Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

88results about How to "Good heat resistance and flame retardant performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heptatridecafluorooctylpropyl polyhedral oligomeric silsesquioxane and functionalized derivates thereof

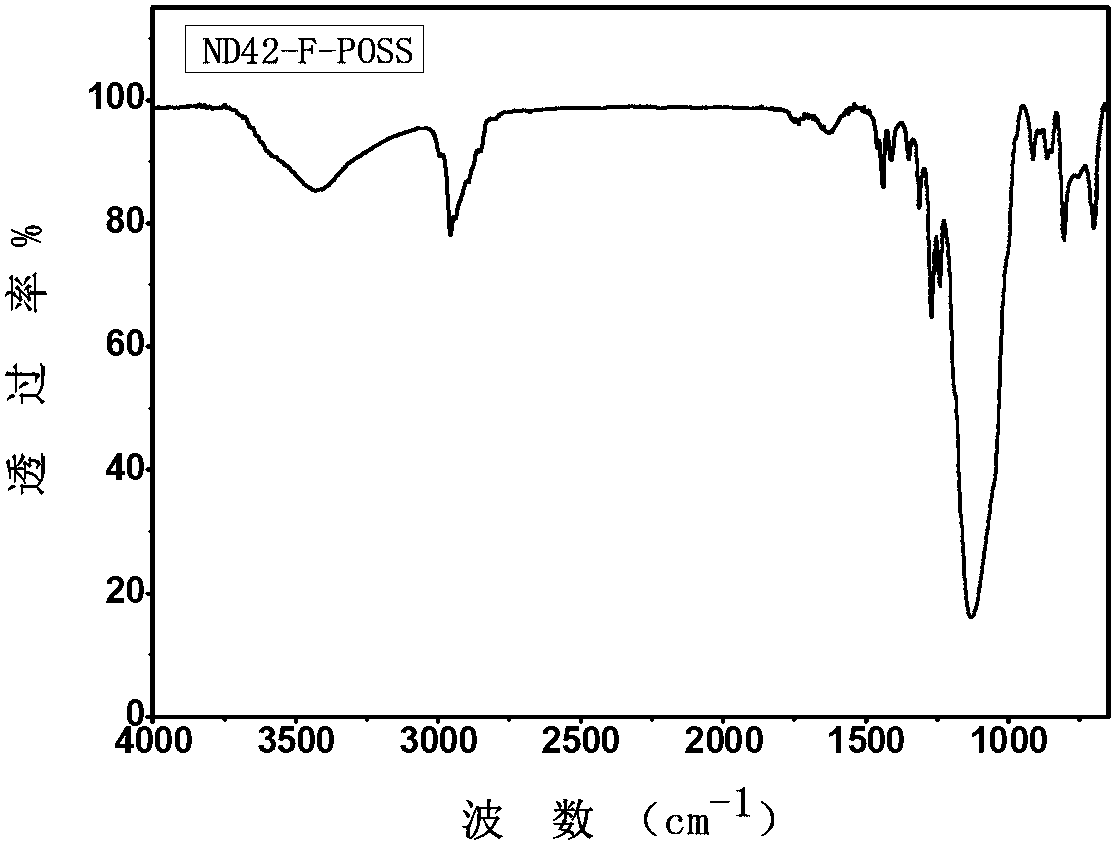

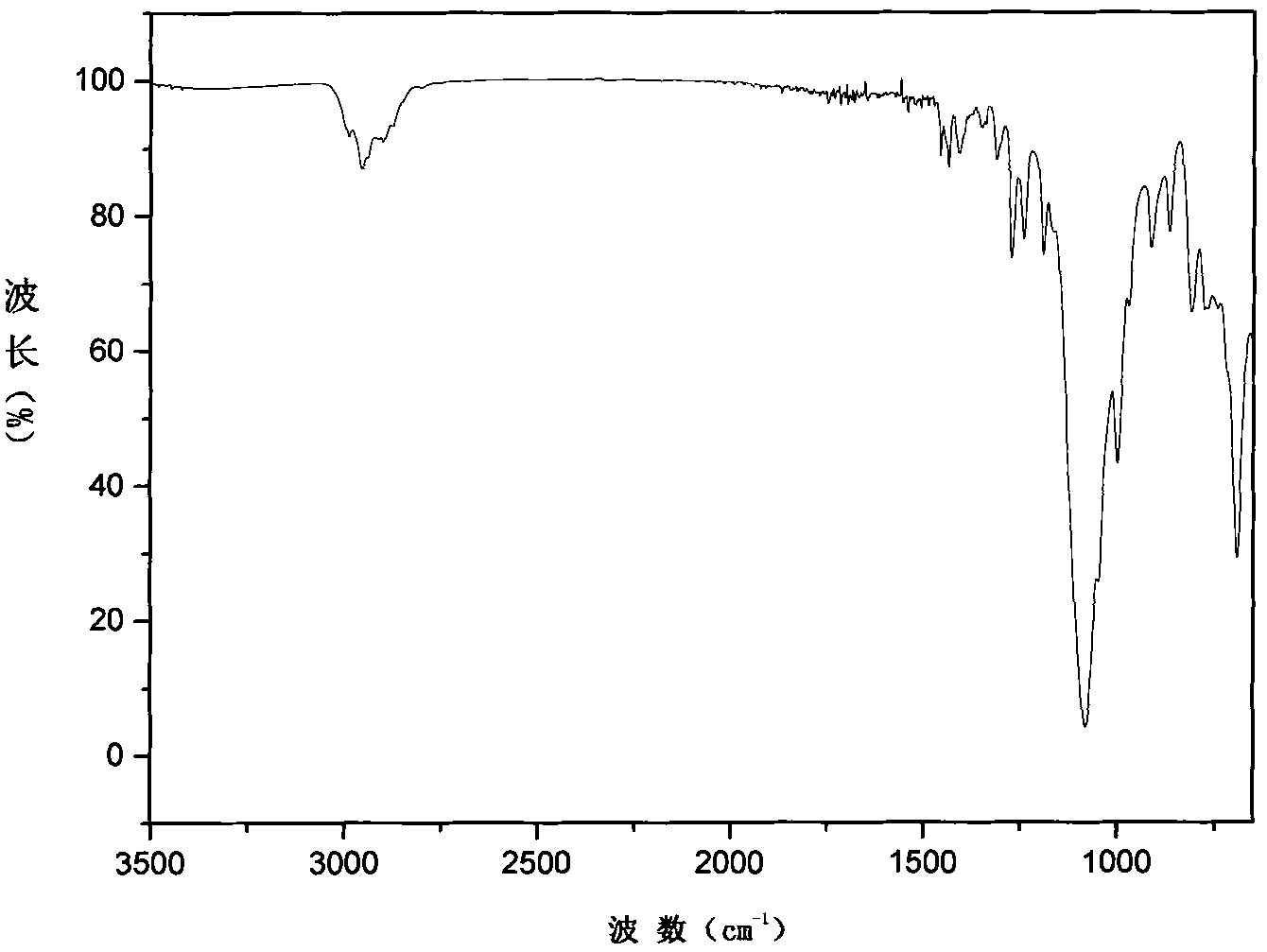

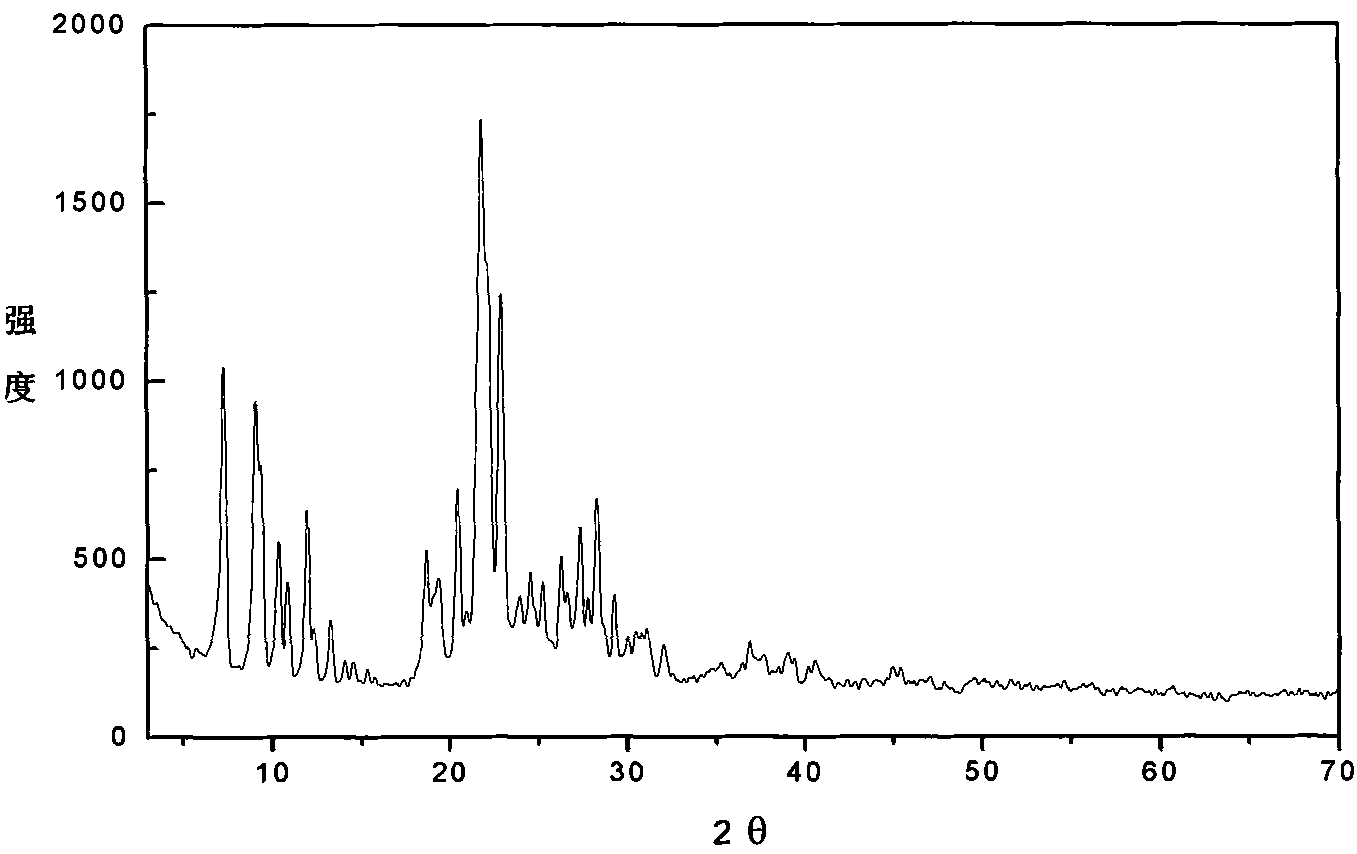

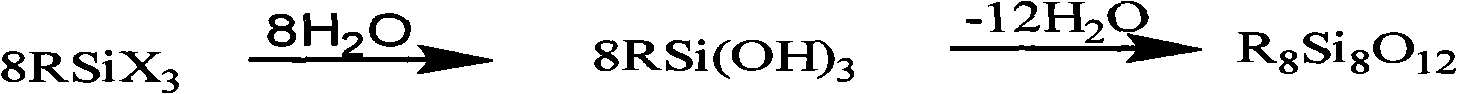

The invention provides a preparation method for heptatridecafluorooctylpropyl polyhedral oligomeric silsesquioxane and functionalized derivates thereof. The preparation method comprises the steps as follows: adding tridecafluorooctylpropyl trimethoxy silane into an organic solvent, adding de-ionized water and NaOH, heating, stirring, reacting under reflux condition, washing by a washing solvent, and drying to obtain trisilanol sodium salt of heptatridecafluorooctylpropyl polyhedral oligomeric silsesquioxane; and adding trisilanol sodium salt into an organic reagent, dropwise adding hydrochloric acid, triethylamine and a silane coupling agent, stirring a mixture at normal temperature for reaction, removing generated deposit, carrying out rotary evaporation, removing the solvent, obtaining white crystals, dissolving the crystals in methanol, filtering for collecting insoluble parts, and carrying out vacuum drying to obtain a T8-type monofunctional tridecafluorooctylpropyl POSS (polyhedral oligomeric silsesquioxane) monomer. The preparation method can obtain long branch chain type active fluorine-containing POSS, is simple and easy in process, low in cost, high in yield and higher in product purity, and is suitable for large-scale industrial production.

Owner:HOHAI UNIV

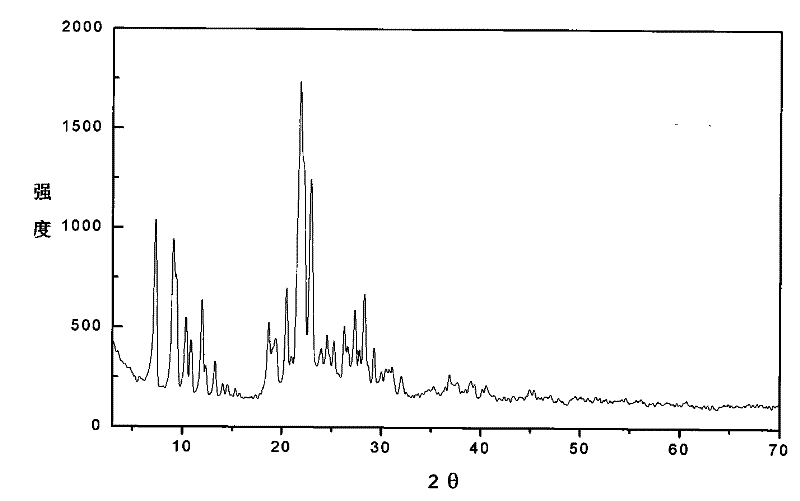

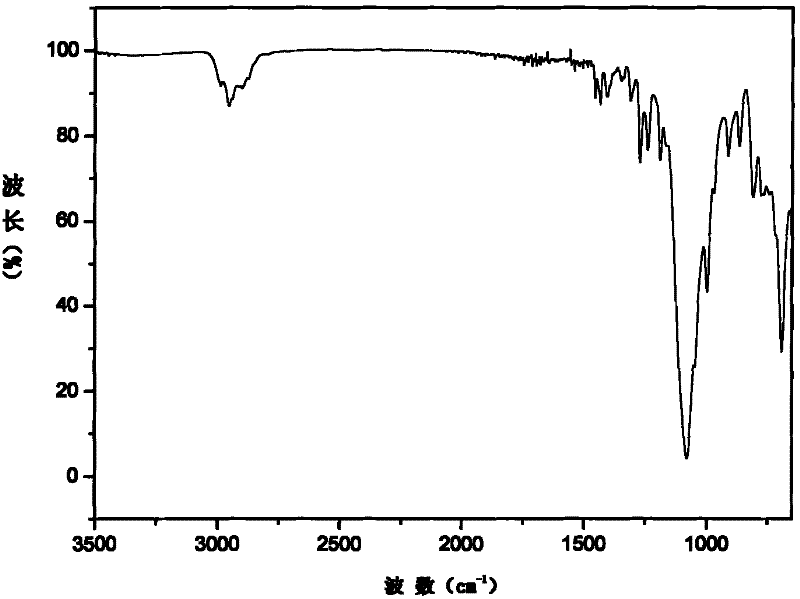

Dodecafluoroheptyl-propyl polyhedral oligomeric silsesquioxane and preparation method thereof

InactiveCN101875667ALower surface energyImprove hydrophobic and oleophobic propertiesSilicon organic compoundsChemistryOrganic solvent

