Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

68results about How to "Guaranteed coefficient of friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

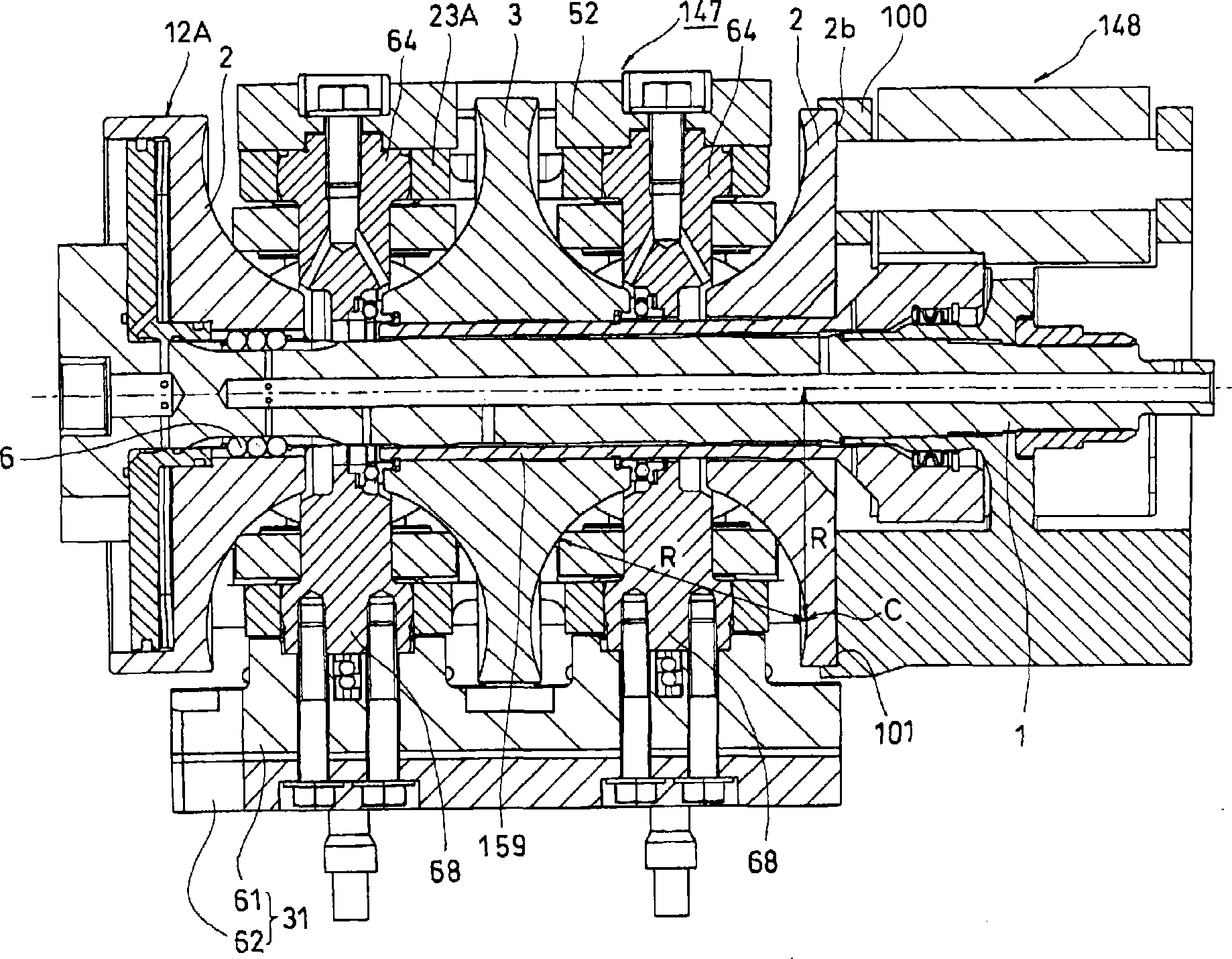

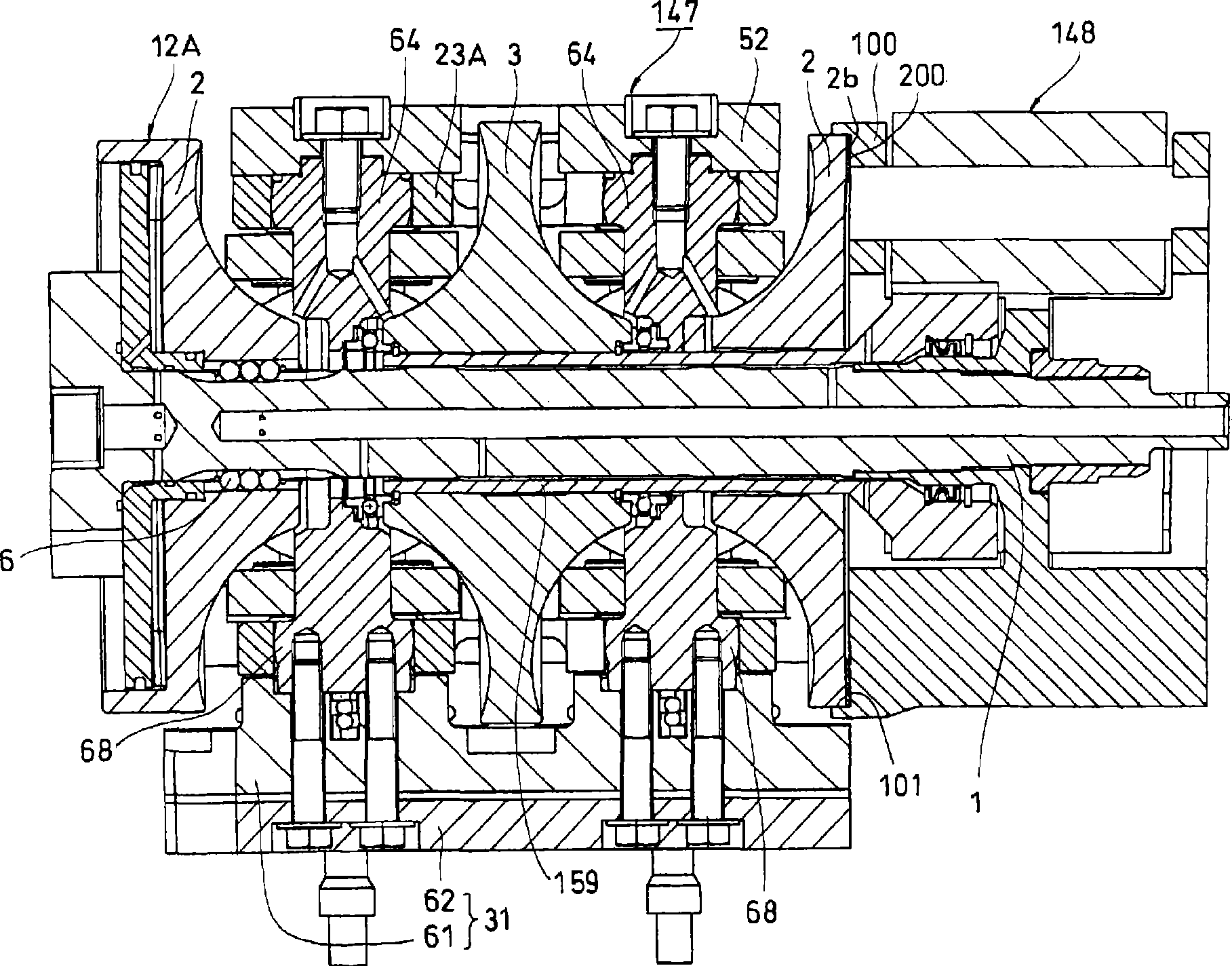

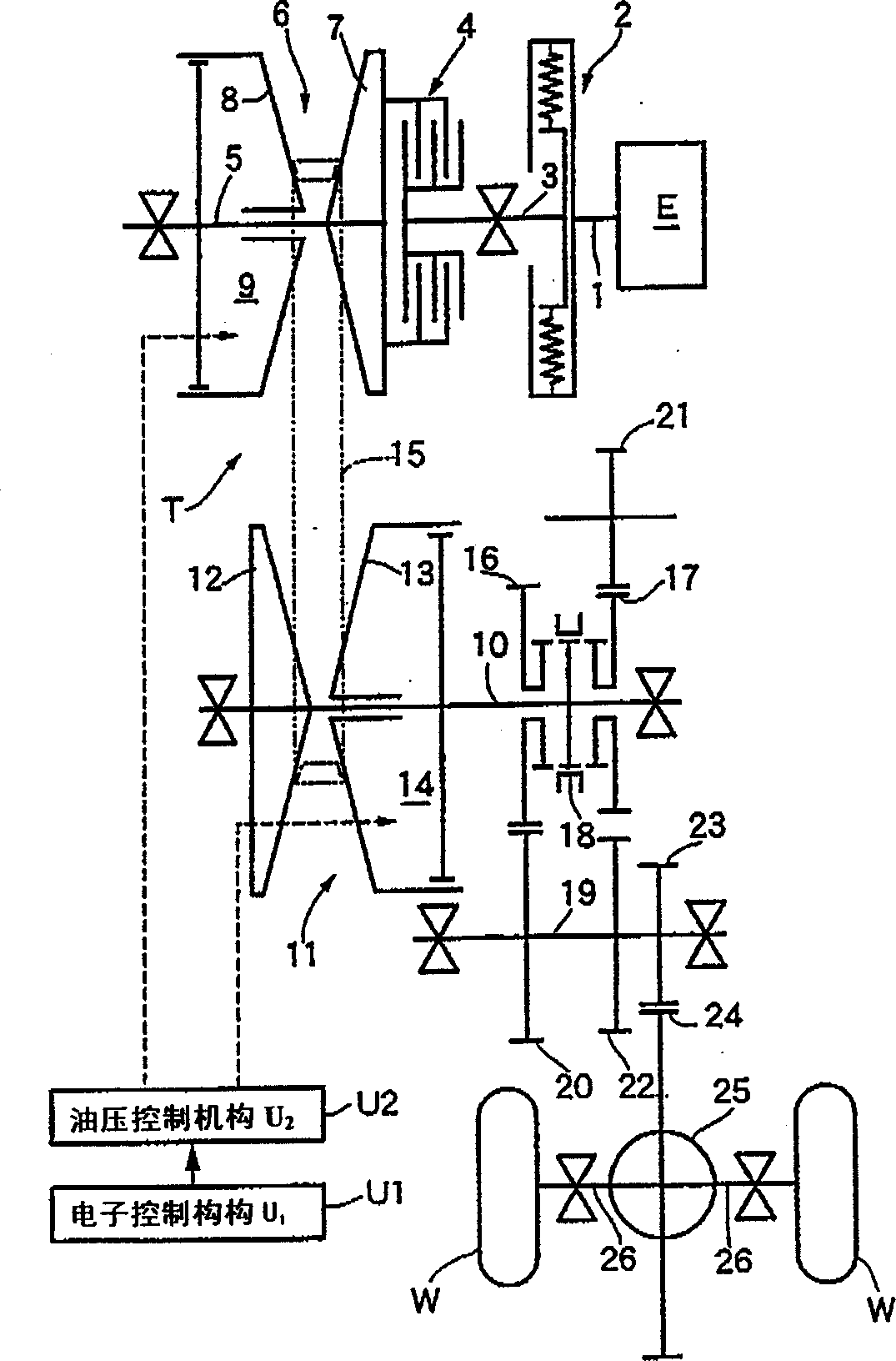

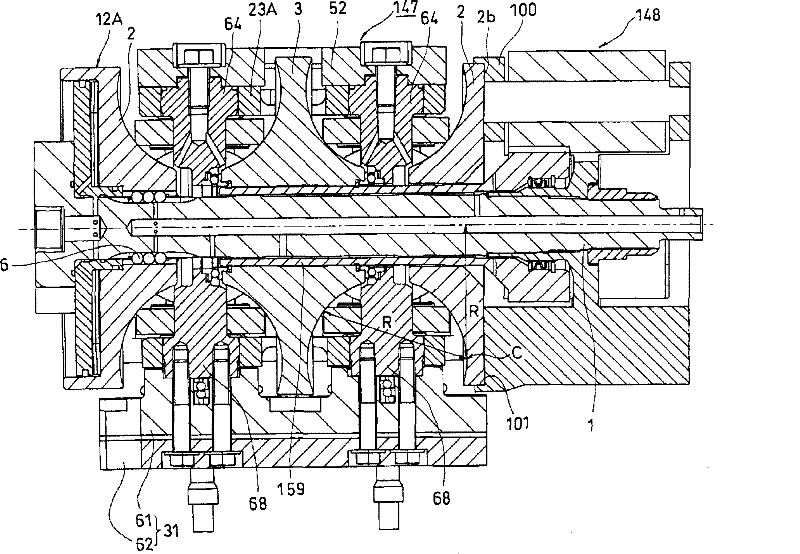

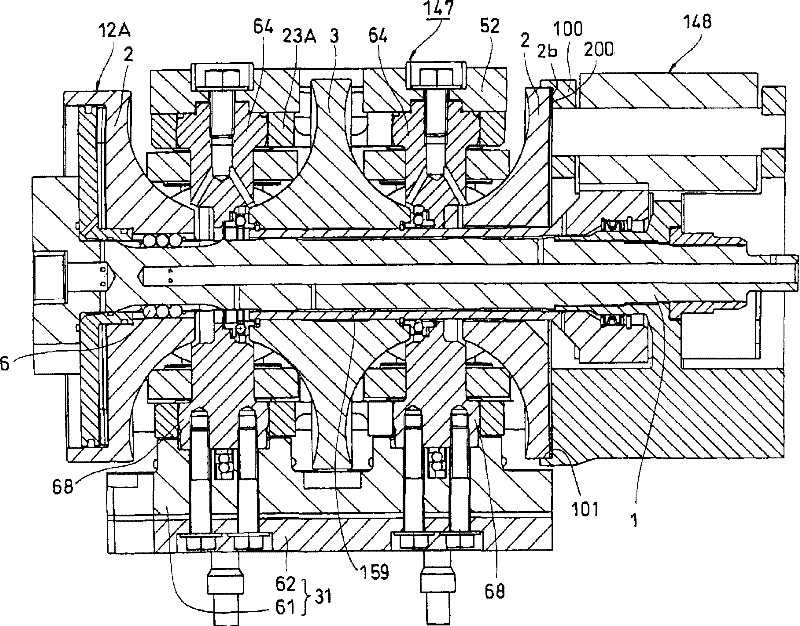

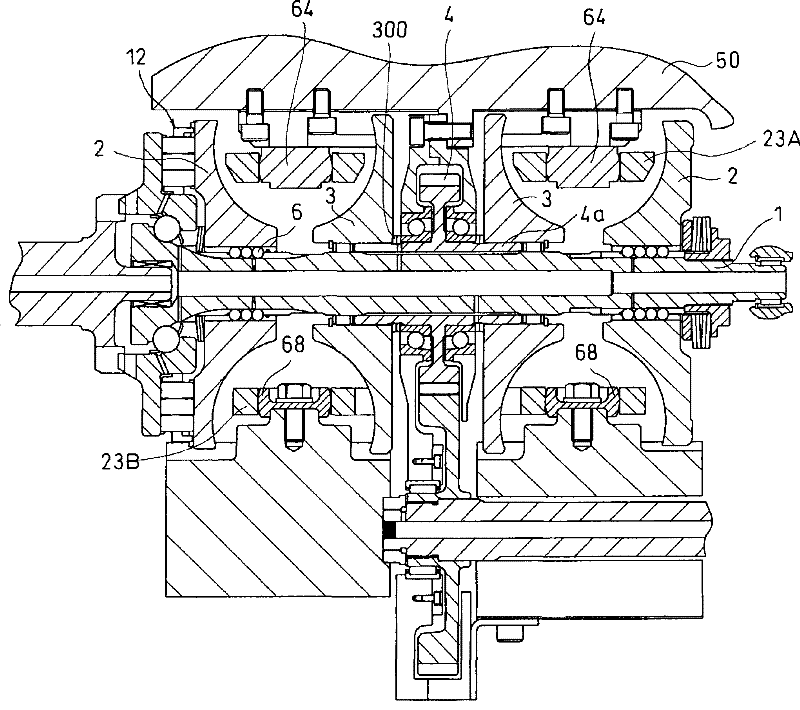

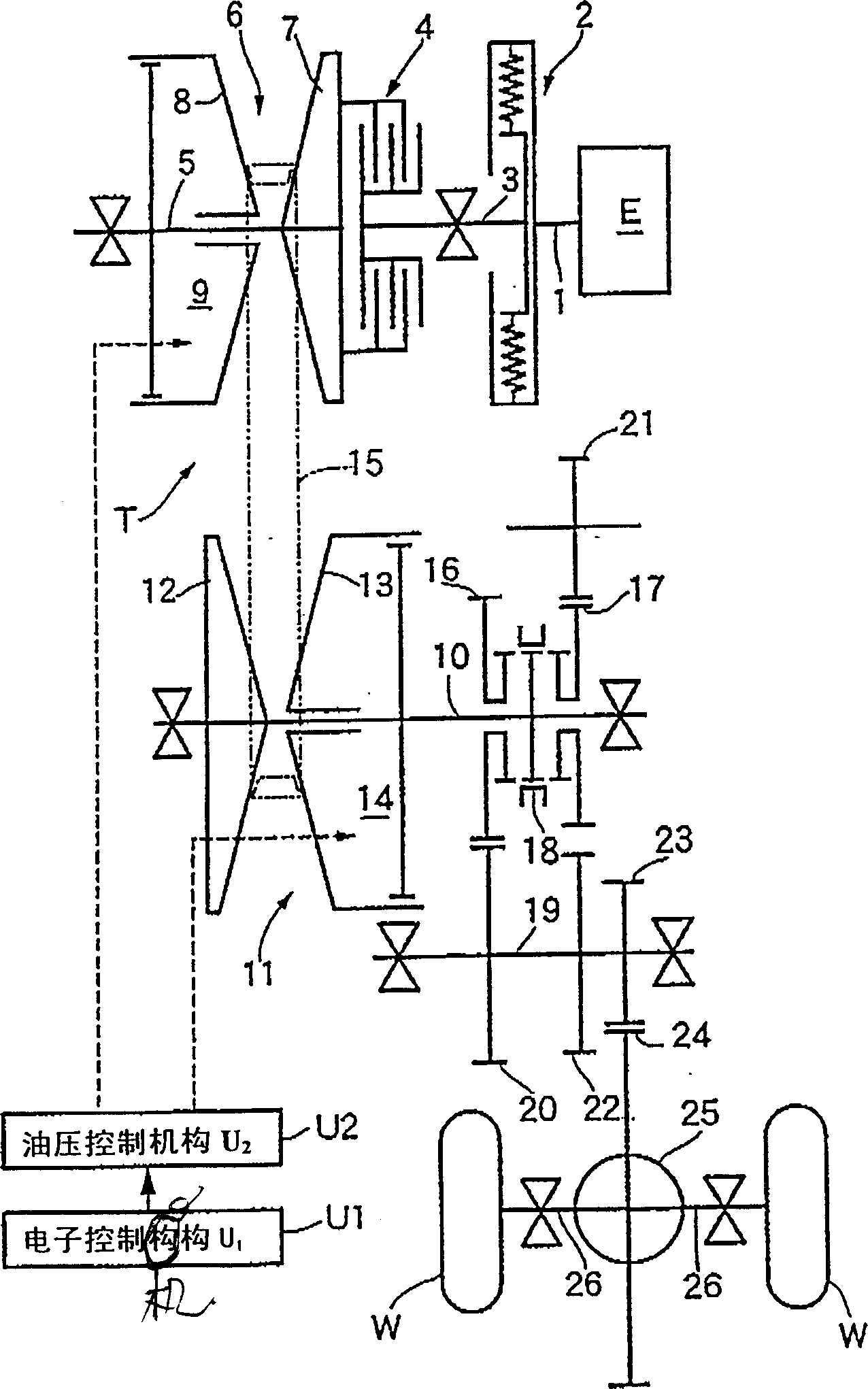

Toroidal type stepless transmission and stepless transmission

InactiveCN101479503AReduce weightAvoid getting stuckFriction gearingsElectric power transmissionGear wheel

A toroidal type stepless transmission where a carrier (100) and a disk (2) are in direct friction contact with each other to allow power transmission between the carrier (100) and the disk (2) by friction force. Accordingly, the transmission does not require processing of gears and claws on the disk or the carrier, which has been required conventionally. As a result, production processes are reduced to enable a considerable reduction in production costs.

Owner:NSK LTD

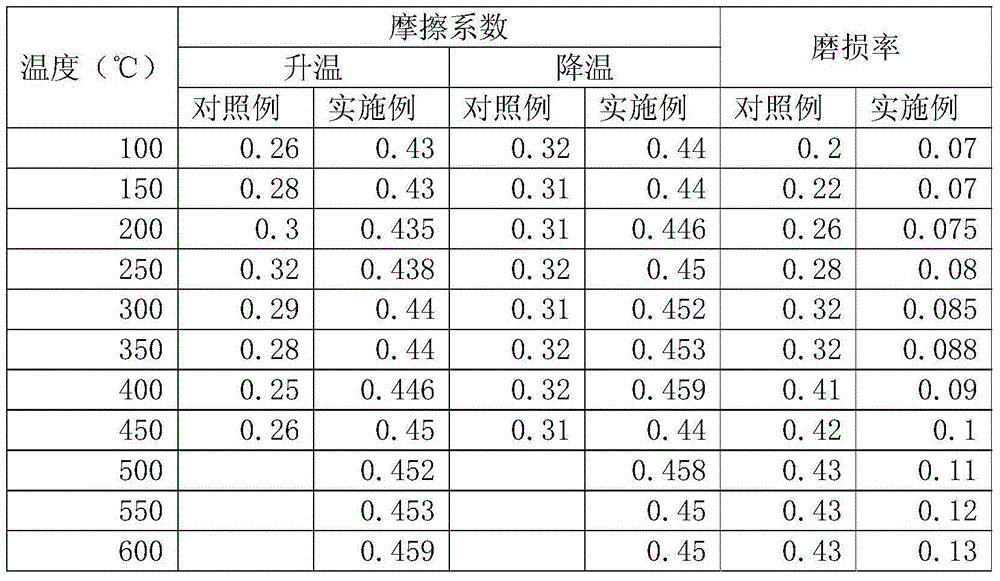

High-performance composite brake disc material

InactiveCN104893256AImprove thermal conductivityEnhanced interface bindingFriction liningMicrosphereWear resistant

The invention discloses a high-performance composite brake disc material, the wear resistant material comprises the following raw materials: bisphenol a novolac epoxy resin, diaminodiphenyl sulfone, hollow microspheres, a lubricant, a silane coupling agent, diamine, an imidazoles compound, an anti-oxidant, chloroprene rubber powder, alumina and reinforced fibers. The reinforced fibers can be a mixture of zylonite fiber, aramid fiber, cotton fiber and ramie fiber; the interface combination of fiber and particles in the materials is good, and the fiber and particles in the materials enable synergistic interaction with antimonony oxide and graphite, generation of thermal decomposition, heat attenuation and heat cracks phenomena can be effectively reduced, thermal conductivity of the materials is good, heat generated when brake friction is carried out can be timely radiated, brake disc surface temperature can be rapidly reduced, high temperature heat attenuation is reduced, hollow microspheres, the lubricant, the silane coupling agent and the enhance fiber are specific, friction coefficient of the wear resistant materials can be enhanced by intermolecular cooperation of the substances, and stability of the friction coefficient can be improved simultaneously.

