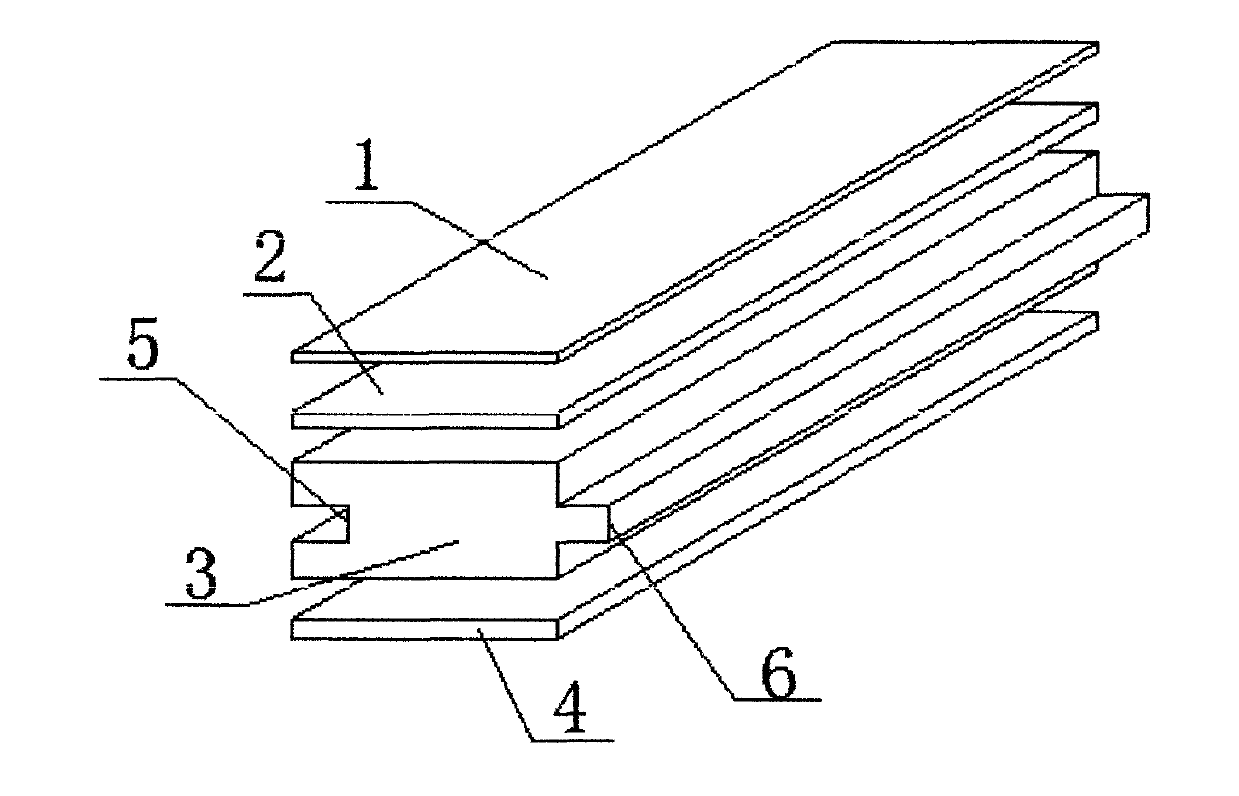

Expandable polystyrene (EPS) waterproof and sound insulation type composite wood floor

A composite wood and floor technology, applied in synthetic resin layered products, paper/cardboard layered products, layered products, etc., can solve problems such as disturbing the daily work and rest of downstairs residents, easily permeating into the floor, and cracking the wooden floor. Achieve good waterproof and sound insulation, simple structure, and increase the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The wear-resistant layer is selected from single-layer all-wood pulp paper containing 25% aluminum oxide, impregnated at a basis weight of 20 / m 2 In the melamine-formaldehyde resin, the wear-resistant layer is finally obtained;

[0024] The decorative layer is made of special paper printed with a specific pattern, impregnated at a quantitative rate of 5 / m 2 in the melamine solution.

