Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

88results about How to "High degree of environmental protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solar photovoltaic inverters

ActiveUS8542512B2High degree of environmental protectionFacilitates spreading and dissipation of heatPrinted circuit assemblingMagnetic/electric field screeningPower inverterComputer module

The invention relates to improved techniques for manufacturing power conditioning units (inverters) for use with photovoltaic (PV) modules, and to inverters manufactured by these techniques. We describe a solar photovoltaic inverter, comprising: a power conditioning circuit mounted on a circuit board, the power conditioning circuit having a dc power input to receive dc power from one or more photovoltaic panels and an ac power output to deliver ac power to an ac mains power supply; an electrically conductive shield enclosing said circuit board; and a plastic overmould over said conductive shield and said circuit board; wherein said electrically conductive shield has one or more holes to allow said plastic overmould to extend through said shield to cover said circuit board.

Owner:TESLA INC

Solar Photovoltaic Inverters

ActiveUS20120057388A1High degree of environmental protectionFacilitates spreading and dissipation of heatPrinted circuit assemblingMagnetic/electric field screeningEngineeringAlternating current

The invention relates to improved techniques for manufacturing power conditioning units (inverters) for use with photovoltaic (PV) modules, and to inverters manufactured by these techniques. We describe a solar photovoltaic inverter, comprising: a power conditioning circuit mounted on a circuit board, the power conditioning circuit having a dc power input to receive dc power from one or more photovoltaic panels and an ac power output to deliver ac power to an ac mains power supply; an electrically conductive shield enclosing said circuit board; and a plastic overmould over said conductive shield and said circuit board; wherein said electrically conductive shield has one or more holes to allow said plastic overmould to extend through said shield to cover said circuit board.

Owner:TESLA INC

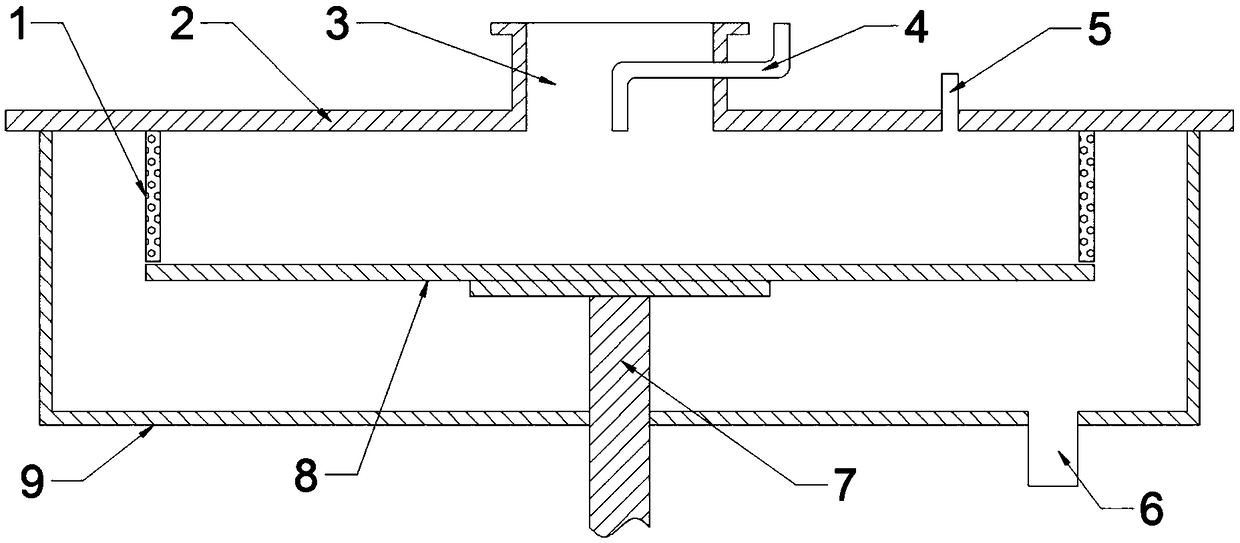

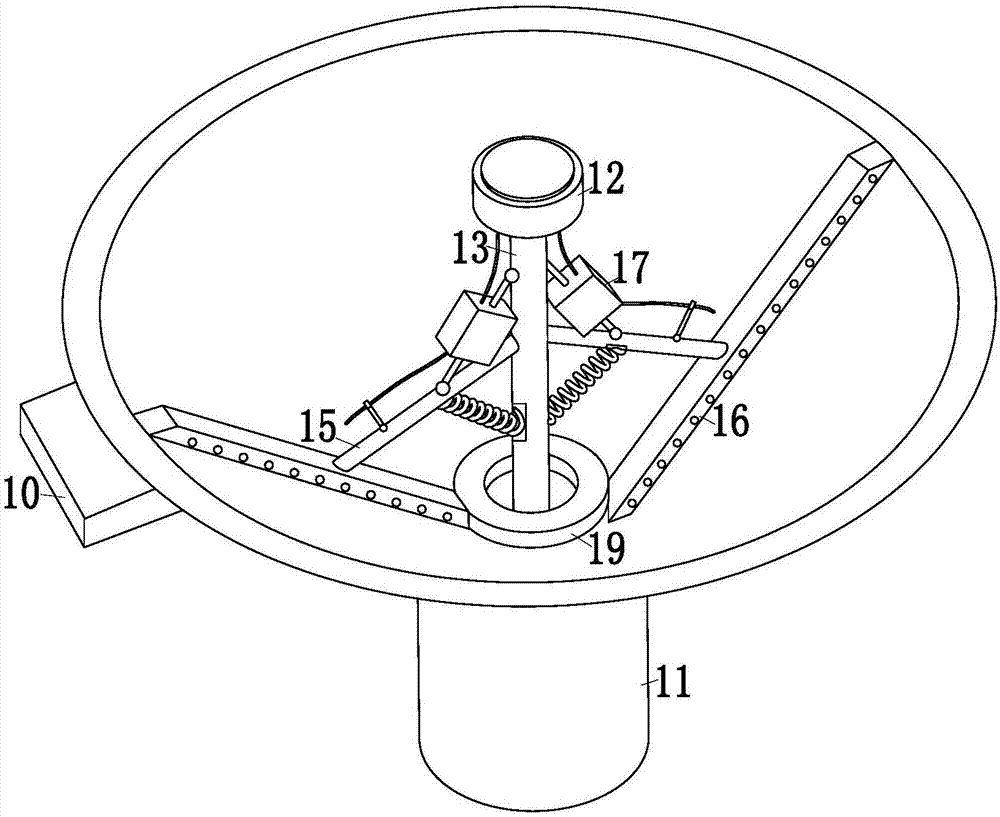

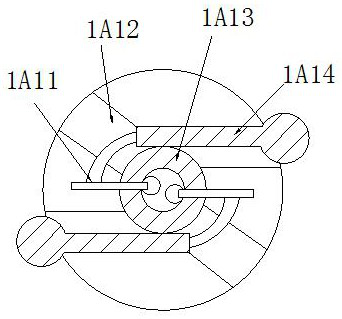

RFID-based soil sampling and automatic marking device

InactiveCN102507255ASimple and fast operationHigh degree of automationWithdrawing sample devicesCo-operative working arrangementsComputer scienceDrill bit

The invention relates to the technical field of quick identification of soil samples. The invention discloses a RFID (Radio Frequency Identification)-based soil sampling and automatic marking device. The device comprises a soil sample marking management module (1), a tag read-write module (4), a sampling drill (6), a soil sample box (8) and a RFID marking tag (9). The soil sample marking management module (1) is used for acquiring soil sample information, and transmitting the acquired soil sample information to the tag read-write module (4); the tag read-write module (4) is used for writing the soil sample information into the RFID marking tag (9); the tag read-write module (4) and the soil sample box (9) both are located in the sampling drill (6); and the RFID marking tag (9) is located on an external surface of the soil sample box (8). The RFID-based soil sampling and automatic marking device can implement high-efficiency soil sampling and automatic marking of soil sample information.

