Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

72results about How to "Cycle simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

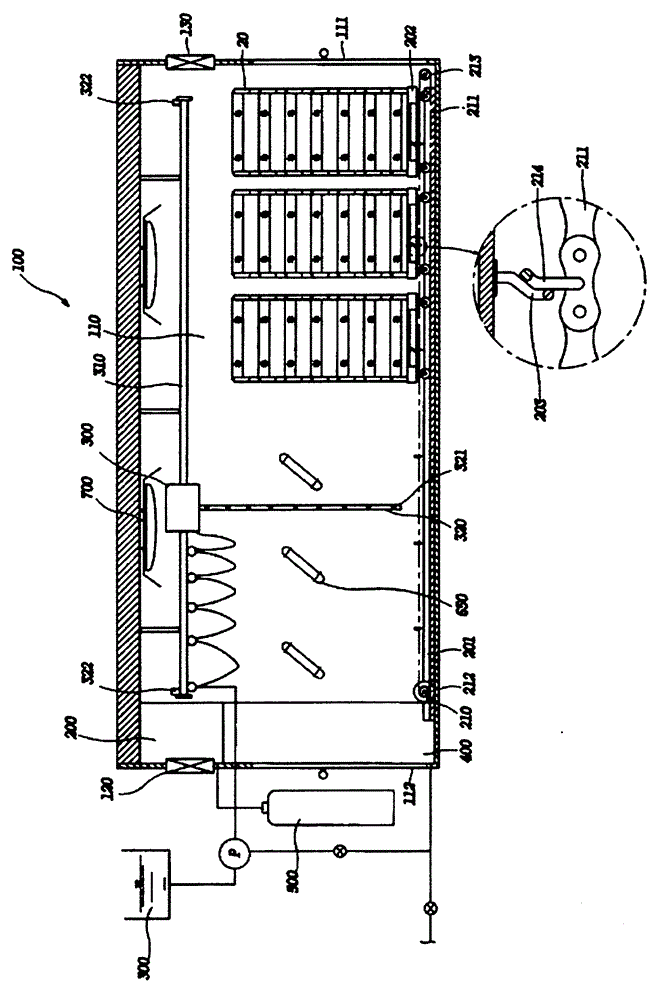

Reconfigurable data path processor

InactiveUS6883084B1Eliminates branchingCycle simpleEnergy efficient ICTConditional code generationMultiplexerProcessing element

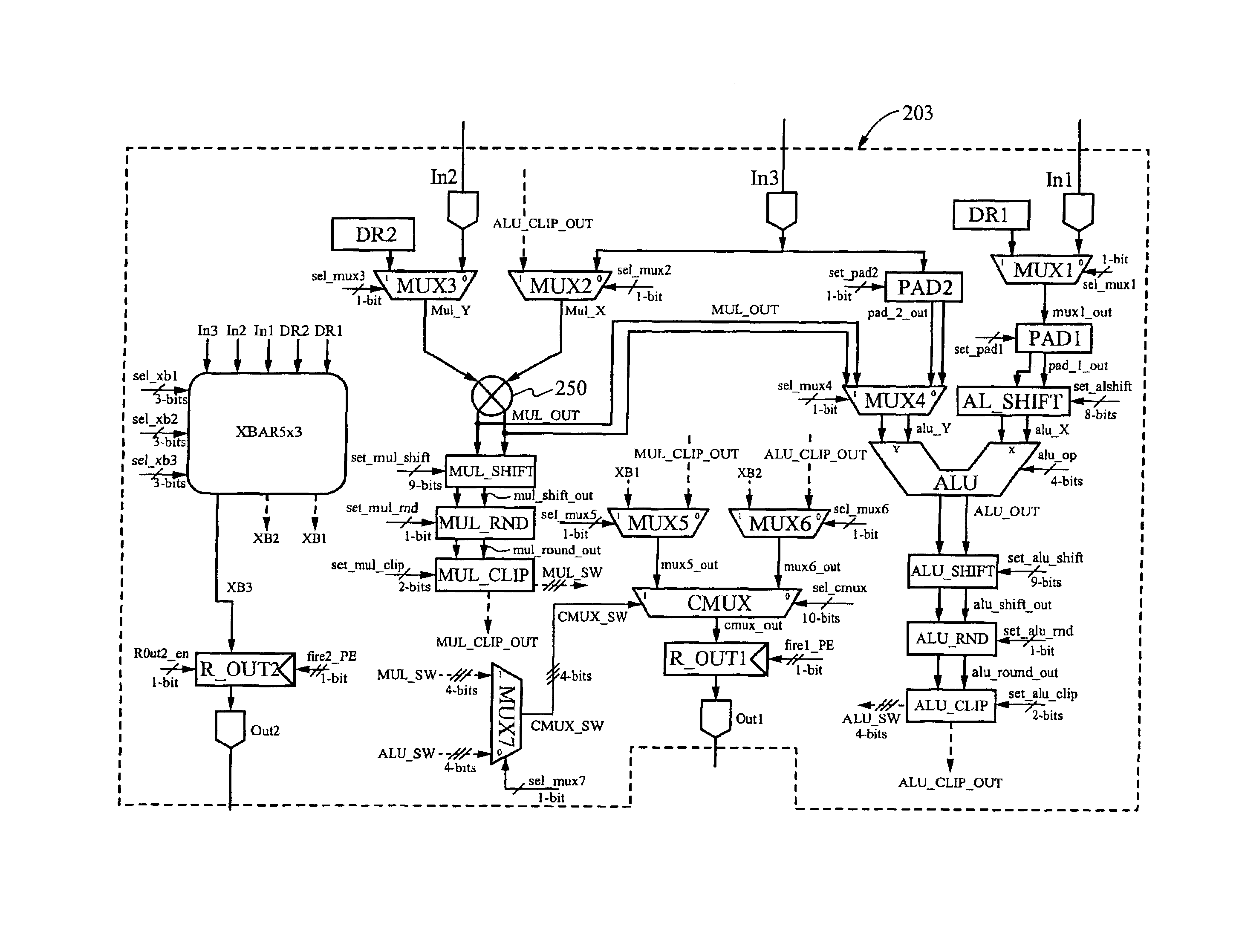

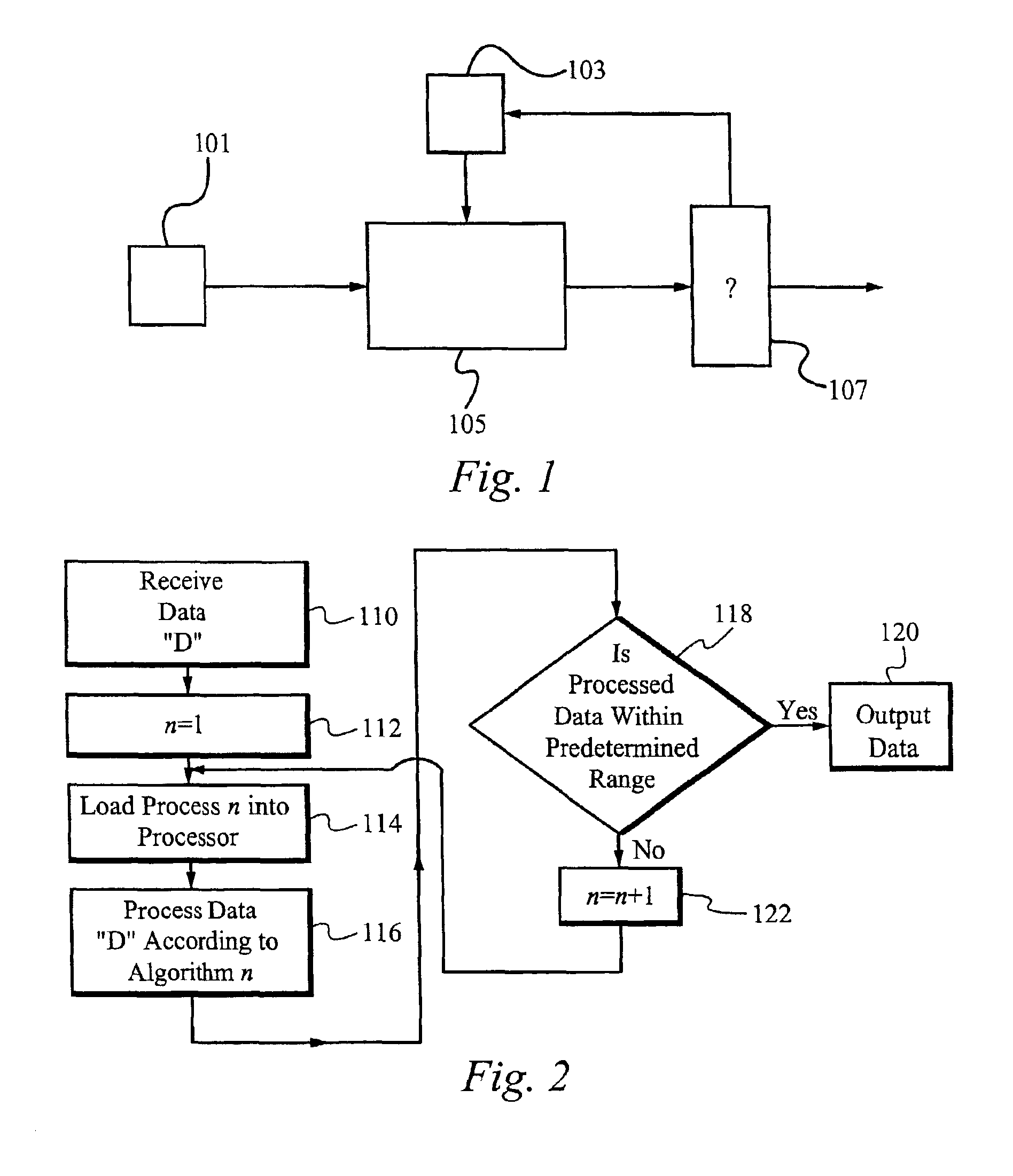

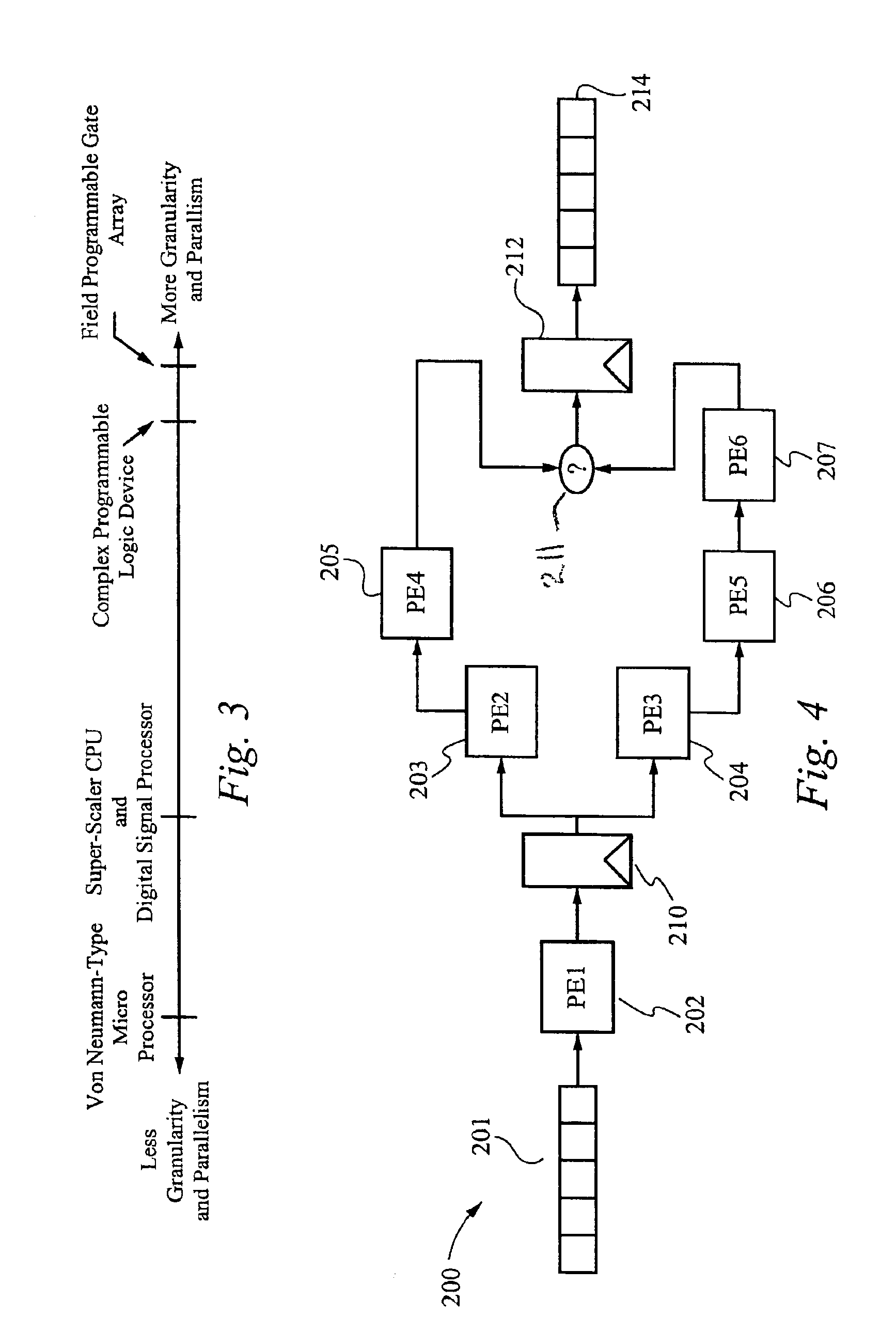

A reconfigurable data path processor comprises a plurality of independent processing elements. Each of the processing elements advantageously comprising an identical architecture. Each processing element comprises a plurality of data processing means for generating a potential output. Each processor is also capable of through-putting an input as a potential output with little or no processing. Each processing element comprises a conditional multiplexer having a first conditional multiplexer input, a second conditional multiplexer input and a conditional multiplexer output. A first potential output value is transmitted to the first conditional multiplexer input, and a second potential output value is transmitted to the second conditional multiplexer output. The conditional multiplexer couples either the first conditional multiplexer input or the second conditional multiplexer input to the conditional multiplexer output, according to an output control command. The output control command is generated by processing a set of arithmetic status-bits through a logical mask. The conditional multiplexer output is coupled to a first processing element output. A first set of arithmetic bits are generated according to the processing of the first processable value. A second set of arithmetic bits may be generated from a second processing operation. The selection of the arithmetic status-bits is performed by an arithmetic-status bit multiplexer selects the desired set of arithmetic status bits from among the first and second set of arithmetic status bits. The conditional multiplexer evaluates the select arithmetic status bits according to logical mask defining an algorithm for evaluating the arithmetic status bits.

Owner:STC UNM +1

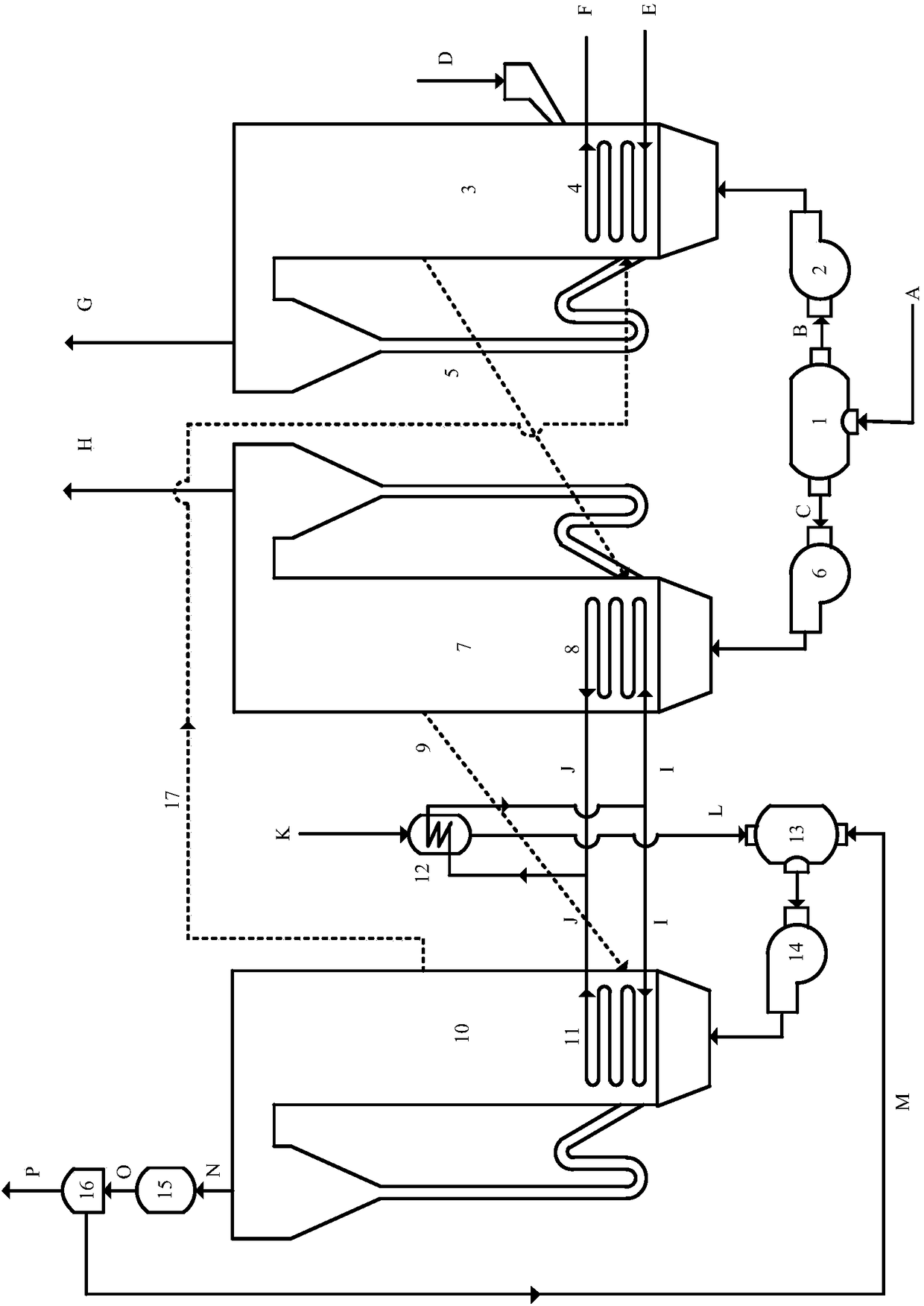

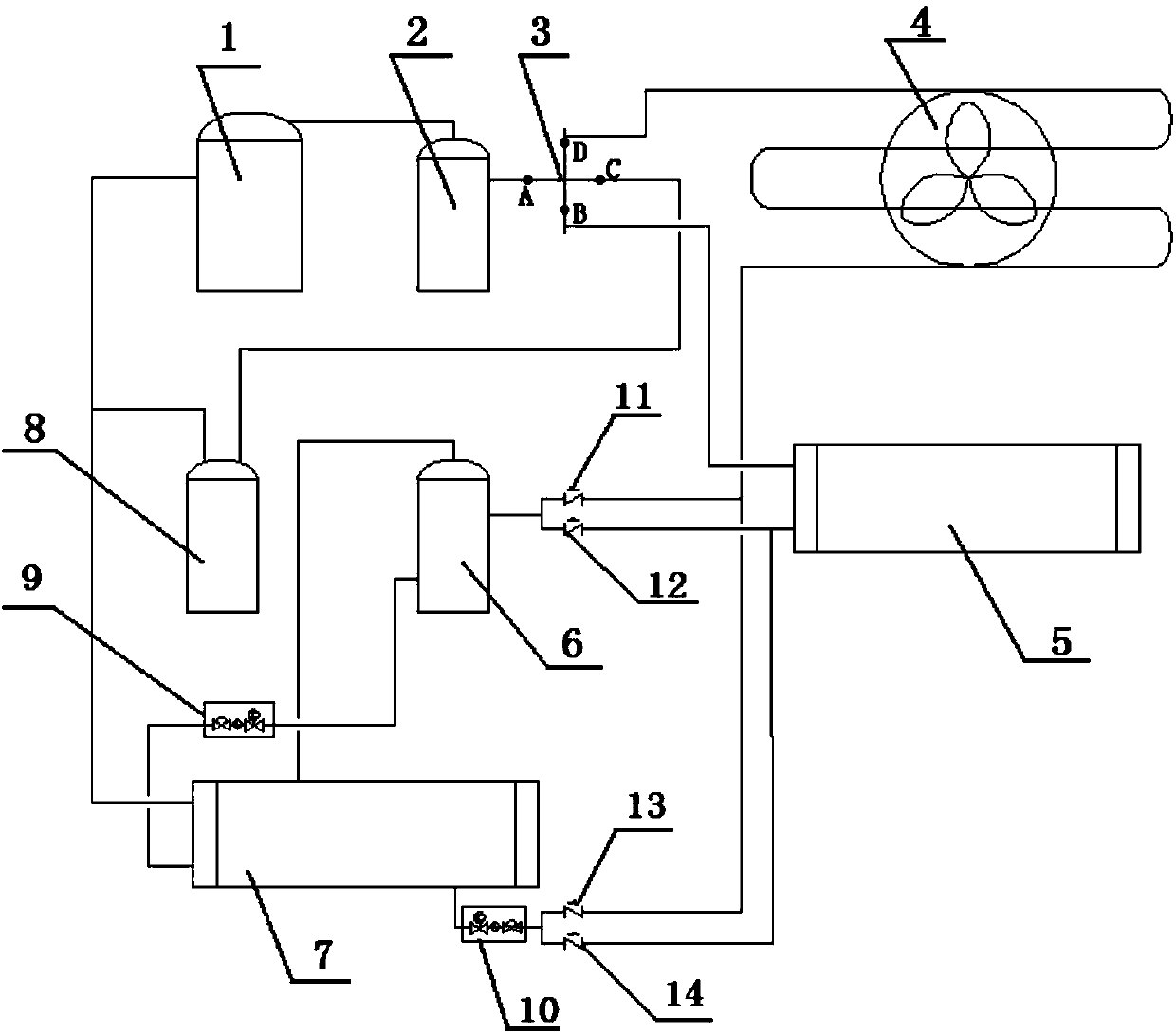

Device for removing CO2 of flue gas by highly active potassium-base absorbing agent dry method and method thereof

InactiveCN101298023AImprove removal efficiencyReduce energy consumptionDispersed particle separationBy chemical separationCoalProcess engineering

The invention discloses a device and a method for removing CO2 in flue gas by dry process and using a highly active potassium based absorbent. The device essentially consists of two circulating fluidized bed reactors, two sets of buried pipe type heat exchangers, two sets of materiel cycle devices and a gas generating, mixing and delivery device. After desulfurization, flue gas and steam generated by the exhausted spare heat of a steam turbine are mixed and sent into a first circulating fluidized bed reactor and react with the highly active potassium based absorbent in the reactor to remove CO2 in the flue gas; after reaction, the absorbent is sent to the other circulating fluidized bed reactor and regenerated in the reactor through the buried pipe by using the heat of hot flue gas generated in a station boiler. Mixed gas generated is dehydrated by a condenser and high purity of CO2 is obtained. Part of CO2 is taken as a fluidizing medium for a regeneration reactor and the rest is collected and disposed. The device is organically integrated with a coal power generation system and utilizes coal flue gas to provide heat needed by the device, which is a prioritization scheme with low energy consumption and investment.

