Rotor type engine

A technology for internal combustion engines and main rotors, applied in combustion engines, machines/engines, rotary piston machinery, etc., can solve problems such as insufficient use of temperature and pressure, low heat conversion efficiency, and high power consumption of compressors , to reduce the requirements of lubrication and cooling, reduce the generation of NOx, and improve the effect of specific gravity power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

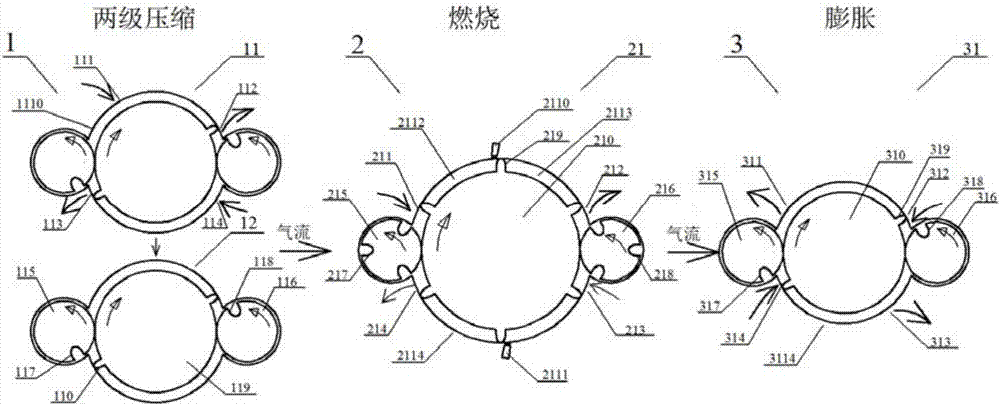

[0031] combine figure 1 and figure 2 Describes the engine system.

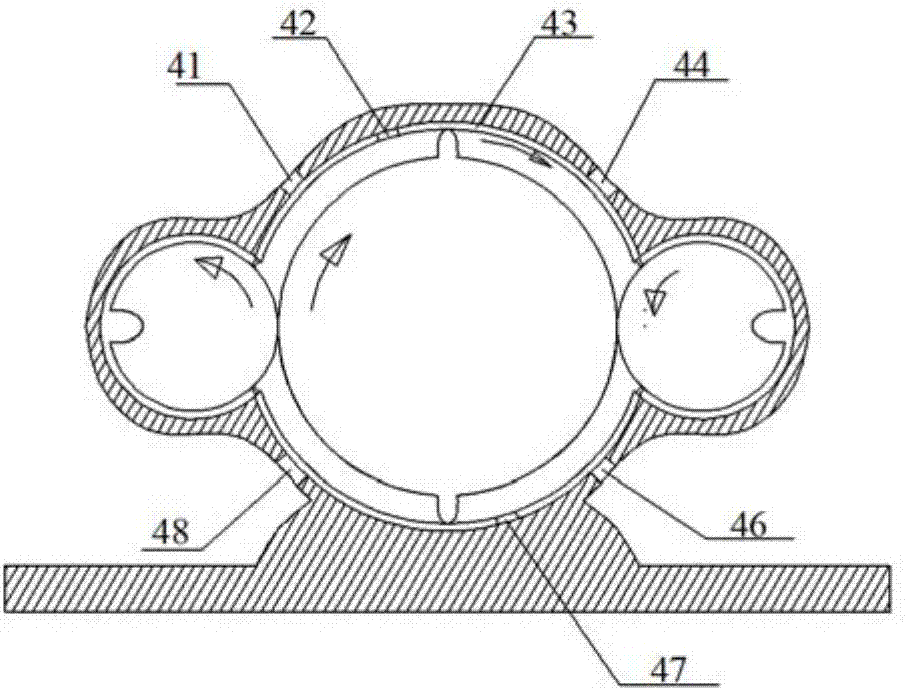

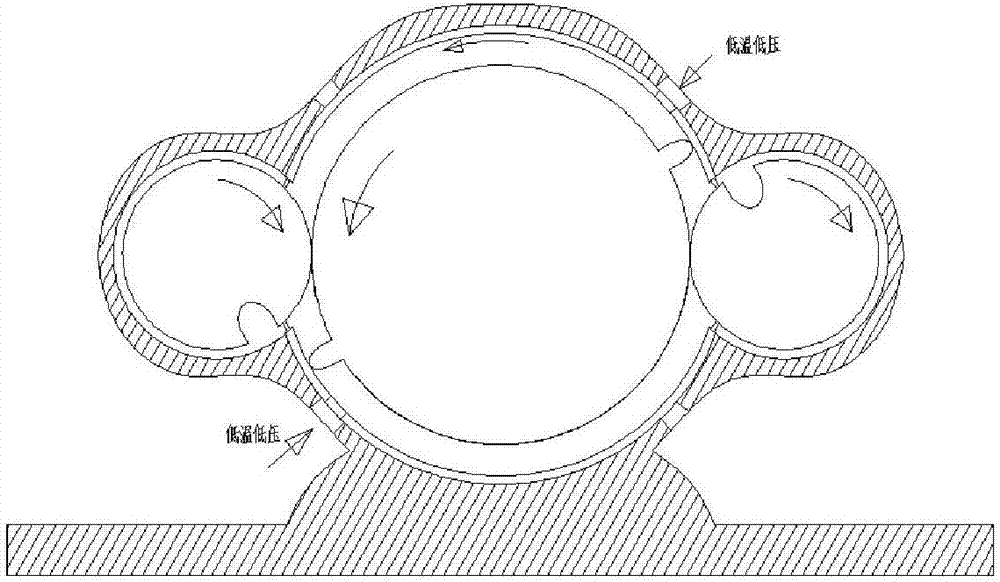

[0032] The rotary engine system includes three functional stages: compression stage 1, combustion stage 2 and expansion stage 3, which are independent of each other and connected in series through the main shaft to form a whole, wherein each stage has one or more The thermal conversion unit is composed of a compressor (a primary compressor 11 and a secondary compressor 12 ), a burner 21 and an expander 31 at different functional levels. The first-stage compressor 11 and the second-stage compressor 12 have the same structure, and are composed of a first group of intake timing devices 111, a first group of exhaust timing devices 112, a second group of intake timing devices 114, The second group of intake timing device 113, first auxiliary driving wheel 115, second auxiliary driving wheel 116, power wheel 119, and housing 110 are composed of the first auxiliary driving wheel 115 and the second auxiliary drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com