Owner:CHINA AGRI UNIV

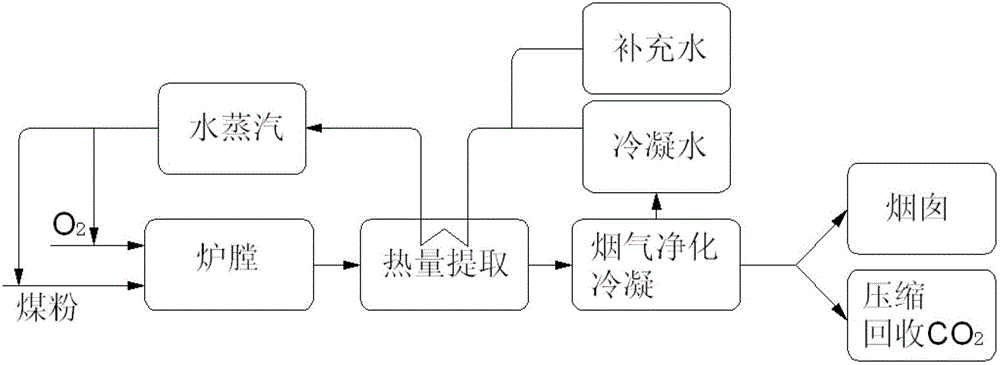

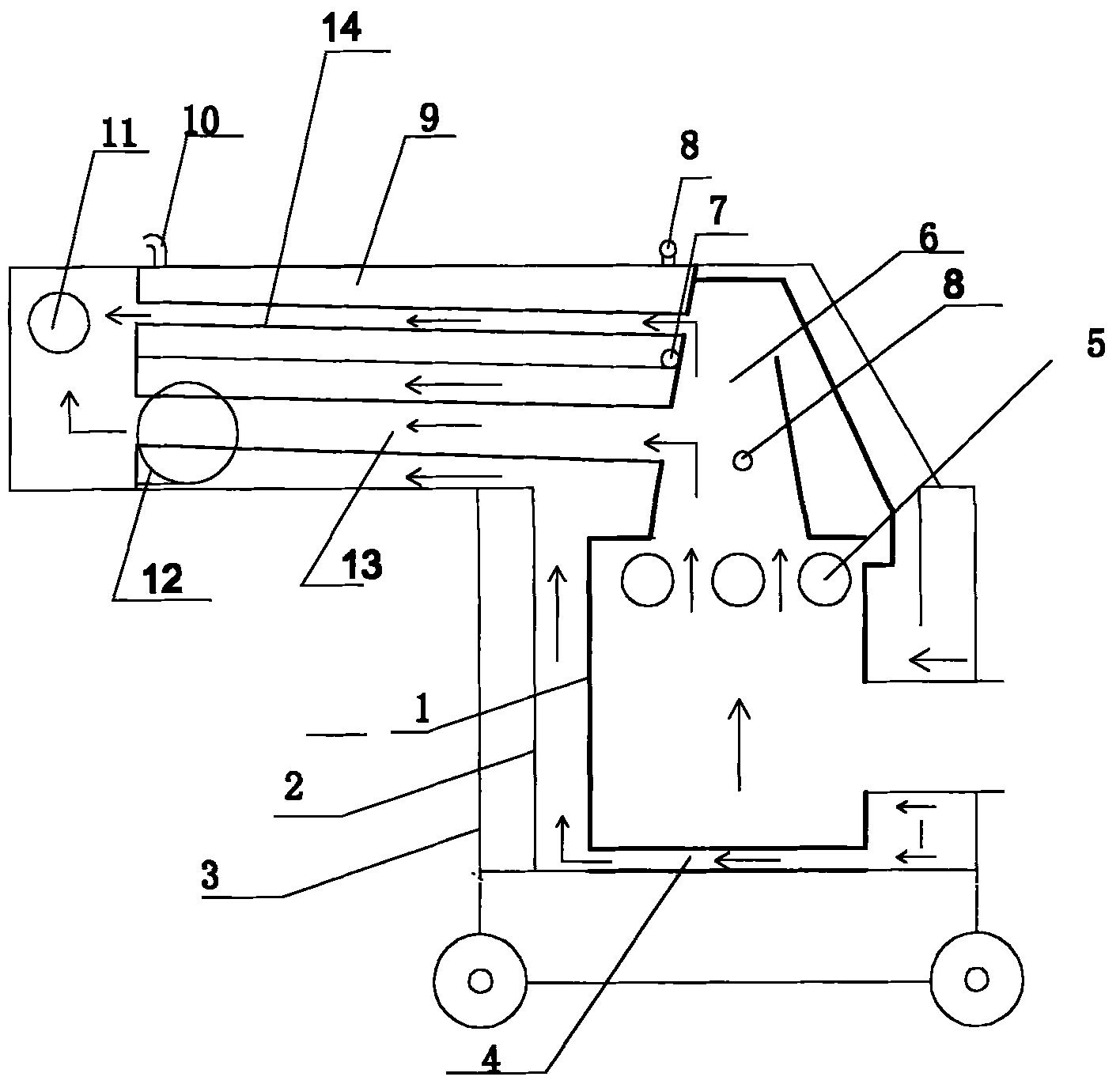

Water vapor circularly adjusting type oxygen-enriched combustion method for pulverized coal boiler

ActiveCN103062745AReduce usageReduce the impact of spillsIndirect carbon-dioxide mitigationNon-combustible gases/liquids supplyHigh concentrationWater vapor

The invention discloses a water vapor circularly adjusting type oxygen-enriched combustion method for a pulverized coal boiler. The method is characterized in that in the whole oxygen-enriched combustion process, smoke generated by combustion is sequentially subjected to heat energy extraction, purification and condensation treatment, condensate water obtained after condensation treatment is heated to be converted into water vapor by using extracted heat energy, and a part of the water vapor is used as primary air to be fed into a boiler chamber of the pulverized coal boiler; and the rest of the water vapor is mixed with oxygen to serve as secondary air to be fed to the boiler chamber of the pulverized coal boiler. The invention further discloses other oxygen-enriched combustion modes by using the water vapor to execute circulation adjustment. By means of the water vapor circularly adjusting type oxygen-enriched combustion method and other oxygen-enriched combustion modes, problems that smoke with high concentration CO2 is difficult to obtain, pollutants of NOx, SO2 and the like are high in concentration and switching of starting and stopping of a system is complicated in prior art are solved, and the water vapor circularly adjusting type oxygen-enriched combustion method is particularly suitable for being used in occasions of pulverized coal boilers and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

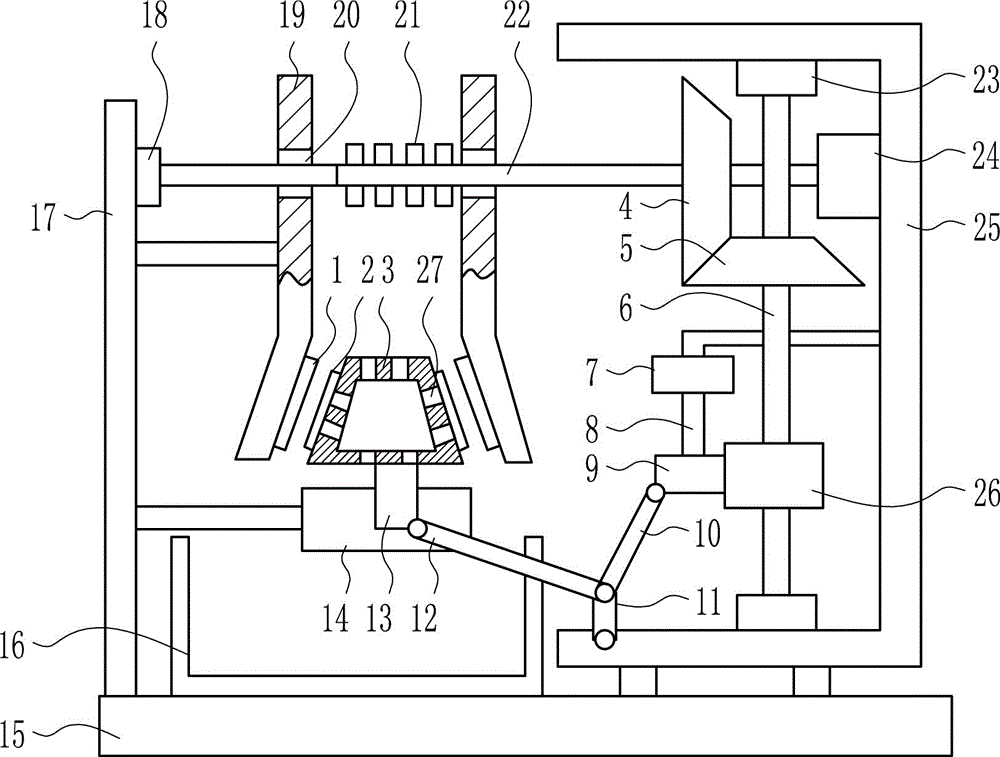

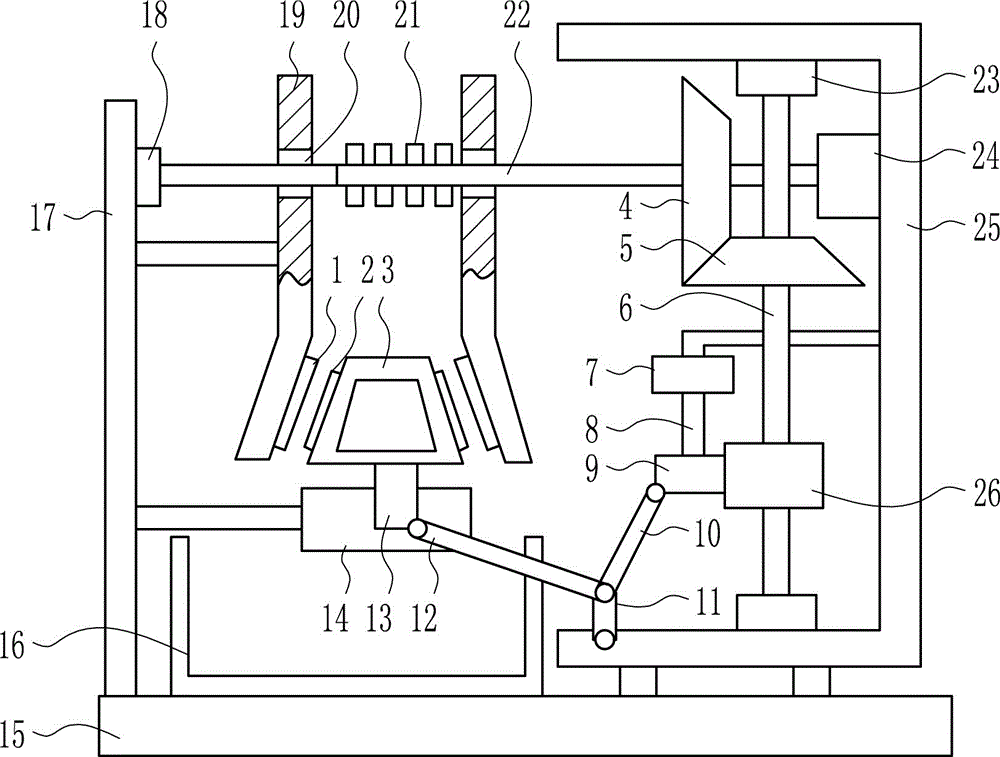

Environment-friendly waste paper multistage breaking device

The invention relates to a waste paper breaking device, in particular to an environment-friendly waste paper multistage breaking device. The environment-friendly waste paper multistage breaking device achieves the technical aims of being thorough in breaking, high in environment-friendly degree and high in practicability and comprises a second blade, a third blade, a trapezoid block, a first conical gear, a second conical gear, a first rotating rod, a small gear, a second connecting rod, a swing rod, a first connecting rod, a sliding block, a sliding rail, a base, a collection box, a left frame, a third bearing pedestal, a breaking box, a first blade, a third rotating rod, a first bearing pedestal, a speed reduction motor, a U-shaped frame, a large gear and the like. The left side of the top of the base is connected with the left frame. The effects of being thorough in breaking, high in environment-friendly degree and high in practicability are achieved. When the device is used for doing waste paper breaking work, waste paper can be cut thoroughly, and the chopping effect is better.