Owner:CHONGQING JIAOTONG UNIVERSITY

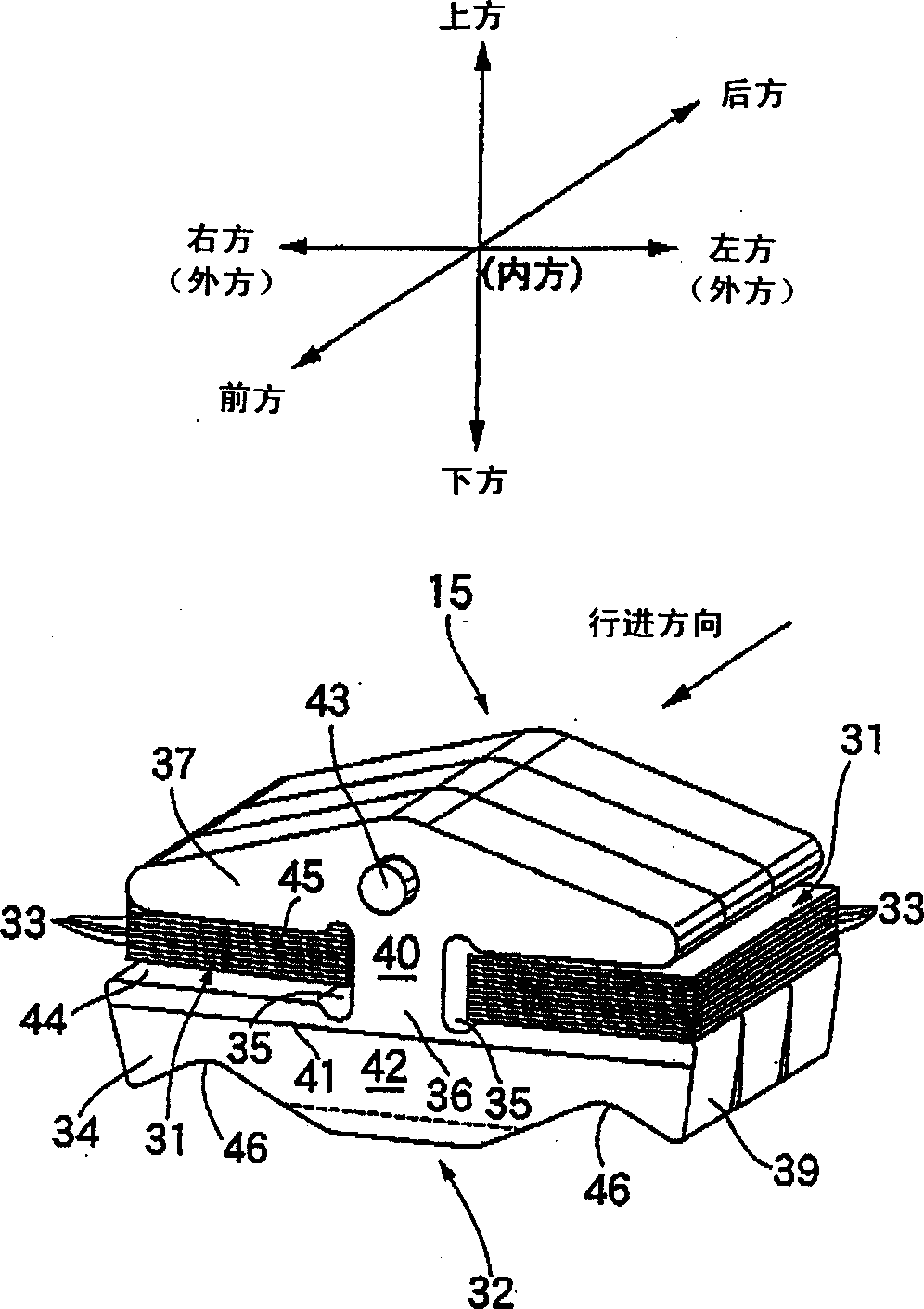

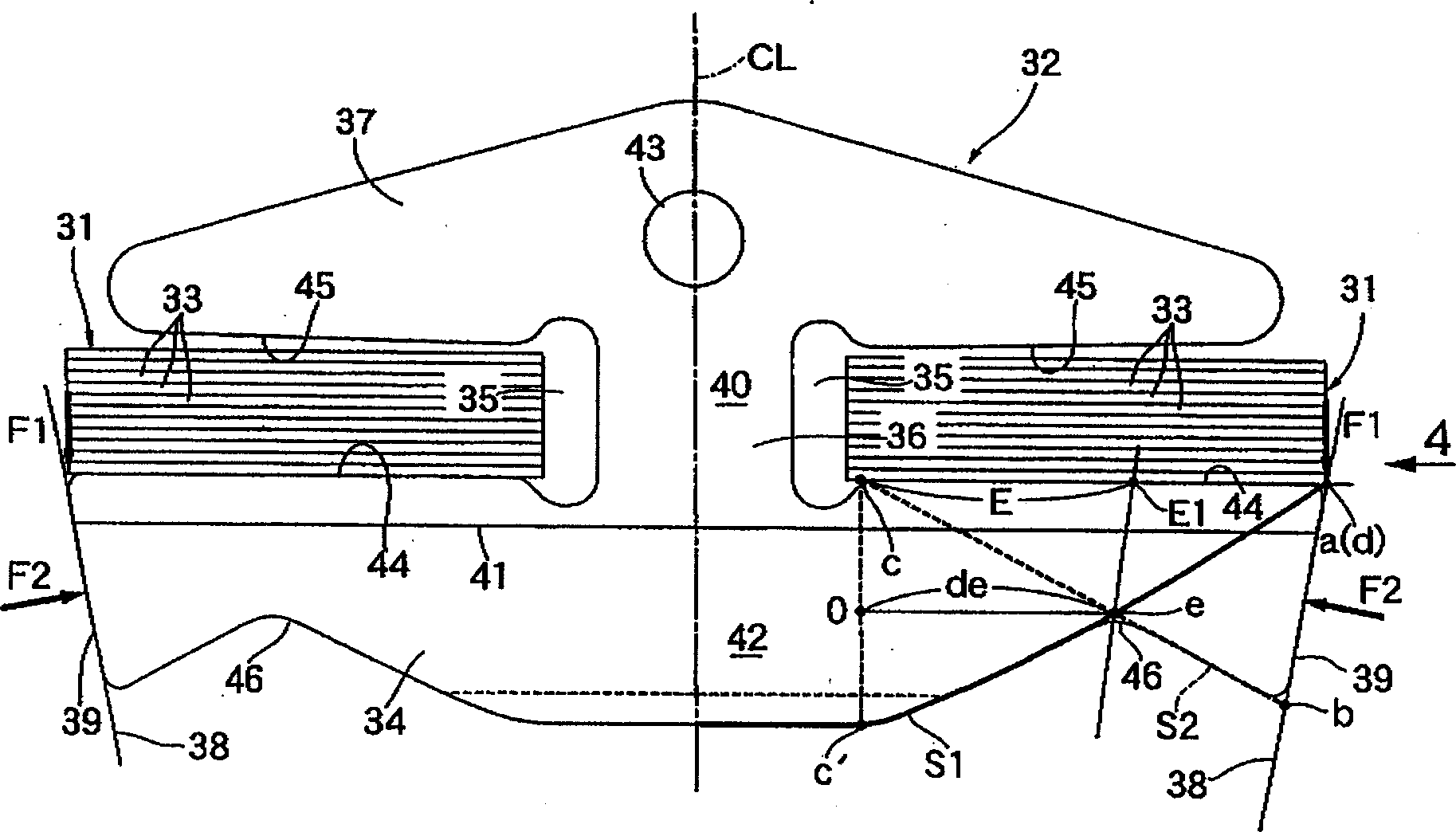

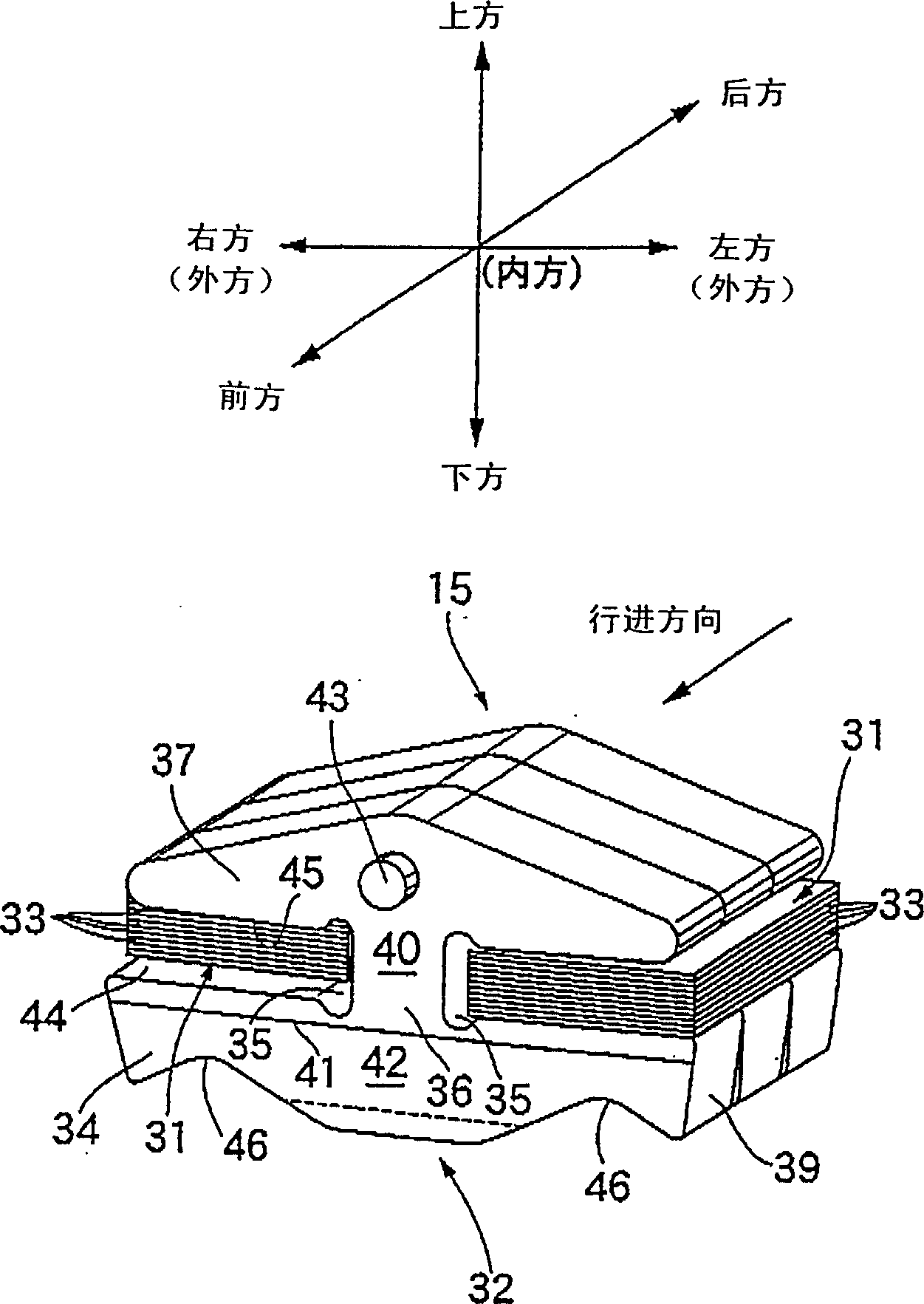

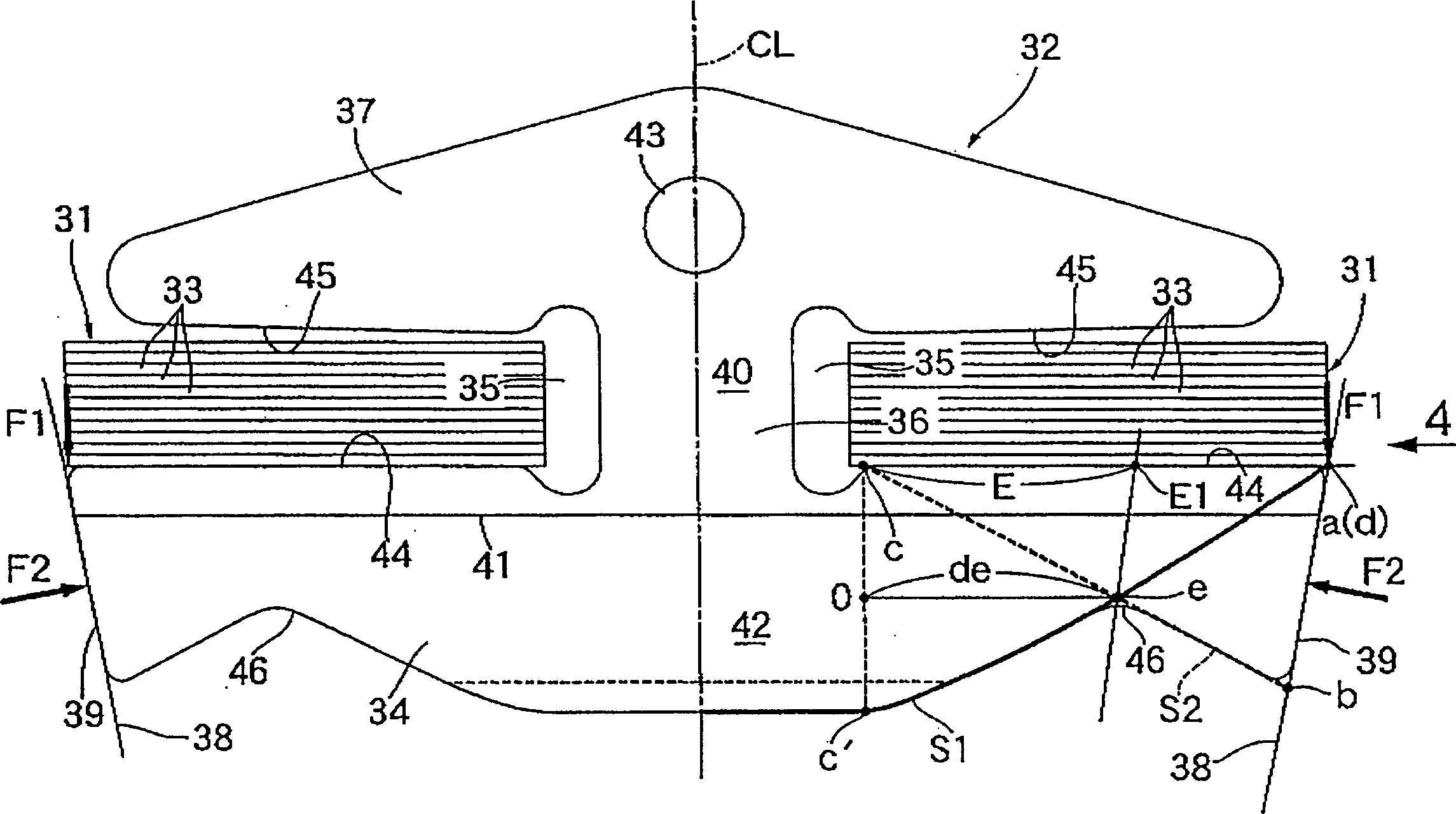

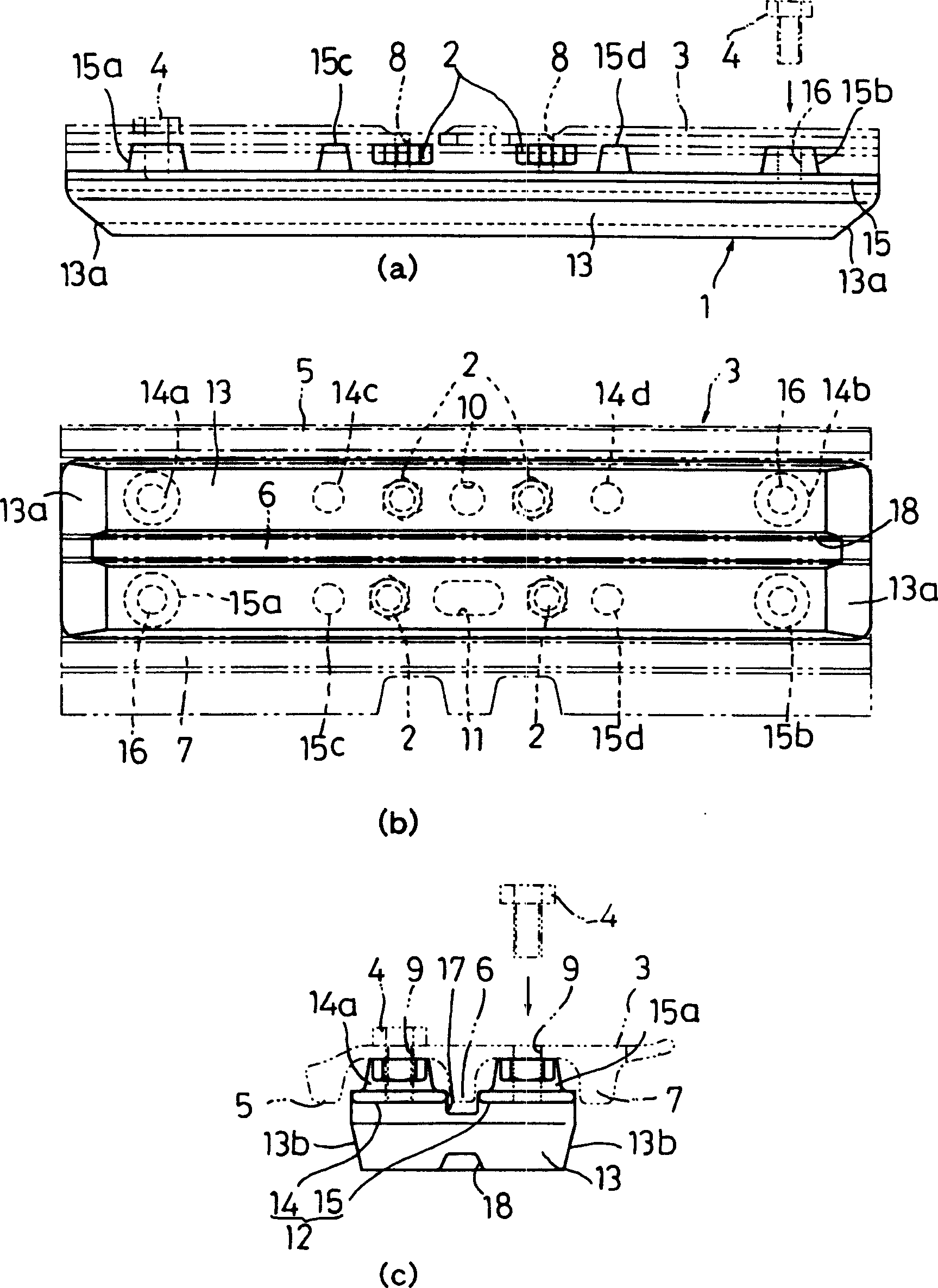

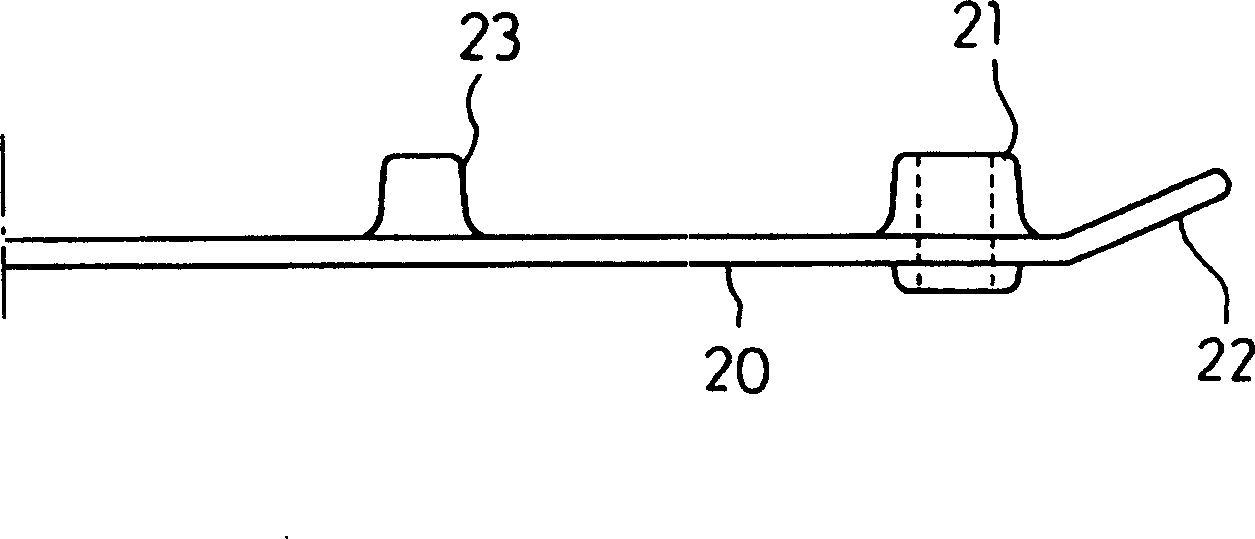

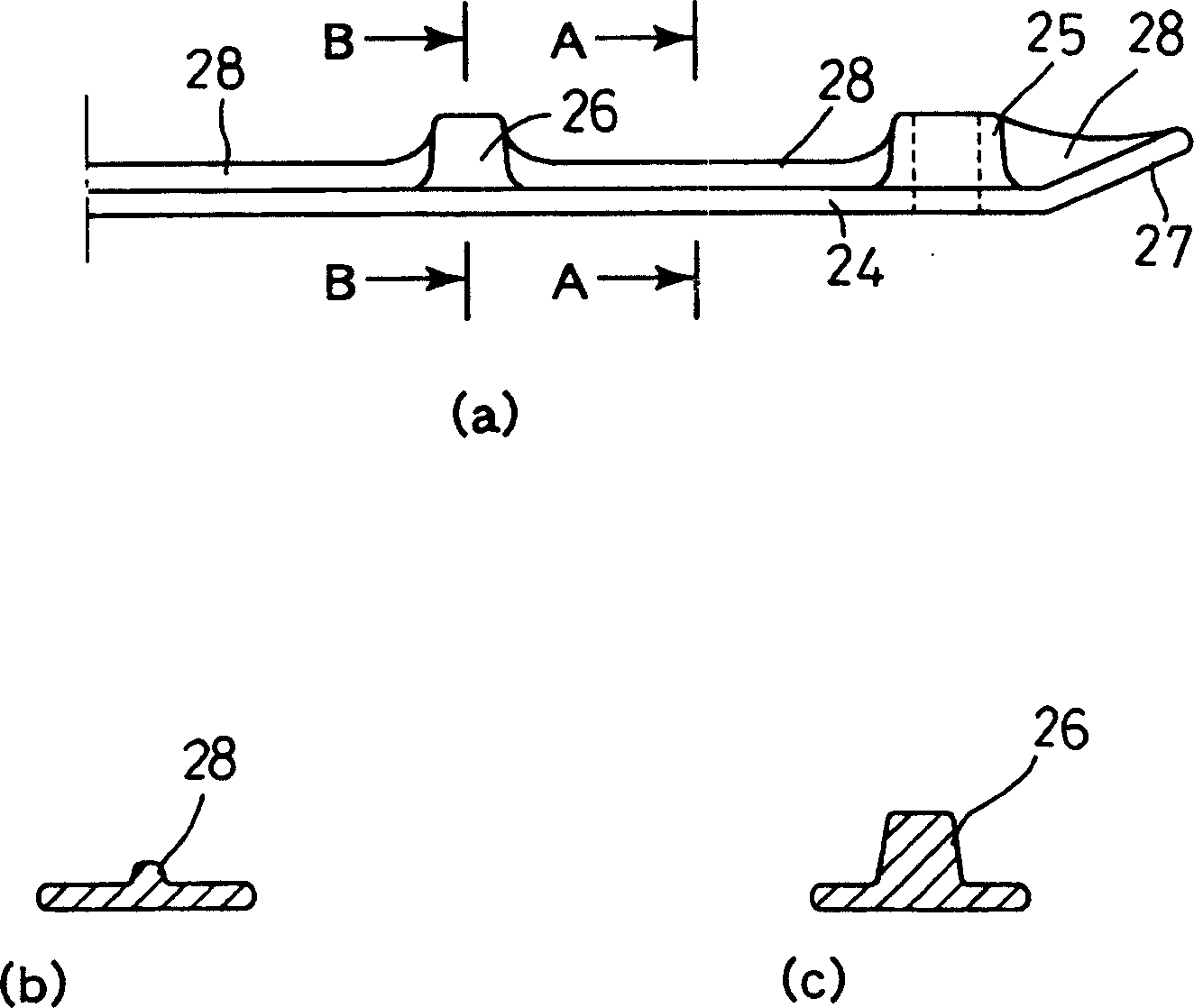

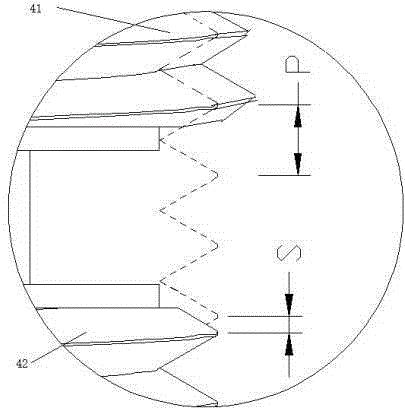

Belt for non-stage transmissions

In a belt for a continuously variable transmission, a first line on a lower edge of an element body of a metal element is determined, and a second line straightforwardly connecting a lower end of a V-face to which a load is applied from a V-groove in a pulley and an inner end of a saddle surface is determined, so that when a downward load is applied from a metal ring assembly to an outer end of the saddle surface, the folding-resistant strength of the element body is uniform laterally. The position of the recess is determined in the vicinity of a point of intersection of the first and second lines. The lower edge of the element body is defined by the first line inside the recess and by the second line outside the recess. The durability of the metal element can be enhanced by devising the shape of the lower edge of the element body of the metal element in this manner.