The invention provides a preparation method of dodecafluoroheptyl-propyl polyhedral oligomeric silsesquioxane, which comprises the following steps: dripping each 1mol of dodecafluoroheptyl-propyl-trimethoxylsilane into 250-10000ml of organic solvent under the condition of 0-40 DEG C, carrying out hydrolysis condensation reaction under the action of acid catalysis, carrying out the reaction for a certain period of time, and carrying out concentration, filtration, drying and other steps for preparing dodecafluoroheptyl-propyl polyhedral oligomeric silsesquioxane (dodecafluoroheptyl-propyl POSS) crystals. The invention further provides the dodecafluoroheptyl-propyl polyhedral oligomeric silsesquioxane. The method has simple and easy process, low cost, high yield and high product purity, and the prepared dodecafluoroheptyl-propyl polyhedral oligomeric silsesquioxane product has excellent hydro-oleophobic performances, heat resistance, flame retardance and low dielectric constant performance, and can be widely applied in the fields of polymer modification, hydro-oleophobic interface materials, flame retardants, low dielectric constant materials, building coatings, space materials, medical materials, light-emitting materials, liquid crystal materials and the like.

Owner:HOHAI UNIV

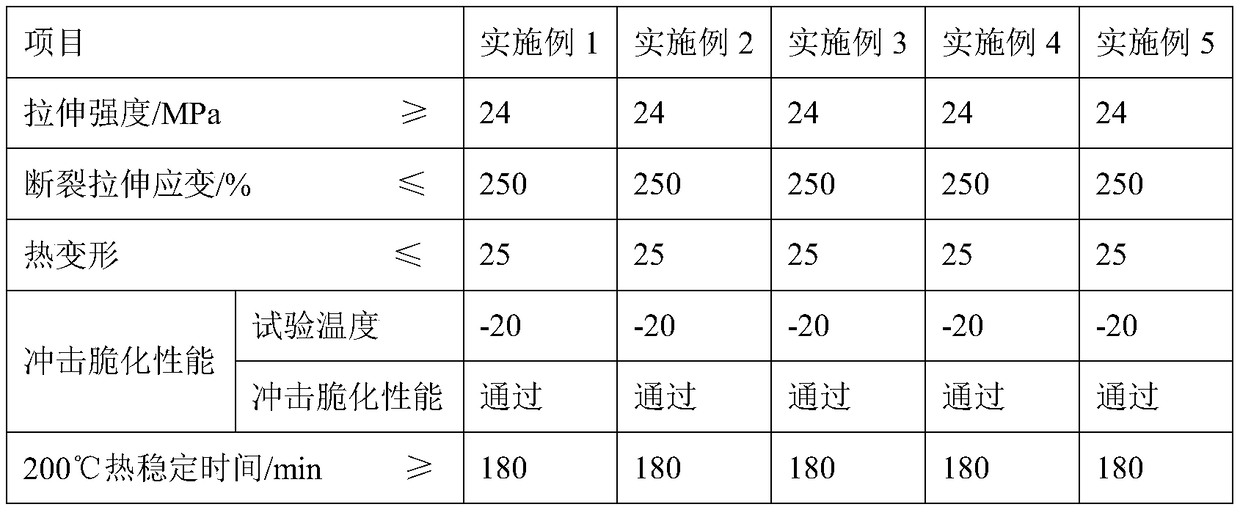

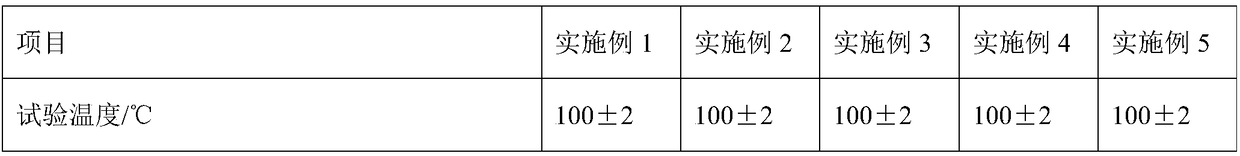

High performance aging resistant cable sheath material

ActiveCN103897272AGood heat resistance and flame retardant performanceExcellent ozone resistanceInsulated cablesInsulatorsSilanesLead salt

The invention discloses a high performance aging resistant cable sheath material which comprises the following raw materials in parts by weight: 30-40 parts of chlorinated polyethylene 135B, 15-20 parts of chlorinated polyethylene, 1.5-3 parts of magnesium oxide, 4-6 parts of dioctyl phthalate, 5-8 parts of dioctyl phthalate, 20-30 parts of white carbon black, 0.5-1 part of rare earth stabilizer, 0.3-0.6 part of a lead salt composite stabilizer, 2-5 parts of antimonous oxide, 8-12 parts of zinc borate, 2-4 parts of trichloroethyl phosphate, 8-12 parts of carbon black N770, 15-20 parts of calcium carbonate, 0.7-0.9 part of a surfactant gamma-mercaptopropyl triethoxyl silane, 0.5-1.3 parts of avulcanizing agent dicumyl peroxide and 0.5-1 part of a co-vulcanizing agent triallyl isocyanurate. The high performance aging resistant cable sheath material disclosed by the invention is excellent in heat resistant and flame retardant effect, good in ozone resistance and oil resistance, excellent in physical and mechanical properties and long in service life.

