Water vapor circularly adjusting type oxygen-enriched combustion method for pulverized coal boiler

A pulverized coal boiler and oxygen-enriched combustion technology, which is applied in the field of pulverized coal combustion, can solve the problems of reducing CO2 capture efficiency, increasing N2 content, and cumbersome switching of oxygen-enriched combustion systems, so as to reduce air leakage, simplify circulation and purification equipment, Effects that are easy to manipulate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

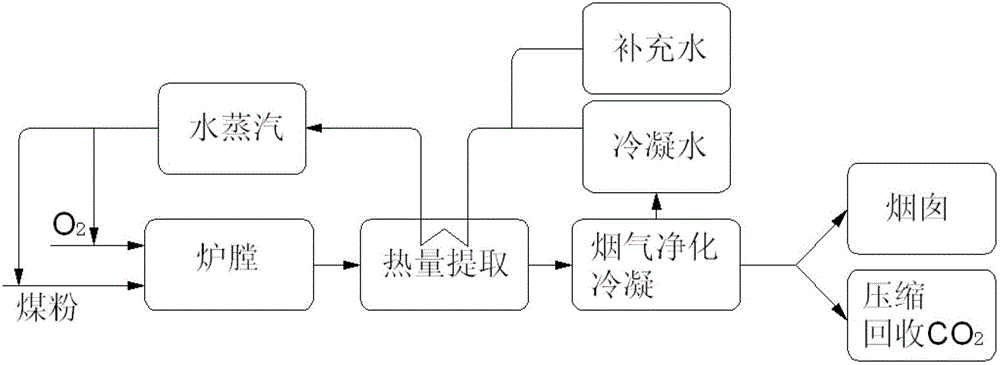

Embodiment 1

[0035] Water vapor is obtained after the flue gas is condensed, and the test shows that the mass of water vapor obtained per kg of coal is 3.7Nm 3 , the water vapor is heated to 150°C by the preheater, 30% of which is used as primary air to transport coal powder, and the rest is used as secondary air to enter the furnace for combustion; the high-temperature flue gas after furnace combustion is heat exchanged, condensed and purified, then Compression system processes into liquid CO 2. The oxygen content entering the furnace accounts for 24.7% of the entire combustion-supporting gas, the water vapor content in the high-temperature flue gas is 65.6%, and the CO in the condensed flue gas 2 The concentration is 91.5%.

[0036] figure 2 is a schematic flow diagram according to another preferred embodiment of the present invention. Such as figure 2 As shown in , the main features of the oxygen-enriched combustion method according to the second preferred embodiment of the prese...

Embodiment 2

[0039] The flue gas produced by combustion is used as the primary air to enter the furnace, and then the flue gas is condensed to obtain water vapor. The test shows that the mass of water vapor obtained per kg of coal is 3.0Nm 3 , the water vapor is heated to 120°C by the preheater, mixed with pure oxygen obtained from air separation, and then enters the furnace as secondary air; the high-temperature flue gas after combustion in the furnace is heat-exchanged, condensed and purified, 51% of which (Equivalent to 26% before condensation) The circulating fan is used as the primary air to transport the pulverized coal into the furnace for combustion, and the rest is processed into liquid CO by the compression system 2 . The oxygen content entering the furnace accounts for 25.6% of the entire combustion-supporting gas, the water vapor content in the high-temperature flue gas is 56%, and the CO in the condensed flue gas 2 The concentration is 88.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com