Owner:HONDA MOTOR CO LTD

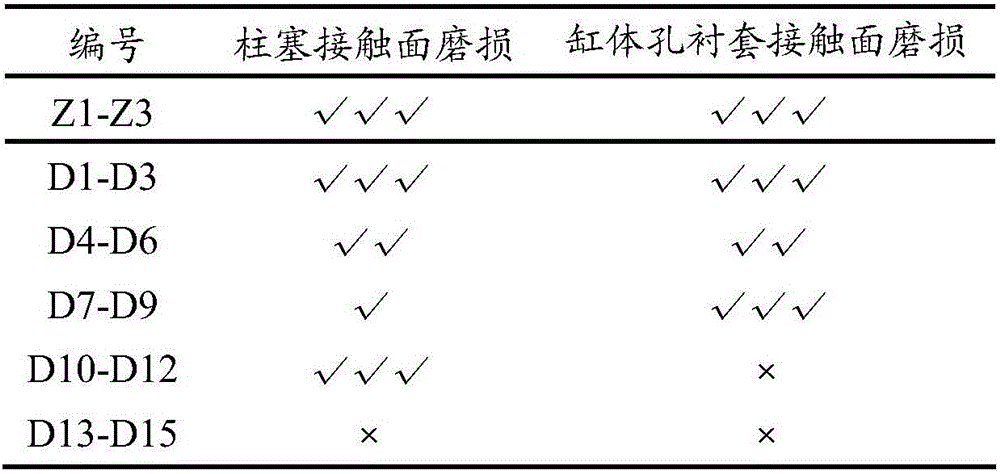

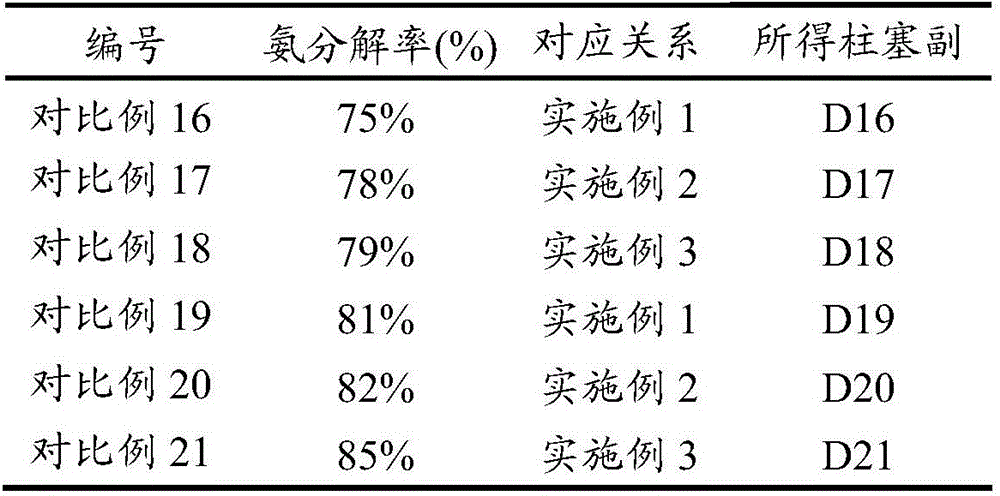

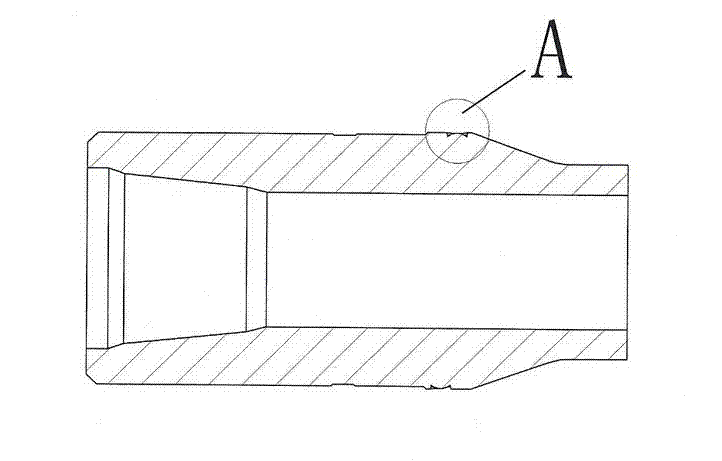

Method for manufacturing plunger pair for plunger pump

InactiveCN105714196AImprove fatigue strengthImprove fracture toughnessMolten spray coatingPositive displacement pump componentsEngineeringMechanical engineering

The invention relates to a method for manufacturing a plunger pair for a plunger pump. The method for manufacturing the plunger pair comprises the following steps that S1,a plunger is manufactured; S2, a cylinder body hole lining is manufactured; and S3, the plunger obtained in the S1 and the cylinder body hole lining obtained in the S2 are mounted in a matched manner, and therefore the plunger pair is obtained. The method for manufacturing the plunger pair can be used for manufacturing the plunger pair with the excellent wear-resisting performance through the unique manufacturing steps and unique compositional selecting of the plungers and the cylinder body hole lining, and the good application potentiality and industrialized production value are achieved.

Owner:FUXIN HAIPU HYDRAULIC MFG

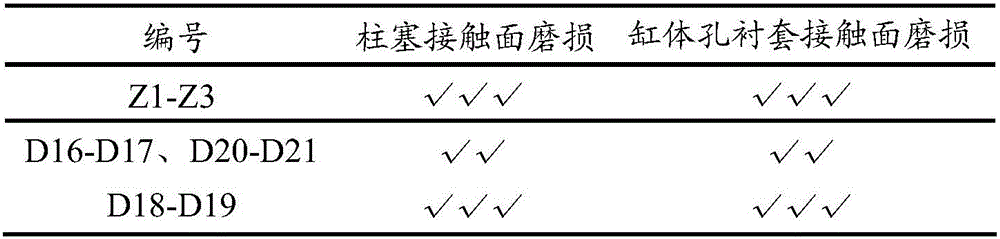

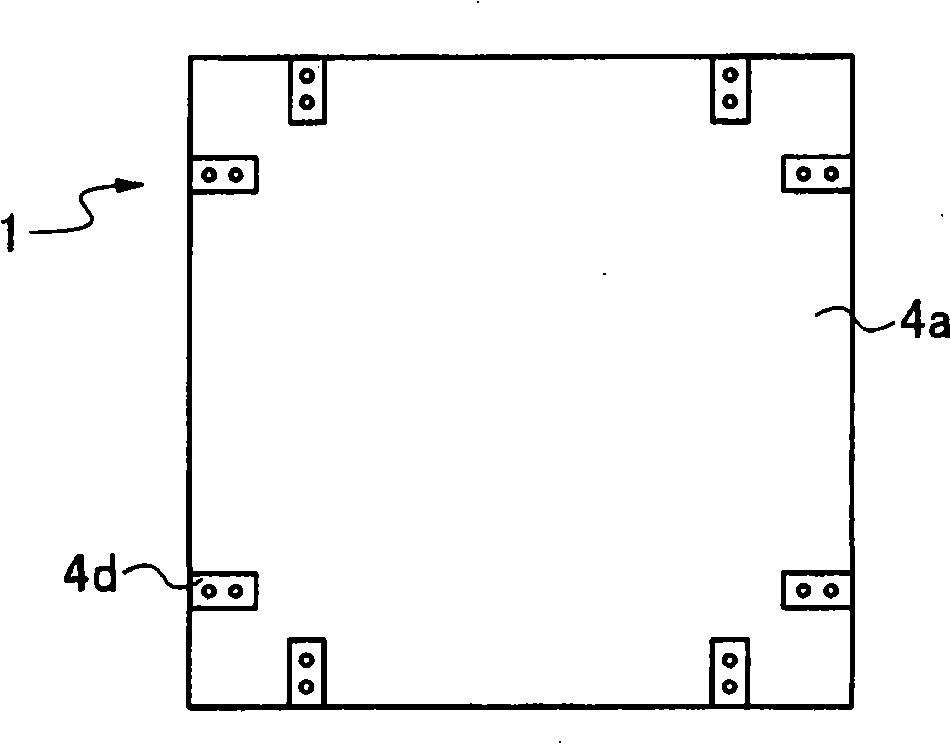

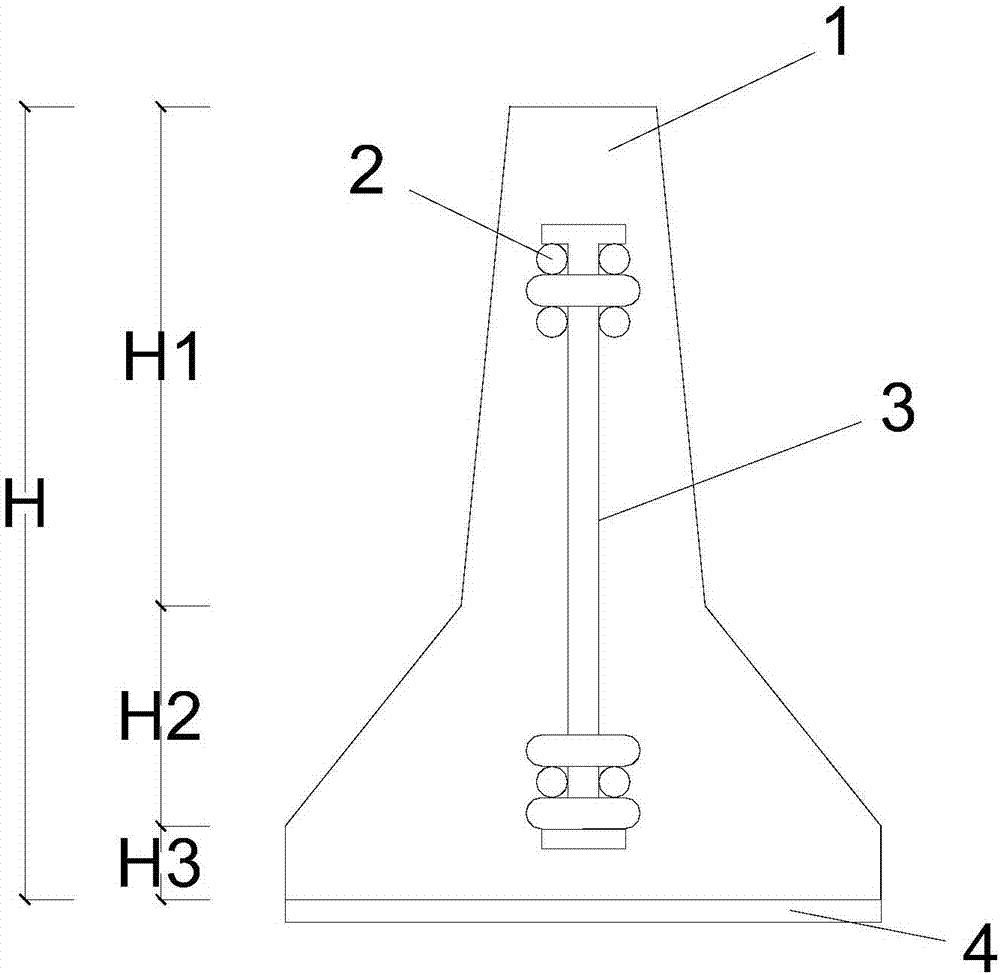

Seismic isolation apparatus and structure having seismic isolation apparatus

ActiveCN101408044AEfficient use ofLow priceProtective buildings/sheltersShock proofingEngineeringSeismic isolation

The present invention provides a seismic isolation apparatus which, as well as widening an applicable shaking range, can be easily configured and is low in height, a seismic isolation apparatus is configured of a low friction combination formed by a point contact between a planar hard plate base, which has a surface on which are disposed at least three convexly curved projections of a uniform height, and a glide plate which is a smooth, hard, flat plate.

Owner:IDEAL BRAIN

Toroidal type stepless transmission and stepless transmission

InactiveCN101479503BReduce weightAvoid getting stuckFriction gearingsElectric power transmissionEngineering

Owner:NSK LTD

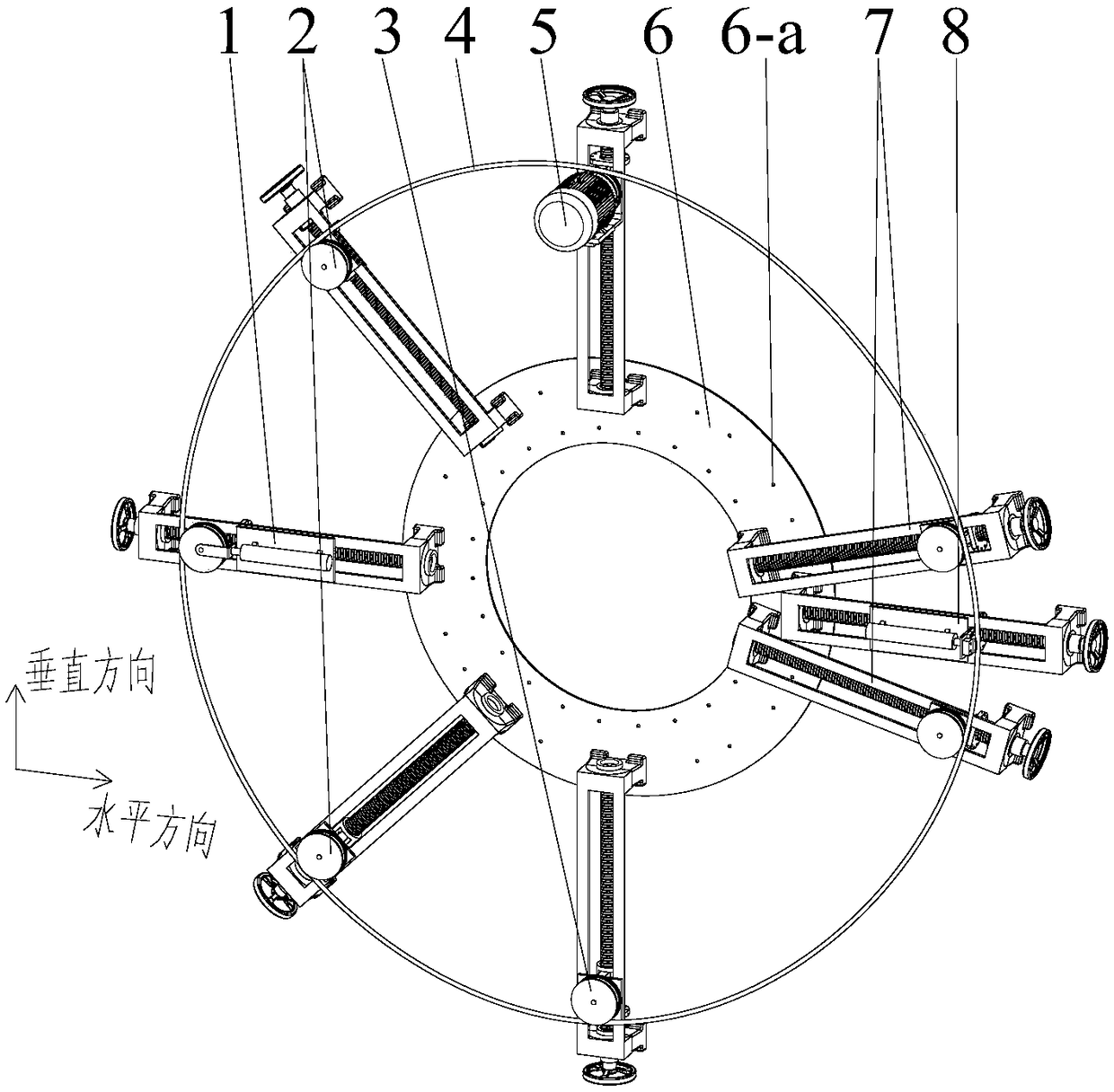

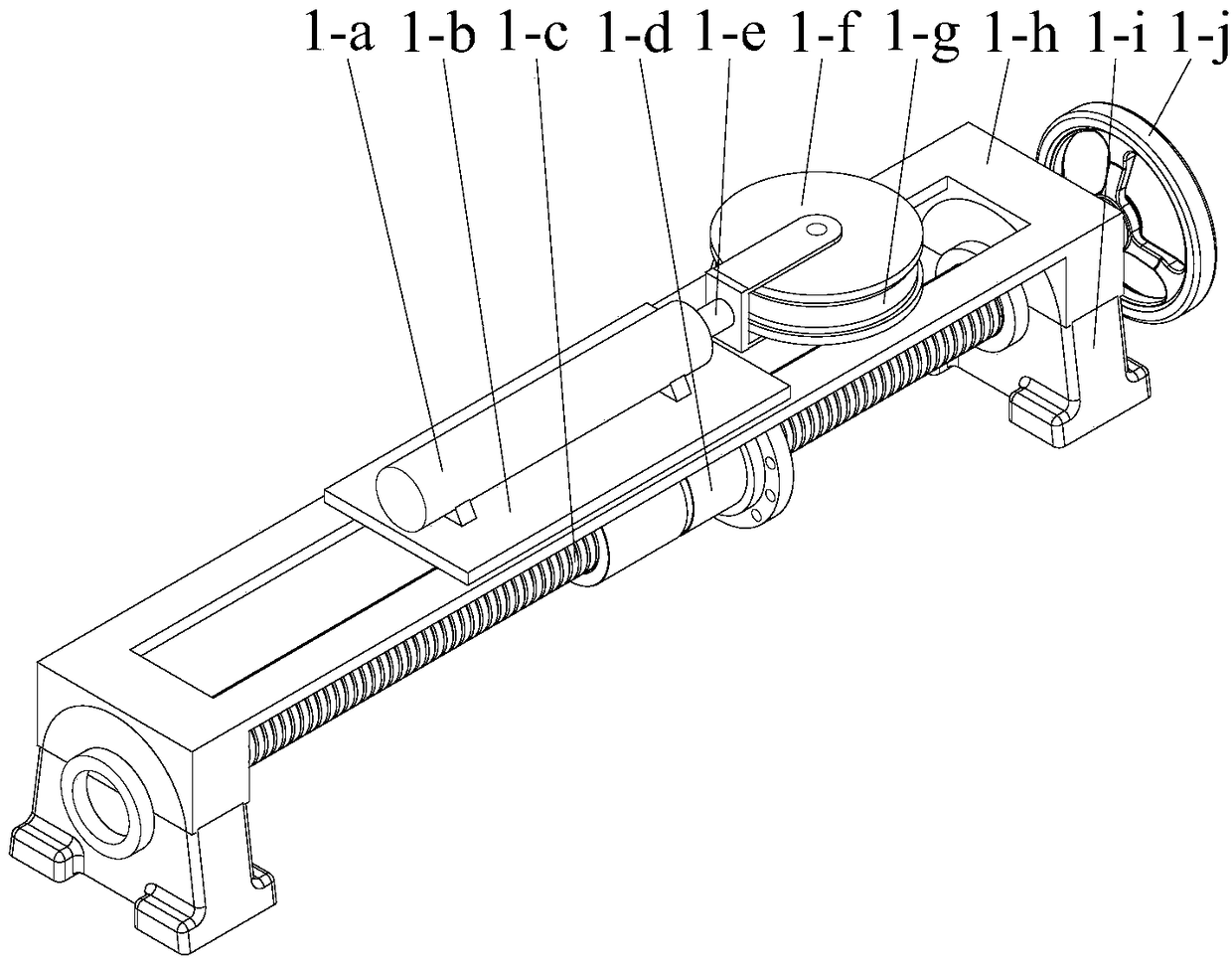

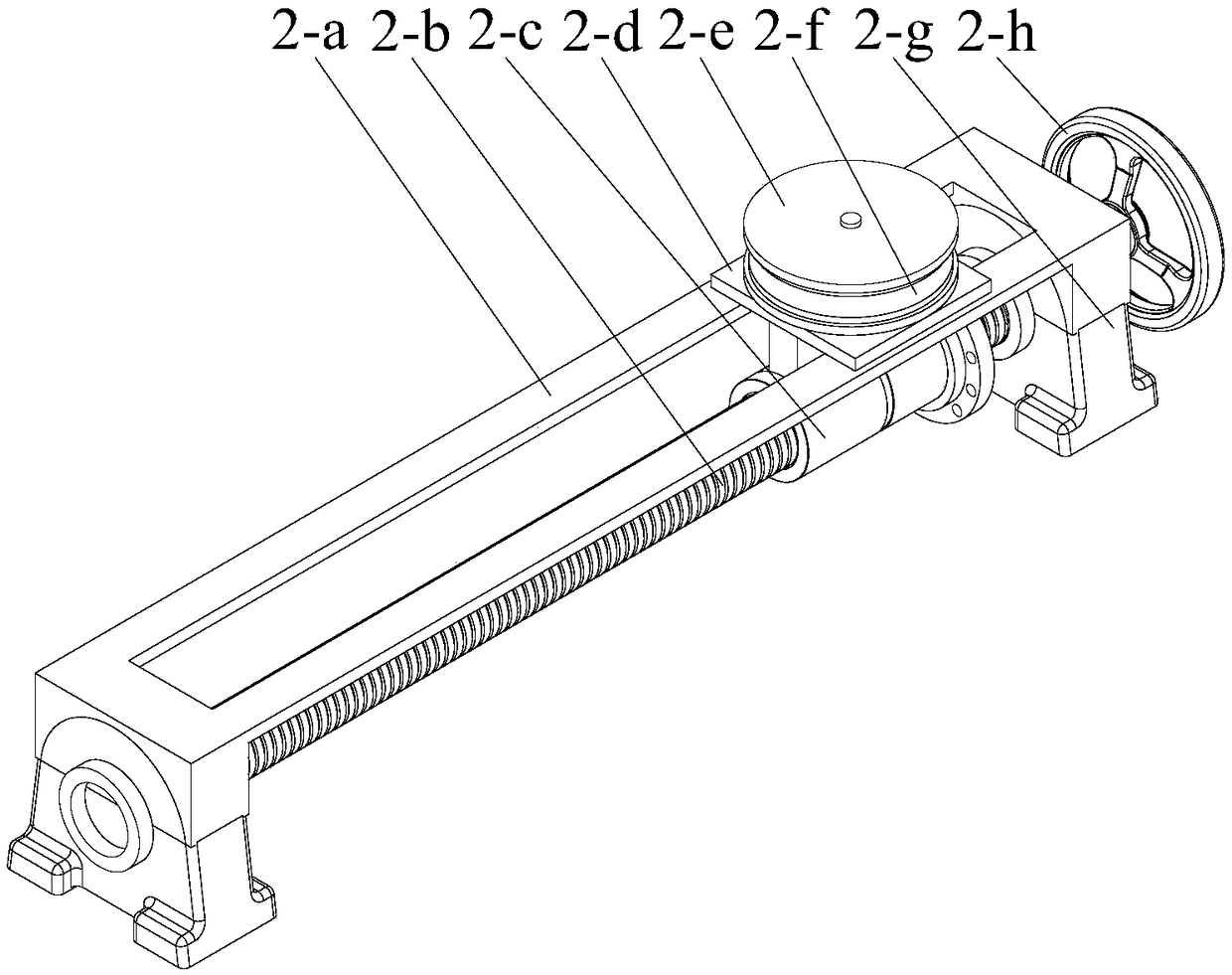

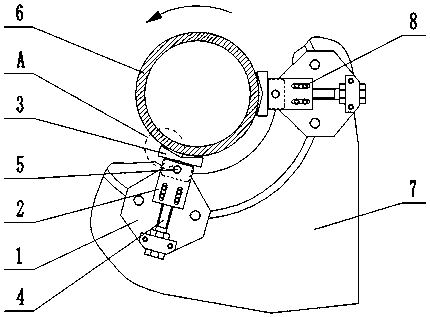

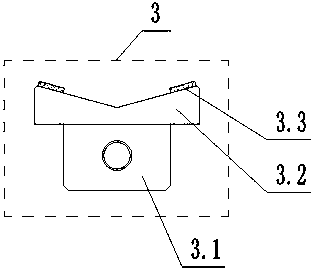

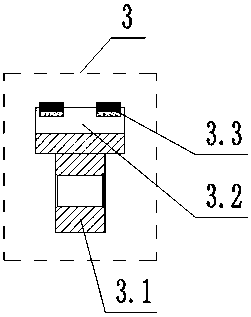

Mine hoisting friction gasket slip resistance testing device and method

InactiveCN109187333AAccurate assessment of wear patternsGuaranteed anti-slip effectUsing mechanical meansMaterial analysisPositive pressureEngineering

The invention discloses a mine hoisting friction gasket slip resistance testing device. The device comprises a positioning platform, a tension loading device, two tension positioning devices, a steelrope limiting device, a steel rope dragging device, two radian positioning devices and a gasket loading device. All sub-devices are arranged on the positioning platform along a peripheral direction. The two radian positioning devices are symmetrically arranged on two sides of the gasket loading device at equal included angles. In hydraulic cylinder loading and endless steel rope dragging modes, positive pressure and friction borne by a friction gasket are simulated. A radian of a winding drum is simulated through utilization of the two radian positioning devices which are arranged at the equalincluded angles. In the endless steel rope dragging mode, friction wear morphology of the friction gasket is tested under different steel rope drive speeds, different positive pressures and differentfriction distance. A friction coefficient of the friction gasket can be tested. High speed slip friction working condition of the gasket can be effectively simulated. The friction gaskets with different rope groove radians and diameters can be tested. Slip resistance of the friction gasket can be accurately evaluated.