Owner:SOUTHEAST UNIV

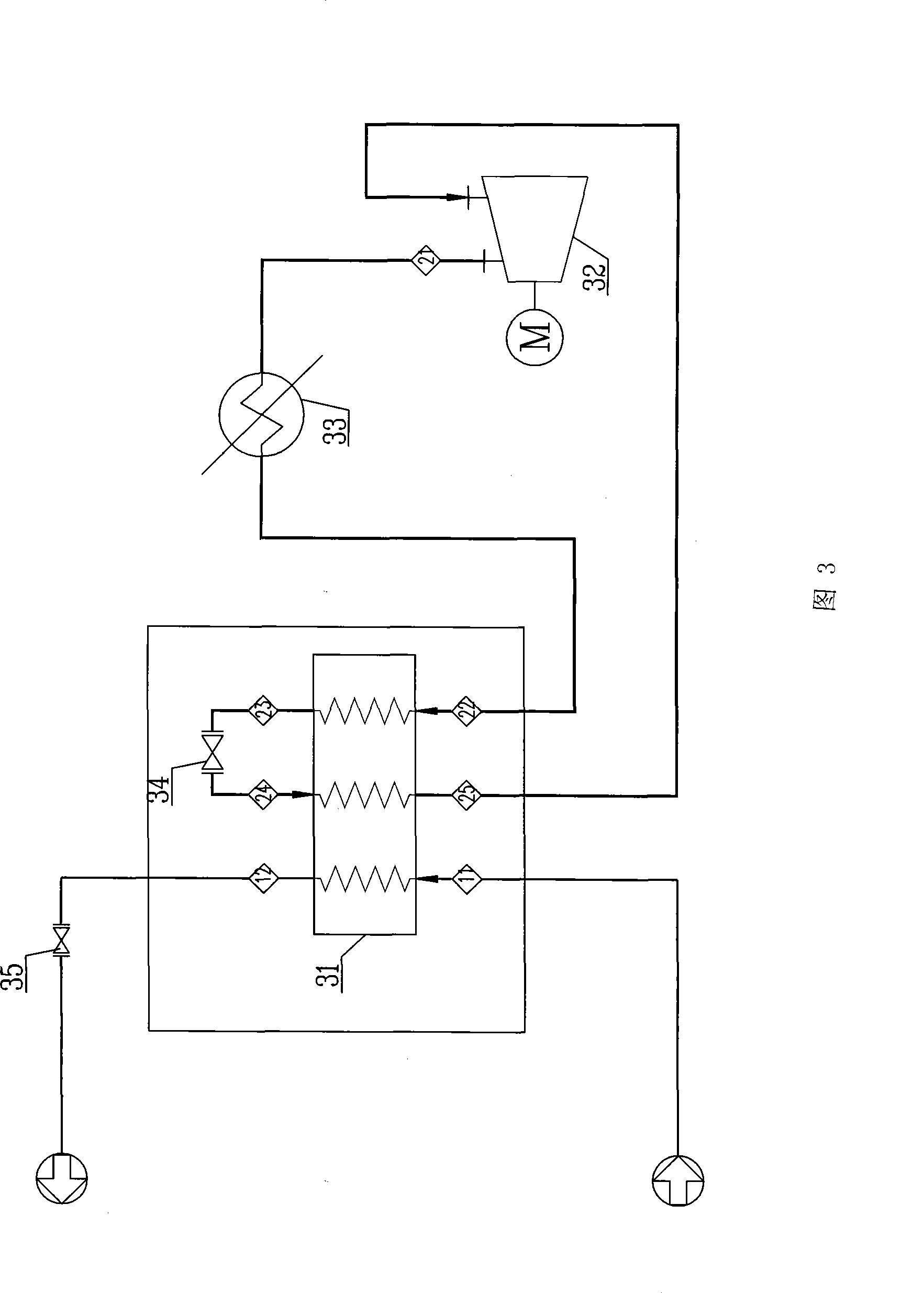

Method and apparatus for single-stage mixing cryogen refrigerating cycle liquefied natural gas

InactiveCN101413749AReduce equipment investmentSimplify cycle flow and operational controlSolidificationLiquefactionRefrigerantChiller

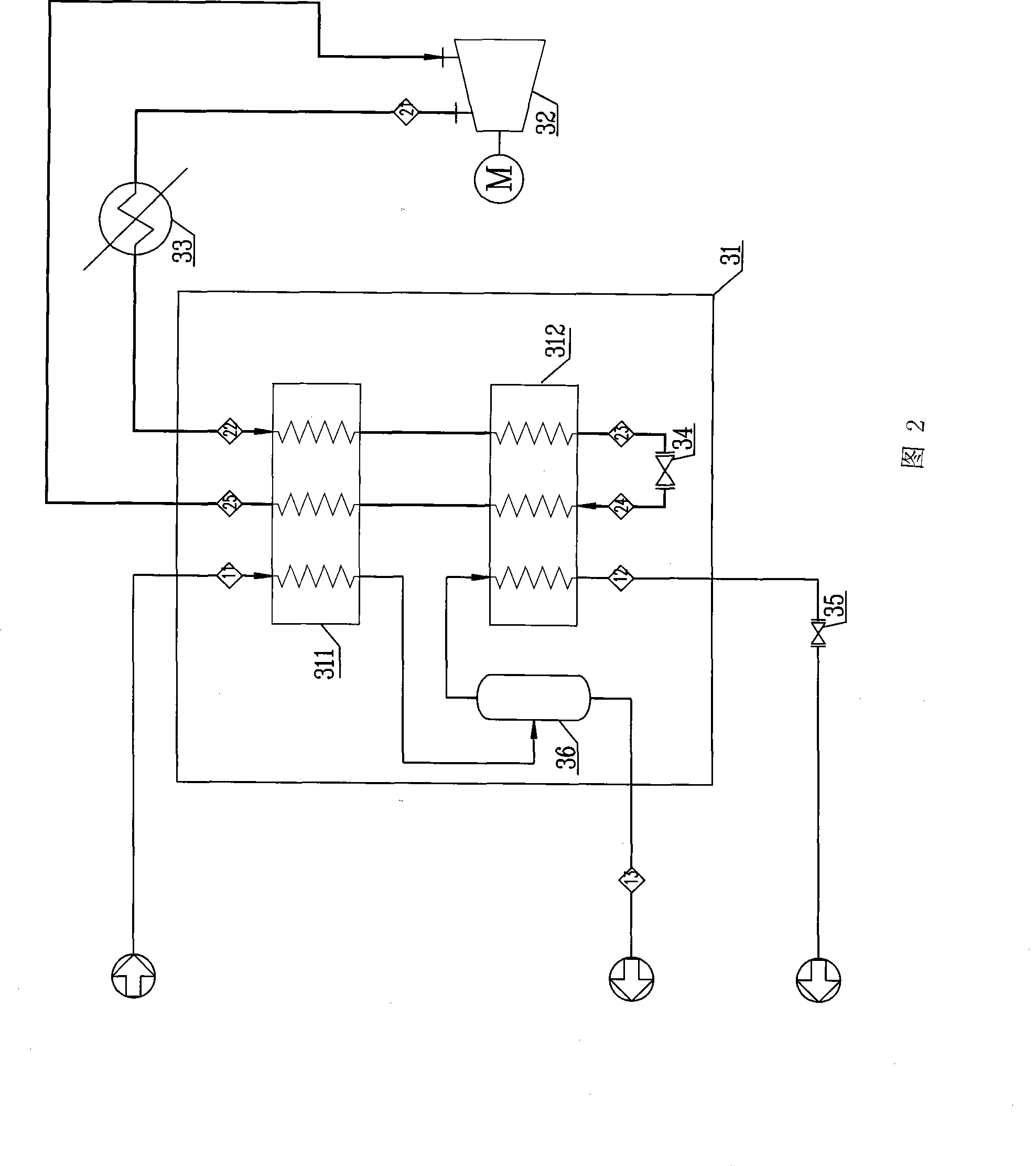

The invention discloses a method for liquefying natural gas by the refrigeration cycle of a single stage mixed refrigerant, which comprises the following steps: raw natural gas passes through a heat exchanger in an ice chest to exchange heat with the mixed refrigerant, and is cooled and liquefied; wherein, in sequence, the mixed refrigerant is first pressurized by a compressor, cooled by a cooler, directly enters the heat exchanger to be precooled without gas-liquid separation, goes out of the heat exchanger for depressurization and temperature reduction and then returns to the heat exchanger to exchange the heat of the natural gas and liquefy the natural gas, as well as is vaporized to gaseous mixed refrigerant and returns to the compressor for the next cycle; by reducing the outlet pressure of the compressor, or boosting the position of the outlet cooler of the compressor or using a way that the mixed refrigerant goes in and out of the ice chest both from the lower part, the method solves the problem of two phase flow of gas and liquid; can reduce the investment of the equipment such as a gas-liquid separator, a pump and the like, simplify the cycle process and operation control and reduce the manufacture cost as well. The invention also discloses a device applied to the method.

Owner:CHENGDU SEPMEM SCI & TECH

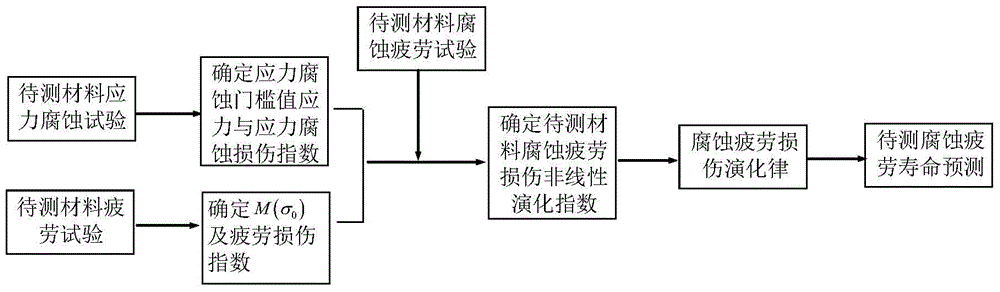

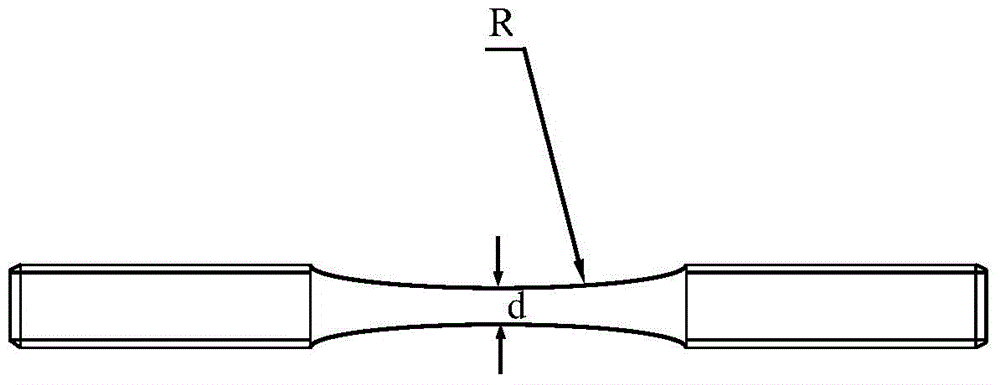

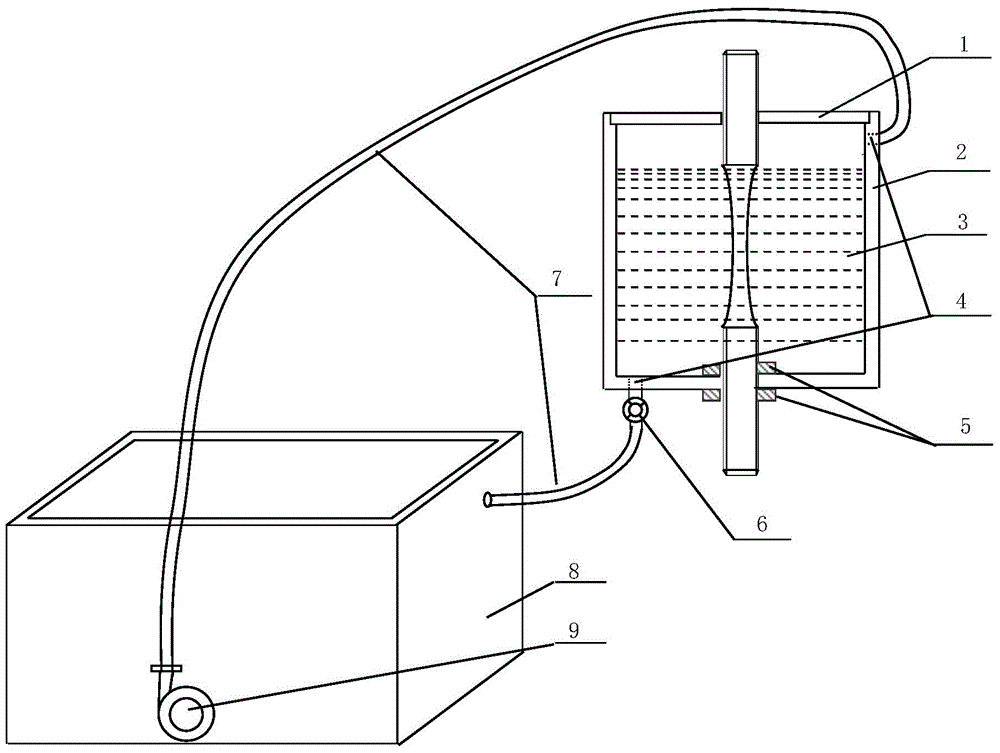

Corrosion fatigue life prediction method based on damage evolution

InactiveCN104062196ACycle simpleOvercome deficienciesWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceFatigue damagePredictive methods

The invention belongs to technical field of metal material corrosion and particularly relates to a corrosion fatigue life prediction method based on damage evolution. The method includes following steps: carrying out a stress corrosion test to a to-be-tested material for determining a stress threshold value of the stress corrosion and a damage index; carrying out a fatigue test to the to-be-tested material for determining a fatigue damage parameter; determining a corrosion fatigue damage nonlinear evolution index of the to-be-tested material; and predicting a corrosion fatigue life of the to-be-tested material. A corrosion solution circulating device in the invention can achieve cyclic refreshing of a corrosion liquid in a metal material corrosion fatigue and stress corrosion test. The corrosion fatigue life is predicted through a method of combining theory with experimental investigation so that defects in an analytical method and a test method are overcome. The prediction method is reasonable and is accurate in result. The predicted result is free of any influence due to combination of environment and the material. The prediction method is simple in operation, is easy to carry out, is strong in popularizing performance and is convenient in engineering application.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for producing solar energy stage polycrystalline silicon by using high-pure quartz sand as raw material

The invention provides a method for producing solar energy level polysilicon by taking quartz sands with high purity as materials. In the method, silica materials, in which the SiO2 content is more than 99 percent, are chosen to undergo water quenching, crushing, sieving, acid cleaning, magnetic separation and high voltage ionizing treatments, which makes the purity of silica particles reach more than 99.99 percent, and the quartz sands with high purity are obtained; carbonaceous reducing agents and graphite electrodes in a mine hot stove are chloridized at a high temperature in a chlorination furnace, making the purity of carbonaceous reducing agents reach more than 99.99 percent; in the mine hot stove, the carbonaceous reducing agents are used to reduce the quartz sands with high purity so as to produce silicon, and while producing, silicon liquids are periodically discharged from the mine hot stove; the obtained silicon liquids are injected in a holding furnace, and the products directly undergo the high-frequency plasma air refining for impurity removal under the non oxidizing atmosphere, and at the same time oxidizing gases are added in the melting silicon; the silicon liquids are injected in a directional solidification furnace for the directional solidification, and the silicon is further purified, so that the solar energy level polysilicon is obtained. The method of the invention has the advantages of low investment, short building period, low manufacturing cost, simple process and no pollution; moreover, the method is also suitable for industrialization.

