Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55results about How to "Good coloring rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

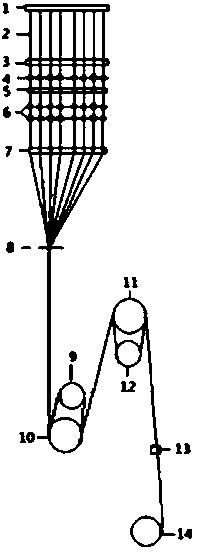

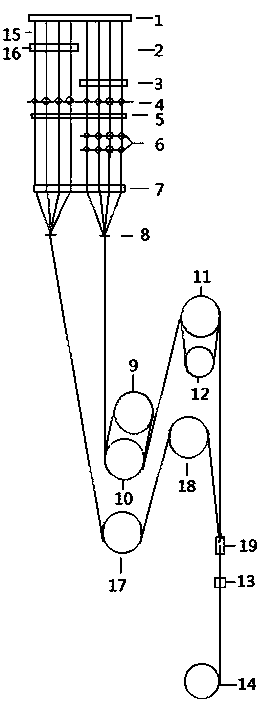

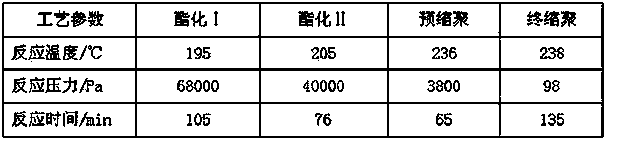

Copolyester melt direct-spinning controllable multiple differential shrinkage composite fiber and preparation method thereof

InactiveCN103526323AFull effectVersatileMonocomponent copolyesters artificial filamentMelt spinning methodsYarnPolyethylene glycol

The invention relates to a copolyester melt direct-spinning controllable multiple differential shrinkage composite fiber and a preparation method thereof. Terephthalic acid and ethylene glycol serve as raw materials, a third component of polyethylene glycol, a fourth component of diethylene glycol and a fifth component of pentaerythritol are added for copolymerization, a copolyester melt is prepared, pressurized through a melt pipeline and a pressurizing pump, conveyed to a spinning box, divided into two ways through two metering pumps, sent into a spinning assembly and a spinneret plate for extrusion and cooled and solidified to form two bundles of yarn, FDY (fully drawn yarn) is obtained after oiling wheel oiling, pre-interlacing, drawing and heat setting of one of the two bundles of yarn, the other bundle of yarn is oiled through an oil spraying nozzle and then led to two yarn guiding disks to obtain POY (polyester pre-oriented yarn), the FDY and the POY are input into a yarn doubling device and a main interlacing device simultaneously for composition, and the composite fiber is obtained after ultra-high-speed winding molding. The composite fiber adopts the better fine three-dimensional multi-layer structure and is large in potential controllable hot-shrinkage rate difference, good in fluffiness, hygroscopicity, air permeability, moisture retention, chromaticity and high color rendering uniformity, multiple in product function and high in additional value.

Owner:SUZHOU UNIV

Tie-dyeing method for cashmere textile

InactiveCN101003951ARich and varied texture graphicsNew Visual EnjoymentPattern makingDyeing processAcetic acidColour fastness

The present invention discloses a tie-dyeing method of cassimere. Said method includes the following steps: designing pattern of said cassimere and binding; adopting quick penetrating agent SP-2 and Peregal according to a certain mixing ratio to prepare solution, temperature is 40-70 deg.C, bath ratio is 1:15-20, making treatment for 15-20 min; adopting reactive dyes for wool as raw material, using sodium sulfate powder, glacial acetic acid, dye leveler Albatex B for wool and penetrating agent Albatex FFA for wool as adjuvant, after the temperature is risen to 98 deg.C from 70 deg.C, heat-insulating for 20-60 min, making sectional dyeing, then rinsing and cleaning; adopting 3-5% of cashmere bulking agent, 0.3-1% of glacial acetic acid and 0.2-1% of high-effective penetrating agent to make relaxing-bulking treatment, temperature is 40-50 deg.C and making treatment for 20-30 min to make cassimere be flabby, then making milling treatment.

