Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Fully aggregated" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method and application of water-soluble fluorine-containing acrylic resin

ActiveCN102617783AImprove heat resistanceGood chemical resistanceCoatingsPolymer scienceFunctional monomer

The invention relates to a preparation method and an application of water-soluble fluorine-containing acrylic resin. The water-soluble fluorine-containing acrylic resin is obtained by copolymerizing an acrylic monomer, a fluorine-containing monomer and a functional monomer in a free radical manner; the use amounts of the reacted monomers are as follows in parts by weight: 15-25 parts of methyl methacrylate, 5-15 parts of butyl acrylate, 10-20 parts of fluorine-containing acrylic monomer, 3-5 parts of methacrylic acid, 3-5 parts of hydroxyethyl acrylate, 0.4-0.8 part of a chain transfer agent, 0.3-0.7 part of an initiator, 4-12 parts of amines neutralizing agent and 50 parts of an organic solvent. The resin is matched with aqueous amino resin and is diluted by water before being used; and the water-soluble fluorine-containing acrylic resin is mainly applied to coating a building metal sectional material and a large part of volatile matters is water when the resin is used, so that the water-soluble fluorine-containing acrylic resin is an environment-friendly product.

Owner:GUANGDONG YINYANG ENVIRONMENT FRIENDLY NEW MATERIALS CO LTD

PVC (polyvinyl chloride) foamed artificial leather and preparation method thereof

The invention discloses PVC (polyvinyl chloride) foamed artificial leather and a preparation method thereof. The PVC foamed artificial leather comprises a fabric base material, a foaming layer and a surface layer which are attached from inside to outside sequentially, wherein the foaming layer comprises components in parts by weight as follows: 95-105 parts of PVC resin, 75-85 parts of filling powder, 75-85 parts of a plasticizer, 3.5-4.0 parts of a stabilizer, 4.5-5.5 parts of a foaming agent and 9.5-10.5 parts of masterbatch; the surface layer comprises components in parts by weight as follows: 65-75 parts of PVC resin, 6-8 parts of filling powder, 46-52 parts of a plasticizer, 1.5-3 parts of a stabilizer and 4.5-5.5 parts of masterbatch. The preparation method comprises steps as follows: (1), blending; (2), mixing, open milling and filtering; (3), calendering attachment; (4), cooling; (5), foaming; (6), embossing, cooling and rolling-up to obtain a finished PVC foamed artificial leather product. The artificial leather prepared with the method feels good, and is good in texture, high in breathability and good in wear resistance.

Owner:DONGTAI FUAN SYNTHETIC MATERIAL CO LTD

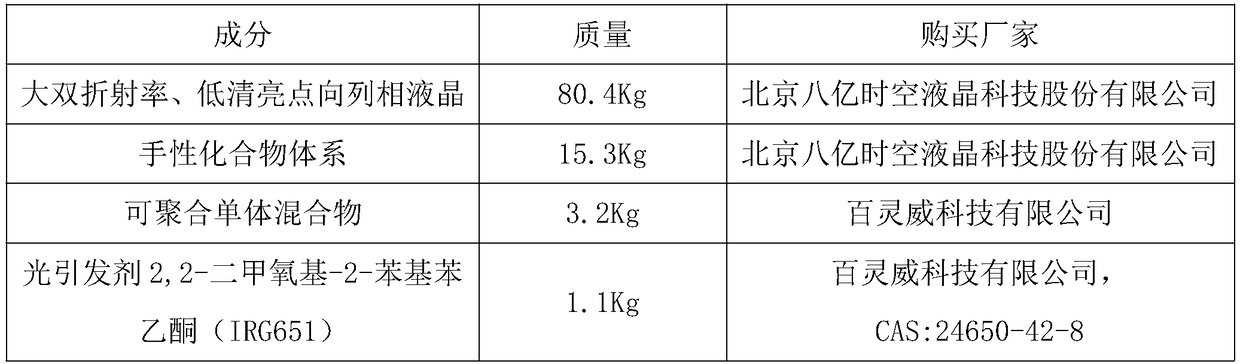

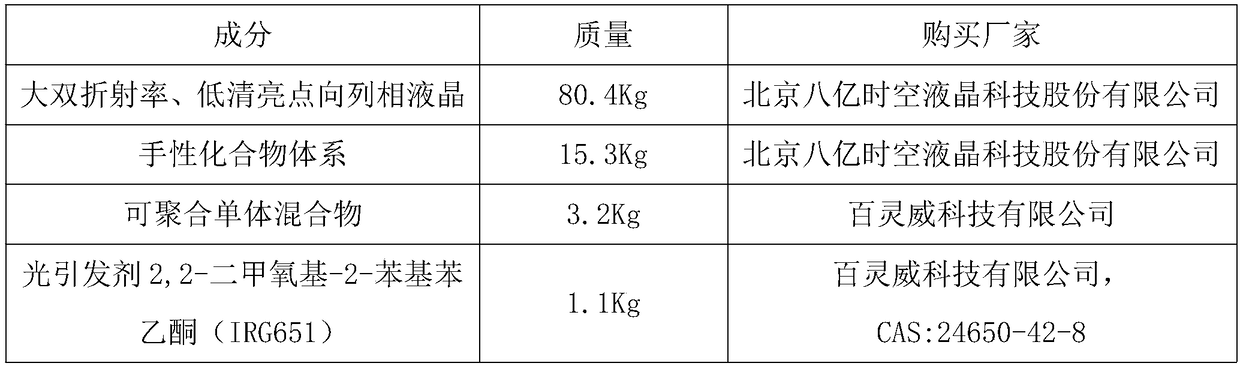

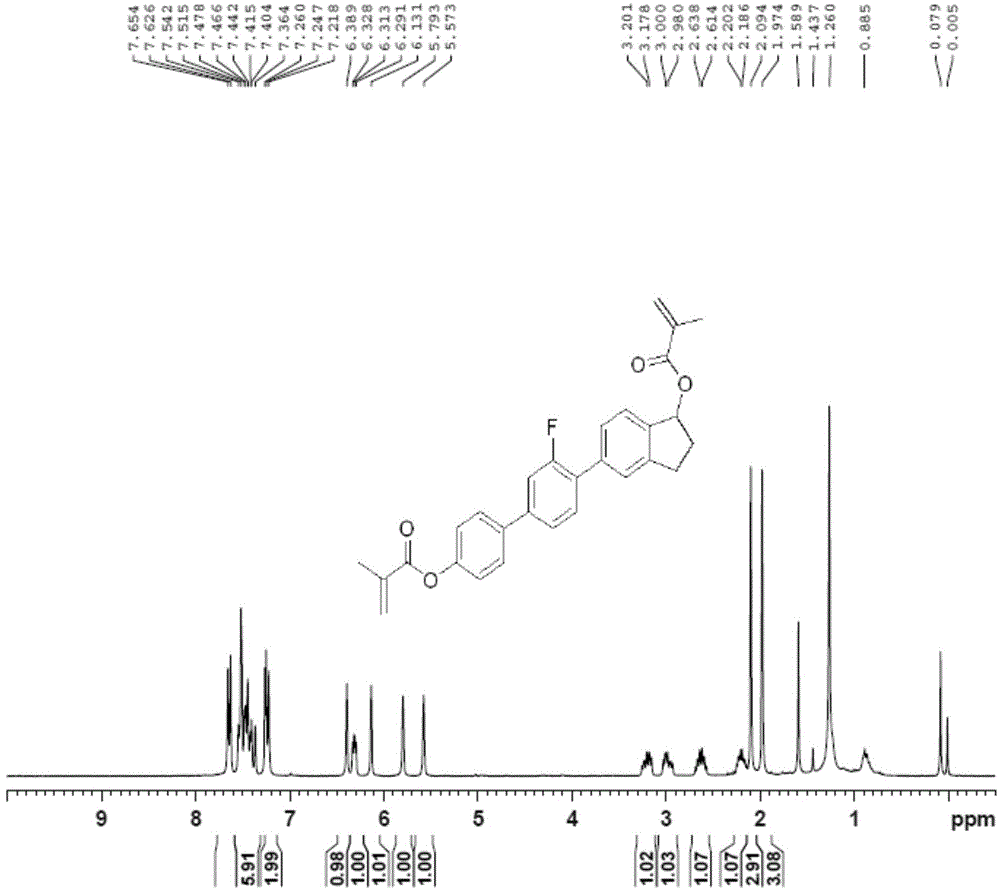

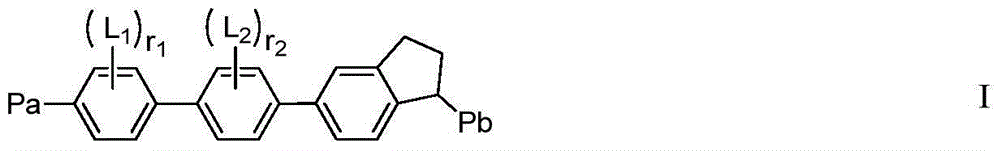

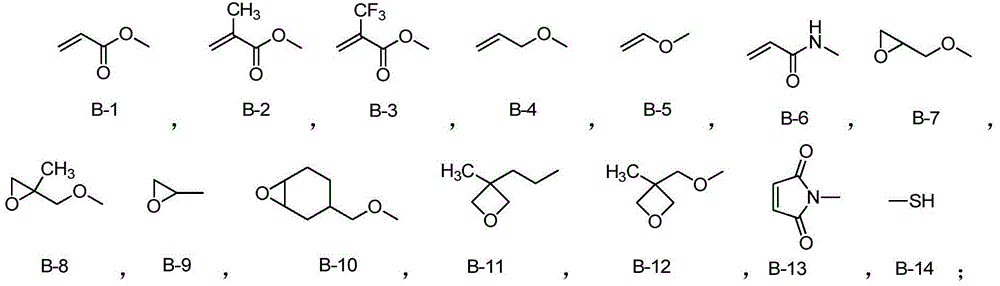

Polymerizable compound and its application in optical anisotropic body and liquid crystal display element

ActiveCN104557545AFully aggregatedImprove solubilityLiquid crystal compositionsOrganic chemistryCrystallographySolubility

The invention relates to a polymerizable compound with general formula I, also provides a polymerizable liquid crystal composition containing the polymerizable compound and a liquid crystal display element containing the polymerizable compound, and especially provides a liquid crystal display element used for PS or PSA (polymer stabilized or polymer stably-aligned) liquid crystal displays. The polymerizable liquid crystal compound has the advantages of good solubility, good orientation effect, fast polymerization rate, complete polymerization and low residue, so the bad display problem can be greatly improved.

Owner:JIANGSU HECHENG DISPLAY TECHCO

Polymerization method of polyvinyl pyrrolidone

A polymerization process of polyvinylpyrrolidone comprises the following steps: (1) selecting 200 parts of a solvent, 100 parts of a NVP raw material and 5-10 parts of an initiator by weight; and (2) adding the solvent once into a polymerization kettle, starting an agitator, proportionally adding the NVP raw material and the initiator to the polymerization kettle for a plurality of times, and controlling reaction temperature at 50-95 DEG C and total reaction time at 7-10h. Polymer products produced by the process (comprising PVPK-12, PVPK-25, PVPK-30, PVPK-60 and PVPK-90) eliminate presence of jellylike crosslinkers, have clear color and no odor and improved yield (higher than 10%) without large-scale investment, and fully utilize the existing equipment in industrial production.

Owner:BOAI NKY PHARMA LTD

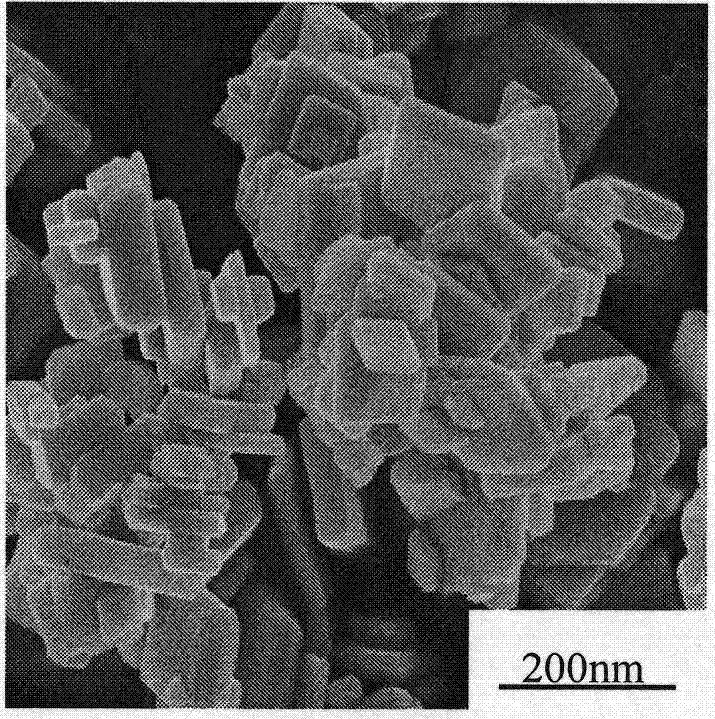

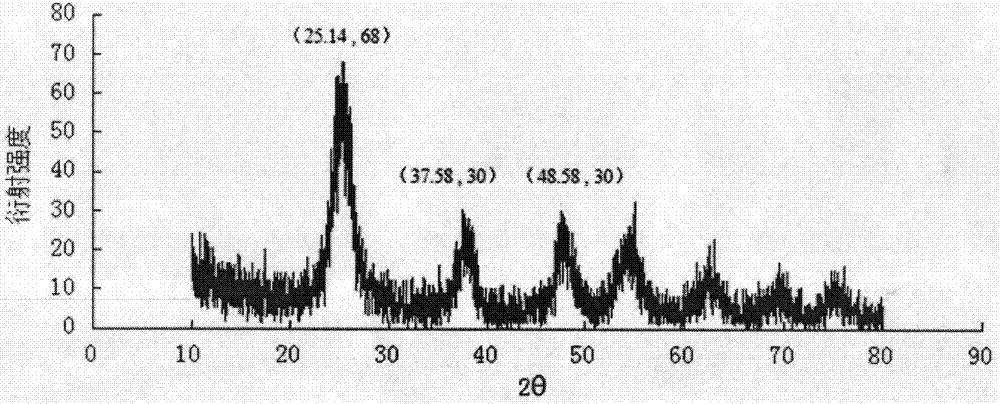

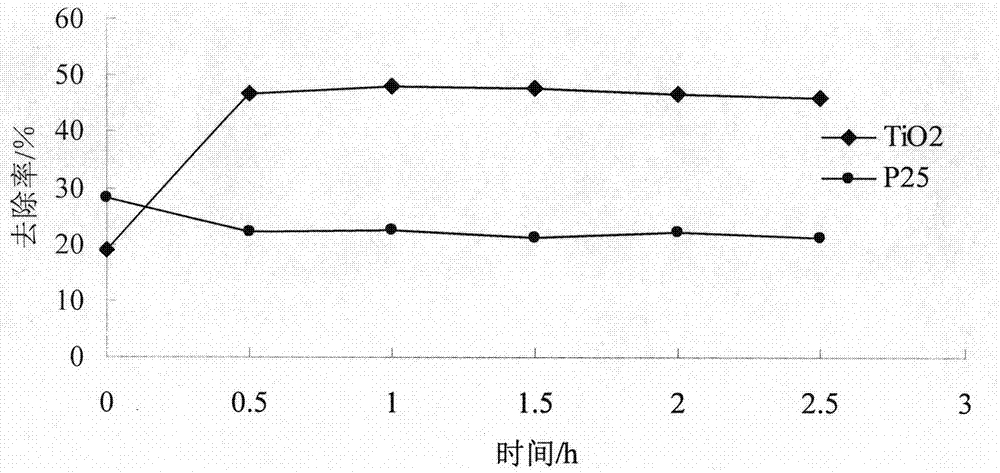

Normal-temperature preparation method of {001} surface anatase TiO2 monocrystals

InactiveCN104275170APromote hydrolysisInhibition of polymerizationPhysical/chemical process catalystsTitanium dioxideSingle crystalPhotocatalytic degradation

