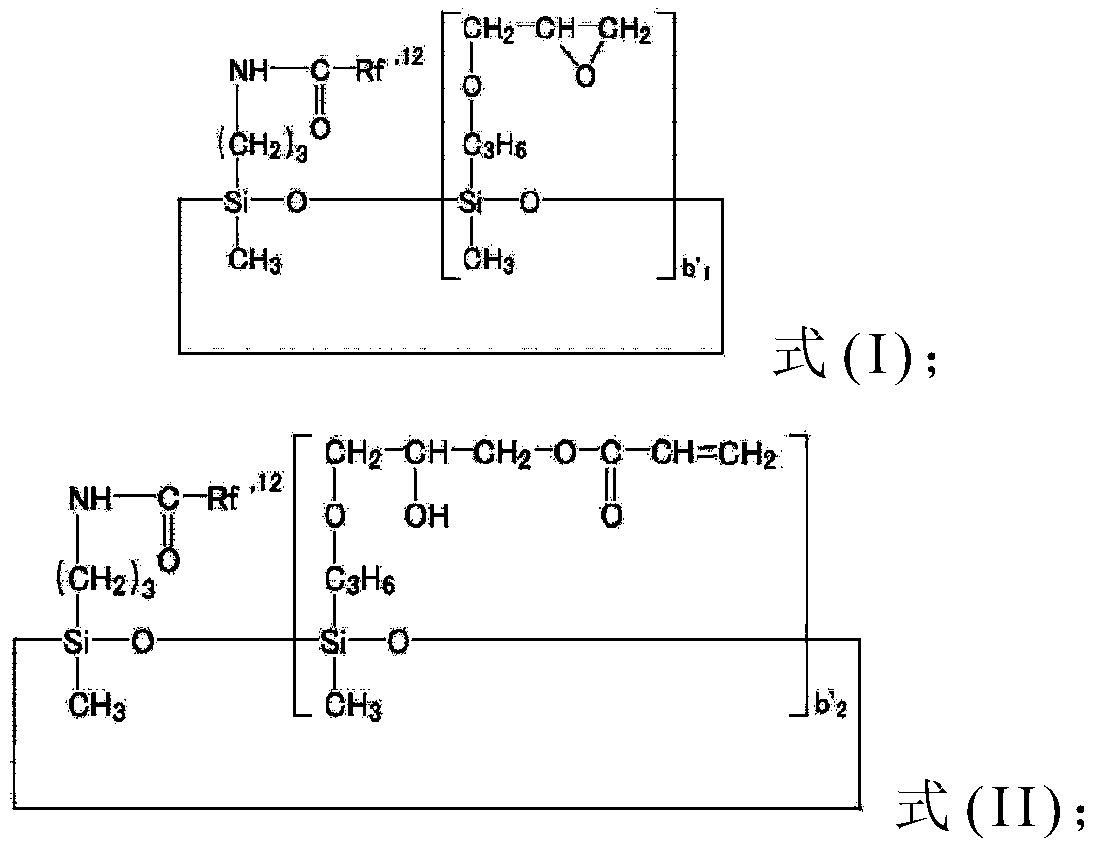

Anti-reflection film and polarizing plate having same

ActiveCN111366993ALower water contact angleIncrease crosslink densityPolarising elementsPolyurea/polyurethane coatingsChemistryOrganosilicon

The invention provides an anti-reflection film and a polarizing plate having the same. The anti-reflection film includes a substrate, a hard coating layer on the substrate, and a low refractive indexlayer on the hard coating layer, wherein the low refractive index layer includes polysiloxane resin modified with fluorine and acrylate, a plurality of hollow silica nanoparticles, an initiator, and leveling agent including a (meth) acryloyl-modified organosilicon compound having a perfluoropolyether functional group, so good processability can be provided, reflectivity of the anti-reflection filmis smaller than 1.1%, and a water contact angle ranges from 90 degrees to 125 degrees. The anti-reflection film is advantaged in that the anti-reflection film is arranged on a surface of a polarizingelement, the crosslinking density of the low-refractive-index layer of the anti-reflection film is improved, and the anti-reflection film has good scratch resistance and low reflectivity, after the low-refractive-index layer is dried and formed, a problem that the optical property is influenced by uneven film surfaces or white fog can be avoided, so the quality of the anti-reflection film and thepolarizing plate with the anti-reflection film is improved.

