Low-additive-amount long-acting low-humidity-resistant washable polyvinyl chloride special antistatic agent

A technology of antistatic agent and polyvinyl chloride, which is applied in the field of antistatic agent, can solve the problems of non-durability and washing resistance, weakened antistatic performance, toxicity and irritation, etc. Fast-acting, less toxic and less irritating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

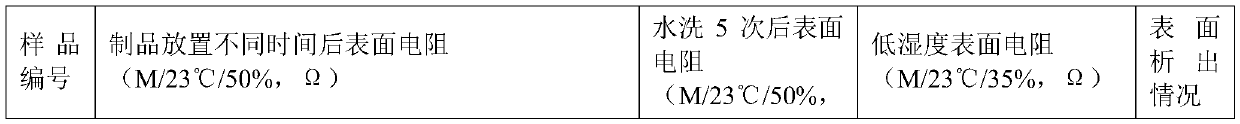

Image

Examples

Embodiment 1

[0099] Potassium Lauryl Phosphate 20%

[0100] Lauryltrimethylammonium Bromide 22%

[0101] Coconut Diethanolamide Phosphate 26%

[0102] Propylene Glycol 8%

[0103] Glycerol 4%

[0104] GP330 glycerol polyether 5%

[0105] Tween 855%

[0106] Potassium acetate 10%.

[0107] (1) After adding all other components except potassium acetate to propylene glycol and glycerin, it is directly dispersed at room temperature;

[0108] (2) Potassium acetate is added under stirring conditions, uniformly dispersed at room temperature or heated to promote dissolution until uniformly dispersed;

[0109] (3) Release the material after cooling, and the obtained light yellow transparent liquid is the antistatic agent 1.

Embodiment 2

[0111] Potassium Didecyl Phosphate Diester 28%

[0112] Lauryltrimethylammonium Bromide 20%

[0113] Diethanolamine Lauroyl 30%

[0114] Propylene Glycol 10%

[0115] Glycerol 3%

[0116] GP330 glycerol polyether 6%

[0117] Tween 803%.

[0118] Its preparation method comprises the following steps:

[0119] (1) After adding all other components to propylene glycol and glycerin, disperse directly at room temperature or slightly heat to promote dissolution until uniform dispersion;

[0120] (2) Release the material after cooling, and the obtained light yellow transparent liquid is the antistatic agent 2.

Embodiment 3

[0122] Monoalkyl ether phosphate potassium salt 30%

[0123] Lauryl Dimethyl Benzyl Ammonium Chloride 14%

[0124] Lauramide ether carboxylate 16%

[0125] Propylene Glycol 25%

[0126] Laurylamine polyoxyethylene ether 5%

[0127] Propylene Glycol Block Polyether 5%

[0128] Tween 405%.

[0129] Its preparation method comprises the following steps:

[0130] (1) After adding all other components to propylene glycol, directly disperse evenly at room temperature or slightly heat to promote dissolution until uniformly dispersed;

[0131] (2) Release the material after cooling, and the obtained light yellow transparent liquid is the antistatic agent 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com