The invention discloses a normal-temperature preparation method of {001} surface anatase TiO2 monocrystals. The normal-temperature preparation method is implemented by adopting the following technical scheme: dropping a mixed solution of absolute ethyl alcohol and butyl titanate into a mixed solution of absolute ethyl alcohol, deionized water and HF to obtain TiO2 sol, aging at the room temperature for 24 hours so as to obtain aged TiO2 gel, performing centrifugal settling on the aged TiO2 gel, washing the TiO2 gel by distilled water and absolute ethyl alcohol for three times, drying and grinding to obtain the anatase TiO2 monocrystal with an exposed {001} surface. The preparation method is basically implemented at the room temperature; the process is simple; the reaction is mild and the method is easy to control; a prepared catalyst is relatively high in catalysis activity and can be used for performing photocatalytic degradation on volatile organic matters and degradation-resistant organic matters.

Owner:XIAN UNIV OF SCI & TECH

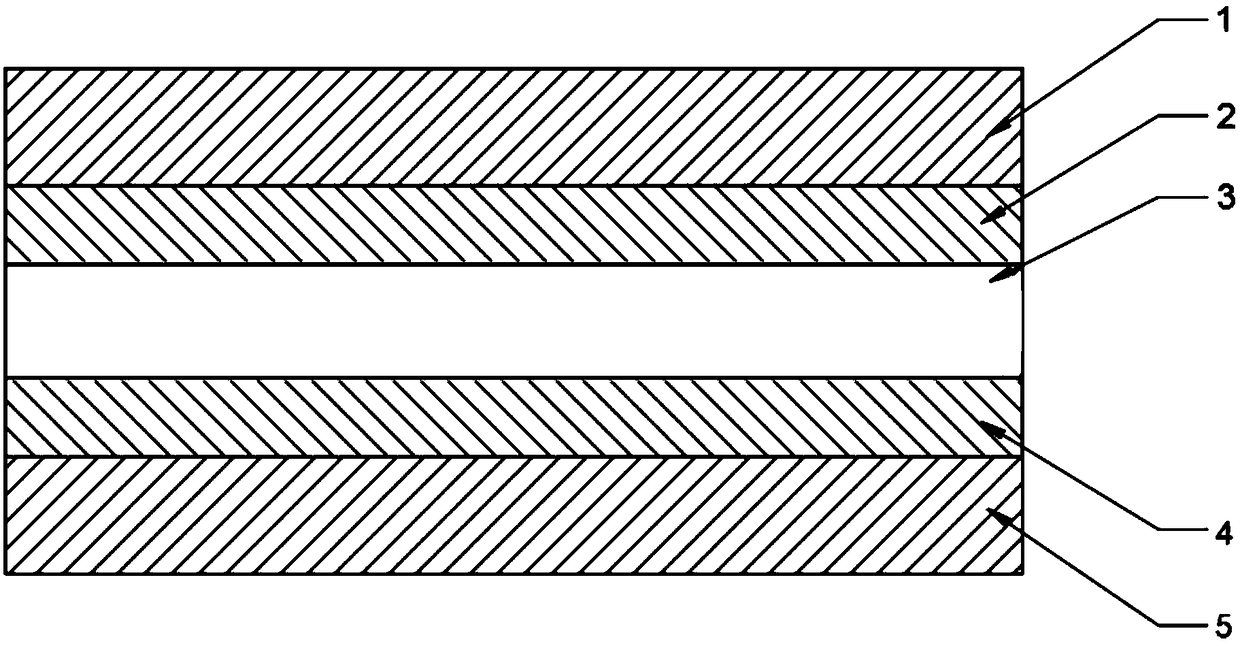

Automobile smart glass and manufacture method thereof

The invention provides automobile smart glass and a manufacture method thereof. The manufacture method comprises steps of preparing a conductive layer, wherein a transparent organic film and an introduced carbon source are prepared into a graphene layer through chemical vapor deposition at over 600DEG C in a less than 103Pa environment; preparing a smart film, wherein graphite nano particles, a smectic liquid crystal material, a polymerizable monomer and an initiator are mixed and blended uniformly, then a mixture is sprayed or etched at the side of the graphene layer in the conductive layer,and then is radiated by 400nm ultraviolet light for 10-30 minutes at 20-70DEG C so as to be cured to form the smart film; providing a first conductive layer and a second conductive layer, on which thesmart film is cured, bonding or laminating the first conductive layer onto the second conductive layer; and providing two glass layers, bonding or laminating the two glass layers on opposite sides ofthe first conductive layer and the second conductive layer respectively, and sealing the edge. Automobile smart glass prepared by the manufacture method can well protect privacy of users, and has high shock resistance and soundproof effect.

Owner:扬州晶彩光电科技有限公司

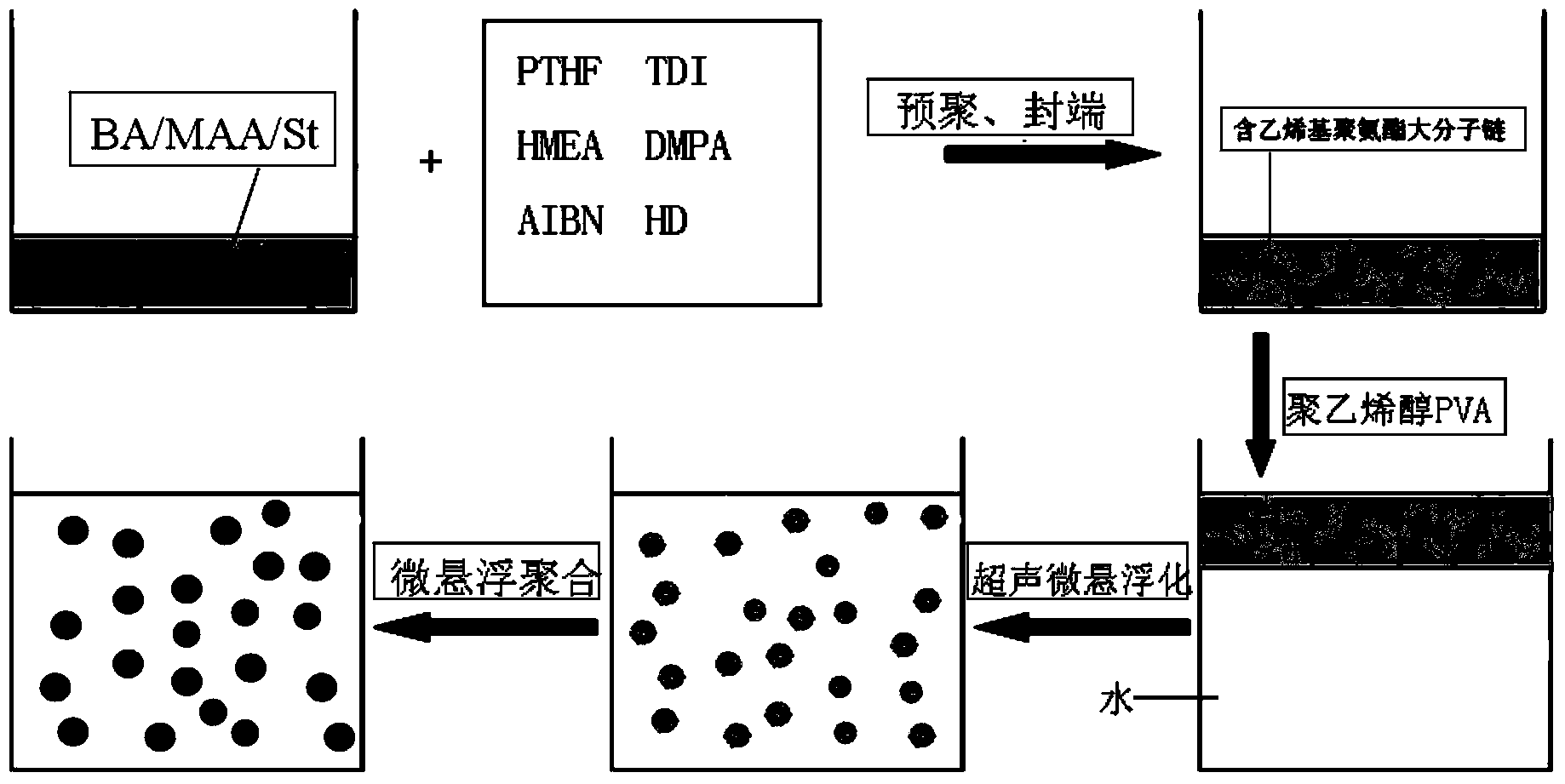

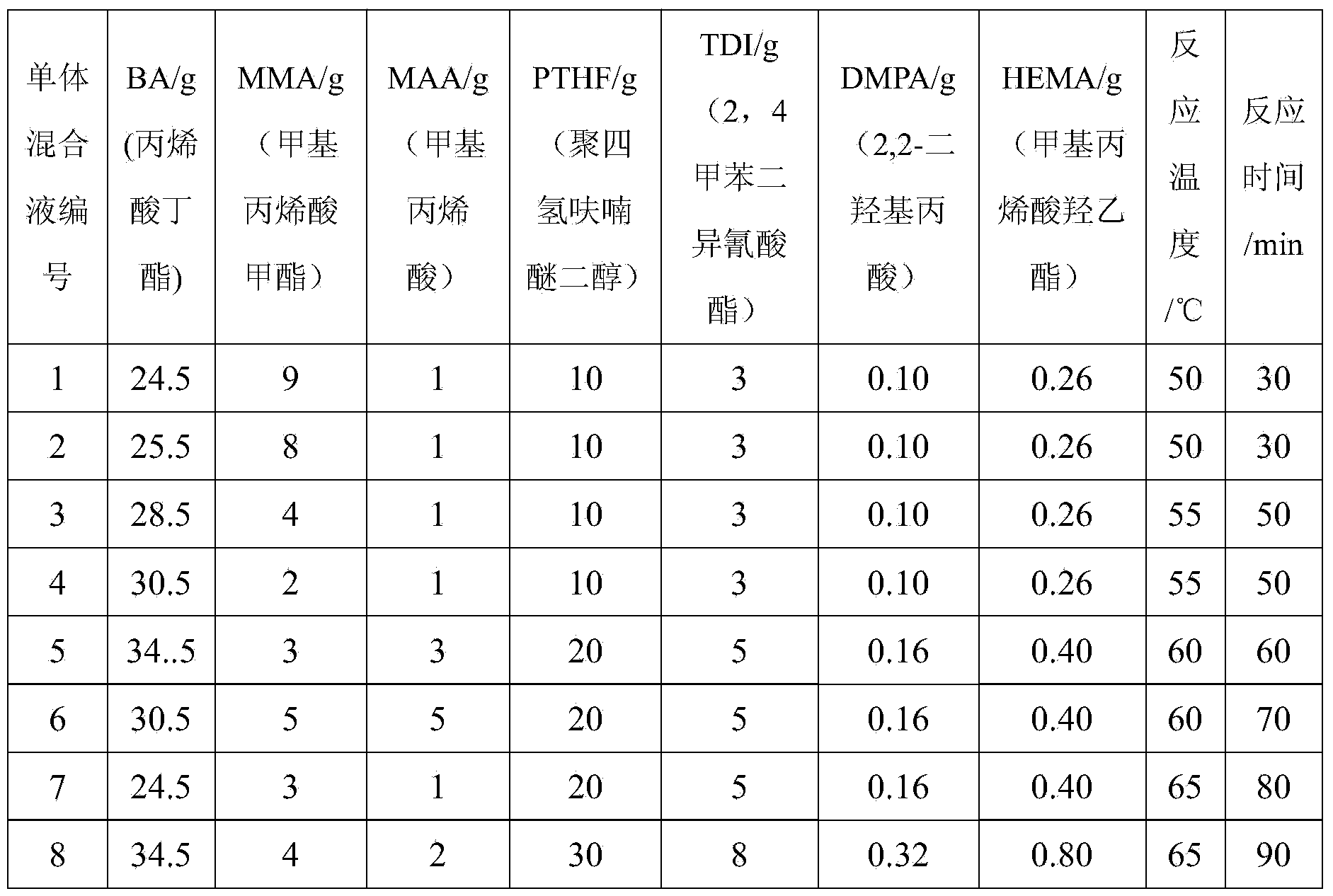

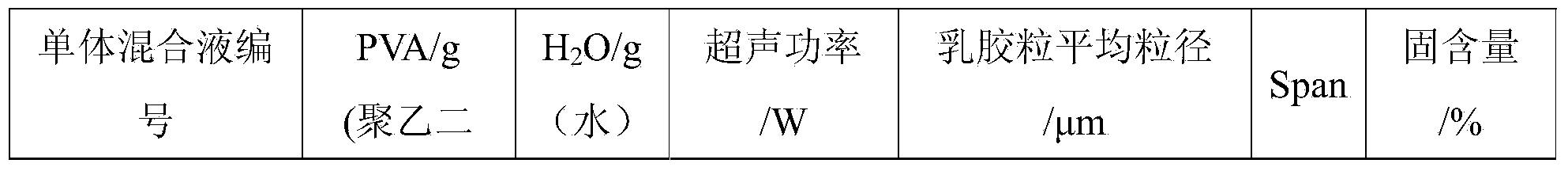

Method for micro-suspension polymerization preparation of sub-micron polyurethane-modified polyacrylate copolymerized latex

ActiveCN104031215ALow viscosityReduce processing linksGraft polymer adhesivesWater basedPolymer science

The invention discloses a method for micro-suspension polymerization preparation of a sub-micron polyurethane-modified polyacrylate copolymerized latex. The method comprises the steps: adding an isocyanate monomer and polyhydric alcohol into an acrylate monomer containing an auxiliary emulsifier cetane, adding a catalyst dibutyl lithium dilaurate, heating up, carrying out a prepolymerization reaction for 20-40 min, adding 2,2-dihydroxy propionic acid, carrying out a chain extension reaction, finally adding an end-capping agent, and thus obtaining an oily monomer mixed solution; adding an initiator azobisisobutyronitrile into the oily monomer mixed solution, then pouring into a dispersant polyvinyl alcohol aqueous solution, and carrying out ultrasonic micro-suspension emulsification; heating the micro-suspension liquid up to 60 DEG C-90 DEG C, carrying out a reaction for 4 h-8 h, dropping the temperature and cooling, and thus obtaining an emulsion. The copolymerized emulsion prepared by the method has the advantages of high solid content, good film-forming property, simple preparation process, and easy implementation, can be used for a water-based latex adhesive, and is used in coating, printing and dyeing, papermaking, printing ink and other fields.

