High-wear-resistance UV resin with anti-fingerprint function and preparation method thereof

An anti-fingerprint and functional technology, applied to paints, coatings, anti-fouling/underwater coatings containing biocides, etc., can solve the problem of high surface tension of the paint film, non-fouling resistance of the paint film surface, and failure to meet high wear resistance performance requirements etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] This embodiment provides a kind of high wear-resistant UV resin 1# sample (UV-1) with anti-fingerprint function, and its preparation method is as follows:

[0074] (1) Dilute 7.25 grams of isophorone diisocyanate trimer (brand T1890 / 100, provided by Evonik) and 0.15 grams of dibutyltin dilaurate with 47.25 grams of trifluorotoluene, and then dry it under nitrogen protection. The temperature was raised to 80°C, and 40.00g of perfluoropolyether alcohol (brand name DOL-4000, molecular formula CF 3 CF 2 CF 2 O(CF(CF 3 ) CF 2 O) n CF(CF 3 )CH 2 OH, the molecular weight is 4000, provided by Taicang Sinochem Environmental Protection Chemical Co., Ltd.), the stirring rate is 200 rpm, the dropwise addition time is 1h, the dropping material is completed, the reaction temperature is maintained and the reaction is continued for 2h to obtain a solution containing the intermediate product 1;

[0075] (2) Dilute 7.25 grams of isophorone diisocyanate trimer (brand name T1890 / 100...

Embodiment 2

[0081]This embodiment provides a kind of high wear-resistant UV resin 1# sample (UV-2) with anti-fingerprint function, and its preparation method is as follows:

[0082] According to the steps and process shown in Example 1, in step (5), tripentaerythritol is replaced by dipentaerythritol, and the corresponding quality is replaced by 16.24g, and the quality of isocyanate ethyl acrylate is replaced by 22.46g. The mass of methyl ethyl ketone was changed to 38.70g, and the remaining conditions and mass were the same as in Example 1 to obtain the product UV-2 with a solid content of 50%.

Embodiment 3

[0084] This embodiment provides a kind of high wear-resistant UV resin 1# sample (UV-3) with anti-fingerprint function, and its preparation method is as follows:

[0085] According to the steps and process shown in Example 1, in step (3), the quality of isophorone diisocyanate is replaced by 8.90g, and the quality of double-ended hydroxysimethicone oil is replaced by 20.00g. In this step The quality of trifluorotoluene is replaced by 28.90g; In step (5), tripentaerythritol is replaced by dipentaerythritol, and the corresponding quality is replaced by 16.24g, and the quality of isocyanate ethyl acrylate is replaced by 22.46g. The mass of methyl ethyl ketone was changed to 38.70g; other conditions and mass were the same as those in Example 1, and the product UV-3 was obtained with a solid content of 50%.

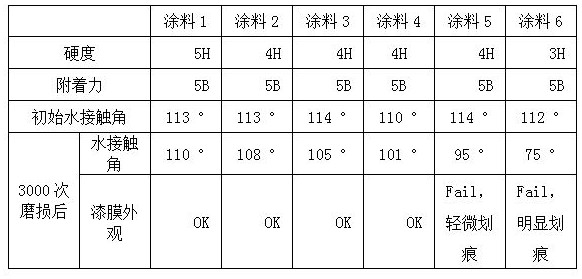

[0086] 2. Preparation of paint and paint film

[0087] Step 1: According to the formula shown in Table 1 (the addition of each component is in parts by weight), compound the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com