Double-component fluorosilicone rubber ice-covering-proof coating material and preparation method thereof

A technology of fluorosilicone rubber and coating material, applied in coating and other directions, can solve problems such as disconnection, plane crash, loss and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

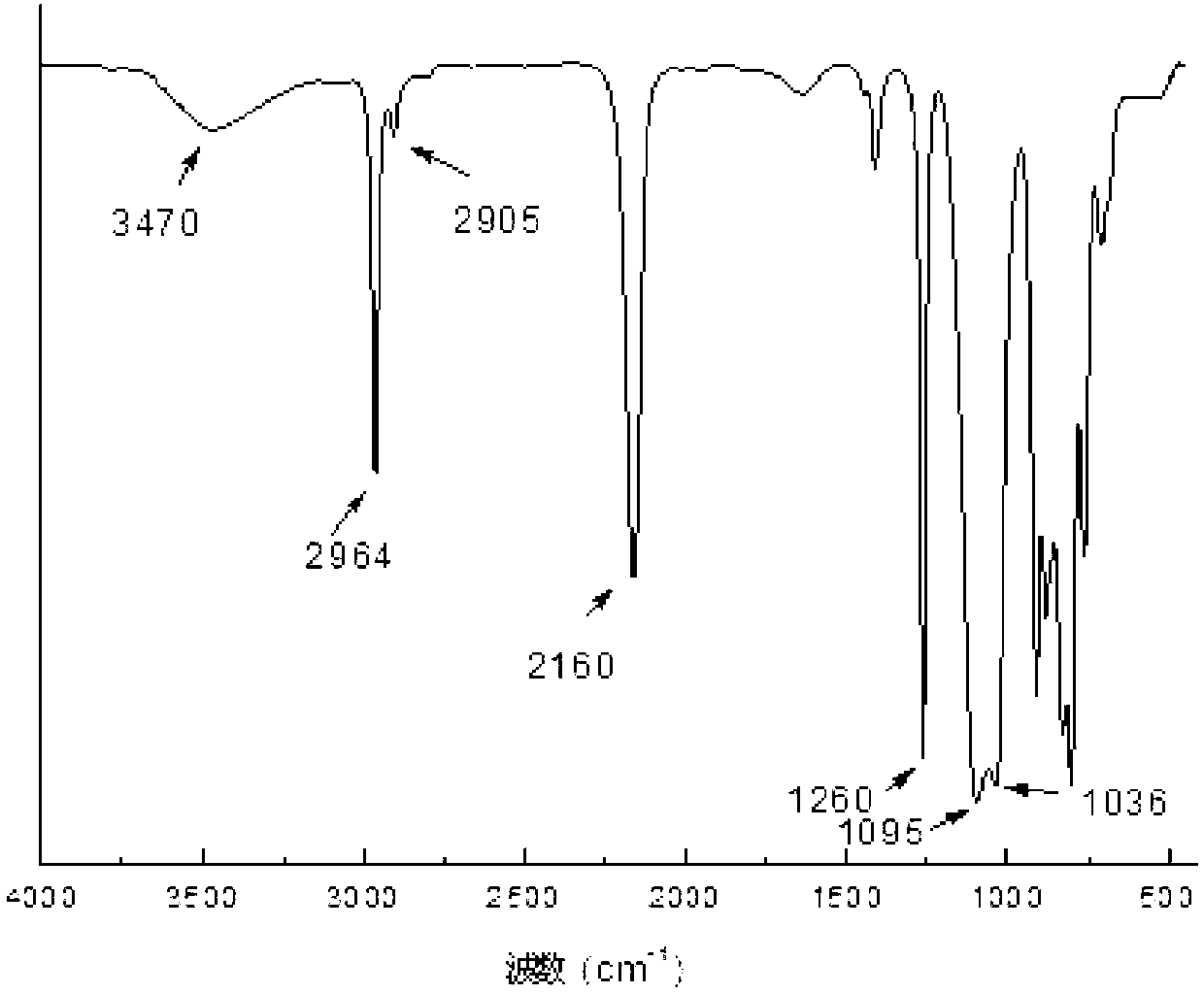

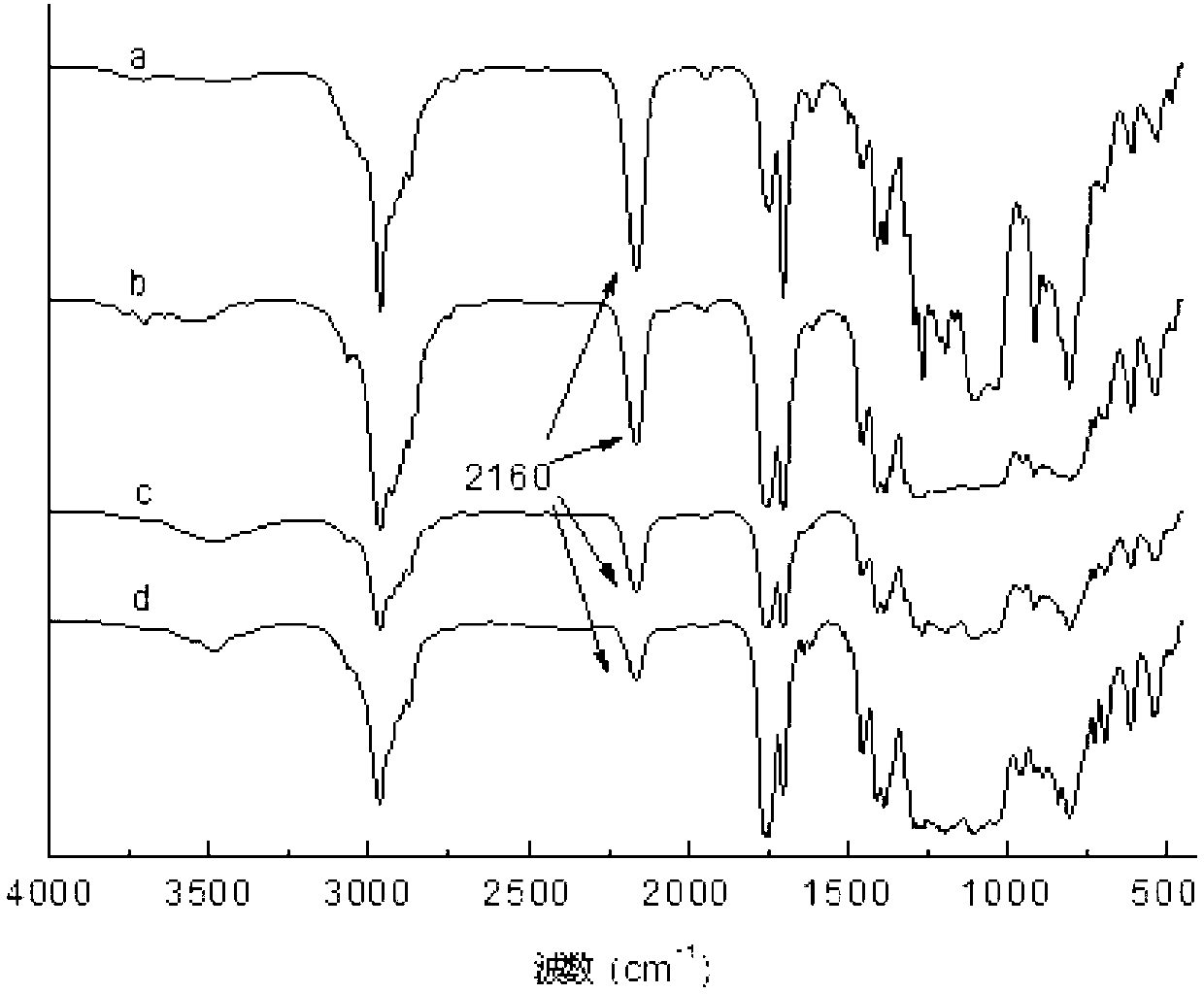

Method used

Image

Examples

Embodiment 1

[0033] (1) In step 1, take 100 g of hexafluorobutyl acrylate, dissolve it in xylene, add 10 μL of platinum catalyst, and stir evenly. Then, under stirring conditions, pass nitrogen gas into it, and add hydrogen-containing silicone oil for reaction to generate fluorine-modified silicone oil. The reaction temperature is 80°C, heated and controlled by heating in a water bath; the reaction time is 30 hours; the ratio of the moles of double bonds in hexafluorobutyl acrylate to the moles of silicon-hydrogen bonds in hydrogen-containing silicone oil is 8:1.

[0034] (2) Step 2, take 100g of vinyl-terminated polydimethylsiloxane, add 15g of white carbon black as a reinforcing filler, stir well and add 5g of whitening agent TiO 2 , stir well

[0035] (3) Step 3, add 5g of hydrogen-containing silicone oil and 5g of fluorine-modified silicone oil prepared in step (1) to the uniformly stirred system in step 2, stir well, add 50μL of platinum catalyst and 40g of xylene, and stir well to ob...

Embodiment 2

[0038](1) In step 1, take 100g of hexafluorobutyl acrylate, dissolve it in xylene, add 50 μL of platinum catalyst, and stir evenly. Then, under stirring conditions, pass argon gas into it, and add hydrogen-containing silicone oil to react to generate fluorine-modified silicone oil. , the reaction temperature is 65°C, heated and controlled by heating in a water bath; the reaction time is 20 hours; the ratio of the moles of double bonds in hexafluorobutyl acrylate to the moles of silicon-hydrogen bonds in hydrogen-containing silicone oil is 0.5:1 .