Owner:山西强伟纸业有限公司

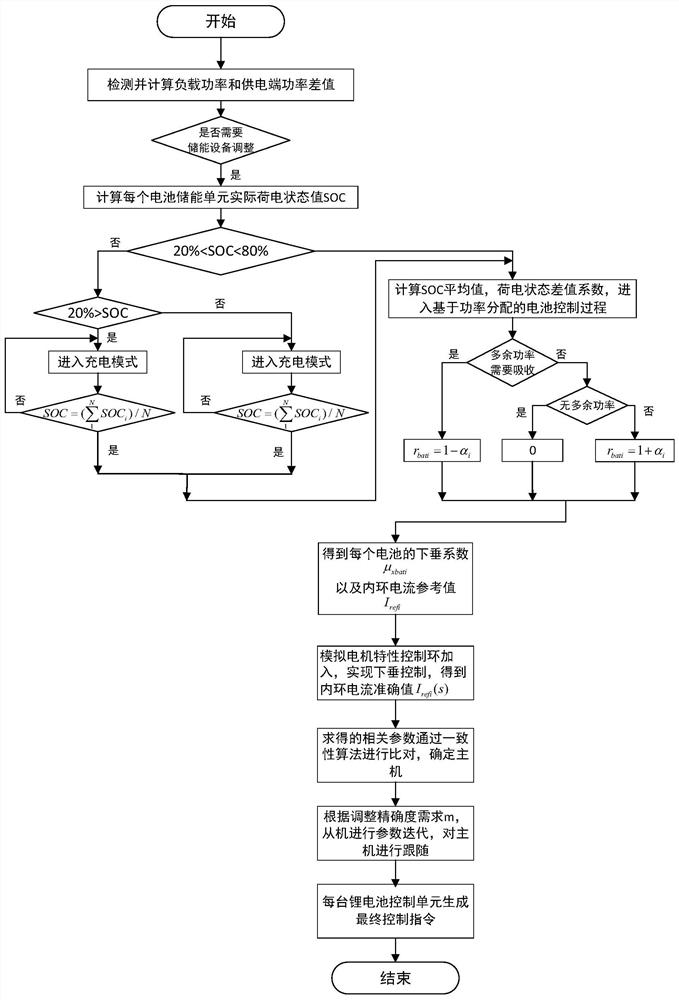

Multi-agent lithium battery cluster energy storage system

PendingCN111969693AExtended service lifeFlexible adjustment of master-slave relationshipBatteries data exchangeElectric powerControl engineeringState of charge

The invention provides a multi-agent lithium battery cluster energy storage system. According to the system, a mathematical model is established through rated capacities, actual capacities and output / input characteristics of different types of lithium batteries; each lithium battery energy storage unit forming the cluster system is provided with a communication module and an analysis module, can realize mutual communication and has certain functions of data processing and analysis and instruction receiving and sending. According to the lithium battery cluster energy storage system, a double-loop control mode is adopted, an inner loop is a self-adjusting loop based on a single module, self-feedback is carried out according to parameters such as the state of charge and the temperature, and then power adjustment is achieved. The outer ring is a system adjusting ring, the battery which most meets the operation requirement in the same kind of batteries is set as a host through mutual communication between the lithium batteries, and based on the consistency principle, other lithium battery packs in the system are controlled to perform self-adjustment, so that the energy storage or energyrelease power of the lithium battery packs is approximately consistent with the ratio of the charge-discharge margin. On the premise of ensuring safety, stable and efficient operation of the energy storage system is realized.

Owner:FOSHAN POWER SUPPLY BUREAU GUANGDONG POWER GRID

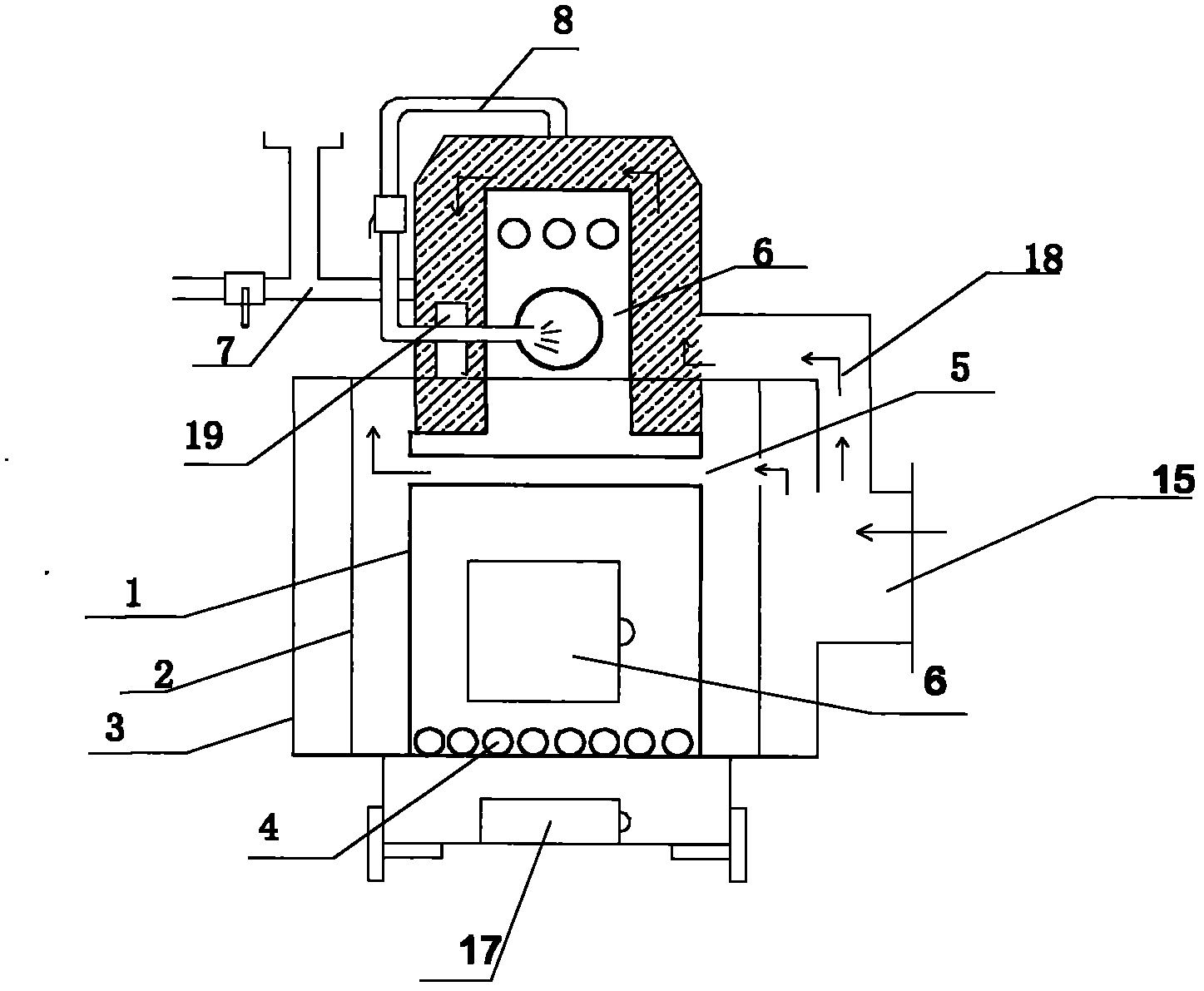

Humidifying air heating furnace

InactiveCN102563859AReduce lossesImprove heat exchange efficiencyAir heatersNon-combustible gases/liquids supplyCold airCombustion chamber

Disclosed is a humidifying air heating furnace. An intermediate-layer sleeve container is arranged on the outside of an inner container, an outer-layer sleeve container is disposed on the outside of the intermediate-layer sleeve container, ventilating malleable cast iron fire bars are disposed on the lower portion of the inner container, malleable cast iron radiating pipes are arranged on the upper portion of the inner container, a secondary combustion chamber is further disposed above the inner container, a water tank and a hot air outlet are disposed on the left side of the secondary combustion chamber, a water adding opening and an indoor auxiliary humidifying opening are disposed on the outside of the water tank, a water tank heating pipe is arranged in the water tank, a hot air heating pipe is arranged inside the hot air outlet, a smoke outlet is disposed on the left side of the water tank, a snail type air blower connecting opening is arranged on the outer-layer sleeve container, and a secondary combustion chamber radiating air inlet channel is arranged above the air blower connecting opening. Air is induced by an induced draft fan to realize combustion supporting, after the temperature of the furnace exceeds 50 DEG C, an air blower delivers cold air to an air channel between the outer-layer sleeve container and the intermediate-layer sleeve container, the cold air is respectively delivered to the surface of the inner container, the ventilating fire bars and the malleable cast iron radiating pipes, and hot air is delivered from a hot air zone to a cultivation room via the air outlet. The humidifying air heating furnace has the advantages that heat exchange efficiency is high, temperature rise is fast, noise is low, smoke leakage is avoided, heat-insulation and energy-saving effects are good, and the humidifying air heating furnace is simple in operation and convenient in maintenance.

