Fluorosilicon modified epoxy resin and preparation method thereof and powder coating

An epoxy resin, fluorosilicon modification technology, used in epoxy resin coatings, powder coatings, anti-corrosion coatings, etc., can solve problems such as the inability to obtain the ideal water contact angle value, the inability to achieve fouling resistance and self-cleaning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

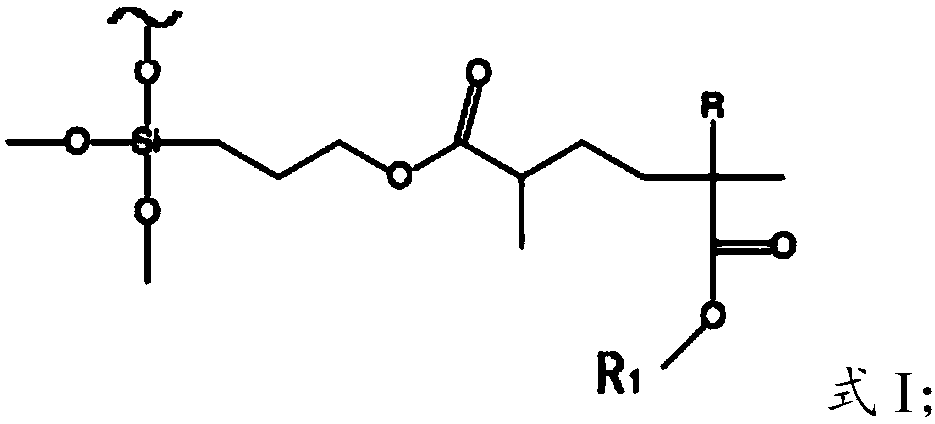

[0033] The present invention provides a preparation method of fluorosilicon modified epoxy resin, which comprises the following steps:

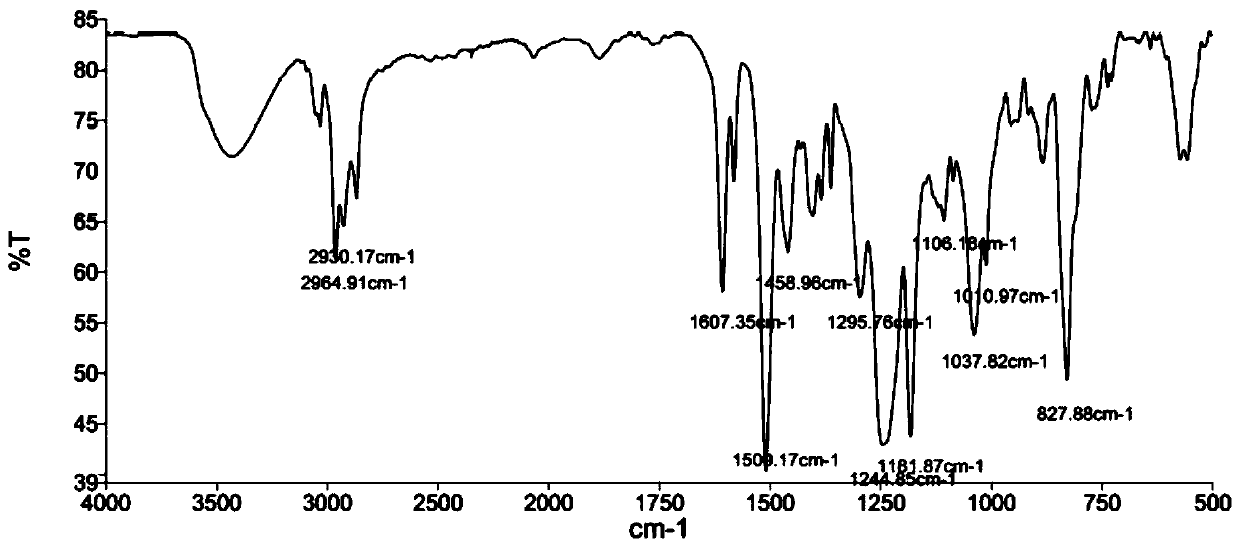

[0034] (1) The fluorine-containing acrylate, γ-(methacryloxy)propyltrimethoxysilane, epoxy reactive diluent and initiator are mixed and then prepolymerized to obtain a fluorosilicone prepolymer;

[0035] (2) After mixing the fluorosilicone prepolymer, bisphenol A epoxy resin, bisphenol A and a phase transfer catalyst, perform a first-level polymerization reaction to obtain a first-level polymer;

[0036] (3) After mixing the primary polymer, bisphenol A and the phase transfer catalyst, a secondary polymerization reaction is performed to obtain a fluorosilicone modified epoxy resin.

[0037] In the preparation method of the present invention, all the raw materials used are commercially available products that are well known to those skilled in the art, and will not be repeated one by one below.

[0038] In the present invention, fluorine-containing acry...

Embodiment 1

[0078] In a 100mL four-necked flask equipped with mechanical stirring, thermometer, reflux condenser, nitrogen introduction and vacuum device, add 10g hexafluorobutyl methacrylate, 10g γ-(methacryloxy)propyltrimethoxysilane and 8g Propylene oxide benzyl ether, stir and mix uniformly, add 0.15g benzoyl peroxide to slowly raise the temperature of the oil bath to 100℃, react for 30min, it can be observed that the viscosity of the reaction system rises slightly, after the reaction is cooled, fluorine is obtained Silicon prepolymerized product.

[0079] Add 50g of liquid bisphenol A epoxy resin (E-54) and 5g of bisphenol A into a 250ml four-necked flask equipped with mechanical stirring, thermometer, reflux condenser and nitrogen introduction device. After heating to 50℃, stir for bisphenol A is completely dissolved, add 20g of the obtained fluorosilicone prepolymerized product, increase the temperature to 100℃ and keep it for 15min, add 0.2g benzyltrimethylammonium bromide, then incr...

Embodiment 2

[0085] Add 11.5g of hexafluorobutyl methacrylate and 8.5g of γ-(methacryloxy)propyltrimethoxysilane into a 100mL four-necked flask equipped with mechanical stirring, thermometer, reflux condenser, nitrogen introduction and vacuum device And 8g of propylene oxide benzyl ether, stir and mix well, add 0.15g of benzoyl peroxide to slowly raise the temperature of the oil bath to 100°C, and react for 30 minutes. A slight increase in the viscosity of the reaction system can be observed. Cool after the reaction. The fluorosilicone prepolymerized product is obtained.

[0086] Add 50g of liquid bisphenol A epoxy resin (E-54) and 5g of bisphenol A into a 250ml four-necked flask equipped with mechanical stirring, thermometer, reflux condenser and nitrogen introduction device. After heating to 50℃, stir for bisphenol A is completely dissolved, add 20g of the obtained fluorosilicone prepolymerized product, increase the temperature to 100℃ and keep it for 15min, add 0.2g benzyltrimethylammonium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com