[0039] (2) Step 2, take 100g of vinyl-terminated polydimethylsiloxane, add 10g of white carbon black as a reinforcing filler, stir well and add 2g of whitening agent TiO 2 , stir well

[0040] (3) Step 3, add 2g of hydrogen-containing silicone oil and 2g of fluorine-modified silicone oil prepared in step (1) to the uniformly stirred system in step 2, stir well, add 25μL of platinum catalyst and 50g of xylene, and stir well to obtai...

Embodiment 3

[0043] (1) In step 1, take 100g of hexafluorobutyl acrylate, dissolve it in xylene, add 30 μL of platinum catalyst, and stir evenly. Then, under stirring conditions, inject helium gas and add hydrogen-containing silicone oil for reaction to generate fluorine-modified silicone oil. , the reaction temperature is 50°C, heated and controlled by heating in a water bath; the reaction time is 15 hours; the ratio of the moles of double bonds in hexafluorobutyl acrylate to the moles of silicon-hydrogen bonds in hydrogen-containing silicone oil is 1:1 .

[0044] (2) Step 2, take 100g of vinyl-terminated polydimethylsiloxane, add 5g of white carbon black as a reinforcing filler, stir well and add 0.5g of whitening agent TiO 2 , stir well

[0045] (3) In step 3, add 1g of hydrogen-containing silicone oil and 1g of fluorine-modified silicone oil prepared in step (1) to the uniformly stirred system in step 2, stir well, add 15μL of platinum catalyst and 20g of xylene, and stir well to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com