Owner:江苏鑫海腾线缆有限公司

High-strength and corrosion-resistant modified polypropylene material

ActiveCN109403014AImprove surface slipImprove friction resistanceLight resistant fibresHeat resistant fibresSisal fiberCarbon nanotube

The invention discloses a high-strength and corrosion-resistant modified polypropylene material. The polypropylene material is prepared from the following raw materials: an abrasion-resistant modifiedpolypropylene base material, a nano silica and sisal fiber composite abrasion-resistant filler, ethylene-propylene-diene monomer dispersing liquid, a multi-walled carbon nanotube and montmorillonitecomposite reinforcing filler and PP flame-retardant masterbatch. During preparation, modified isotactic polypropylene is taken as the base material, after the base material is mixed with the compositeabrasion-resistant filler, the composite reinforcing filler and the PP flame-retardant masterbatch for filling modification, melt spinning is conducted, and thus a fiber mesh cloth matrix with good abrasion resistance, tensile strength, compressive strength, heat resistance and flame retardancy is obtained; and then on the basis that the polypropylene material obtained after infiltration treatment through the ethylene-propylene-diene monomer dispersing liquid and electret discharging keeps good impact resistance and mechanical properties, a woven bag woven by the polypropylene material has good properties of abrasion resistance, tensile strength, dust prevention and ultraviolet resistance, and the multifunctional development demands of the packaging bag are met.

Owner:温州晨光集团有限公司

Flame retardant sealing ring used in electronic equipment

The invention provides a flame retardant sealing ring used in electronic equipment. The flame retardant sealing ring is characterized by being prepared from the following components in parts by mass: 25 to 32 parts of fluororubber, 18 to 27 parts of chloroprene rubber, 13 to 18 parts of phenolic resin, 17 to 28 parts of cresol, 3 to 8 parts of polyhydroxy acrylic resin, 2 to 5 parts of a flame retardant, 3 to 5 parts of an activator, 3 to 7 parts of expansible graphite, 2 to 5 parts of a charring agent, 7 to 13 parts of an adjuvant and 10 to 17 parts of a filler. The flame retardant sealing ring can keep the excellent sealing property and obviously improve the flame retardant performance, so that the sealing ring has the good heat resistance and flame retardance effect in the operating electronic equipment, and a fire caused by extremely high temperature is avoided; furthermore, the treatment cost is low, and the treatment method is simple.