Owner:HUAHENG TECH DEV JIANGSU

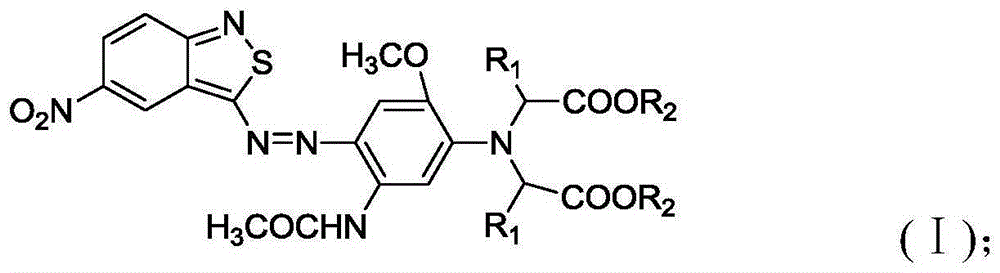

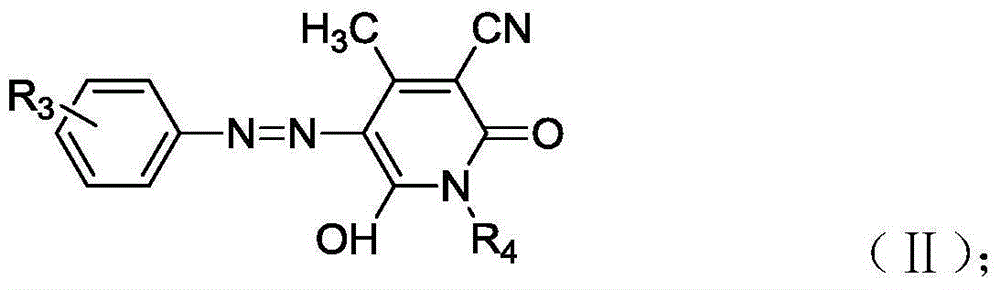

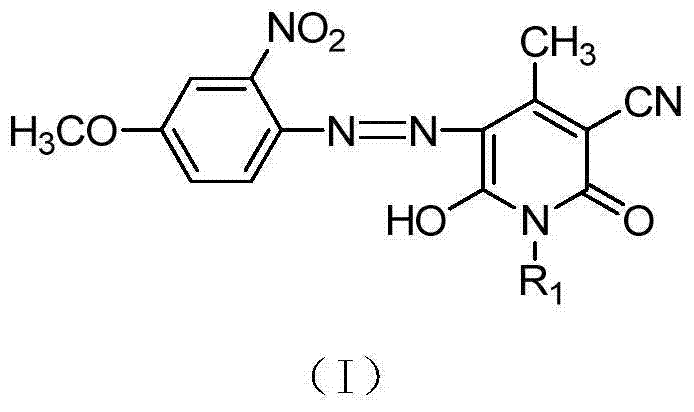

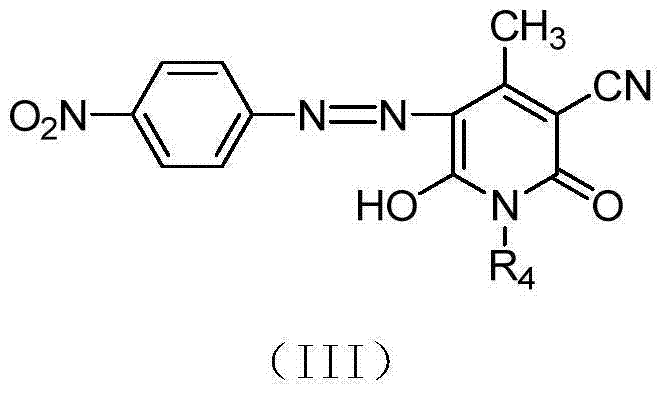

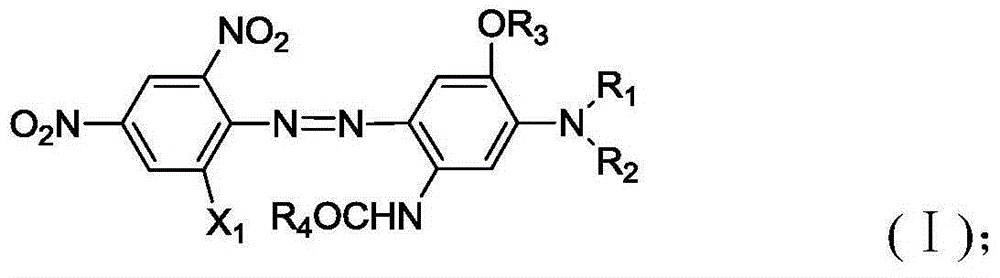

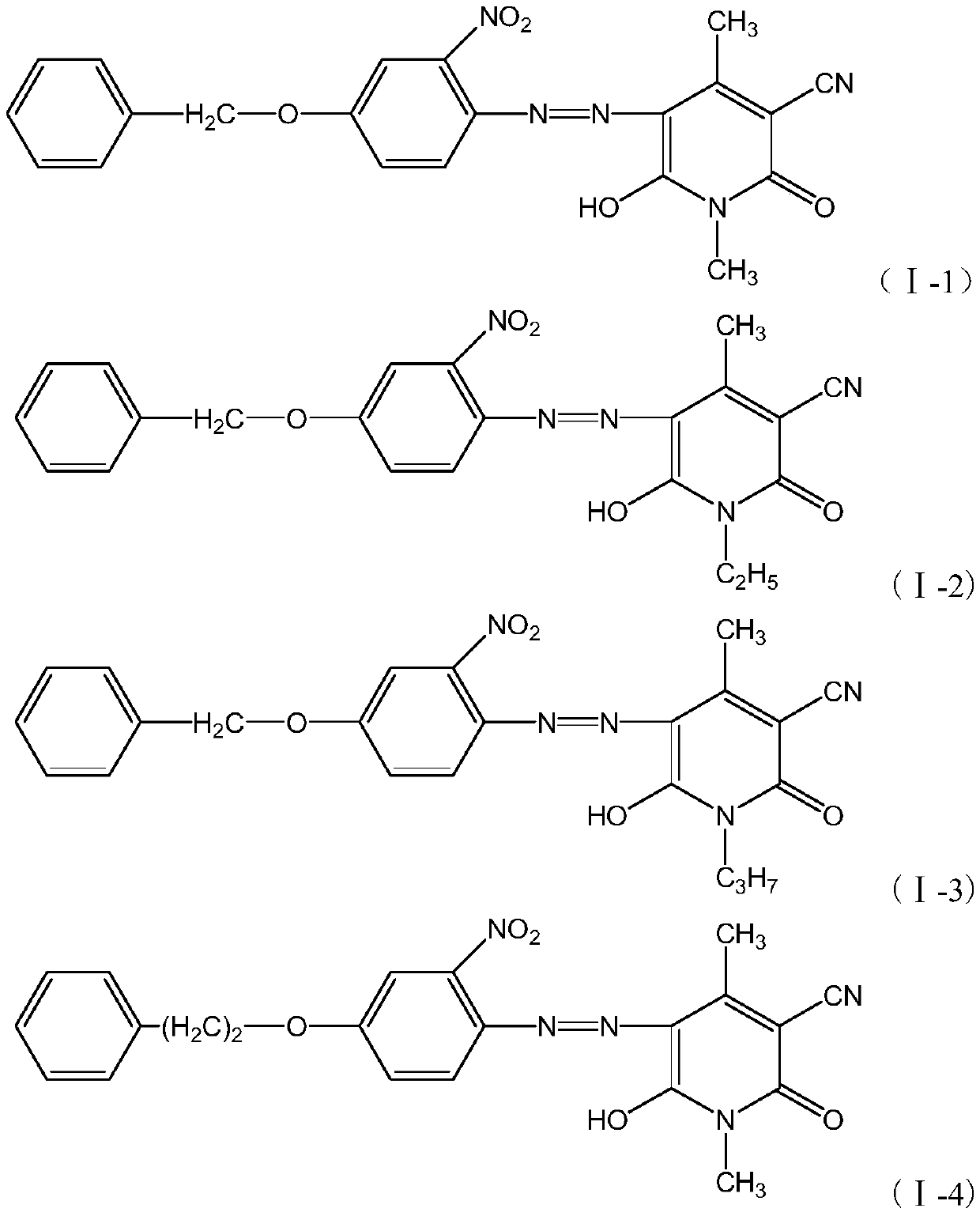

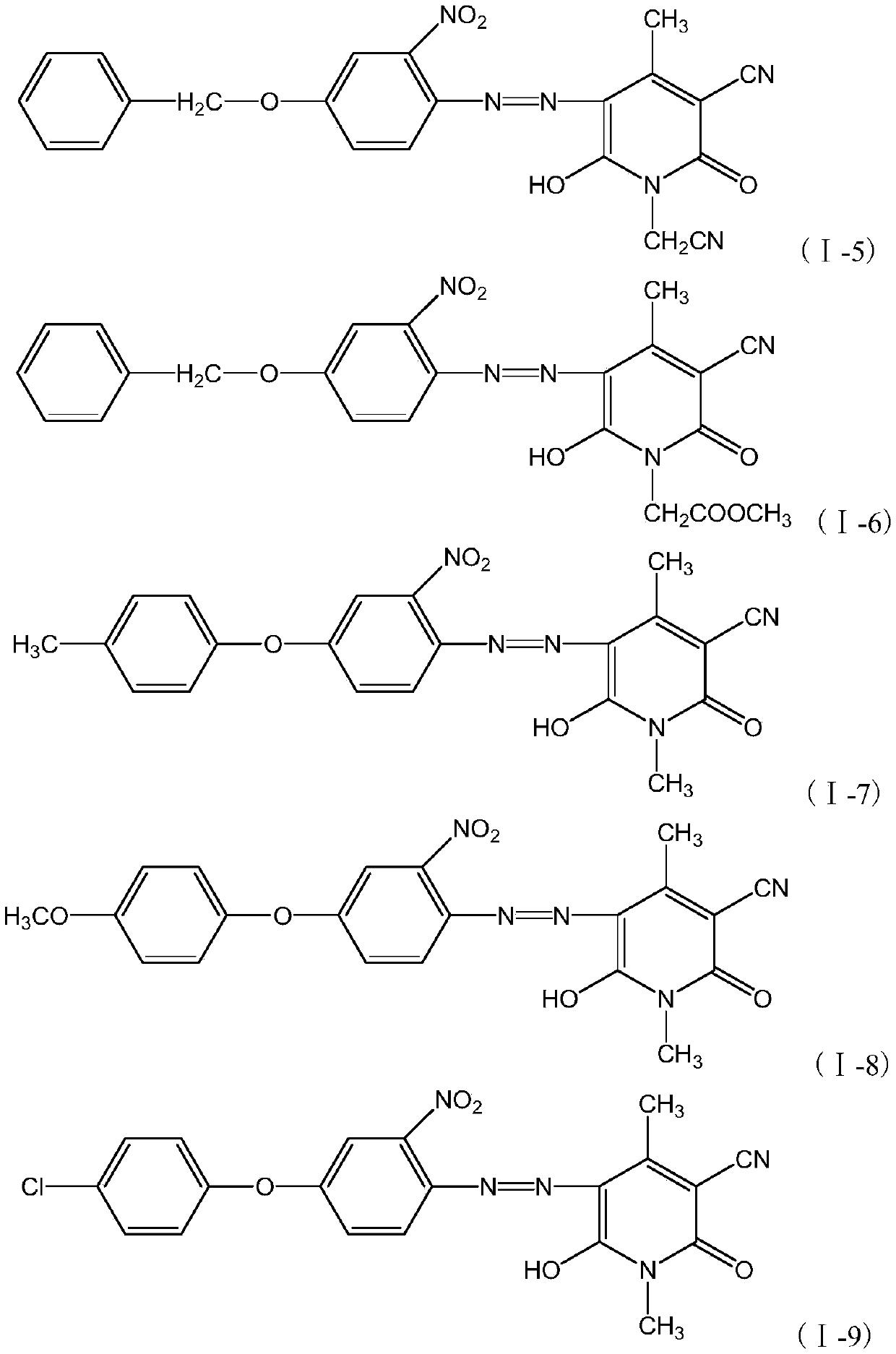

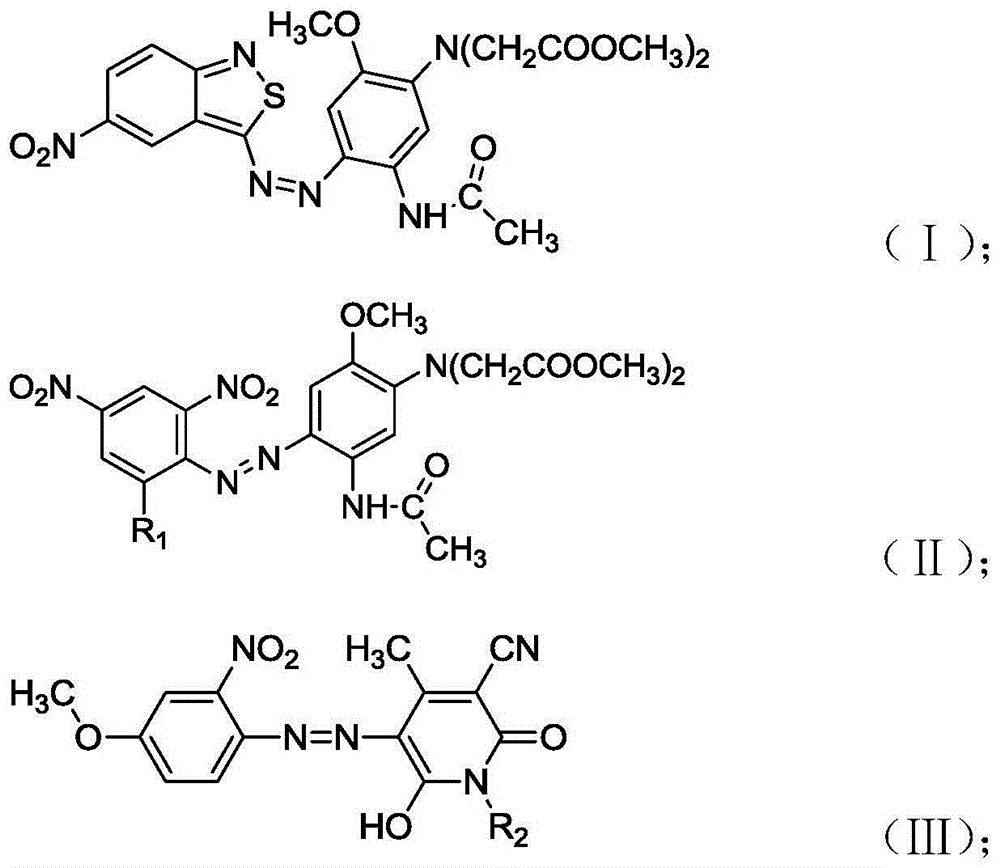

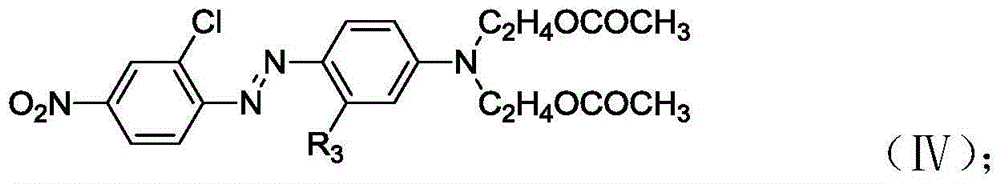

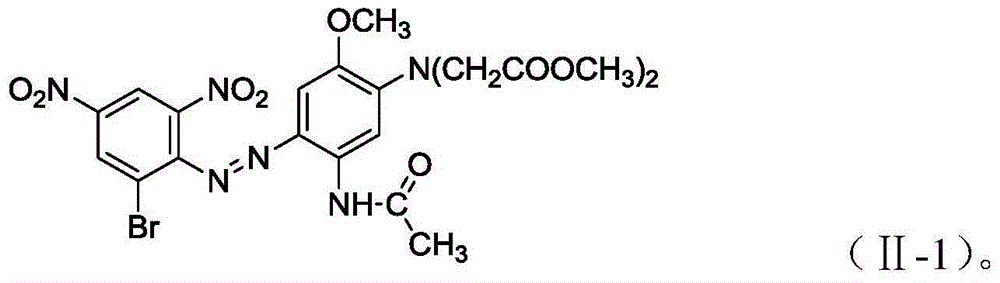

Dark blue-dark disperse dye composition with high dyeing rate

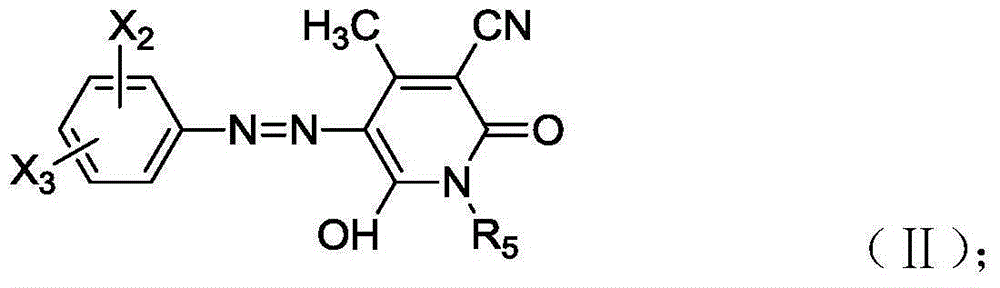

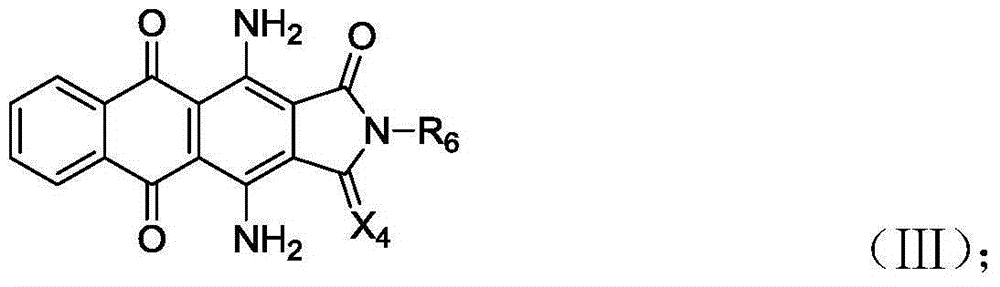

ActiveCN106479219AGood coloring rateHigh color fastnessOrganic dyesDyeing processPerspirationPhotochemistry

The invention discloses a dark blue-dark disperse dye composition with high dyeing rate, wherein the dye composition is composed of a component A shown in a structural formula (I), a component B shown in structural formula (II), a component C shown in structural formula (III), a component D shown in structural formula (IV), a component E shown in structural formula (V), a component F shown in structural formula (VI) and an assistant; according to the mass percent, the pass percent of the component A is 1-15%, the pass percent of the component B is 10-45%, the pass percent of the component C is 1-10%, the pass percent of the component D is 1-10%, the pass percent of the component E is 1-10%, and the pass percent of the component F is 1-10%; the rest is assistant. The sample cloth dyed by the dye composition has bright color and light, and is excellent in fastness to washing, fastness to rubbing, perspiration fastness, fastness to sun and degree of dyeing.