Owner:ZHEJIANG SCI-TECH UNIV

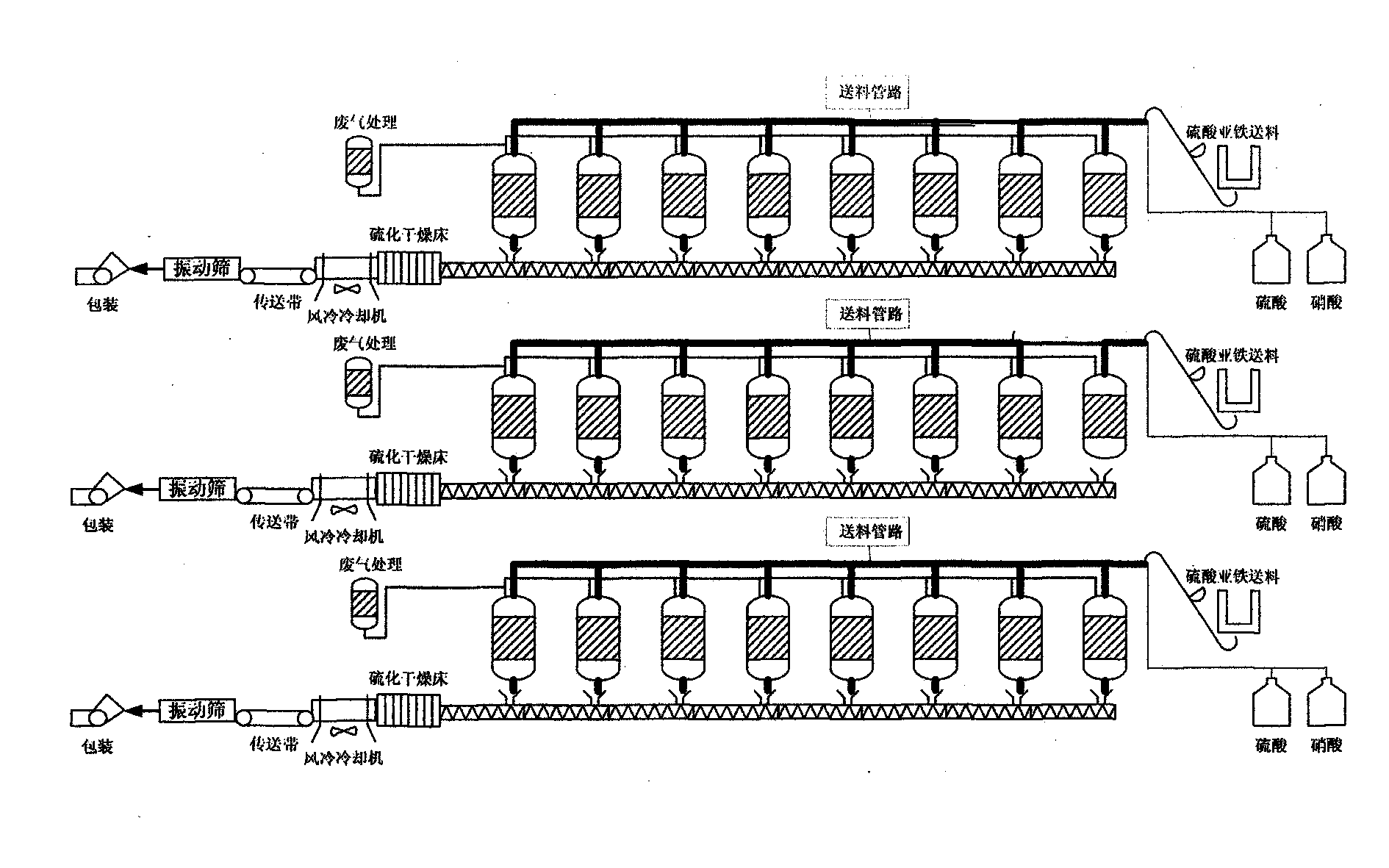

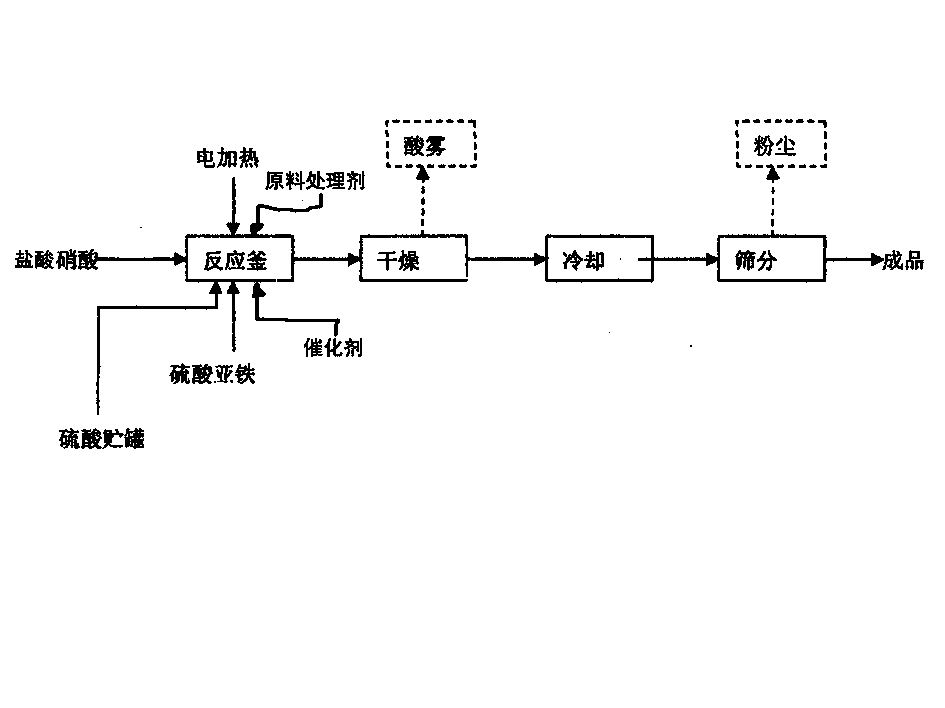

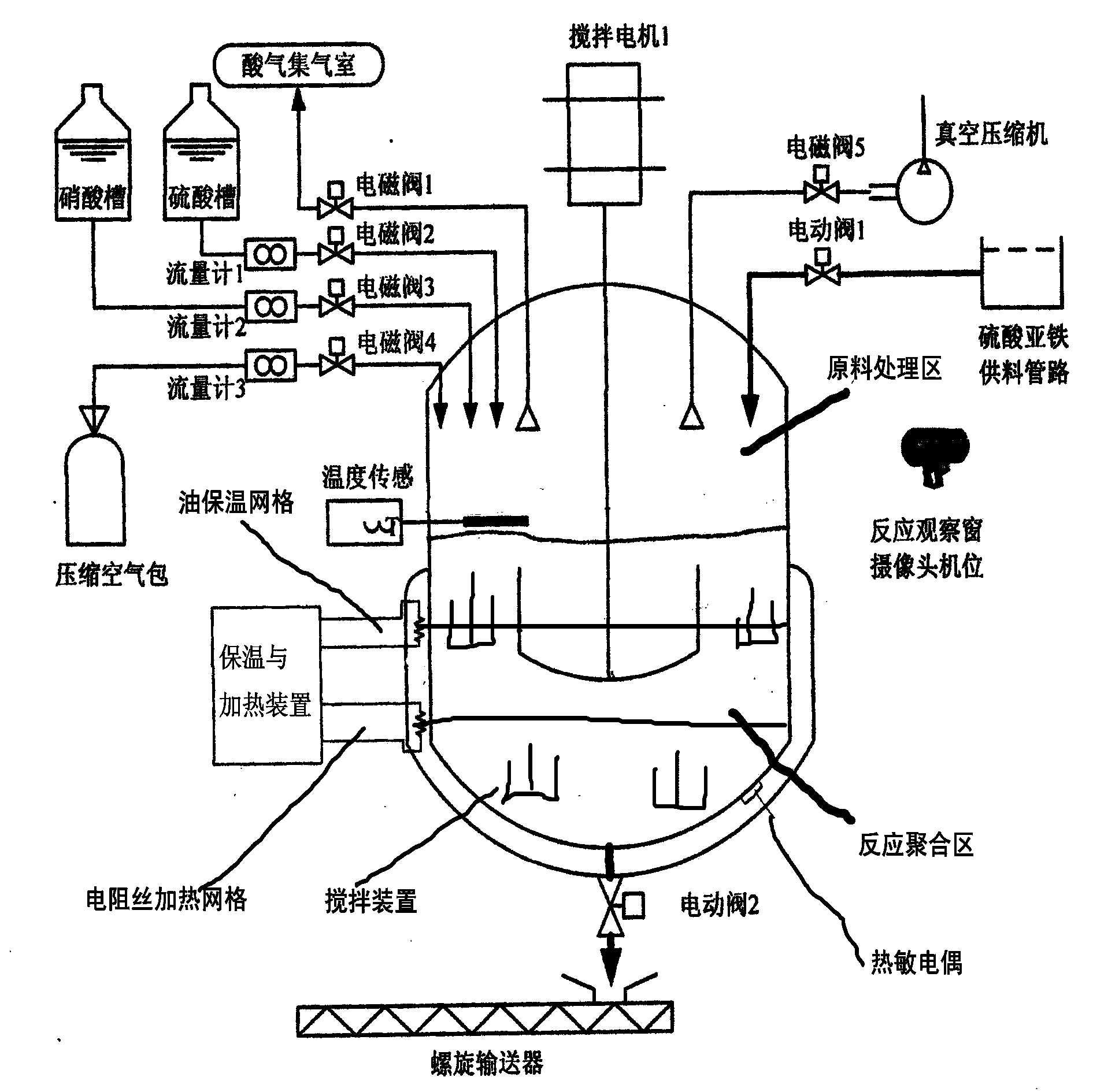

Production method for solid polyferric sulphate

InactiveCN103449535AFully aggregatedFully miscibleIron sulfatesWater/sewage treatment using germicide/oligodynamic-processIron sulfatePhysical chemistry

The invention belongs to the field of water treatment, and particularly discloses a production method for high-purity solid polyferric sulphate, wherein ferrous sulphate and concentrated sulphuric acid are used as raw materials, and ferrous sulphate is treated at first in a reaction kettle; the treatment method comprises the following steps of: uniformly mixing 7-11% of solid acid and 1-2% of rare earth in ferrous sulphate; pouring the ferrous sulphate in the heating area of the reaction kettle; and feeding the treated ferrous sulphate in the reaction area of the reaction kettle, and performing reaction polymerization. The solid polyferric sulphate (SPFS) produced by the production method disclosed by the invention is high in purity, high in iron content of greater than 23%, high in heating amount after being contacted with water, serious in reaction and capable of generating a dynamic energy. The product can be directly poured in water and used for performing a purification treatment on water, simple in use method, low in dosage, and remarkable in water treatment effect.