Owner:潍坊康富养殖设备有限公司

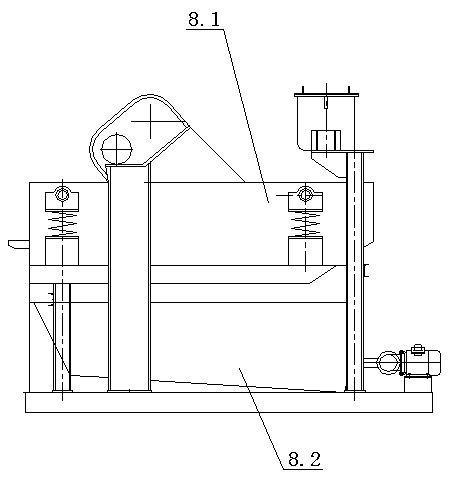

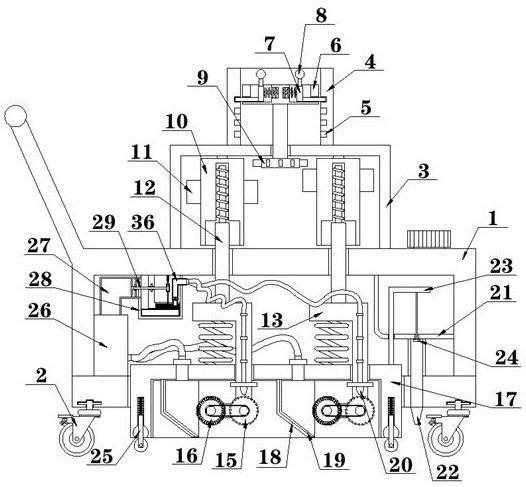

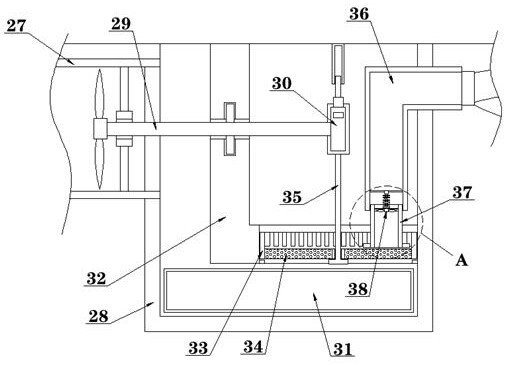

Sludge dredging processing equipment and method for urban sewer line

ActiveCN105507419AEfficient dehydrationNo pollution in the processSludge treatment by de-watering/drying/thickeningSewer systemsSeparation technologySludge

The invention provides sludge dredging processing equipment and method for an urban sewer line. The sludge dredging processing equipment comprises a frame, wherein the frame is provided with a submersible pump; the submersible pump is connected with a slicing machine; the slicing machine is connected with a medicine-mixed sludge stirrer; the medicine-mixed sludge stirrer is connected with a sewage separation tower; the sewage separation tower is connected with a sludge pump I; the sludge pump I is connected with a distributing device; the distributing device is connected with a separation agent medicine stirrer and an addition pump; the separation agent medicine stirrer and the addition pump are connected with a high-frequency sludge screen; the high-frequency sludge screen is connected with the sludge pump II; the sludge pump II is connected with a flocculant medicine stirrer and the addition pump; the flocculant medicine stirrer and the addition pump are connected with a filter press; and corresponding chemical agents are added to the separation agent medicine stirrer, the addition pump, the flocculant medicine stirrer and the addition pump respectively. According to the device and method, a quick separation technology of sewage and sludge is achieved; the volume of the equipment is reduced; movement convenience of the equipment is achieved; the manual labor of a worker is relieved; the environmental pollution is improved; and the adaptability is good.

Owner:XUZHOU YUANDA SCI & TECH DEV

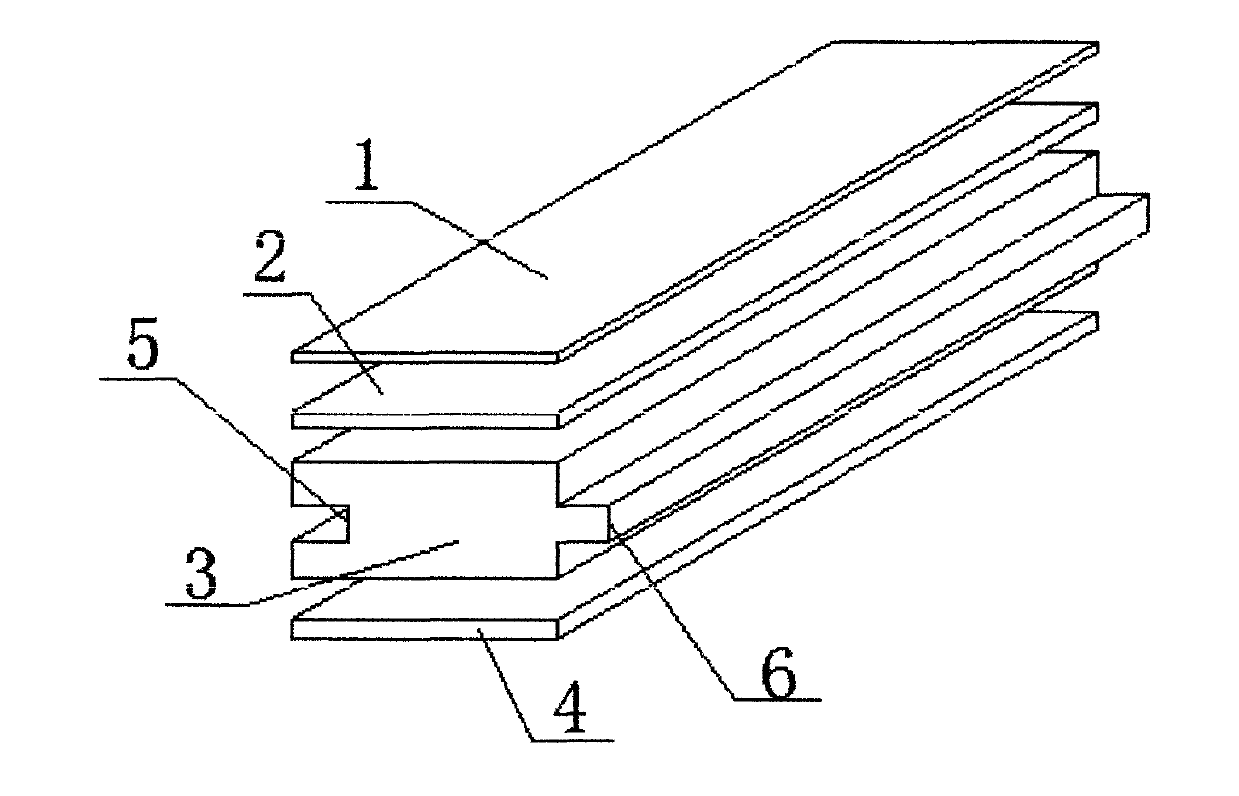

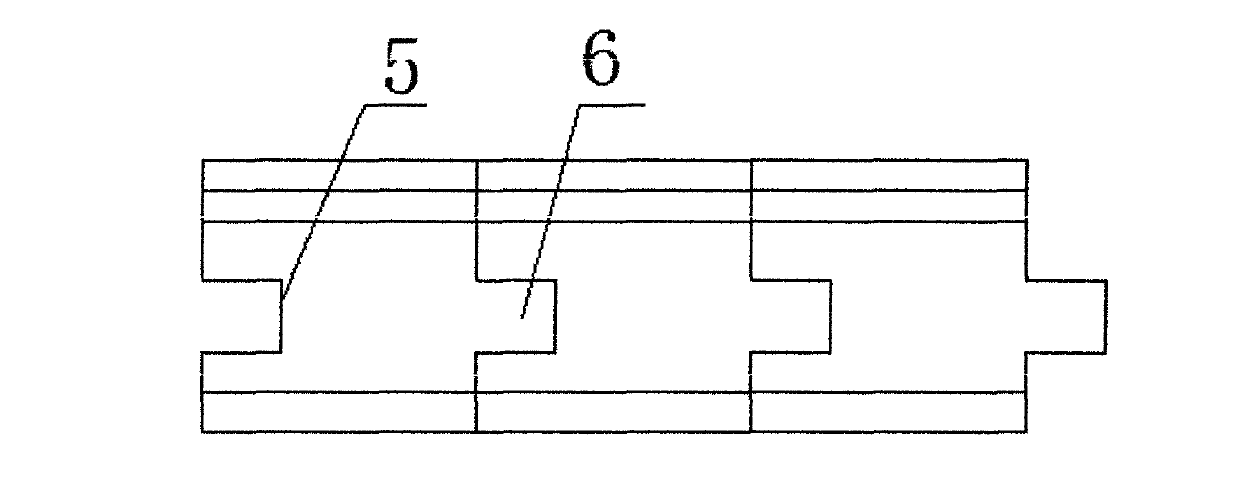

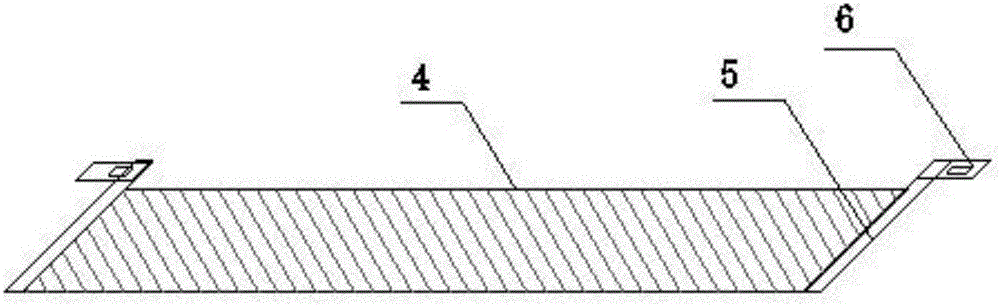

Expandable polystyrene (EPS) waterproof and sound insulation type composite wood floor

InactiveCN103122687AReduce deforestationImprove waterproof performanceSynthetic resin layered productsPaper/cardboard layered productsEnvironmental resistanceEcological environment

The invention discloses an expandable polystyrene (EPS) waterproof and sound insulation type composite wood floor. The EPS waterproof and sound insulation type composite wood floor comprises a wearing layer, a decorating layer, a base material layer and an equilibrium layer. The layers are sequentially stacked through binder. The EPS waterproof and sound insulation type composite wood floor has the advantages that with the adoption of the EPS waterproof and sound insulation type composite wood floor, cutting down of trees is reduced, application of chemical material is reduced, ecological environment is protected, and the EPS material is recoverable material, and environmental protection degree of the EPS waterproof and sound insulation type composite wood floor is further strengthened, meanwhile, the EPS material has good water proof performance and sound insulation performance, the composite wood floor is enabled to have water proof and sound insulation effect in the true sense, structure is simple, utilization and installation are convenient and the like, and promotion and utilization in daily life is suitable.