Owner:李晓光

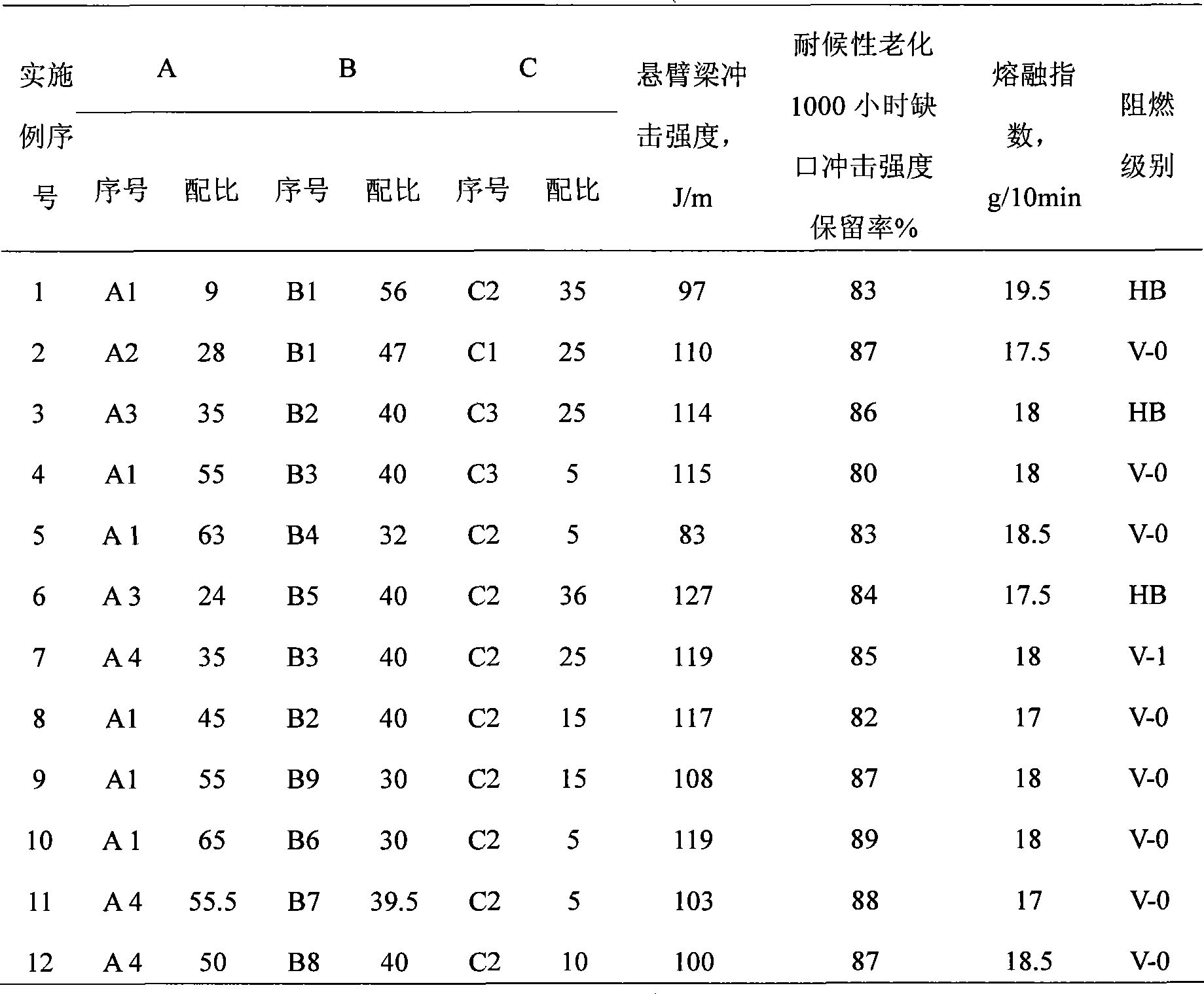

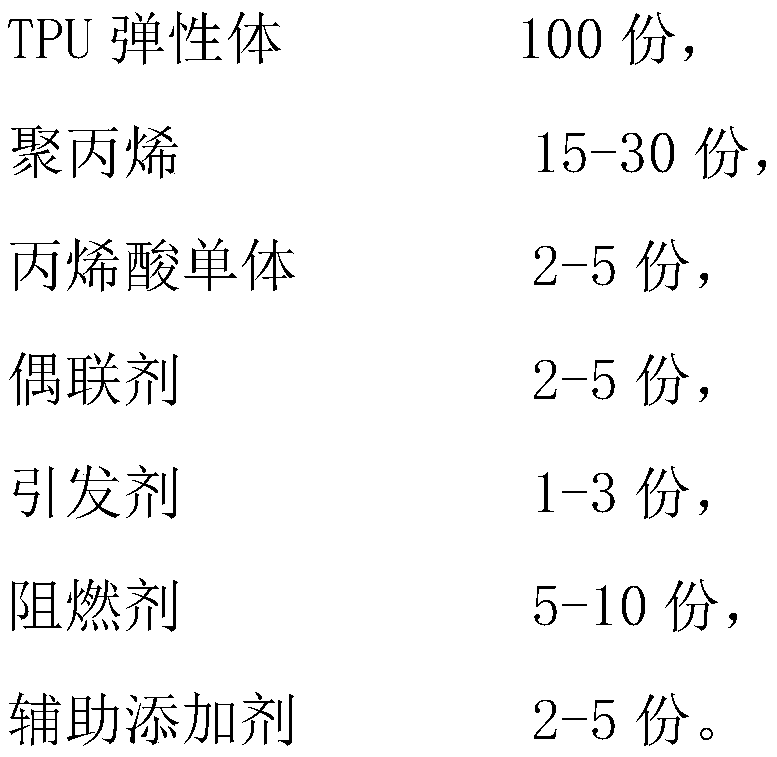

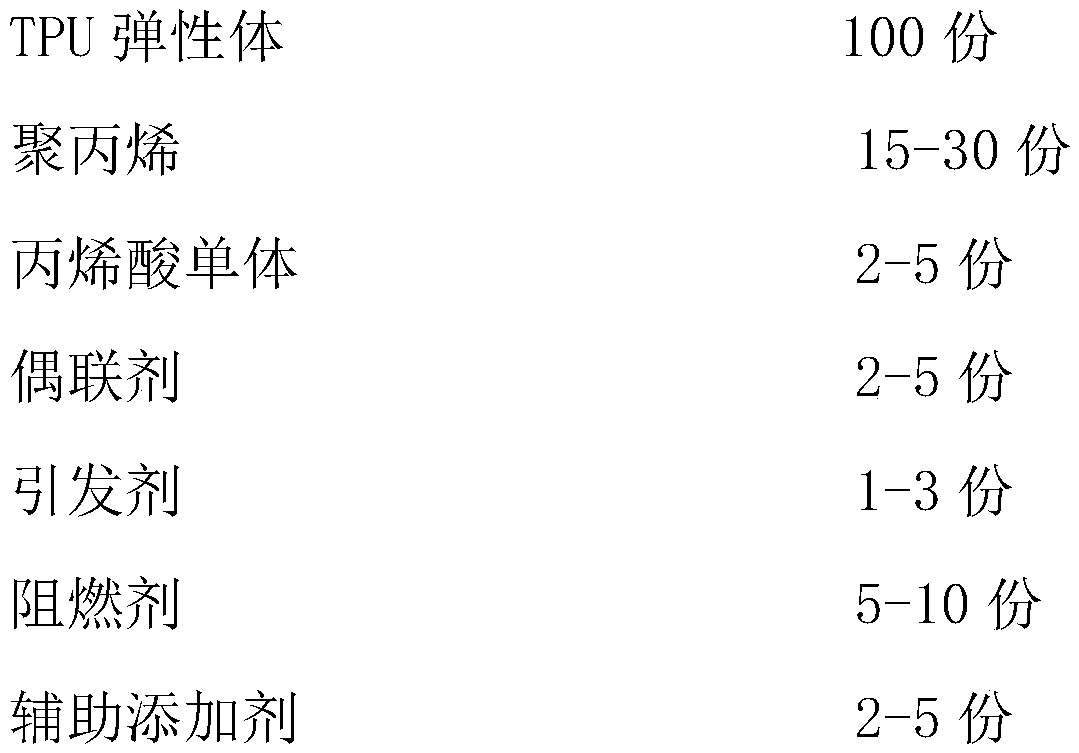

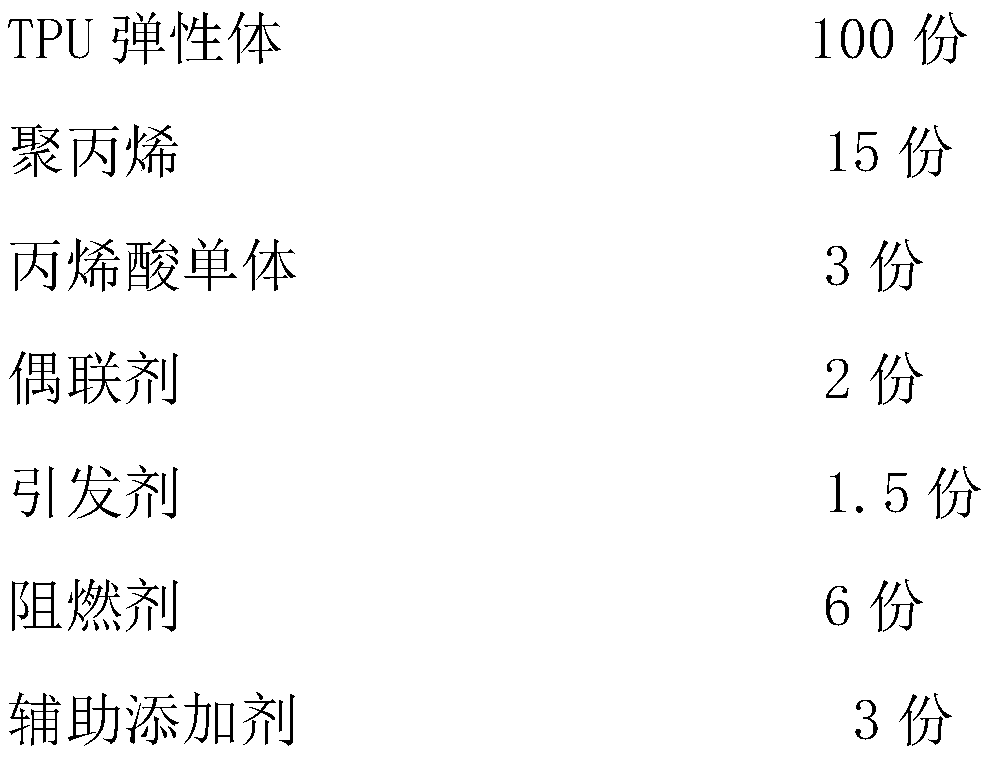

Weather resistant heat resisting flame retardant resin composition and preparation thereof

Owner:PETROCHINA CO LTD

High-strength heat-resistant corrosion-resistant polyurethane board and preparation method thereof

The invention discloses a high-strength heat-resistant corrosion-resistant polyurethane board which is prepared from diisocyanate, polycarbonate dibasic alcohol, dioctyl azelate, ethoxylated alkylphenol ammonium sulfate, toluene diisocyanate, heavy calcium carbonate, carbon black, nano attapulgite, nano silicon dioxide, bisphenol a diglycidyl ether, epoxy octyl stearate, a modified filler, methylsilicone oil, sulfur, a phenolic resin, a curing agent, melamine, hypophosphate, a flame-retardant synergistic agent, triallyl isocyanurate, dicumyl peroxide, 3,5-dimethylthiotoluylene diamine and a copper sheet. The invention also discloses a preparation method of the high-strength heat-resistant corrosion-resistant polyurethane board. The polyurethane board has the advantages of high strength, excellent heat resistance and excellent corrosion resistance.

Owner:安徽浩丰特种电子材料有限公司

Thermoplastic polyurethane optical film and coating method thereof

InactiveCN109735240ARigid and flexible performanceNo impact resistanceOrganic non-macromolecular adhesiveFilm/foil adhesives without carriersRubber materialMass ratio

The invention provides a thermoplastic polyurethane optical film. The thermoplastic polyurethane optical film is obtained by mixing thermoplastic polyurethane (TPU) and polypropylene (PP) according toa mass ratio to obtain a basic material and preparing from acrylic monomers, coupling agents, initiators, fire retardants and auxiliary additives. The thermoplastic polyurethane optical film has hightransparency, excellent mechanical properties, high weather and chemical resistance, high-and-low temperature resistance and good bonding properties, and can be melted, flowable, transparent, and extremely-low initially viscous under a certain temperature, thereby being capable of serving as an optical coating rubber material for touch display screens; touch display screen components bonded by the thermoplastic polyurethane optical film have the advantages of simplicity and convenience in process, convenience in bubble elimination, easiness in rework, high production efficiency, low cost andthe like, and touch display screen components coated with the thermoplastic polyurethane optical film have the advantages of good optical performance, excellent mechanical property, high chemical andweather resistance and good environmental performance, so that the thermoplastic polyurethane optical film is an excellent optical rubber material.

Owner:SHENZHEN GAOREN ELECTRONICS NEW MATERIAL

Processing technology of drilling-prevention down jacket fabric

InactiveCN107604683AImprove soft performanceGood adhesionSolvent-treatmentPolyurea/polyurethane coatingsPolyesterCold tolerance

The invention discloses a processing technology of drilling-prevention down jacket fabric, and relates to the technical field of fabric treatment. The processing technology of the drilling-preventiondown jacket fabric disclosed by the invention comprises the following steps: (1) fabric selection: selecting cotton-polyester blended fabric with the yarn count of 15 to 25 D and the fineness of 300 to 420 tex; (2) water repellent finish; (3) calendaring drying; (4) preparing a coating adhesive; (5) coating: coating a prepared coating on fabric after calendaring drying by using a floating knife type coating machine, and drying at the temperature of 150 to 160 DEG C for 3 to 8 min. According to the processing technology disclosed by the invention, the drilling prevention effect is improved while little weight of the down jacket fabric is increased, and the cold tolerance and softening property are improved.

Owner:安徽锦翔纺织服饰有限公司

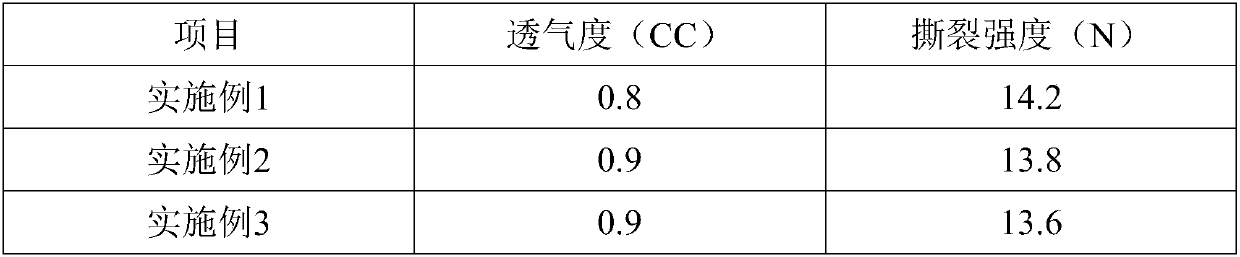

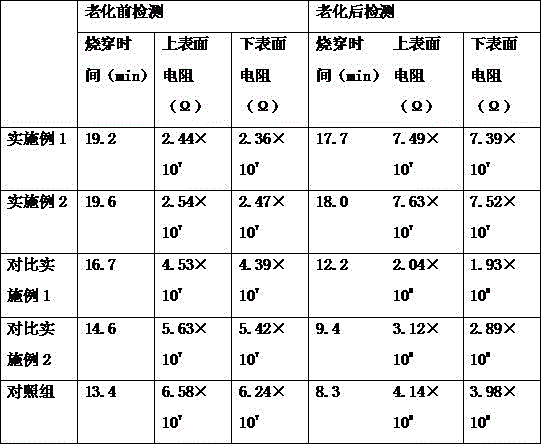

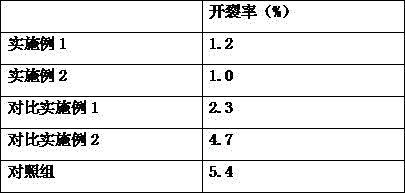

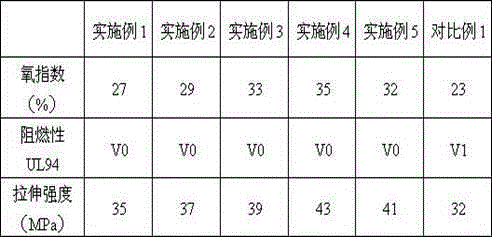

Processing method for temperature-resistant and flame-retardant wood composite fiber decorative plate

ActiveCN107142763AGood heat resistance and flame retardant performanceHigh oxygen indexWood treatment detailsDomestic articlesFiberHigh resistance

The invention discloses a processing method for a temperature-resistant and flame-retardant wood composite fiber decorative plate. The method comprises the steps of (1) processing of wood fibers, (2) mixture preparation and (3) thermal pressing shaping. According to the invention, during preparation of the wood composite fiber decorative plate, raw material ingredients are selected rationally; processing technologies are improved and optimized especially; the finally prepared plate material has high resistance to temperature and flame, and a high oxygen index; performance such as strength and corrosion resistance is greatly improved; and economic benefits and use values are very high.