Owner:白占卿

Method for efficiently preparing petroleum asphalt-based mesocarbon microbeads

The invention discloses a method for efficiently preparing petroleum asphalt-based mesocarbon microbeads. The method comprises the following steps: firstly, carrying out full mixing and preheating treatment on petroleum asphalt and an additive under a certain temperature, a certain N2 flow and a certain stirring speed, thus removing a small molecule compound which is difficult to polymerize; secondly, carrying out thermal polymerization reaction by keeping constant temperature for 2 to 6 hours under N2 protection and under the conditions that the pressure is 0.5 to 2.0 MPa and the temperatureis 380 to 420 DEG C, thus obtaining polymerized asphalt containing mesocarbon microbeads; finally, carrying out hot melting and filtration on the polymerized asphalt by using wash oil of which the boiling range is 245 to 290 DEG C, and carrying out vacuum drying after extracting filter cake by organic solvents of pyridine, methylbenzene and the like, thus obtaining the petroleum asphalt-based mesocarbon microbeads. According to the method disclosed by the invention, the petroleum asphalt and the additive which are used in the invention are rich in sources and lower in cost; by controlling themass percentage of the additive, the mesocarbon microbeads which are uniform in particle size distribution, controllable in size and relatively higher in yield can be prepared, and the mesocarbon microbeads can be used as lithium ion battery cathode materials after the mesocarbon microbeads are carbonized and graphitized.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

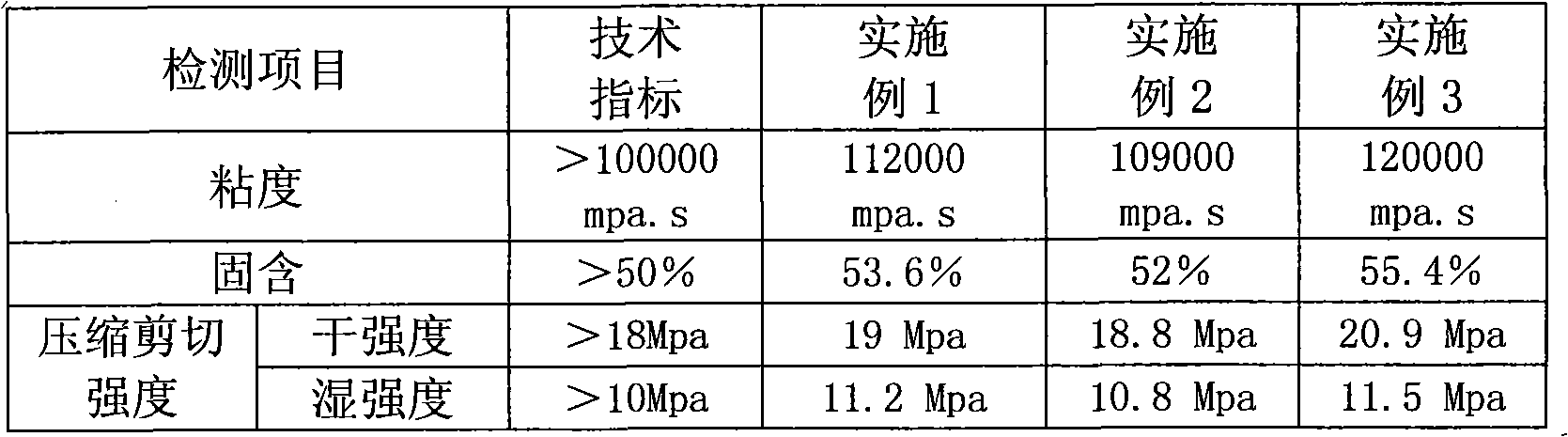

Preparation method of energy-saving, environment-protecting and sag-resistant water-based instant adhesive

ActiveCN101851475ASmall particle sizeImprove stabilityMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesWater basedPolyvinyl alcohol

The invention relates to a preparation method of energy-saving, environment-protecting and sag-resistant water-based instant adhesive. The adhesive is widely applied in self-adhesion or cross-adhesion in the furniture, handicrafts, car interiors and other industries, and is prepared with the following raw materials of certain parts by weight: acetylated polyvinyl alcohol, vinyl acetate, plasticizer, nano-montmorillonite soil, emulsifier, initiator and the like. Instead of the method of preparing the existing product that the common polyvinyl alcohol is filled once into the reactor as the protective colloid, the preparation of the invention adopts the method of dropping the monomers and the initiator through two ports, the acetylated polyvinyl alcohol is filled in batches as the protective colloid, and the monomers, the initiator and the protective colloid are dropped simultaneously through a three-port dropping device, thereby improving the water resistance, stability, adhesive strength and sag resistance; and the reaction rate is controlled and the nano-montmorillonite soil, the environmental protection type plasticizer, the environmental protection type emulsifier and the like are added during preparation, thereby improving the adhesive property, environmental performance and sag resistance.

Owner:JIANGSU HEISONGLIN ADHESIVE FACTORY

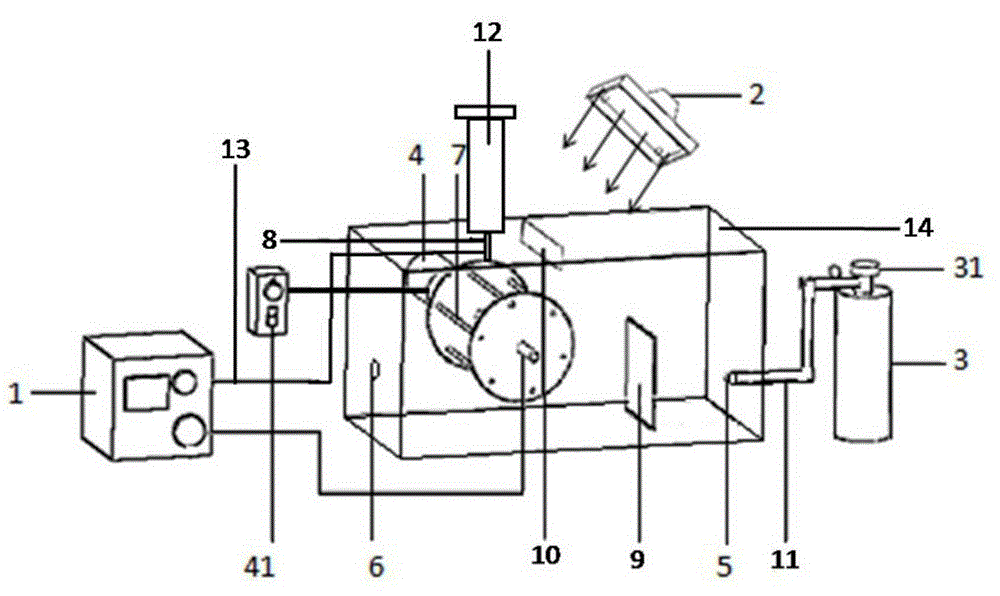

Conductive micro-nanometer fiber stranded wire based on solvent-free electrospinning and preparing method thereof

The invention discloses a conductive micro-nanometer fiber stranded wire based on solvent-free electrospinning and a preparing method thereof. The conductive micro-nanometer fiber stranded wire comprises a photocuring material template stranded wire and a conductive macromolecule layer. The photocuring material template stranded wire is formed by winding micro-nanometer fiber cured by solvent-free electrospinning ultraviolet light. The conductive macromolecule layer is manufactured through an in-situ polymerization method and comprises conductive macromolecule layer bodies permeating into the template stranded wire and wrapping the template stranded wire. According to the conductive micro-nanometer fiber stranded wire, conductivity of the fiber stranded wire is further improved while excellent stretchability is kept, organic solvent does not need to be added in the electrostatic spun yarn preparing process, the preparing process is safer and more environmentally friendly, and the stranded wire is suitable for large-scale production.

Owner:QINGDAO UNIV

Maleimide copolymer and synthetic method thereof

ActiveCN101538347AImprove production environmentStrong industrial applicabilityMaleopimaric acidAcrylonitrile

The invention provides a maleimide copolymer which comprises the following components: 30% to 55% (w / w) of maleimide, 40% to 69.9% (w / w) of aromatic olefins and 0.1% to 5% (w / w) of maleic acid or maleic anhydride. The maleimide copolymer is prepared by the suspension polymerization method, wherein, the Tg temperature (glass transition temperature) thereof can reach over 200 DEG C; the color thereof can be significantly improved; the residual content of monomers is lower than 3,000ppm; and neither acrylonitrile nor acrylate is involved in the synthesis process as monomers, thereby effectively improving the production environment and improving the industrial applicability.

Owner:SHANGHAI HUAYI GRP CO

Crazing-resistance and high-toughness organic glass and preparation method thereof

The invention discloses crazing-resistance and high-toughness organic glass and a preparation method thereof. The organic glass is prepared from the following raw materials in parts by weight: methyl methacrylate, isobornyl methacrylate, ethylene glycol dimethacrylate, epoxidized soybean oil acrylate, an impact-resistant modifier, ethanol, polyacrylamide, rubber particles, polybutyl acrylate, ternary copolymerized nylon, modified nano-silicon dioxide, diisopropyl peroxydicarbonate, dicumyl peroxide, dioctyl phthalate, ethyl p-hydroxybenzoate, zinc stearate and emulsified silicone oil. The invention provides the crazing-resistance and high-toughness organic glass and the preparation method thereof; the organic glass disclosed by the invention has good toughness, heat resistance and crazing resistance, is not easy to damage and has long service life and good economic benefits.

