Protection treatment method of stone surfaces

A treatment process and anti-fouling treatment technology, which is applied in the field of stone materials, can solve problems such as the decline of waterproof and anti-fouling effects, pollution of water resources and energy resources, labor and time-consuming, etc., and achieve the effect of improving waterproof and anti-fouling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

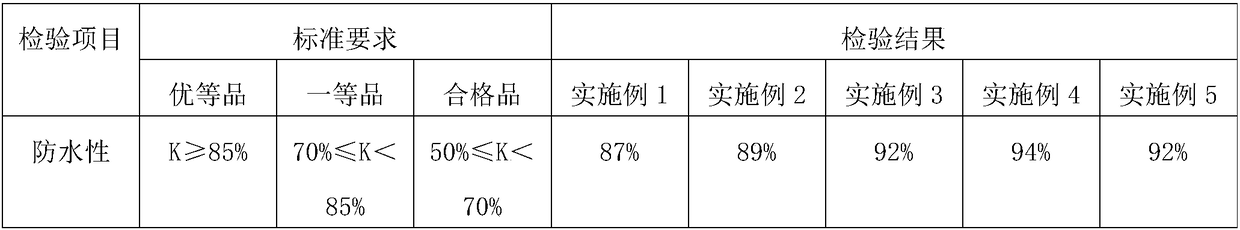

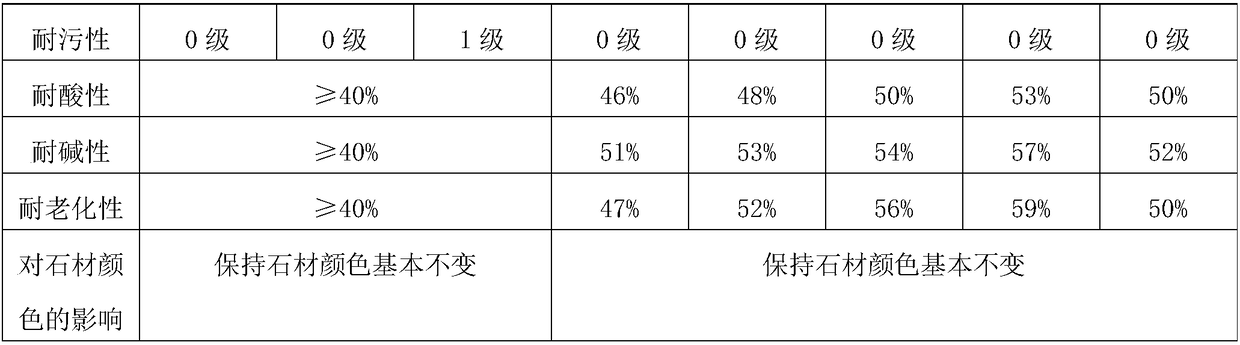

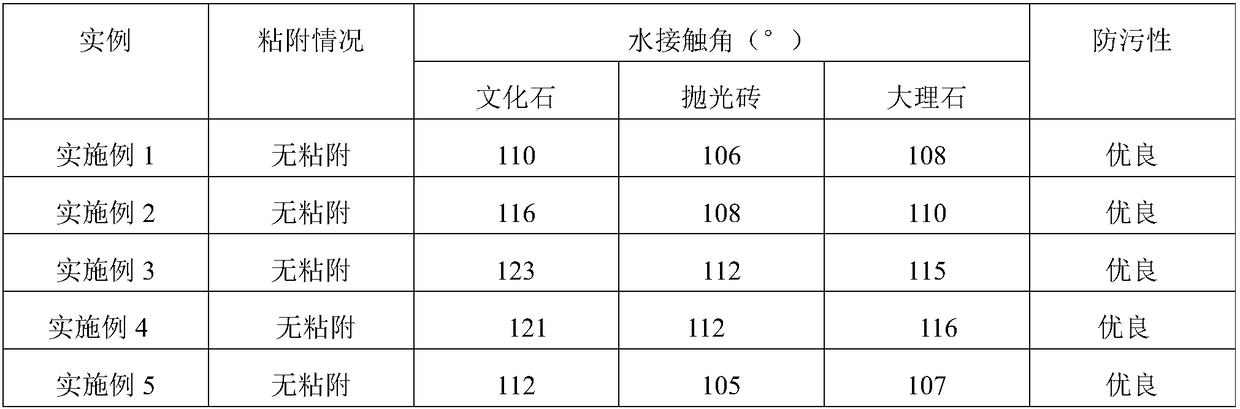

Examples

Embodiment 1

[0034] A protective treatment process for stone surfaces, which sequentially includes pretreatment and waterproof and antifouling treatment on the stone surface, the protective treatment process is:

[0035] (1) Pre-processing:

[0036] A. Use 30-mesh emery to polish the surface of the stone to be processed;

[0037] B. Use 0.8MPa high-pressure air or normal temperature and pressure water to clean the stone surface;

[0038] C. Drying the stone cleaned in step B at a temperature of 60° C. to remove moisture from the stone;

[0039] (2) Waterproof and antifouling treatment

[0040]Use a stone protective agent to carry out waterproof and antifouling treatment on the stone surface. The used stone protective agent includes A component and B component. The A component contains the following ingredients in parts by weight: 2 parts of hydrogen containing 0.2 wt% Hydrogen-containing silicone oil, 3 parts of hydrogen-containing silicone oil with a hydrogen content of 1.0 wt%, a mixe...

Embodiment 2

[0042] A protective treatment process for stone surfaces, which sequentially includes pretreatment and waterproof and antifouling treatment on the stone surface, the protective treatment process is:

[0043] (1) Pre-processing:

[0044] A. Use 40-mesh emery to polish the surface of the stone to be processed;

[0045] B. Use 0.8MPa high-pressure air or normal temperature and pressure water to clean the stone surface;

[0046] C. Drying the stone cleaned in step B to remove moisture from the stone;

[0047] (2) Waterproof and antifouling treatment

[0048] A stone protective agent is used to carry out waterproof and antifouling treatment on the stone surface. The used stone protective agent includes A component and B component. The A component contains the following components in parts by weight: 5 parts of hydrogen containing 0.4wt% Hydrogen-containing silicone oil, 1.5 parts of hydrogen-containing silicone oil with a hydrogen content of 1.0 wt%, a mixed solvent of 73 parts ...

Embodiment 3

[0050] A protective treatment process for stone surfaces, which sequentially includes pretreatment and waterproof and antifouling treatment on the stone surface, the protective treatment process is:

[0051] (1) Pre-processing:

[0052] A. Use 50-mesh emery to polish the surface of the stone to be processed;

[0053] B. Use 0.8-1.0MPa high-pressure gas or normal temperature and pressure water to clean the stone surface;

[0054] C. Drying the stone cleaned in step B to remove moisture from the stone;

[0055] D, carry out oil pollution treatment to the stone material that is dried through step C by using a surface treatment agent;

[0056] (2) Waterproof and antifouling treatment

[0057] A stone protective agent is used to carry out waterproof and antifouling treatment on the surface of the stone. The used stone protective agent includes component A and component B. The component A contains the following components in parts by weight: Hydrogen-containing silicone oil, 3.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com