Owner:HANGZHOU FLARIANT SPECIALTY

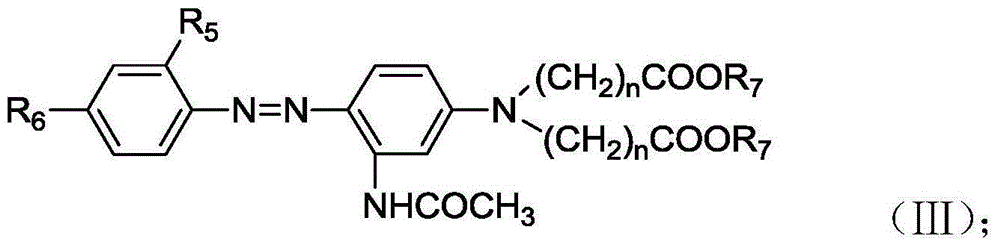

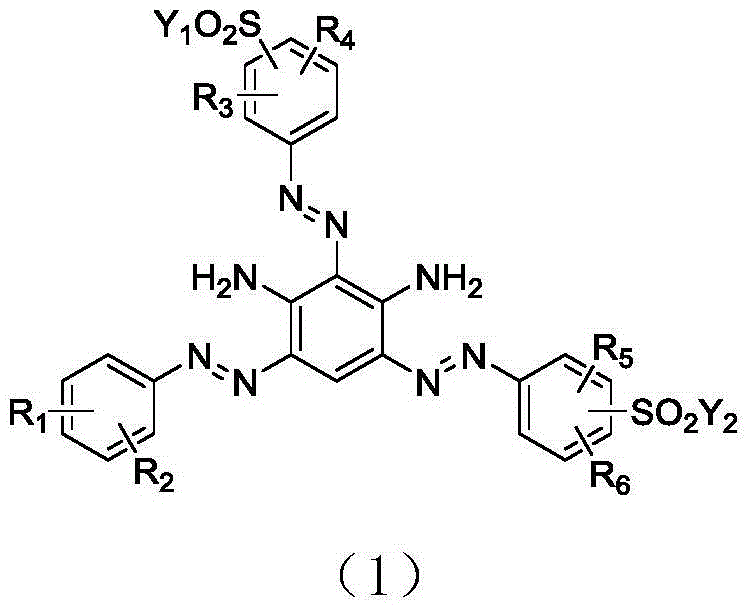

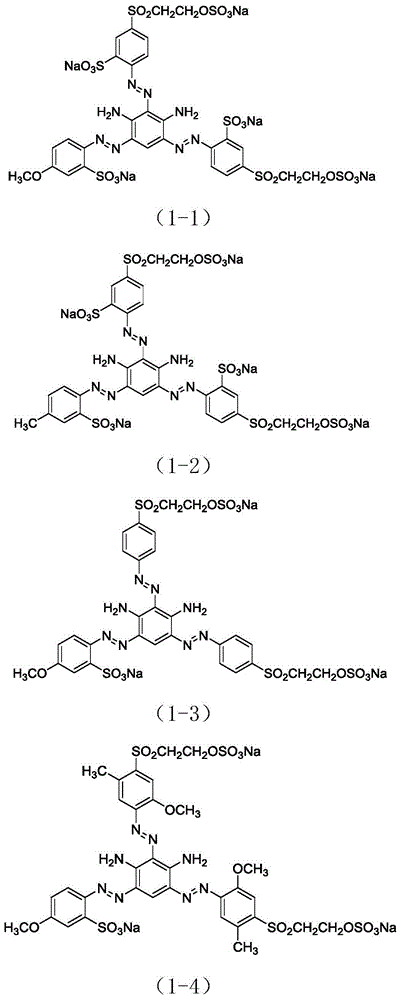

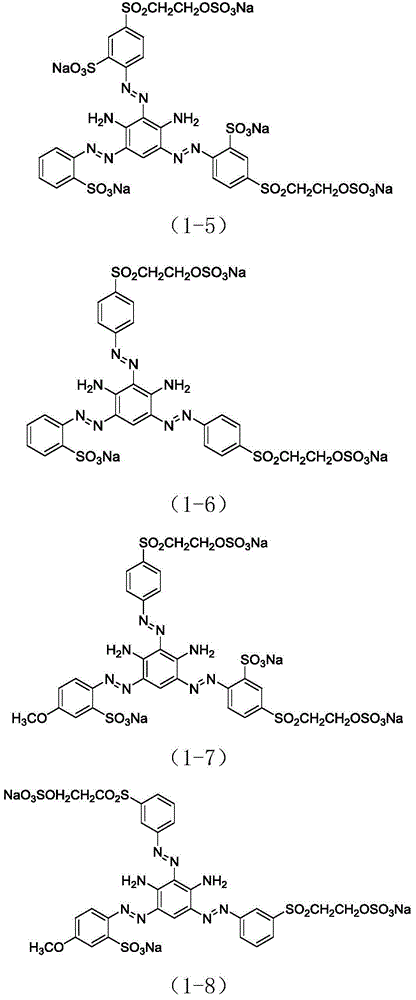

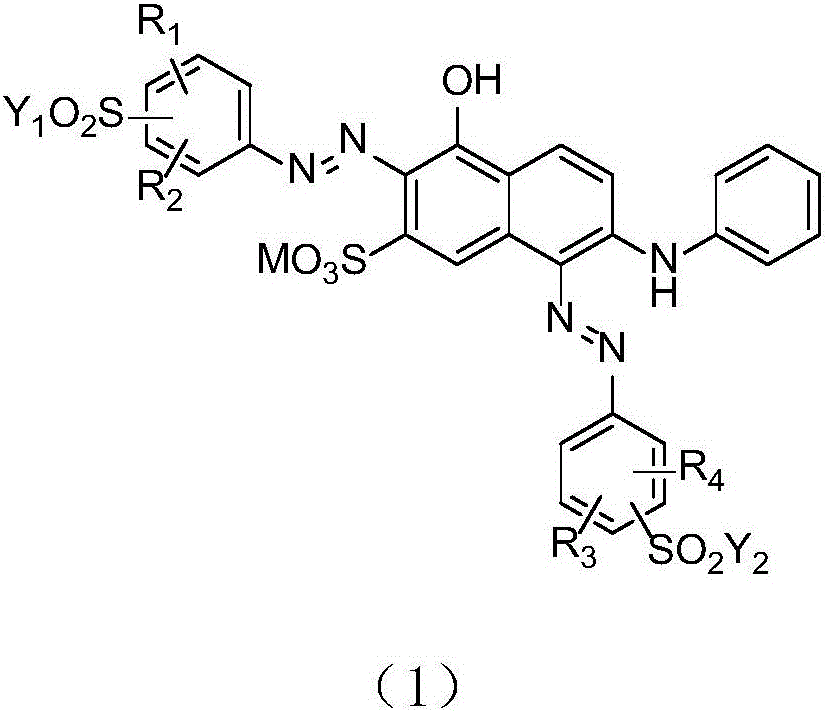

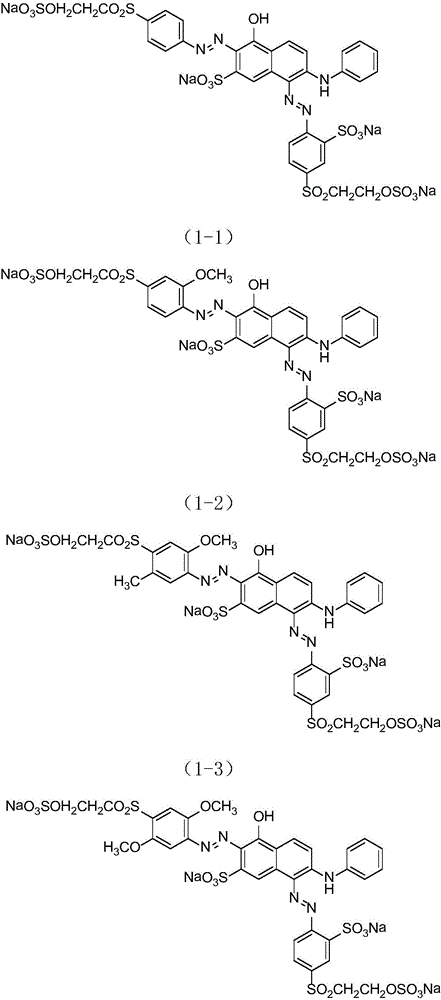

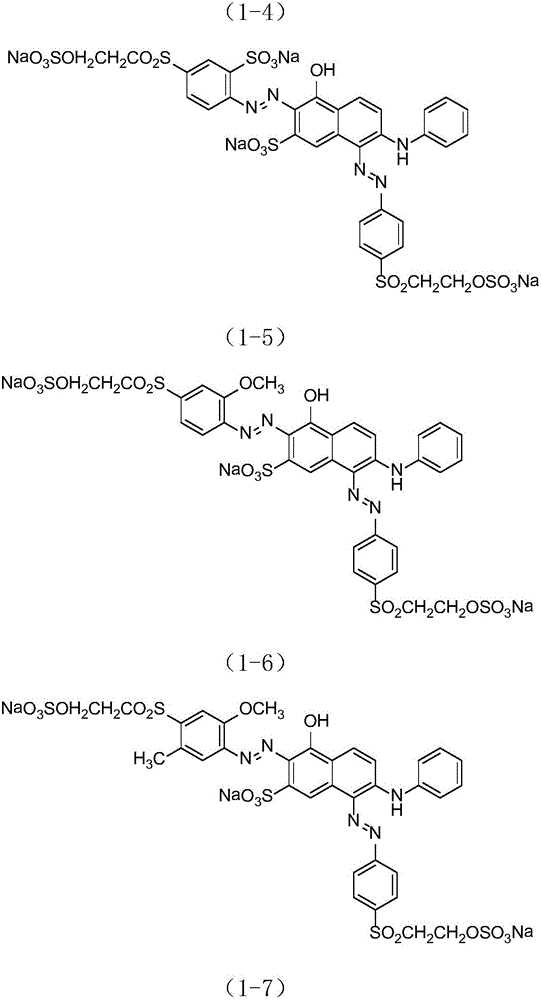

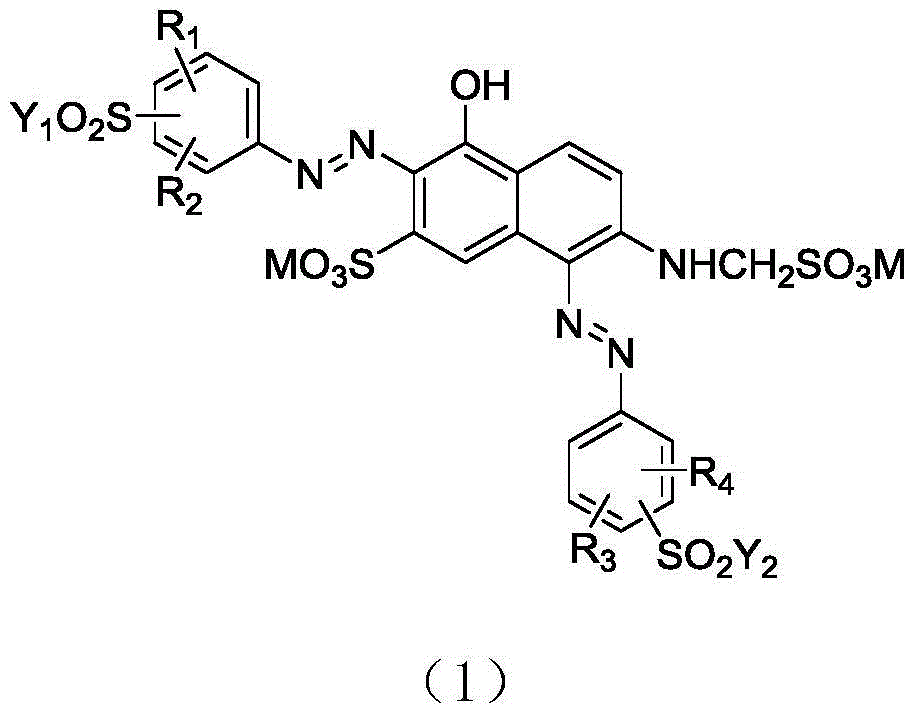

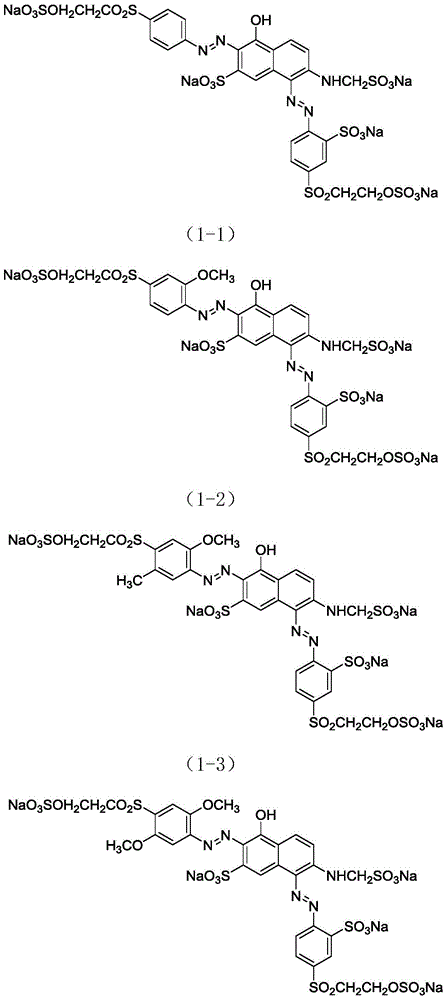

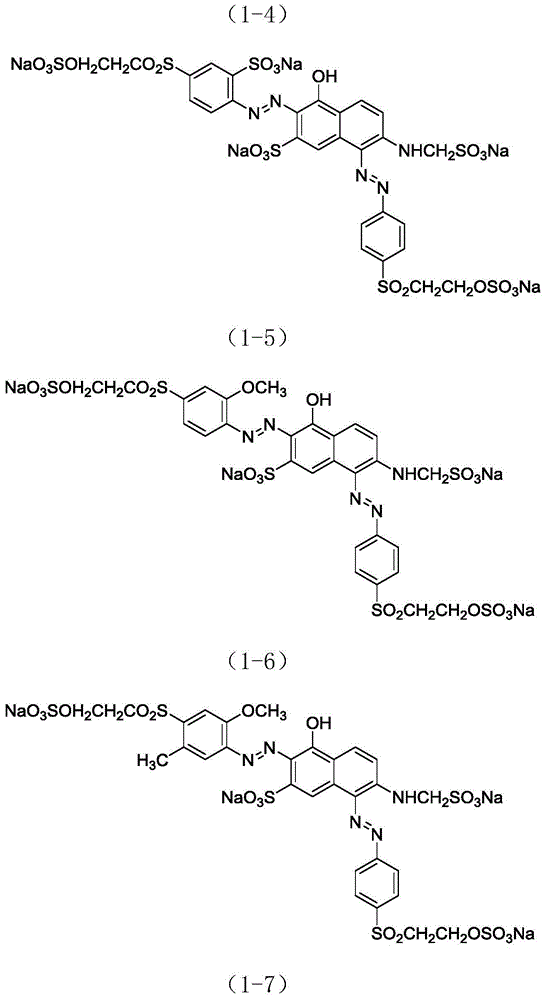

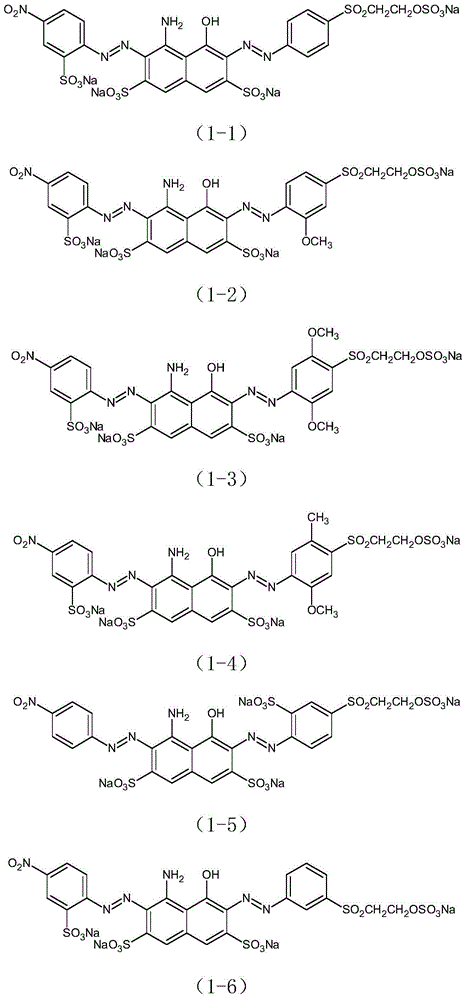

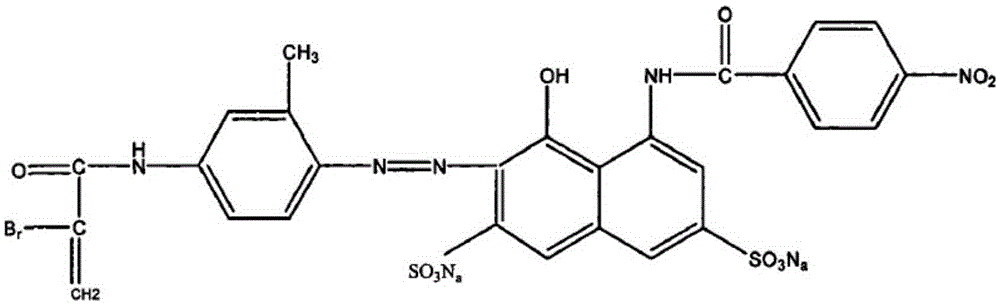

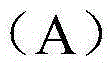

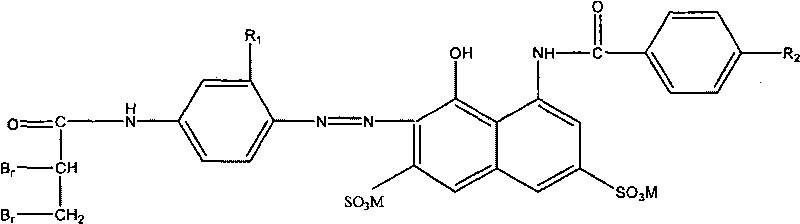

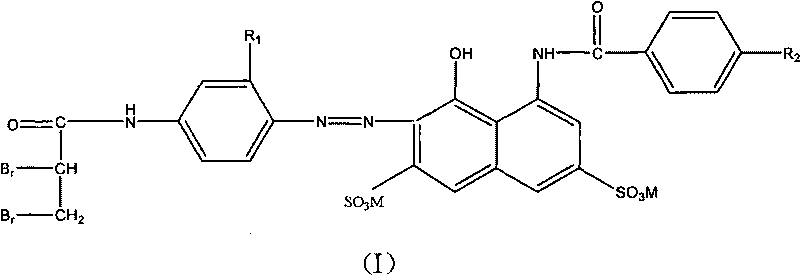

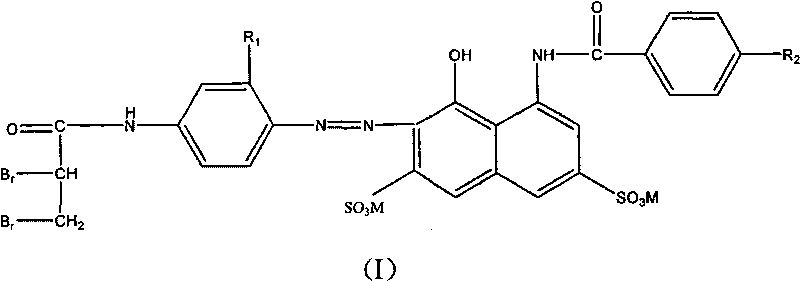

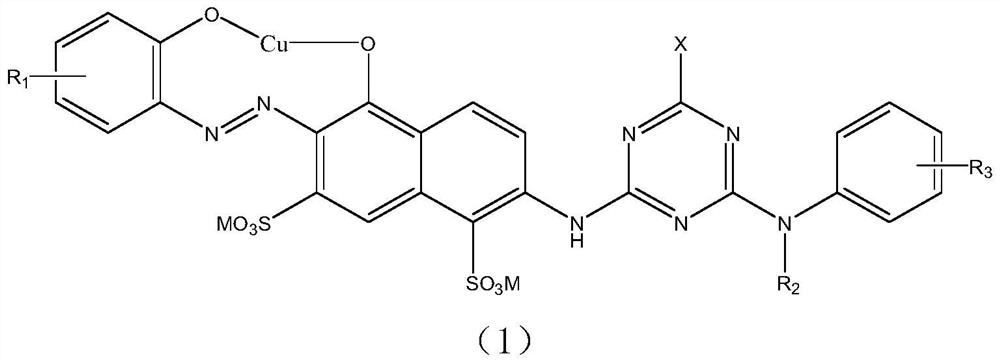

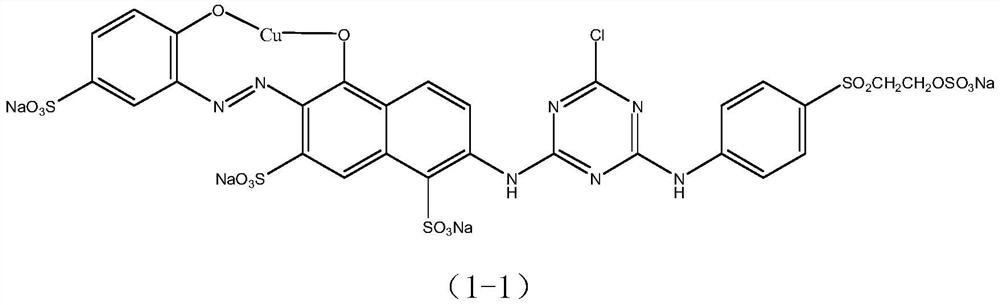

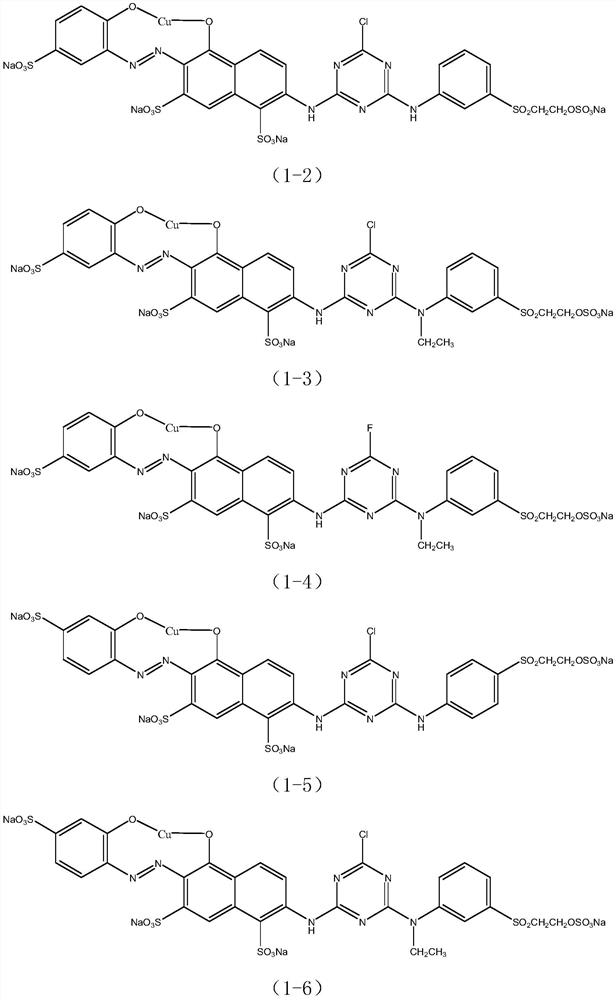

Yellowish-brown reactive dye and preparation method thereof

InactiveCN104830097AExcellent color synchronizationImprove dye uptake and color fixationOrganic chemistryOrganic compound preparationReactive dyePhotochemistry

A yellowish-brown reactive dye and a preparation method thereof. The invention relates to a yellowish-brown reactive dye and a preparation method thereof. The yellowish-brown reactive dye includes one compound selected from a general formula (1), or a mixture compounded by more than two compounds in the general formula (1) in any proportion. R1, R2, R3, R4, R5 and R6 in the formula (1) independently represent -H, -CH3, -OCH3 and -SO3M; Y1 and Y2 independently represent -CH=CH2 and -C2H4OSO3M; and M represents hydrogen or alkali metal. The yellowish-brown reactive dye has excellent coloration synchronization, high dye uptake and fixation rate, good levelness, and excellent solarization and friction fastness.

Owner:ZHEJIANG YIDE CHEM