Owner:王程皓

Vacancy perovskite material-based solar cell and preparation method thereof

PendingCN111987221AGood chemical stabilityImprove stabilitySolid-state devicesSemiconductor/solid-state device manufacturingMetallic electrodeTitanium zirconium

The invention discloses a perovskite solar cell taking vacancy perovskite as a perovskite light absorption layer, and mainly solves the problems of poor toxicity, poor stability and low light absorption coefficient of an existing perovskite light absorption layer. The perovskite solar cell comprises a transparent conductive substrate, an electron transport layer, a perovskite absorption layer, a hole transport layer and a metal electrode from bottom to top. The perovskite light absorption layer adopts a composite material with a chemical formula of A2BXmY6-m composed of cations A, cations B, anions X and anions Y, wherein A is one or more of potassium, rubidium or cesium, B is one or more of molybdenum, tungsten, titanium, zirconium, hafnium, germanium, tin, iridium, platinum, palladium and gold, X and Y are chlorine, bromine or iodine, and m is 1-6. According to the invention, the toxicity of the perovskite light absorption layer is eliminated, the light absorption coefficient is improved, the photoelectric conversion performance and stability are improved, and the perovskite solar cell can be used for photoelectric conversion in the fields of photovoltaic transformer stations, artificial satellites, household solar energy and the like.

Owner:XIDIAN UNIV

Warning device used in surveying and mapping

InactiveCN106097643AAdapt to a wide range of scenariosHigh degree of environmental protectionPhotovoltaic supportsBatteries circuit arrangementsPush outElectric energy

The invention relates to the field of surveying and mapping, and specifically relates to a warning device used in surveying and mapping. The warning device comprises a base, moving wheels, an open groove, a solar cell panel, an electric telescopic rod, a drive device, a telescopic arm, a warning sign, a photosensitive sensor, a human body sensor, a power supply, and an alarm. The warning device is applicable to a wider range of scenes, and different fonts can be set in order to adapt to corresponding scenes. External light is detected using the photosensitive sensor. When a light signal is detected, the photosensitive sensor makes the drive device started, the drive device drives the electric telescopic rod to stretch out, and the solar cell panel connected to the electric telescopic rod is pushed out. Solar energy is used as the electric energy of the warning device, and the degree of environmental protection is high. The human body sensor detects whether there is a human body signal around the warning device and makes the alarm sound when detecting a human body signal approaching, and a very eye-catching warning effect is achieved.

Owner:河南华泰规划勘测设计咨询有限公司

Method for producing nano cerium oxide under supergravity action

InactiveCN108658117AAchieve strict controlParticle size controllableRare earth metal oxides/hydroxidesNanotechnologyCeriumSolvent

The invention discloses a method for producing nano cerium oxide under the supergravity action. In a supergravity field, cerous nitrate or cerium chloride is used as a raw material, an alkaline liquidsuch as urea and ammonium bicarbonate is used as a uniform precipitant, a precursor is prepared in deionized water by controlling the pH value of a reaction solution, impurity removal and neutralization of the precursor are realized through ultrasonic washing, and nano cerium oxide particles are prepared finally through firing. The particle size and the distribution condition of the precursor arestrictly controlled by use of the improved supergravity method and control of the precipitation environment, so that the particle size distribution condition of the finally product, namely, nano cerium oxide particles, is strictly controlled, and the nano cerium oxide particles with controllable particle size and very narrow distribution are obtained. The homogenous precipitation process can be realized in polar solvent deionized water in a breakthrough manner, the production process is safe and reliable, the reliability is significantly improved, and the method is applicable to industrial production.

Owner:德昌县志能稀土有限责任公司

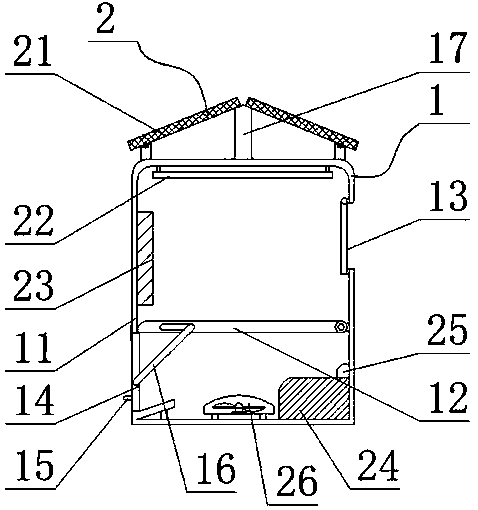

Clothing recovery box with functions of convenient taking and overall drying

InactiveCN108545369AGuaranteed second useThe impact of secondary useWaste collection and transferRefuse receptaclesMildewEngineering

The invention is suitable for the field of environment-friendly devices, and provides a clothing recovery box with the functions of convenient taking and overall drying. The clothing recovery box comprises a supporting assembly and a functional assembly. The supporting assembly comprises a recovery box body, a partition plate, an inlet baffle, an outlet baffle, a gripping handle, a transmission rod and a supporting seat. The partition plate is arranged and rotationally connected to the recovery box body, keeps balanced through the outlet baffle, and rotates along with opening and closing of the outlet baffle through the transmission rod; when the outlet baffle is opened, the partition plate is inclined so as to conveniently take recovery clothing, and thus the working efficiency is improved; and after the clothing is thrown into the recovery box body to be accumulated, a fan arranged on the lower surface of partition plate can blow air to the clothing on the bottom surface through holes formed in the partition plate, so that the clothing keeps ventilating drying overall, and the situation that secondary using of the clothing is affected by moist mildew is avoided.

Owner:嘉兴市亚联科技有限公司

Environment-friendly fireproof coating and preparation method thereof

The invention mainly relates to the technical field of fireproof coatings, in particular to an environment-friendly fireproof coating and a preparation method thereof.The environment-friendly fireproof coating comprises a coating base material and a fire extinguishing agent microcapsule, and the fire extinguishing agent microcapsule is broken after being exposed to the temperature not lower than 75 DEG C and / or an open fire environment and can be vaporized to release a fire extinguishing material to achieve the purposes of cooling and / or fire prevention and / or fire extinguishment. In order to break through the current situation that the traditional fireproof, fire-extinguishing and flame-retardant coating can only prevent spreading of an ignition area but is difficult to sensitively and actively extinguish fire in a short time, the invention provides a plurality of coatings and / or coating films which can actively cool, prevent fire and extinguish fire, have short response time, stably exist fire-extinguishing components in the coatings and / or coating films and can be repeatedly triggered to extinguish fire.

