Water-based gravure white ink for film printing and preparation method of water-based gravure white ink

A white ink, water-based technology, applied in the field of water-based gravure white ink and its preparation, can solve the problems of volatile organic compounds emission and pollute the environment, and achieve the effects of reducing VOC emissions, high color and improving environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

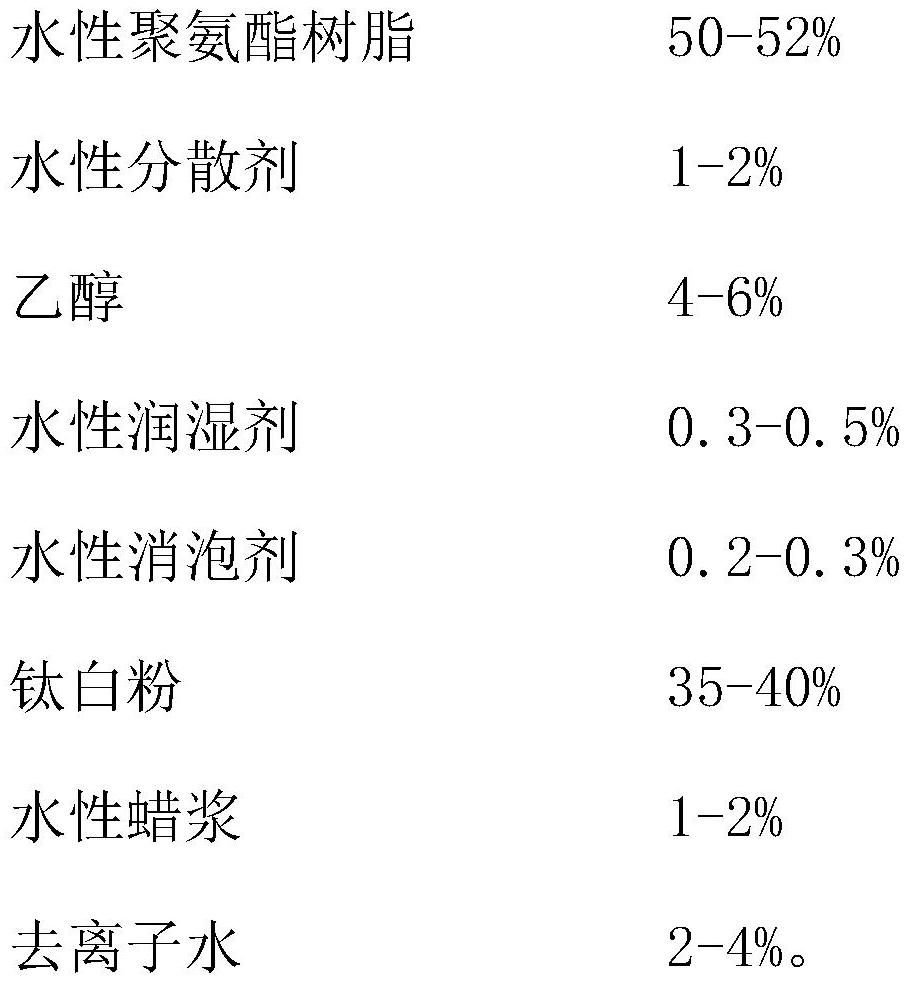

[0028] A preparation method for water-based gravure white ink for film printing, comprising the following steps:

[0029] S1: Prepare the raw materials according to the parts by weight in Table 1, put the water-based polyurethane resin, titanium dioxide, and water-based dispersant into the container, stir and mix evenly, the stirring time is 18 minutes, the stirring speed is 1000 rpm, and the stirring condition is 30°C, the pressure is normal pressure;

[0030] S2: use a sand mill to grind to a fineness of less than 5 microns, the grinding pressure is 5MPa, and the temperature is 60°C;

[0031] S3: Then add ethanol, water-based wetting agent, water-based defoamer, water-based wax slurry, and deionized water, and stir to mix evenly. The stirring time is 5 minutes, the stirring speed is 6000 rpm, the stirring condition is 30°C, and the pressure is constant. pressure;

[0032] S4: After the stirring is completed, filter through a 150-mesh gauze to obtain the product.

Embodiment 2

[0034] A preparation method for water-based gravure white ink for film printing, comprising the following steps:

[0035] S1: Prepare the raw materials according to the parts by weight in Table 1, put the water-based polyurethane resin, titanium dioxide, and water-based dispersant into the container, stir and mix evenly, the stirring time is 20 minutes, the stirring speed is 800 rpm, and the stirring condition is Celsius 35°C, the pressure is normal pressure;

[0036] S2: use a sand mill to grind to a fineness of less than 5 microns, the grinding pressure is 4MPa, and the temperature is 65°C;

[0037] S3: Add ethanol, water-based wetting agent, water-based defoamer, water-based wax slurry, and deionized water, and stir to mix evenly. The stirring time is 3 minutes, the stirring speed is 800 rpm, the stirring condition is 35°C, and the pressure is constant. pressure;

[0038] S4: After the stirring is completed, filter through a 150-mesh gauze to obtain the product.

Embodiment 3

[0040] A preparation method for water-based gravure white ink for film printing, comprising the following steps:

[0041] S1: Prepare the raw materials according to the parts by weight in Table 1, put the water-based polyurethane resin, titanium dioxide, and water-based dispersant into the container, stir and mix evenly, the stirring time is 22 minutes, the stirring speed is 900 rpm, and the stirring condition is Celsius 25°C, the pressure is normal pressure;

[0042] S2: use a sand mill to grind to a fineness of less than 5 microns, the grinding pressure is 5MPa, and the temperature is 55°C;

[0043] S3: Then add ethanol, water-based wetting agent, water-based defoamer, water-based wax slurry, and deionized water, stir and mix evenly, the stirring time is 5 minutes, the stirring speed is 800 rpm, the stirring condition is 25°C, and the pressure is constant pressure;

[0044] S4: After the stirring is completed, filter through a 150-mesh gauze to obtain the product.

[0045...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com