Owner:北新国际木业有限公司

Water-proof heat-proof inflaming retarding cable sheath material

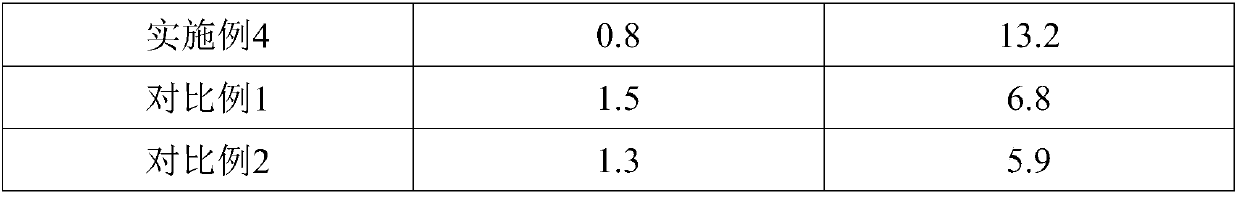

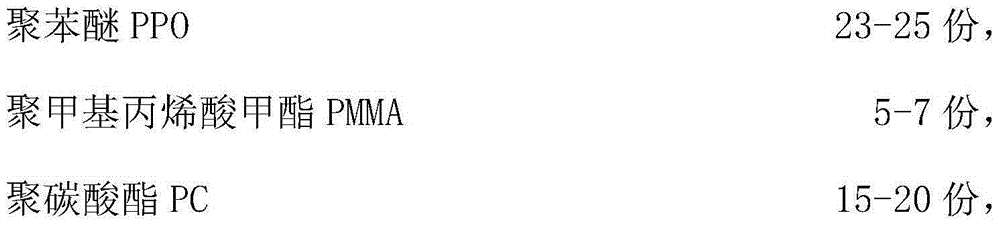

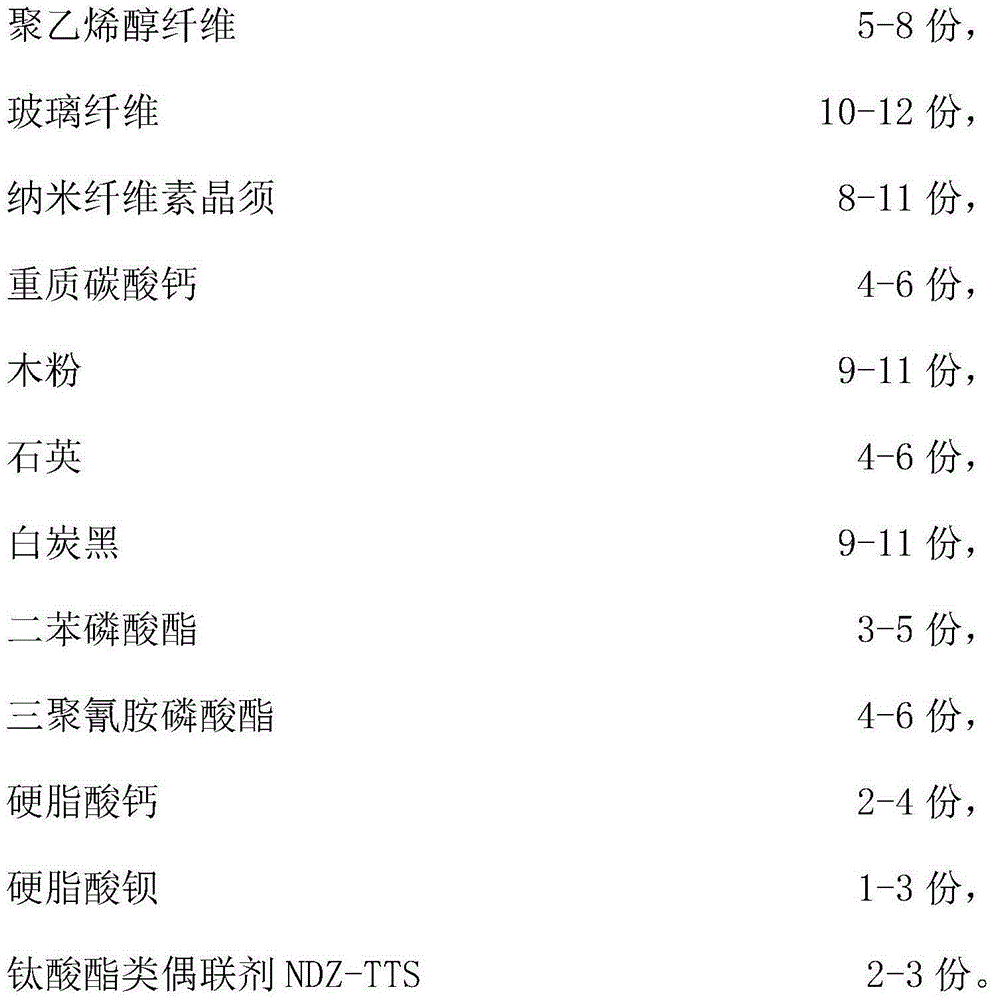

InactiveCN104098886AGood heat resistance and flame retardant performanceGood compatibilityInsulated cablesInsulated conductorsFiberMelamine phosphate

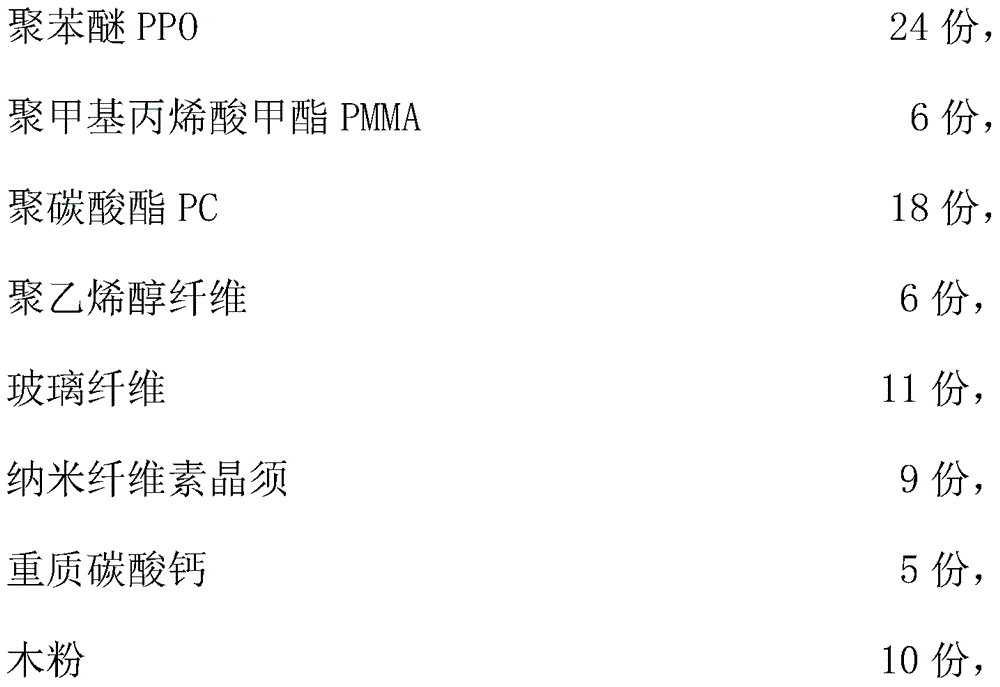

The invention discloses a water-proof heat-proof inflaming retarding cable sheath material which comprises the following raw materials in parts by weight: 23-25 parts of polyphenyl ether PPO, 5-7 parts of polymethyl methacrylate (PMMA), 15-20 parts of polycarbonate (PC), 5-8 parts of polyvinyl alcohol fiber, 10-12 parts of glass fiber, 8-11 parts of nanocellulose whisker, 4-6 parts of ground calcium carbonate, 9-11 parts of wood powder, 4-6 parts of quartz, 9-11 parts of white carbon black, 3-5 parts of diphenyl phosphate ester, 4-6 parts of melamine phosphate ester, 2-4 parts of calcium stearate, 1-3 parts of barium stearate and 2-3 parts of a titanate coupling agent NDZ-TTS. The water-proof heat-proof inflaming retarding cable sheath material has excellent water-proof performance and heatproof inflaming retarding performance, has higher stretch-proof ability and shock strength, and is suitable for underground cable usage environment.

Owner:安徽宁国市高新管业有限公司

High-quality coating solution applied to coated fabrics

InactiveCN106634259AEffect of improving physical and chemical propertiesImprove heat resistanceFireproof paintsAnti-corrosive paintsEpoxyPolymer science

The invention discloses a high-quality coating solution applied to coated fabrics and belongs to the technical field of processing of coated fabrics. The high-quality coating solution is prepared from the following materials: polyvinyl chloride, polytetrafluoroethylene, polyacrylate, epoxy resin, polyimide, functional additive powder, stabilizers, plasticizers, diluents, antioxidants, defoaming agents, propylene glycol methyl ether and methyl ethyl ketone. The prepared coating solution is high in adhesion to the fabric weaving material and has high corrosion resistance, abrasion resistance, temperature resistance, cold resistance, aging resistance, static electricity resistance and impact resistance; the stability in use is effectively improved; the coating solution has a high popularization value.

Owner:安徽惠尔矿用设备有限公司

Hybridized melamine-formaldehyde silicon aerogel modified flame-retardant polypropylene foaming plate and preparation method thereof

InactiveCN106750940APromote environmental protectionImprove the defect of poor affinityPolymer scienceHeat stability

The invention discloses a hybridized melamine-formaldehyde silicon aerogel modified flame-retardant polypropylene foaming plate and a preparation method thereof. The foaming material is good in toughness and better heat stability, and melt strength is improved; hybridized melamine-formaldehyde silicon aerogel added has a unique nano-porous structure and can be absorbed in a resin melt during foaming, melt strength can be further improved, heat-resisting and flame-retardant performances of resin can be effectively improved, good synergistic effect of hybridized aerogel on a flame retardant in the system can be achieved, and use amount of the flame retardant is effectively controlled; the prepared polypropylene foaming plate is good in environment protection property, high in foaming rate, lightweight and heat insulating, hydrophobic and corrosion resisting and economic and durable, and use scope of a traditional polypropylene foaming material is greatly widened.

