Sound absorption plate and preparation method thereof

The technology of sound-absorbing board and attapulgite clay, which is applied in the field of decorative materials, can solve the problems of non-compliance with green environmental protection, etc., and achieve the effects of improving uniformity and stability of quality, improving heat-resistance and flame-retardant properties, and excellent temperature-resistance and flame-retardant properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

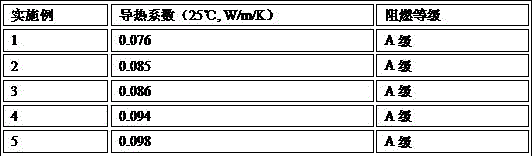

Examples

Embodiment 1

[0023] A sound-absorbing board, comprising the following raw materials in parts by weight: 32 parts of gypsum powder, 26 parts of bamboo charcoal fiber, 8 parts of glass fiber, 2 parts of attapulgite clay, 6 parts of blast furnace slag, 2 parts of magnesium oxide, inorganic adhesive silicic acid 0.8 parts of sodium, 0.8 parts of water-repellent SHP-50, and 0.4 parts of flame retardant aluminum tripolyphosphate.

[0024] The preparation method of the above-mentioned sound-absorbing panel comprises the following steps:

[0025] (1) Purification of attapulgite clay: Weigh attapulgite clay, put in 10-20 times the mass of water, centrifuge at 1200-1400 r / min for 3-5 minutes, filter, and dry the filter cake until use;

[0026] (2) Preparation of base material: Mix bamboo charcoal fiber and glass fiber according to parts by weight, soak in hydrochloric acid solution with 3%-8% mass concentration for 1-2 hours, wash with purified water until neutral, add gypsum powder, The blast fur...

Embodiment 2

[0030] A sound-absorbing panel, comprising the following raw materials in parts by weight: 38 parts of gypsum powder, 25 parts of bamboo charcoal fiber, 12 parts of glass fiber, 3 parts of attapulgite clay, 8 parts of blast furnace slag, 2 parts of magnesium oxide, inorganic adhesive copper oxide - 1.2 parts of phosphoric acid glue, 0.5 parts of water repellent FN80, 0.5 parts of flame retardant tribromophenol.

[0031] The preparation method of the above-mentioned sound-absorbing panel comprises the following steps:

[0032] (1) Purification of attapulgite clay: Weigh attapulgite clay, put in 10-20 times the mass of water, centrifuge at 1200-1400 r / min for 3-5 minutes, filter, and dry the filter cake until use;

[0033] (2) Preparation of base material: Mix bamboo charcoal fiber and glass fiber according to parts by weight, soak in hydrochloric acid solution with 3%-8% mass concentration for 1-2 hours, wash with purified water until neutral, add gypsum powder, The blast fur...

Embodiment 3

[0037] A sound-absorbing board, comprising the following raw materials in parts by weight: 42 parts of gypsum powder, 20 parts of bamboo charcoal fiber, 8 parts of glass fiber, 5 parts of attapulgite clay, 9 parts of blast furnace slag, 1 part of magnesium oxide, inorganic adhesive silicic acid 1.8 parts of sodium, 1.5 parts of water repellent P750, 0.3 parts of flame retardant dimethyl methyl phosphate.

[0038] The preparation method of the above-mentioned sound-absorbing panel comprises the following steps:

[0039] (1) Purification of attapulgite clay: Weigh attapulgite clay, put in 10-20 times the mass of water, centrifuge at 1200-1400 r / min for 3-5 minutes, filter, and dry the filter cake until use;

[0040] (2) Preparation of base material: Mix bamboo charcoal fiber and glass fiber according to parts by weight, soak in hydrochloric acid solution with 3%-8% mass concentration for 1-2 hours, wash with purified water until neutral, add gypsum powder, The blast furnace sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com