Black liquid dye composition

InactiveCN104292883AGood storage stabilityGood fastness performanceOrganic dyesDyeing processSolubilityReactive orange

The invention relates to a black liquid dye composition. The dye composition comprises the following components: a component A, namely, Deksol black B (C.I reactive black 5), a component B, namely, reactive orange G and a component C, namely, reactive yellow (C.I reactive yellow 201). The dye composition disclosed by the invention has the advantages of environmental friendliness, relatively high stability, good even dyeing property, high black degree, good low-temperature water solubility and excellent fastness properties and the application method is simple and feasible.

Owner:TIANJIN DEK CHEM

Preparation method of dye composition for dyeing of fiber material

InactiveCN104371367AGood storage stabilityGood fastness performanceReactive dyesDyeing processSolubilityFiber

The invention relates to a preparation method of a dye composition for dyeing of fiber materials. The method comprises the following steps: fully grinding three dyes including a component A, a component B and a component C, successively adding the components into a mixing tank, then adding a component F and a component D, fully stirring for 1-2 h, so as to prepare the dye composition. The component A is Deksol B (C.I. reactive black 5), the component B is active orange G, the component C is reactive yellow (C.I. reactive yellow 201), the component D is an auxiliary agent, and the component F is water. The dye composition prepared by the invention is not only environment-friendly but also has the advantages of high stability, good levelling property, high blackening degree, good low temperature water solubility, excellent fastness properties, and simple and feasible usage method.