Owner:CHINA UNIV OF MINING & TECH

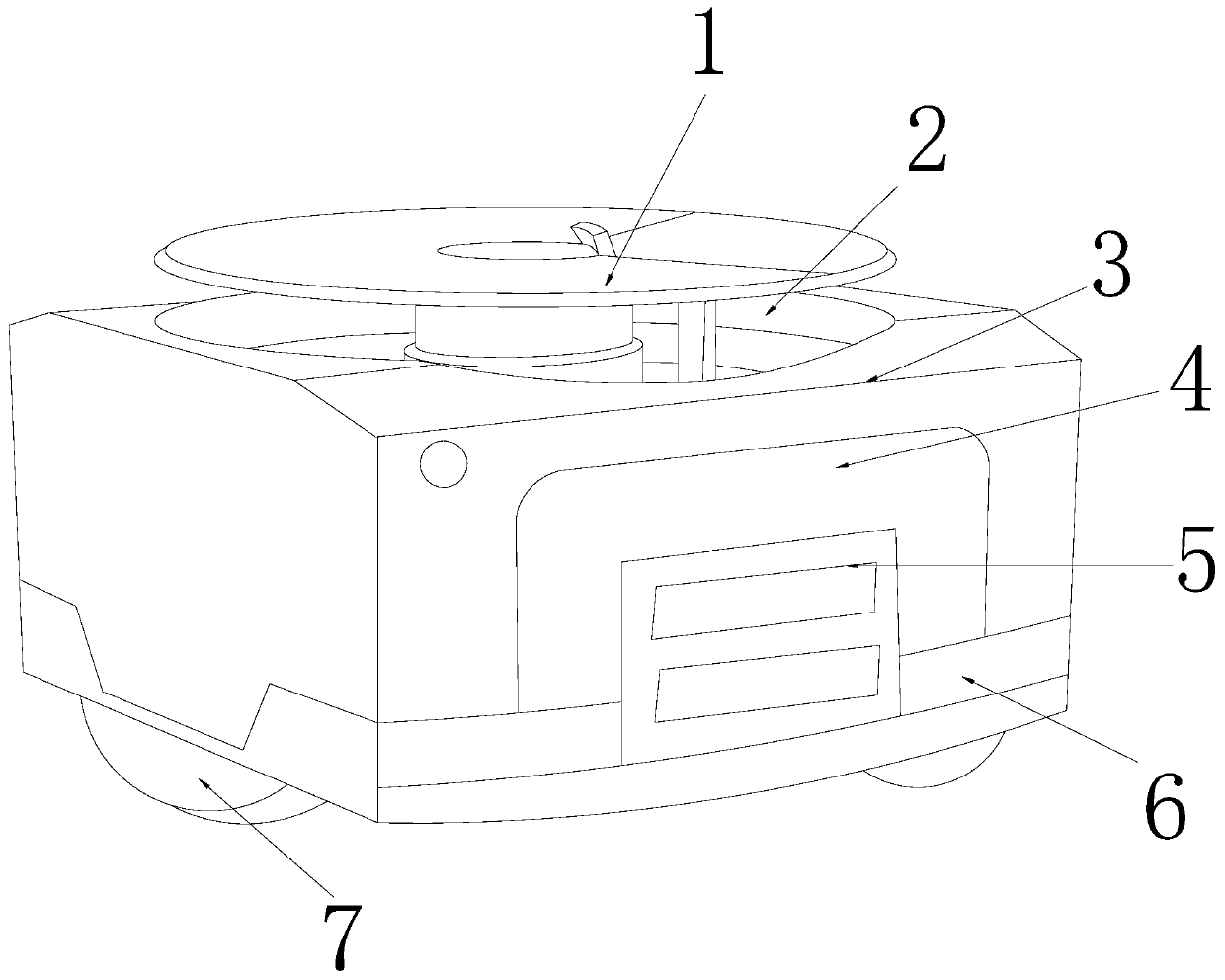

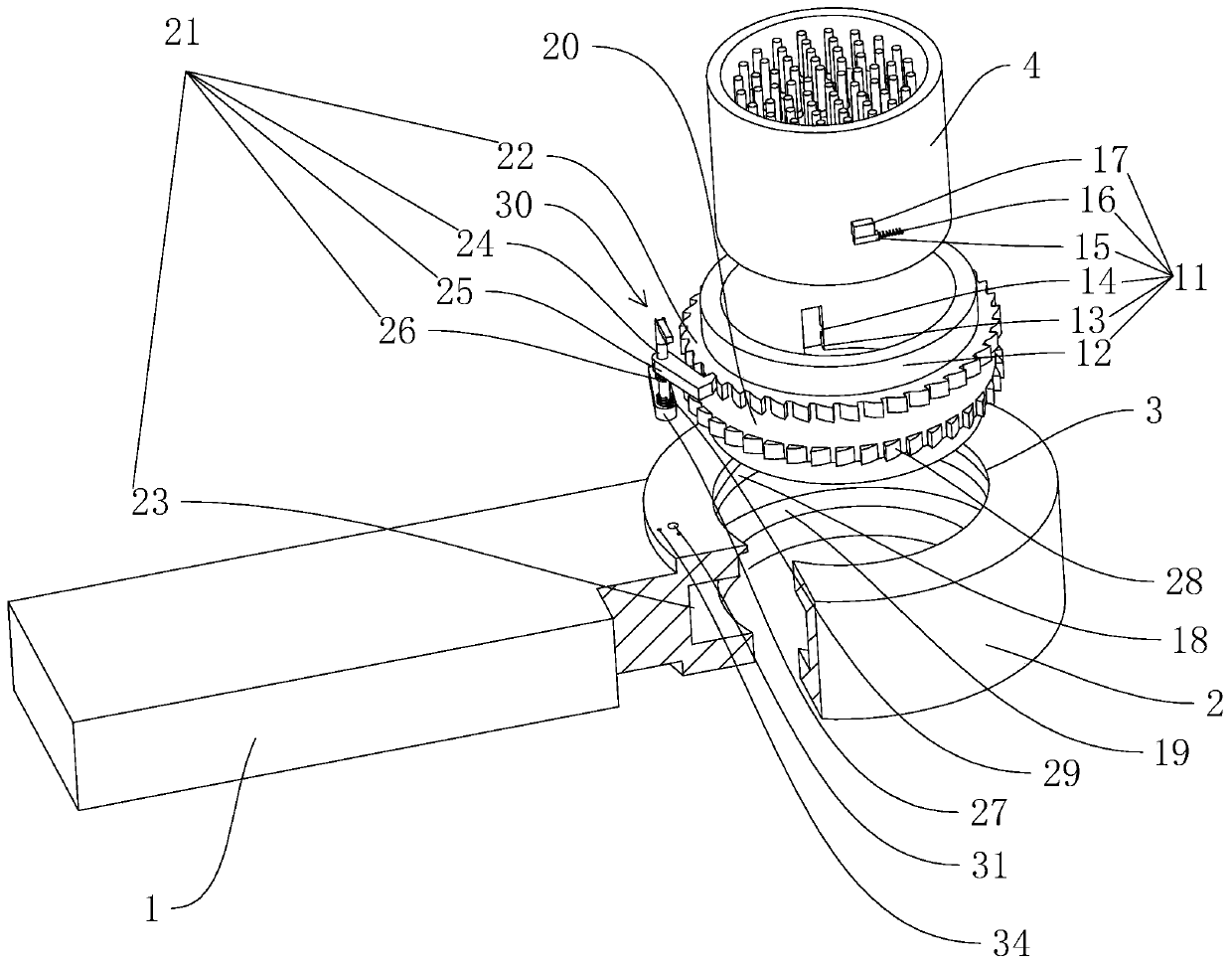

Annular warehouse logistics intelligent handling equipment adopting circle distance trajectory pushing, padding and press buckling

InactiveCN111086809AExtended output effectivelyGuaranteed tightness of angular velocityControl devices for conveyorsStorage devicesLogistics managementStructural engineering

The invention discloses annular warehouse logistics intelligent handling equipment adopting circle distance trajectory pushing, padding and press buckling. The annular warehouse logistics intelligenthandling equipment structurally comprises a plunger tray support, a wide-opening cylinder groove, a shell cover, a front baffle, a scanning detection panel, a bottom frame base plate and moving wheels. According to the annular warehouse logistics intelligent handling equipment, by using the plunger tray support and the scanning detection panel in cooperation, with a torus surface lifting effect, acircular surface is opened to the largest area for padding, padding sector plates can effectively extend in output, and an automatic detection and adjustment lifting effect of large logistics boxes is achieved; in cooperation with an arc buckle convex rubber block, the effect that the circular surface slidably pushes out goods by 360 degrees along the circle center for annular warehouse placementis achieved, the stability of axially thickly holding a plunger for pushing lifting is formed for a whole clamping supporting column base, and the friction coefficient is increased; and besides, thesliding pressure is reduced, the damping value is increased, the angular velocity precision of lifting rotation of a robot is ensured, uniform motion at a transverse pushing linear velocity in a second step is also realized, and the flexible lifting placement operation of logistics intelligent handling on square storage cabinets and annular storage is improved.

Owner:方雅晴

Movable friction type central guardrail and manufacturing method thereof

InactiveCN106988245AReduce damageStrong crashworthinessRoadway safety arrangementsCushioningGravitation

A movable friction type central guardrail and its manufacturing method, comprising a plurality of guardrail segments, the bottom surface of the guardrail segment is slidingly connected with the road, and the bottom surface of the guardrail segment is provided with a friction surface to improve friction with the road, The head and tail ends of the adjacent guardrail segments are hinged by connectors, so that the adjacent guardrail segments can slide and rotate relative to each other around the hinge point on the road. This device adopts double-slope cross-section guardrail segments to lift the center of gravity of the vehicle after the collision , relying on the connecting pins to realize the continuity and guiding ability of the guardrail, using the friction between the guardrail and the ground and the relative lateral movement between the guardrail and the ground to realize the buffering and energy dissipation in the process of the vehicle colliding with the guardrail, which is good for small cars and large cars The anti-collision ability can greatly reduce the damage of the vehicle and the occupants have higher safety.

Owner:CENT SOUTH UNIV

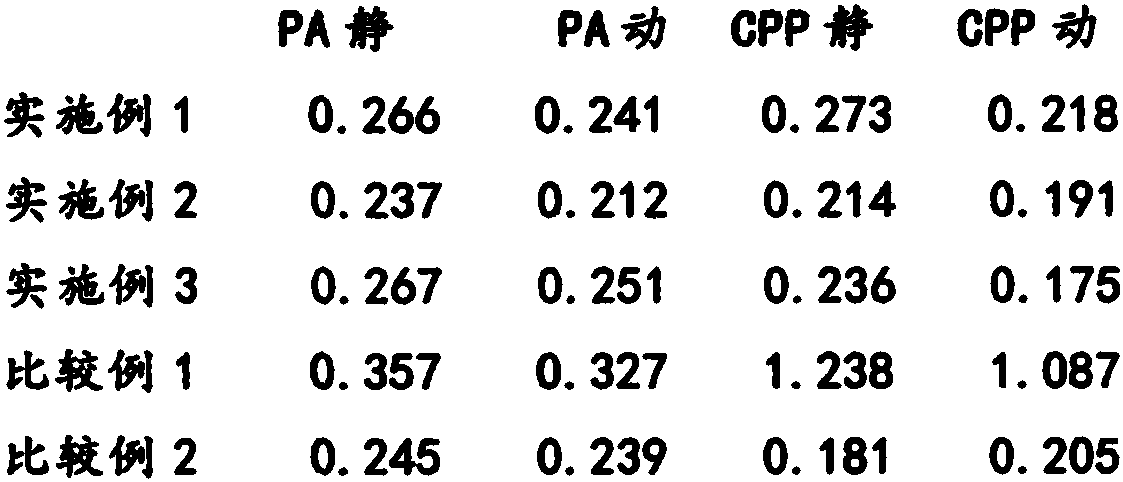

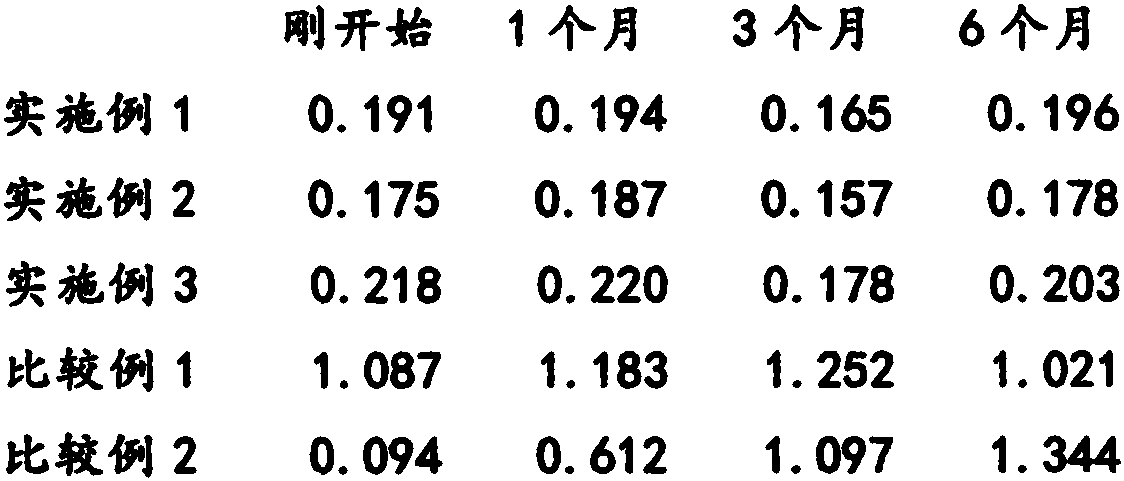

Smooth coating liquid for aluminum plastic thin film and coating process thereof

ActiveCN110760259AGuaranteed stabilityReduced stabilityPolyurea/polyurethane coatingsSpecial surfacesPolyamideOrganosolv

The invention provides smooth coating liquid for an aluminum plastic thin film and a coating process thereof. The coating liquid is prepared from ion-molecular weight organosiloxane, a flatting agent,organic silicon resin, an organic solvent and water. The smooth coating liquid for the aluminum plastic thin film provided by the invention has a favorable effect on remarkably reducing a friction coefficient of a nylon membrane so as to enable a dynamic friction coefficient to be smaller than 0.30; and can be further used for reducing a friction coefficient of a polypropylene thin film so as toenable a dynamic friction coefficient to be smaller than 0.30. The coating process is characterized by coating double surfaces at the same time, and the coating sequence is firstly coating the polypropylene thin film surface and then coating a polyamide thin film surface. The coating process of the smooth coating liquid is simple, no curing is needed, low-temperature drying can be carried out, theproduction efficiency can be effectively improved, and the economic cost can be effectively saved. After an aluminum plastic film product is coated with the smooth coating liquid, a scouring depth performance can be improved, and the stability of the friction coefficient at the high temperature is ensured at the same time.

Owner:广东广麟材耀新能源材料有限公司

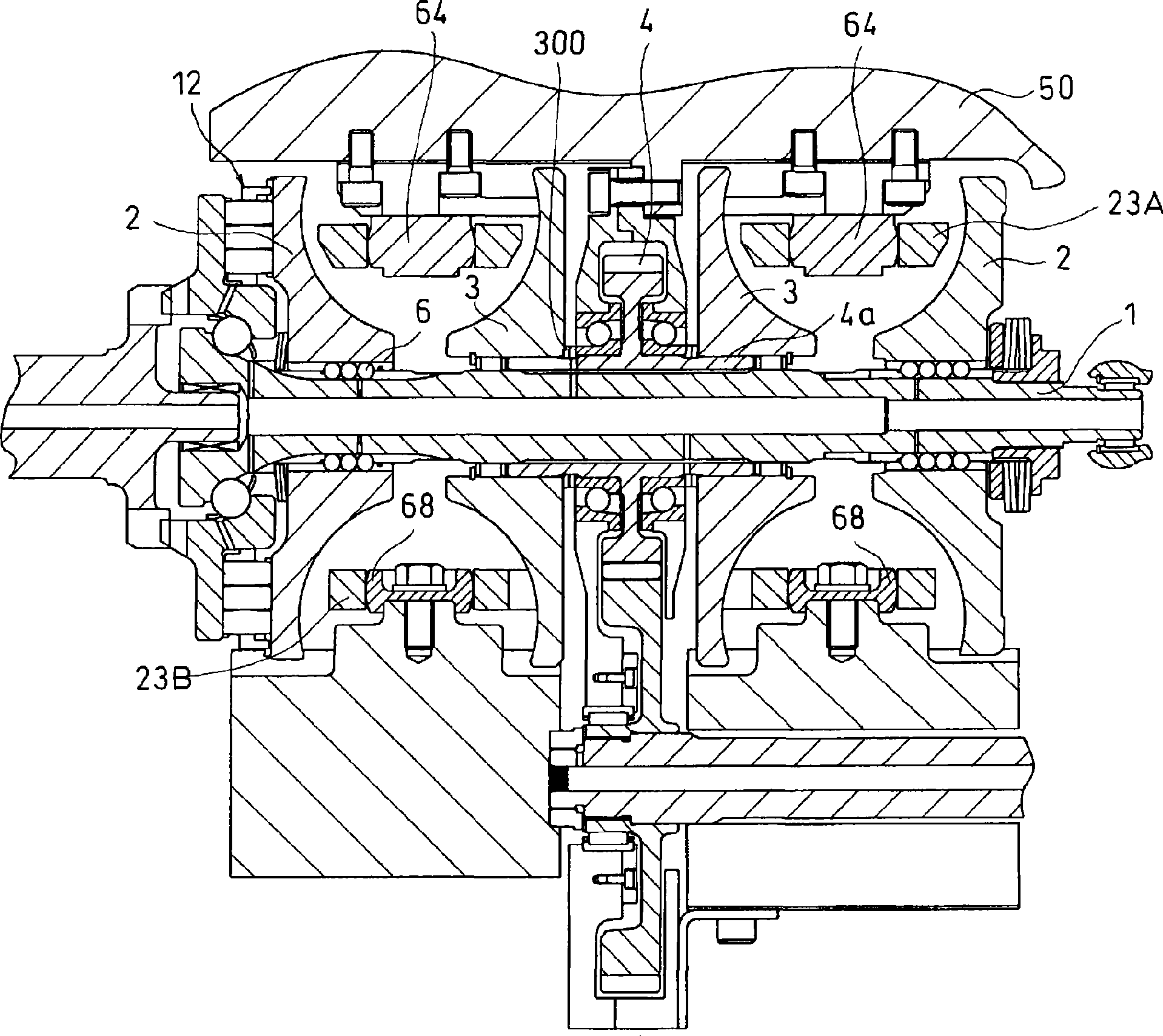

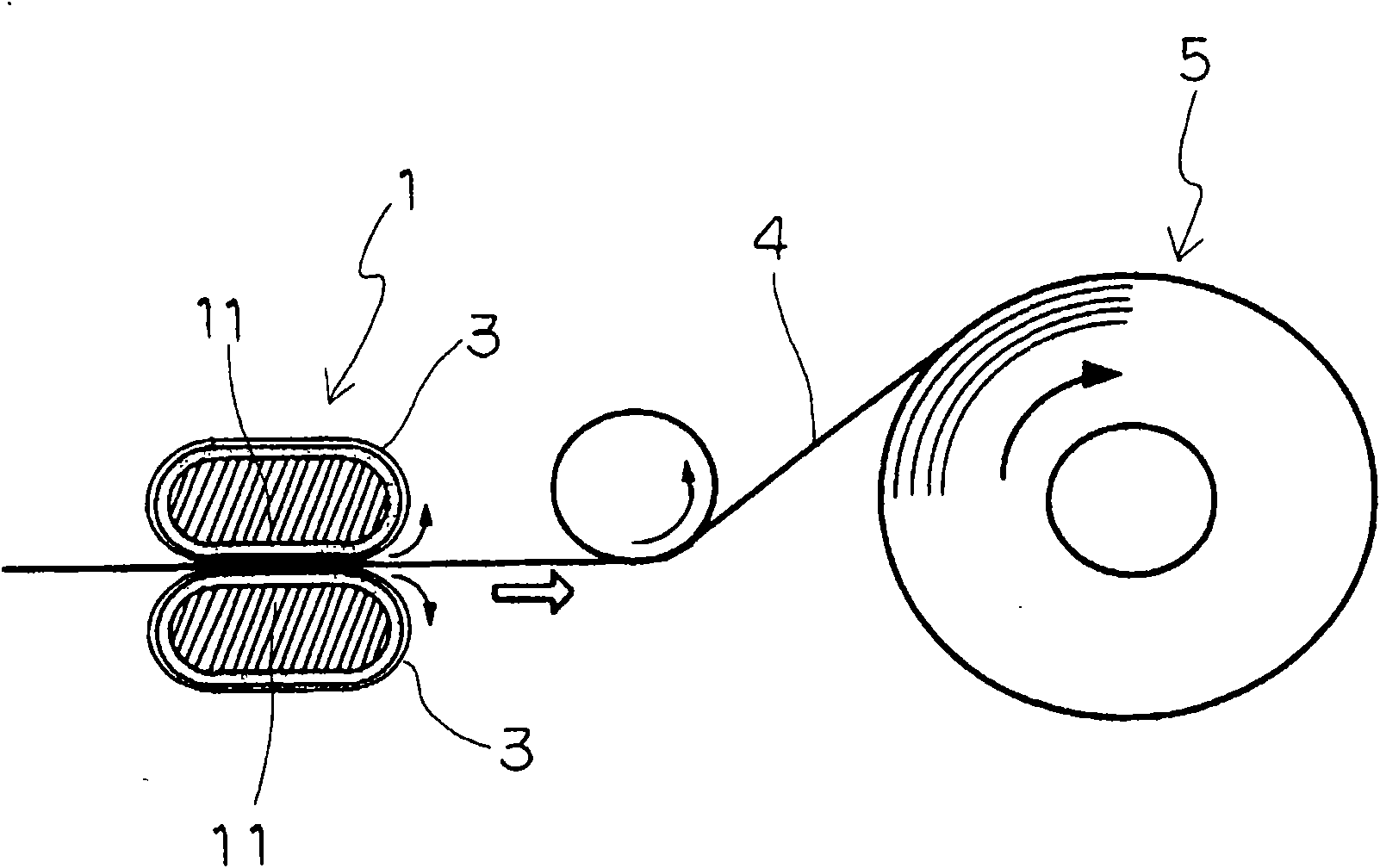

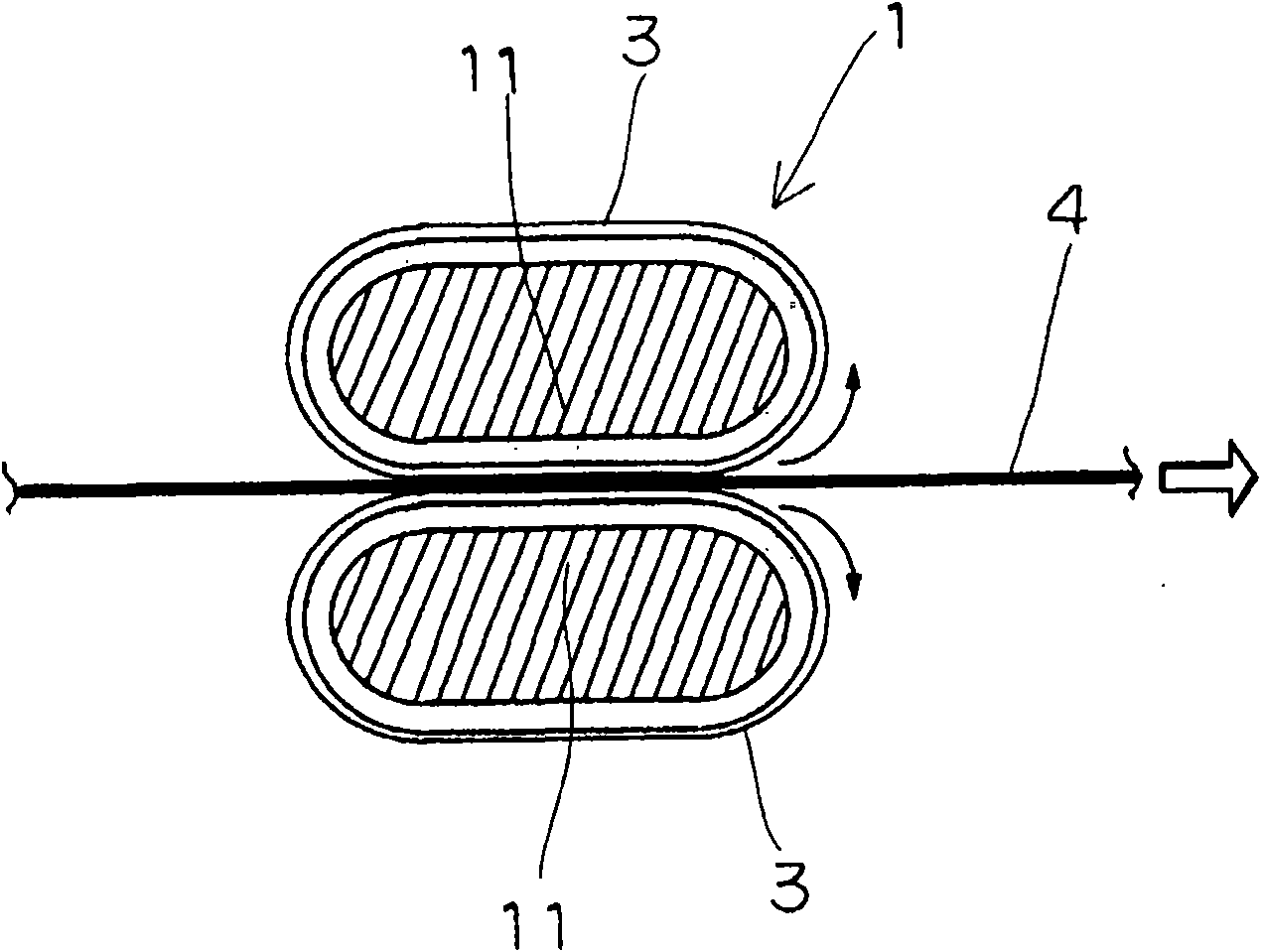

Transmission belt for buncher

InactiveCN1105838CGuaranteed coefficient of frictionAvoid abnormal wearV-beltsTransmission beltEngineering

In a belt for a continuously variable transmission, a first line on a lower edge of an element body of a metal element is determined, and a second line straightforwardly connecting a lower end of a V-face to which a load is applied from a V-groove in a pulley and an inner end of a saddle surface is determined, so that when a downward load is applied from a metal ring assembly to an outer end of the saddle surface, the folding-resistant strength of the element body is uniform laterally. The position of the recess is determined in the vicinity of a point of intersection of the first and second lines. The lower edge of the element body is defined by the first line inside the recess and by the second line outside the recess. The durability of the metal element can be enhanced by devising the shape of the lower edge of the element body of the metal element in this manner.

