Synchronous ring of car gearbox synchronizer

A technology of automobile gearbox and synchronizer, applied in the field of synchronizing ring, can solve the problems of damage strength, affecting the service life of products, etc., and achieve the effects of improving oil discharge performance, improving service life and increasing dispersion gap.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

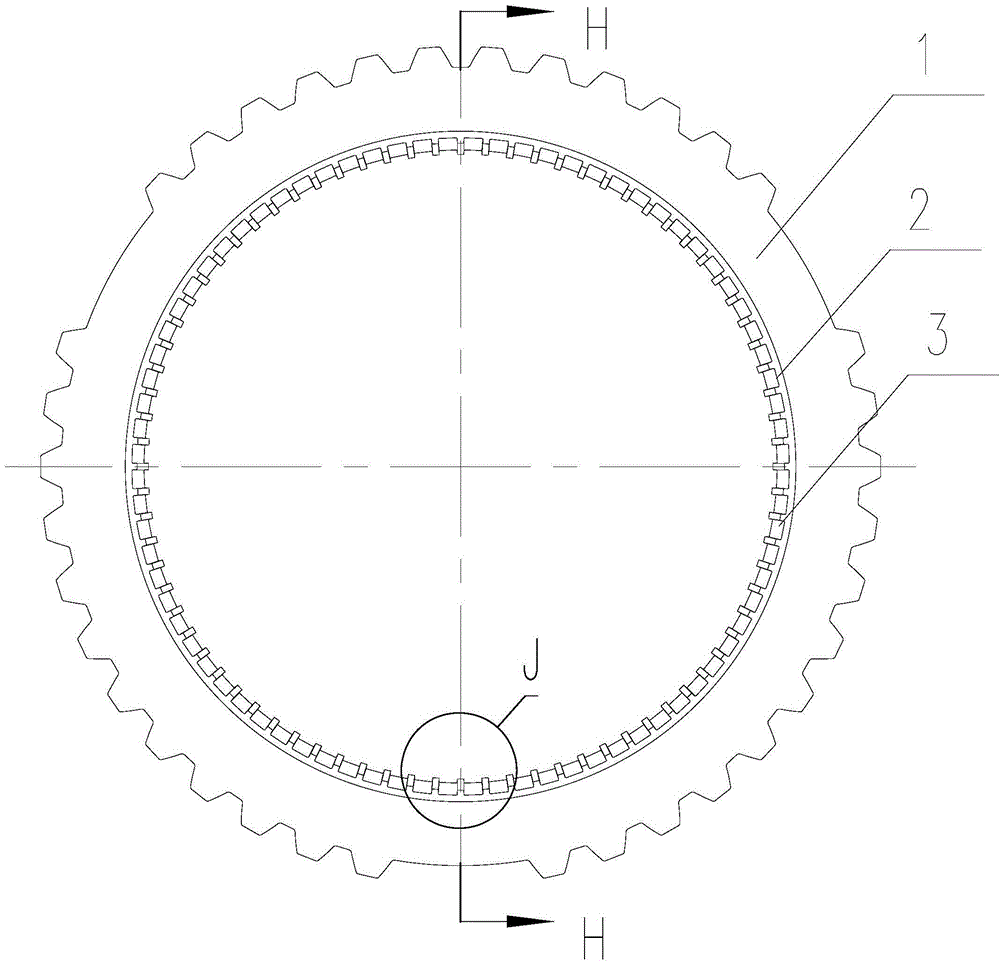

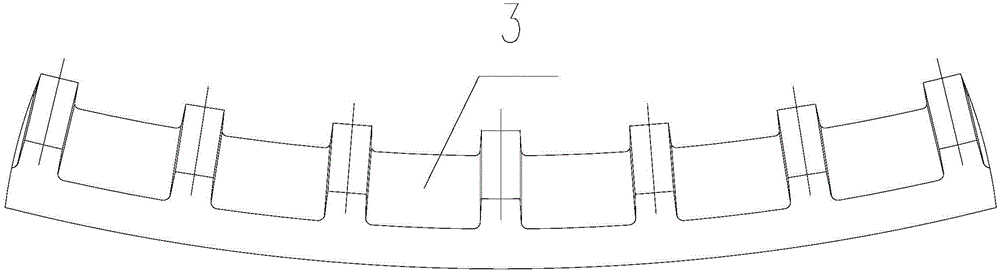

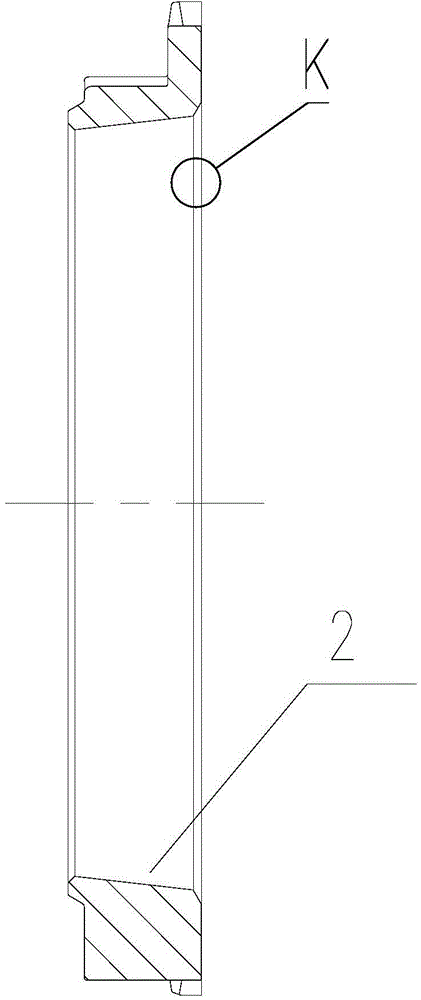

[0024] Such as Figure 1-4 As shown, the axial dense oil groove synchronous ring of the present invention is processed with a plurality of axial dense oil grooves 3 evenly distributed on the inner tapered surface 2 of the synchronous ring 1, and the number of axial dense oil grooves 3 needs to be determined according to the inner diameter of the specific synchronous ring. The cone diameter is determined. The diameter of the inner cone of the axial dense oil groove of the present invention is φ38-φ90 mm, and the number of dense oil grooves 3 is 88-235. For products with an inner cone diameter of φ38mm, the number of oil grooves is 77 to 114; for products with an inner cone diameter of φ57mm, the number of oil grooves is 116 to 171; for products with an inner cone diameter of φ90mm, the number of oil grooves is 183 to 270; the depth C of the oil groove is 0.30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com