Owner:TIANJIN DEK CHEM

Bamboo fiber and silk interlaced fabric dyeing and finishing process

InactiveCN103103830AGood coloring rateFeel goodDry-cleaning apparatus for textilesDyeing processSodium bicarbonateDisperse dye

The invention discloses a bamboo fiber and silk interlaced fabric dyeing and finishing process which comprises the following steps: (1) sewing a gray fabric; (2) presetting the fabric; 3) performing pretreatment, namely desizing the preset fabric, wherein a desizing solution contains sodium hydroxide, hydrogen peroxide and amylase, and the temperature of the desizing solution is 30-65 DEG C; (4) dyeing, namely soaking the fabric for 25-35 minutes in 75 percent of an alcohol solution, and dyeing bamboo fibers by low-temperature disperse dyes at 50-100 DEG C and in a dye bath with the pH value of 5.2-6.1, performing reduction clearing on the dyed bamboo fibers for 10-18 minutes at the clearing temperature of 55-60 DEG C, and performing silk dyeing after reduction clearing, wherein a reduction clearing solution comprises 0.3g / L-1.2g / L sodium hydrosulfite, 1.2g / L-2.3g / L an anionic detergent and 0.3g / L-1.2g / L sodium bicarbonate; (5) dehydrating; and (6) performing after-treatment, namely padding the dyed fabric in a hydrophilic aminosilane softening agent, and drying and performing tentering setting on the padded fabric at 85-95 DEG C. The fabric has a high degree of dyeing, integrates the advantages of silk and bamboo fibers, and is cool as well as good in hand-feeling.

Owner:CHANGSHU ZHAOSHI HUADA DYEING & FINISHING

Polylactic acid/Richcel/bamboo fiber blended fabric dark color dyeing process

The invention relates to a polylactic acid / Richcel / bamboo fiber blended fabric dark color dyeing process with the steps of pre-dyeing de-sizing, enzyme treatment, first bath polylactic acid dyeing, reduction washing, second bath Richcel / bamboo fiber overdyeing, and post-dyeing soap boiling. The process has the advantages that: two dyes can be used for dyeing under respective appropriate process conditions, such that excellent color degree of dyeing and fastnesses can be respectively obtained. Active dye is used after disperse dye. The high-temperature weak-acidity dyeing conditions of the disperse dye do not affect the covalent bond fastness between active dye and cotton fiber. The process is a novel preferable process for polylactic acid / Richcel / bamboo fiber blended fabric dark color dyeing. With the process, dye utilization rate can be improved, and color fixing rate can be improved.

Owner:KUNSHAN P&X GARMENTS

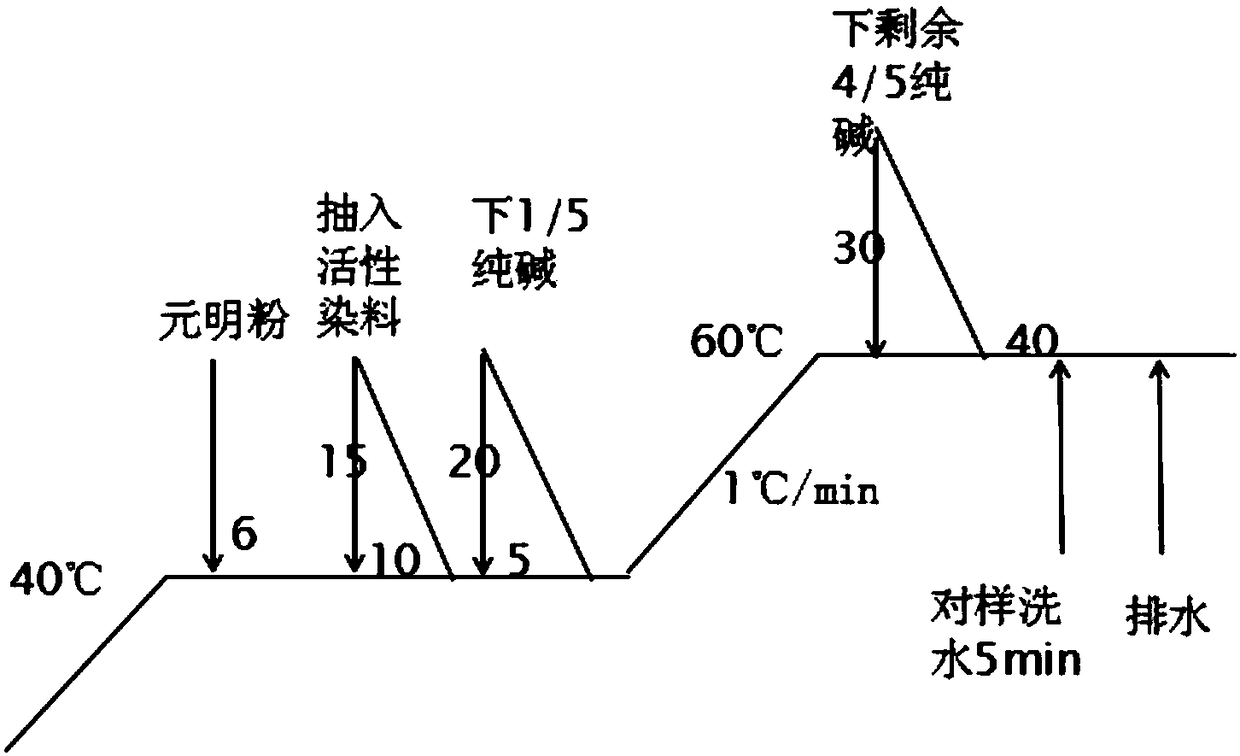

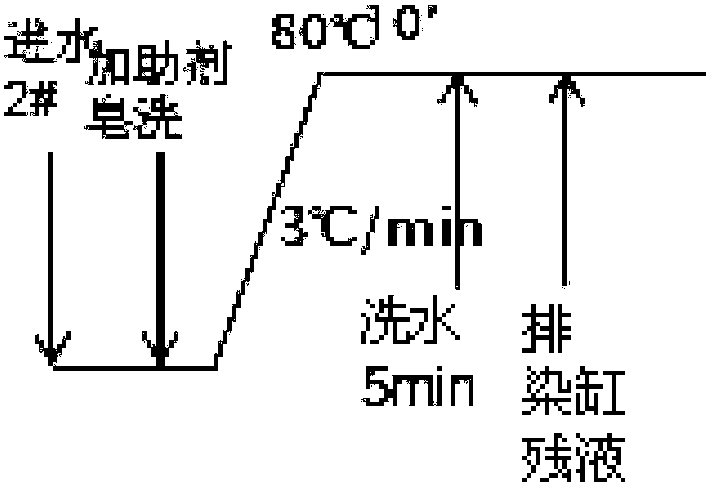

Dyeing and wrinkling synchronized process for wrinkling cloth

The invention relates a dyeing and wrinkling synchronized process for a wrinkling cloth. The dyeing and wrinkling synchronized process comprises the following steps: 1) unrolling a gray cloth of the wrinkling cloth, sewing, weighing to determine the use levels of dyes and additives used in the steps 2) and 3); 2) dyeing the sewed gray cloth of the wrinkling cloth by using an active dye in an air flow dyeing vessel, cleaning, removing a residual liquid; 3) introducing clear water into the dyeing vessel, pumping a glacial acetic acid and an acid dye into the dyeing vessel, continuing to dye by using the acid dye in the air flow dyeing vessel, conducing wrinkling treatment at the same time, then cleaning, discharging from the vessel; controlling the dyeing temperature to a plurality of gradually warming stages when the acid dye is used to dye, implementing heat insulation treatment correspondingly on each stage, and then cooling to 55-65 DEG C; gradually increasing the revolving speed ofa cloth lifting wheel of the dyeing vessel on each stage at the same time, wrinkling through the radial drawing of the cloth lifting wheel and the natural shrinking of the falling gray cloth of the wrinkling cloth; and 4) scutching the dyed wrinkled wrinkling cloth, dehydrating, drying and rolling. The process effectively shortens the work hours, and the surface of the cloth is prevented from getting wrinkled to level the style.

Owner:浙江劲光纺织科技有限公司

Dark red reactive dye and preparation method thereof

InactiveCN106634045AHigh liftHigh color fixing rateReactive dyesDyeing processHydrogenHeat stability

The invention discloses dark red reactive dye and a preparation method thereof. The dark red reactive dye is one material selected from general formulas of the formula (I) or is a mixture obtained through compounding two or more structures selected from the general formulas of the formula (I) according to any proportion. One material shown by the formula (I) is selected from any one of materials of the following structure general formulas or is a mixture of two or more materials of the structural general formulas, wherein R1, R2, R3 and R4 in the formula (I) respectively and independently represent -H, -CH3, -OCH3 or -SO3M; Y1 and Y2 respectively and independently represent -CH=CH2 or -C2H4OSO3M; M represents hydrogen or alkali metal. The dark red reactive dye has the advantages that the lifting performance is good; the friction firmness, the water washing firmness, the light fastness and the heat stability are high. The formula (I) is shown as the accompanying drawing.

Owner:ZHEJIANG YIDE CHEM

Red reactive dye and preparation method thereof

InactiveCN104861739AImprove washabilityImprove rubbing fastnessReactive dyesDyeing processHydrogenThermal stability

The invention relates to a red reactive dye and a preparation method thereof. The dye is a mixture compounded by one or more than two structures selected from a formula (1) according to any proportion. One shown on the formula (1) is a mixture selected from any one or more than two of the following structural general formula: R1, R2, R3 and R4 represent -H, -CH3, -OCH3 or -SO3 independently respectively, Y1 and Y2 represent -CH=CH2 or -C2H4OSO3M independently respectively, and M represents hydrogen or alkali metal. The red reactive dye has the advantages of being good in crocking fastness and washing fastness and high in light fastness and heat-resistant stability. (img file= 'DDA0000708189600000011. TIF' wi = '917' he = '725').

Owner:ZHEJIANG YIDE CHEM

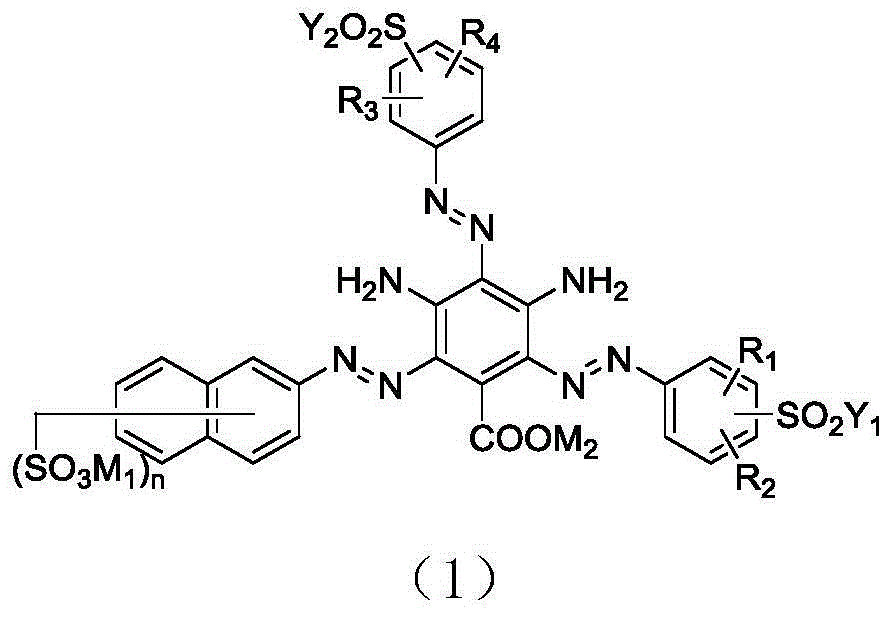

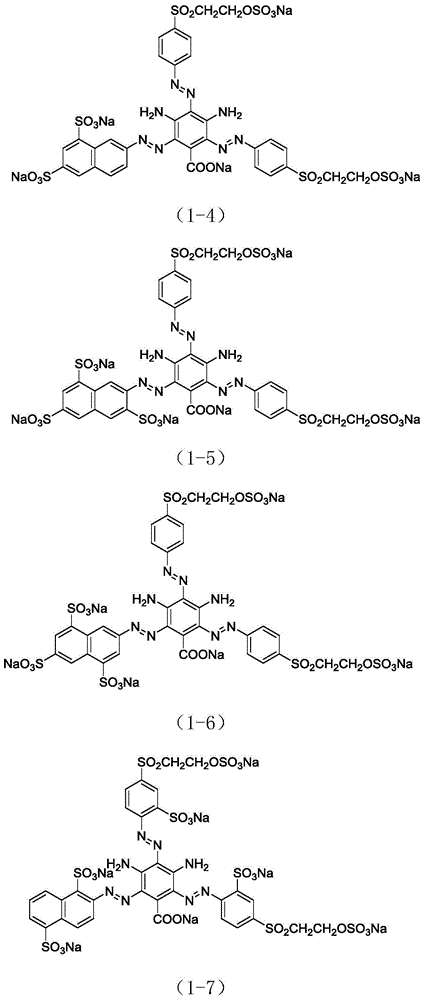

Yellow reactive dye and preparation method thereof

InactiveCN104893357AGood lifting effectGood dyeing depthReactive dyesPolymer sciencePolymer chemistry

The invention relates to a yellow reactive dye and a preparation method thereof. The reactive dye comprises any one compound selected from a general formula (1) or a mixture of any more than two compounds with any proportion selected from the general formula (1) through complex formulation; wherein in the formula (1), R1, R2, R3, R4 are respectively and independently represented as -H, -CH3, -OCH3 or -SO3M1; Y1 and Y2 are respectively represented as -CH=CH2 or -C2H4OSO3M1; M1 and M2 are respectively and independently represented as hydrogen or alkali metal, and n is 1, 2, 3. The yellow reactive dye has excellent coloring synchronicity, high dyeing rate and color fixing rate, good level-dyeing property, excellent solarization and excellent friction fastness.