Owner:阜阳市三郁包装材料有限公司

Preparation method of flame-resistant polypropylene board

InactiveCN109880231AImprove flame retardant performanceImprove heat resistancePolymer scienceHydrolysate

The invention belongs to the field of polypropylene board, and more specifically relates to a preparation method of a flame-resistant polypropylene board. The preparation method comprises following steps: 1, an organosilicon raw material is added into toluene, room temperature stirring is carried out until complete dissolving is realized so as to obtain a toluene solution; 2, distilled water is added into a constant pressure dropping funnel, and is added into the toluene solution dropwise slowly, uniform stirring is carried out, and an obtained product is allowed to stand for 2 to 5h so as toobtain an acidic hydrolysate; 3, ammonia gas is introduced into the acidic hydrolysate until the pH value of the hydrolysate is 7, an alumina silicate catalyst, co-polypropylene powder, and homo-polypropylene powder are added for uniform stirring so as to obtain a suspending liquid; and 4, the suspending liquid is subjected to gradient heating reaction, and is subjected to pressurization and cooling moulding so as to obtain the flame-resistant polypropylene board. The preparation method is capable of solving problems in the prior art that conventional polypropylene boards are poor in toughness, low temperature resistance, aging resistance, and flame resistance, and are high in moulding shrinkage rate; combined modification of organic silicone resin and alumina silicate is capable of improving the entire flame resistance and heat resistance.

Owner:江苏宏佳华新材料科技有限公司

Sound absorption plate and preparation method thereof

The invention discloses a sound absorption plate and a preparation method thereof. The sound absorption plate is prepared from the following raw materials in parts by weight: 30 to 50 parts of gypsum powder, 20 to 30 parts of bamboo carbon fiber, 8 to 15 parts of glass fiber, 1 to 5 parts of attapulgite clay, 5 to 10 parts of blast furnace slag, 1 to 3 parts of magnesium oxide, 0.6 to 2.8 parts of an inorganic adhesive, 0.5 to 1.6 parts of a water repellent and 0.2 to 0.8 part of a flame retardant. The preparation method of the sound absorption plate comprises the steps of purification of the attapulgite clay, preparation of a substrate material, preparation of a molding blank and natural maintenance. The components of the sound absorption plate are safe and environment-friendly, and the sound absorption plate is good in waterproofing and flame retardancy effect and can isolate sound and heat; the intensity and the hardness of a gypsum board are retained.