Owner:BENQ MATERIALS +1

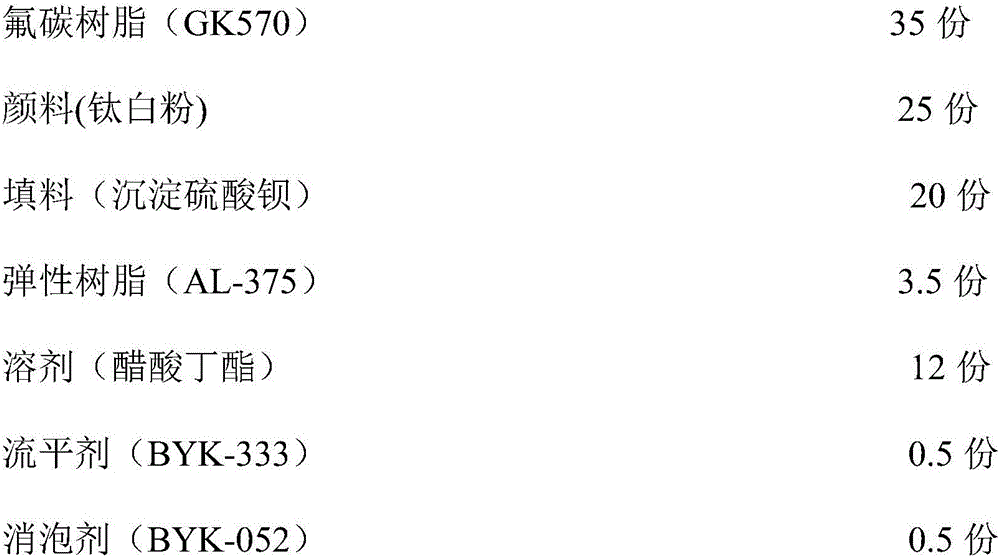

Preparation method for elastic fluorocarbon paint

InactiveCN106366788ASimple preparation processImprove thermal insulationAnti-corrosive paintsFluorocarbonAnti ageing

The invention provides a preparation method for elastic fluorocarbon paint. The preparation method for the elastic fluorocarbon paint includes the steps: (1) uniformly stirring fluorocarbon resin, partial solvents and dispersing agents in a stirrer; (2) adding the dispersing agents, pigments and fillers, and grinding to obtain grinding thick liquid; (3) placing the grinding thick liquid in the stirrer, sequentially adding elastic resin, defoaming agents and flatting agents, and uniformly stirring; (4) sequentially adding theological additives and residual solvents after the thick liquid is dispersed, and uniformly stirring to obtain main agents; (5) individually packaging curing agents to obtain packaged curing agents. According to the paint, anti-aging protection life of a coated substance can reach 25 years or more, and the paint has low VOCs (volatile organic compounds) and is better in toughness and elasticity and applicable to bridge concrete base surfaces, positions with easily cracked surfaces such as tunnels and piers and surfaces of other buildings with a certain water-proof and anticorrosion requirement.

Owner:TIANJIN MEISHIBANG PAINT CHEM IND

Preparation process of chromium oxynitride and diamond-like carbon film composite coating fine dried noodle knife roller

InactiveCN103741093AAffect adhesionPlay an etching roleVacuum evaporation coatingSputtering coatingCarbon filmAnti bacteria

The invention discloses a process of a chromium oxynitride and diamond-like carbon film (DLC) composite coating fine dried noodle knife roller or stick. The process comprises the following steps of cleaning, drying, performing pre-treatment, coating a NO2Cr film layer as a transition layer (an anchoring layer) and coating a DLC outer film layer. By utilizing the process disclosed by the invention to coat a diamond-like carbon film on the fine dried noodle knife roller or stick, the hardness, toughness, wear resistance, corrosion resistance, antibacterial performance and lubrication performance of a fine dried noodle knife bar can be improved, so that the service life can be prolonged by 8-10 times. The process disclosed by the invention can be widely applied to other food machines.