Owner:华新珍

Vegetable dye color matching and printing process

PendingCN112663354AHigh color fastnessAvoid the problem of anti-staining on white backgroundDyeing processTextile printerMaterials science

The invention discloses a vegetable dye color matching and printing process, and belongs to the technical field of vegetable dye printing. Due to good environmental compatibility and resource reproducibility of vegetable dyes, numerous dye plants have the effects of bacteriostasis, ultraviolet prevention and the like. Due to the fact that the vegetable dyes are large in structure difference and poor in compatibility, color matching is difficult, and application of the vegetable dyes to printing is relatively little. According to the invention, appropriate conditions such as a preparation method, the ageing temperature and the washing pH of vegetable dye color paste are found, the compatibility among various different vegetable dyes is improved, the color matching and printing effect of the vegetable dyes is remarkably improved, and meanwhile, rosemary extract is provided as an antioxidant and can be better matched with the vegetable dyes, so that the economic value of vegetable dye printing is improved.

Owner:淄博祥源纺织有限公司

Transferring printing process for natural fabric

Owner:WUJIANG LINGZHI TEXTILE

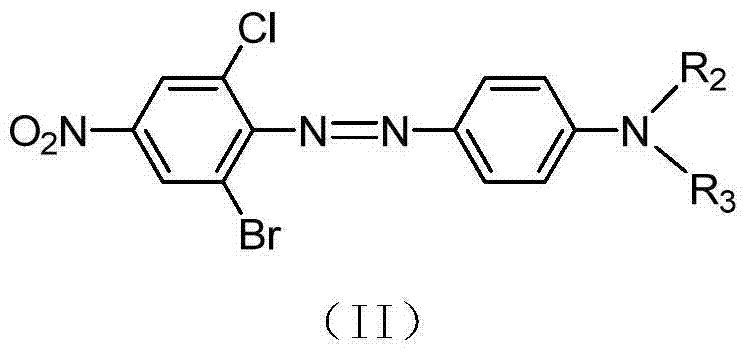

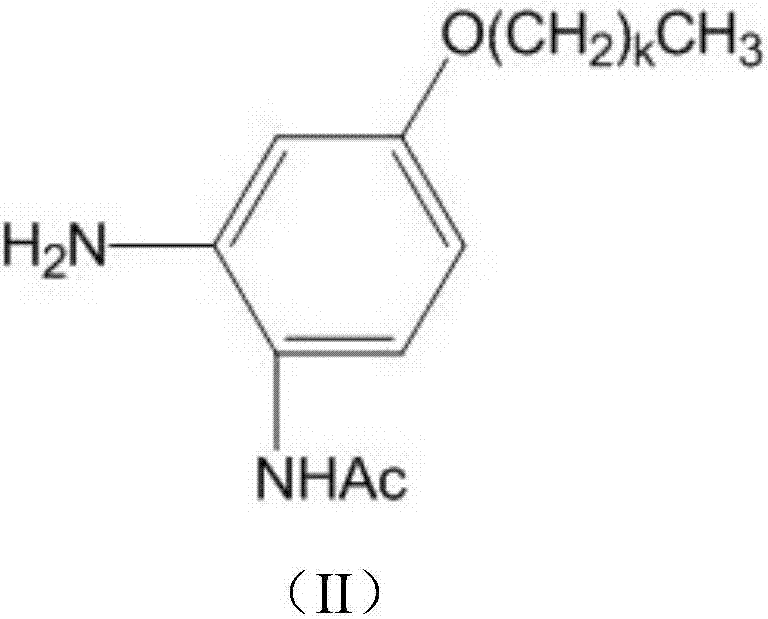

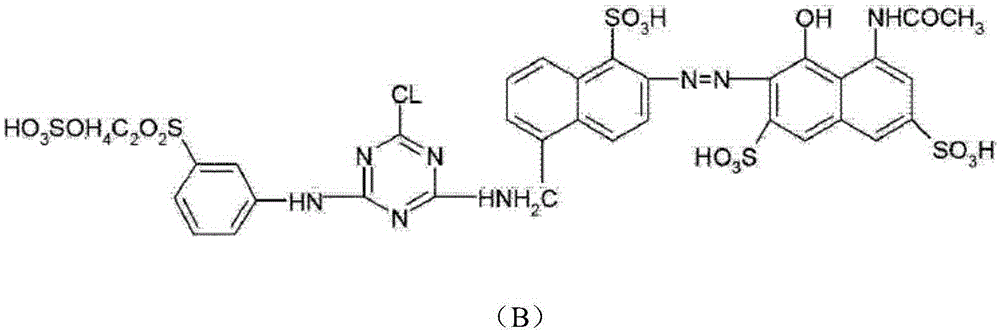

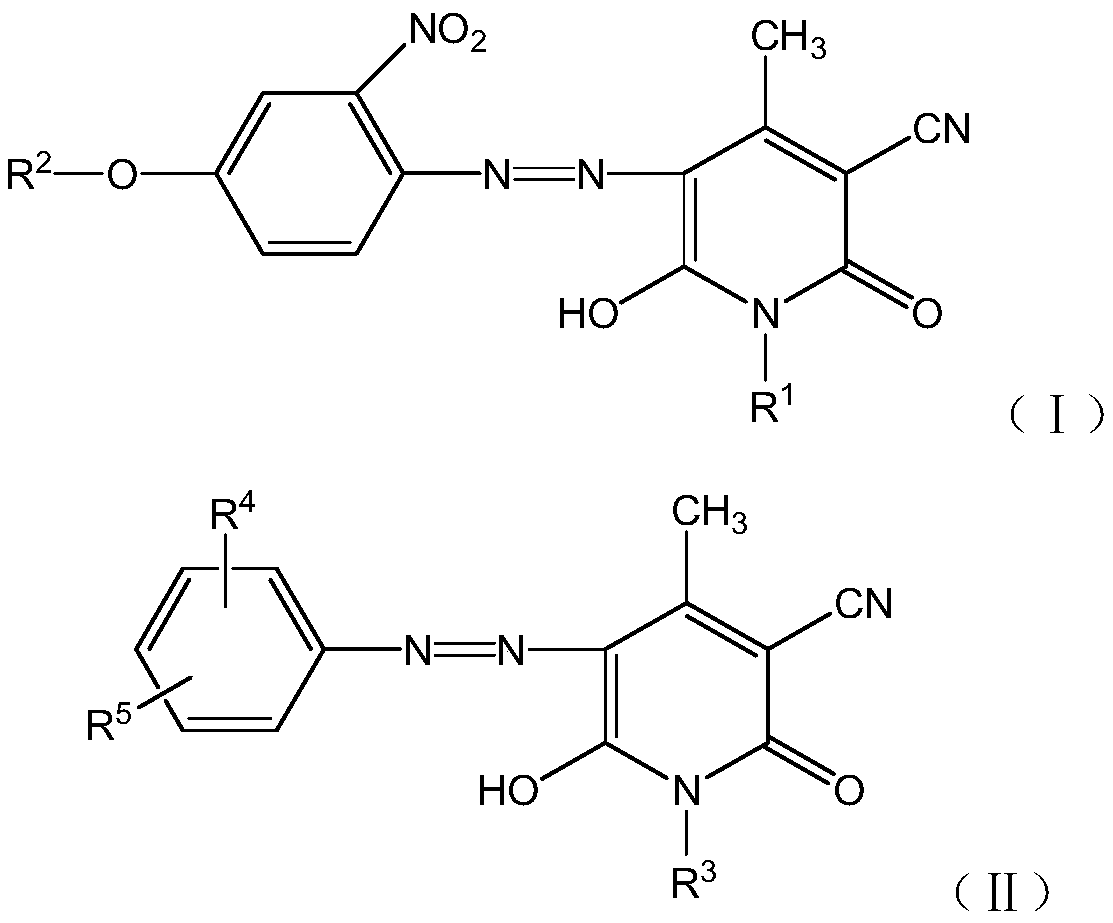

Environment-friendly disperse dye composition with infant standards

The invention relates to the field of a dye, and particularly relates to an environment-friendly disperse dye composition with infant standards. The environment-friendly disperse dye composition with the infant standards comprises the following components by mass percent: 10-80% of dye component A shown in a general formula (I), 10-80% of dye component B shown in a general formula (II), 5-50% of dye component C shown in a general formula (III), and 5-50% of dispersant. The fabric dyed by the environment-friendly disperse dye composition not only has excellent properties such as dyeing rate, washing fastness, rubbing fastness, sublimation fastness and the like, but also is smaller than 0.05mg / kg in chlorine-containing phenol content by a test, and is free of harm to a human body, and applicable to infants.