Owner:蚌埠承永玻璃制品有限公司

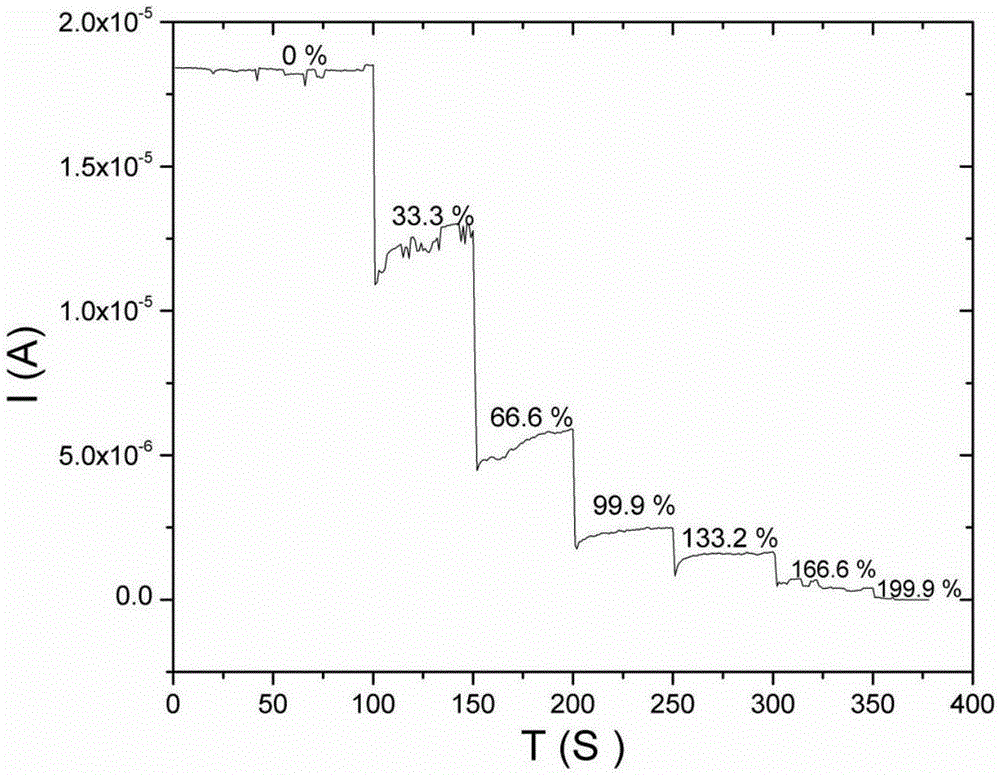

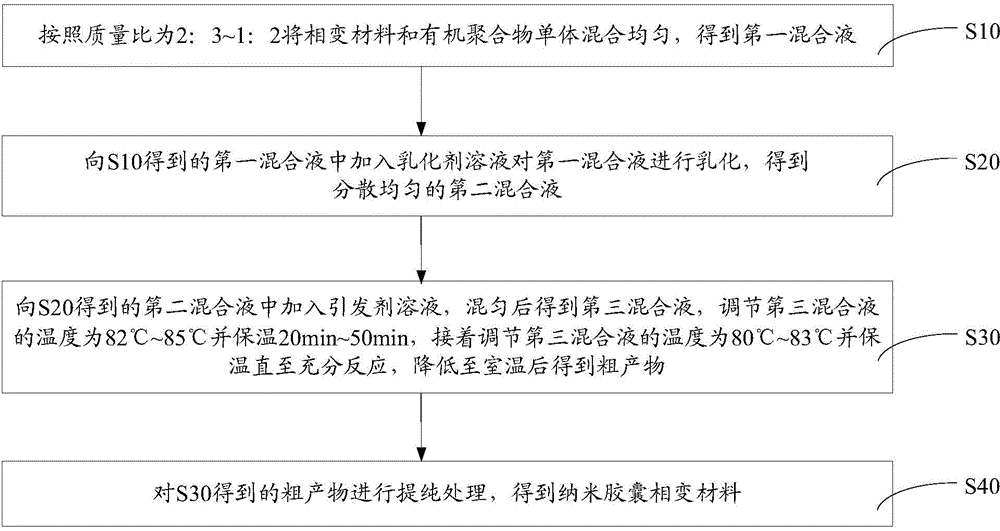

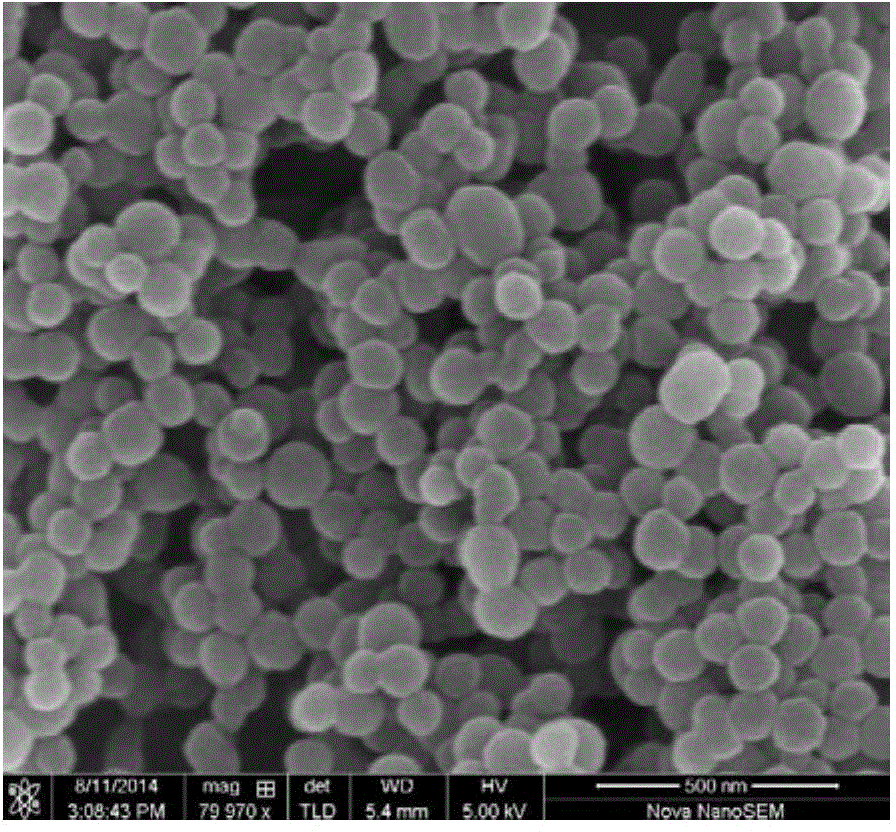

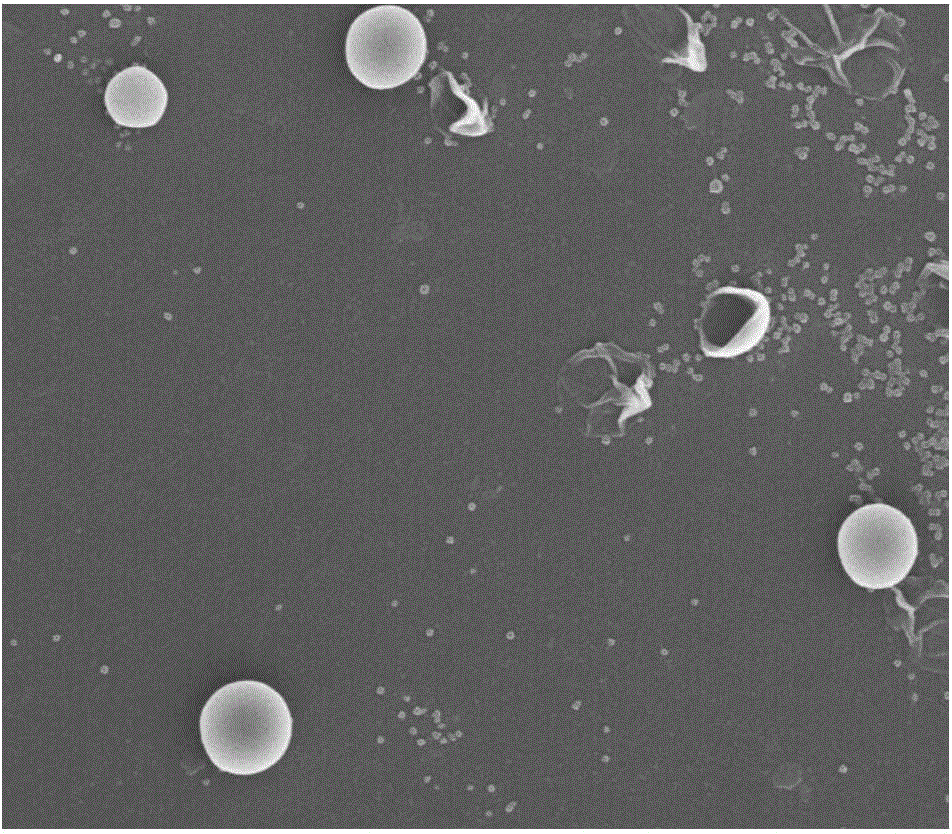

Preparation method of nano-encapsulated phase change material

InactiveCN105586010AShort preparation timeThe experiment process is simpleHeat-exchange elementsMicroballoon preparationMass ratioRoom temperature

The invention discloses a preparation method of a nano-encapsulated phase change material. The preparation method comprises the following steps: a phase change material and acrylic ester are uniformly mixed according to a mass ratio 2:3-1:2, and first mixed liquor is obtained; an emulsifier solution is added for emulsification of the first mixed liquor, and uniformly dispersed second mixed liquor is obtained; an initiator solution is added with uniformly mixing, a third mixed liquor is obtained, temperature of the third mixed liquor is adjusted to 82-85 DEG C, insulation is carried out for 20-50 minutes, temperature of the third mixed liquor is adjusted to 80-83 DEG C, insulation is carried out till full reaction, temperature is reduced to room temperature, and a crude product is obtained; purification is carried out for the crude product, and the nano-encapsulated phase change material is obtained. Conditions for polymerization are controlled, so that on one hand full polymerization of the acrylic ester is guaranteed, and on the other hand reaction time is substantially reduced; the method is suitable for large scale production.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Application of composite initiating agent in preparation of ion exchange resin

The invention belongs to the technical field of ion exchange resin, and relates to application of a composite initiating agent in preparation of the ion exchange resin. The application includes the steps of (1) adding industrial salt in a recycled NaCl liquid, stirring to dissolve, adjusting specific gravity, adding hydroxyethyl cellulose, and heating with stirring to obtain a water phase; (2) weighing and mixing acrylonitrile, methyl acrylate and triallyl isocyanurate, adding a mixed solution of the composite initiating agent and divinylbenzene, and adding methylbenzene with stirring to obtain an oil phase; (3) mixing the water phase with the oil phase, heating to react, transferring into an oil blowing kettle to filter off the liquid, adding hot water to immerse a ball body, stirring, heating to a certain temperature by vapor, reacting under the condition that pressure in the oil blowing kettle is controlled, and screening through a hot air drying screen to obtain polymerized white beads. By adopting the composite initiating agent, in a production and operation process, reactions are performed in stages, processes are enabled to be stable in reaction, operations are easy to control, and an obtained product is excellent in performance, safe and environment-friendly.

Owner:扬州金珠树脂有限公司

Heat-resistant crack-resistant organic glass and preparation method thereof

InactiveCN107057254AIncrease steric hindranceImprove molecular weightEthyl hydroxybenzoateMethacrylate

The invention discloses heat-resistant crack-resistant organic glass and a preparation method thereof; the heat-resistant crack-resistant organic glass comprises, by weight, methyl methacrylate, polycyclic norbornene methacrylate, butanediol diacrylate, epoxidized soybean oil acrylate, an impact modifier, 1-dodecanethiol, polyacrylamide, rubber particles, poly(butyl acrylate), nylon terpolymer, rare earth, azobisisobutyronitrile, dicumyl peroxide, diisobutyl phthalate, and ethyl 4-hydroxybenzoate. The heat-resistant crack-resistant organic glass and the preparation method thereof are provided herein; the organic glass has high glass transition temperature, good heat resistance and good mechanical properties, rarely cracks and has good economic benefit.

Owner:蚌埠承永玻璃制品有限公司

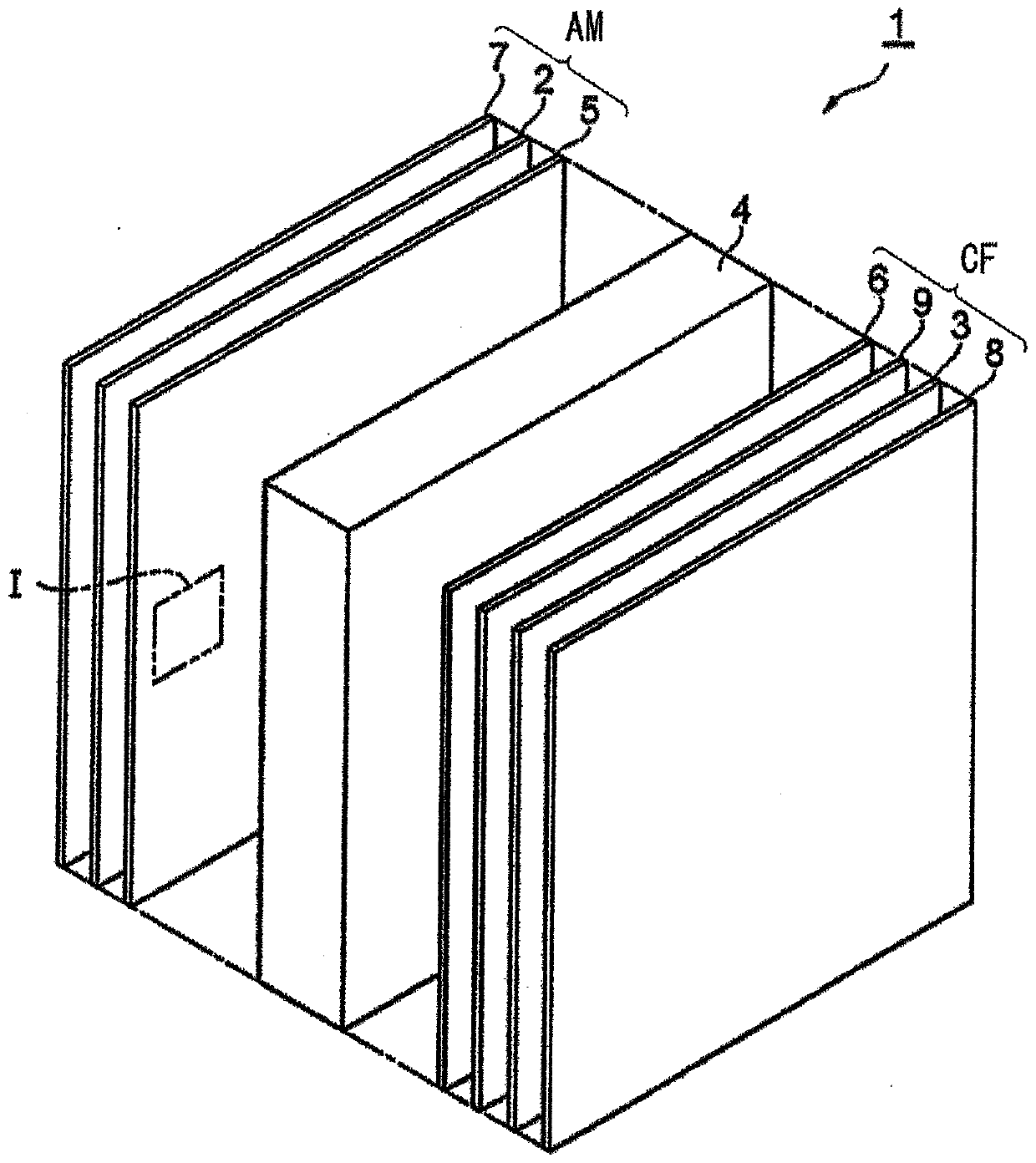

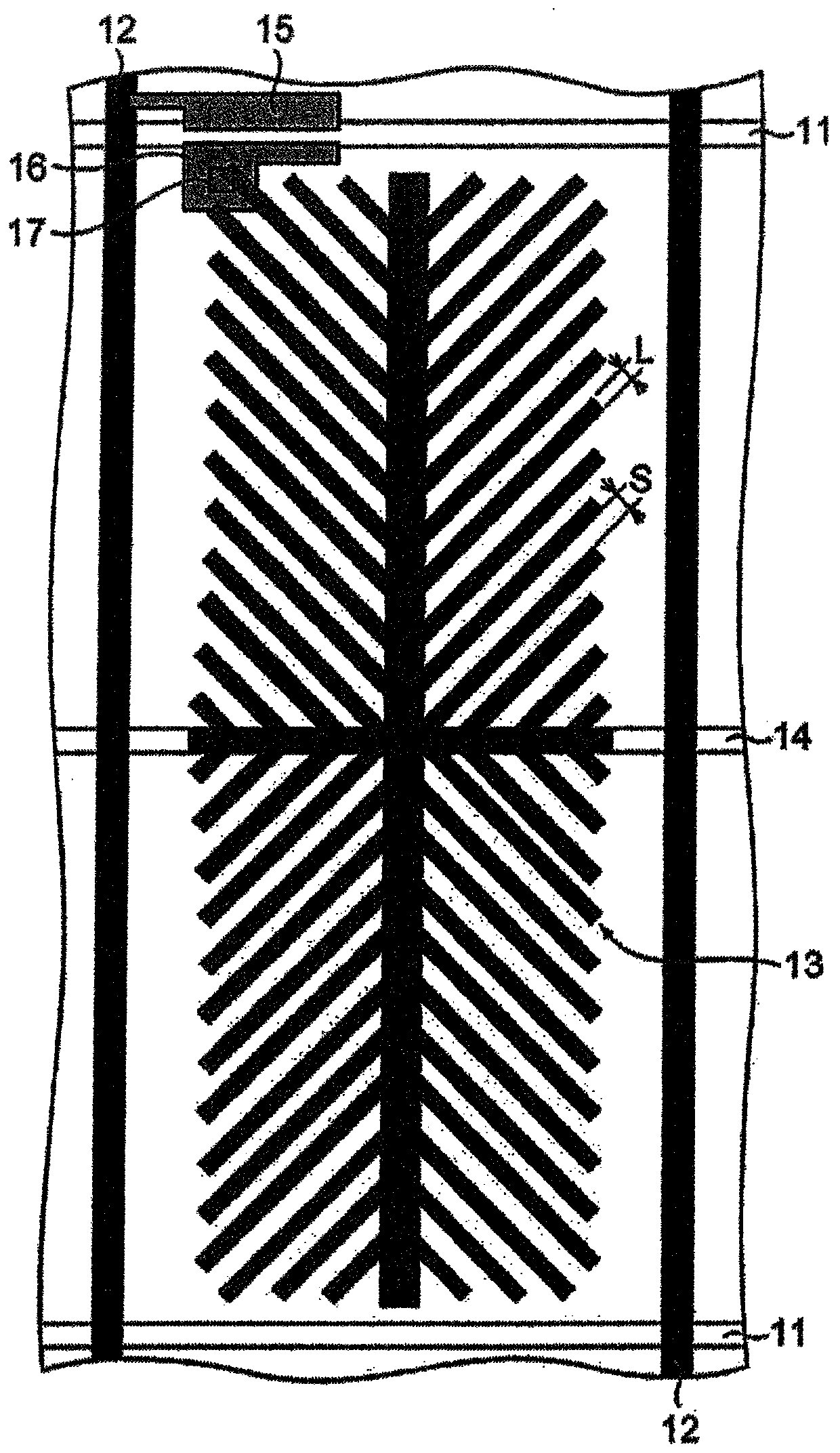

Method for setting pretilt angle of liquid crystal molecules

ActiveCN102902106AUniform light transmittanceGuaranteed ContrastNon-linear opticsSmall amplitudeUltraviolet lights

The invention provides a method for setting a pretilt angle of liquid crystal molecules, comprising the following steps of: step 1, providing a liquid crystal material, a CF (Color Filter) substrate and a TFT (Thin Film Transistor) substrate; step 2, arranging the CF substrate and the TFT substrate in parallel to form a receiving gap, and filling the liquid crystal material in the receiving gap to form a liquid crystal box; step 3, providing a driving control circuit capable of generating a plurality of driving voltages, and electrically connecting the driving control circuit with the TFT substrate; step 4, providing a small-amplitude oscillating device and an ultraviolet light source variable in irradiation intensity, and arranging the liquid crystal box on the small-amplitude oscillating device; step 5, starting the small-amplitude oscillating device so that the liquid crystal box generates small-amplitude oscillation, closing the driving control circuit and employing the plurality of driving voltages to drive the liquid crystal material, and simultaneously, irradiating the liquid crystal through the ultraviolet light source by different intensities; and step 6, performing the operation of the step 5 not less than one time on the liquid crystal box, thereby completing the setting of the pretilt angle.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Preparation method of poly[2, 5-dyhydroxy-1, 4-phenylene pyridine diimidazole] polymer