Owner:JINZHOU NEW CENTURY QUARTZ GROUP CO LTD

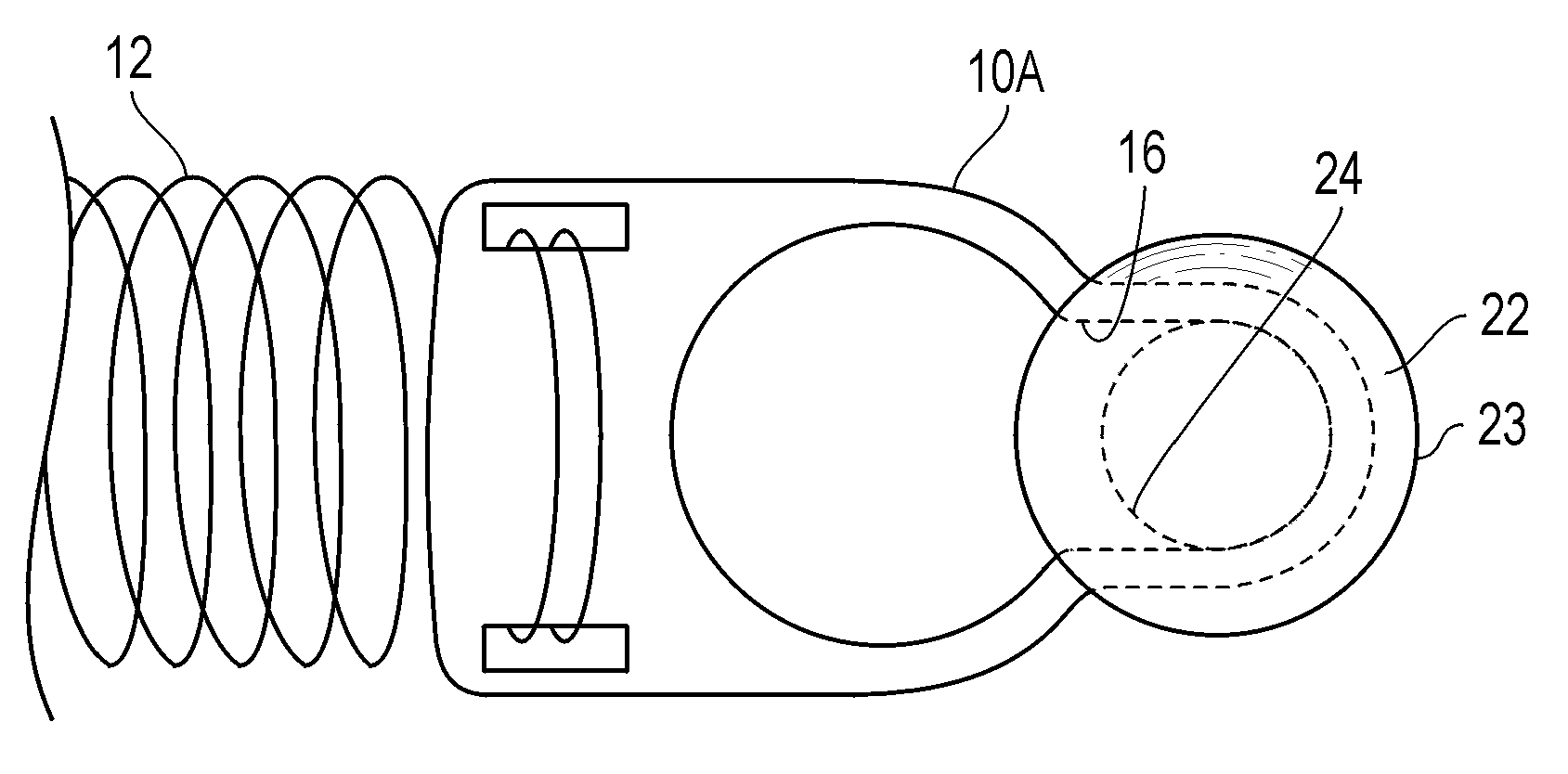

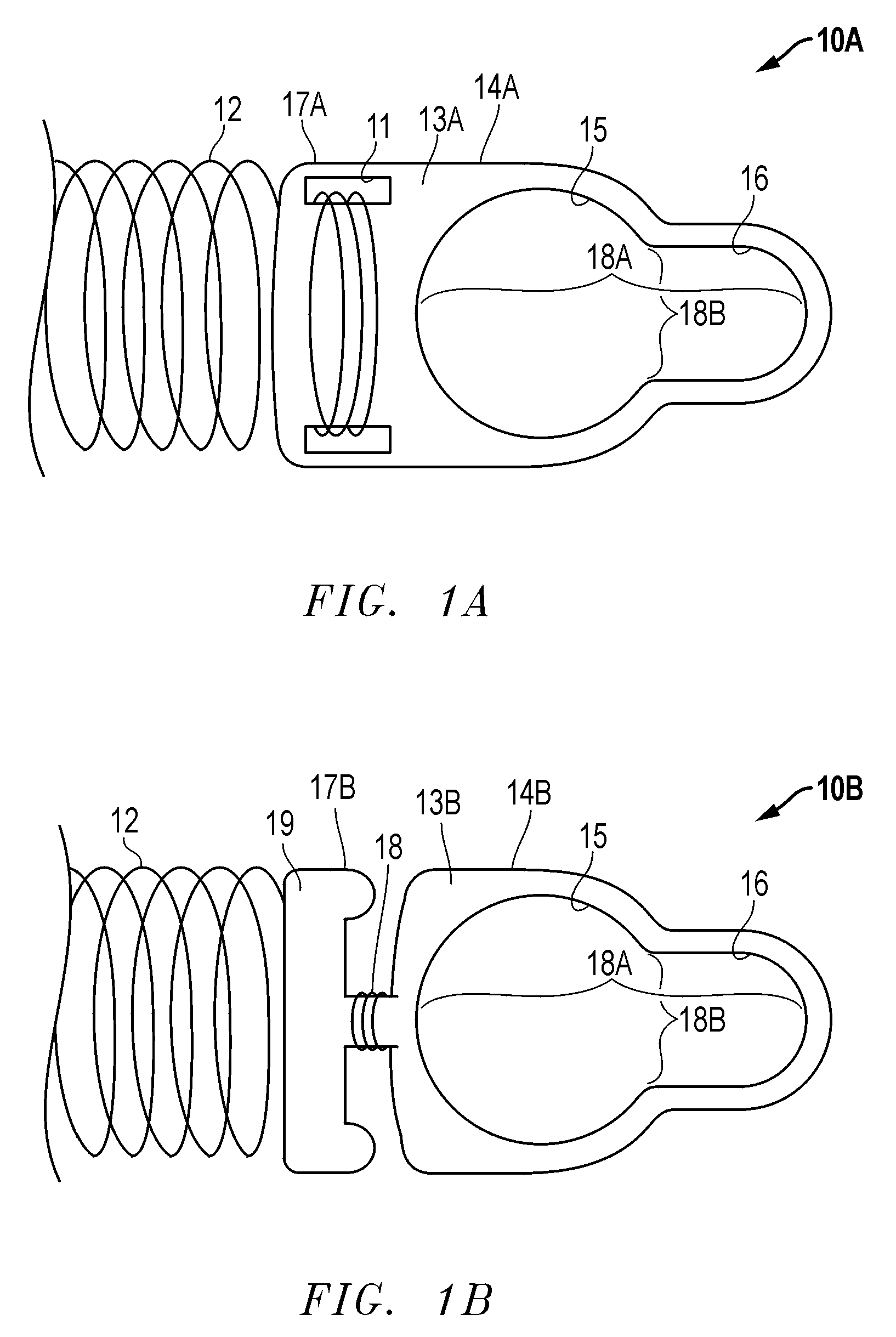

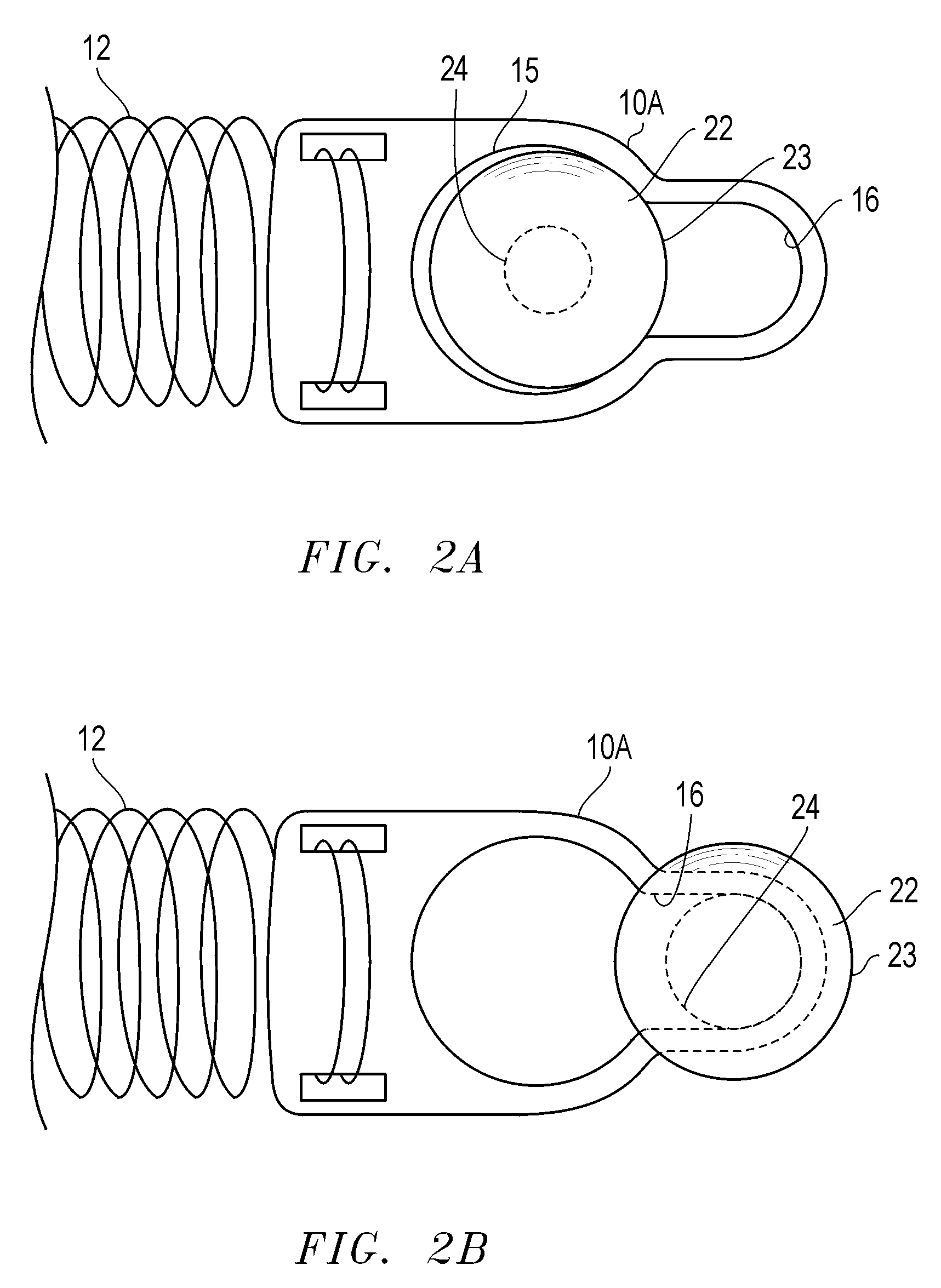

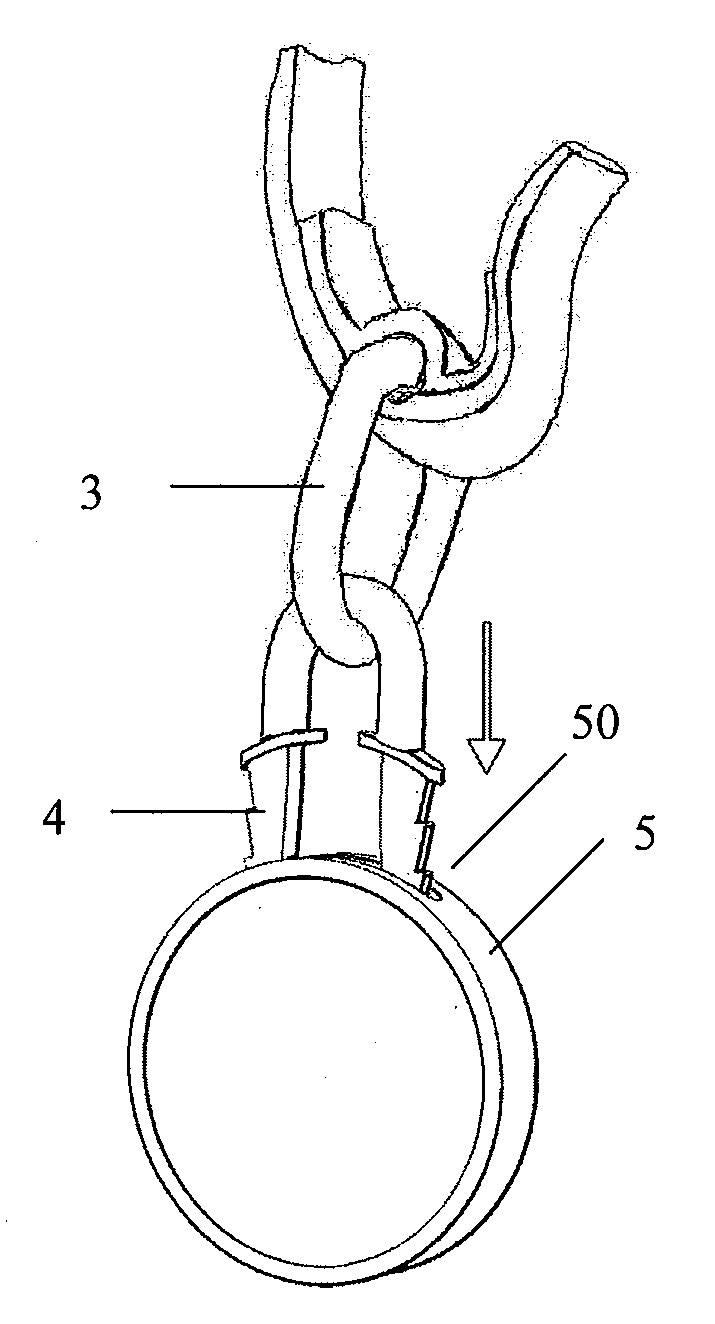

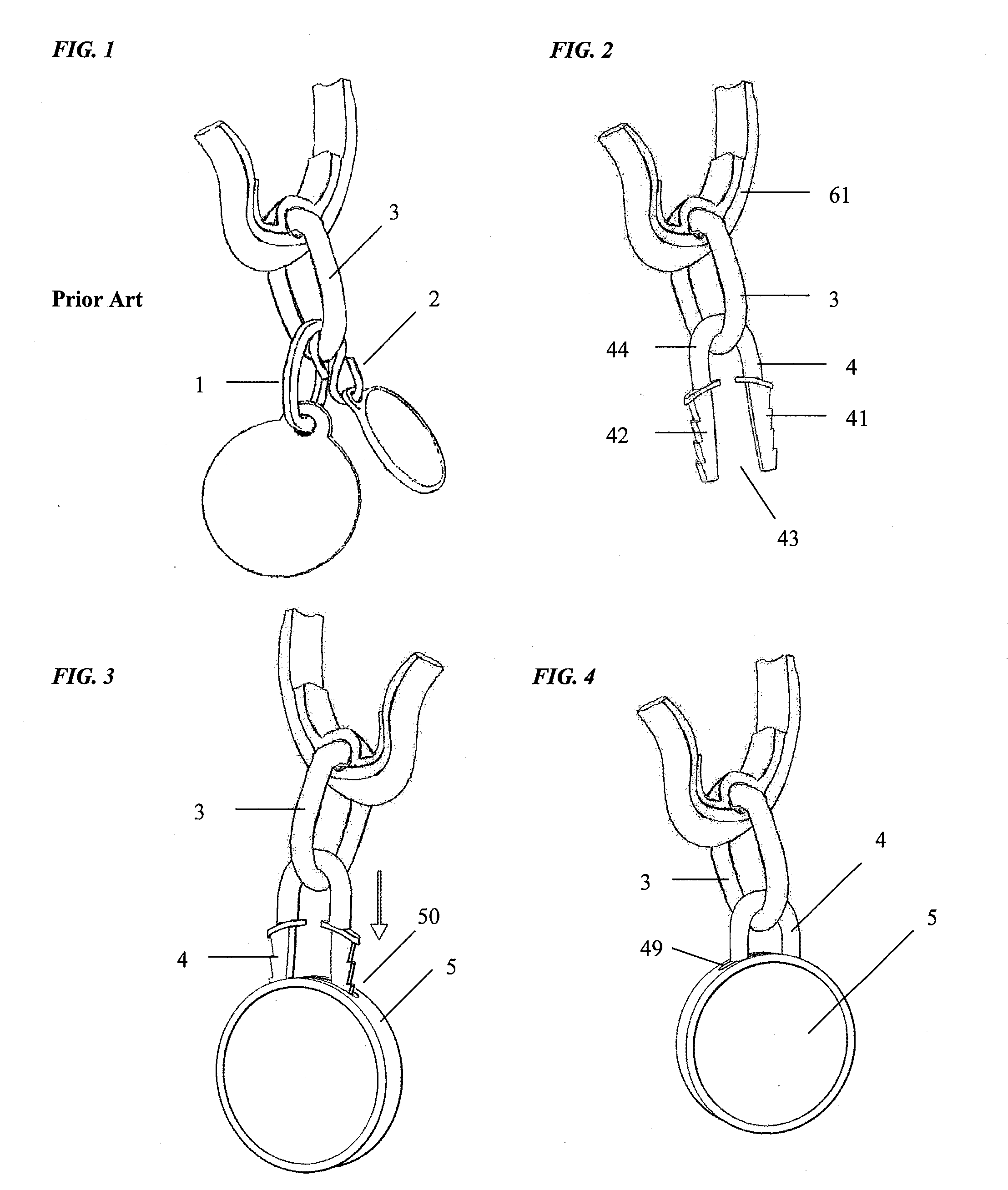

Orthodontic closed coil spring assembly and method of use thereof

An orthodontic tensioning assembly, comprising a tensioner attachment body having a first end and a second end, wherein the first end of the tensioner attachment body has an opening adapted to removably receive a dental anchorage structure, and wherein the second end of the tensioner attachment body is adapted to removably couple a tensioning element.

Owner:UNDER DOG MEDIA

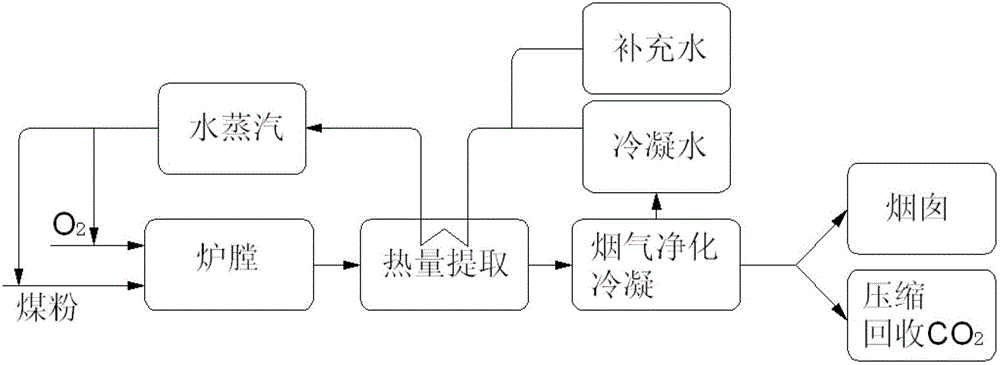

Water vapor circularly adjusting type oxygen-enriched combustion method for pulverized coal boiler

ActiveCN103062745AReduce usageReduce the impact of spillsIndirect carbon-dioxide mitigationNon-combustible gases/liquids supplyHigh concentrationWater vapor

The invention discloses a water vapor circularly adjusting type oxygen-enriched combustion method for a pulverized coal boiler. The method is characterized in that in the whole oxygen-enriched combustion process, smoke generated by combustion is sequentially subjected to heat energy extraction, purification and condensation treatment, condensate water obtained after condensation treatment is heated to be converted into water vapor by using extracted heat energy, and a part of the water vapor is used as primary air to be fed into a boiler chamber of the pulverized coal boiler; and the rest of the water vapor is mixed with oxygen to serve as secondary air to be fed to the boiler chamber of the pulverized coal boiler. The invention further discloses other oxygen-enriched combustion modes by using the water vapor to execute circulation adjustment. By means of the water vapor circularly adjusting type oxygen-enriched combustion method and other oxygen-enriched combustion modes, problems that smoke with high concentration CO2 is difficult to obtain, pollutants of NOx, SO2 and the like are high in concentration and switching of starting and stopping of a system is complicated in prior art are solved, and the water vapor circularly adjusting type oxygen-enriched combustion method is particularly suitable for being used in occasions of pulverized coal boilers and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

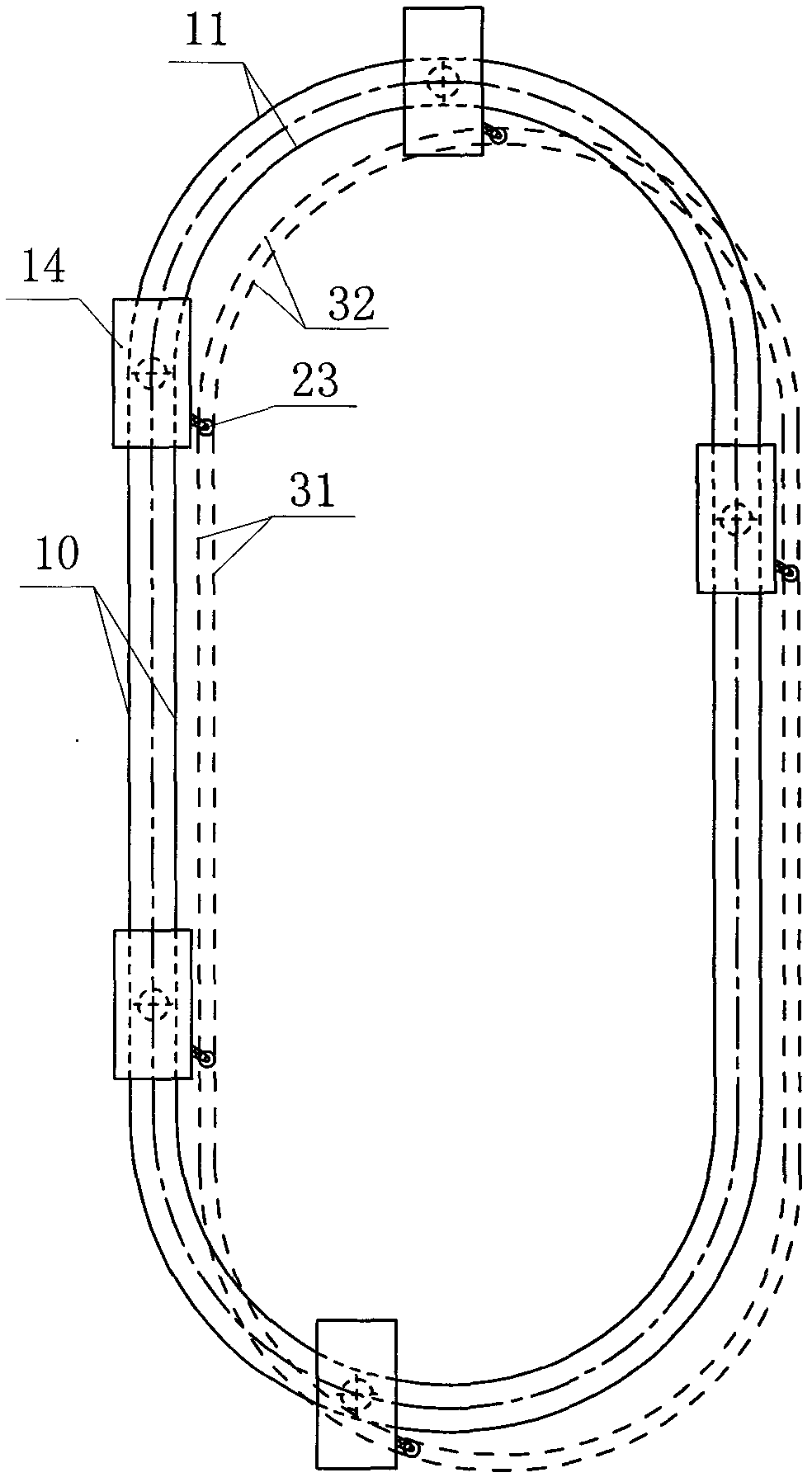

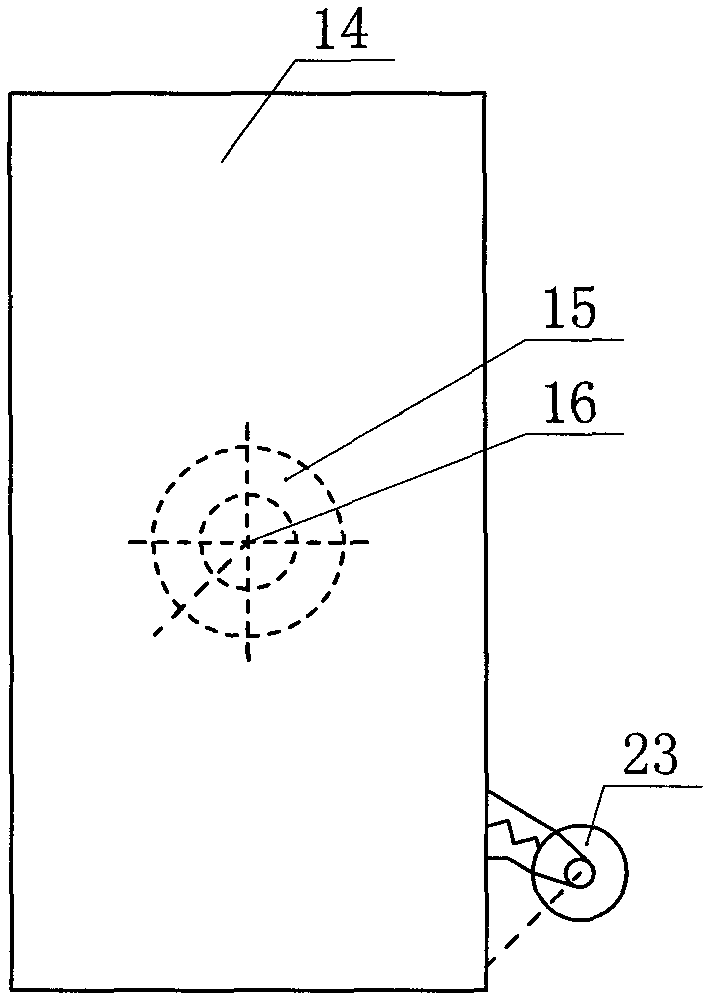

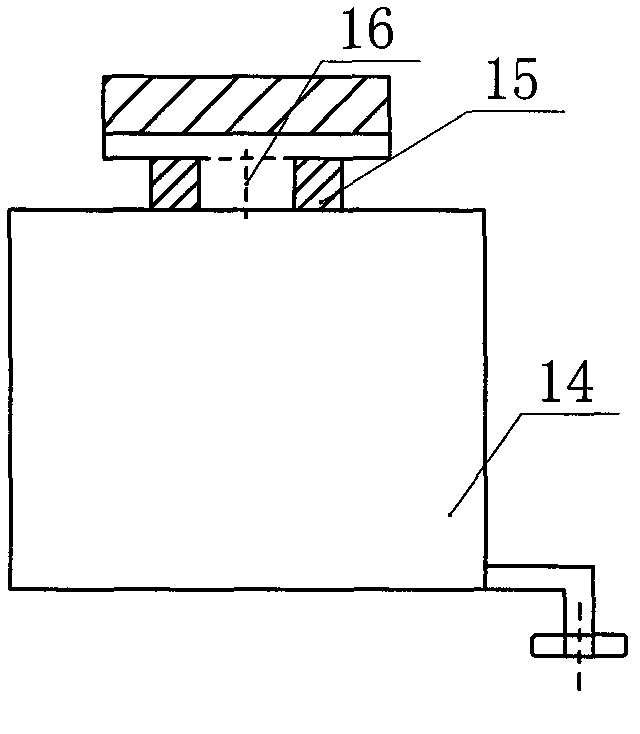

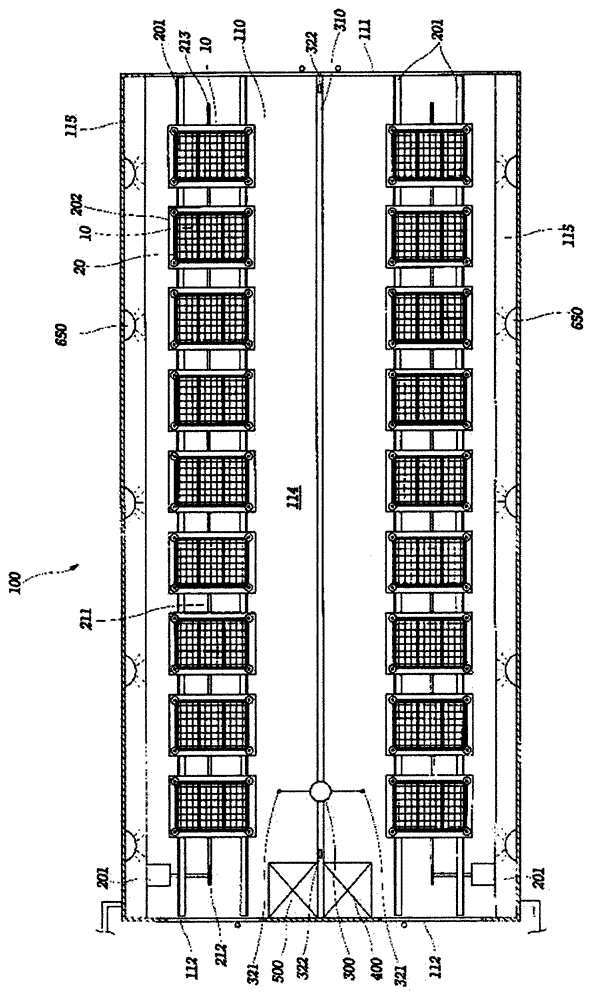

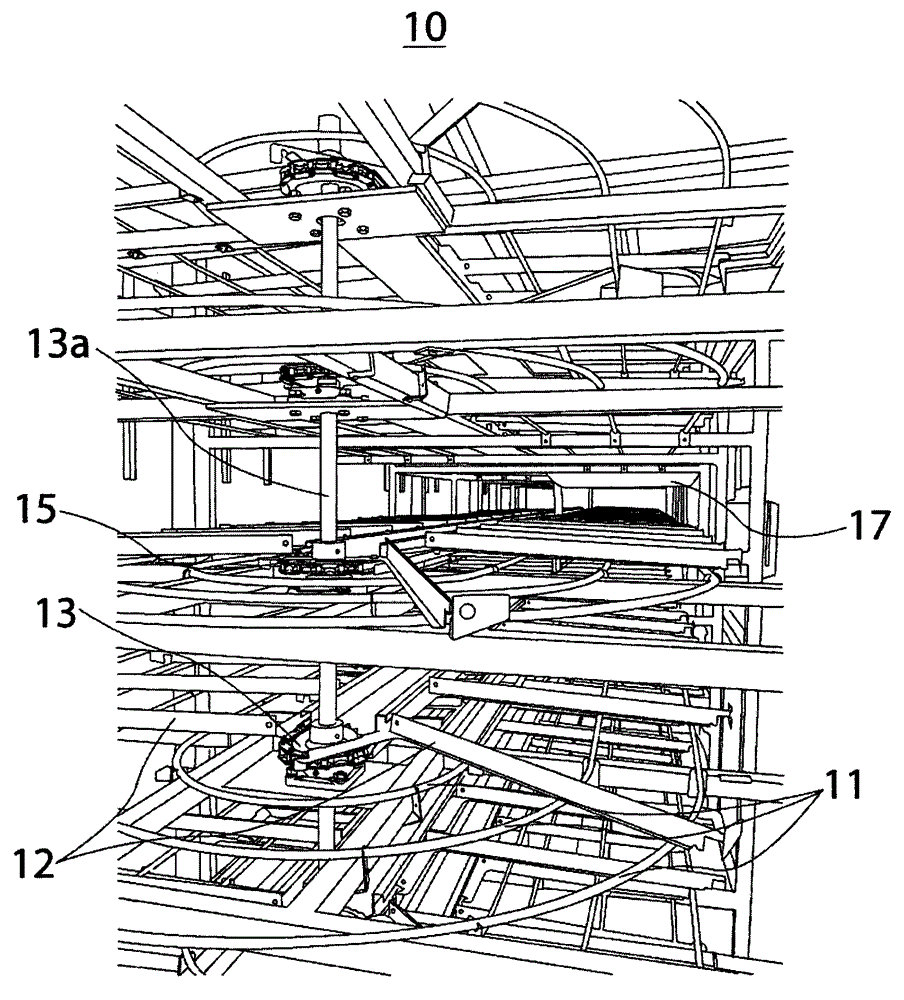

Single-wheel cycled multi-car elevator

The invention discloses a single-wheel cycled multi-car elevator comprises cars, a driving mechanism and car positioning rails, wherein each car is provided with a car wheel; the car wheels are arranged inside car wheel positioning rails; each car wheel positioning rail comprises car wheel positioning rail vertical sections and car wheel positioning rail curved passage sections; each car is connected with the driving mechanism through a rotary disk and a connecting shaft; and each car positioning rail comprises car positioning rail vertical sections and car positioning rail curved passage sections. According to the single-wheel cycled multi-car elevator, the driving mechanism drives the cars to move along the car positioning rails, while the car wheels always run along the car wheel positioning rails so as to ensure that the cars cannot turn over during the running process; and the rails are continuous, so that the cycle of the cars is relatively simple. A plurality of cars can exist inside the car positioning rails simultaneously, so that the well space utilization rate of the elevator is improved, the elevator waiting time is shortened, the transport capacity is increased, and the single-wheel cycled multi-car elevator is particularly suitable for being used in high-rise buildings.