Owner:HANGZHOU FLARIANT SPECIALTY

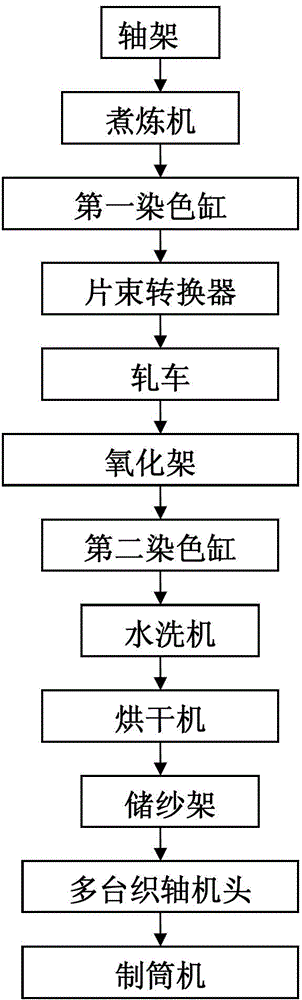

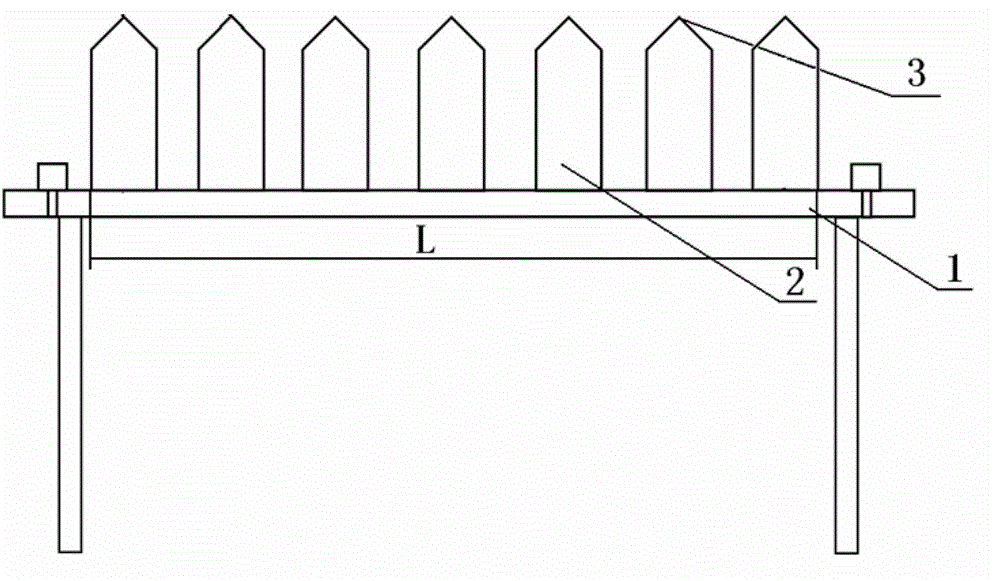

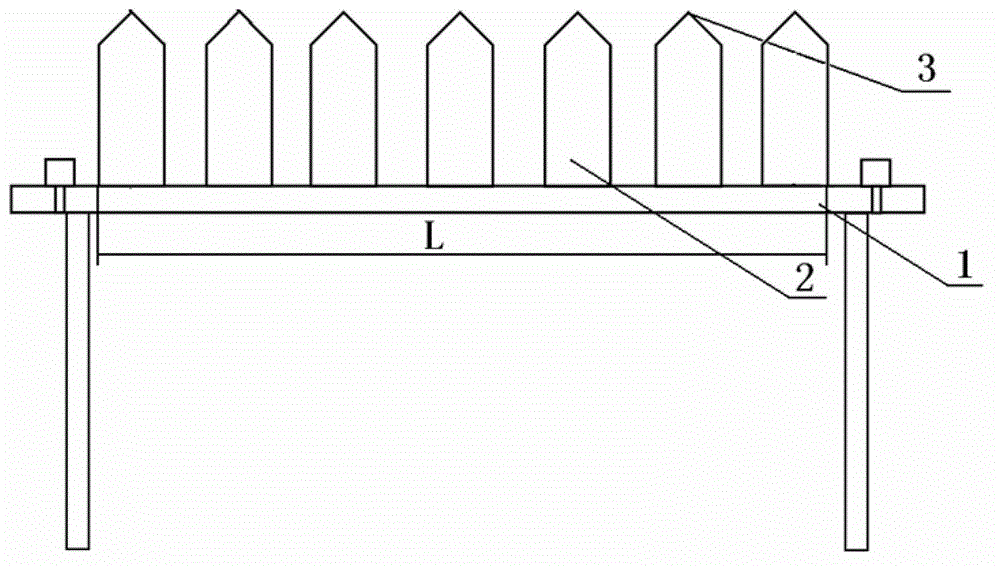

Piece bundle combination machine

InactiveCN102978856AIncrease profitUniform pressureTextile treatment machine partsLiquid/gas/vapor yarns/filaments treatmentYarnColour fastness

A piece bundle combination machine comprises a shaft frame, a scouring machine, a first staining jar, a padder, an oxidization frame, a second staining jar, a water washing machine, a dryer, a yarn storage frame, weaving machine noses being a front vehicle and a cylinder maker which are arranged sequentially, wherein a plurality of weaving machine noses are provided; a piece bundle converter is arranged between the first staining jar and the padder, is used for converting piece type yarn pieces to bundle type yarns, and comprises a bottom plate (1) and separation plates (2) which are arranged on the bottom plate (1) at fixed intervals; and the bundle type yarns are naturally recovered to the piece type yarn pieces on the oxidization frame. The piece bundle combination machine converts the piece type yarn pieces to the bundle type yarns, so that the thickness of the yarns is increased, the dry rolling rate of the padder to the yarns is improved, the dyeing degree and the dyeing firmness are improved, the dyeing is even and reliable, and the edge difference due to bad dyeing firmness and uneven dyeing degree is reduced; and the bag dyeing firmness is caused by wet rolling and uneven rolling of the padder.

Owner:WUXI JINNIU TEXTILE

Compound scattered black dye high in color fastness

InactiveCN105038315AEasy to produceLow priceOrganic dyesDyeing processPerspirationStructural formula

The invention discloses a composite scattered black dye high in color fastness. The composition is composed of a component A represented in structural formula (I), a component B represented in structural formula (II), a component C represented in structural formula (III), a component D represented in structural formula (IV) and auxiliaries. According to the mass percentage, the mass fraction of the component A is 1-10%, the mass fraction of the component B is 5-25%, the mass fraction of the component C is 5-25%, the mass fraction of the component D is 10-40%, and the remainder is the auxiliaries. Sample cloth dyed through the composite scattered black dye is bright in color light and has excellent wash fastness, rub fastness, perspiration fastness, sun-proof fastness and degree of dyeing, and the production cost of the composite scattered black dye is low.

Owner:HANGZHOU FLARIANT SPECIALTY

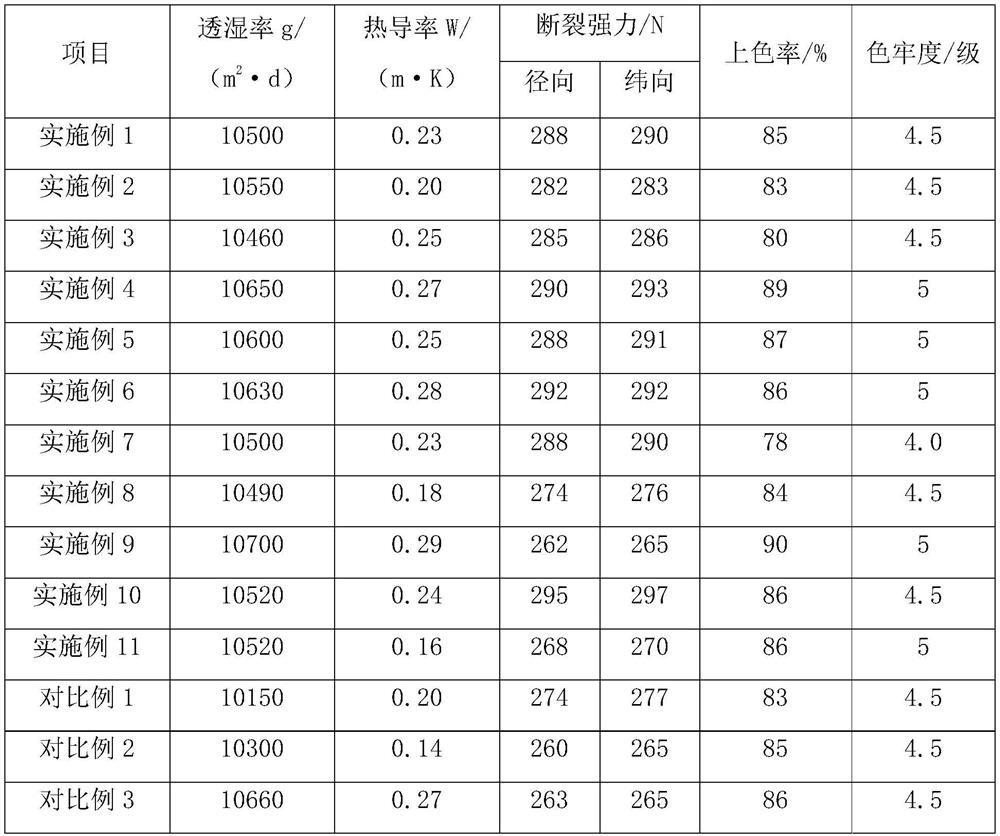

Preparation process of a cool-feeling three-dimensional spacer knitted fabric and its knitted fabric

This application relates to the field of textiles, and specifically discloses a preparation process of a cool-feeling three-dimensional interval knitted fabric and the knitted fabric; the preparation process includes the following steps: preparing ultra-high molecular weight polyethylene fiber filaments by using the stock solution coloring method, and preparing modified fabrics by using mica powder. Polyester fiber yarn; weaving nylon fiber yarn, viscose fiber yarn, ultra-high molecular weight polyethylene fiber yarn, and modified polyester fiber yarn into gray cloth; polyethylene fiber accounts for 15%-25% of the total weight of the gray cloth, and modified polyester fiber Accounting for 5%-15% of the total weight of the gray cloth, nylon fiber accounting for 20%-30% of the total weight of the gray cloth, viscose fiber accounting for 40%-50% of the total weight of the gray cloth; The method prepares cool-feeling three-dimensional interval knitted fabric; it has the advantages of good thermal conductivity, good moisture absorption performance, good dyeing rate, and high color fastness, so that the clothes or mattresses and other fabrics prepared by it can give people a cool and dry feeling when used. .

Owner:山东针巧经编有限公司

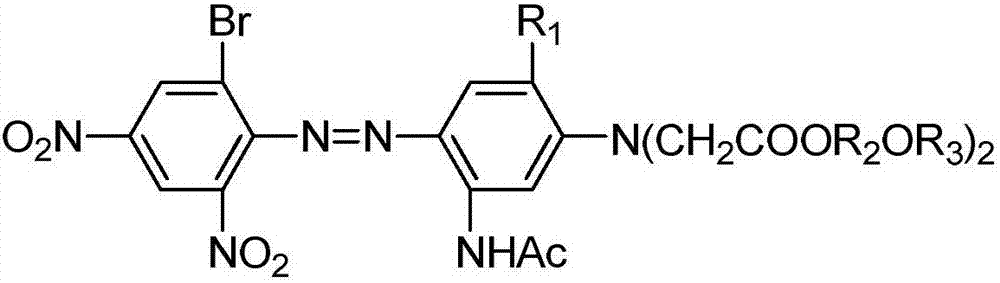

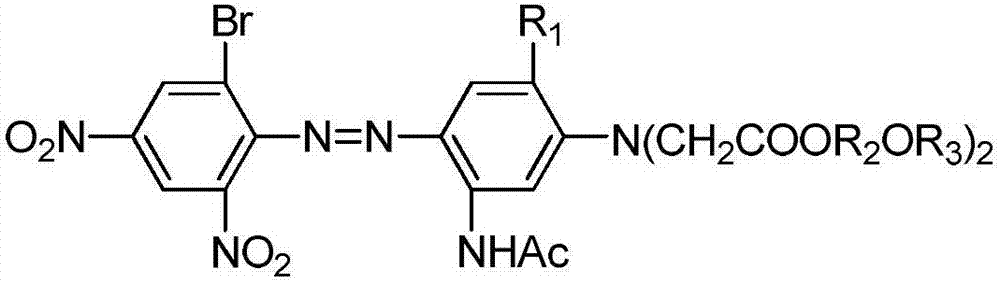

Blue azo dye as well as preparation method and application thereof

The invention discloses a blue azo dye as well as a preparation method and application thereof. A structural formula of the blue azo dye is shown as a formula (I). The invention further discloses application of the blue azo dye in dyeing or printing of polyester fibers. The blue azo dye is selected from at least one compound in the structural general formula (I) and a dispersed dye composition is obtained by mixing; the dispersed dye composition can be applied to the dyeing or printing of the polyester fibers. When the blue azo dye disclosed by the invention is used for dyeing, fastness to washing, fastness to rubbing, fastness to perspiration, color fastness to sunlight and dyeing degree of the blue azo dye are excellent; the dispersed dye composition disclosed by the invention has the advantages of high staining intensity, bright color, good dyeing performance, excellent washing fastness, stable color and luster, low possibility of fading and lower cost.

Owner:HANGZHOU FLARIANT SPECIALTY

Plant coloring agent and preparation method thereof

The invention discloses a plant coloring agent and a preparation method thereof. The plant coloring agent is composed of 1-3 parts of a compound thickening agent, 12-18 parts of a compound mordant and 0.5-2 parts of soybean meal. The compound thickening agent comprises sesbania gum, guar gum or carrageenan. The compound mordant is prepared from copperas, tannic acid and water. The weight ratio of the sesbania gum to the guar gum is 9: 1, and the weight ratio of the sesbania gum to the carrageenan is 7: 3. The weight ratio of the copperas to the tannic acid is 9: 1. The invention also provides the preparation method of the plant coloring agent. The plant coloring agent is relatively good in printing performance, clear in pattern outline edge after fabric dyeing, good in permeability and relatively high in color fastness.