Owner:武汉世纪中航超强金刚石膜高科技有限公司

Modified hollow-fiber membrane

InactiveUS7108787B2Performance deteriorationLittle interactionSemi-permeable membranesMembranesFiberHigh concentration

A modified hollow-fiber membrane which has improved surface hydrophilicity without increasing the amount of components released therefrom, is less apt to interact with living-body components, does not adsorb proteins, and is less apt to deteriorate in performance. The hollow-fiber membrane has a copolymer of 2-methacryloyloxyethylphosphorylcholine and other polymerizable vinyl monomer held on a surface of the membrane, the copolymer being present on the surface in a higher concentration than in other parts of the membrane. The modified hollow-fiber membrane is useful in medical applications such as hemodialysis and blood filtration and in the medical industry, food industry etc.

Owner:NOF CORP

Processing method for improving colour fastness of dacron fabric

The invention discloses a processing method for improving the colour fastness of a dacron fabric and relates to the technical field of processing of clothes. The processing method comprises the following steps: (1) pretreatment; (2) plasma treatment; (3) preparation of active treating fluid; (4) modification treatment; (5) ultrasonic processing; and (6) cleaning. By virtue of performing surface low-temperature plasma treatment on the dacron fabric, the surface substantivity of the dacron fabric can be obviously improved, and the combination property of the dacron fabric with dye molecules is promoted, so that the colour fastness is improved.

Owner:阜南美凯服饰有限公司

Resistance-reducing and antifouling coating composition and resistance-reducing and antifouling coating prepared from same

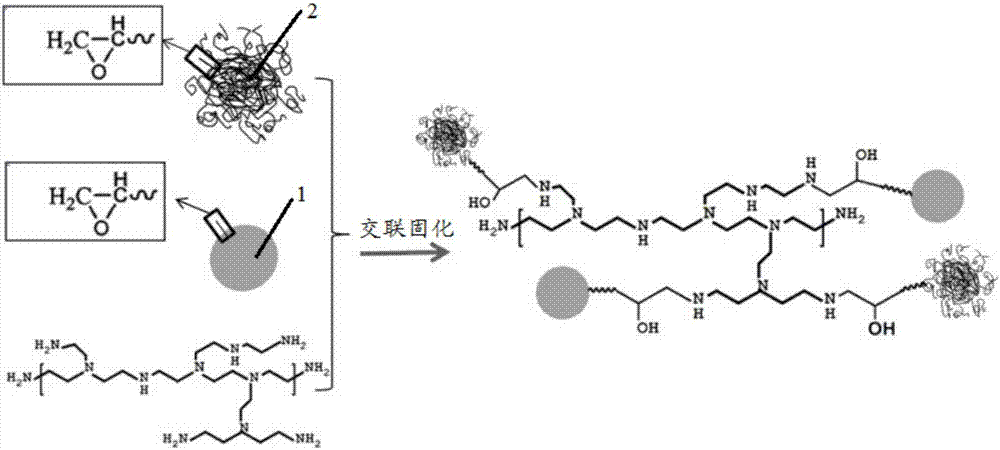

ActiveCN107400438ANo distractionNo risk of contaminationAntifouling/underwater paintsPaints with biocidesCross-linkBiological body

The invention discloses a resistance-reducing and antifouling coating composition and a resistance-reducing and antifouling coating prepared from the same. The composition contains a first component, a second component and a third component, wherein the first component is a polymer emulsion prepared through polymerization of acrylic acid monomers and epoxy monomers; the second component is microgel suspension liquid prepared through polymerization of substituted acrylamide, amphiphilic macromolecule monomers, a cross-linking agent and epoxy monomers; and the third component is a curing agent. The resistance-reducing and antifouling coating prepared from the components has thermosensitivity, and the surface of the coating is in a dynamic form under a temperature variation condition, so that the adhesion of living bodies is prevented, and the antifouling property is realized; and meanwhile, the coating layer has amphipathy, so that the resistance in a water medium is effectively reduced, and a resistance reduction effect is realized. By taking water as a solvent during the preparation of the composition and the coating, the composition and the coating are safe, environmentally friendly and free of pollution, the raw materials are easily available, a preparation method is simple, and large-scale production and application are easily realized.