ActiveCN103601886ASolve the problem of low molecular weightHigh molecular weightMonocomponent synthetic polymer artificial filamentPolymer scienceSpinning

The invention relates to a preparation method of a poly[2, 5-dyhydroxy-1, 4-phenylene pyridine diimidazole] polymer. The preparation method comprises two steps of prepolymerization reaction and post-polycondensation reaction. The reaction time of a prepolymer in a double-screw extruder is 10-60 minutes, and the double-screw extruder is provided with three temperature zones according to a sequence from a feeding port to a discharging port, wherein the temperatures of the tree temperature zones are respectively 160-180 DEG C, 180-190 DEG C and 190-200 DEG C. According to the preparation method, the double-screw extruder is used for carrying out the post-polycondensation reaction, and specific temperature and time are used for controlling parameters, so that the intrinsic viscosity [eta] of the PIPD polymer obtained in the end is 28-30dL / g, the molecular weight of the polymer is greatly increased, meanwhile, the stirring is facilitated, and the PIPD polymer can be easily conveyed and transferred to a spinning working section, thus the production efficiency is improved, and the production cost is reduced.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

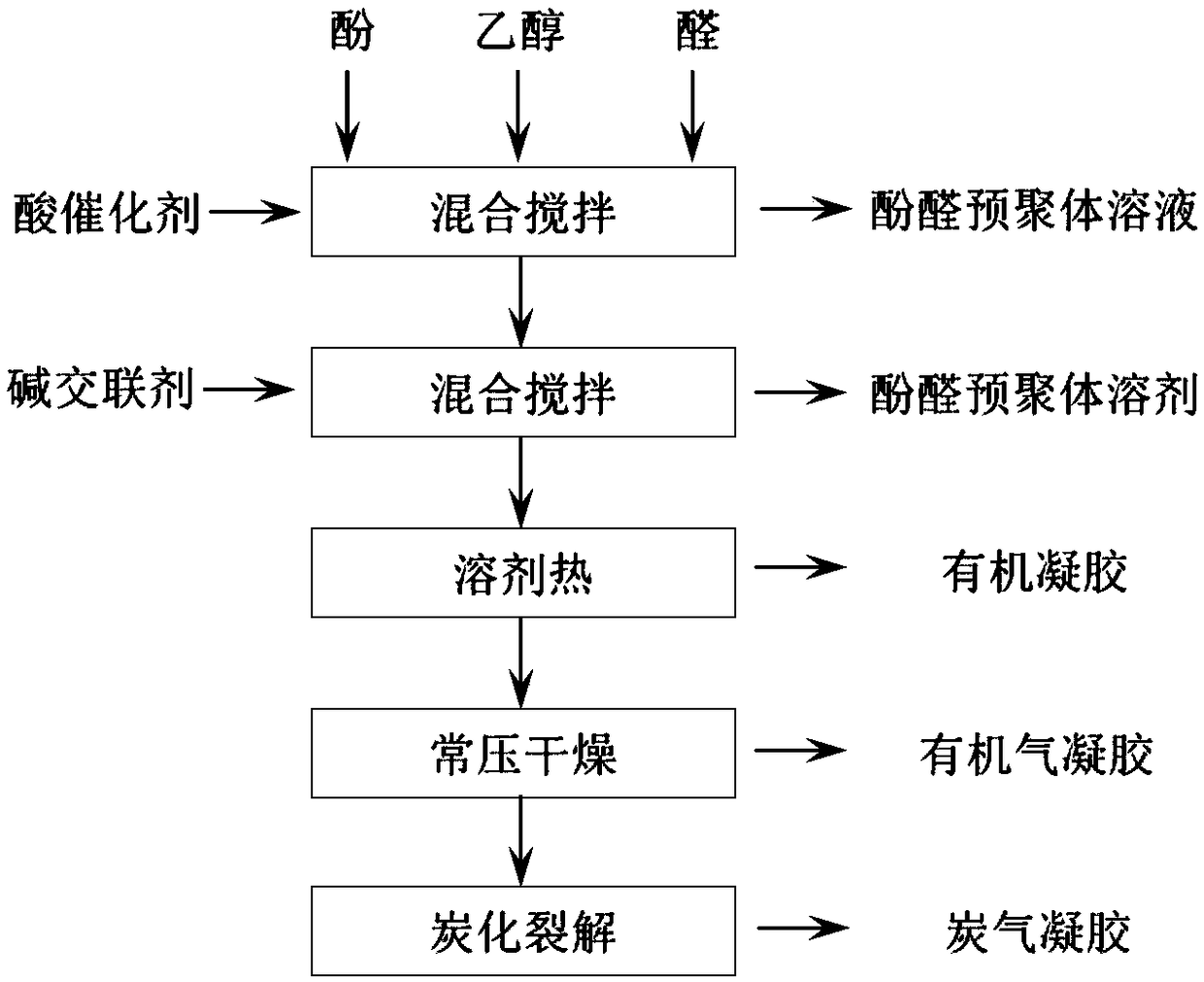

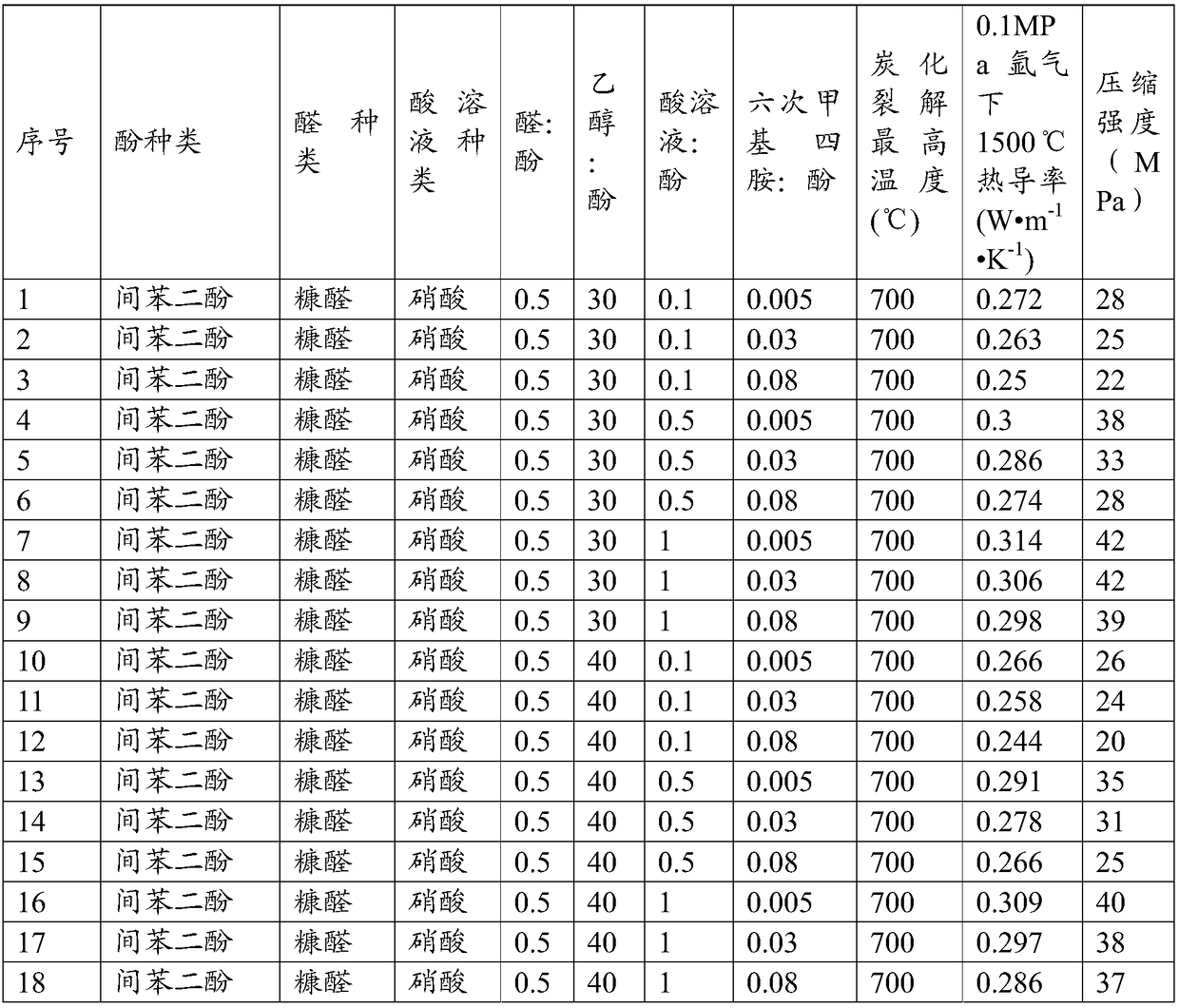

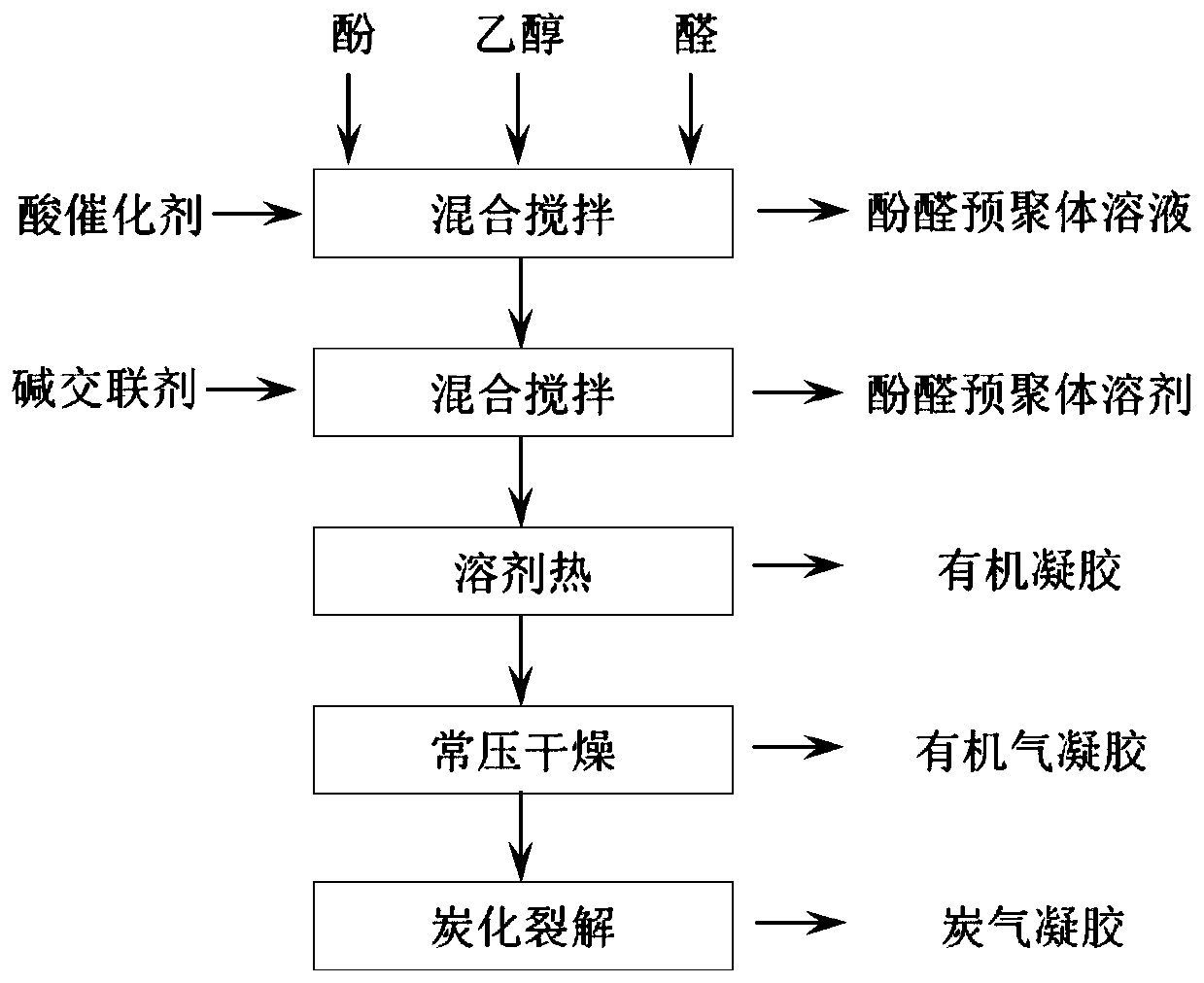

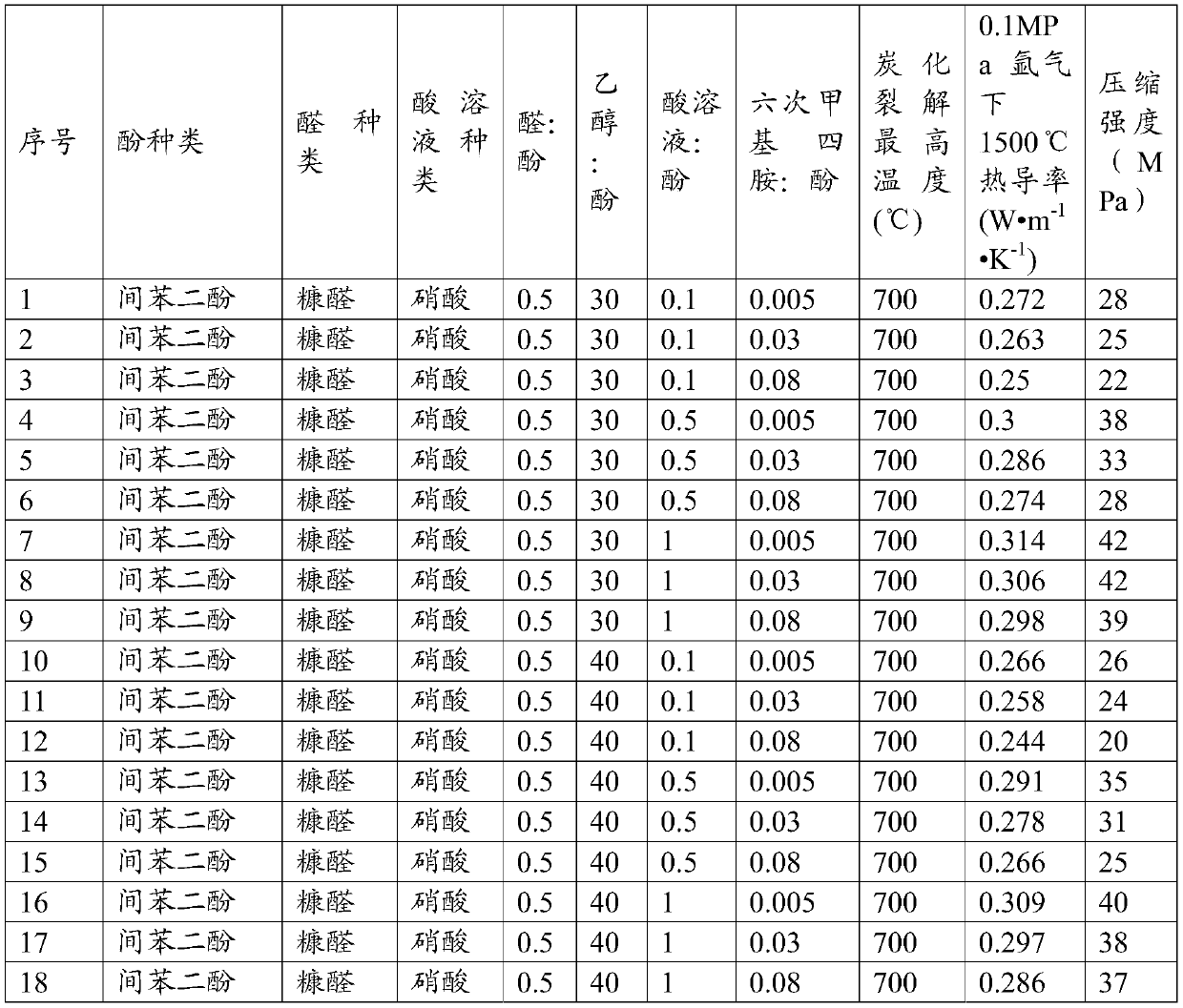

Preparation method of carbon aerogel thermal insulation material

ActiveCN108609606AImprove mechanical propertiesGood heat insulationCarbon preparation/purificationPolymer scienceThermal insulation

A preparation method of a carbon aerogel thermal insulation material comprises the steps as follows: 1) preparing phenolic prepolymer sol with an acid-base two-step method; 2) preparing organic gel with a solvothermal method; 3) preparing organic aerogel with a normal-pressure drying technology; 4) preparing carbon aerogel with a carbonization cracking technology. Linear phenolic molecules are linked and woven into an isotropic 3D network structure with hexamethylene tetramine as a crosslinking point on the nanoscale with the acid-base two-step method which firstly adopts acid catalysis and then alkaline crosslinking, the framework strength is improved, and the crosslinking degree and uniformity of the framework structure are increased. By the aid of the solvothermal method, the gel polymerization reaction is accelerated, the technological period is shortened, and the gel polymerization reaction is fully conducted, so that the crosslinking degree and strength of the nano network framework are enhanced. The method is simple, efficient and low in cost, the problems of long preparation period and high cost of traditional technologies and higher shrinkage in a normal-pressure drying technology are solved, and the obtained carbon aerogel thermal insulation material has high mechanical strength and low heat conductivity.

Owner:NAT UNIV OF DEFENSE TECH

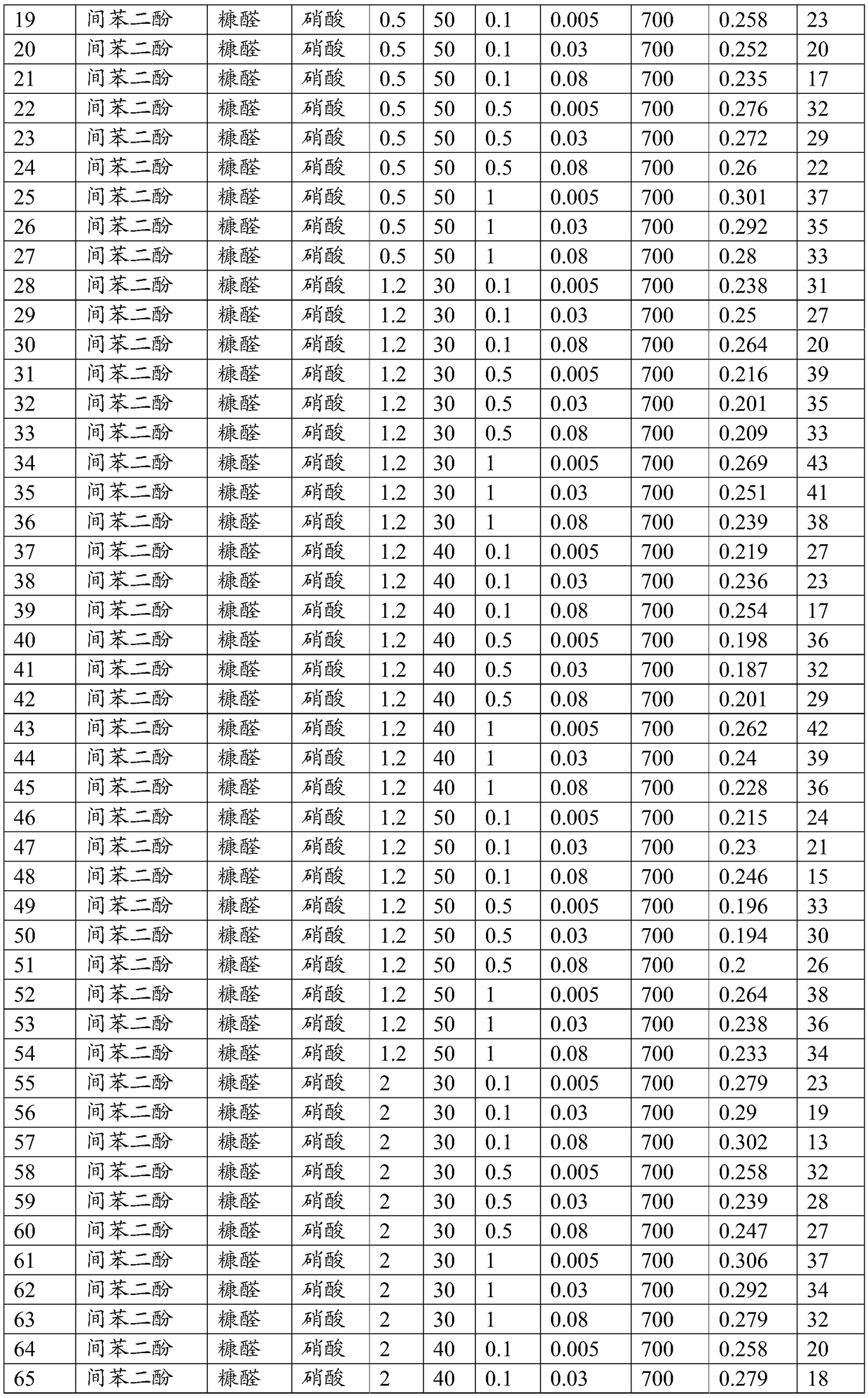