Owner:BEIJING INST OF TECH ZHUHAI CAMPUS

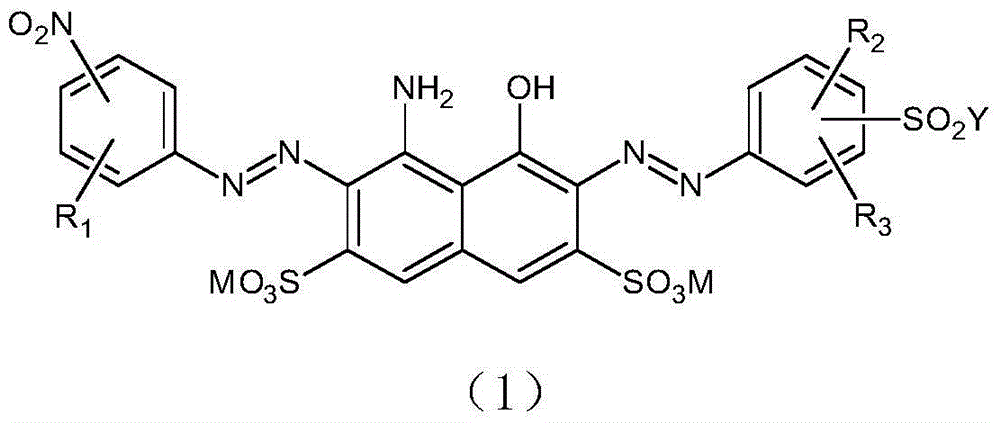

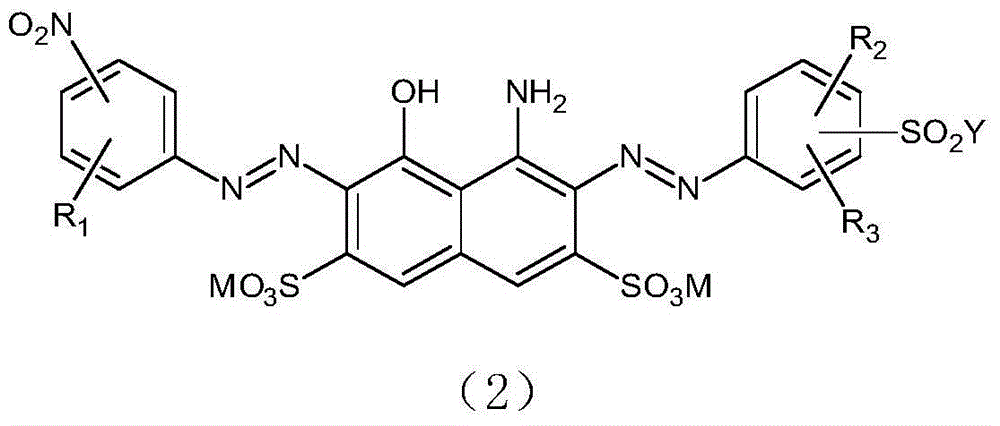

Green reactive dye and preparation method thereof

InactiveCN104693838AGood compatibilityStrong electron-withdrawing abilityOrganic dyesDyeing processReactive dyeSolubility

The invention discloses a green reactive dye and a preparation method thereof. The green reactive dye is a substance having structure general formula selected from one of a formula (1) and a formula (2) and is a mixture by compounding substances having the structure general formulas selected from the formula (1) and the formula (2) in an any proportion. In the green reactive dye, an auxiliary is also added. The formula (1) or formula (2) monomer compound of the green reactive dye can be green and is not compounded; due to the similarity of the parent structure, the mixed dye shows good effects on fabric dyeing degree, degree of fixation, uniform dyeing rate, solarization resistance, water washing resistance, and friction resistance; in addition, the water solubility, uniform dyeing rate and other dyeing effects of the green reactive dye added with the additives are improved.

Owner:ZHEJIANG YIDE CHEM

Black dye composition for hair and dyeing method thereof

InactiveCN101481541AAvoid damageHigh coloring rateOrganic dyesDyeing processAcetic acidProtein fiber

The invention relates to a dye composition which comprises deksol black B, deksol orange PS and deksol yellow PS. Dyeing is carried out on protein fiber materials such as hair, wool and the like, according to a preferable dye process by adopting the dye of the invention, high dyeing rate, good level-dyeing property, bright chromatic light can be ensured, with pH adjusted by adding sulphuric acid, acetic acid and methanoic acid to a compound to be dyed, fastness properties are excellent, moreover, the dye meets environmental requirements.

Owner:TIANJIN DEK CHEM

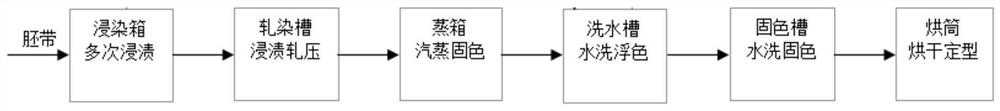

Continuous pad dyeing method for braids

PendingCN113026381AImprove permeabilityImprove wettabilityDyeing processProcess engineeringIndustrial engineering

A continuous pad dyeing method for braids includes the following steps: preparing a dip dyeing box and a pad dyeing box, wherein the dip dyeing box and the pad dyeing box are filled with dye liquor, adding a leveling agent and a penetrating agent, wherein the dip dyeing box is a high-temperature box, and the pad dyeing box is a normal-temperature box; feeding a blank belt into the dip dyeing box for dip dyeing, and after the blank belt is discharged, feeding the blank belt into the dip dyeing box again, wherein dip dyeing is carried out for at least two times in the dip dyeing box; then feeding the blank belt into the pad dyeing box for pad dyeing and rolling the blank belt by a compression roller assembly, and thus enabling the dye liquor to permeate into the blank belt; then feeding the blank belt into a steam box, and steaming and fixing color with saturated steam; feeding into a water washing tank for washing to remove flooding, and then feeding into a color fixing washing tank for color fixing; and drying and shaping to finish processing. Through continuous arrangement of the dip dyeing box and the pad dyeing box, direct continuous dyeing is achieved; the number of times of dipping in dye liquor is increased through the dip dyeing box, the dipping time is prolonged, meanwhile, level dyeing and thorough dyeing are promoted, and the phenomena of white section, dyeing defects, color impure and large color difference of the front face and the back face caused by the uneven dyeing process of the braid are improved.

Owner:NEW HORIZON ELASTIC FABRIC

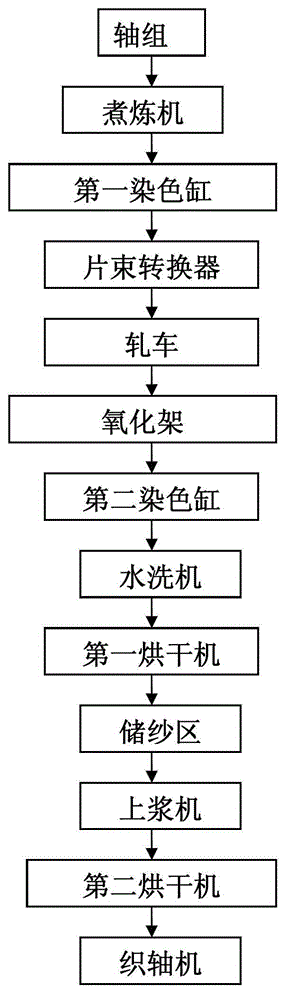

Piece bundle slurry dyeing machine

InactiveCN102978859AIncrease profitUniform pressureTextile treatment machine partsYarnNatural recovery

A piece bundle slurry dyeing machine comprises a shaft set, a scouring machine, a first staining jar, a padder, an oxidization frame, a second staining jar, a water washing machine, a first drier, a sizing machine, a second drier and a weaving machine which are arranged sequentially. The machine is characterized in that a piece bundle converter is arranged between the first staining jar and the padder, is used for converting piece type yarn pieces to bundle type yarns, and comprises a bottom plate (1) and separation plates (2) which are arranged on the bottom plate (1) at fixed intervals; and the bundle type yarns are naturally recovered to the piece type yarn pieces on the oxidization frame. The piece bundle slurry dyeing machine converts the piece type yarn pieces to the bundle type yarns, so that the thickness of the yarns is increased, the dry rolling rate of the padder to the yarns is improved, the dyeing degree and the dyeing firmness are improved, the dyeing is even and reliable, and the edge difference due to bad dyeing firmness and uneven dyeing degree is reduced, and bad dyeing firmness is caused by wet rolling and uneven rolling of the padder.

Owner:WUXI JINNIU TEXTILE

Environment-friendly purple reactive dye mixture for wool

InactiveCN105295442AImprove dyeing effectHigh fastnessOrganic dyesDyeing processInorganic saltsFiber

The invention discloses an environment-friendly purple reactive dye mixture for wool. The mixture comprises the following ingredients in parts by weight: 60-90 parts of dye A, 40-60 parts of dye B and 50-80 parts of dye C. The environment-friendly purple reactive dye mixture for wool, disclosed by the invention, is high in fixation ratio and fiber dye combination stability, good in fastness, excellent in improving property, levelling property, solubility and eluting property; compared with the conventional dye, the dye disclosed by the invention consumes less inorganic salt and alkali, thereby belonging to environment-friendly dyes.

Owner:WUXI SINTEX PRINTING & DYEING CO LTD

A kind of yellow disperse dye composition and dye product

The invention provides a yellow disperse dye composition. The yellow disperse dye composition comprises 5-95% by mass of component A and 5-95% by mass of component B, wherein the component A is selected from at least one of compounds shown as formula (I); the component B is selected from at least one of components shown as formula (II). The invention also provides a yellow disperse dye product. The yellow disperse dye product comprises the abovementioned yellow disperse dye composition and additives based on the weight ratio of 1: 0.2-5. The yellow disperse dye composition and the dye producthave the advantages of being high in degree of dyeing, high in improving power, outstanding in color fastness to sublimation, outstanding in crockfastness and rwashing fastness while being applicableto dyeing of hydrophobic fiber materials; the dyed yellow is full and bright.

Owner:ZHEJIANG LONGSHENG CHEM RES

Purple active dye

InactiveCN101724293AGood coloring rateGood color fixation rateReactive dyesDyeing processSolubilityColored light

The invention discloses a purple active dye, which has a structure as follows: FORMULA, wherein R1 is H,-CH3, -OCH3 or-SO3M; R2 is H, -CH3, -NO2 or-OH; and M is H or alkali metal. The purple active dye for wool has higher reactivity, good solubility, colorful and beautiful colored light, and low cot, and is environment-friendly.

Owner:TIANJIN DEK CHEM

Dispersive dark blue dye composition

The invention discloses a dispersive dark blue dye composition which consists of by mass percent, 5-25% of a component A shown by a structural formula (I), 10-40%of a component B shown by a structural formula (II), 1-10% of a component C shown by a structural formula (III), 1-10% of a component D shown by a structural formula (IV) and the balance of an auxiliary agent. A piece of sample cloth dyed by the dye composition disclosed by the invention is bright in color, has excellent washing-resistance fastness, rubbing-resistance fastness, sweat stain resistance fastness, daylight-resistance fastness and high degree of dyeing, and the production cost of the dye composition is low.

Owner:HANGZHOU FLARIANT SPECIALTY

High-solarization red reactive dye and preparation method thereof

InactiveCN111925666AImproves resistance to sun discolorationImprove high light fastnessReactive dyesOrganic chemistryPhotochemistry

The invention discloses a high-solarization red reactive dye and a preparation method thereof, and belongs to the field of reactive dyes in a new material technology. The high-solarization red reactive dye is selected from one or a mixture formed by compounding more than two structures in a general formula (1) according to any proportion, one of the compounds shown in the formula (1) is selected from any one or a mixture of more than two of the following structural general formulas, wherein in the formula (1), R1 represents-SO3M; R2 represents-H,-CH < 3 > or-CH < 2 > CH < 3 >; R3 represents-H,-CH3,-CH2CH3,-SO3M,-SO2CH = CH2 or-SO2C2H4OSO3M; M represents-H,-Na,-K or-Li; X represents Cl or F. The high-solarization red reactive dye has the advantages of high light fastness and heat-resistantstability, and also has good rubbing fastness and washing fastness.

Owner:ZHEJIANG YIDE CHEM

Method for preparing carmine reactive dye

InactiveCN102558903AGood coloring rateGood color fixation rateReactive dyesHydrogen SulfateIce water

The invention discloses a method for preparing a carmine reactive dye. The method comprises the following steps of: 1, synthesizing sulfonated methyl J-acid sodium salt; 2, preparing sulfonated para-ester diazo; 3, keeping the sulfonated para-ester diazo obtained in step 2 and a reaction product in step 1 at the temperature of between 5 and 10 DEG C under acidic conditions, and condensing for 3 to 4 hours; 4, adding 31.1g of 2-[(3-amino-4-methoxyphenyl)sulphonyl]ethyl hydrogen sulfate at the concentration of 100 percent into 150g of ice and water mixture, beating for 1 hour, adding 30 percent hydrochloric acid, adding 6.9g of aqueous solution of 100 percent sodium nitrite, keeping the temperature at 5 to 8 DEG C, reacting for 2 hours when the solution is faint blue on starch potassium iodide paper, and removing an excess amount of nitrous acid by using a small amount of sulfamic acid; and 5, mixing a reaction solution in step 4 and an acidic coupling liquid in step 3, regulating the pH value to be 6 to 6.5 by using baking soda, and coupling at the temperature of between 10 and 15 DEG C for 3 to 4 hours to obtain the carmine reactive dye.

Owner:褚平忠

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com