Owner:HENAN POLYTECHNIC UNIV

Identification Tag and Releasable Attachment Clip

Owner:HILL ROBERT

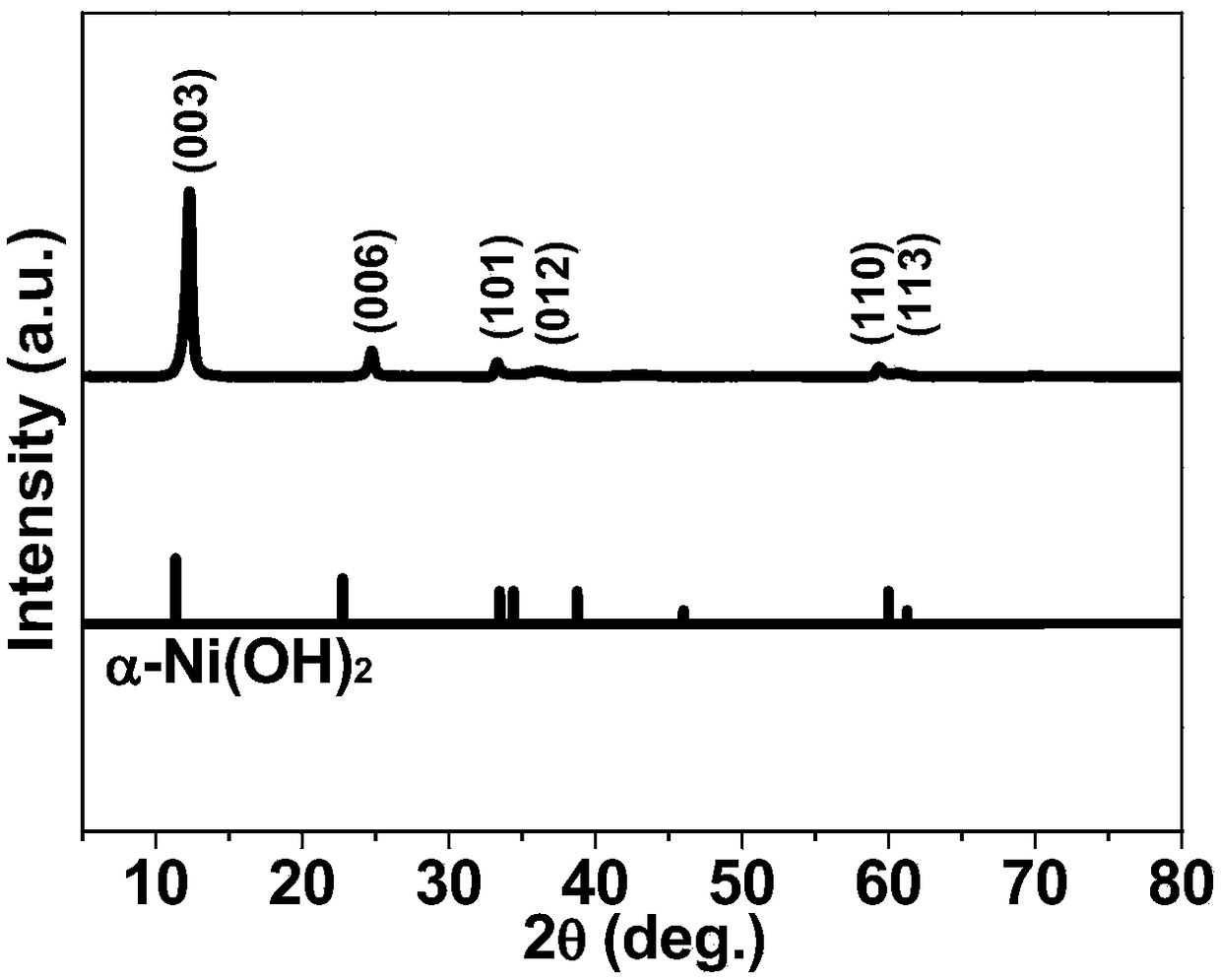

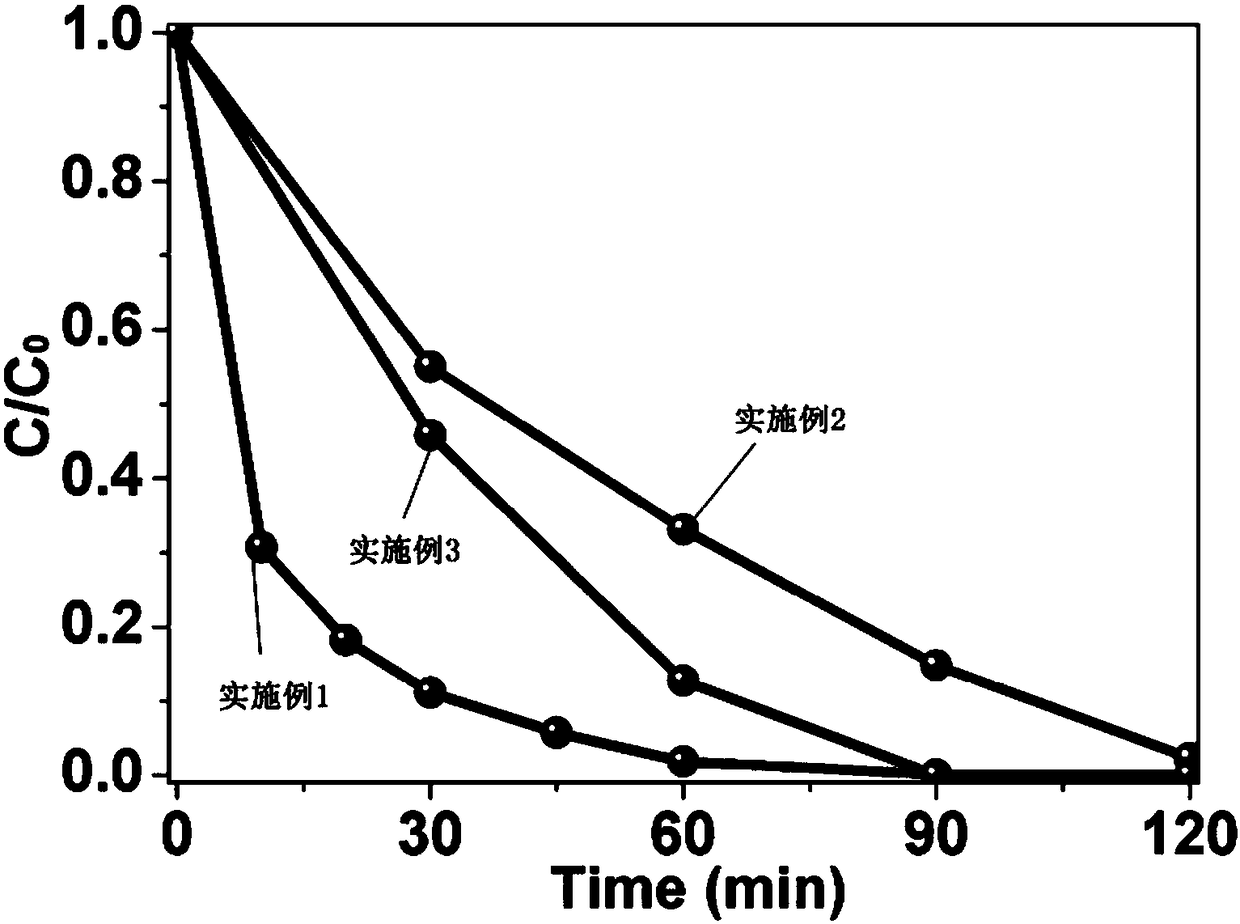

Degradation method of organic pollutants

InactiveCN108314172AImprove bindingCurb churnWater contaminantsWater/sewage treatment by oxidationNickel saltPersulfate

The invention provides a degradation method of organic pollutants. The degradation method comprises following steps: nickel hydroxide nanometer sheets are prepared; the nickel hydroxide nanometer sheets are added into a solution containing organic pollutants, a persulfate is added, and stirring is carried out for degradation so as to realize mineralization of the organic pollutants. A preparationmethod of the nickel hydroxide nanometer sheets comprises following steps: a water soluble nickel salt and urea are dissolved in a mixed solution of water and glycol, an obtained mixture is mixed to be uniform, and is subjected to hydro-thermal reaction at 120 DEG C, and washing and drying are carried out so as to obtain the nickel hydroxide nanometer sheets. Compared with the prior art, the degradation method possesses following beneficial effects: 1, the adopted nickel hydroxide is of a nanometer sheet shaped structure, so that it is beneficial for combination of the catalyst with pollutantsand PS, and the loss of Ni metal can be inhibited effectively; and 2, the preparation method of nickel hydroxide nanometer sheets is simple and convenient.

Owner:SHANGHAI JIAO TONG UNIV

Pure aloe fiber warp and weft double-elasticity yarn-dyed fabric and production technology thereof

The invention discloses pure aloe fiber warp and weft double-elasticity yarn-dyed fabric and a production technology thereof. The pure aloe fiber warp and weft double-elasticity yarn-dyed fabric comprises a warp yarn, a weft yarn and an elastic yarn, wherein 60S aloe fiber yarns are adopted as the warp yarn and the weft yarn; aloe 50S / 20D is adopted as the elastic yarn; a plain fancy cellular structure is adopted as a fabric structure; a bottom structure formed by plain as main material and triple fancy cellular structures in the transverse direction and longitudinal direction; an edge structure is the plain; and a jacquard part is formed by the fancy cellular structure as main part in transverse direction and horizontal direction matched with the shrinkage action of an aloe fiber spandex core-spun yarn. The production technology comprises a spooling step, a warping step, a slashing step, a drafting step and a weaving step. The fabric is reasonable in color match, light and thin in texture and slight in wrinkle, and gives a casual feeling to a consumer. Meanwhile, the pattern is relatively large in cycle, and is matched with unique plain fancy cellular structure, so that the fabric is high in third dimension and good in breathability. The weaving efficiency reaches 91%; and the first grade percentage put in storage reaches 99%.

Owner:IANGSU COLLEGE OF ENG & TECH

Boiler using rotary force

InactiveCN101893225AIncrease powerIncreased friction distanceSteam generation using mechanical energyOther heat production devicesWater flowEngineering

The present invention relates to a boiler using mechanical rotating power as a rotating force of a rotary body of a driving source to accelerate water molecules to move (friction), and heating water by using frictional heat generated by the movement of the water molecules. The boiler is composed of a rotary body connected to a driving source and a housing accepting and supporting the rotary body, the housing is provided with a water inlet and water outlet, and a water flowpath is formed in the housing. The outer circumferential face of the rotary body is provided with at least two sunken holes sloped to a normal line or a tangent line direction, the inner circumferential face of the housing is provided with at least two grooves apart from by a certain distance in the circumference direction and continuously slopedly or helically arranged in the axis direction. According to the boiler, when the water moves axially along the water flowpath and contacts with the outer circumferential face of the rotary body so as to greatly increase friction distance, and friction efficiency is maximized by the sunken holes. In addition, by means of the grooves, the water is flowed smoothly in the housing, and the water is easy to be sucked, discharged and circulated with an external circulating system by using self suction.

Owner:千庸基

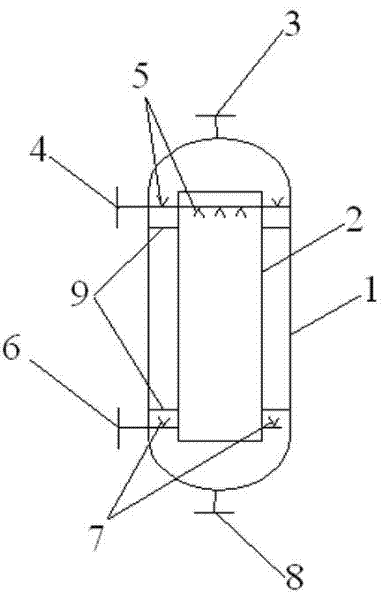

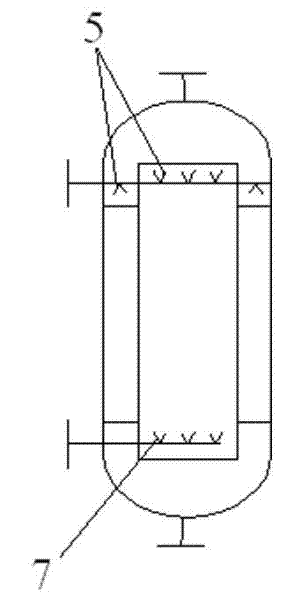

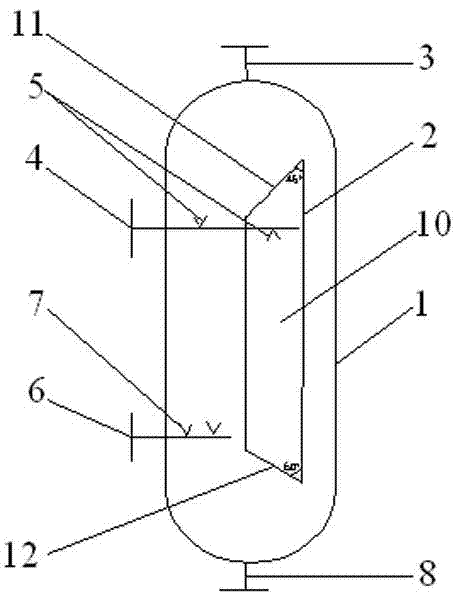

Carbonylation reacting kettle

ActiveCN102430381AShorten the running distanceIncrease heightChemical/physical/physico-chemical nozzle-type rreactorsCarboxylic preparation from carbon monoxide reactionEngineeringCarbonylation

The invention relates to a carbonylation reacting kettle, comprising a kettle body, and a separation plate which is arranged in the kettle body and used for separating the kettle body to form an upstream and a downstream area of which the two ends communicates with each other. A liquid outlet is arranged on the bottom part of the kettle body, and a gas outlet is arranged on the top part of the kettle body. A liquid inlet and a liquid distributor are arranged on the upper part of the kettle body. A liquid jetting opening of the liquid distributor of which at least one opening faces upwards is arranged in the upstream or located in the vertical extending area of the upstream which faces the top part, and a liquid jetting opening of the liquid distributor of which at least one opening faces downwards is arranged in the downstream area or located in the vertical extending area of the downstream area which faces the top part. A gas inlet and a gas distributor are arranged on the lower part of the kettle body. A gas jetting micro-pore of the gas distributor is located in the upstream or located in the vertical extending area of the upstream which faces the bottom part, and the opening faces upwards. The arrangement position of the liquid distributor is higher than that of the gas distributor.

Owner:陕西煤业化工技术开发中心有限责任公司

Water culturing system with multi-layer circulation structure

InactiveCN105028169ACycle simplePrevents discrepancies in breeding ratesAgriculture gas emission reductionCultivating equipmentsEngineeringDrive motor

The invention relates to a water culturing system with a multi-layer circulation structure. The water culturing system has a plurality of layers and is allowed to be nurtured by a plurality of transfer plates placed on each layer of the structure to be transmitted to each layer. According to one aspect of the present invention, a water culture system having a plurality of circular structure is provided, which is in a disk shape and is stacked in a vertical direction with a plurality of transfer plates placed on a transmission rail and is mounted in a transmission guide rail; the drive sprocket and the driven sprocket are mounted in a direction opposite to the drive sprocket and the driven sprocket.

Owner:秦东烈 +1

Device and method for preparing ammonia gas based on chemical chain reaction

ActiveCN108554324AExtensive sources of raw materialsLow priceChemical/physical processesAmmonia preparation/separationChemistryCompound (substance)

The invention discloses a device and method for preparing ammonia gas based on a chemical chain reaction. The device comprise a circulating fluidized bed reactor, a buried pipe type heat exchanger, amaterial circulating device and a gas generating, mixing, separating and conveying device. Air is separated and then conveyed into a nitrogen absorption reactor, the air and pulverized coal act together to convert an oxygen carrier into a nitrogen carrier, after the reaction is carried out sufficiently, residual solid is conveyed into a decarbonization reactor through the material circulating device and fully reacts with the residual air from an air separator, the unreacted pulverized coal is sufficiently burnt, and the pulverized coal is separated from the nitrogen carrier. The nitrogen carrier is conveyed into a nitrogen-releasing reactor through the material circulating device, generates the ammonia gas under the action of water vapor, and is reduced into the oxygen carrier. The reducedoxygen carrier is conveyed back into the nitrogen absorption reactor through the circulation device for a circulation reaction. Compared with a traditional ammonia production technology, raw materials are wide in source, the conversion rate is high, and the method is a resource-saving and environment-friendly ammonia production method.

Owner:NANJING UNIV OF SCI & TECH

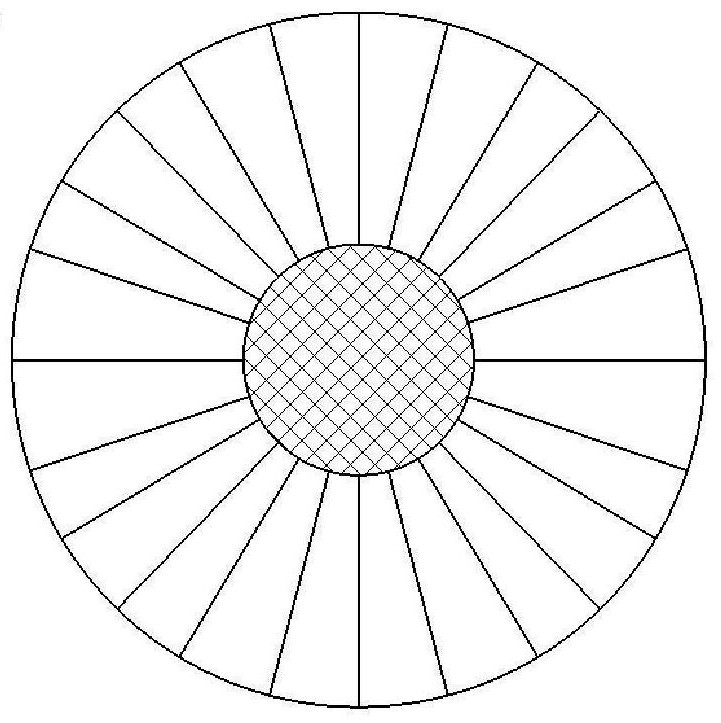

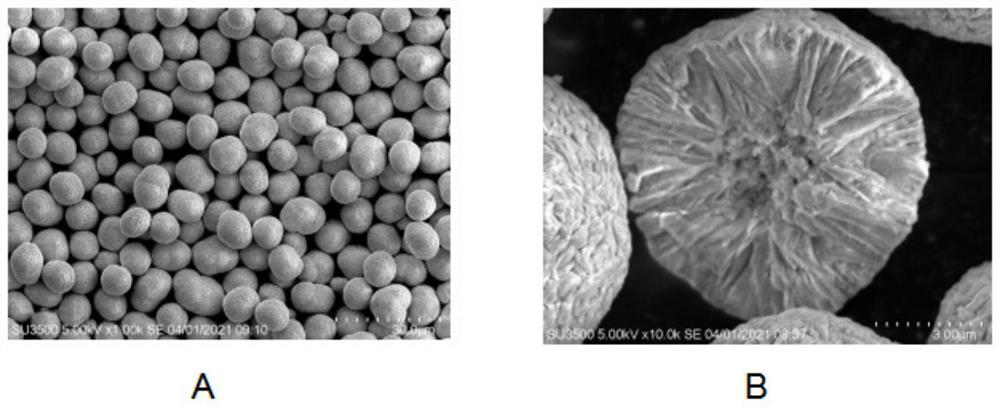

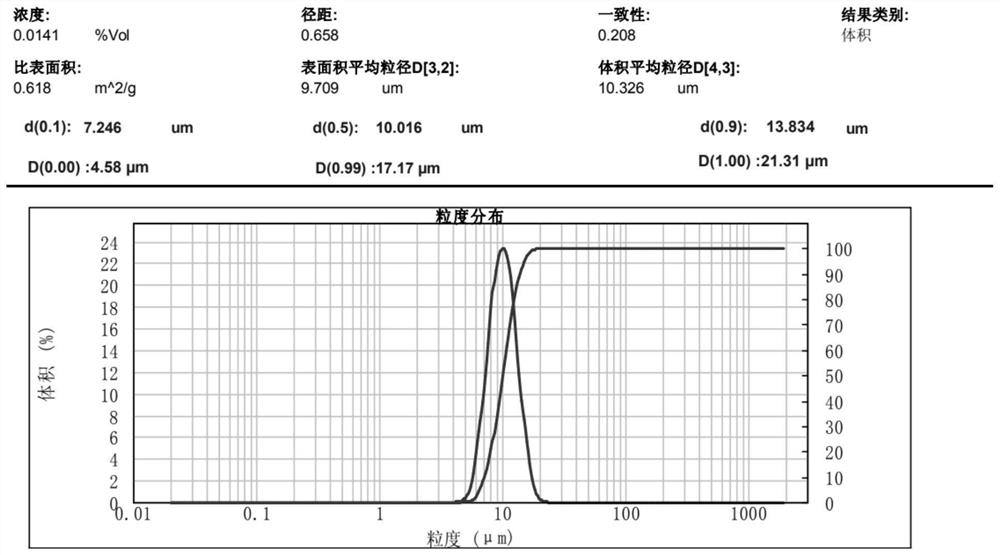

Ternary precursor and preparation method and application thereof

ActiveCN113880148AAvoid microcracksReduce DCRNickel compoundsMass transfer resistanceLithium-ion battery

The invention relates to the technical field of lithium ion battery materials, in particular to a ternary precursor and a preparation method and application thereof. The ternary precursor is of a core-shell structure, the inner core is of a loose and porous compact orange slice type structure, the shell is of a center epitaxial amplification shape, and the fan-shaped central angle of the orange slice type structure is 10-30 degrees; the core of the obtained ternary precursor particle has a loose and porous structure, so that the internal stress is reduced in the charging and discharging process of a lithium battery, and microcracks of the particle are avoided; the shell is compact and is of an orange slice structure, lithium salt can permeate into the core of the ternary precursor more easily in the sintering process of preparing the positive electrode material, the diffusion mass transfer resistance is smaller, the sintering temperature is lower, the dynamic performance is better, and use is more facilitated; the material is large in tap density, good in sphericity degree, uniform in primary particle distribution and narrow in particle size distribution, and a good premise and foundation are provided for subsequent preparation of high-quality positive electrode materials.