Owner:BEIJING UNIV OF CHEM TECH

Polar cycloalkene copolymer and preparation method thereof

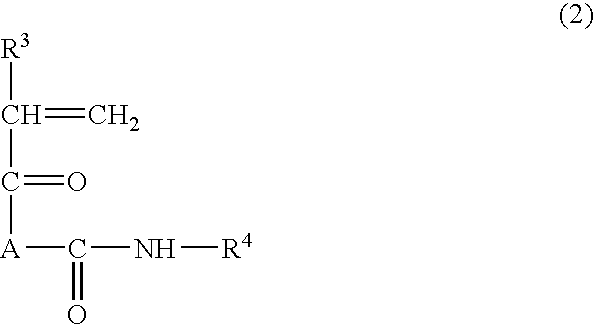

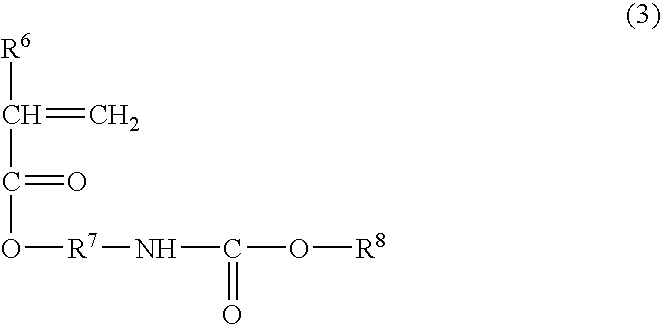

ActiveCN108610446AGood mechanical and thermal propertiesLower water contact angleCycloalkeneStructural unit

The invention relates to the field of cycloalkene copolymers, in particular to a polar cycloalkene copolymer and a preparation method thereof. The polar cyclic cycloalkene copolymer comprises a structural unit shown in formula (1), a structural unit shown in formula (2) and a structural unit shown in formula (3), wherein, based on the molar amount of the total structural unit in the copolymer, thecontent of the structural unit shown in formula (1) is 40-75mol%, the content of the structural unit shown in formula (2) is 20-40mol%, and the content of the structural unit shown in formula (3) is5-30mol%. The polar cycloalkene copolymer has high molecular weight and high glass transition temperature, so that better thermal property and mechanical property are obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

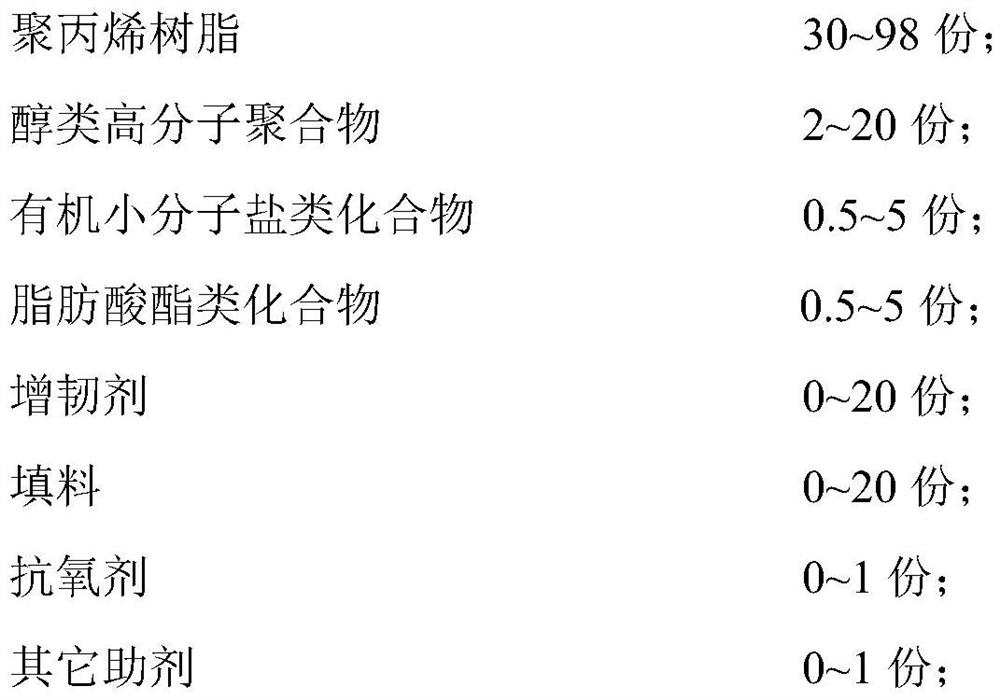

Polypropylene composition as well as preparation method and application thereof

The invention discloses a polypropylene composition as well as a preparation method and application thereof. The polypropylene composition comprises the following components in parts by weight: 30-98 parts of polypropylene resin, 2-20 parts of alcohol high-molecular polymer, 0.5-5 parts of an organic small molecular salt compound, 0.5-5 parts of a fatty acid ester compound, 0-20 parts of a toughening agent, 0-20 parts of a filler, 0.1-1 part of an antioxidant, and 0-1 part of other auxiliary agents. The organic small molecule salt compound is one of a carboxylate compound, a sulfonate compound, a sulfate compound or an acrylate compound. By adding the alcohol high-molecular polymer, the organic small molecular salt compound and the fatty acid ester compound into the polypropylene composition, the long-acting oil stain resistance of the polypropylene resin can be greatly improved under the combined action of the three.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD +2