Owner:HONDA MOTOR CO LTD

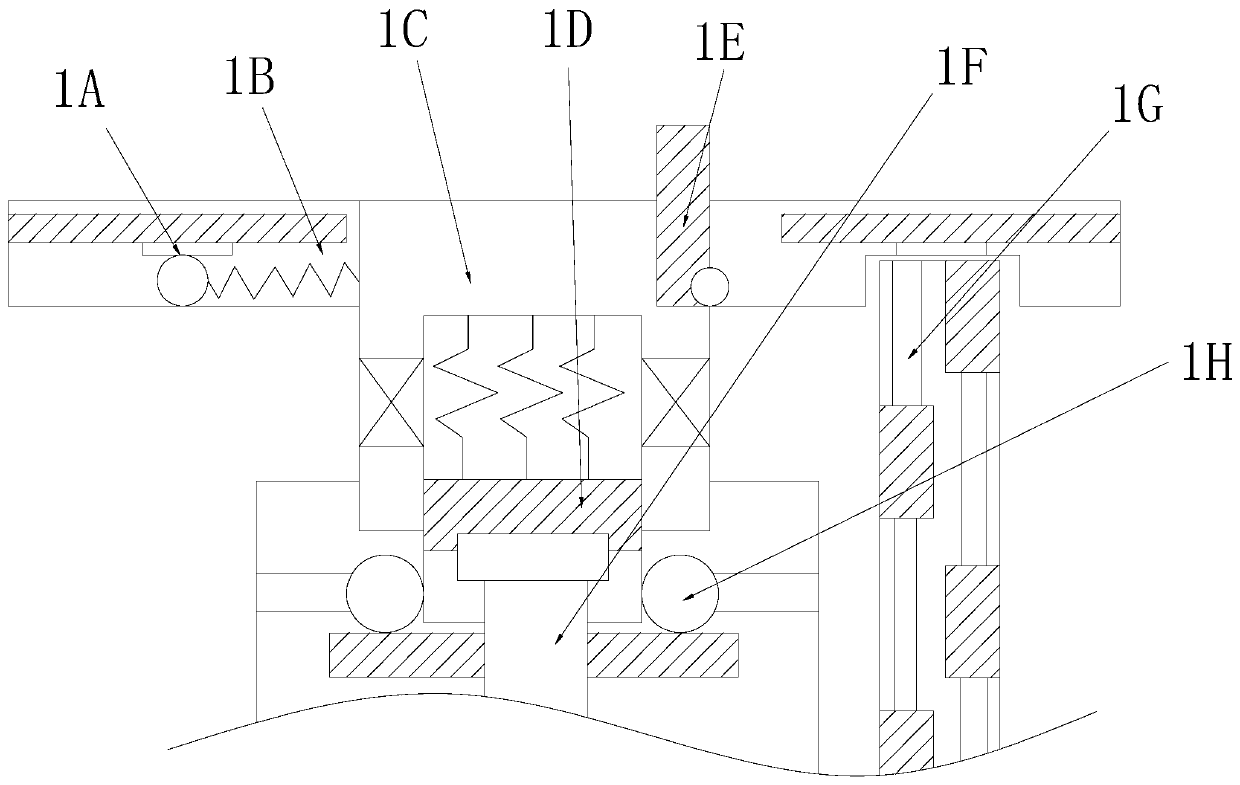

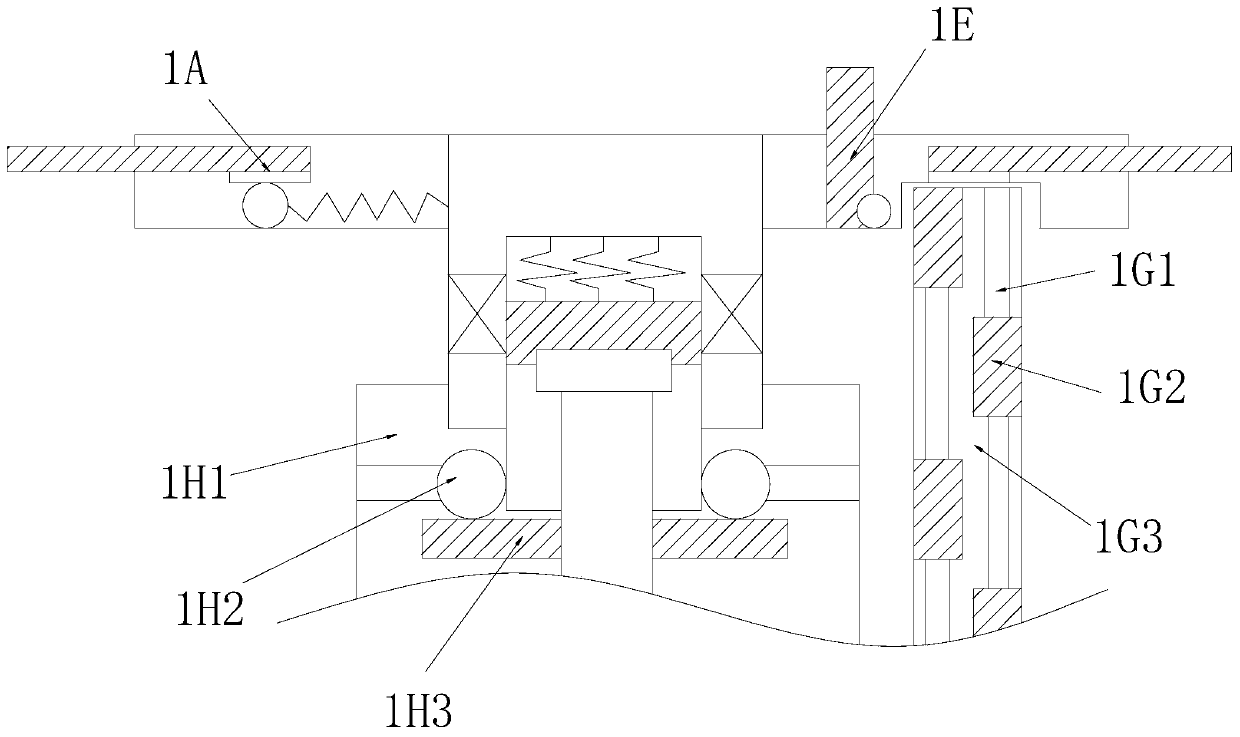

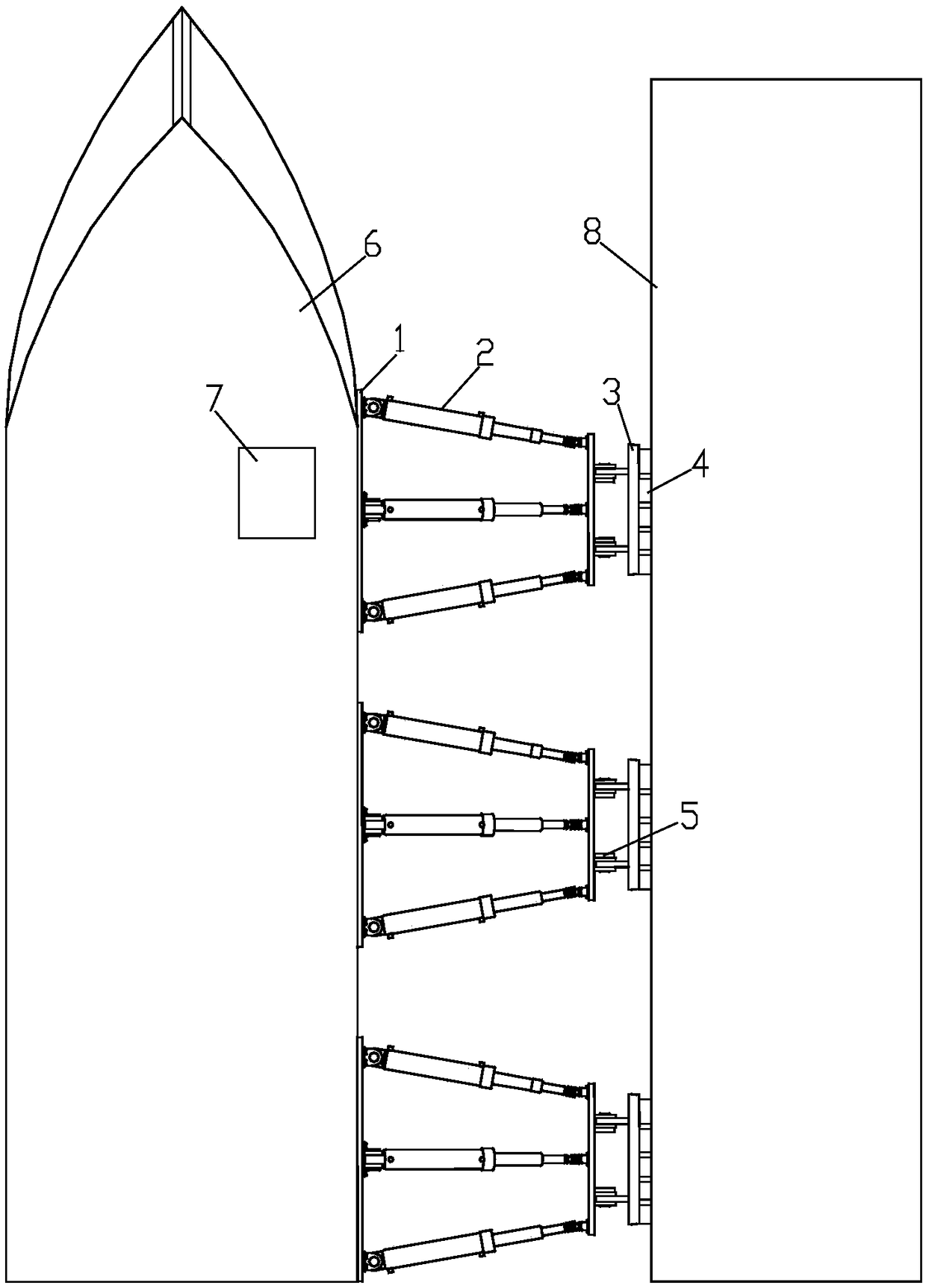

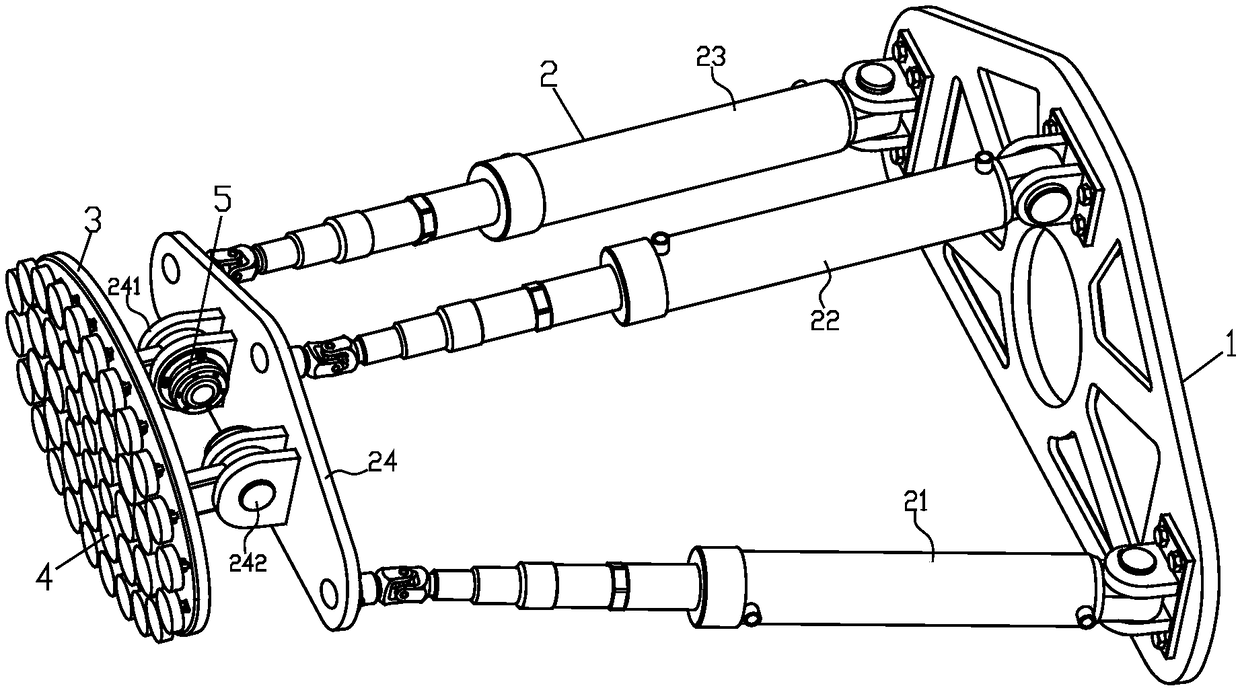

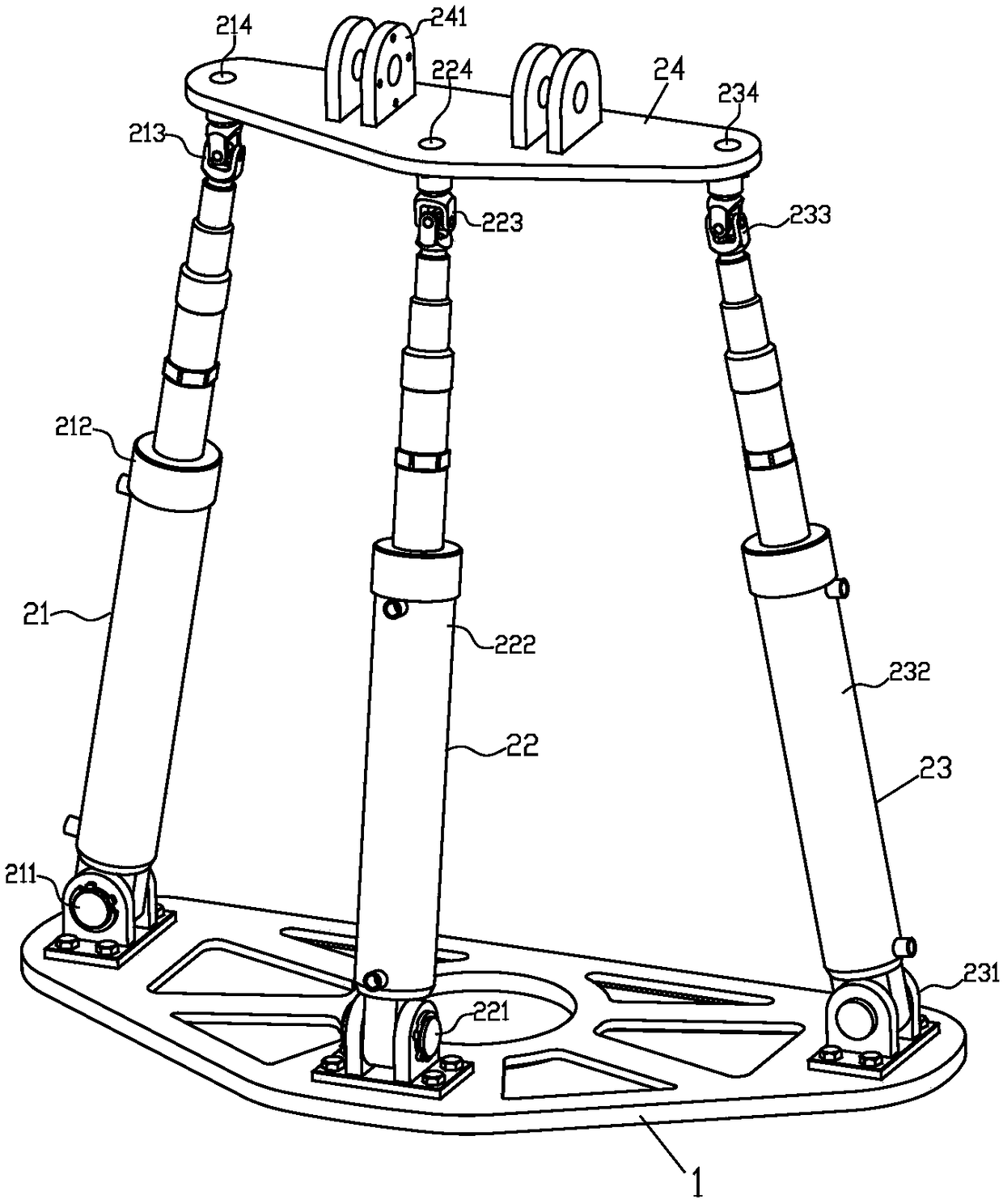

Five-degree-of-freedom metamorphic multi-purpose ship berthing device

ActiveCN107521623BReduce impact forceReduce impactVessel cleaningArtificial islandsMulti siteHydraulic cylinder

Owner:ANHUI UNIV OF SCI & TECH

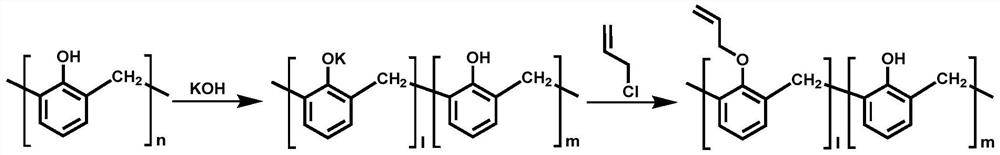

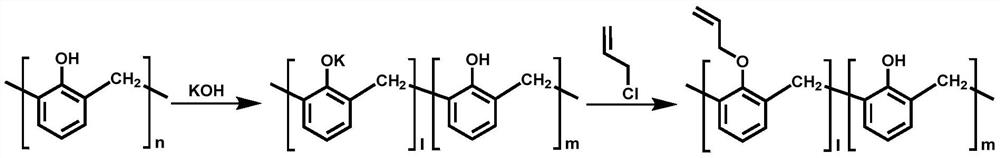

High-wear-resistance and high-water-contact-angle hardened film

ActiveCN113929948AHigh water contact angleGuaranteed coefficient of frictionPolyurea/polyurethane coatingsPolymer scienceEnd-group

The invention discloses a high-wear-resistance and high-water-contact-angle hardened film which comprises a transparent base material, a bottom coating layer and an AF layer which are sequentially attached from bottom to top; the bottom coating layer is formed by coating the transparent base material with a bottom coating solution for light curing, the AF layer is formed by coating the bottom coating layer with an AF coating solution for heat curing, and the bottom coating solution comprises the components in parts by weight: 10 to 50 parts by weight of a polyurethane acrylate resin oligomer with the functionality of 4 to 20 and the molecular weight of 800 to 5000, 2 to 30 parts by weight of allyl-modified terminal allyl phenolic resin with the functionality of 5 to 30 and the molecular weight of 500 to 5000, 0.3 to 3 parts by weight of a flatting agent, 0.5 to 2.5 parts by weight of a photoinitiator, and 30 to 80 parts by weight of an organic solvent; and an AF coating liquid is a perfluoropolyether coating liquid with the solid content of 0.1% to 2% and with an end group modified by siloxane. The high-wear-resistance and high-water-contact-angle hardened film has the advantages of low friction coefficient, high water contact angle, simple process, low manufacturing cost and benefit for mass production.