Owner:GUANGDONG JIANA ENERGY TECH CO LTD +1

Solution humidity-regulation air treatment system utilizing geothermal hot spring resources and treatment method thereof

ActiveCN103528154AReduce conversion lossIncrease profitSpace heating and ventilation safety systemsLighting and heating apparatusAir treatmentEngineering

The invention provides a solution humidity-regulation air treatment system utilizing geothermal hot spring resources and a treatment method for performing dehumidification and humidification on indoor air. According to the solution humidity-regulation air treatment system, the geothermal hot spring resources are directly utilized as a heat source to achieve regeneration of a humidity regulating solution and accordingly conversion energy sources such as electric energy are avoided so as to achieve energy conservation and emission reduction; meanwhile humidity regulating treatment and temperature regulating treatment on treated air are separated from each other through structural optimization and accordingly refrigeration coefficients of a surface air cooler can be improved, the efficiency of the temperature regulating treatment and the humidity regulating treatment can be improved, the energy consumption of the surface air cooler can be reduced, and energy sources can be saved; dual functions of cooling dehumidification and warming humidification can be achieved and the solution humidity-regulation air treatment system can be suitable for summer and winter air conditioning just through simple conversion control and accordingly the problem that solution humidity-regulation air conditioning systems are single in function in the prior art is solved and the market application prospect of the solution humidity-regulation air treatment system is extended.

Owner:CHONGQING UNIV

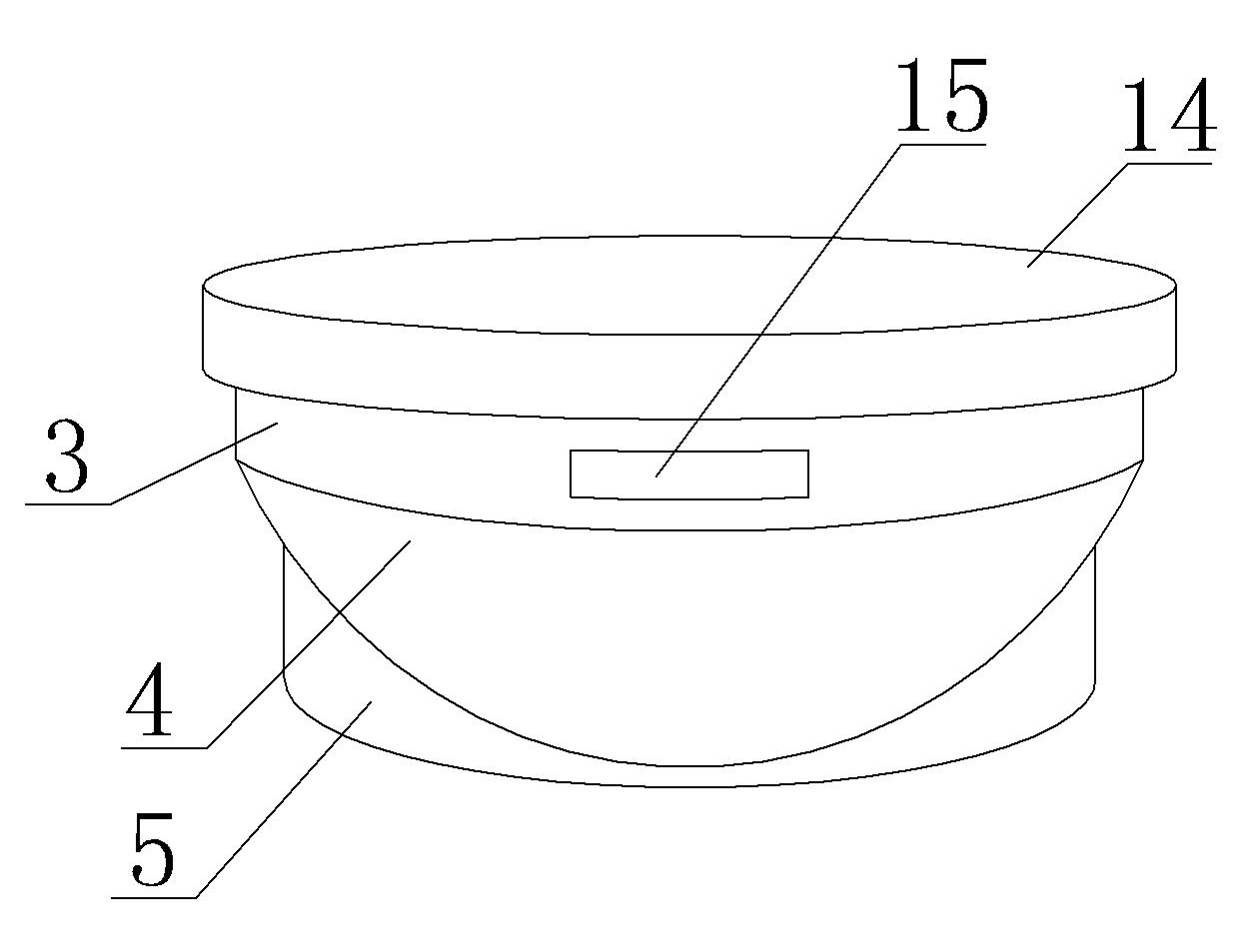

Swing-driven circular cell culture device

InactiveCN101974424ARealize up and down cycleCycle simpleBioreactor/fermenter combinationsBiological substance pretreatmentsCulture fluidEngineering

The invention relates to a swing-driven circular cell culture device. The culture device comprises a hard culture container the lower part of which is provided with a solution chamber; the bottom surface of the solution chamber is a smooth concave surface; a slope surface is arranged on the side wall surface of the solution chamber; the slope surface and the concave surface are in smooth transition; a circular pipe is arranged on the side wall of the solution chamber along the slope surface in a matched manner; the circular pipe is provided with an upper opening and a lower opening; and a one-way discharge valve structure is arranged at the lower opening. When the circular cell culture device is driven to swing left and right, the upper culture solution constantly enters from the upper openings of the two circular pipes and rushes out from the lower openings, while the original lower culture solution is turned upwards in the process to realize up-down circulation of the culture solution; the circulation is simple and effective, and the mixing and ventilation effect is good; and moreover, the circulation frequency can be minimized and the shearing force of the circulation is little.

Owner:ZHENGZHOU VIRIGE BIOTECH

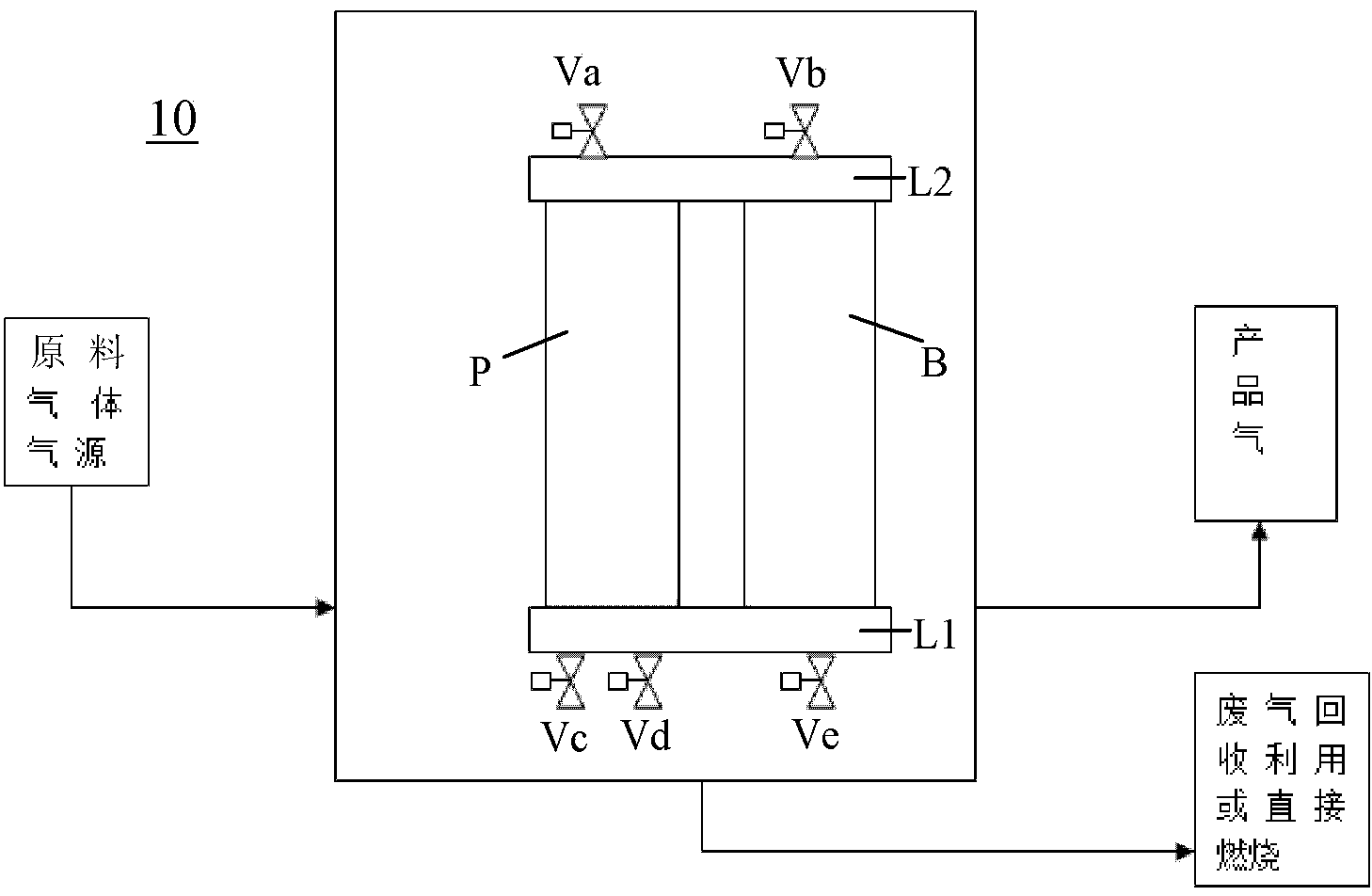

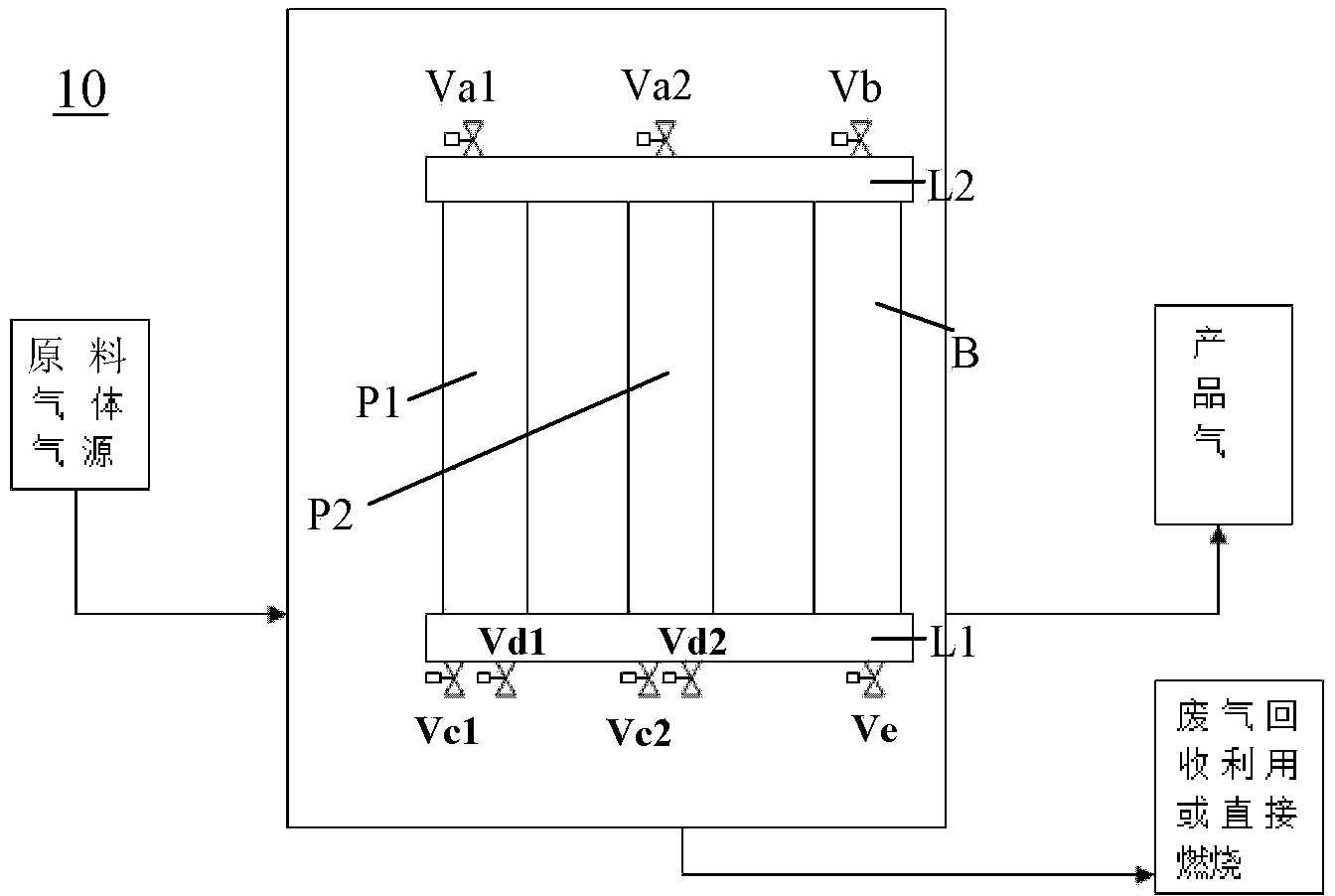

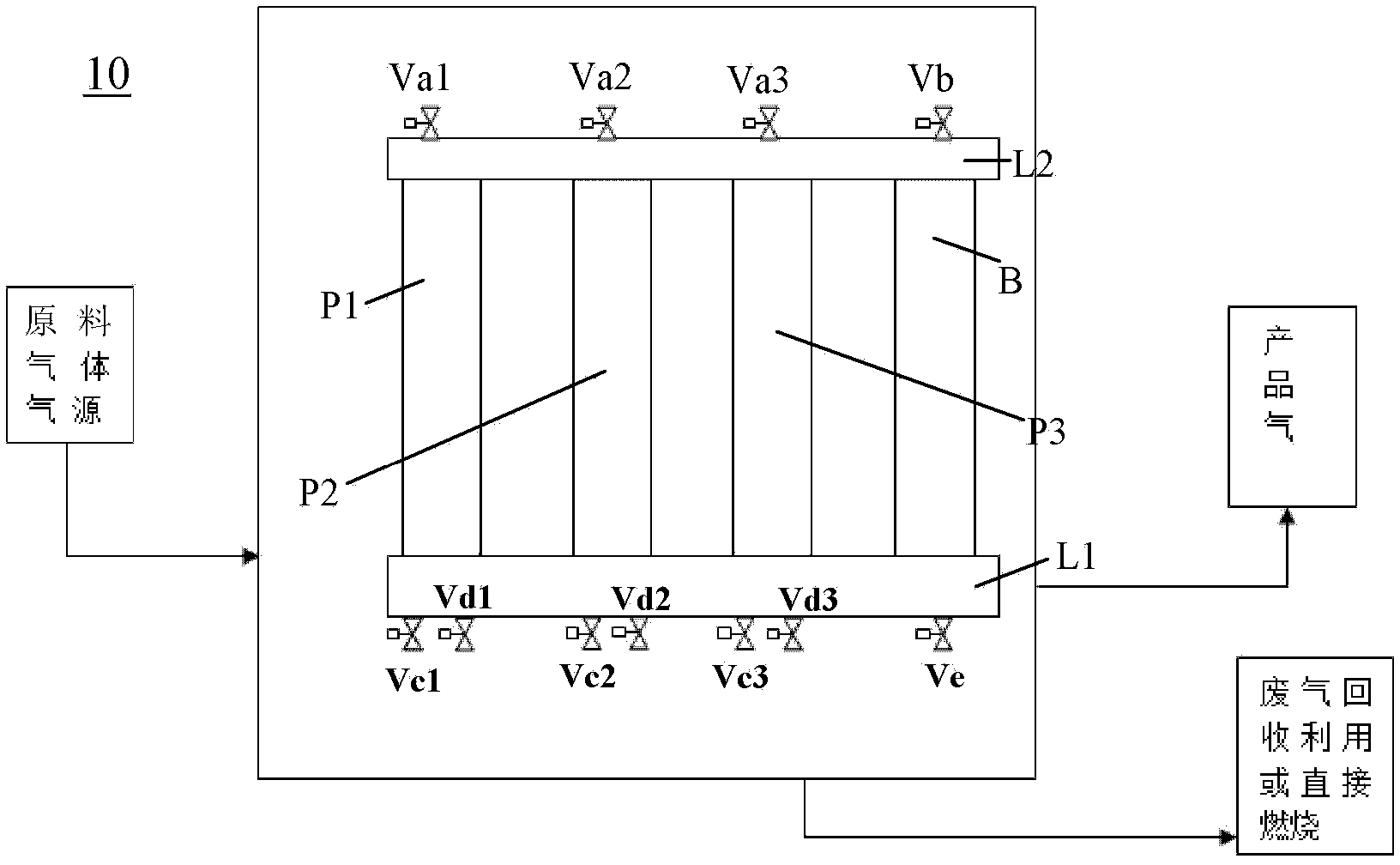

Pressure swing adsorption gas purifier

ActiveCN104028077AStructural integrationSimple PSA cycleHydrogen separation using solid contactDispersed particle separationProcess engineeringMiniaturization

The invention provides a gas purification device using a pressure swing adsorption principle. The pressure swing adsorption gas purifier provided by the invention has the characteristics of integration and miniaturization in structure, easiness in PSA (Pressure Swing Adsorption) circulation, high flexibility, easiness for assembling, high purification efficiency, low cost and the like.

Owner:BEIJING NOWOGEN TECH CO LTD

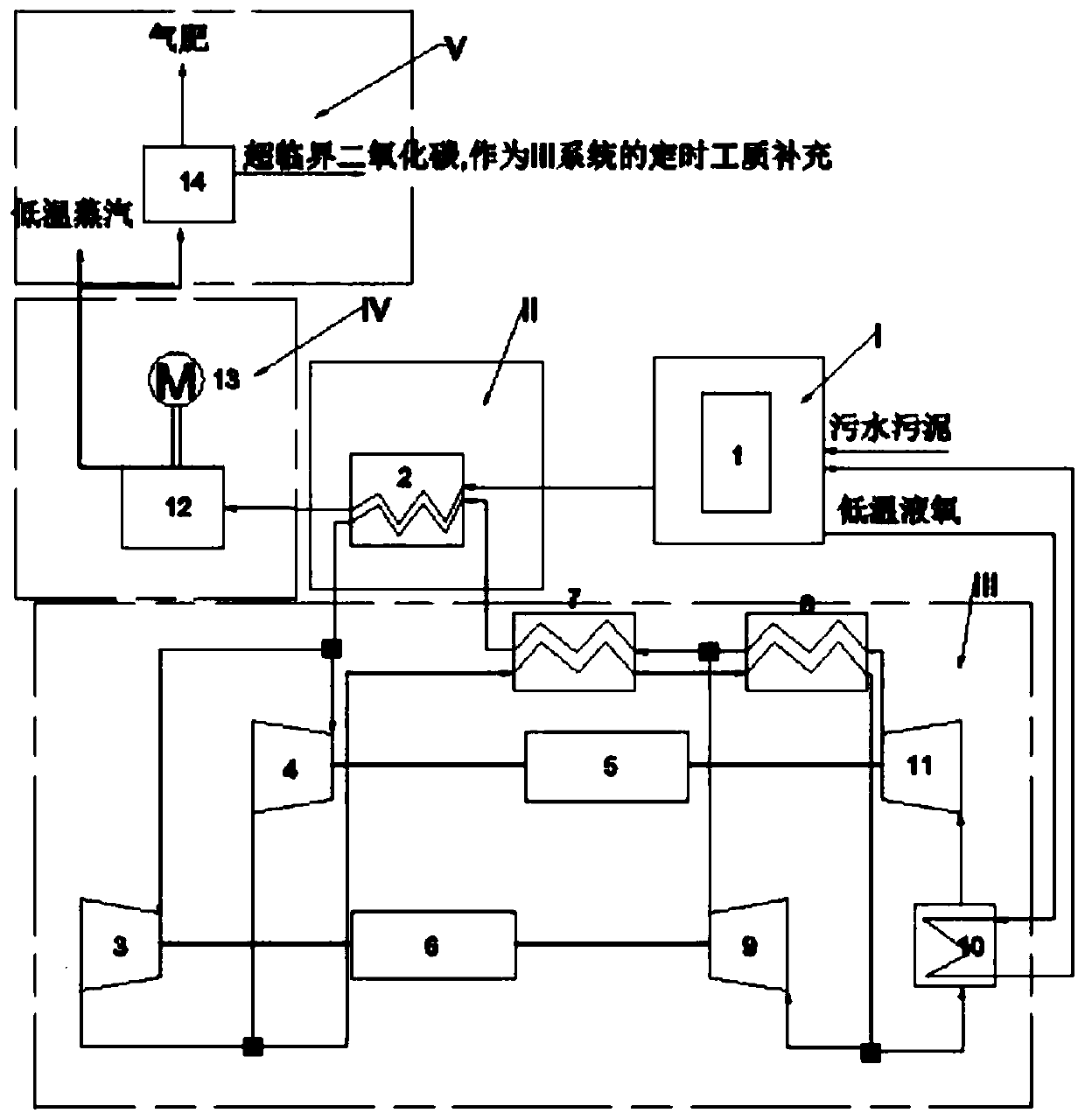

Supercritical carbon dioxide power generation system and method combining supercritical water oxidation technology

PendingCN110486107AEasy to recycleImprove utilizationSludge treatment by oxidationSteam useSludgeSupercritical water oxidation

The invention relates to a supercritical carbon dioxide power generation system combining a supercritical water oxidation technology. The system comprises a supercritical water oxidation unit, a heatexchange unit, a supercritical carbon dioxide power generation unit, an expansion machine power generation unit and a tail gas heat energy utilization recovery unit; the supercritical water oxidationunit involves a supercritical water oxidation reactor, the heat exchange unit involves a main heat exchanger, the supercritical carbon dioxide power generation unit involves a turbine, a motor, a high-temperature heat exchanger, a low-temperature heat exchanger, a high-temperature compressor, a low-temperature compressor and a cooler, and the expansion machine power generation unit involves an expansion machine and a generator; and the tail gas heat energy utilization recovery unit involves a liquefying separation treatment device. The supercritical carbon dioxide power generation system and method combining the supercritical water oxidation technology can effectively treat sewage sludge and generate electric energy; and an ecological development mode combining environmental pollution treatment and energy development and utilization is realized.