Owner:浙江铭诺新材料科技有限公司

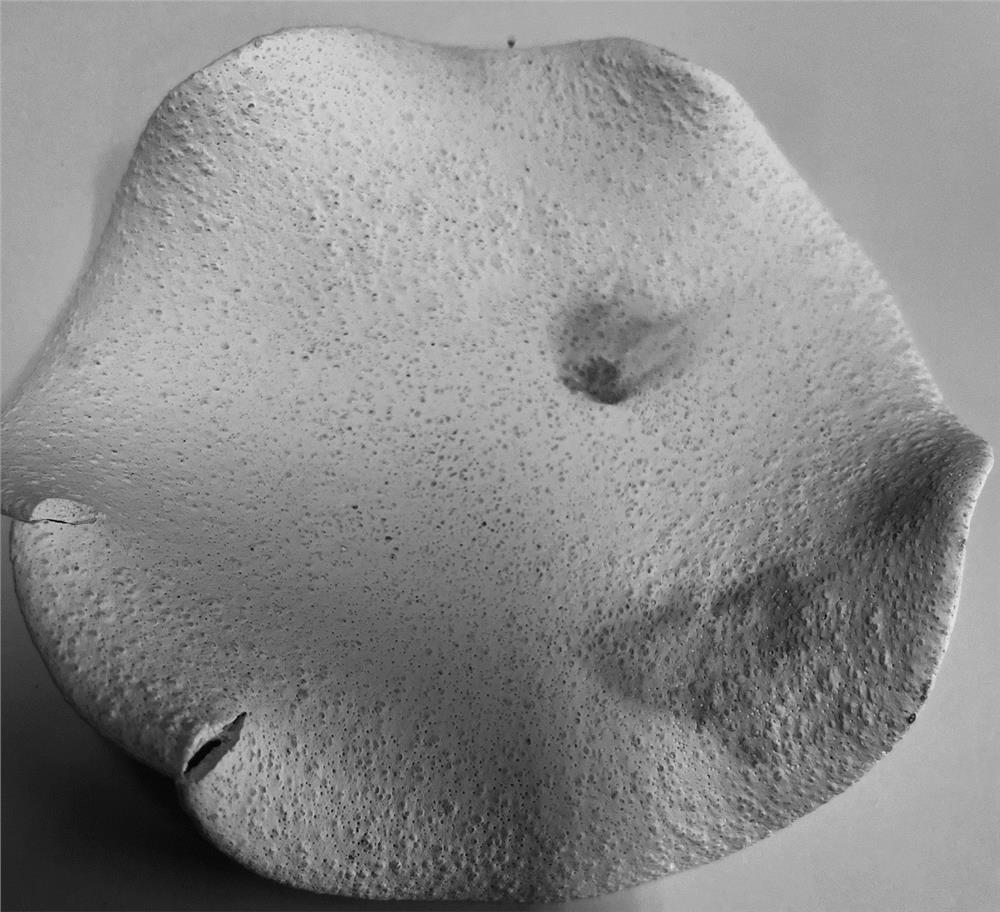

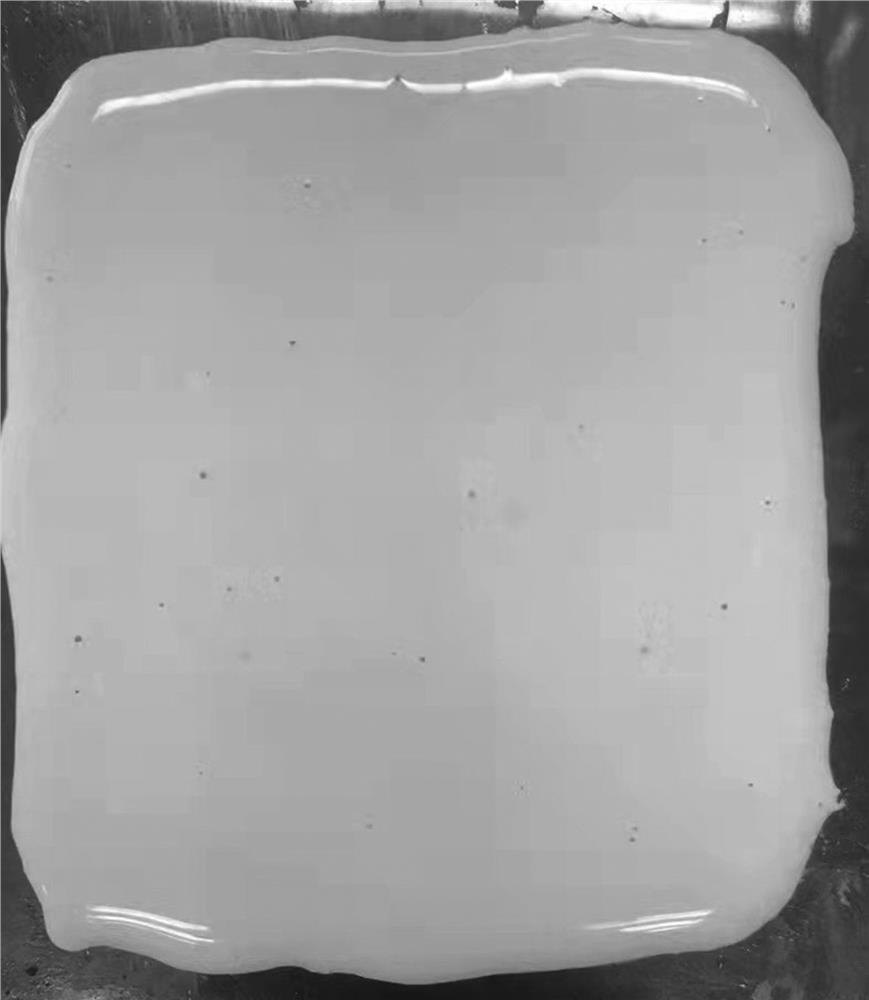

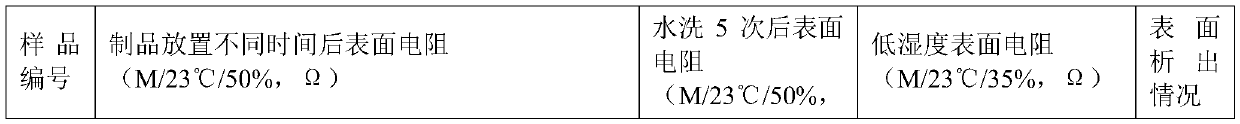

Low-additive-amount long-acting low-humidity-resistant washable polyvinyl chloride special antistatic agent

The invention relates to the field of antistatic agents, and discloses a low-additive-amount long-acting low-humidity-resistant washable polyvinyl chloride special antistatic agent and a preparation method thereof. The antistatic agent is prepared from components in percentage by mass as follows: 5%-35% of an anionic surfactant, 0%-25% of a cationic surfactant, 0%-25% of an ionic compound, 15%-35%of alkanolamide and / or a derivative nonionic surfactant thereof, 10%-30% of a dispersing agent and 5%-18% of a functional aid, wherein at least one of the cationic surfactant and the ionic compound exists. The liquid antistatic agent is light in color, transparent and low in viscosity, after a small amount of the liquid antistatic agent is added to a PVC matrix, the transparency and mechanical properties of the PVC product are hardly affected, and the obtained product has excellent antistatic performance and can still keep good, lasting and stable antistatic performance in a low-temperature and low-humidity environment and is excellent in washing resistance.

Owner:杭实科技发展(杭州)有限公司

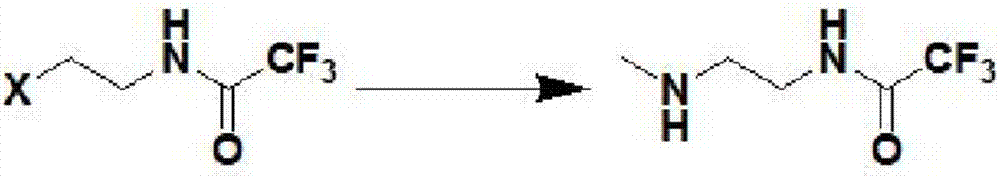

Process for preparing N-methyl homopiperazine from 2-haloethylamine compound

InactiveCN107382883AHigh degree of environmental protectionImprove the safety of production operationsOrganic chemistryEthylenediamineTrifluoroacetic acid

The invention discloses a process for preparing N-methyl homopiperazine from 2-haloethylamine compound, and the process comprises the following steps: Step 1, taking the 2-halogenated ethylamine compound as a raw materia to react with ethyl trifluoroacetate to obtain N-(2-Haloethyl) trifluoroacetamide; Step (2) taking the N-(2-Haloethyl) trifluoroacetamide as a raw material to react with methylamine or methylamine hydrochloride to obtain N-methyl-N'-trifluoroacetyl ethylenediamine; Step (3) taking the N-methyl-N'-trifluoroacetyl ethylenediamine as a raw material to react with 1,3-disubstituted propane compound to obtain N-methyl-N'-trifluoroacetyl homopiperazine; Step (4) taking the N-methyl-N'-trifluoroacetyl homopiperazine as a raw material to react with a hydrogen chloride ethanol solution to obtain N-methyl homopiperazine dihydrochloride; and Step (5) taking the N-methyl homopiperazine dihydrochloride as a raw material to prepare the N-methyl homopiperazine by alkalization. The process has the advantages of simple operation, low cost, high yield, low pollution and suitability for industrialized production.

Owner:SUZHOU BAILINGWEI HYPERFINE MATERIAL

Environment-friendly garbage can for municipal construction

PendingCN107499771ASave waterHigh degree of environmental protectionRefuse receptaclesPistonEngineering

The invention belongs to the technical field of municipal construction, and particularly relates to an environment-friendly garbage can for municipal construction. The environment-friendly garbage can comprises a can lid, a side plate, a can base and a circulation module. The can lid comprises a handle, a can lid plate, a screw cap, a rotary shaft, a piston, elastic rods, cleaning brushes, a sucking module, extension springs and a sleeve ring. The can lid plate is hinged to the side plate. The handle is located above the can lid plate and fixedly connected with the can lid plate. The screw cap is located above the rotary shaft. The rotary shaft is located above the piston and fixedly connected with the piston. The cleaning brushes are connected with the rotary shaft through the elastic rods. The sucking module is located between the rotary shaft and the elastic rods. The extension springs are located between the rotary shaft and the elastic rods. The sleeve ring is located below the rotary shaft and connected with the cleaning brushes through buckles. According to the environment-friendly garbage can, the circulation module is matched with the can lid, thus, the automatic sewage cleaning function and the can lid cleaning function are achieved, the can lid is easy to clean, the appearance of the garbage can is improved, and then the city appearance is improved.

Owner:宿州冬宇环保科技有限公司

Holographic paper information anti-counterfeit label

InactiveCN104751735ASolve non-degradableOvercoming the problem of not being able to print barcodesStampsIdentification meansBiochemical engineeringPaper based

The invention provides a holographic paper information anti-counterfeit label and belongs to the field of anti-counterfeit labels. The holographic paper information anti-counterfeit label comprises a paper base layer; base paper, an adhesive layer, a coloring layer, an anti-counterfeit code layer and an isolation layer are arranged below the paper base layer from bottom to up in turn; a holographic layer, a printing layer, a variable digital layer and a protection layer are arranged above the paper base layer from bottom to top in turn; the holographic layer can be degraded and cannot be utilized again. According to the holographic paper information anti-counterfeit label, the problem that the anti-counterfeiting is cracked can be solved due to the multiple anti-counterfeiting.

Owner:SHANDONG TAIBAO PREVENTING COUNTERFEIT

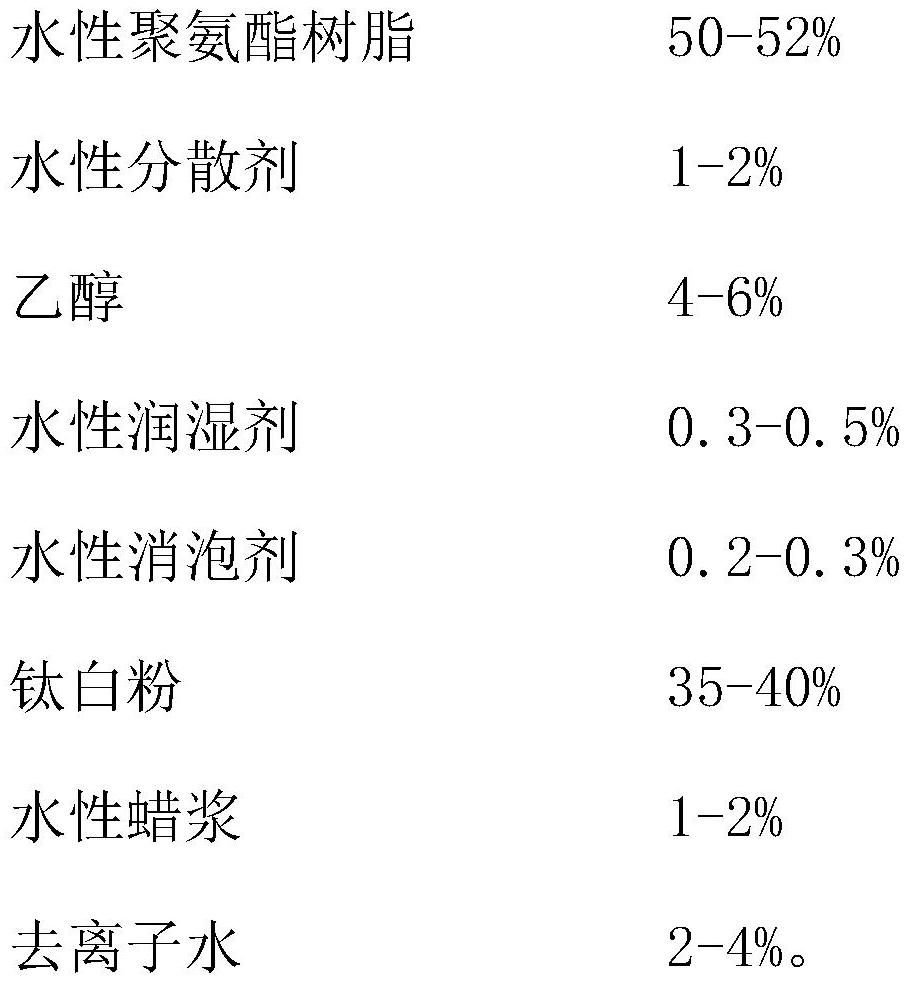

Water-based gravure white ink for film printing and preparation method of water-based gravure white ink

The invention provides water-based gravure white ink for film printing and a preparation method of the water-based gravure white ink, and the water-based gravure white ink is prepared from 50-52% of water-based polyurethane resin, 1-2% of a water-based dispersing agent, 4-6% of ethyl alcohol, 0.3-0.5% of a water-based wetting agent, 0.2-0.3% of a water-based defoaming agent, 35-40% of titanium dioxide, 1-2% of water-based wax slurry and 2-4% of deionized water. According to the gravure white product, through reasonable formula proportion and no addition of any solvent harmful to human bodies in the production process, VOC emission is greatly reduced, the odor of the product is reduced, a traditional solvent type gravure white product is replaced, and the gravure white product is good in film material adhesive force, good in wear resistance, high in color and luster, quick to dry and low in residual odor, and can be printed on the product, so that the gravure white product has a good application prospect. And the printing requirement is met, and meanwhile the environment-friendly degree is improved.