Owner:合肥慧林建材有限公司

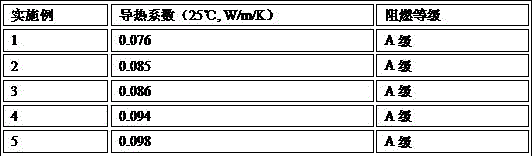

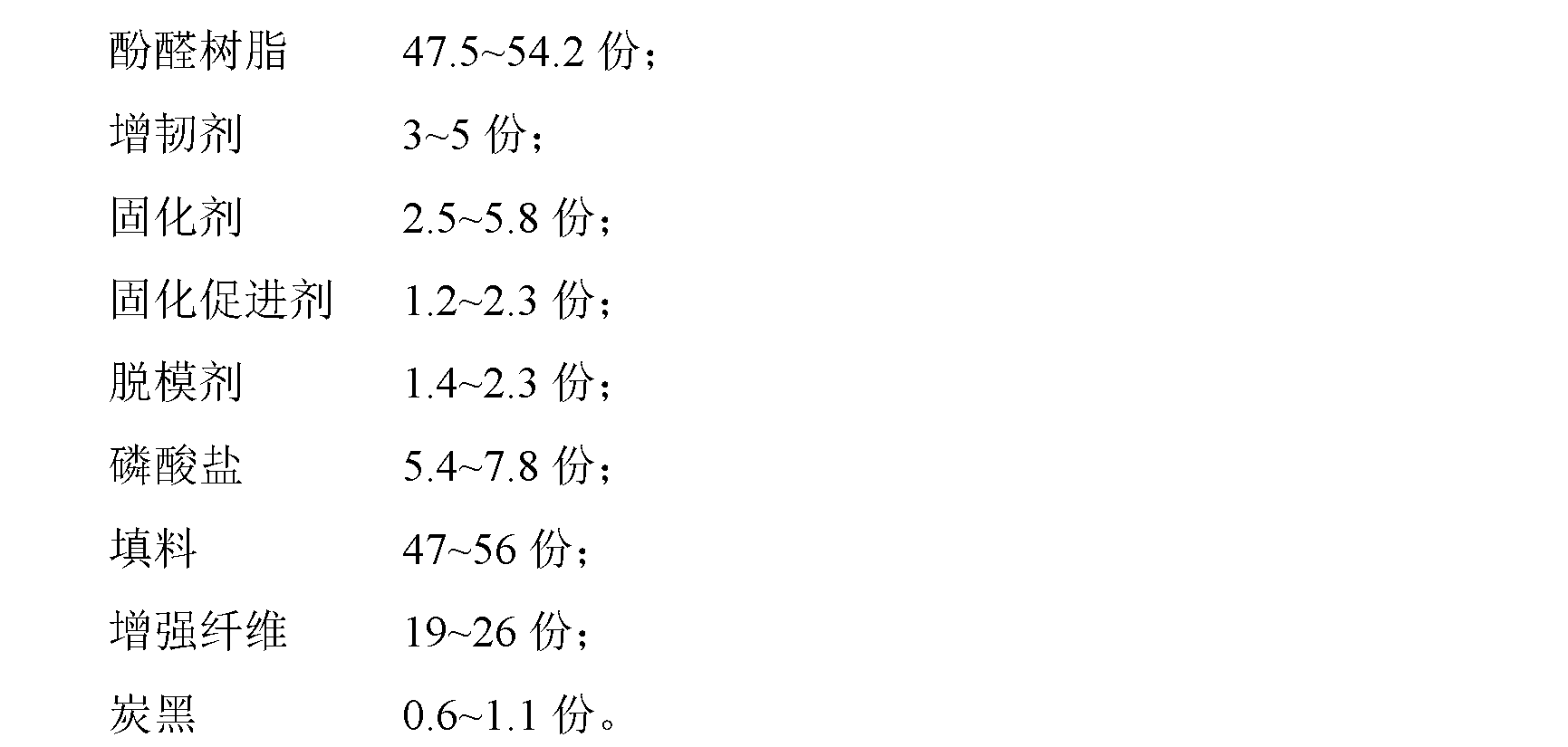

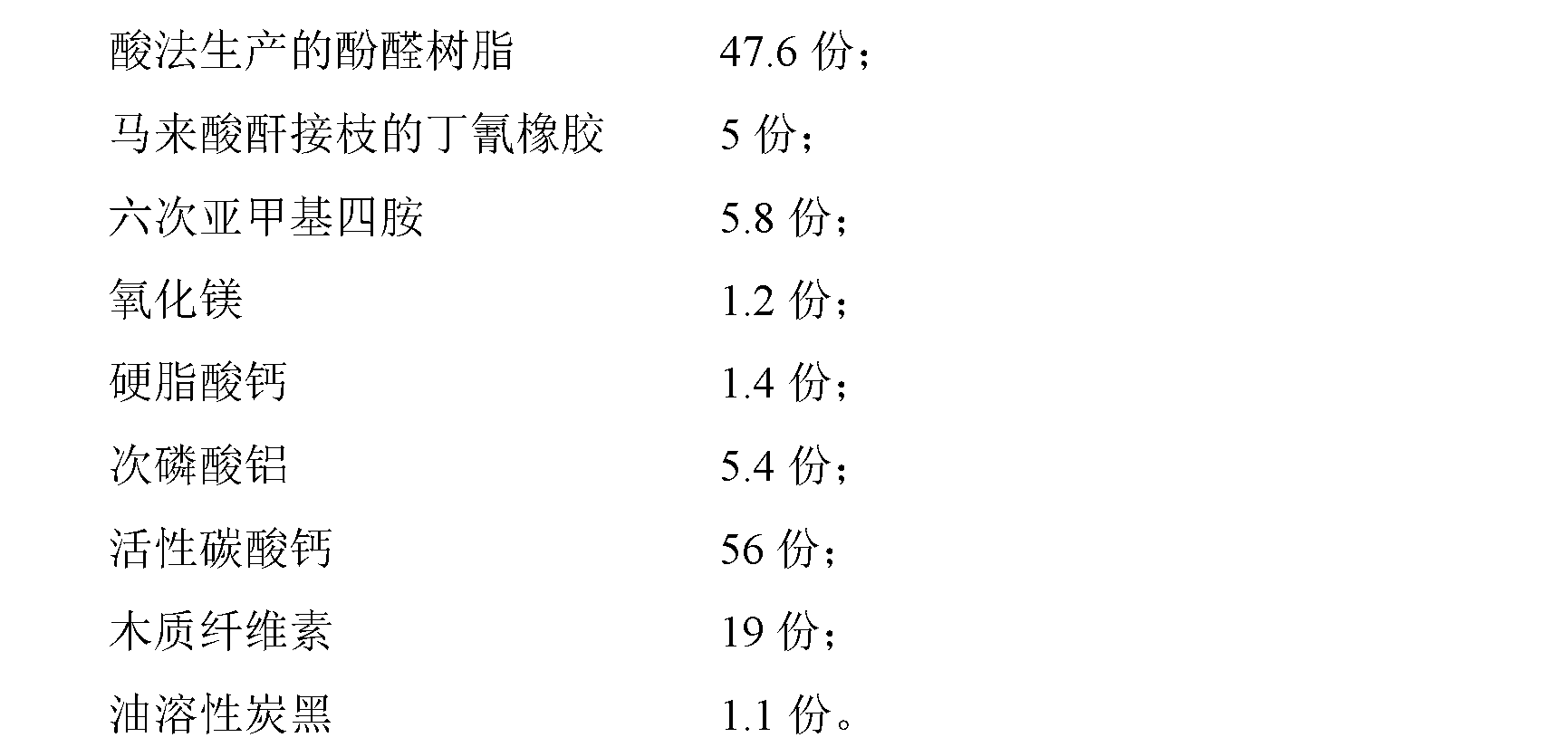

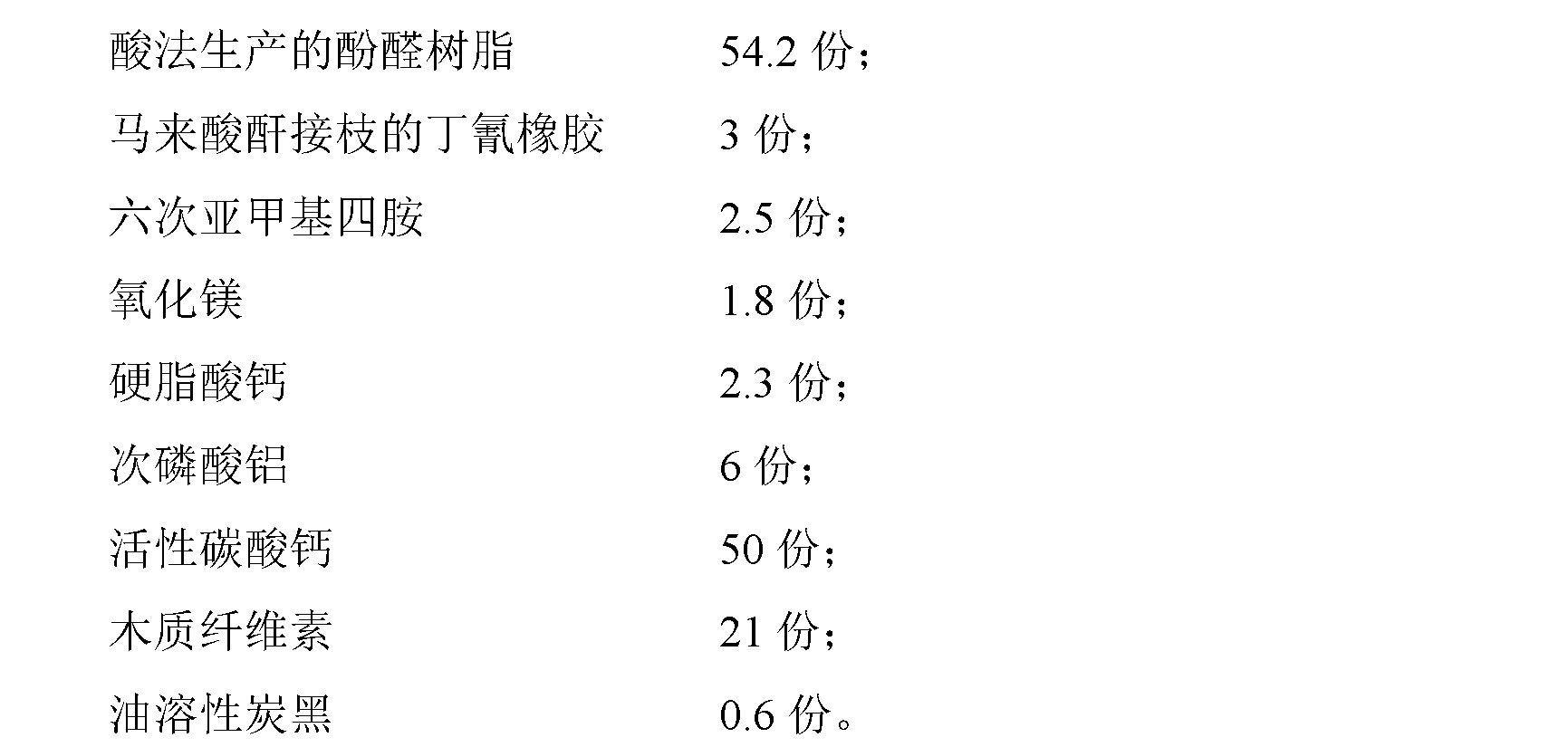

Halogen-free environmentally-friendly phenolic moulding plastic

The invention provides a halogen-free environmentally-friendly phenolic moulding plastic and belongs to the technical field of high-polymer materials. The halogen-free environmentally-friendly phenolic moulding plastic is prepared from the following raw materials in parts by weight: 47.5-54.2 parts of phenolic resin, 3-5 parts of flexibilizer, 2.5-5.8 parts of curing agent, 1.2-2.3 parts of curing accelerator, 1.4-2.3 parts of demoulding agent, 5.4-7.8 parts of phosphate, 47-56 parts of filler, 19-26 parts of reinforced fibers, and 0.6-1.1 parts of carbon black. The halogen-free environmentally-friendly phenolic moulding plastic has the characteristics of being good in thermal resistance and flame retardance, high in strength, and environmentally-friendly, and can achieve the bending strength of 90-110MPa, the thermal deformation temperature of 215-228 DEG C, the flame retardance property of UL-94-V-0 level (3mm), and the gap impact strength of 3-4kj / m<2>.

Owner:CHANGSHU YAMEI MODEL CLOTHES RACK

Safe, stable and high-performance wire enamel and preparation method thereof

InactiveCN107286841AImprove adhesionImprove insulation performanceFireproof paintsPolyurea/polyurethane coatingsLiquid viscosityLacquer

The invention discloses safe, stable and high-performance wire enamel. The wire enamel is prepared from the following raw materials in parts by weight: 25-35 parts of a mixed high molecular compound, 15-25 parts of composite resin, 8-14 parts of an insulating filler, 7-11 parts of a fire-retardant additive, 5-7 parts of a nano additive, 4-6 parts of a processing agent, 30-40 parts of a compound solvent, 3-5 parts of a coupling agent, 1-2 parts of m-cresol and p-cresol, 1-3 parts of epoxy acrylate, 1-2 parts of triethyl citrate, 1-2 parts of propyl gallate, 4-6 parts of glycerin and 2-4 parts of paraffin. The wire enamel has a relatively low water absorption rate and excellent mechanical and electrical properties, the temperature of the knee of a curve of medium loss is relatively high, the wire enamel can be directly used for coating an enamelled wire, the wire enamel is superior in the indexes of intermiscibility, precipitation and lacquer liquid viscosity, meanwhile, the costs of raw materials are relatively low, the preparation process is concise, the application method is quick and convenient, and the wire enamel has a relatively high practical value and an excellent application prospect.

Owner:HEFEI ANLI ELECTRIC POWER ENG CO LTD

Heat-resistant flame-retardant waterproof paint and preparation method thereof

InactiveCN107163760AEasy to makeStrong adhesionFireproof paintsPolyester coatingsHydroxyethyl cellulosePollution

The invention discloses a heat-resistant flame-retardant waterproof paint, and belongs to the technical field of paints. The heat-resistant flame-retardant waterproof paint is prepared from the following raw materials in parts by weight: 38 to 44 parts of a silicone-acrylate emulsion, 17 to 21 parts of a chloroethylene-vinyl chloride copolymer, 15 to 19 parts of quartz powder, 8 to 10 parts of poly-2,6-naphthalene dicarboxylate, 9 to 11 parts of organosilicone hydrophobic powder, 8 to 10 parts of Portland cement, 6 to 8 parts of aluminum oxide, 6 to 8 parts of epoxidized methyl acetorieinoleate, 1 to 5 parts of Texanol, 2 to 4 parts of sodium hexametaphosphate, 1 to 2 parts of hydroxyethyl cellulose, 1 to 3 parts of a defoamer, 0.5 to 1.5 parts of a water reducing agent, 0.5 to 1 part of an early strength agent and an appropriate amount of water. The invention also discloses a preparation method of the heat-resistant flame-retardant waterproof paint. The heat-resistant flame-retardant waterproof paint is high in adhesive ability, little in environmental protection pollution, good in waterproof effect and long in service life, and has excellent heat-resistant and flame-retardant capacities.

Owner:HEFEI OUSHIJIA ELECTRICAL & MECHANICAL EQUIP CO LTD

Environment-friendly flame-retardant type wood-plastic composite and preparation method thereof

InactiveCN105111764AGood heat resistance and flame retardant performanceSuitable for general promotionCalcium silicateWater based

The invention discloses an environment-friendly flame-retardant type wood-plastic composite. The composite is prepared from, by weight, 80-200 parts of wood powder, 20-40 parts of polystyrene, 20-50 parts of polyvinyl chloride, 10-30 parts of calcium silicate, 8-25 parts of aluminum oxide, 5-20 parts of magnesium ammonium phosphate, 5-18 parts of water base sepiolite, 7-20 parts of acrylic resin, 5-16 parts of alkenyl succinic acid copper, 2-12 parts of silane coupling agents, 3-15 parts of cross-linking agents and 4-12 parts of solvent. The invention further discloses a preparation method of the environment-friendly flame-retardant type wood-plastic composite. The wood-plastic composite prepared through the method has good heat resistance and flame resistance, meanwhile, the tensile strength of the prepared wood-plastic material also meets basic application requirements, in addition, no halogenous fire retardant is used in the preparation process, the eco-environment protection is achieved, and the composite is fairly suitable for being used and popularized generally.

Owner:SUZHOU FAST INFORMATION TECH CO LTD

Heat-resistant and flame-resistant PVC (Polyvinyl Chloride) injection molding material

InactiveCN108707297AExcellent injection molding performanceGood heat resistance and flame retardant performancePolyvinyl alcoholPlasticizer

The invention relates to the field of PVC (Polyvinyl Chloride) materials, in particular to a heat-resistant and flame-resistant PVC injection molding material. The heat-resistant and flame-resistant PVC injection molding material is prepared from the following raw materials in parts by weight: 100 to 120 parts of PVC resin, 25 to 35 parts of epoxy modified organosilicone resin, 15 to 40 parts of alundum powder, 15 to 35 parts of composite filler, 10 to 15 parts of plasticizer, 7 to 12 parts of lubricant, 5 to 12 parts of thermal stabilizer, 2 to 6 parts of flow modifier and 15 to 22 parts of oxidized polyvinyl alcohol.