Owner:碧流天能(北京)科技股份有限公司

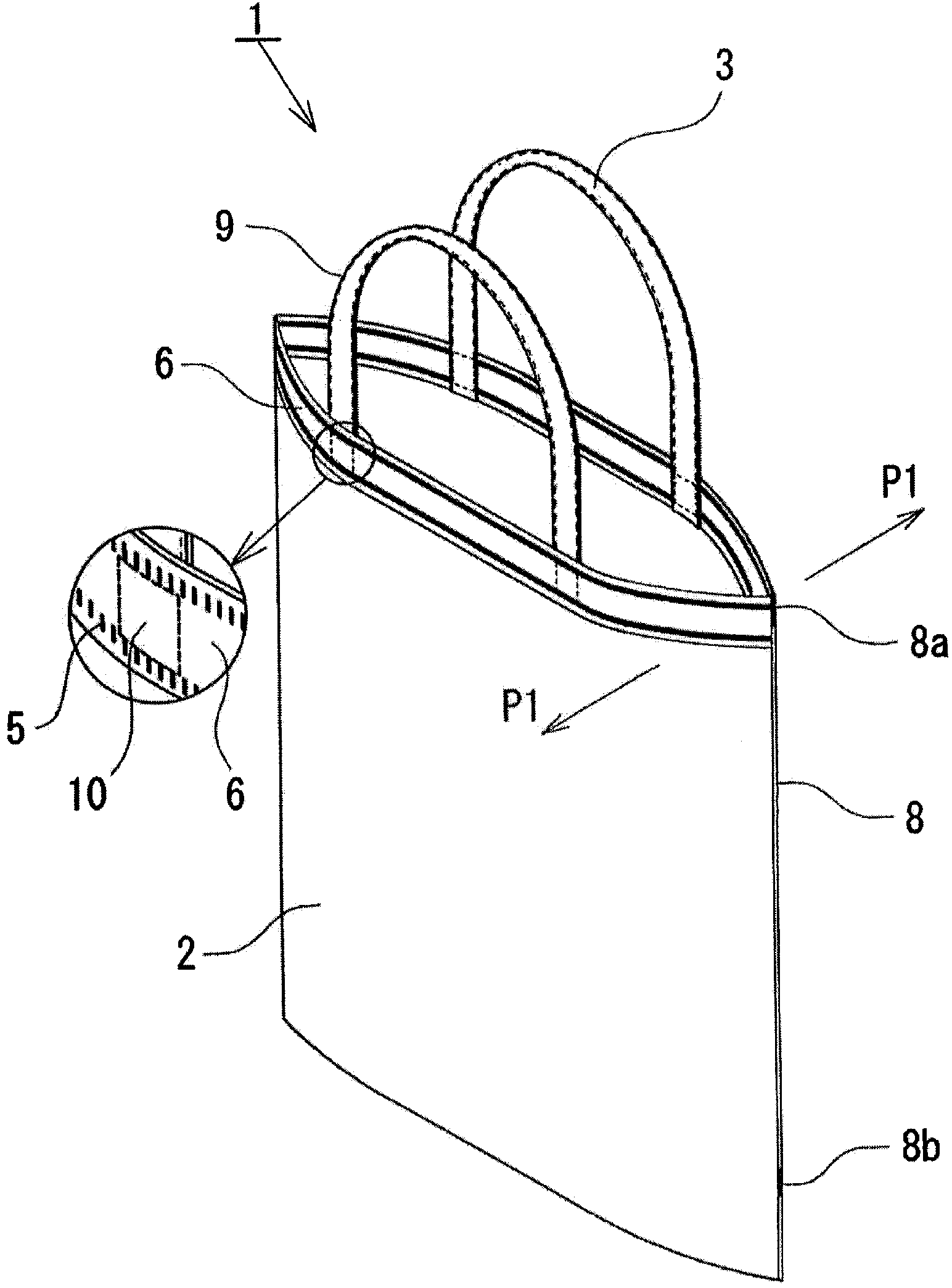

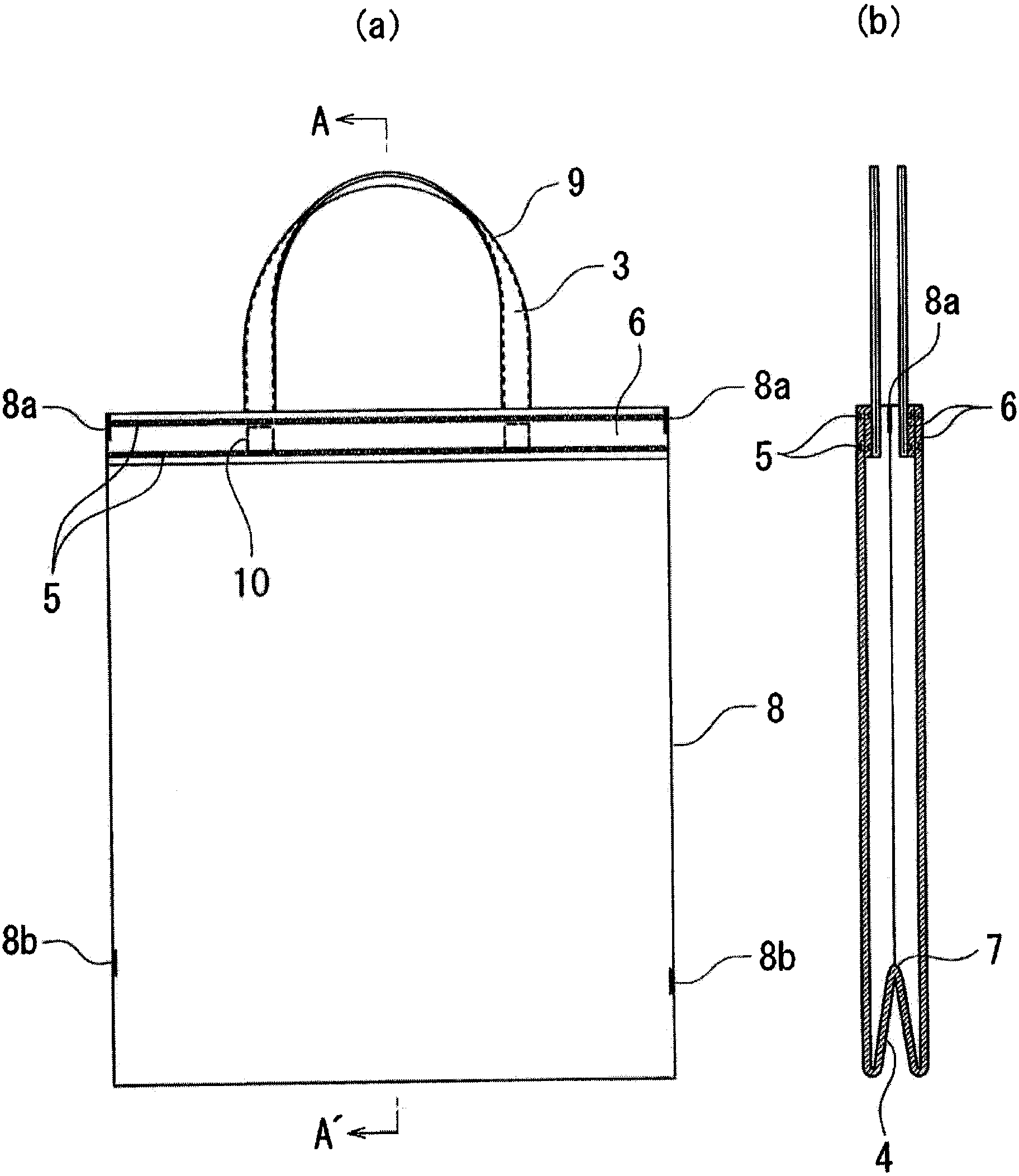

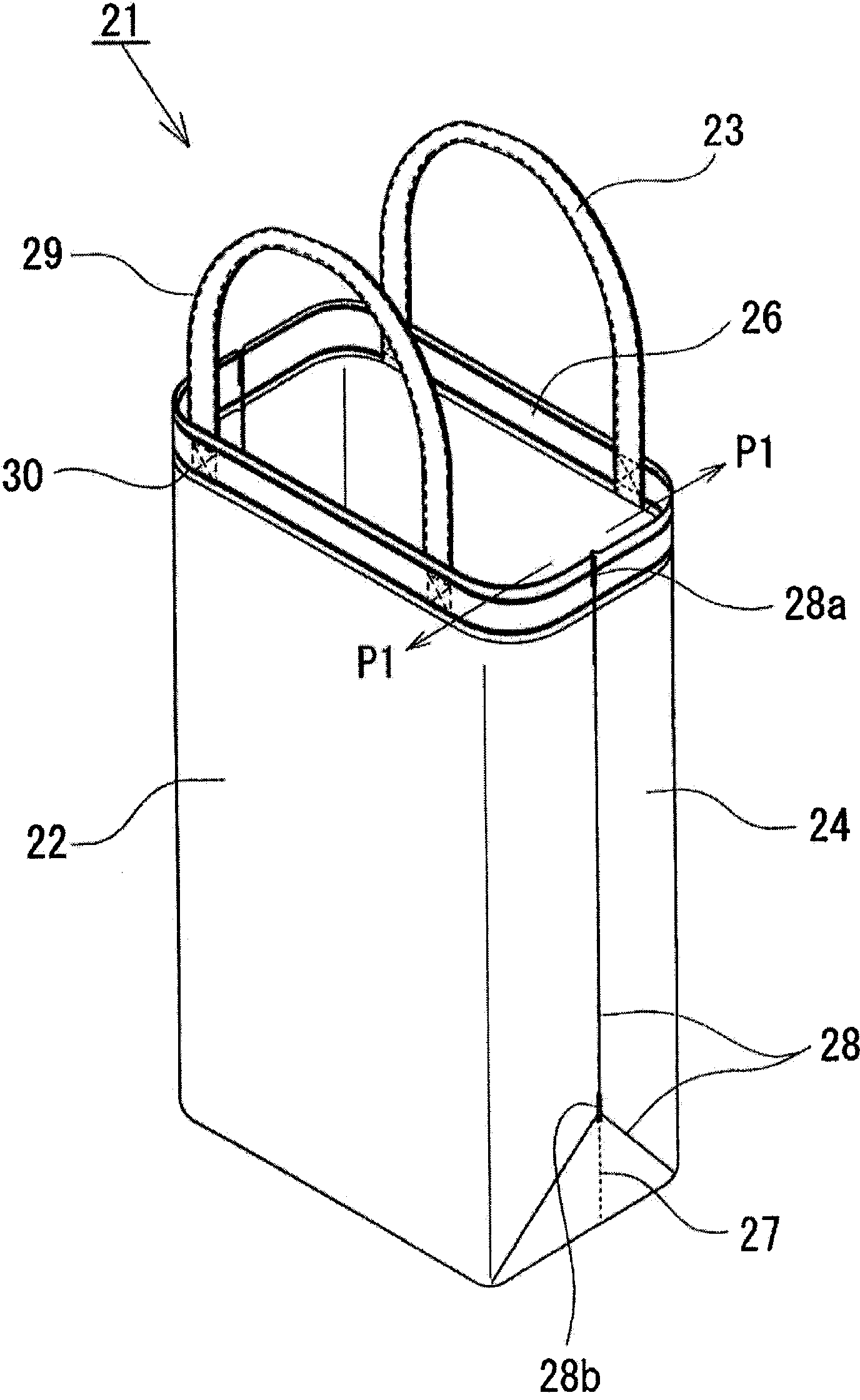

Nonwoven fabric bag with handles

A nonwoven fabric bag includes: a bag body; and a pair of handles. A fabric sheet is folded in two. A bottom of the bag is formed by a sheet portion including the fold line. Side edges of the opposing folded halves of the sheet are bonded together on right and left sides to form a bag. A sheet portion along a peripheral edge of an opening of the bag is folded inward and bonded to form a double-layer portion, thereby forming the bag body. Two strips are attached to the double-layer portion, thereby forming the pair of handles. The side edges are bonded by impulse heat sealing. The peripheral edge of the opening and a vicinity thereof, and a part connecting to the fold line are sewn. The double-layer portion is bonded by discontinuous ultrasonic sealing. Attachment portions between the double-layer portion and the handles are sewn.

Owner:株式会社亚科喜缌

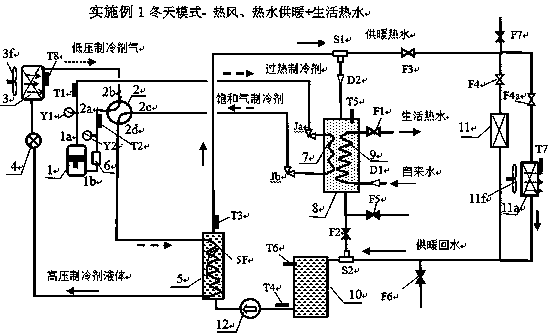

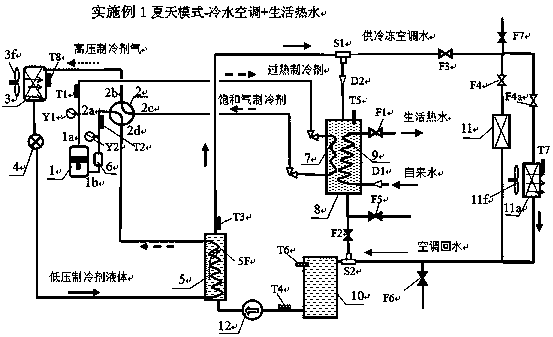

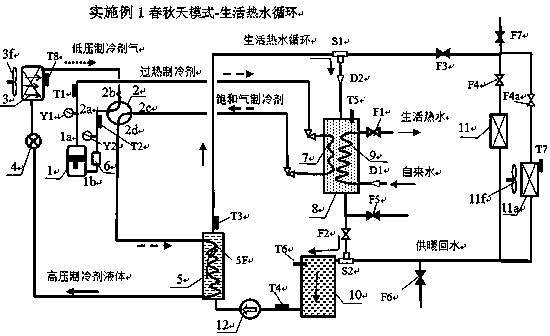

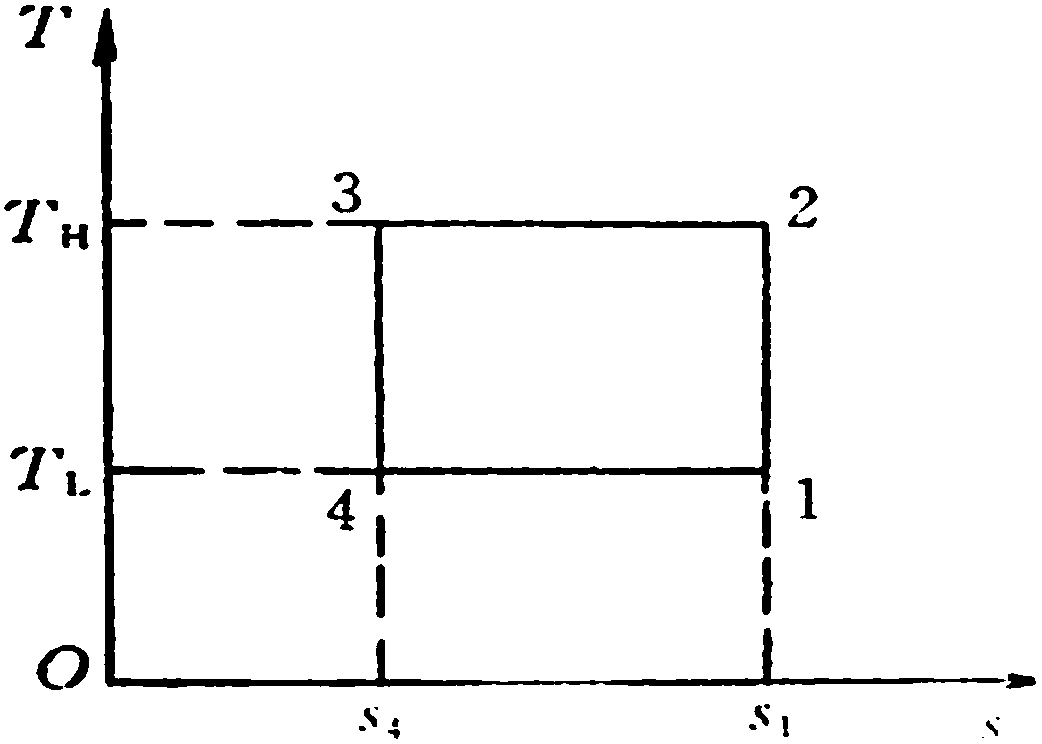

Heat storage type domestic central air-conditioning, heat supply and water heating three-purpose machine

InactiveCN108800650AAvoid affecting equipment efficiencyCycle simpleFluid heatersMechanical apparatusFour-way valveWater cycling

The invention discloses a heat storage type domestic central air-conditioning, heat supply and water heating three-purpose machine. The heat storage type domestic central air-conditioning, heat supplyand water heating three-purpose machine comprises a refrigerant, heat supply / air conditioning water circulation and control system, and is characterized by further comprising a domestic hot water heat exchanging and heat storing machine; the domestic hot water heat exchanging and heat storing machine consists of a preceding-stage water heat exchanger, a hot water tank and a domestic hot water heat exchange tube; a refrigerant circulation system comprises a loop which is formed by sequential connection of a compressor, the preceding-stage water heat exchanger, a four-way valve, a water heat exchanger, a throttling valve, an outdoor air heat exchanger, a four-way valve, an air and liquid separator and a compressor; a heat supply / air conditioning water circulation system comprises a loop formed by sequential connection of a circulating water pump, a water access of the water heat exchanger, a coil tube fan and a dual-purpose water tank; a loop for generating domestic hot water by using aheat pump in spring and autumn consists of a circulating water pump, a water access of the water heat exchanger, a hot water tank and a dual-purpose water tank which are connected in sequence; the hot water tank is used for storing heat and supplying domestic hot water; and the heat exchange amount of the preceding-stage water heat exchanger is smaller than 1 / 5 of that of the water heat exchanger. The three-purpose machine disclosed by the invention has the functions of supplying head, conditioning air and supplying domestic hot water in four seasons, is extremely simple in both structure andcontrol, is high in efficiency and saves energy.

Owner:陈则韶

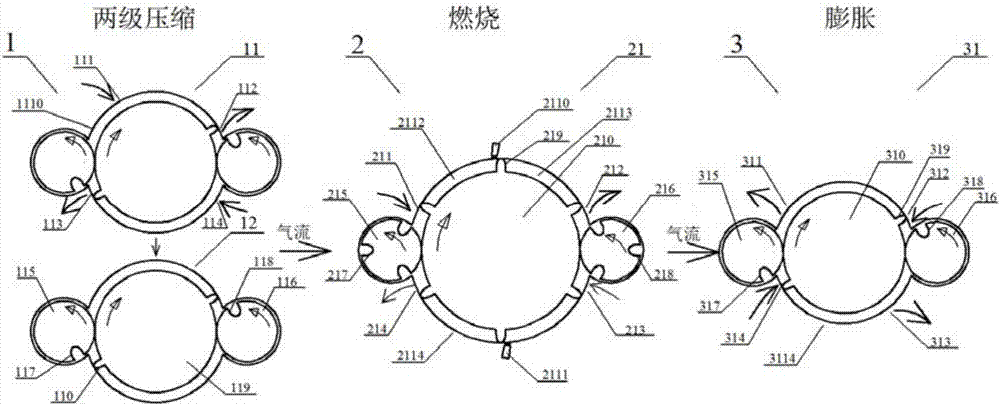

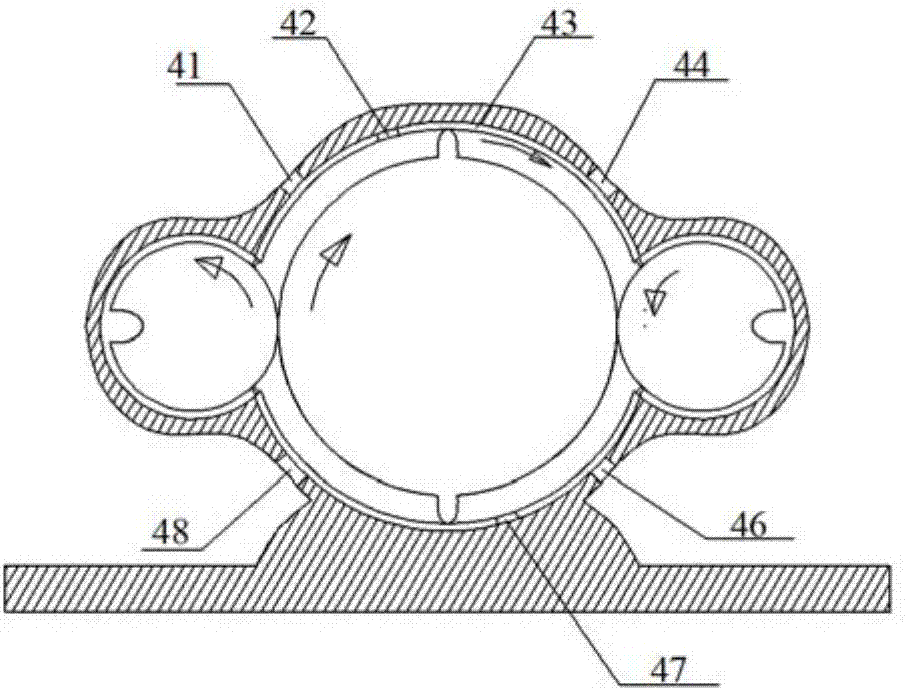

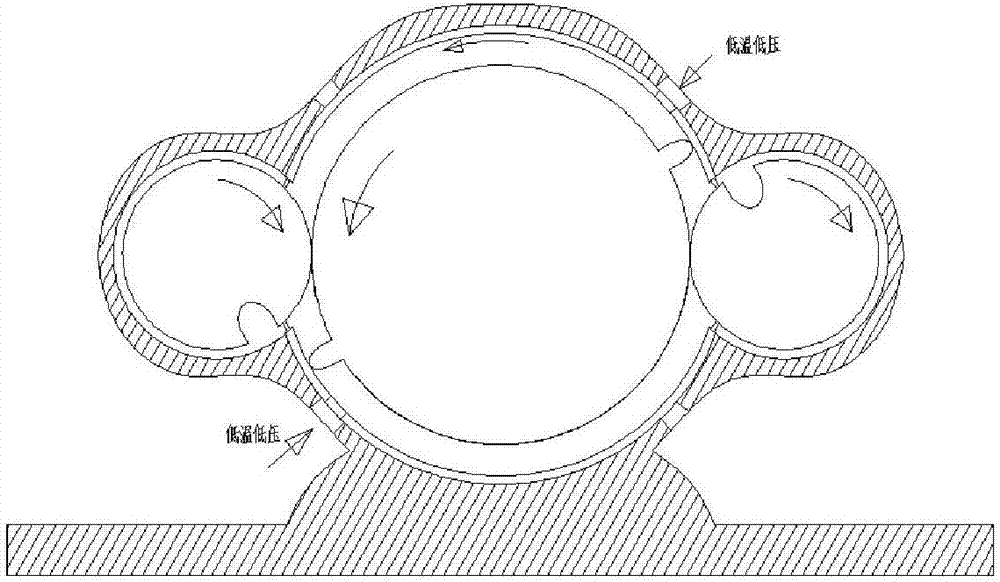

Rotor type engine

ActiveCN106948936ALow lubrication requirementsCycle simpleInternal combustion piston enginesRotary piston pumpsCombustorCore component

The invention provides a rotor type engine and relates to the technical field of engines. The rotor type engine comprises three functional levels including a compression level, a combustion level and an expansion level. The rotor type engine is characterized in that all levels are independent to one another and are connected in series into a whole through a main shaft, and each level is composed of one or more heating power conversion units. The heating power conversion units comprise compressors, combustors and expansion machines at different functional levels. The engine is mainly composed of a main rotor, an auxiliary rotor, a shell and a timing device; main components are all subjected to revolved body machining, the outer diameter of the main rotor is tangent to that of the auxiliary rotor and is two times that of the auxiliary rotor, and the angular speed of the auxiliary rotor is two times that of the main rotor; and the shell contains fixed air feeding openings and exhausting openings, the timing device is a cylindrical piece containing a circumferential air opening, and the timing device and the shell are subjected to sealed treatment through comb teeth. Core components of the compressors, the combustors and the expansion machines are all served as the timing device.