Owner:中山市中益油墨涂料有限公司

Environment-friendly joint cutting device capable of controlling joint cutting depth for bridge road construction

ActiveCN113529554ACutting depth controllableExtended service lifeDispersed particle filtrationRoad cleaningGear wheelEngineering

The invention discloses an environment-friendly joint cutting device capable of controlling the joint cutting depth for bridge road construction, and belongs to the technical field of road construction. The environment-friendly joint cutting device comprises a mounting box, a displacement wheel, a mounting frame, a limiting frame and a cutting wheel, wherein the displacement wheel is arranged on the lower surface of the mounting box, and a hose is connected between an air outlet pipe and a cooling head. According to the environment-friendly joint cutting device capable of controlling the joint cutting depth for bridge road construction, a rotating ring which can be held to rotate can drive an adjusting block to rotate through an adjusting gear when the rotating ring rotates, and the adjusting block is in threaded connection with a displacement rod to drive the displacement rod and a mounting rod to slide downwards, and then the cutting depth of the cutting wheel mounted at the lower end of the mounting rod is changed. By means of the mode that the adjusting gear can be alternately clamped with two adjusting blocks or clamped with the two adjusting blocks at the same time when sliding up and down, the two cutting wheels can cut into the road surface at different depths, and then the needed depth is obtained through cutting in two times, so that the edge of the cutting joint is neat, attractive and not easy to crack, and the service life of the pavement is prolonged.

Owner:SHANDONG LUQIAO GROUP

Environmentally friendly industrial anti-falling type van

InactiveCN106697025AExtended service lifeCushion the shockSupporting partsHand carts with multiple axesEnvironmental engineeringPollution

The invention relates to an industrial van, in particular to an environmentally friendly industrial anti-falling van. The invention aims to provide the environmentally friendly industrial anti-falling van which is high in anti-falling property, high in environmental friendliness degree and high in practicability. In order to solve the technical problem, the environmentally friendly industrial anti-falling van is provided and comprises a water inlet tube, a water absorbing tube, a water pump, a water outlet tube, a water tank, a hard water tube, a first steel wire rope, a sliding track,, a first electric wheel, a second electric wheel, a second steel wire rope and the like; and a supporting plate is in contact with the rear wall of a van head, the upper part of the right side of the supporting plate is connected with the sliding track, a first sliding block is arranged on the sliding track, a spring is connected between the first sliding block and the left end of the sliding track, and the first electric wheel is arranged on the right part of the front side of the sliding track. The environmentally friendly industrial anti-falling van is high in anti-falling property, high in environmental friendliness degree and high in practicality. By the van, the working efficiency can be improved, pollution of dust to air is reduced, and the effect of protecting the environment is achieved.

Owner:盛江

Efficient controllable sewage treatment equipment for factory

InactiveCN111807547AEfficient outputHigh degree of environmental protectionTreatment involving filtrationMultistage water/sewage treatmentBeam tubeWater use

The invention discloses efficient controllable sewage treatment equipment for a factory. The equipment structurally comprises a star-jet aeration pipe cylinder, a pressure gauge, a plunger seat cap, apurification tank, a pressure discharge pipe, a flow guide pipe and a sedimentation tank. The cooperation of the star-jet aeration pipe cylinder and the purification tank is realized, the purification tank is connected with a star beam pipe frame on the rear side of an aeration pipe horizontal cylinder to be communicated with water flow, the water quality monitoring sensing operation is carried out by a shunting detection tank, pipeline aeration lifting branch pipe treatment is adapted in the later period, a trace amount of controllable polluted water source enters an aeration integration star beam tube rack, a purified water source is used for quantizing the communication effect of an edge side frame pipeline, a disc frame type swirling through pipe star-jet connecting pipe aeration operation after water flow monitoring and separation is guaranteed, the oxidation circulation efficiency is improved, a whole fluidized bed type oxygen channel obtains an effective frame folding propelling effect, the circulation quantification work effect of later-period factory controllable sewage treatment is facilitated, and the continuous supply efficiency of later-period factory water is improved.

Owner:广州蓝清环保工程有限公司

Flexible circuit board manufacturing process and flexible circuit board

InactiveCN110267450AHigh degree of environmental protectionLow costConductive pattern formationCost savingsEngineering

The invention provides a flexible circuit board manufacturing process and a flexible circuit board. The manufacturing process comprises the steps of mixing a conductive material and a high-molecular material to obtain a mixture; forming a hollowed-out part on a substrate, wherein the hollowed-out part is consistent with a conductive circuit in shape; laying the mixture in the hollowed-out part; and carrying out high-temperature heating on the substrate laid with the mixture, and drying the mixture. According to the manufacturing process provided by the invention of the flexible circuit board, the whole manufacturing process does not involve a chemical corrosion process, so that it is necessary to adopt a chemical reagent, the whole manufacturing process is high in environmental protection degree and does not produce sewage. Meanwhile, compared with the traditional process in which corrosion is carried out after the conductive material is completely laid, the manufacturing process provided by the invention does not involve the waste of the conductive material, thereby being more cost saving.

Owner:江门市华浦照明有限公司

Composite fiber artificial board and manufacturing method thereof

InactiveCN106994730AHigh degree of environmental protectionImprove water resistanceWood working apparatusDomestic articlesSolid componentFiber

The invention discloses a composite fiber artificial board and a manufacturing method thereof. The composite fiber artificial board is formed by bamboo fibers, wood fibers, polyacrylamide resin and paraffin; ionicity of the polyacrylamide resin is bisexual, according to the molar ratio being 6.5:2-2:6.5, a monomer with a cationic basic group and a monomer with an anionic basic group are contained, the molecular weight ranges from 800 thousands to 3000 thousands, and the ionicity of the paraffin is the positive ion. In addition, according to the manufacturing method of the composite fiber artificial board, slurry is prepared according to the manner that the solid component mass percent concentration ranges from 3% to 4%, and the pH ranges from 3 to 5; and only the polyacrylamide resin and the paraffin are added into the slurry. The static bending intensity and the tensile strength of the composite fiber artificial board reach and even exceed those of a natural wood board, the composite fiber artificial board can completely replace the natural wood board, and even can replace a bakelite board and a plastic board, the environment-friendly degree is high, and the water resistance is good.

Owner:广西贵港市长雄干燥科技有限公司

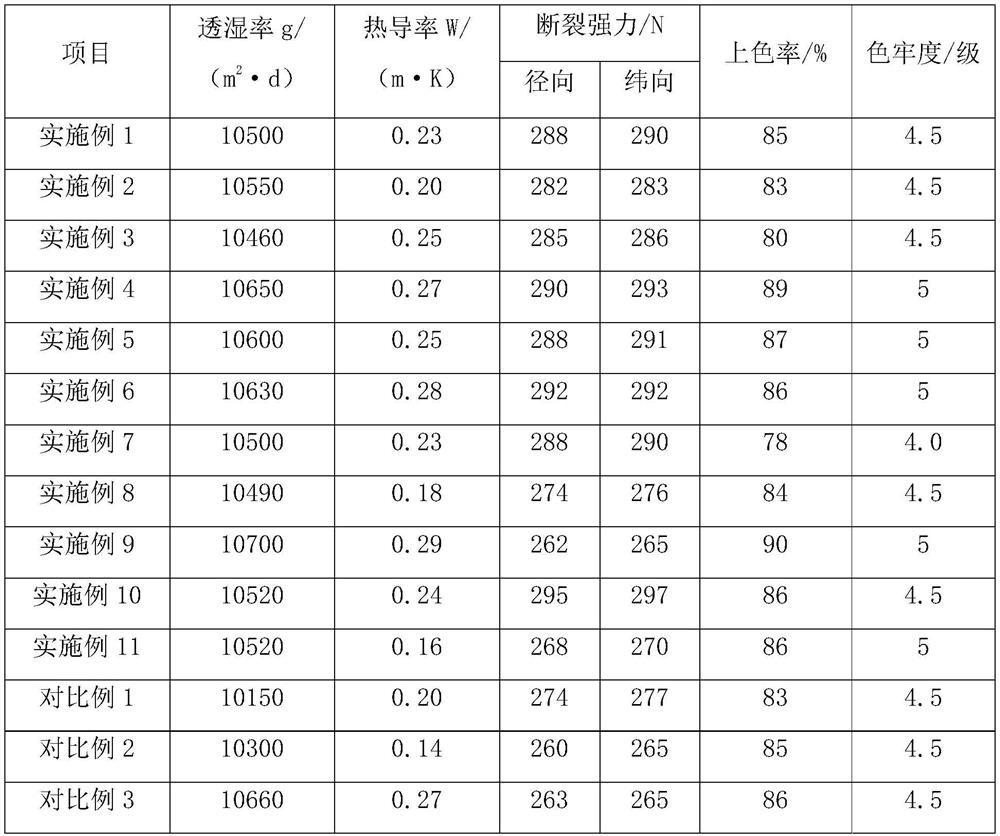

Preparation process of a cool-feeling three-dimensional spacer knitted fabric and its knitted fabric

This application relates to the field of textiles, and specifically discloses a preparation process of a cool-feeling three-dimensional interval knitted fabric and the knitted fabric; the preparation process includes the following steps: preparing ultra-high molecular weight polyethylene fiber filaments by using the stock solution coloring method, and preparing modified fabrics by using mica powder. Polyester fiber yarn; weaving nylon fiber yarn, viscose fiber yarn, ultra-high molecular weight polyethylene fiber yarn, and modified polyester fiber yarn into gray cloth; polyethylene fiber accounts for 15%-25% of the total weight of the gray cloth, and modified polyester fiber Accounting for 5%-15% of the total weight of the gray cloth, nylon fiber accounting for 20%-30% of the total weight of the gray cloth, viscose fiber accounting for 40%-50% of the total weight of the gray cloth; The method prepares cool-feeling three-dimensional interval knitted fabric; it has the advantages of good thermal conductivity, good moisture absorption performance, good dyeing rate, and high color fastness, so that the clothes or mattresses and other fabrics prepared by it can give people a cool and dry feeling when used. .