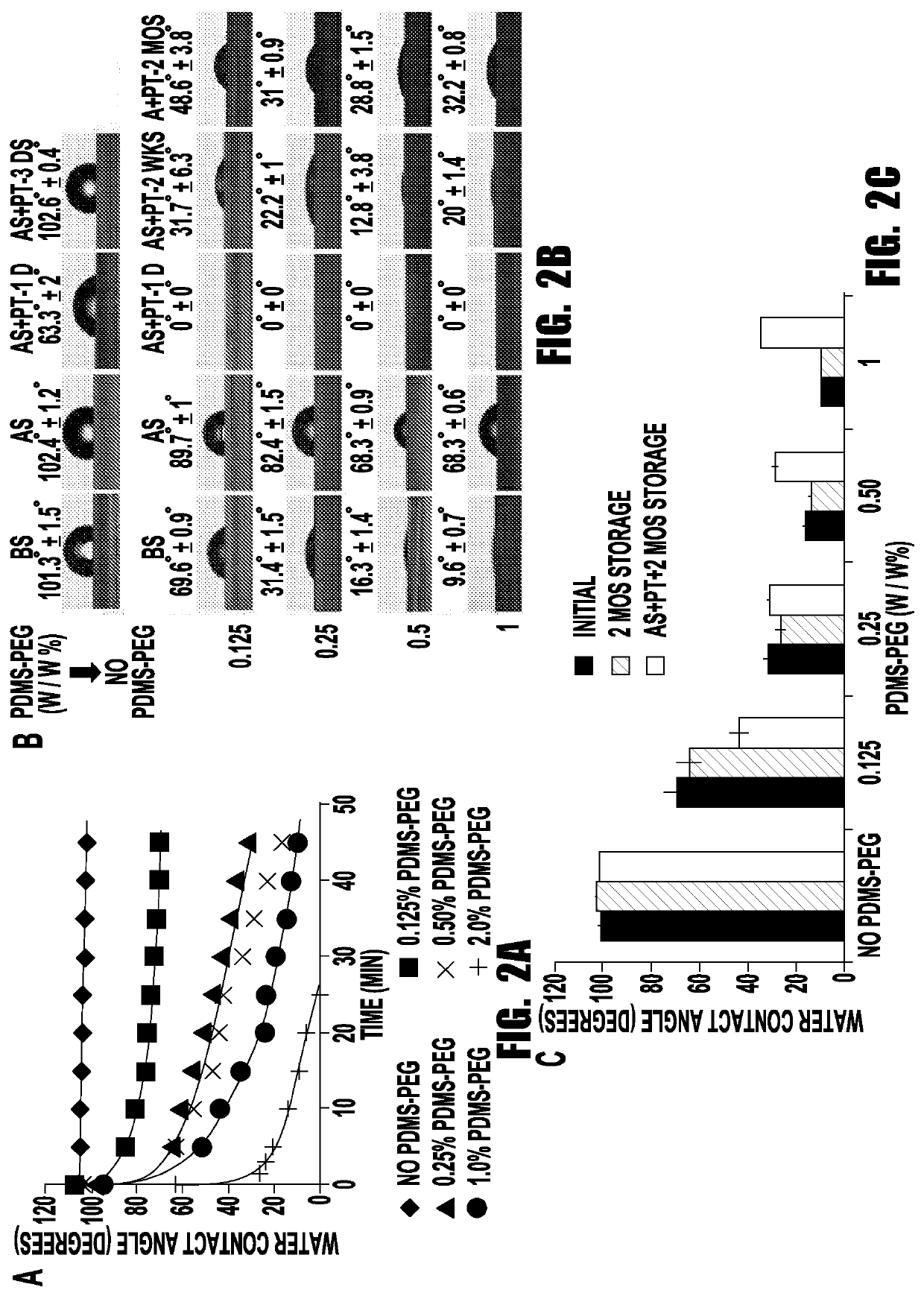

Amphiphilic surface-segregating polymer mixtures

PendingUS20200071563A1Improve hydrophilicityDecrease non-specific protein adsorptionLaboratory glasswaresCoatingsPolymer scienceHydrophobic polymer