Owner:ZHEJIANG WELLSCOM PLASTIC CO LTD

Stable weather-resistant high-insulating-property enamel wire coating and preparation method thereof

InactiveCN108587290AImprove securityImprove reliabilityInsulatorsPolyester coatingsLiquid viscosityOrganic solvent

The invention discloses a stable weather-resistant high-insulating-property enamel wire coating and a preparation method thereof. The coating includes, by weight, 40-50 parts of compound resin, 8-10 parts of a nano-modifying additive, 4-6 parts of organic glass powder, 3-5 parts of hydroxyapatite nano-particles, 9-13 parts of a processing aid, 6-8 parts of a silane coupling agent, 28-34 parts of organic solvent, 7-11 parts of a flame retardant, 4-6 parts of an ester additive, and 9-11 parts of auxiliary filler. The enamel wire coating is quick to dry, has great leveling property, is great in high temperature resistance, is acid and alkali resistant, has stable performance, is low in water absorption rate, and has excellent mechanical and insulation performances, is high in inflection pointtemperature on a dielectric loss curve, has excellent indices of dissolvability, precipitation and liquid viscosity, is low in raw material cost, has definite preparation process and convenient use method, and has great practical value and application prospect.

Owner:HEFEI SHANGQIANG ELECTRIC TECH CO LTD

Flame-retardant anti-corrosion acrylic coating

InactiveCN104356803AEvenly dispersedSuppress generationFireproof paintsConjugated diene hydrocarbon coatingsAcrylic resinMelamine phosphate

The invention discloses a flame-retardant anti-corrosion acrylic coating. The flame-retardant anti-corrosion acrylic coating is prepared from the following raw materials in parts by weight: 60-70 parts of water-soluble acrylic resin, 12-15 parts of water-soluble phenolic resin, 8-11 parts of butadiene styrene resin, 3-4 parts of laurate dihydroxyethylamide, 2.8-3.1 parts of hydroxypropyl methyl cellulose, 15-18 parts of sepiolite, 5-8 parts of talc powder, 1-2 parts of montmorillonite powder, 2-3 parts of melamine phosphate, 14-17 parts of magnesium hydroxide nanoparticles, 3-4 parts of tricresyl phosphate, 10-15 parts of methylated amino resin, 2-3 parts of manganese abietate, 0.4-0.6 part of an epoxy-silane coupling agent, 15-25 parts of a pigment, 2.1-2.4 parts of a flexibilizer, 0.5-0.8 part of a defoamer, 0.7-1 part of a smoothing agent, 0.4-0.5 part of a mildew preventive, and 50-55 parts of a solvent. The flame-retardant anti-corrosion acrylic coating disclosed by the invention is excellent in flame-retardant and heat-resisting properties, and good in anti-corrosion property.

Owner:ANHUI JINDUN PAINT

Heat-resisting flame-retardant plastic film and preparation method thereof

InactiveCN107177103AThe ingredients are safe and non-toxicThe preparation method is simple and controllablePolymer sciencePolyvinyl alcohol

The invention discloses a heat-resisting flame-retardant plastic film and a preparation method thereof. The plastic film comprises the following raw materials in parts by weight: 60-80 parts of polypropylene resin, 10-20 parts of polyvinyl alcohol, 3-8 parts of starch, 8-15 parts of nanometer silicon dioxide, 1-5 parts of bis(tert-butyldioxyisopropyl) benzene, 5-10 parts of polycarbonate, 1-5 parts of sodium carboxymethylcellulose, 0.2-0.6 part of an inorganic flame retardant, 3-6 parts of a plasticizer, 1-5 parts of a styrene-butadiene thermoplastic elastomer and 0.06-0.28 part of a thermal stabilizer. The preparation method comprises the steps of modifying polypropylene resin, mixing materials and reacting. The components of the plastic film disclosed by the invention are safe and nontoxic; the preparation method is simple and controllable; the plastic film has excellent heat resistance, flame resistance and weather fastness; and the plastic is light in weight and has excellent mechanical properties, such as, chemical substance resistance, impact strength and tearing strength.

Owner:HEFEI WANZHIJING DOORS & WINDOWS CO LTD

Flame-retardation sealing ring

InactiveCN107383711AImprove flame retardant performanceImprove sealingHeat resistanceCalcium Palmitate

The invention discloses a flame-retardation sealing ring. The flame-retardation sealing ring comprises the following raw materials in parts by weight: 25-32 parts of fluorubber, 18-27 parts of chloroprene rubber, 13-18 parts of phenolic resin, 17-28 parts of m-p-cresol, 2-5 parts of a fire retardant, 3-5 parts of an activator, 3-7 parts of expandable graphite, 2-5 parts of a charing agent, 3-4 parts of calcium palmitate, 7-13 parts of an auxiliary agent, and 10-17 parts of a filling material. The flame-retardation sealing ring has the advantages that the excellent sealing is kept, the flame retardation performance of the sealing ring is obviously increased, the flame-retardation sealing ring has good heat resistance and flame retardation effects in operating electrical equipment, fire hazard due to overtemperature is avoided, the processing cost is low, and a processing method is simple.

Owner:JIANGSU FEILER ELECTRIC CO LTD

Silver-ion waterborne polyurethane coating adhesive with deodorant and antibacterial functions

InactiveCN106833361AStrong adhesionHigh hardnessFireproof paintsAntifouling/underwater paintsWeather resistanceChemistry

Owner:广州优瑞塑料有限公司

Dodecafluoroheptyl-propyl polyhedral oligomeric silsesquioxane and preparation method thereof

InactiveCN101875667BHigh densityLower surface energySilicon organic compoundsPolymer modifiedOrganic solvent

The invention provides a preparation method of dodecafluoroheptyl-propyl polyhedral oligomeric silsesquioxane, which comprises the following steps: dripping each 1mol of dodecafluoroheptyl-propyl-trimethoxylsilane into 250-10000ml of organic solvent under the condition of 0-40 DEG C, carrying out hydrolysis condensation reaction under the action of acid catalysis, carrying out the reaction for a certain period of time, and carrying out concentration, filtration, drying and other steps for preparing dodecafluoroheptyl-propyl polyhedral oligomeric silsesquioxane (dodecafluoroheptyl-propyl POSS)crystals. The invention further provides the dodecafluoroheptyl-propyl polyhedral oligomeric silsesquioxane. The method has simple and easy process, low cost, high yield and high product purity, and the prepared dodecafluoroheptyl-propyl polyhedral oligomeric silsesquioxane product has excellent hydro-oleophobic performances, heat resistance, flame retardance and low dielectric constant performance, and can be widely applied in the fields of polymer modification, hydro-oleophobic interface materials, flame retardants, low dielectric constant materials, building coatings, space materials, medical materials, light-emitting materials, liquid crystal materials and the like.

Owner:HOHAI UNIV

Silicon rubber composite cable material and preparation method thereof

InactiveCN108659538AImprove heat resistanceImprove aging resistancePlastic/resin/waxes insulatorsCarbon fibersCarbon nanotube

The invention discloses a silicon rubber composite cable material and a preparation method thereof. The cable material comprises silicon rubber, ethylene propylene rubber, butadiene rubber, polyarylacetylene resin, stearic acid, zinc oxide, sulfur, 2, 4-dichlorobenzoyl peroxide, coupling agents, graphite, accelerants, anti-aging agents, modified fire retardants, 1, 4-cyclohexanedimethanol diglycidyl ether, carbon fibers, white mica and melamine polyphosphate. The modified fire retardants are prepared according to the process including the steps: gelatinizing starch; adding the starch into water; adding nano-sized magnesium oxide, zirconium oxide, iron oxide and carbon nano-tubes; performing ultrasonic treatment, drying, carbonization, crushing and sieving. The preparation method of the silicon rubber composite cable material is simple in process, and the prepared silicon rubber composite cable material is good in heat resistance and aging resistance and excellent in fire resistance.

Owner:李侠

Preparation method of heat-resistant high-strength PVC cable material

InactiveCN109054239AExcellent heat resistance and flame retardant performanceExcellent flame retardant effectPlastic/resin/waxes insulatorsBuilding insulationsPlasticizerChlorinated polyvinyl chloride

The invention relates to the field of PVC materials, in particular to a preparation method of a heat-resistant high-strength PVC cable material. The preparation method comprises the following preparation steps of (1) material preparation, wherein 100 parts by weight of PVC resin, 85-110 parts by weight of chlorinated polyvinyl chloride, 65-95 parts by weight of silicon compound filler, 10-22 partsby weight of surface modifier, 70-105 parts by weight of plasticizer, 7-12 parts by weight of lubricant, 1-3.5 parts by weight of heat stabilizer, 6-10 parts by weight of flow modifier, 8-17 parts byweight of film-forming agent and 1-3 parts by weight of spray inhibitor are weighed separately; (2) mixing, wherein the components weighed in the step (1) are evenly stirred after being mixed, a stirring temperature is 45-60 DEG C, a stirring rate is 60-80 r / min, stirring time is 5-10 h, and a mixture is obtained after even mixing is conducted; (3) pelleting, wherein the mixture obtained in the step (2) is subjected to pelleting to obtain the heat-resistant high-strength PVC cable material.

Owner:ZHEJIANG WELLSCOM PLASTIC CO LTD

Water-based fireproof coating and preparation method thereof

The invention belongs to the technical field of coating processing, and particularly relates to a water-based fireproof coating which comprises the following substances in parts by weight: 25-30 partsof vinyl acetate-acrylic emulsion, 6-10 parts of organic silicon resin, 4-7 parts of alumina fiber, 2-4 parts of thickener, 0.5-1 part of defoamer, 1-3 parts of silane coupling agent, 3-5 parts of ammonium polyphosphate, 2-5 parts of potassium tripolyphosphate, 1-4 parts of paraformaldehyde, 7-10 parts of compound modified filler and 80-85 parts of deionized water. The coating provided by the invention has very strong temperature resistance and fire resistance, and is high in overall mechanical strength and good in use stability. In addition, the preparation method of the coating is simple and easy to commercialize, popularize and apply.

Owner:田超群

Nano double-component cane paint and preparation method thereof

InactiveCN106243982AApply evenlyStir wellFireproof paintsPolyurea/polyurethane coatingsDecompositionOxygen

The invention discloses a nano double-component cane paint. The paint consists of a component A and a component B in a mass ratio of 1.5-2:1. The modified siloxane disclosed by the invention is a nano-particle containing an Si-O-Si skeletal structure, can prevent release of volatile matters during further oxidation and decomposition of organics in a polymer, has very good thermal stability, can be functionalized easily at the same time, can be well introduced into an organic matrix to improve the performance of the polymer, will generate SiO2 coating on the surface under an oxidation condition, and can enable a material to be isolated from oxygen and heat and result in that a flame-retardant effect is increased.

Owner:FUNAN NATURE ARTS & CRAFTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com