Owner:山东针巧经编有限公司

Ozone reduction module and air purifier

PendingCN112762560ALong-lasting and effective restoring abilityAvoid secondary pollutionMechanical apparatusLighting and heating apparatusAir purifiersProcess engineering

The invention relates to the technical field of air purifiers, in particular to an ozone reduction module and an air purifier. The ozone reduction module comprises: a reduction net, wherein the reduction net is configured to be of a hollow-out structure, air passing holes are formed in at least partial area of the reduction net, and the reduction net is suitable for being heated to X DEG C in a power-on state; and an insulating frame, wherein the insulating frame is made of an insulating material, at least part of the insulating frame surrounds the reduction net, the insulating frame is suitable for supporting the reduction net, and X >= 0. According to the ozone reduction module provided by the invention, by arranging the hollow-out reduction net and heating the reduction net in a power-on state, air can flow through the air passing holes of the reduction net, so that ozone is reduced and decomposed by high temperature when the ozone passes through the reduction net, the purification efficiency is kept stable, consumables do not need to be replaced, the user cost is saved, the environmental protection degree is higher, and secondary pollution of ozone to air is avoided.

Owner:GREE ELECTRIC APPLIANCES INC

Water vapor circularly adjusting type oxygen-enriched combustion method for pulverized coal boiler

ActiveCN103062745BReduce usageReduce the impact of spillsIndirect carbon-dioxide mitigationNon-combustible gases/liquids supplyHigh concentrationWater vapor

Owner:HUAZHONG UNIV OF SCI & TECH

An environmentally friendly slitting device for bridge and road construction with controllable slitting depth

ActiveCN113529554BCutting depth controllableExtended service lifeDispersed particle filtrationRoad cleaningGear wheelConstruction engineering

The invention discloses an environment-friendly cutting device for bridge road construction with controllable cutting depth, which belongs to the technical field of road construction, and comprises a mounting box, a displacement wheel, a mounting frame, a limit frame and a cutting wheel. The mounting box A displacement wheel is arranged on the lower surface of the bottom surface, and a hose is connected between the outlet pipe and the cooling head. The environment-friendly slitting device for bridge and road construction with controllable slitting depth, through the rotating ring that can be held and rotated, the rotating ring can drive the adjusting block to rotate through the adjusting gear, and the adjusting block is driven by the screw connection with the displacement rod. The displacement rod and the installation rod slide down to change the cutting depth of the cutting wheel installed at the lower end of the installation rod. When the adjustment gear slides up and down, it can be engaged with the two adjustment blocks alternately or at the same time, so that the two cutting wheels The wheel can cut into the road surface at different depths, so that the required depth can be cut twice to ensure that the edges of the cut are neat and beautiful and not easy to crack, prolonging the service life of the road surface.

Owner:SHANDONG LUQIAO GROUP

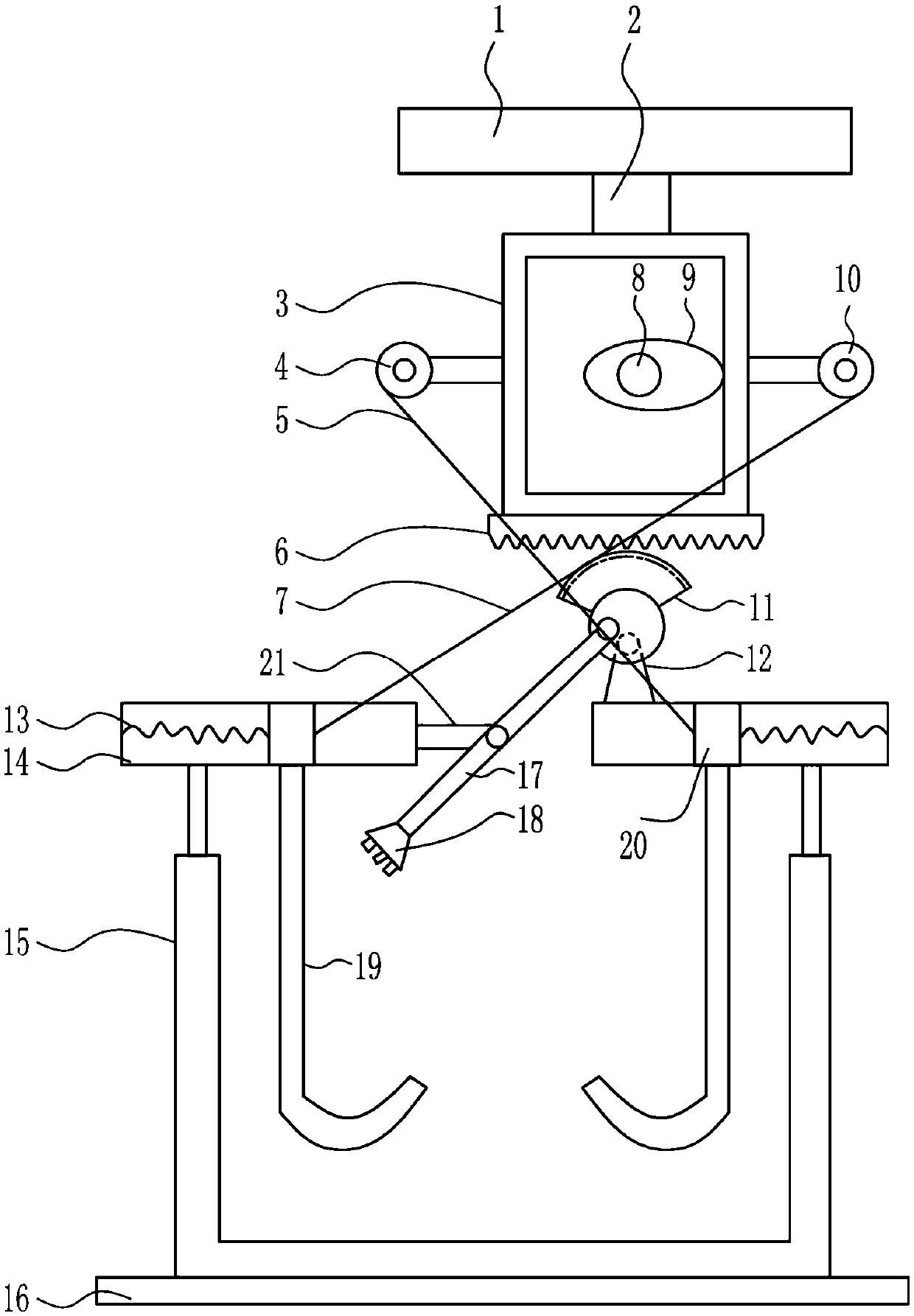

A kind of industrial wastewater disinfection device for environmental protection

ActiveCN106335980BDisinfect thoroughlyHigh degree of environmental protectionShaking/oscillating/vibrating mixersTransportation and packagingIndustrial waste waterReducer

The invention relates to an industrial wastewater disinfection device, in particular to an environmental protection industrial wastewater disinfection device. The technical problem to be solved by the present invention is to provide an environmental protection industrial wastewater disinfection device with thorough disinfection, high degree of environmental protection and strong practicability. In order to solve the above technical problems, the present invention provides such an environment-friendly industrial wastewater disinfection device, which includes a frame, a first slide rail, a first slider, a moving frame, a first roller, a first pull wire, a rack, a second Two backguys, geared motors, oval wheels, second rollers, etc.; the left and right sides of the top of the waste water tank are symmetrically provided with second slide rails, and second slide blocks are provided on the second slide rails. The invention achieves the effects of thorough disinfection, high degree of environmental protection, and strong practicability. When industrial waste water is to be disinfected, the working efficiency of the whole work can be improved by using the device.

Owner:ZHONGSHAN ZHONGYE ENVIRONMENTAL PROTECTION TECH CO LTD

Method for preparing homopiperazine by utilizing ethyl trifluoroacetate

ActiveCN106699674AHigh degree of environmental protectionImprove the safety of production operationsOrganic chemistrySolventChemistry

The invention discloses a method for preparing homopiperazine by utilizing ethyl trifluoroacetate. The method comprises the following steps: (1) taking ethylenediamine as an initial raw material; enabling the ethylenediamine to react with the ethyl trifluoroacetate under the action of an organic solvent, so as to prepare bistrifluoroacetylethylenediamine; (2) enabling the bistrifluoroacetylethylenediamine obtained by the step (1) to react with a 1,3-disubstituted propane compound under the action of a solvent and a catalyst, so as to obtain bistrifluoroacetyl homopiperazine; (3) enabling the bistrifluoroacetyl homopiperazine obtained by the step (2) to react with a hydrogen chloride ethanol solution to obtain homopiperazine bihydrochloride; recycling the ethyl trifluoroacetate; (4) enabling the homopiperazine bihydrochloride obtained by the step (3) to react with alkali under the action of a solvent and a catalyst, so as to prepare the homopiperazine. The method disclosed by the invention has the beneficial effects of simplicity and convenience for operation, relatively low cost, relatively high yield, relatively small pollution and wide applicable range, and can meet the requirements on industrial production of products.

Owner:SUZHOU BAILINGWEI HYPERFINE MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com