Owner:HUNAN UNIV

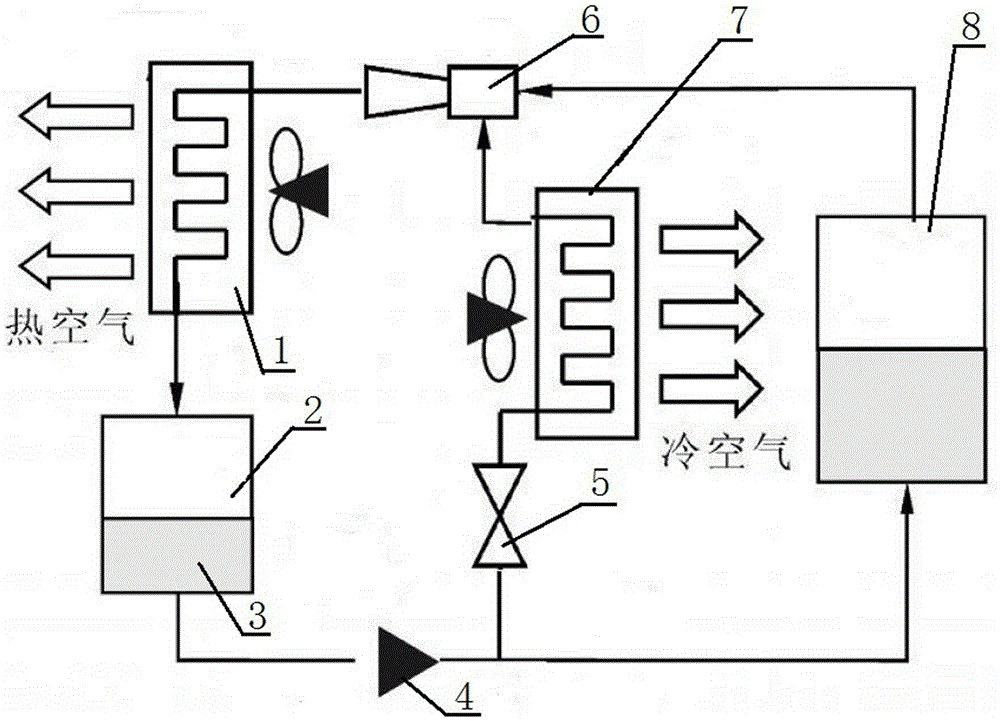

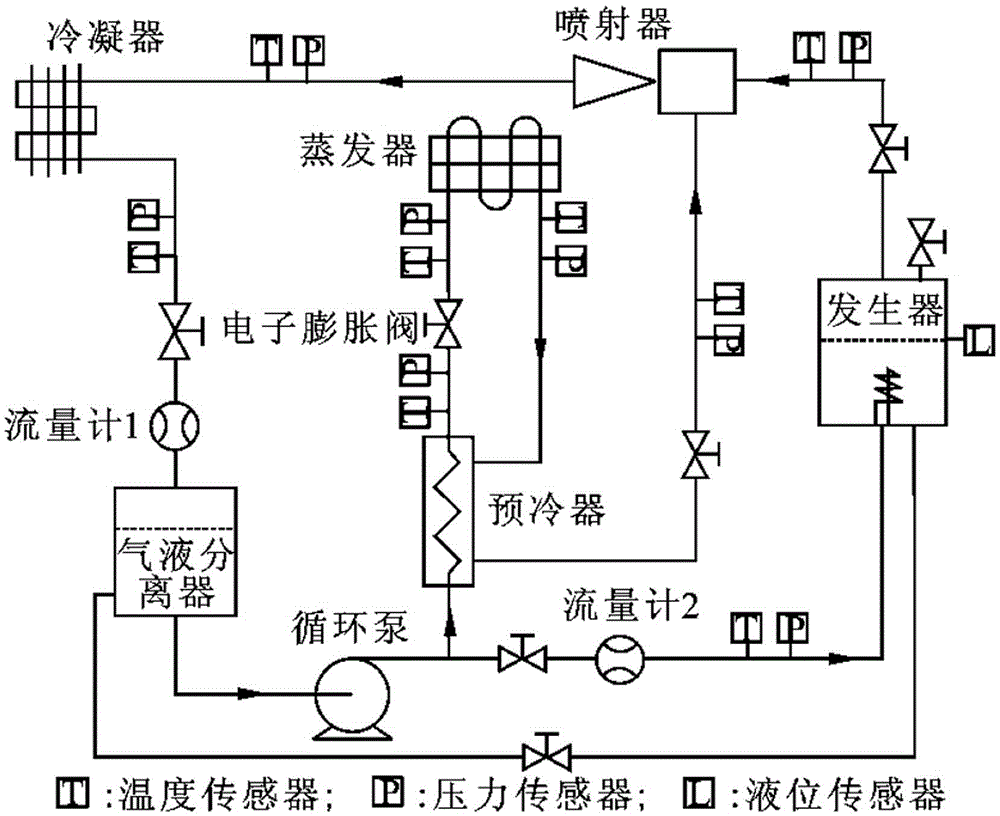

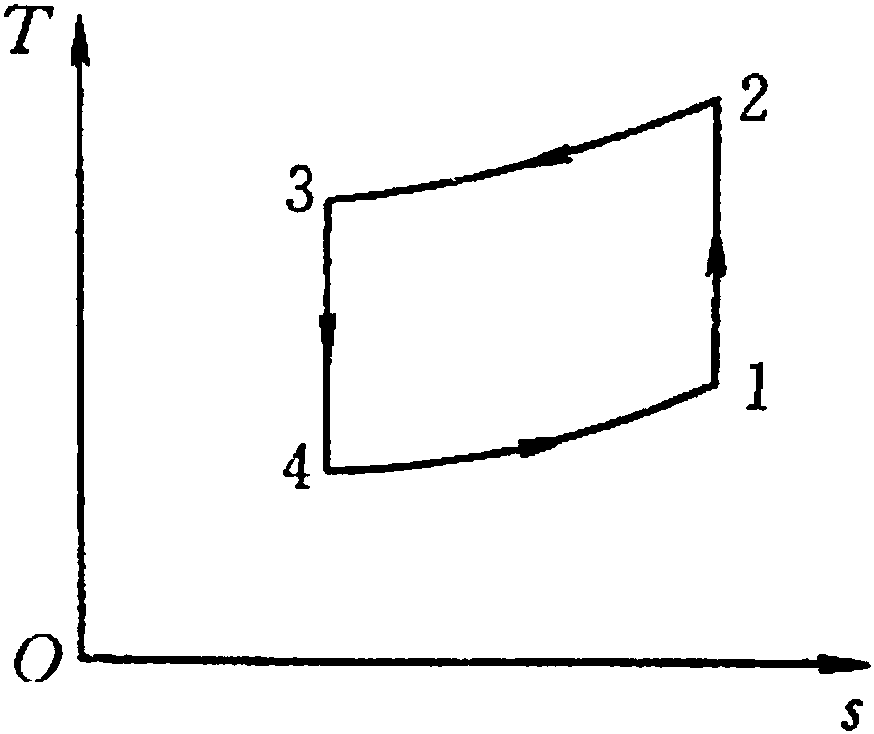

Ejection refrigeration circulation system

InactiveCN106642797APredictive performanceCycle simpleMachines using refrigerant evaporationVapor–liquid separatorEngineering

The invention discloses an ejection refrigeration circulation system with the advantages of higher accuracy, simple structure and convenience in application. The ejection refrigeration circulation system comprises an ejector, a gas generator, a condenser, a gas-liquid separator, an expansion valve, two evaporators and a circulation pump and has the structure key points that the evaporators are composed of a first evaporator and a second evaporator; the input end of the ejector is connected with the output end of the second evaporator; the input end of the second evaporator is connected with one end of the expansion valve; the other end of the expansion valve is connected with one end of the gas generator and the output end of the circulation pump separately; the other end of the gas generator is connected with the input end of the ejector; the output end of the ejector is connected with the input end of the first evaporator; the output end of the first evaporator is connected with the one end of the condenser; the other end of the condenser is connected with one end of the gas-liquid separator; and the other end of the gas-liquid separator is connected with the input end of the circulation pump.

Owner:赵俭

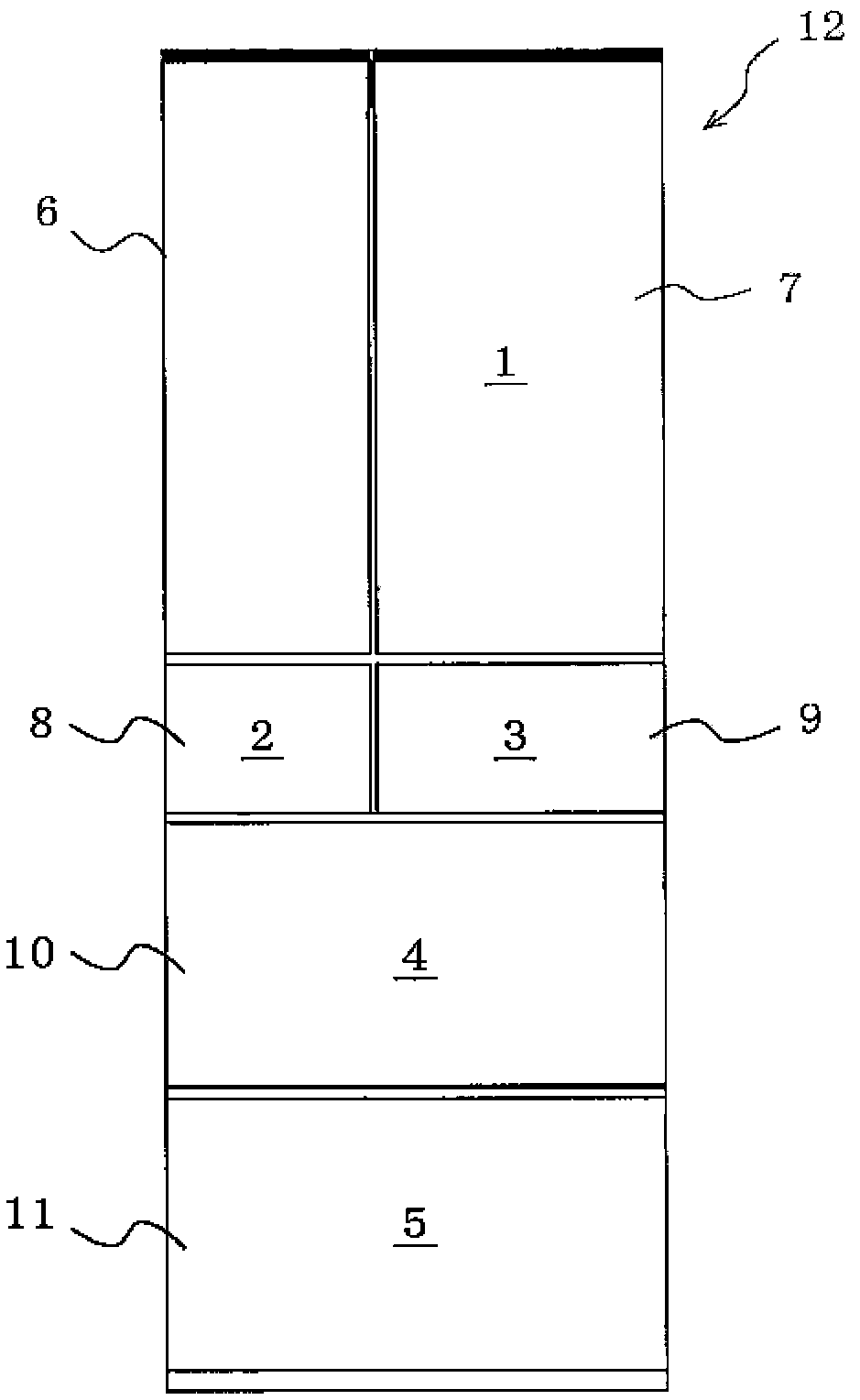

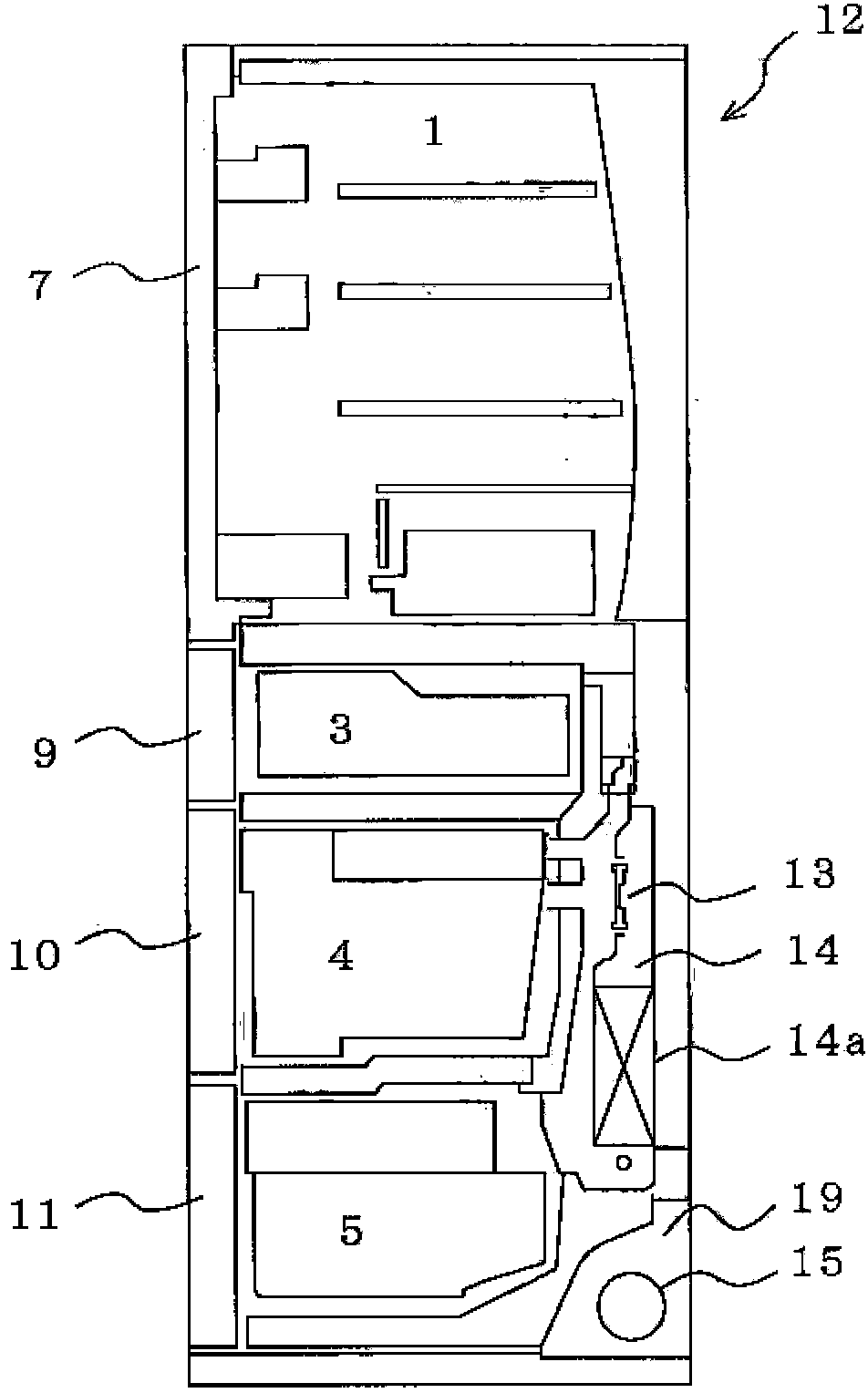

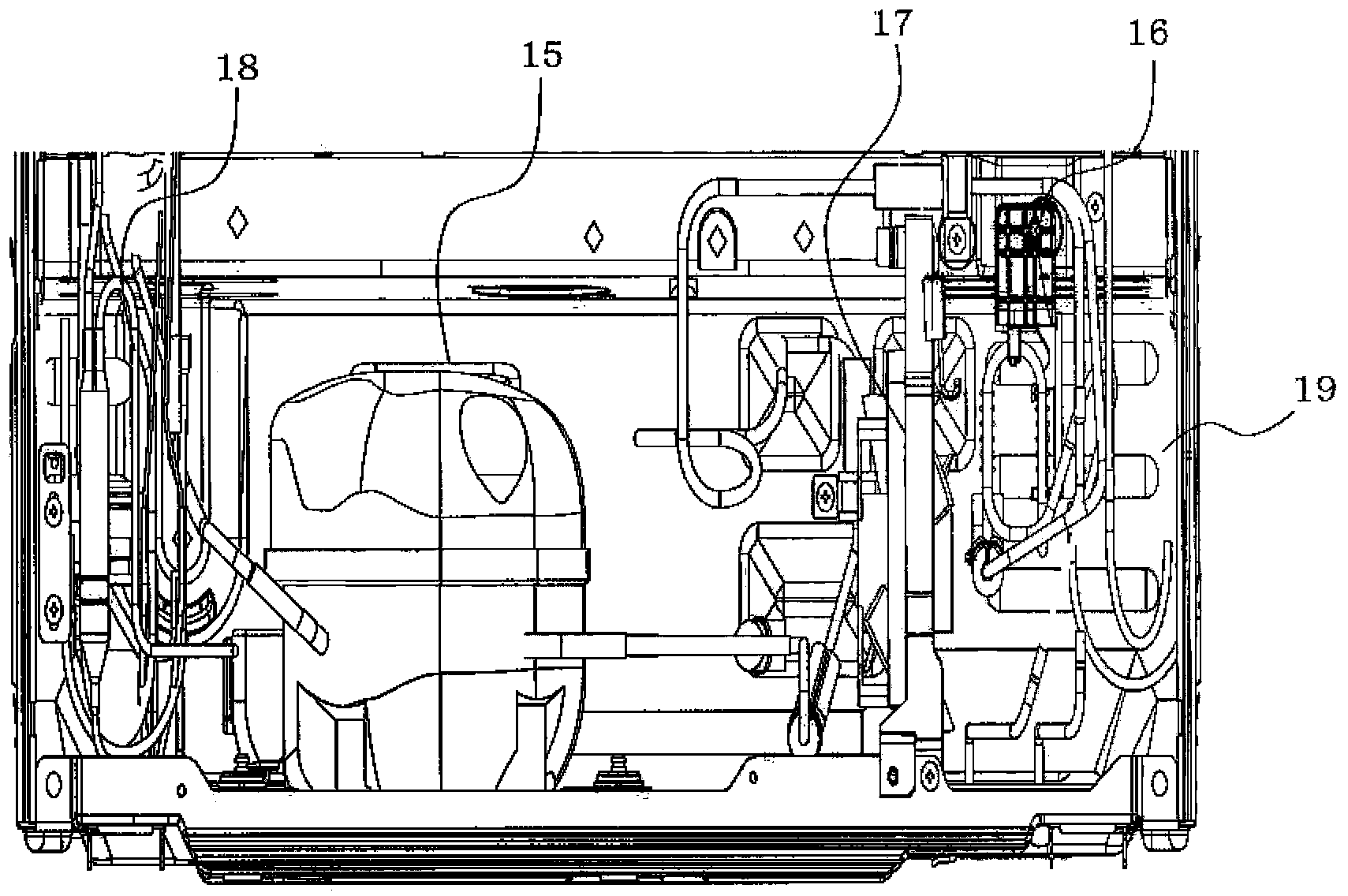

Refrigerator and freezer

ActiveCN103575025AImprove qualityCycle simpleEvaporators/condensersRefrigeration devicesRadiationRefrigerated temperature

The invention provides a refrigerator and freezer which is not subjected to the main body of the refrigerator and freezer and improves the heat radiation efficiency of a condenser. The refrigerator and freezer comprises a mechanical chamber (19) arranged on the lower portion of the back of the main body, wherein at least one compressor (15) and a blower (17) for the mechanical chamber are arranged in the mechanical chamber; a pipe (25) arranged on the front lower portion of the mechanical chamber of the main body; and a metal wire type condenser (20) in the pipe, wherein the pipe (25) is provided with an air suction port (21) on the right side of the main body, an air inflow path (23) communicating the suction port and an air intake port (19a) of the mechanical chamber and being arranged on the metal wire type condenser (20), an air exhaust port (22) arranged on the front side of the main body and being adjacent to the air suction port (21), and an air flow path (24) communicating the air exhaust port and an air outlet port (19b) of the mechanical chamber.

Owner:MITSUBISHI ELECTRIC CORP

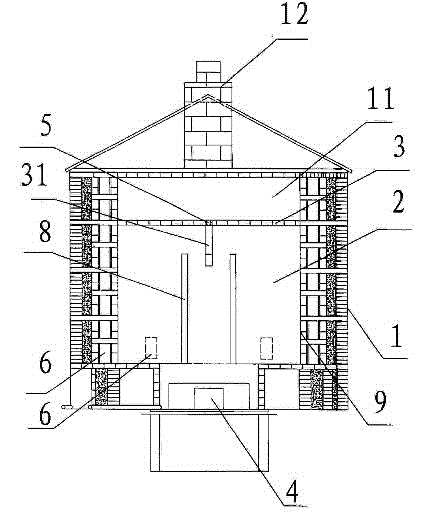

Strain sterilizer

InactiveCN104686189AEasy to absorb heatEndothermic maintenanceCultivating equipmentsHeatCombustionHigh intensity

The invention relates to a strain sterilizer. By aiming at the defects of non-sealing combustion due to structure defects of the existing edible fungus sterilizer, poor heat insulation effect, insufficient smoke dust combustion, non-effective utilization of smoke gas afterheat, long work time, high work intensity of people and non-thorough sterilization due to inconstant temperature, the strain sterilizer is provided with a double-layer heater under a temperature rise wall, water pipes are crossed and stacked for forming herringbone to be distributed at the bottom of the heater. The strain sterilizer has the advantages that the full sealing is realized, the energy is saved, time and labor are saved, the smoke and the dust are removed, the pollution is reduced, the constant temperature is realized, and the sterilization is more thorough.