Owner:NINGBO HUGHSTAR ADVANCED MATERIAL TECH

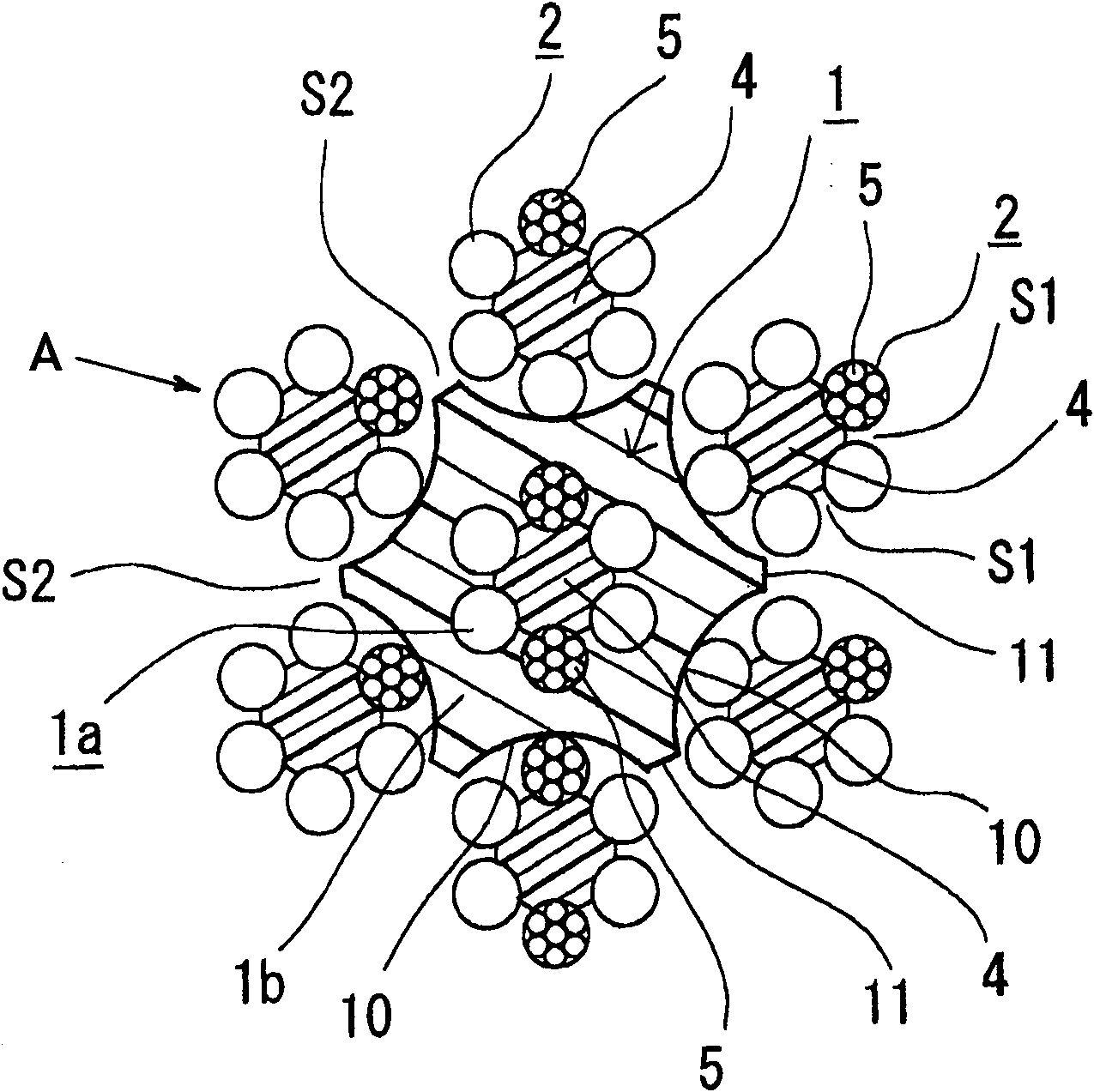

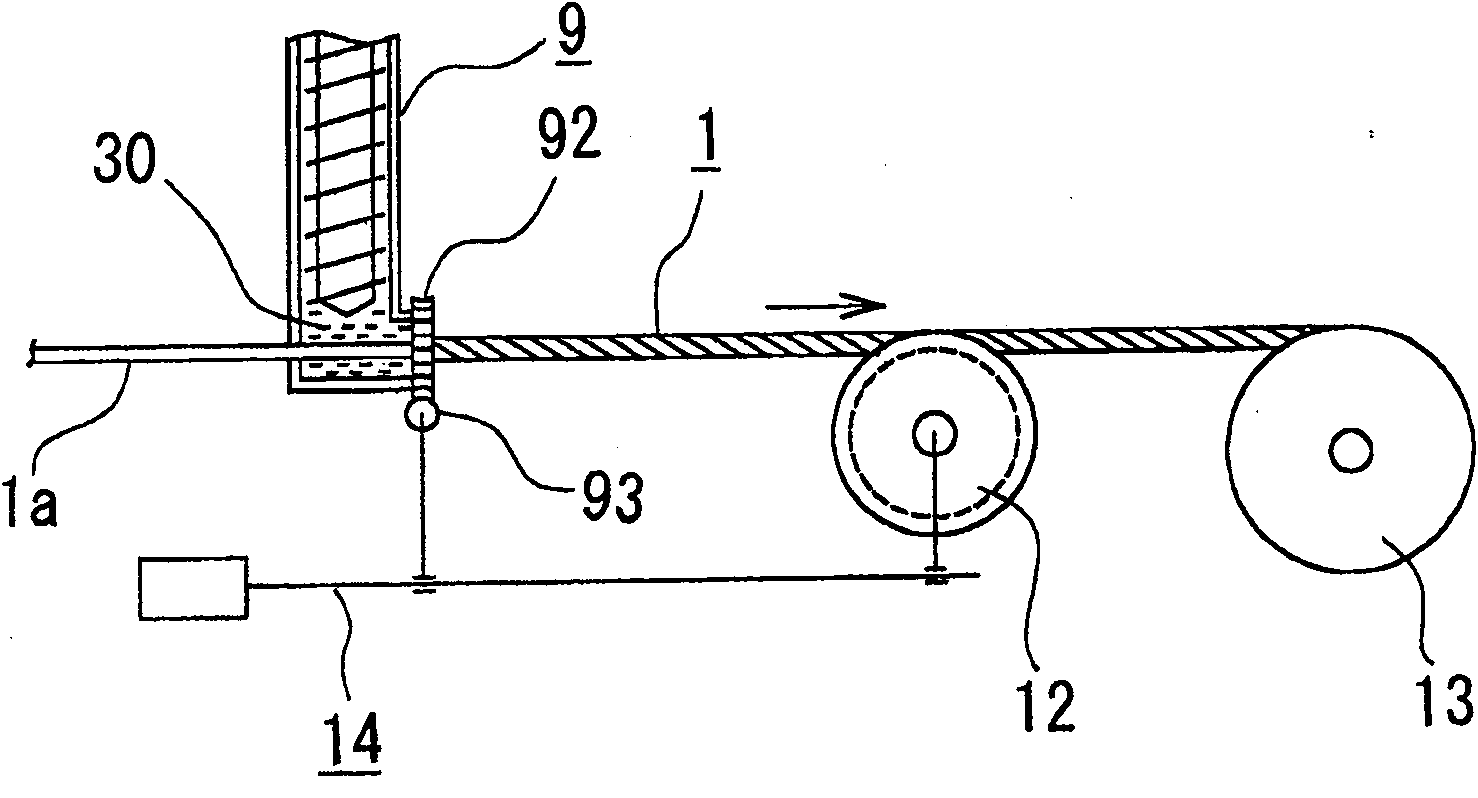

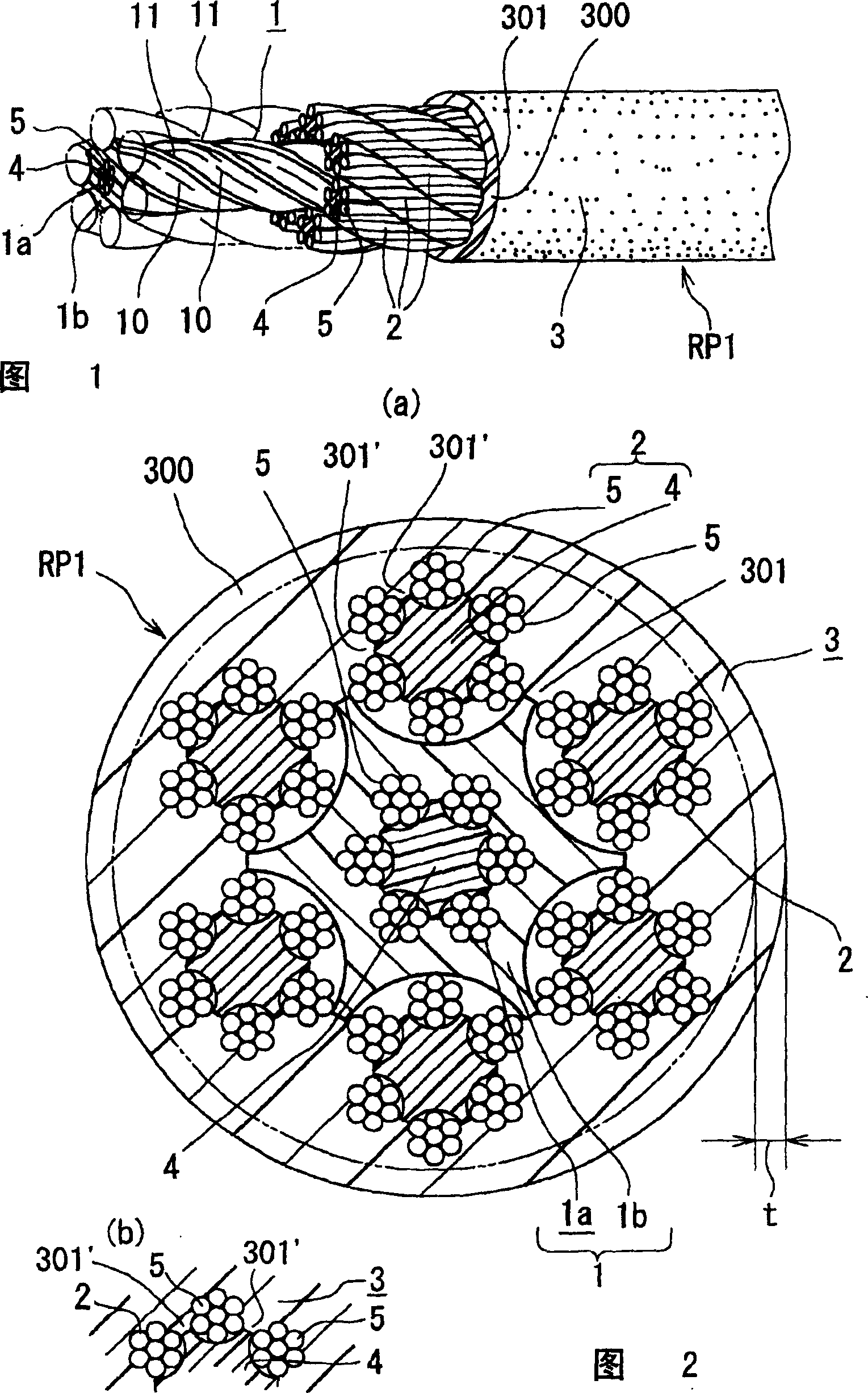

Coated cable

ActiveCN1712635BNot easy to wear and damageAvoid wear and tearRope making machinesElevatorsWire ropeMaterials science

The invention provides a covered wire rope for a running wire, having good flexibility against bending, prevented from abrasion caused by the contact of wires of a core rope and side members with each other, the contact of the core rope with the side members and the contact of the side members with each other, and achieving good transmission of driving force to a sheave and silence. The core ropehas a core rope body having a synthetic resin core and two or more side strands arranged around the resin core and twisted so as to have spaces between them at one or more parts, and a resin coveringlayer including the core rope body. The side member has a synthetic resin core and two or more strands or wires twisted around the core. The resin covering layer has spacer parts at the outer periphery, and uniform spaces are formed among respective side members by the spacer parts. A resin layer integrated with the resin layer of the outer layer, going over the circumcircle of the side member fills the spaces, and also fills the spaces among the strands or wires of each of the side members.

Owner:TOKYO ROPE MFG +1

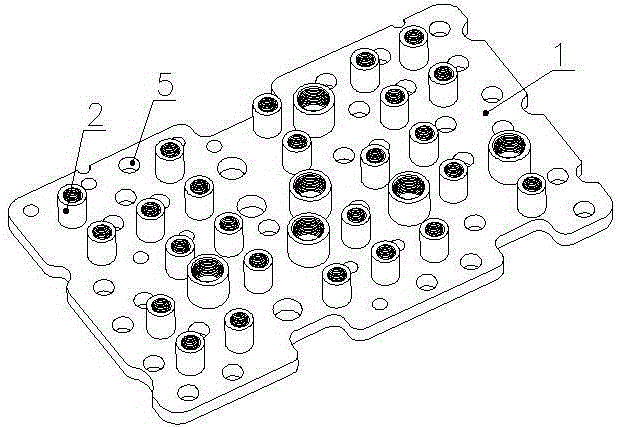

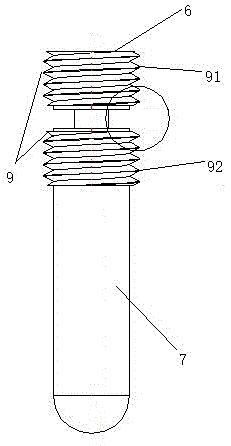

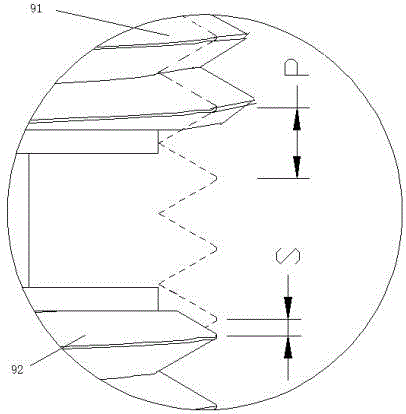

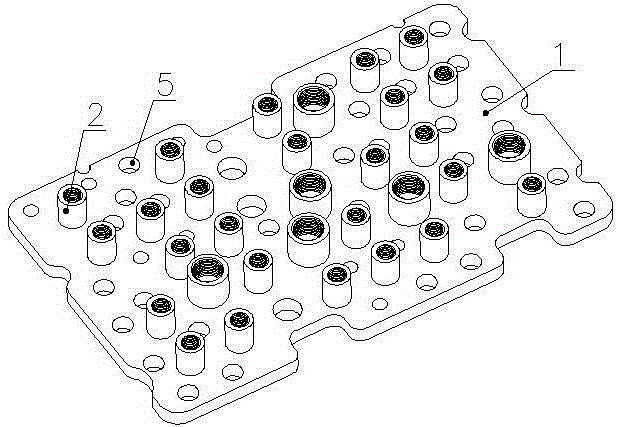

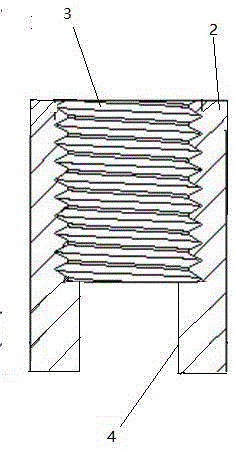

Cavity filter

The invention discloses a cavity filter, which comprises a cavity, a cover board and a tuning self-locking bolt, wherein the cover board is used for closing the cavity of the cavity filter; the cover board comprises a cover board body; the cover board body is made of an aluminum product; a tuning threaded hole is formed in the cover board body and specifically is a lug boss which extends towards the direction of the cavity and is molded integrally with the cover board body; the tuning self-locking bolt is divided into a head part and a rod part and is fabricated by copper; the head part is arranged at one end of the bolt; the rod part is arranged at the other end of the bolt; two sets of threads are arranged on the head part of the bolt to form screws; the upper and lower two sets of threads are the same in diameter L and screw pitch P; and the diameter of the part between the two threads is 40%-70% that of the rod part. The cavity filter disclosed by the invention has the advantages of low cost and tuning performance.

Owner:JOHNSON PRECISION ENG SUZHOU

Preparation method of high abrasion resistance and high heat resistance automobile clutch surface

InactiveCN109027034AIncrease contactImprove wear resistanceFriction clutchesFriction liningHeat conductingPhysical property

The invention discloses a preparation method of a high abrasion resistance and high heat resistance automobile clutch surface, and relates to the technical field of clutch surface preparation. The preparation method specifically comprises the following step of S1 preparation of a friction surface material, specifically, 2-5 parts of high manganese steel alloy, 2-5 parts of tungsten carbides, 2-5 parts of chromium carbides and 5-8 parts of silicone rubber are selected respectively. Through the preparation method of the high abrasion resistance and high heat resistance automobile clutch surface,the abrasion resistance of the clutch surface is improved through a metallic inorganic material, and meanwhile the heat conducting effect is also improved, so that the abrasion resistance performanceand the heat resistance performance of the clutch surface are greatly improved; the phenomenon that the clutch surface can generate high heat so that the physical property of the clutch surface can be changed in the long-time using process is avoided, the friction coefficient of the clutch surface is guaranteed, the phenomenon that the friction performance of the clutch surface is changed to be poor or lost is prevented, and the heat conducting performance of the clutch surface is improved while the friction performance of the clutch surface is improved.

Owner:湖北久鸣汽车零部件有限公司

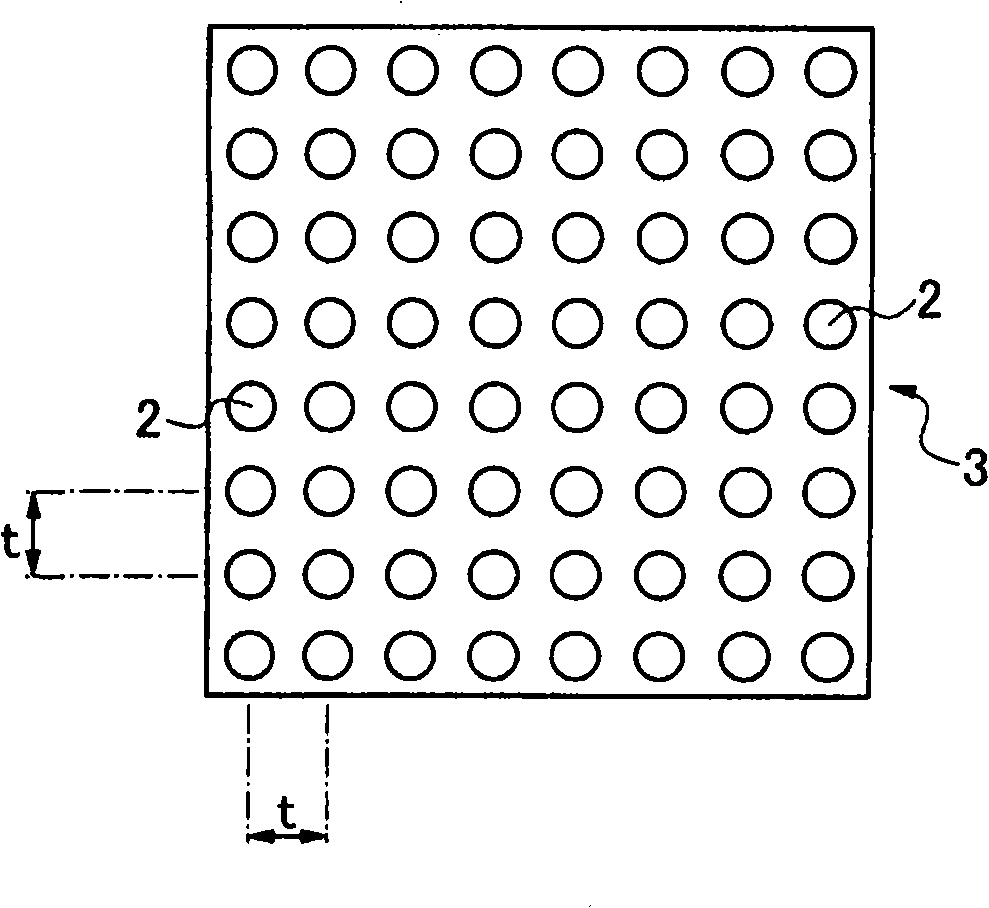

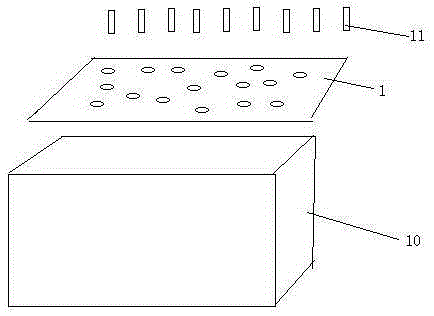

Wear-resisting weak-abrasiveness bionic tool joint

InactiveCN102828701AImprove wear resistanceReduce abrasivenessDrilling rodsDrilling casingsInterference fitWear resistance

The invention discloses a wear-resisting weak-abrasiveness bionic tool joint, which is characterized in that a plurality of pit unsmooth structure units which are regularly distributed are arranged on a bionic wear-resisting belt of the tool joint, each pit unsmooth structure unit is internally provided with a convex-hull-shaped unsmooth structure unit, the depth of the pit unsmooth structure unit is identical to the overall height of the convex-hull unsmooth structure unit, the aperture of each pit unsmooth structure unit is 0.001 to 0.1mm smaller than the diameter of the convex-hull unsmooth structure unit, the top of each pit unsmooth structure unit is in arc transition of a pit prismatic surface to be connected together with the low-friction-coefficient high-wear-resisting convex-hull unsmooth structure unit in an interference fit way to form a wear-resisting unsmooth structure surface, and the top surface of the combined convex-hull unsmooth structure unit is leveled to the surface of the tool joint. The wear-resisting weak-abrasiveness bionic tool joint has characteristics that the service life of a drill pipe is prolonged, the abrasion on a bushing is reduced, the anti-viscosity is strong, the wear resistance of the drill pipe is improved, and the like, and can effectively reduce the underground accident, improve the drilling quality and save the drilling cost.

Owner:JILIN UNIV

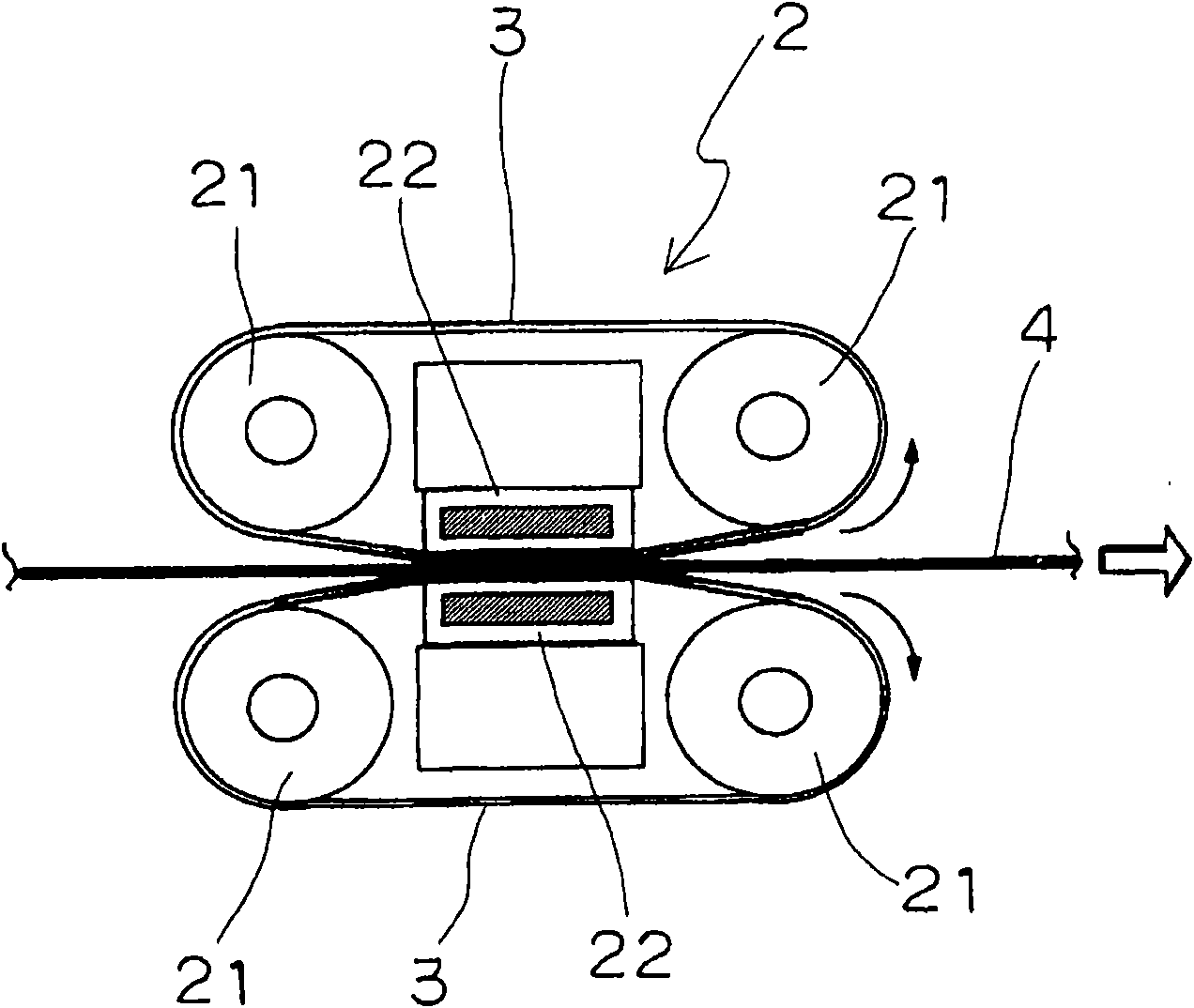

Endless belt with slits for sheet belt coiling tension offering device

The invention provides an endless belt with slits for a sheet belt coiling tension offering device, which comprises the endless belt (3) and a plurality of slits (35), wherein the endless belt (3) is formed by superposing an outer lateral surface layer (31) and an inner lateral surface layer (33) which are made from at least more than two layers of different materials; and the plurality of slits (35) are formed by cutting the overall width of the width direction of the length (longitudinal) direction of the endless belt by a predetermined depth at predetermined intervals on the outer lateral surface (31a), in contact with sheet belts (4), of the endless belt, are in sealing connection, can be provided for the sinking of micro bumps on the surfaces of each sheet belt and are pulled and deformed by the bumps to form micro cavities and generate negative pressures. As the endless belt (3) adopts the structure, when the micro bumps on the surfaces of the sheet belts are sunken into each slit (35), the sheet belts of which the surfaces have remaining oil films can be reliably captured; and simultaneously, as the slits in the sealing connection still can be pulled and deformed by the sunken micro bumps to generate the negative pressures, most of the slits, in contact with the surfaces of the sheet belts, of the endless belt all develop the function of a vacuum pump to absorb the sheet belts with the remaining oil films to reliably offer (apply) coiling tension.

Owner:JDC INC

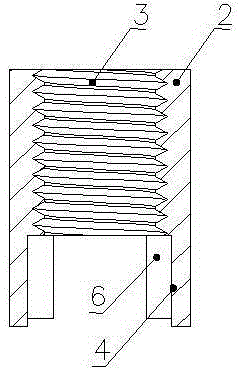

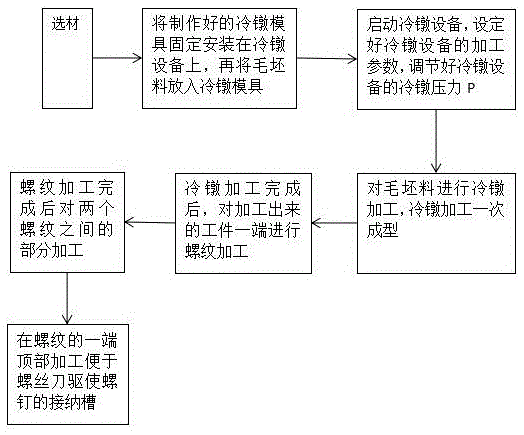

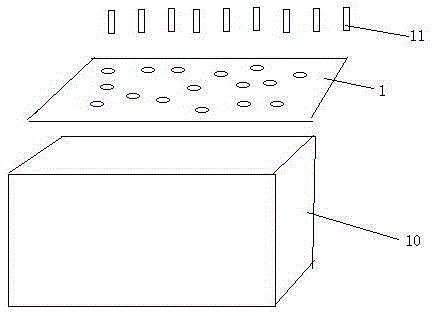

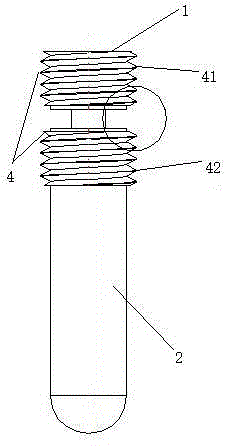

Manufacturing method of tuning self-locking screw

InactiveCN105563019AGuaranteed coefficient of frictionGuaranteed dimensional accuracyScrewsWaveguide type devicesNumerical controlEngineering

A manufacturing method of a tuning self-locking screw comprises the following steps of selecting materials; fixedly mounting a manufactured cold upsetting die on cold upsetting equipment; then placing a prepared blank in the cold upsetting die; starting the cold upsetting equipment; setting machining parameters of the cold upsetting equipment, wherein the machining parameters comprise machining temperature, speed and the like; adjusting cold upsetting pressure P of the cold upsetting equipment; starting to carry out cold upsetting machining on the blank; forming at one step during cold upsetting machining; carrying out thread machining on one end of a machined workpiece after cold upsetting machining is finished, wherein two sets of threads are arranged and are not connected, screw pitches P between the upper set of threads and the lower set of threads are the same, the diameters of the upper threads are greater than the diameters of the lower threads, and a part between the two threads is machined until the diameter of the part is 40%-70% of the diameter of a non-machined part of the workpieceafter thread machining is finished; and forming an accommodating groove in the top of one end of each thread after a step seven is finished. Compared with the traditional mode of machining with a numerically-controlled machine tool, the manufacturing method of the tuning self-locking screw saves equipment cost and labor cost, and is better in effect.

