Moisture-repellent protective layer for a winding head of an electric machine

A technology of end winding and protective layer, which is applied in the direction of winding, winding insulation shape/style/structure, electric components, etc. It can solve the problems of easy formation of cracks and motor damage, so as to prolong the service life and reduce the difficulty of cleaning work. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

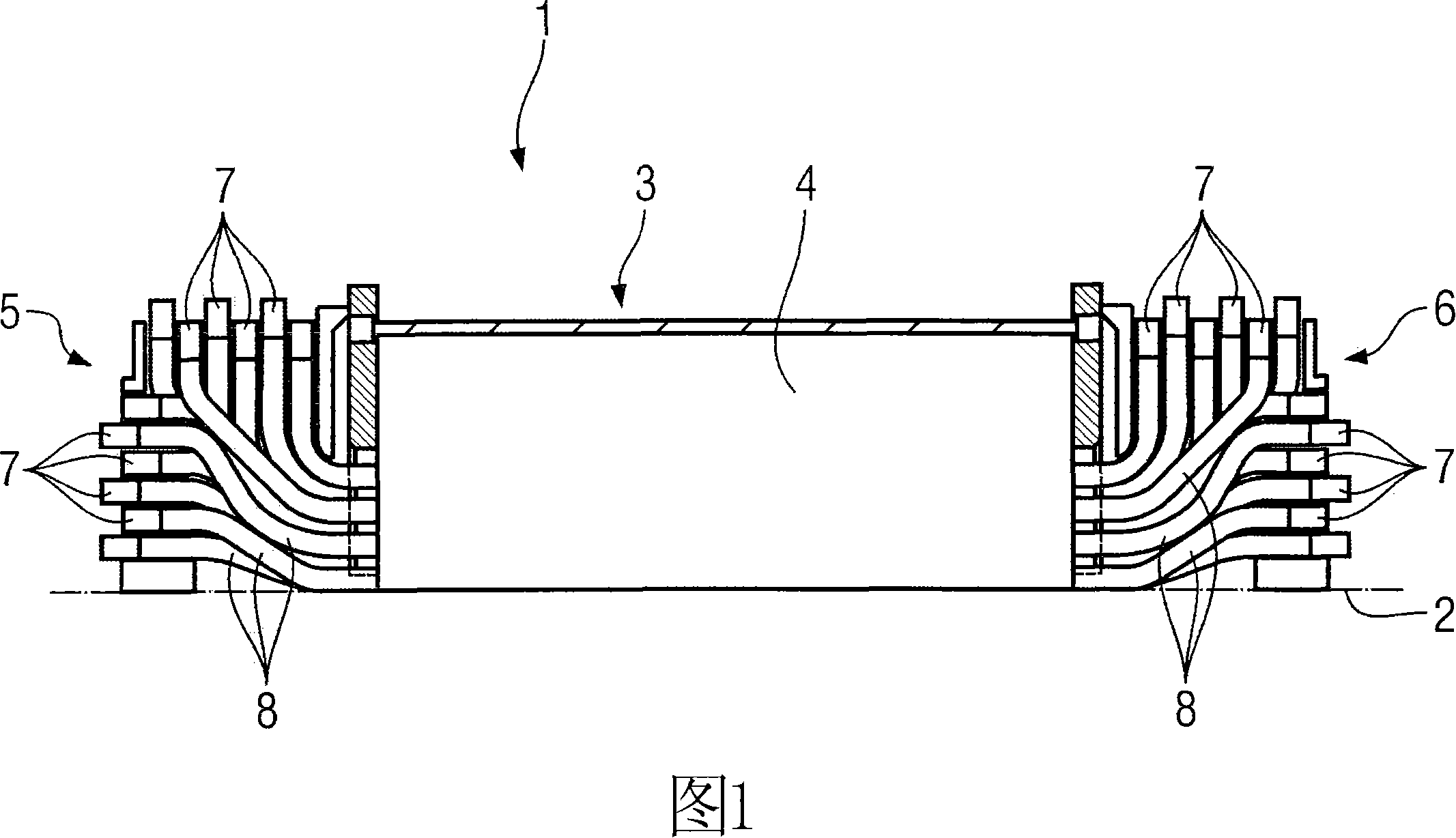

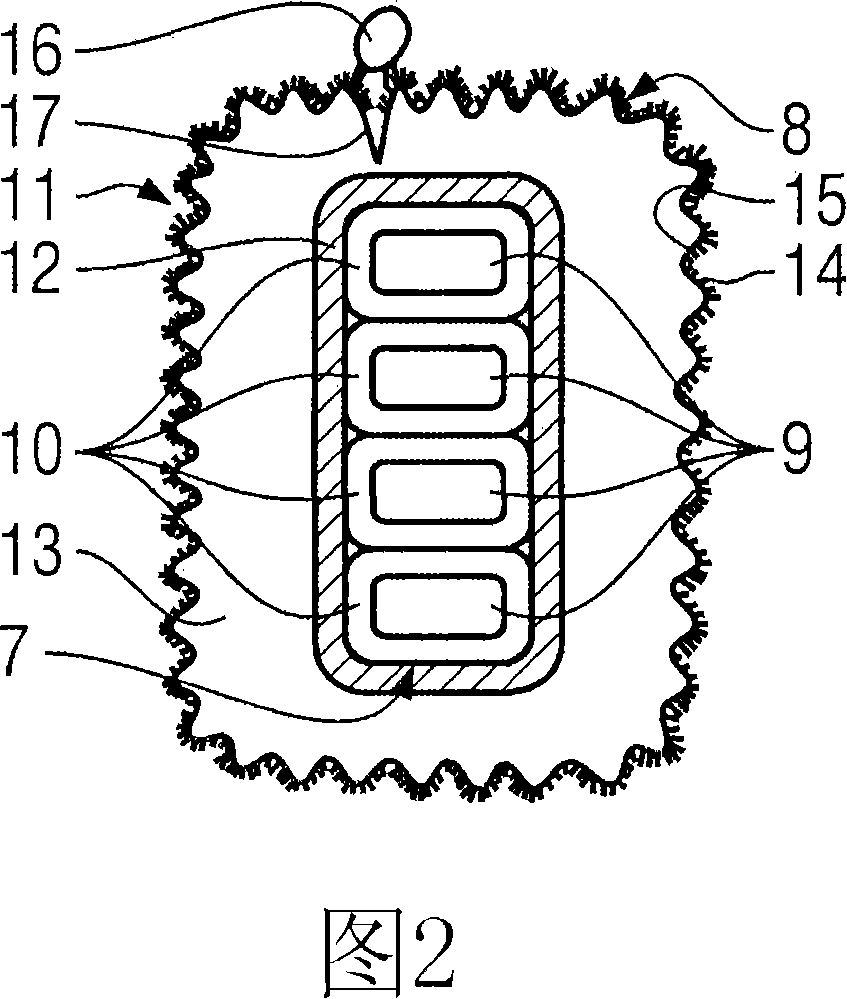

[0021] The same components are denoted by the same reference symbols in both Fig. 1 and Fig. 2 .

[0022] FIG. 1 shows an exemplary embodiment of an electric machine 1 in a partial cross-sectional view. The sectional view of the motor 1 is in fact a sectional view of a stator 3 of the motor 1 taken along the axis of rotation 2 , but only the upper half of the stator 3 is shown. FIG. 1 does not show the area 4 with the stator core laminations and the electrical coil conductors embedded in the slots in detail, but only shows this active area in schematic form. The two end windings 5 and 6 which the stator 3 has are respectively arranged on both axial sides of the active region 4 .

[0023] The end windings 5 and 6 consist of a plurality of electrical conductor arrangements 7 leading out of the stator laminate core in the direction of the axis of rotation 2 . The coil winding is formed by a suitable electrical connection of the conductor arrangement 7 in the region of the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com