Owner:蔡凌

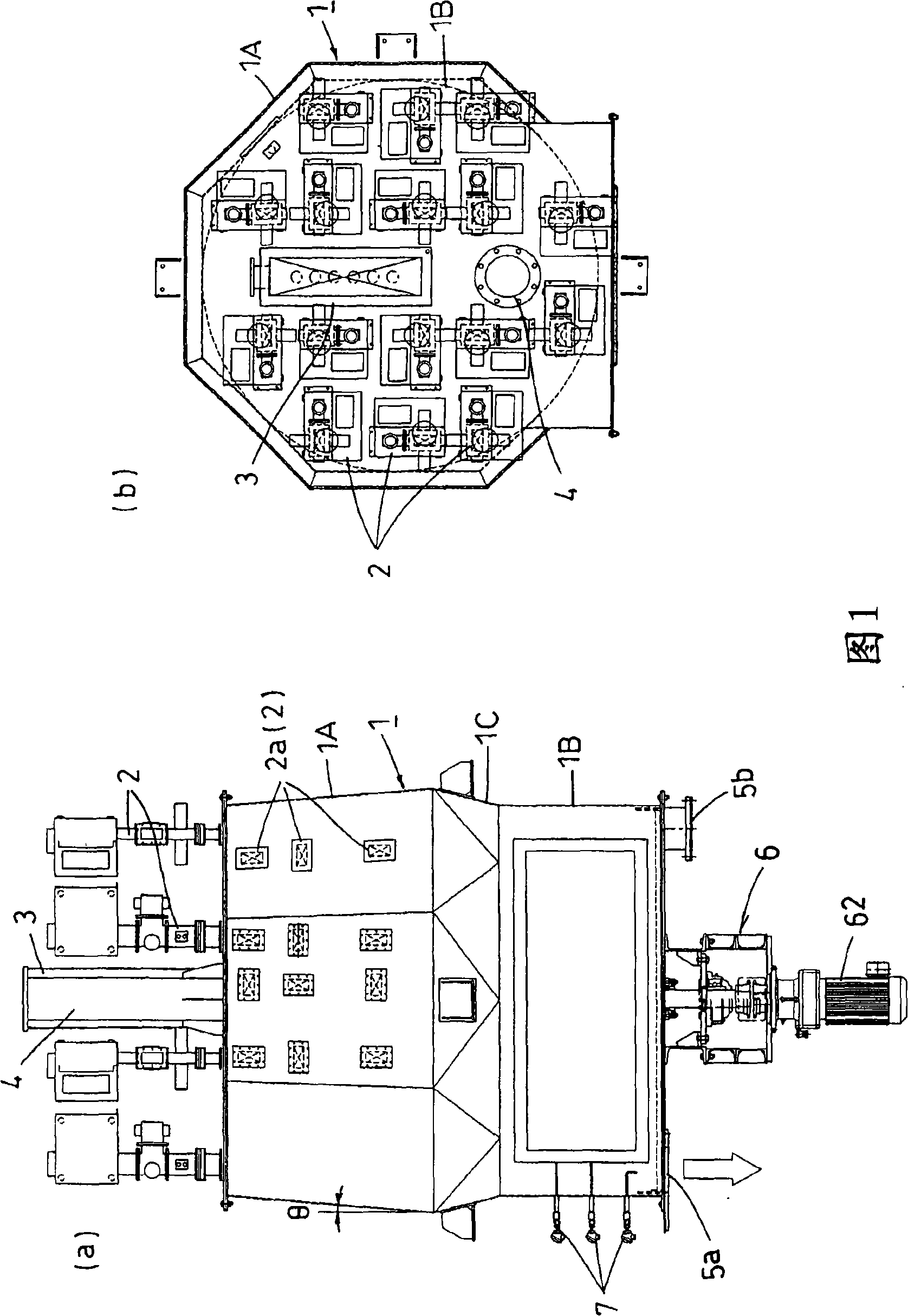

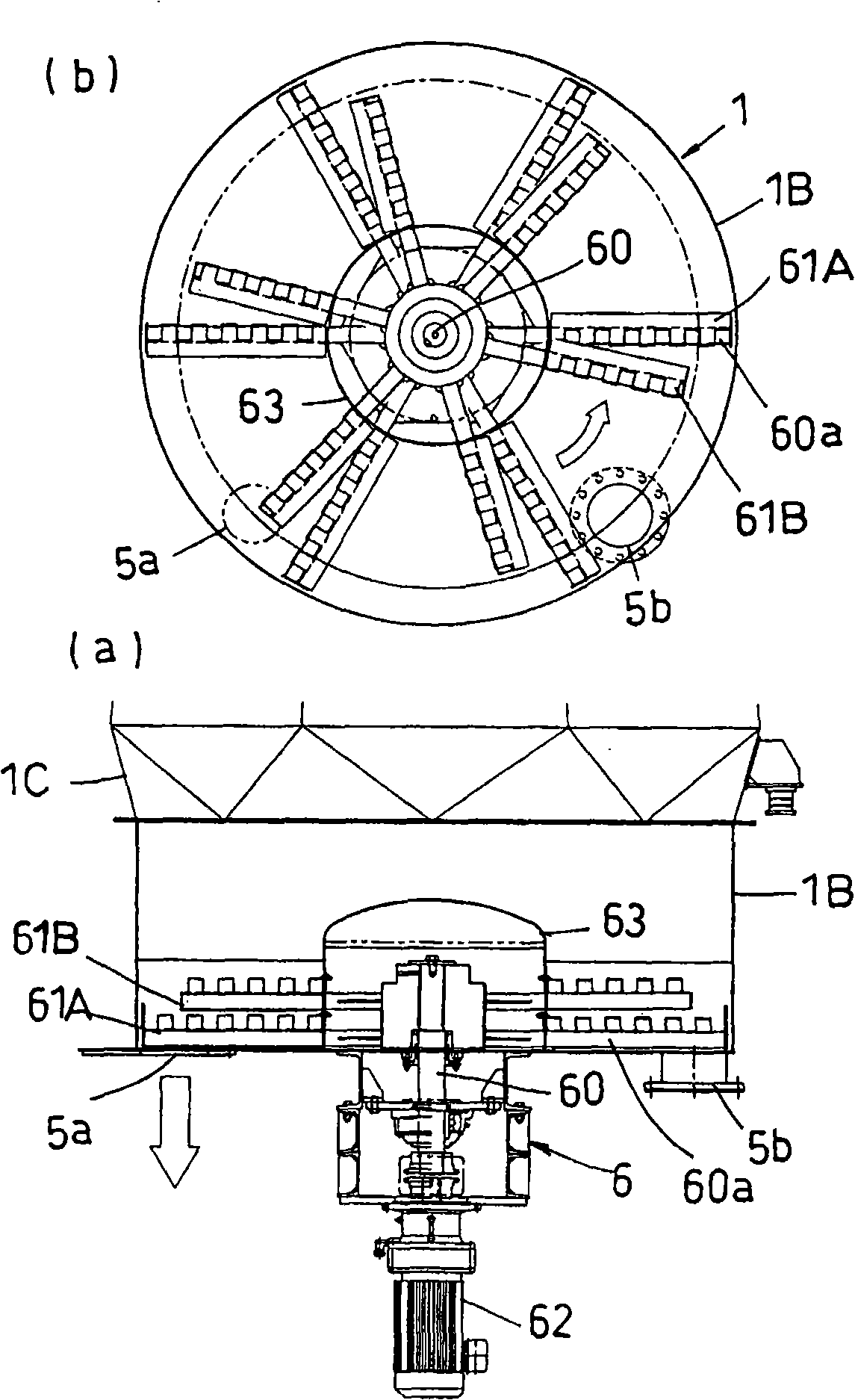

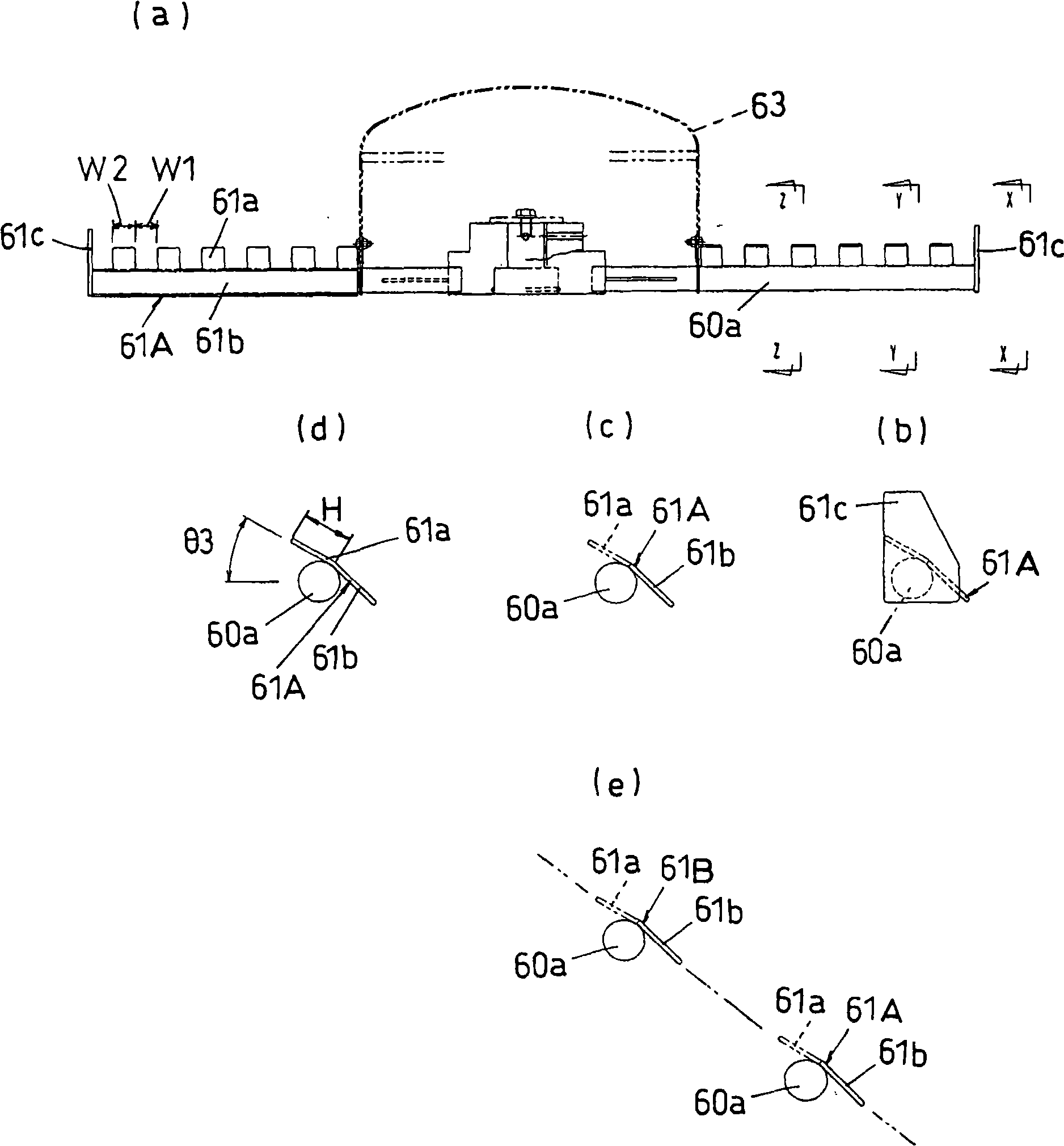

Treatment device of harmful substance such as organic halogenation compound

InactiveCN101288794AImprove processing efficiencyEffective stirringEnergy based chemical/physical/physico-chemical processesMicrowaveHazardous substance

The invention provides a treatment device for harmful substance like organohalogen compound which can efficiently stir, by a stirring mechanism, a solid to which harmful substances are adhered, and can improve treatment efficiency. The invention includes a basket body 1, a microwave irradiating mechanism 2, the stirring mechanism 6; the basket body 1 guides the solid to which harmful substance like organohalogen compounds are adhered; the microwave irradiating mechanism 2 irradiates the solid to which harmful substance is adhered and which is guided into the basket body 1; the stirring mechanism 6 includes rotary laminas 61A, 61B which are in multistage assembly in upper and lower directions and stir the the solid to which harmful substance is adhered and which is guided into the basket body 1.

Owner:NIHON SPINDLE MFG CO LTD

Preparation method of exosome-like structural lipid microcapsule

PendingCN112007012AReduce volumeCycle simplePharmaceutical non-active ingredientsMicrocapsulesBiophysicsBiological organism

The invention discloses a preparation method of an exosome-like structural lipid microcapsule. The preparation method comprises the following steps of: A, culturing PBMC cells by using a culture medium to obtain in-vitro mature dendritic cells; B, adding Proteinase K into the in-vitro mature dendritic cells to perform pre-treatment; C, adding an exosome extraction reagent, the volume of which is 0.3-1.2 times of that of the in-vitro mature dendritic cells, into the pre-treated in-vitro mature dendritic cells, centrifuging for 30-50 min, and collecting supernatant with the centrifugal force of3000-5000 g; and D, centrifuging the supernatant for 100-150 min, and collecting the supernatant again. The lipid microcapsule prepared by the method is small in volume and easy in in-vivo circulation; the lipid microcapsule can reach damaged tissues easily; meanwhile, the absorption speed and the absorption amount of the lipid microcapsule by gastrointestinal mucous membranes of organisms are also increased; the lipid microcapsule is good in in-vivo absorption; therefore, the effects of relatively high bioavailability and rapid drug effect exertion are achieved; and furthermore, the lipid microcapsule is mild in preparation condition, simple, controllable, suitable for large-scale production and low in preparation cost, and has price advantage.

Owner:广州北斗生物科技有限公司

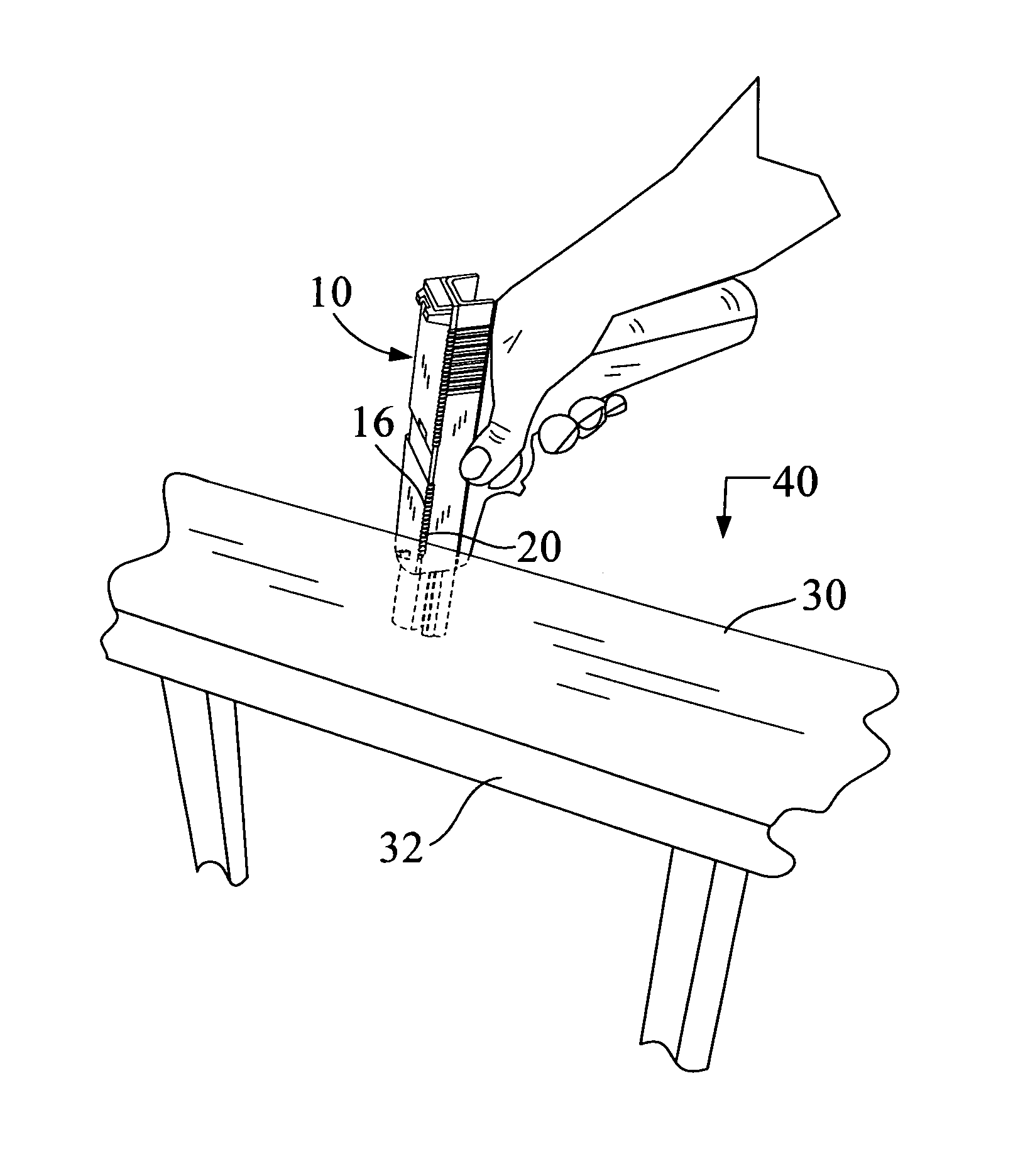

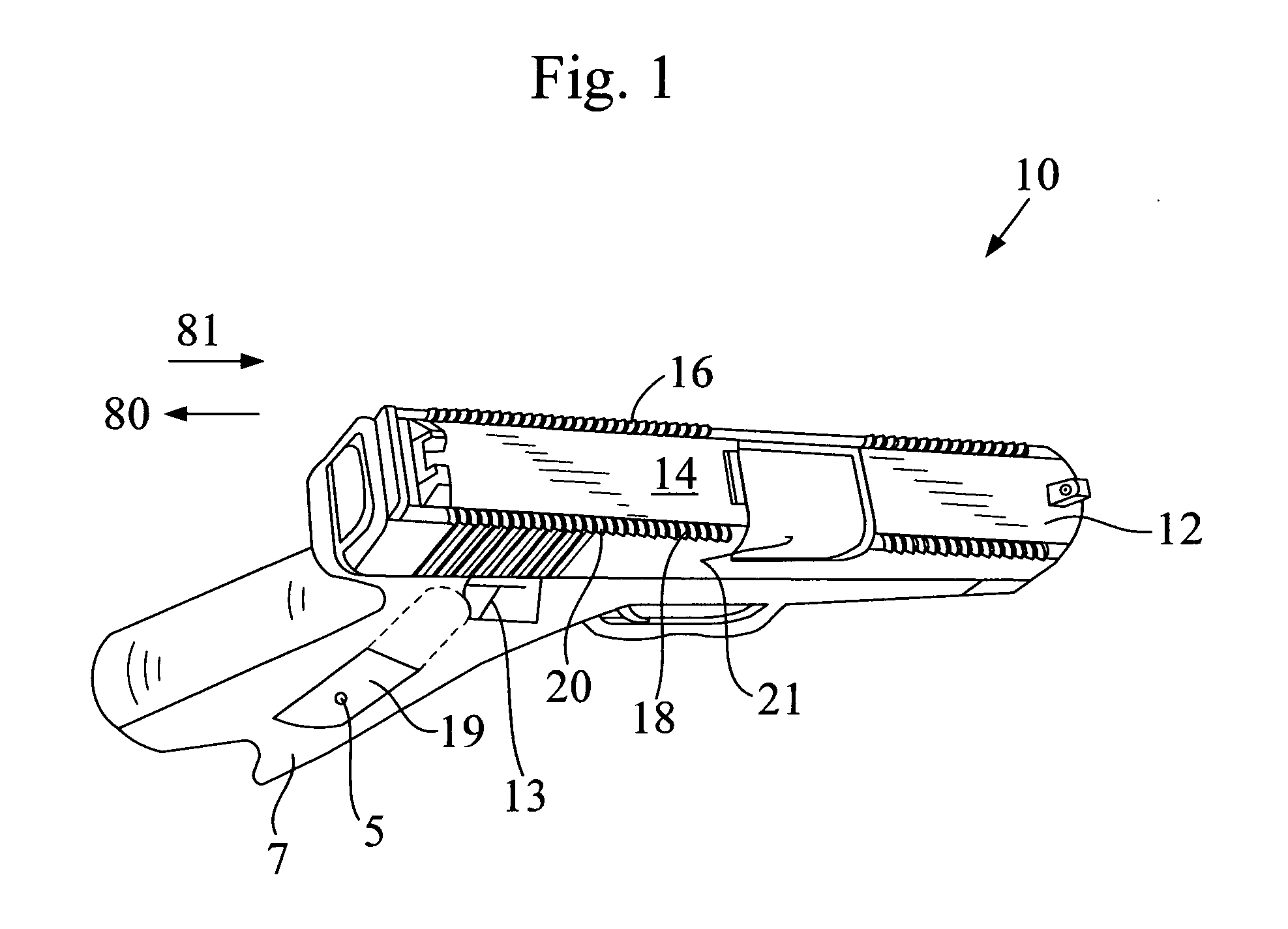

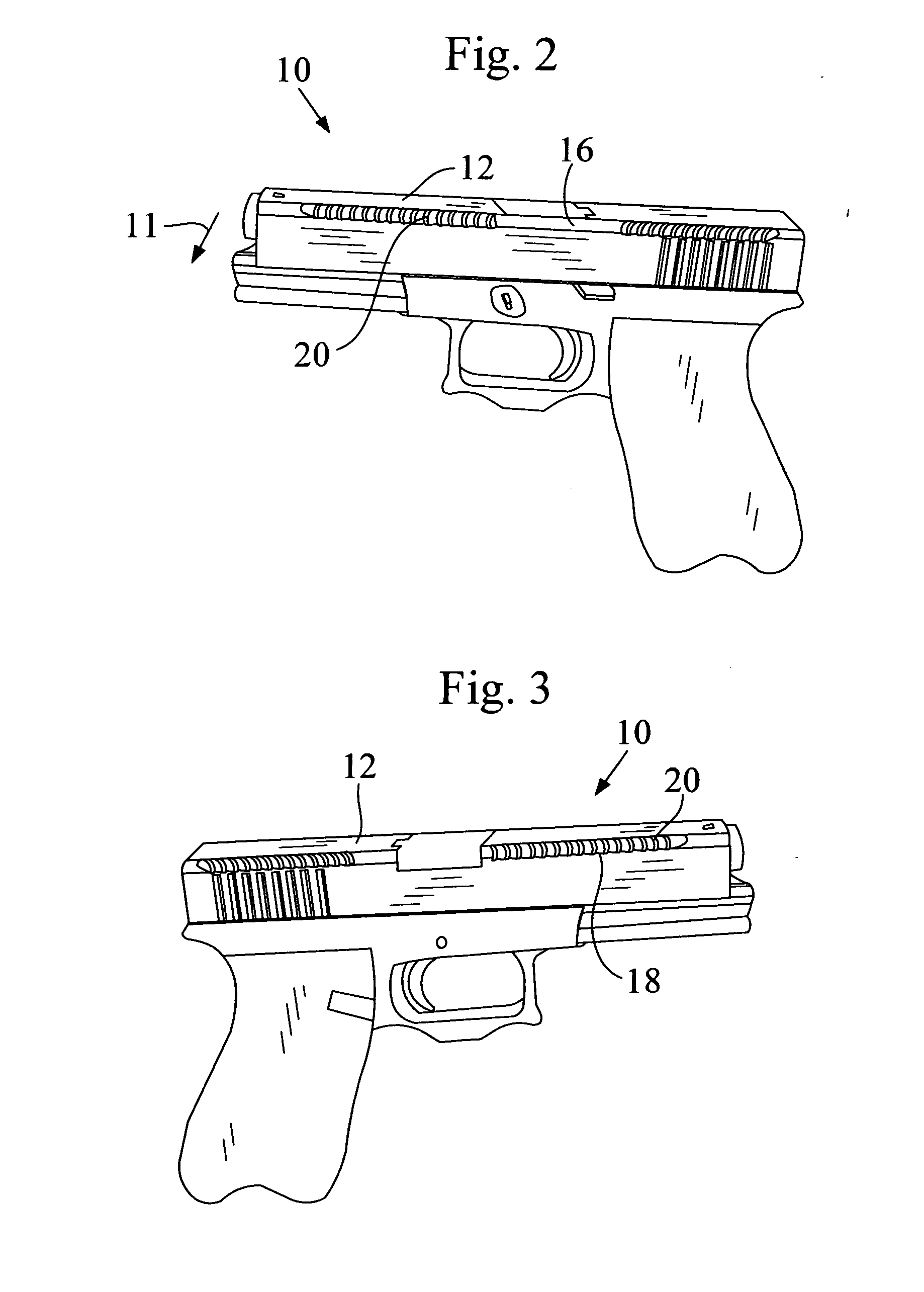

Firearm and a method for loading a firearm

InactiveUS20140360071A1Promote circulationOvercomes drawbackFiring/trigger mechanismsBreech mechanismsEngineeringMechanical engineering

A firearm 10 having a selectively movable slide portion 12 which includes at least one serrated radius or shoulder edge 14, 16 and which allows the firearm 10 to be selectively cycled by engaging the at least one serrated edge 14, 16 with a surface, such as table edge 32, thereby allowing for selective and relative movement between the frame 7 and the slide portion 12.

Owner:SAVITSKY JEFFRY JEROME +1

Auto-cascade heat pump circulating system

PendingCN107631508AImprove energy efficiency ratioSatisfy refrigerationMechanical apparatusEvaporators/condensersUltrasound attenuationFour-way valve

The invention belongs to the field of energy source power engineering and relates to an auto-cascade heat pump circulating system. An outlet of a compressor is connected with an inlet of an oil-gas separator. An opening A, an opening B, an opening C and an opening D of a four-way valve are connected with an outlet of the oil-gas separator, a second end opening of an evaporator, an inlet of a gas-liquid separator and a first end opening of an air cooled condenser correspondingly. An inlet of a separation liquid storage device is connected with a second end opening of the air cooled condenser and a first end opening of the evaporator. A liquid phase outlet of the separation liquid storage device is connected with a first inlet of an evaporation type condenser through a first throttling assembly. A gas phase outlet of the separation liquid storage device is connected with a second inlet of the evaporation type condenser. A first outlet of the evaporation type condenser is connected with an inlet of the compressor. A second outlet of the evaporation type condenser is connected with a second end opening of an air cooled condenser and a first end opening of the evaporator through a second throttling assembly. The auto-cascade heat pump circulating system overcomes the existing theory limitation and technological bias and is wide in application working condition range, high in energyefficiency ratio and small in attenuation under the low-temperature working condition.

Owner:焦景田

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com