Owner:JOHNSON PRECISION ENG SUZHOU

Cavity filter

The invention discloses a cavity filter, which comprises a cavity, a cover board and a tuning self-locking bolt, wherein the cover board is used for closing the cavity of the cavity filter; the cover board comprises a cover board body; the cover board body is made of an aluminum product; a tuning threaded hole is formed in the cover board body and specifically is a lug boss which extends towards the direction of the cavity and is molded integrally with the cover board body; the tuning self-locking bolt is divided into a head part and a rod part and is fabricated by copper; the head part is arranged at one end of the bolt; the rod part is arranged at the other end of the bolt; two sets of threads are arranged on the head part of the bolt to form screws; the upper and lower two sets of threads are the same in screw pitch P; the diameter of the upper thread is greater than that of the lower thread; and the diameter of the part between the two threads is 40%-70% that of the rod part. The cavity filter disclosed by the invention has the advantages of cost and tuning performance.

Owner:JOHNSON PRECISION ENG SUZHOU

Environmentally-friendly water-based coating for ensuring printing smoothness of cigarette packing paper, and production technology thereof

InactiveCN110093079AMoisture stableMaintain proper coefficient of frictionCoatingsCardboardWater based

The invention discloses an environmentally-friendly water-based coating for ensuring the printing smoothness of cigarette packing paper, and a production technology thereof. The coating comprises 5-10parts of deionized water, 3-5 parts of edible alcohol, 30-40 parts of a styrene copolymer, 40-60 parts of acrylic resin and 1-5 parts of an assistant. The production technology comprises the following steps: mixing the deionized water and edible alcohol in a dispersing kettle, then adding a defoaming aid, and performing mixing and dispersing to obtain a cosolvent mixture for later use; taking andmixing the acrylic resin, the styrene copolymer and a high density polyethylene wax dispersant aid in the dispersing kettle, then adding a dipropylene glycol monomethyl ether film forming aid, and continuously performing dispersing; and slowly filtering and adding the prepared solvent mixture, performing dispersing until the obtained solution is uniform, and filtering and packaging the uniform solution. The coating is used for coating the back sides of coated paper, transfer cardboards and composite cardboards for cigarette packaging to keep the paper have a stable water content and be not prone to deform, so poor printing caused by unsmooth paper feeding during printing of an UV offset printing machine and printing deviation caused by non-stability of paper back sticking wheels during high-speed rotary intaglio printing is avoided.

Owner:中山市海恒包装材料有限公司

Elastic track shoe

An elastic track shoe, comprising a mandrel integrally formed by casting, forging, or cutting, wherein the ground-contact surface side of the mandrel is covered with an elastic body, and the shape of the portion of the mandrel on which the ground-contact surface of the elastic body is projected is formed such that the mandrel is divided into two parts, whereby, by using the rigid mandrel, the occurrence of looseness of bolts can be avoided, and the thickness of the elastic body receiving a load can be increased irrespective of a grouser.

Owner:KOMATSU LTD

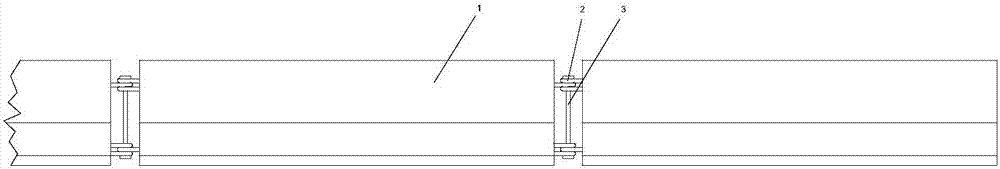

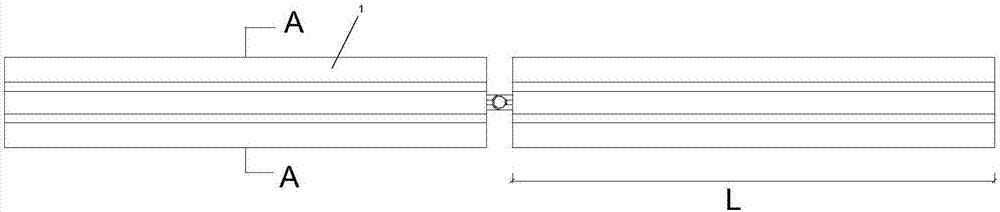

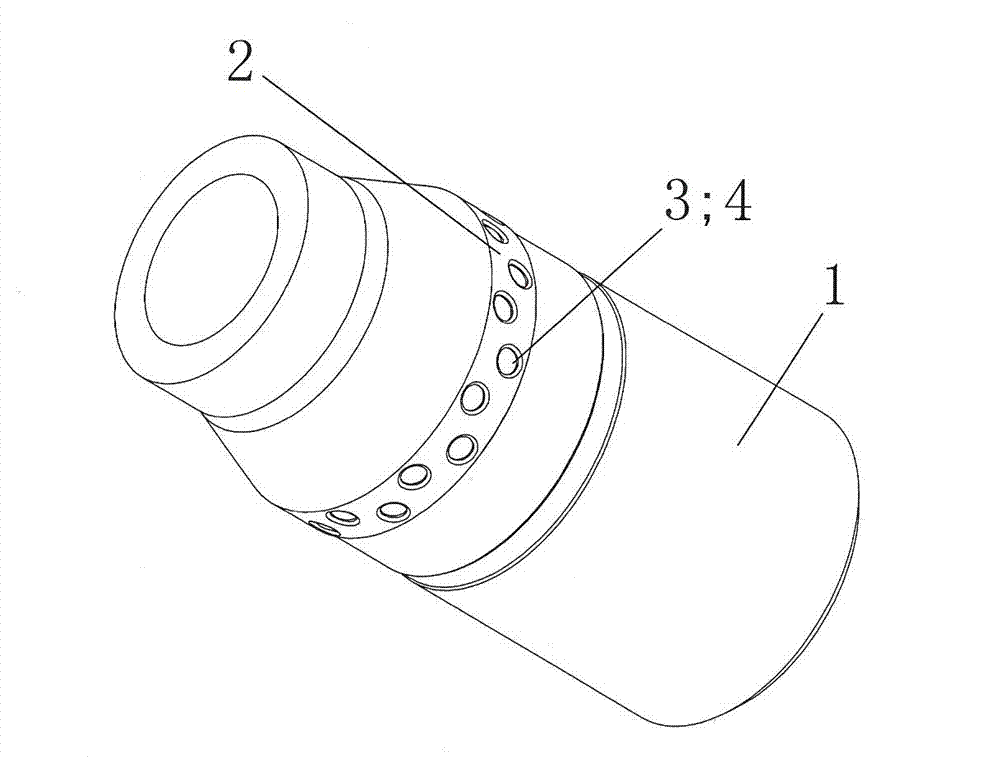

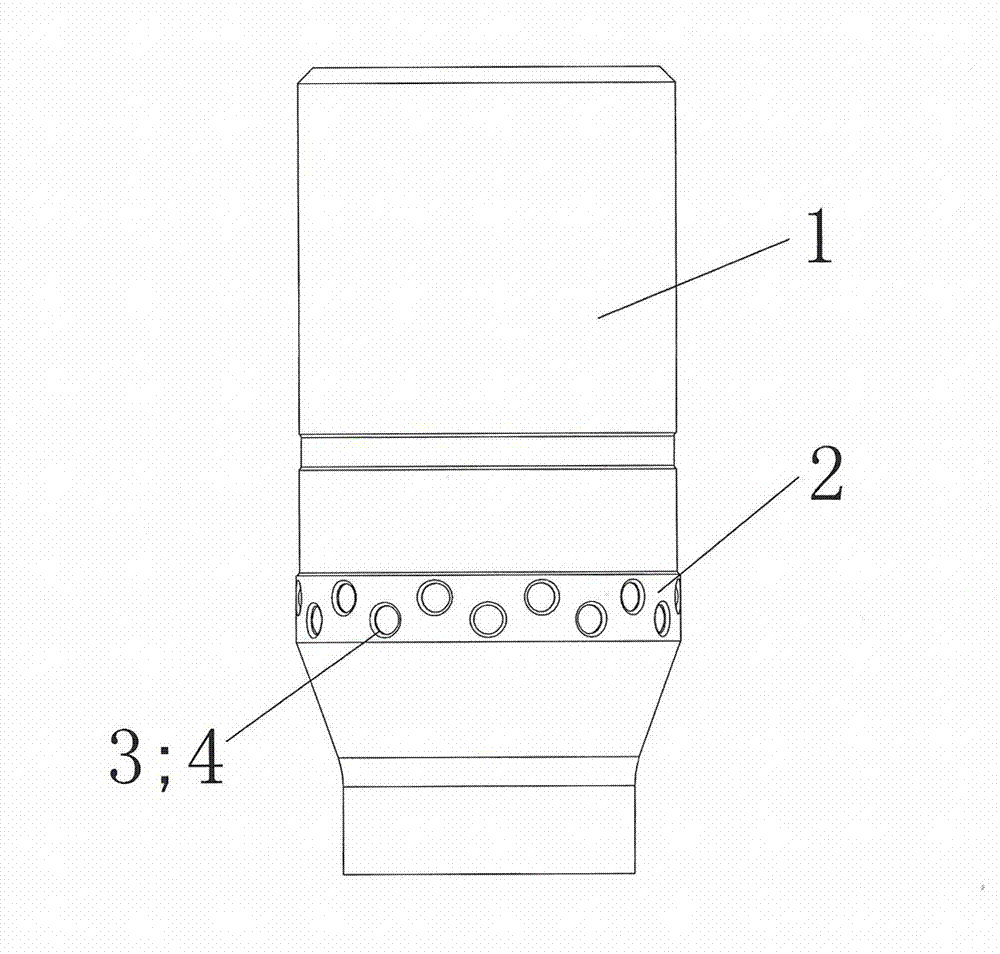

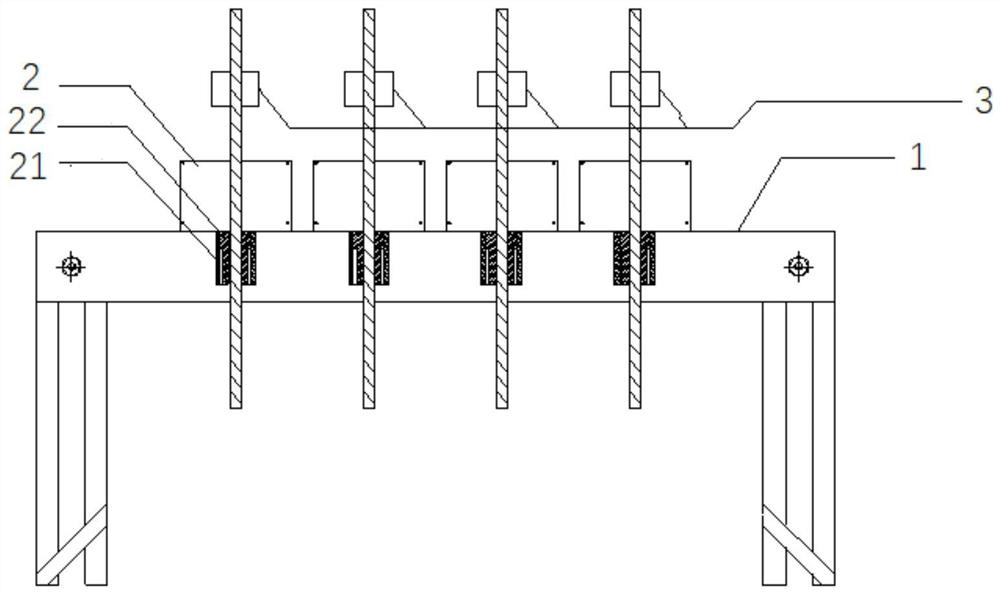

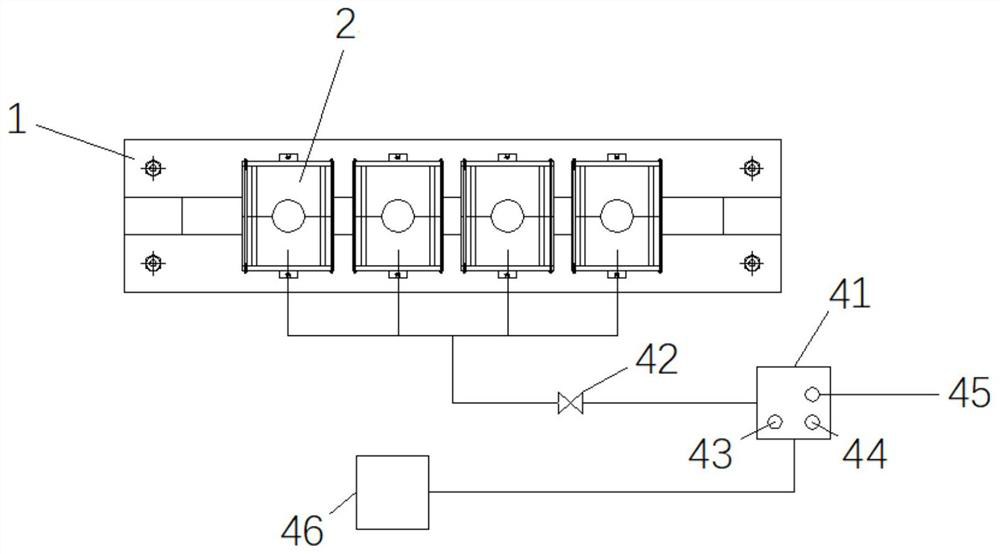

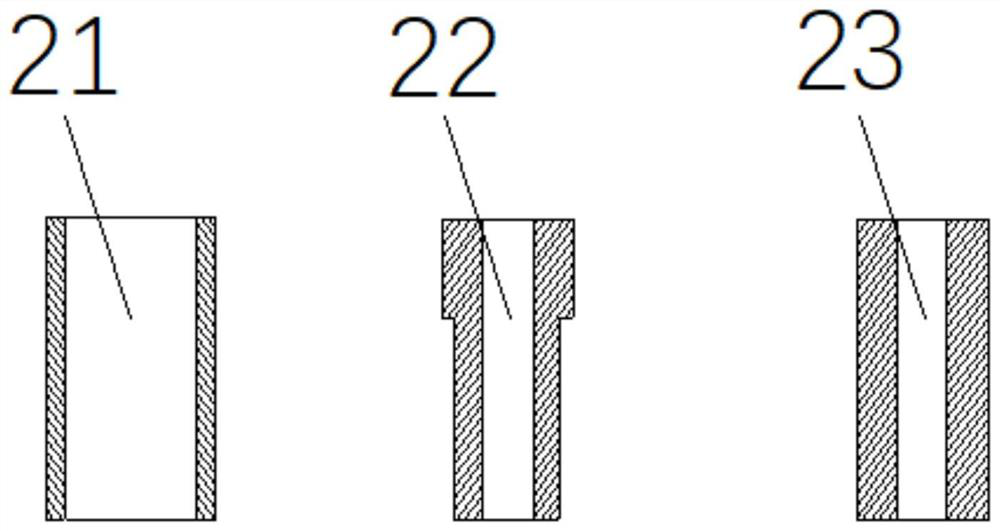

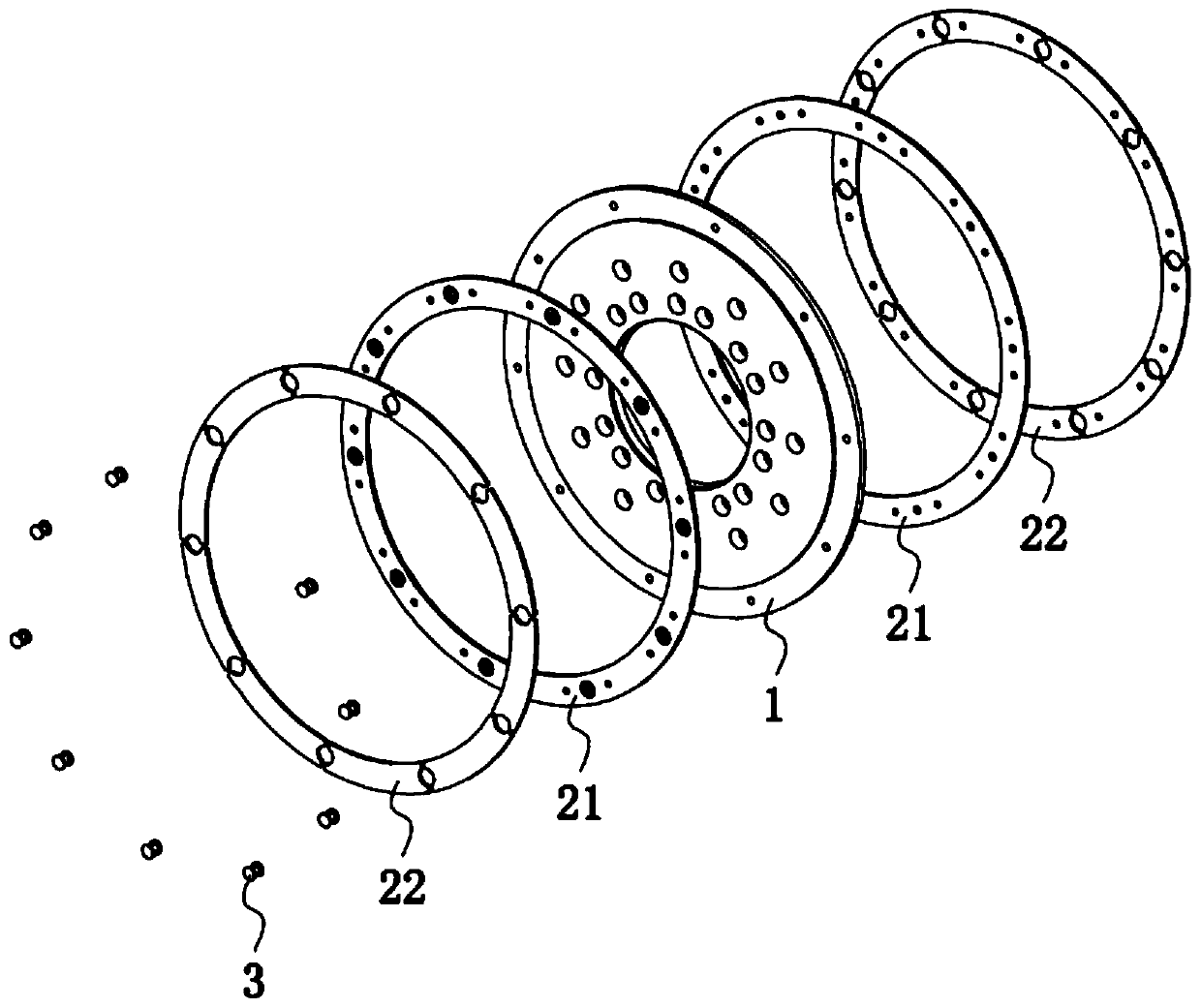

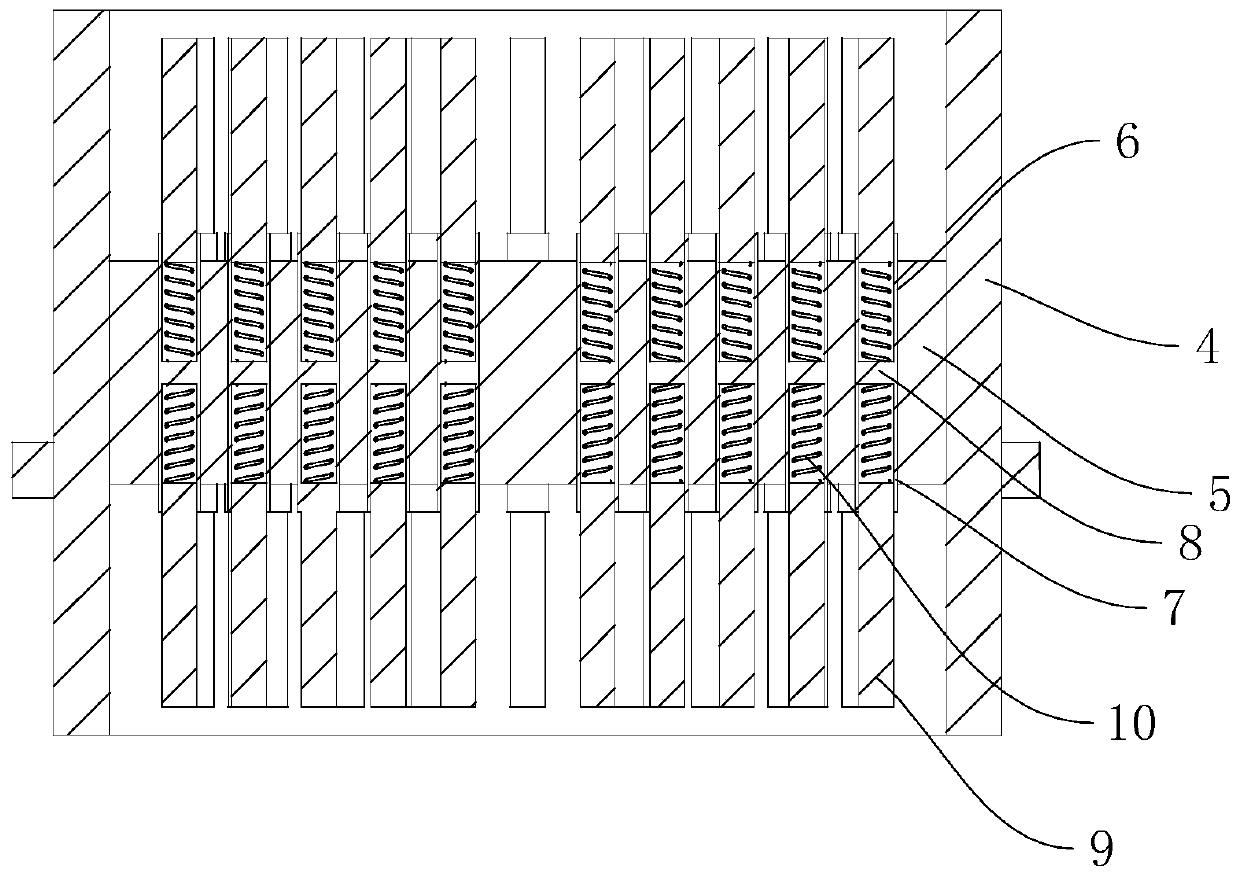

Novel multi-rope friction hoisting rope oiling device and implementation method thereof

ActiveCN111853508AImprove refueling efficiencyGuaranteed coefficient of frictionEngine temperatureSignal processingTemperature controlOil and grease

The invention relates to a multi-rope friction hoisting rope oiling device and an implementation method thereof. The multi-rope friction hoisting rope oiling device comprises a split type fixed seat frame, an oil filling box, a medium-frequency induction heating device, an oiling device and a central control processor; by arranging the central control processor and connecting the central control processor with a liquid level detector, a clamping device, a hoisting machine, a speed detector, the medium-frequency induction heating device, a diameter detector, a temperature detector and the oiling device, the medium-frequency induction heating device is controlled to select the corresponding preheating temperature according to the diameter of a steel wire rope, the hoister is controlled to enable the steel wire rope to move at the designated speed, and whether grease in the oil filling box seeps outwards or not is monitored in the oiling process of the steel wire rope; and when the deviceaims at the steel wire ropes of different diameters, all the components are controlled to select the corresponding operation parameters so that the device can complete oiling of the steel wire ropesof different diameters, and the oiling efficiency of the device on the steel wire ropes of different diameters is improved.

Owner:呼伦贝尔山金矿业有限公司

High-strength and low-abrasion automobile brake pad

InactiveCN105587810AImprove wear resistanceHigh carbon contentOther chemical processesFriction liningFiberPorosity

The invention discloses a high-strength and low-abrasion automobile brake pad. The high-strength and low-abrasion automobile brake pad is characterized in that a raw material comprises, by weight, 12-15 parts of nitrile rubber, 15-20 parts of tyre powder, 6-8 parts of polytetrafluoroethylene, 3-5 parts of graphite, 2-4 parts of calcium carbonate, 4-6 parts of modified phenolic resin, 1-1.5 parts of a friction increase agent, 2-3 parts of calcined coke, 0.6-0.8 part of zirconium silicate, 0.8-1.2 parts of lead sulfide, 2-4 parts of mixed fibers and 2-4 parts of titanium dioxide. By means of recycling of the tyre powder in the high-strength and low-abrasion automobile brake pad, waste can be fully utilized, resources and energy can be recycled to create economic benefits, and the beneficial effect of being high in carbon content and porosity is achieved; the friction coefficient and the service life are guaranteed through the mixed fibers, and meanwhile brake noise can be effectively absorbed in the brake process; and the manufactured brake pad is good in abrasion resistance and small in high-speed and high-temperature declining, the average friction coefficient is 0.30 mu, the friction coefficient during automobile high-speed braking is 0.30 mu, and the friction coefficient and safety are high.