A segregated polymeric material is described that includes a silicon-based hydrophobic polymer and a copolymer comprising a silicon-based hydrophobic polymer and a hydrophilic segment, wherein the copolymer has been segregated to a surface of the material by contacting the surface with an aqueous solution. The segregated polymeric material can be used to improve the wettability and decrease the protein adsorption of a surface.

Owner:TRUSTEES OF TUFTS COLLEGE +1

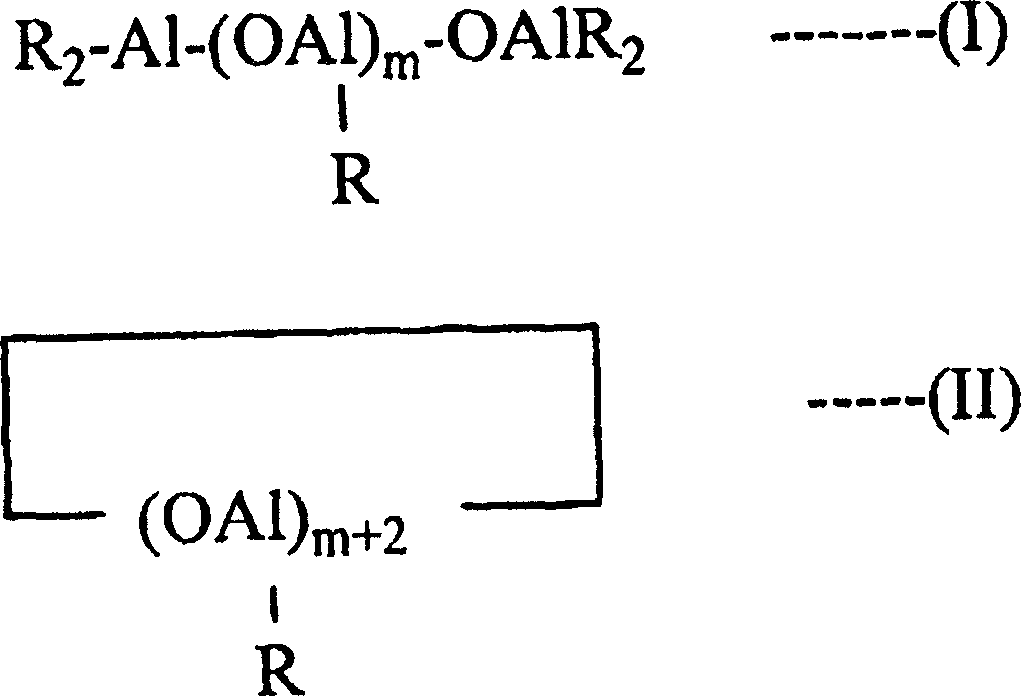

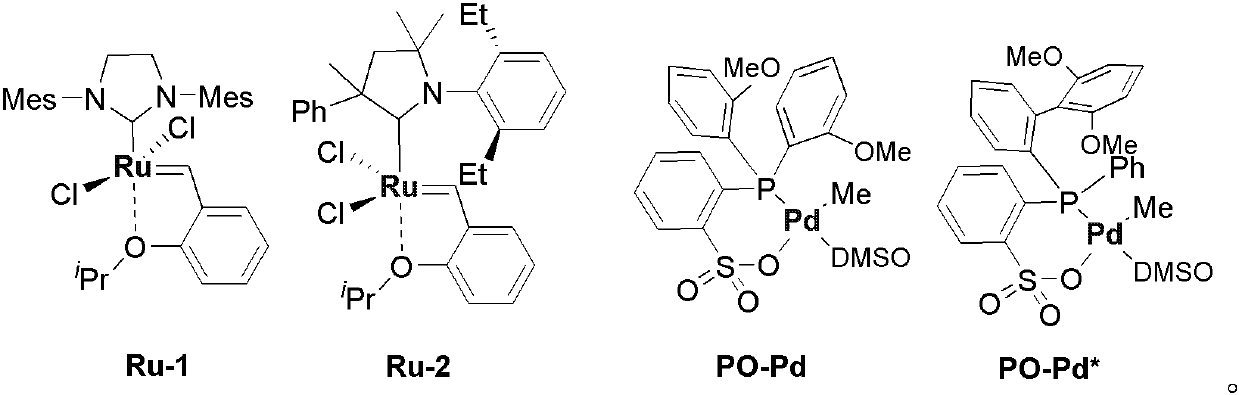

Method of one-pot cascade catalytic copolymerization of ethylene and 1,2-disubstituted polar isomerised olefin and product of the method