[0025] The base paper is hard paper with a weight of 80g / mm and a paper thickness of 0.3mm;

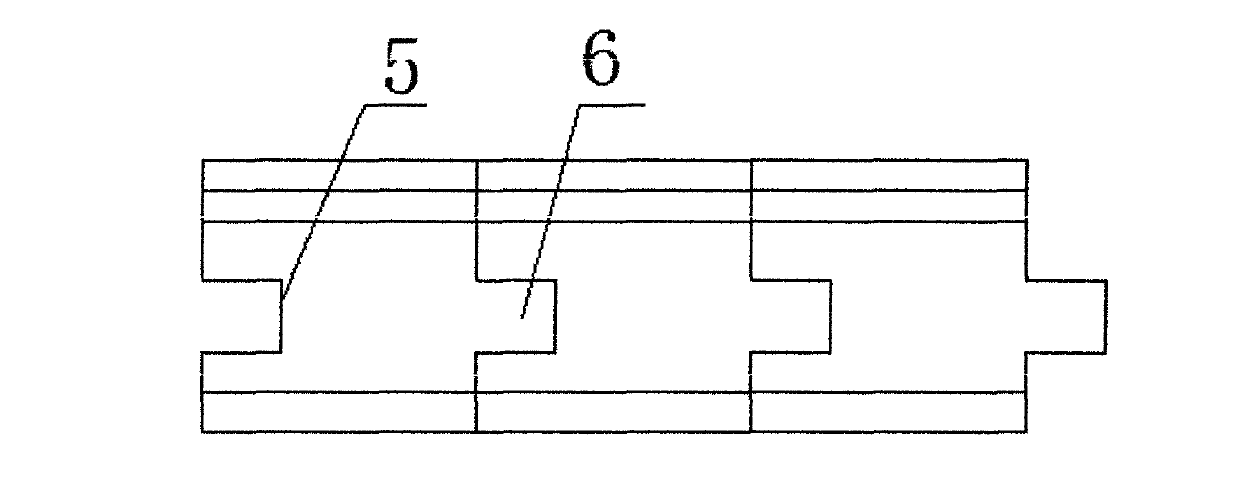

[0026] The substrate layer is made of 45% expandable polystyrene raw material (EPS), 15% special polymer clay, 15% alkali-resistant glass fiber and 25% wood pulp. process made;

[0027] The balance layer is made of kraft paper made of sulfite wood pulp, impregnated at a weight of 10g / m 2 Made of melamine resin after heat curing;

[0028] Then between the wear-resistant layer, the decorative layer, the base material layer and the balance layer, the adhesive is brushed, pressed, and finally mad...

Embodiment 2

[0031] The wear-resistant layer is selected from single-layer all-wood pulp paper containing 27% aluminum oxide, impregnated at a basis weight of 35 / m 2 In the melamine-formaldehyde resin, the wear-resistant layer is finally obtained;

[0032] The decorative layer is made of special paper printed with a specific pattern, which is soaked in a melamine solution with a quantitative ratio of 10 / m2;

[0033] The bottom paper is hard paper with a weight of 100g / mm and a paper thickness of 0.32mm;

[0034] The substrate layer is made of 50% expandable polystyrene raw material (EPS), 20% special polymer clay, 17% alkali-resistant glass fiber and 23% wood pulp. process made;

[0035] The balance layer is made of kraft paper made of sulfite wood pulp, impregnated at a weight of 15g / m 2 Made of melamine resin after heat curing;

[0036] Then between the wear-resistant layer, the decorative layer, the base material layer and the balance layer, the adhesive is brushed, pressed, and fin...

Embodiment 3

[0039] The wear-resistant layer is selected from single-layer all-wood pulp paper containing 30% aluminum oxide, impregnated at a basis weight of 45 / m 2 In the melamine formaldehyde resin;

[0040] The decorative layer is made of special paper printed with a specific pattern, impregnated at a quantitative rate of 15 / m 2 In the melamine solution;

[0041] The base paper is hard paper with a weight of 120g / mm and a paper thickness of 0.35mm;

[0042] The substrate layer is made of 45% expandable polystyrene raw material (EPS), 25% special polymer clay, 15% alkali-resistant glass fiber and 15% wood pulp. process made;

[0043] The balance layer is made of kraft paper made of sulfite wood pulp, impregnated at a basis weight of 20g / m 2 Made of melamine resin after heat curing;

[0044] Then between the wear-resistant layer, the decorative layer, the base material layer and the balance layer, the adhesive is brushed, pressed, and finally made into the present invention;

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com