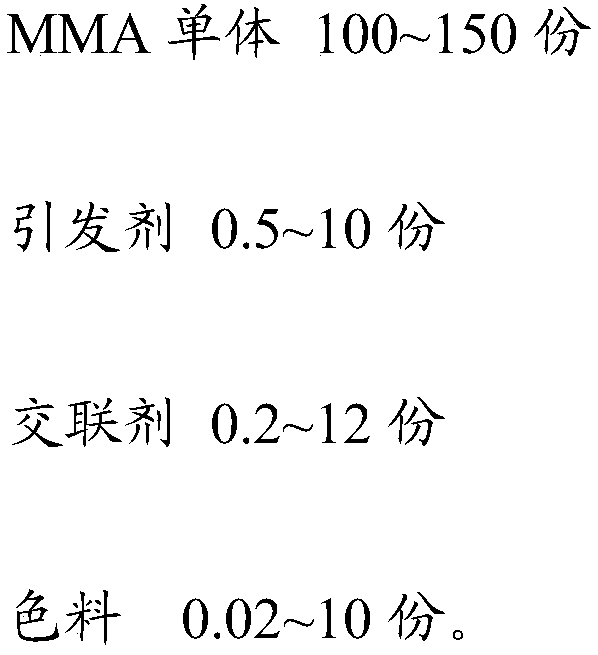

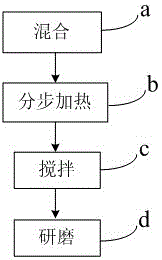

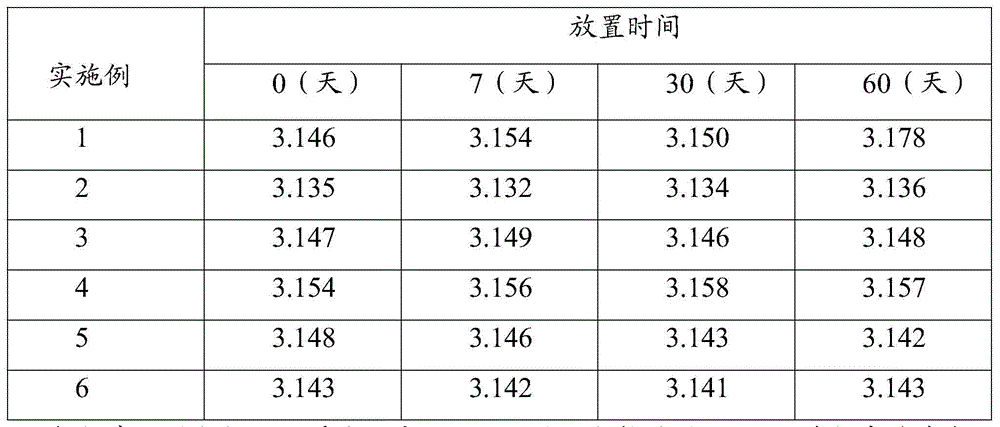

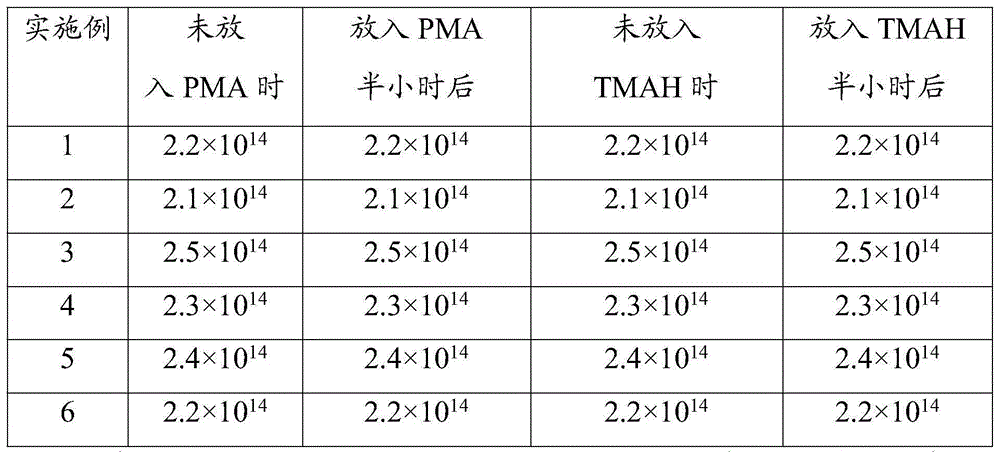

Dental CAD/CAM machinable PMMA and preparation method thereof

The invention discloses a dental CAD / CAM machinable PMMA and a preparation method thereof. Raw materials used are MMA monomers, initiators, cross-linking agents and colorants; the MMA monomers, the initiators and the cross-linking agents are added to a reactor, clockwise stirring of 20-30 turns is conducted, standing is conducted for 10-20 minutes, the MMA monomers, the initiators and the cross-linking agents are put into a water bath at 60-80 DEG C, and pre-polymerization is carried out; the raw materials are taken out after the pre-polymerization is completed, and the raw materials are placed in ice water to be cooled to 20-30 DEG C; the colorants are added to pre-polymerized slurry, then stirred for 30-60 minutes by using a stirrer, and packed into a mold by weight according to the product specifications, a polymerization reaction is carried out, after the completion of the polymerization, the mold is removed, and the PMMA is obtained. A bulk polymerization method has high production efficiency, no waste discharge, simple process, small floor space, low cost and convenient equipment cleaning.

Owner:AIDITE (QINHUANGDAO) TECH CO LTD

Fiberboard with improved water resistance

InactiveCN101506121AImprove waterproof performanceFast aggregationSolid waste managementThin material handlingSlurryWater resistant

Articles, including fiberboard, are made from a pumpable, flowable slurry including alpha-calcined calcium sulfate hemihydrate anchored in pores of host particles, alpha-calcined calcium sulfate hemihydrate, a silicone compound, magnesium oxide, and water. The magnesium oxide catalyzes the reaction of the silicone compound into a silicone resin. In a preferred method of making a water resistant fiberboard calcium sulfate dihydrate is combined with the host particles and water to form a slurry which is heated under pressure to calcine the calcium sulfate dihydrate to form alpha-calcined calcium sulfate hemihydrate. After relieving the pressure, a silicone compound and magnesium oxide are added to the slurry. The slurry is dewatered to form a filter cake, which is then formed into a desired shape and allowed to set.

Owner:USG CORP

Modified polylactic acid material as well as preparation method and application thereof

InactiveCN113583412AEfficient degradationDegradation can be adjustedSurgeryPolymer sciencePLLA polymer

The invention discloses a modified polylactic acid material as well as a preparation method and application thereof. The modified polylactic acid material comprises polylactic acid, a polymer and a block polymer, wherein the mass ratio of the polylactic acid to the full-degradable polymer to the block polymer is (0.3-0.7): (0.2-0.5): (0.03-0.1). The modified polylactic acid material can effectively solve the problem that an existing polylactic acid material is poor in compatibility, degradability and mechanical property.