ActiveCN110938164AFill technology gapsHigh melting pointOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPolymer sciencePtru catalyst

The invention provides a method of one-pot cascade catalytic copolymerization of ethylene and 1,2-disubstituted polar isomerised olefin monomer represented as the formula (I) and a product of the method. The method includes: performing an ethylene decomposition reaction on a 1,2-disubstituted polar isomerised olefin monomer and an ethylene monomer in the presence of a ruthenium catalyst Ru-1 or Ru-2 at 20-50 DEG C to form an ethylene decomposition monomer product; then performing a copolymerization reaction on the ethylene decomposition monomer product and the ethylene monomer in the presenceof a palladium phosphinosulfonate catalyst PO-Pd or PO-Pd* at 70-90 DEG C, wherein the R1 and R2 in the formula (I) are defined as the specification. By means of the specific Ru and Pa catalysts, a novel process of the cascade copolymerization of the 1,2-disubstituted polar isomerised olefin monomer, capable of being derived from biomass, and the ethylene monomer under a gentle condition, thus obtaining the functionalized polar copolymer having a specific performance. In addition, the invention fills the technical gap of the copolymerization of the 1,2-disubstituted polar isomerised olefin, capable of being derived from biomass, and the ethylene monomer to produce the functionalized polar copolymer.

Owner:UNIV OF SCI & TECH OF CHINA

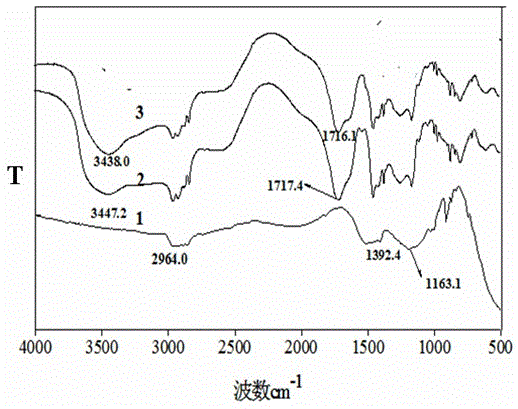

A kind of surface modification method of polypropylene non-woven fabric

InactiveCN104562666BImprove water absorptionLower water contact angleFibre treatmentTwo stepNonwoven fabric

Owner:KUNMING UNIV OF SCI & TECH

Stain-resistant fluorocarbon coating for building external wall and preparation method of stain-resistant fluorocarbon coating

ActiveCN110951332AImprove stain resistanceImprove densification performanceAntifouling/underwater paintsPaints with biocidesPolymer sciencePtru catalyst

The invention discloses a stain-resistant fluorocarbon coating for a building external wall and a preparation method of the stain-resistant fluorocarbon coating. Raw materials of the stain-resistant fluorocarbon coating comprise a component A and a component B in a weight ratio of 100:(8-20); the component A is composed of the raw materials by weight: 40-60 parts of a water-based fluorocarbon emulsion, 20-30 parts of titanium dioxide, 0.5-10 parts of quaternized polysiloxane, 0.2-1 part of a defoaming agent, 0.1-1 part of a wetting agent, 0.2-1 part of a dispersing agent, 0.1-1 part of nano silicon dioxide, 1-3 parts of propylene glycol, 2-10 parts of a coalescing agent, 0.1-0.5 part of a leveling agent, 0.1-1 part of a base material wetting agent, 0.1-1 part of a rheological auxiliary agent, 0.1-0.3 part of a multifunctional amine auxiliary agent, 0.01-0.2 part of a catalyst and 5-20 parts of water. The component B comprises the raw materials by weight: 40-60 parts of an HDI curing agent and 40-60 parts of propylene glycol methyl ether acetate. The stain resistance of the coating is remarkably enhanced.

Owner:武汉长弢新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com