Owner:王洪珠

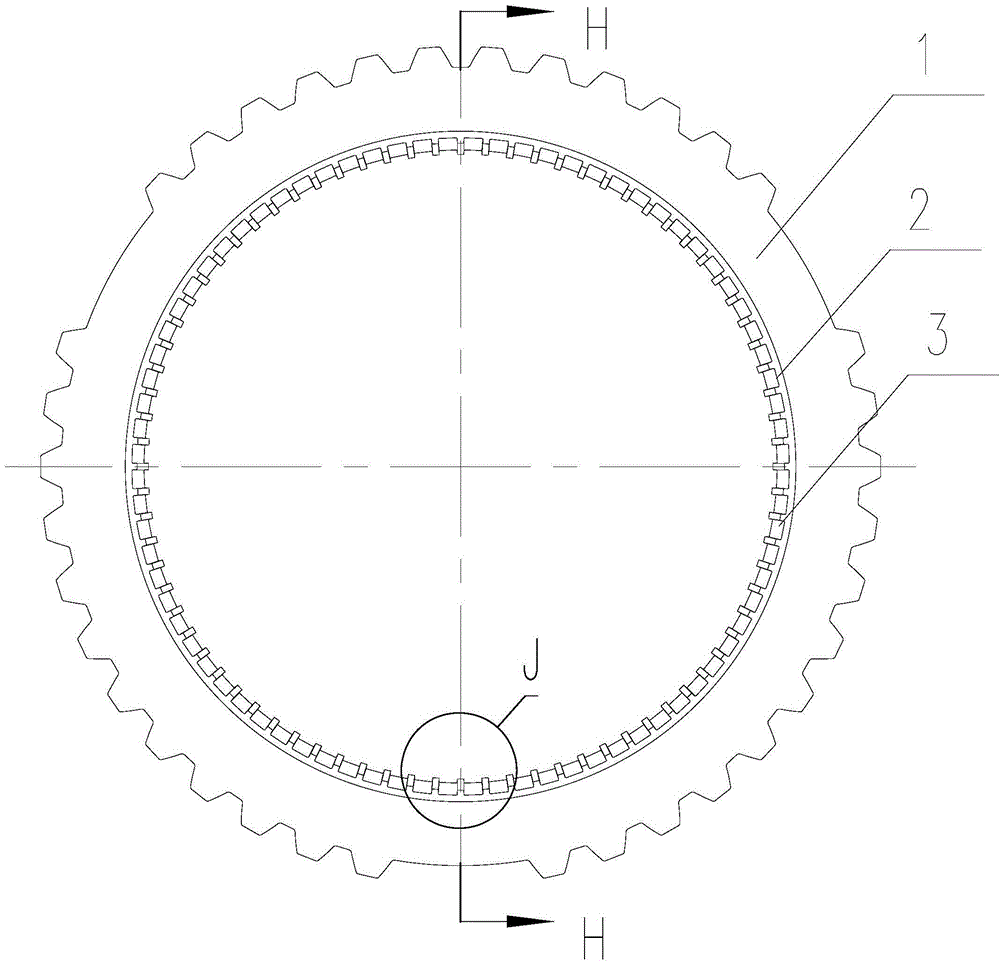

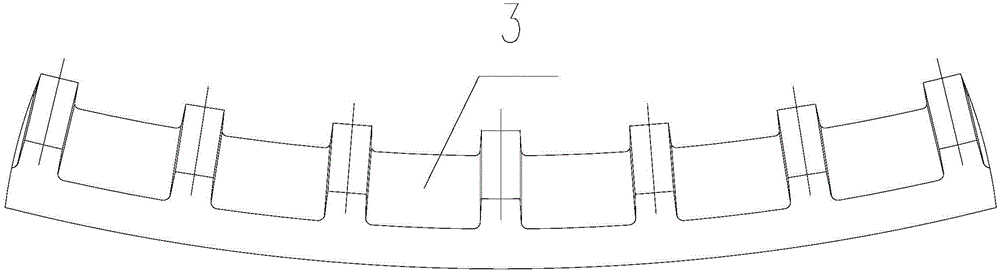

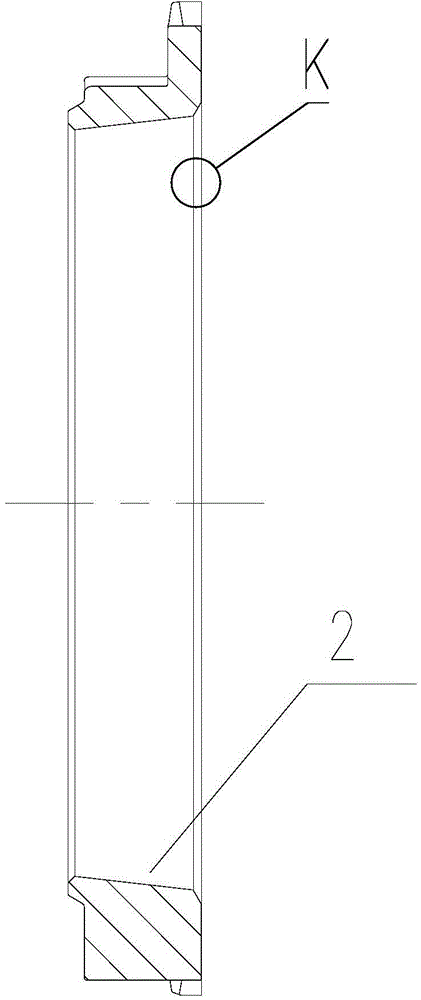

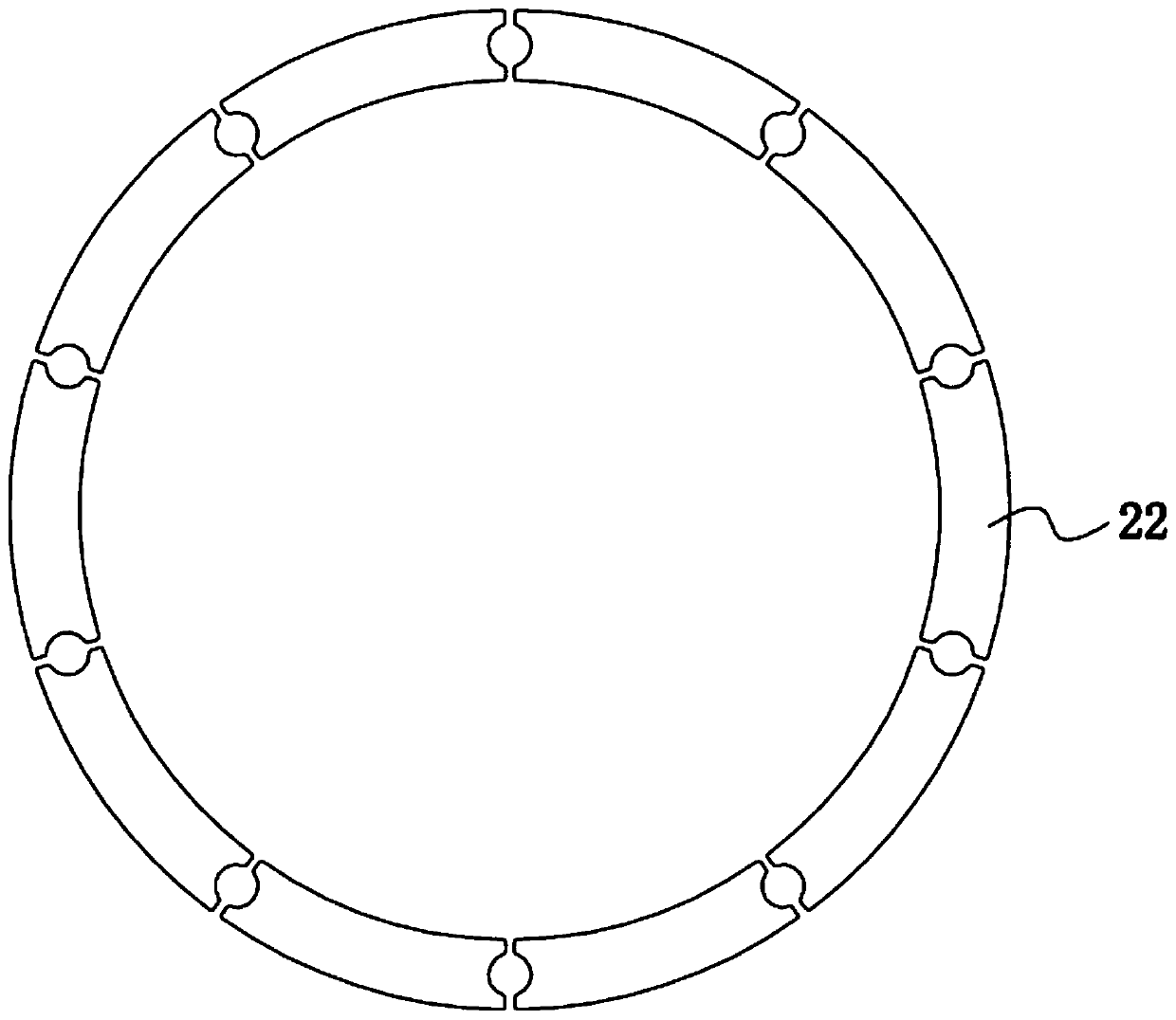

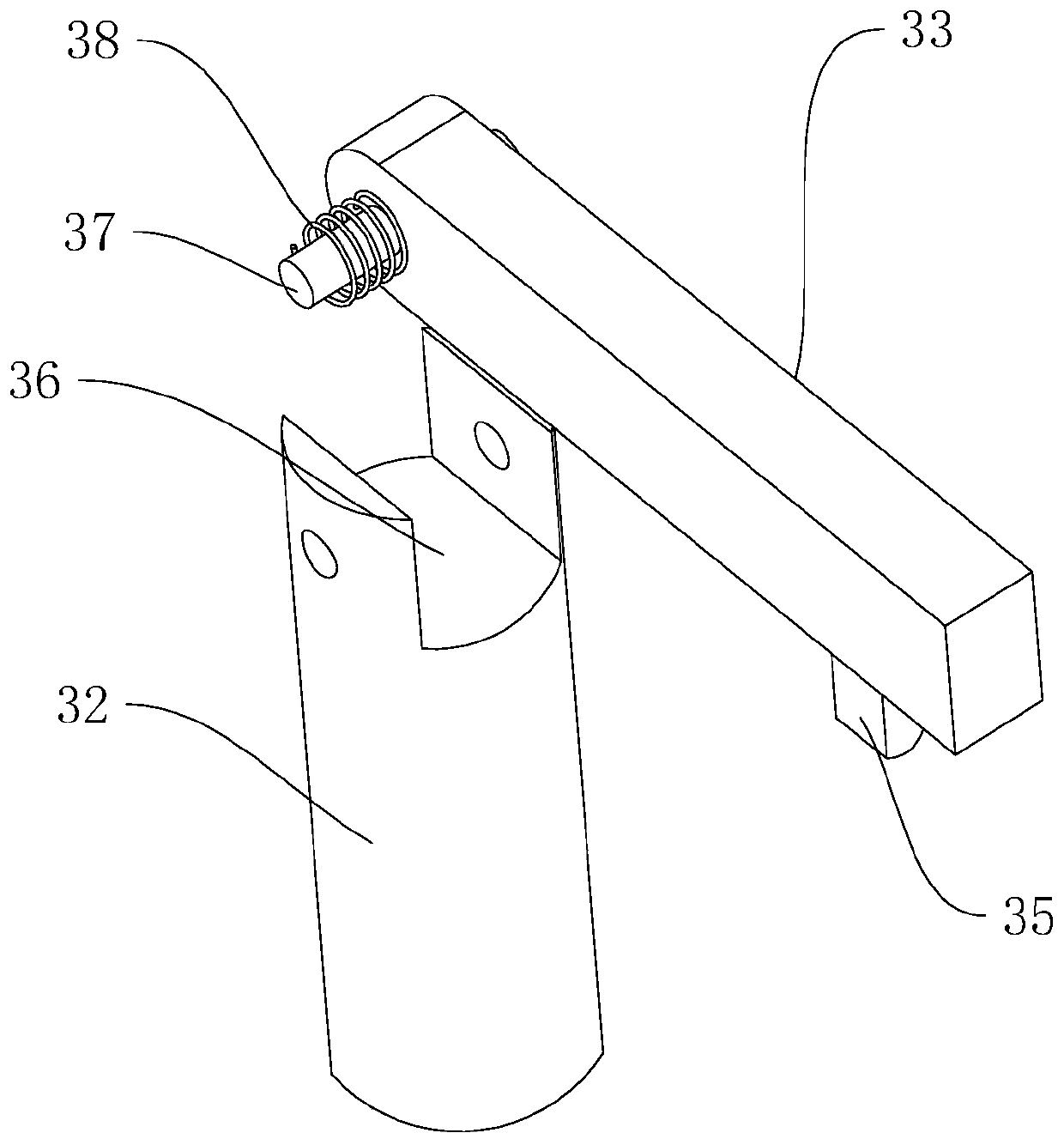

Synchronous ring of car gearbox synchronizer

InactiveCN104632924AGuaranteed coefficient of frictionImprove shift performanceMechanical actuated clutchesEngineeringAutomotive transmission

The invention provides a synchronous ring of a car gearbox synchronizer. A large number of axial oil grooves are machined in the inner cone face of the synchronous ring. The tooth top width of each axial oil groove is 0.30-0.45 mm. The width of each oil groove is 0.7-1.0 mm. The oil groove section area of the axial-dense oil groove synchronous ring is larger than the section area of an existing synchronous ring thread groove, so that the oil dispersing gap is enlarged, oil dispersing effect is improved, oil discharging performance is improved, gear shifting performance is improved, abrasion cannot happen easily, and the gear shifting performance of the synchronous ring is effectively improved, and the service life of the synchronous ring is effectively prolonged.

Owner:LUZHOU CHANGJIANG MACHINERY

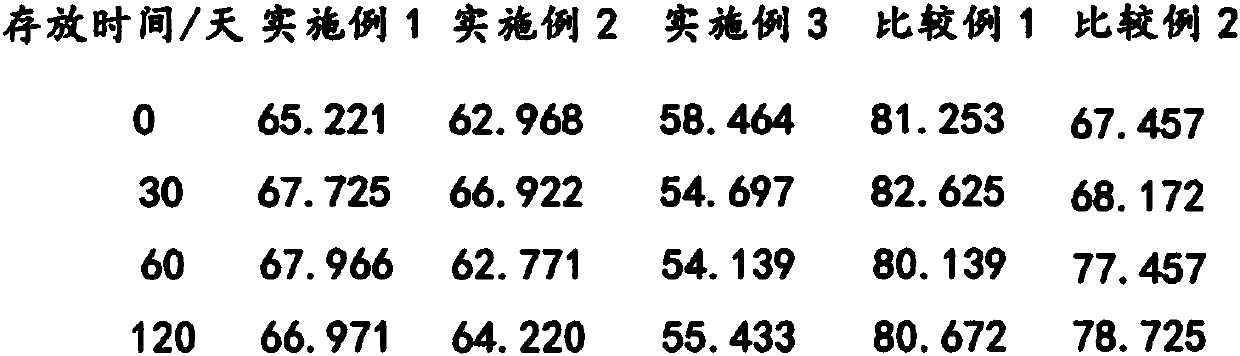

Graphene composite material applied in preparing spinning rubber covered roller and preparation method thereof

The invention discloses a graphene composite material applied in preparing a spinning rubber covered roller and a preparation method thereof. The graphene composite material comprises, by weight, 100parts of polyurethane, 32 parts of graphene, 11 parts of zinc acetate, 8 parts of high-strength carbon fiber, 1 part of antimony dioxide, 1 part of cobalt aluminate, 2 parts of electrolyzed silver powder, 4 parts of allyl nitrile-styrene dipolymer, 3 parts of epoxy fatty acid methyl ester, 3-7 parts of SDS mineral powder, 1-3 parts of polymerized aluminum sulfate, 2-4 parts of cyclohexanone, 1-5 parts of 3-aminopropyl triethoxy silane and 1-3 parts of (3-lauroamide propyl) trimethyl ammonium sulfate. The graphene composite material is reasonable in component arrangement, the preparation methodis simple, and performances of the spinning rubber covered roller can be improved effectively; the graphene composite material has excellent wear resistance, so that strength of the rubber covered roller is enhanced, softness of the surface of the roller is ensured while the surface of the roller has certain friction coefficient, and static electricity and spinning burrs can be avoided effectively.

Owner:NANJING XUYURUI MATERIAL TECH CO LTD

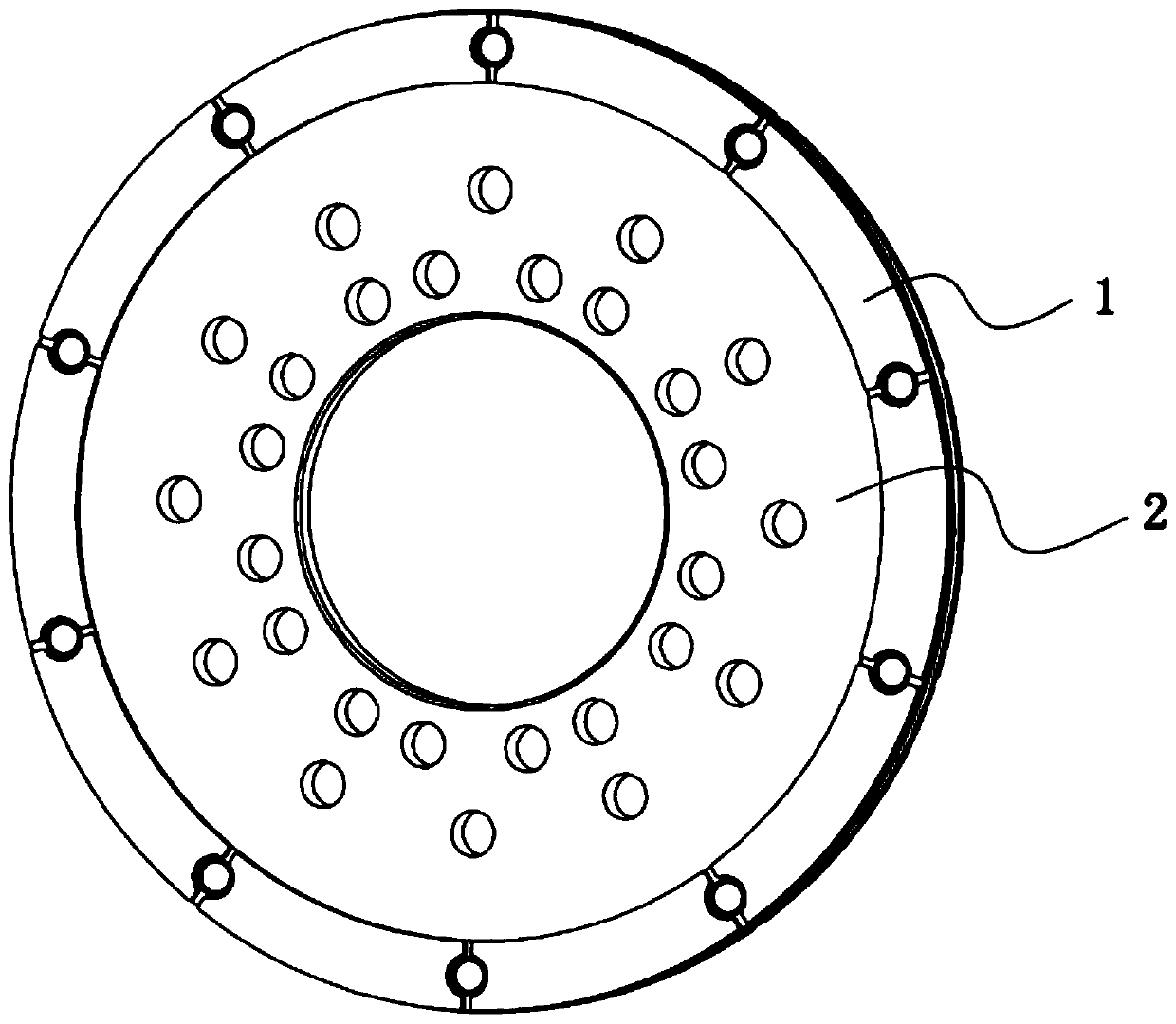

Powder metallurgy material and friction body and friction disc applied by same

PendingCN110144488AImprove temperature resistanceExtended service lifeFriction liningActuatorsPowder metallurgyComposite material

The invention relates to the field of friction devices, in particular to a powder metallurgy material and a friction body and a friction disc applied by the same. The powder metallurgy material is applied to the friction disc; and through application of the powder metallurgy material to the friction disc, as the powder metallurgy material is better in temperature resistance compared with an organic resin material, the temperature resistance of the friction disc can be improved, and the service life of the friction disc can be prolonged to a certain extent.

Owner:浙江乐粉轨道交通科技有限公司

Tuning self-locking bolt

The invention discloses a tuning self-locking bolt, which is applied to a cavity filter. The tuning self-locking bolt is divided into a head part and a rod part and is fabricated by copper; the head part is arranged at one end of the bolt; the rod part is arranged at the other end of the bolt; the rod part extends into the cavity of the filter to tune radio frequency parameters; the head part fixes the self-locking bolt on a cover board of the filter; the top end of the head part is provided with a receiving groove which is used for receiving a screw driver and screwing the tuning bolt into the cavity filter according to the drive of the screw driver; two sets of threads are formed in the head part of the bolt to form screws; the diameters of the screws formed by the threads are greater than or equal to M4; the two sets of threads are not connected with each other; the upper and lower sets of threads are the same in screw pitch P; the diameter of the upper thread is greater than that of the lower thread; the diameter ratio of the upper thread to the lower thread is (1.01 to 1) to (1.1 to 1); and the diameter of the part between the two threads is 40%-70% that of the rod part. The bolt disclosed by the invention has a relatively good self-locking effect.

Owner:JOHNSON PRECISION ENG SUZHOU

Torque wrench and steel box beam high-strength bolt tightening applying technology using same

The invention relates to a torque wrench. The torque wrench comprises a handle, and the front end of the handle is fixedly connected with a connection head; the connection head is provided with a connection hole, a sleeve is installed on the inner wall of the connection hole, and an installation plate is fixedly connected to the inner wall of the sleeve; a plurality of sets of installation holes are uniformly formed in the installation plate at intervals, and the inner walls of the installation holes are fixedly connected with installation pipes; the inner walls of the installation pipes are fixedly connected with baffles, stop rods are slidably connected into the inner walls of the two ends of the installation pipes, and abutting springs are installed in the two ends of the installation pipes; by fixedly connecting the installation plates to the inner walls of the sleeves, the installation pipes are fixedly connected into the installation holes, by slidably connecting the stop rods into the installation pipes, during using, the sleeves are arranged on a bolt head in a sleeving mode, the bolt head drives the stop rods to compress the abutting springs, the side walls of the stop rods which are not compressed abut against the side wall of the bolt head, thus, an operator can tighten bolts different in specification conveniently, and the quantity of wrenches needing to be carriedby an operator is decreased.

Owner:山东省公路桥梁建设集团有限公司

Double-V-shaped floating self-aligning supporting structure and machining method of supporting block in double-V-shaped floating self-aligning supporting structure

InactiveCN111571435ASloped slopesmoothEven by forceGrinding machinesGrinding work supportsPolycrystalline diamondEngineering

The invention relates to a double-V-shaped floating self-aligning supporting structure which comprises two supporting frame combinations and an arc-shaped positioning seat. The two supporting frame combinations are fixed to an arc-shaped positioning seat of a grinding machine through bolts, each supporting frame combination comprises a supporting frame, a supporting seat and a supporting head, wherein an adjusting screw is rotationally arranged on the supporting frame, the supporting seat is movably connected with the supporting frame through the adjusting screw, the supporting head is rotationally connected with the supporting seat through a pin, the supporting head comprises a supporting block, and the supporting block is made of polycrystalline diamond PCD or polycrystalline pure diamond CVD. The machining method of the supporting blocks comprises the following steps of conducting scanning and ablating by adopting an ultraviolet laser, and ablating a wedge groove of an array microstructure on the upper surface of the supporting block. According to the double-V-shaped floating self-aligning supporting structure, the machining precision of a bearing ring is guaranteed, meanwhile,the obvious appearance defects of spots, uneven local color and luster and the like generated by an outer diameter surface phosphating film during rolling path grinding of the bearing ring in the prior art are overcome, and therefore the appearance quality of a bearing meets the requirements of customers.

Owner:LUOYANG LYC BEARING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com