Owner:SICHUAN UNIV

Inorganic pigment slurry processing method

The invention relates to an inorganic pigment slurry processing method. The method comprises the following steps that 20 parts of epoxidized soybean oil, 0.5 part of high-polymeric vinyl chloride resin and 0.5 part of a dispersing agent are mixed evenly, stirring is performed for 12-20 min, and then filtering is performed to obtain a mixture H; 50 parts of epoxidized soybean oil, 0.5 part of dioctyl terephthalate and 0.5 part of a dispersing agent are added into a stirring tank, heating is performed to reach the temperature of 50-60 DEG C, the temperature is kept for 30-50 min, the mixture H is poured into the stirring tank for stirring for 12-20 min, then, heating is performed to reach the temperature of 120-130 DEG C, and standing is performed to obtain a mixture R; remaining components are added into the mixture R, stirring is performed for 5-10 min, then the rotating speed is decreased, inorganic pigment and coarse whiting are added, and then stirring is performed for 15-20 min to obtain a prefabricated material K; the prefabricated material K is ground to reach the grain size of 3-5 micrometers, and polyvinyl chloride inorganic pigment slurry is obtained.

Owner:湖州市云巢染料化工厂

Composition, black matrix and preparation method thereof, display devices

InactiveCN104808441AIncrease resistanceFully aggregatedOptical filtersPhotomechanical apparatusCooking & bakingDisplay device

The invention discloses a black photoresist composition, a black matrix and a preparation method thereof, an OLED display device, an LCD display device and a flexible display device. The black photoresist composition comprises the following components: 30-35 parts of a monomer solid substance, 25-35 parts of a resin solid substance, 20-30 parts of a black liquid pigment solid substance, 6-20 parts of initiating agents and 5-10 parts of additives, wherein the initiating agents comprise thermal initiating agents and a photoinitiator. The black matrix is prepared from the black photoresist composition. Each of the OLED display device, the LCD display device and the flexible display device comprises the black matrix. When the black photoresist composition is used for preparation of the black matrix and the post-baking operation is cooled to 180 DEG C or lower, the prepared black matrix is 7 magnitudes higher than the conventional black matrix, and can be applied to the OLED display device, the LCD display device and the flexible display device.

Owner:BEIJING SINEVA TECH

A kind of preparation method of carbon airgel thermal insulation material

ActiveCN108609606BImprove mechanical propertiesGood heat insulationCarbon preparation/purificationPolymer scienceThermal insulation

A preparation method of a carbon aerogel thermal insulation material comprises the steps as follows: 1) preparing phenolic prepolymer sol with an acid-base two-step method; 2) preparing organic gel with a solvothermal method; 3) preparing organic aerogel with a normal-pressure drying technology; 4) preparing carbon aerogel with a carbonization cracking technology. Linear phenolic molecules are linked and woven into an isotropic 3D network structure with hexamethylene tetramine as a crosslinking point on the nanoscale with the acid-base two-step method which firstly adopts acid catalysis and then alkaline crosslinking, the framework strength is improved, and the crosslinking degree and uniformity of the framework structure are increased. By the aid of the solvothermal method, the gel polymerization reaction is accelerated, the technological period is shortened, and the gel polymerization reaction is fully conducted, so that the crosslinking degree and strength of the nano network framework are enhanced. The method is simple, efficient and low in cost, the problems of long preparation period and high cost of traditional technologies and higher shrinkage in a normal-pressure drying technology are solved, and the obtained carbon aerogel thermal insulation material has high mechanical strength and low heat conductivity.

Owner:NAT UNIV OF DEFENSE TECH

Heat-resistant high-toughness organic glass and preparation method thereof

The invention discloses heat-resistant high-toughness organic glass and a preparation method thereof. The organic glass comprises the following raw materials in parts by weight: methyl methacrylate, aryl methacrylate, N-(substituted phenyl) itaconimide, ethylene glycol diacrylate, acrylonitrile, impact modifier, ethylene glycol, acetyl tributyl citrate, polybutylene terephthalate, low-density polyethylene, glass fibers, polyethylene fibers, modified nano silicon dioxide, nano aluminum oxide, diisopropyl peroxydicarbonate, di(2-ethylhexyl) peroxydicarbonate, dioctyl phthalate, ethyl p-hydroxybenzoate, sodium soap and glycerol. According to the heat-resistant high-toughness organic glass and the preparation method thereof, the organic glass has the advantages of high toughness, high glass transition temperature, favorable heat resistance and long service life, and achieves favorable economic benefits.

Owner:蚌埠承永玻璃制品有限公司

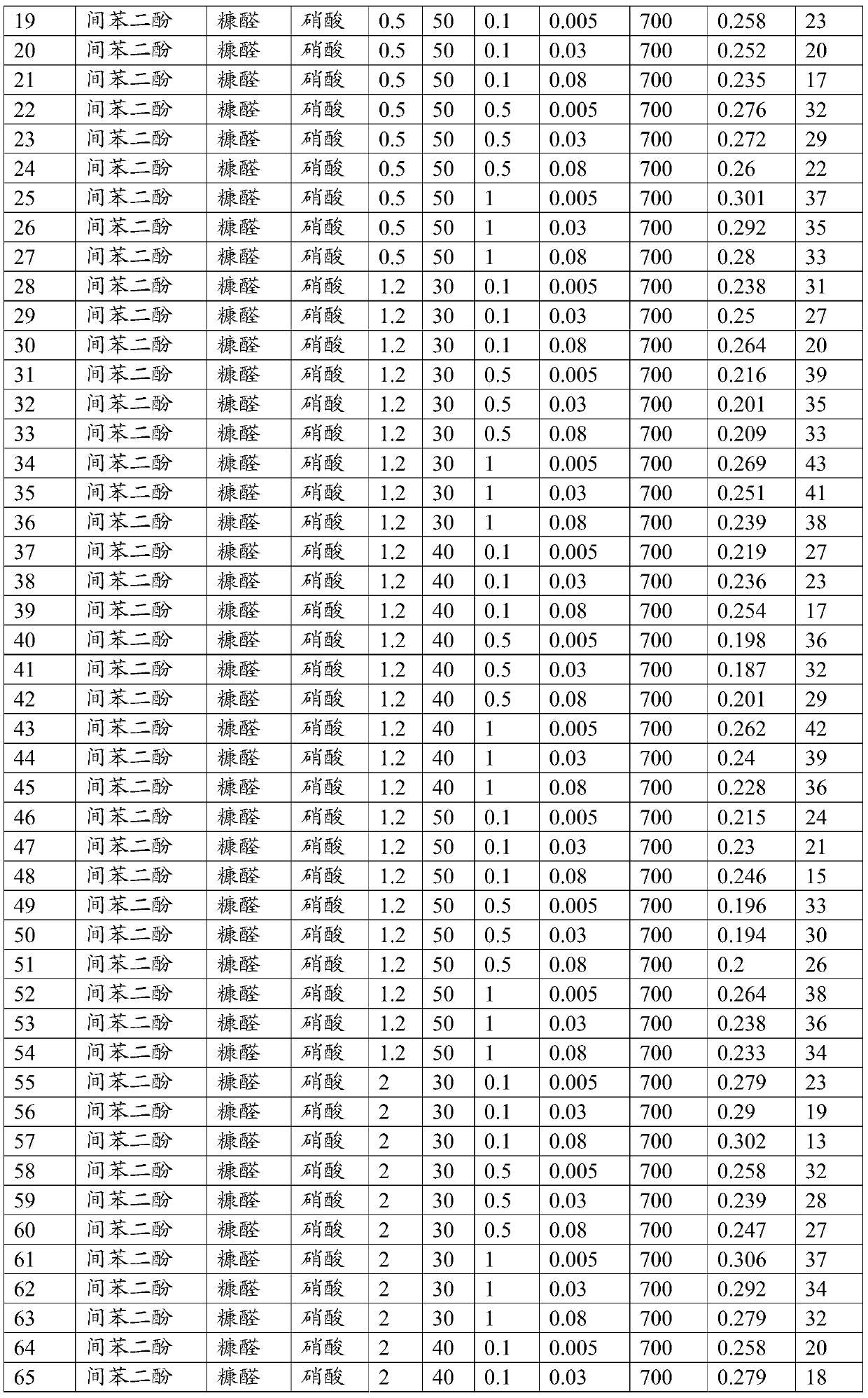

Liquid crystal composite film with writing display function and preparation method thereof

InactiveCN109188802AImprove conductivityEasy to controlNon-linear opticsInput/output processes for data processingHandwritingComposite film

The invention discloses a liquid crystal composite film with a writing display function and a preparation method thereof. The liquid crystal composite film with the writing display function sequentially comprises from top to bottom a polyethylene terephthalate transparent film coated with a conductive polymer layer on the lower surface, an upper liquid crystal composite layer, a PET transparent film coated with a conductive polymer layer on both upper and lower surfaces, a lower liquid crystal composite layer, and an upper surface plating a PET black film with a conductive polymer layer, wherein all of the conductive layers were sputtered with silicon dioxide and coated with a polyvinyl alcohol insulating layer, and some of the insulating layers contain spacer particles. The liquid crystalcomposite film with the writing display function creatively adopts a double-layer liquid crystal film, and the double-layer rotation to different liquid crystals not only improves the brightness of the handwriting display, but also allows the upper and lower layers of liquid crystal to reflect different colors of light.

Owner:武汉毓鸿科技有限公司

A kind of PVC foam artificial leather and preparation method thereof

The invention discloses PVC (polyvinyl chloride) foamed artificial leather and a preparation method thereof. The PVC foamed artificial leather comprises a fabric base material, a foaming layer and a surface layer which are attached from inside to outside sequentially, wherein the foaming layer comprises components in parts by weight as follows: 95-105 parts of PVC resin, 75-85 parts of filling powder, 75-85 parts of a plasticizer, 3.5-4.0 parts of a stabilizer, 4.5-5.5 parts of a foaming agent and 9.5-10.5 parts of masterbatch; the surface layer comprises components in parts by weight as follows: 65-75 parts of PVC resin, 6-8 parts of filling powder, 46-52 parts of a plasticizer, 1.5-3 parts of a stabilizer and 4.5-5.5 parts of masterbatch. The preparation method comprises steps as follows: (1), blending; (2), mixing, open milling and filtering; (3), calendering attachment; (4), cooling; (5), foaming; (6), embossing, cooling and rolling-up to obtain a finished PVC foamed artificial leather product. The artificial leather prepared with the method feels good, and is good in texture, high in breathability and good in wear resistance.

Owner:DONGTAI FUAN SYNTHETIC MATERIAL CO LTD

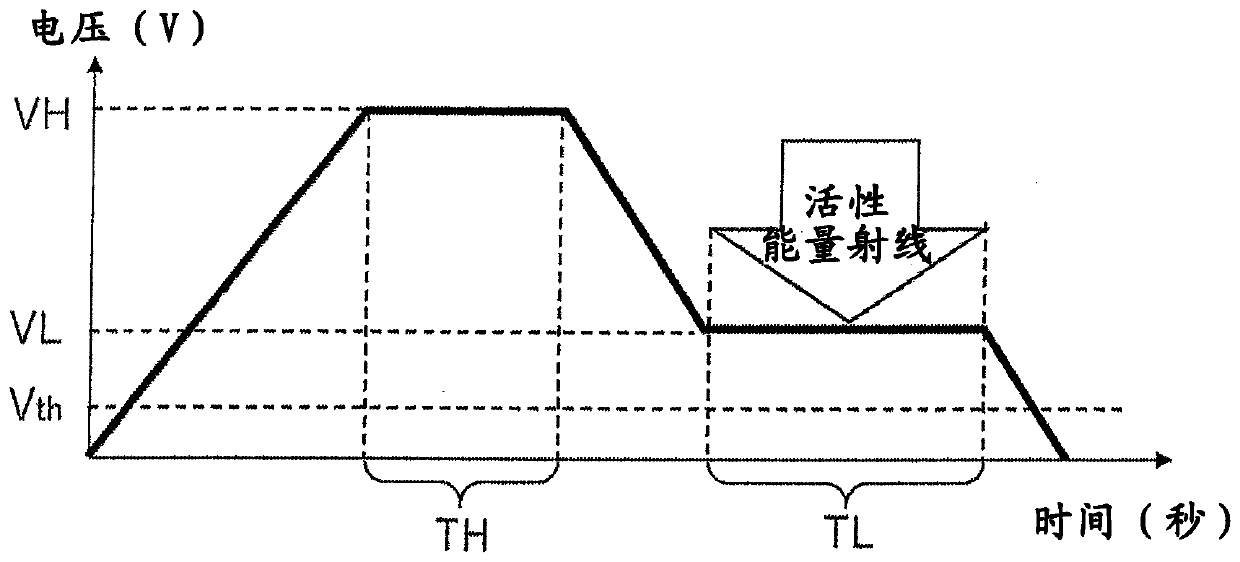

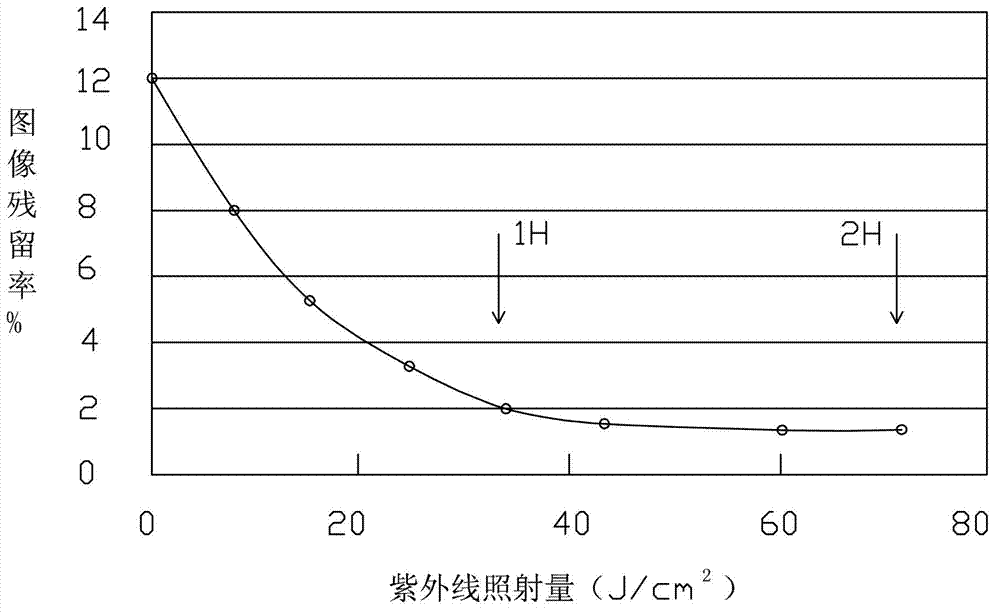

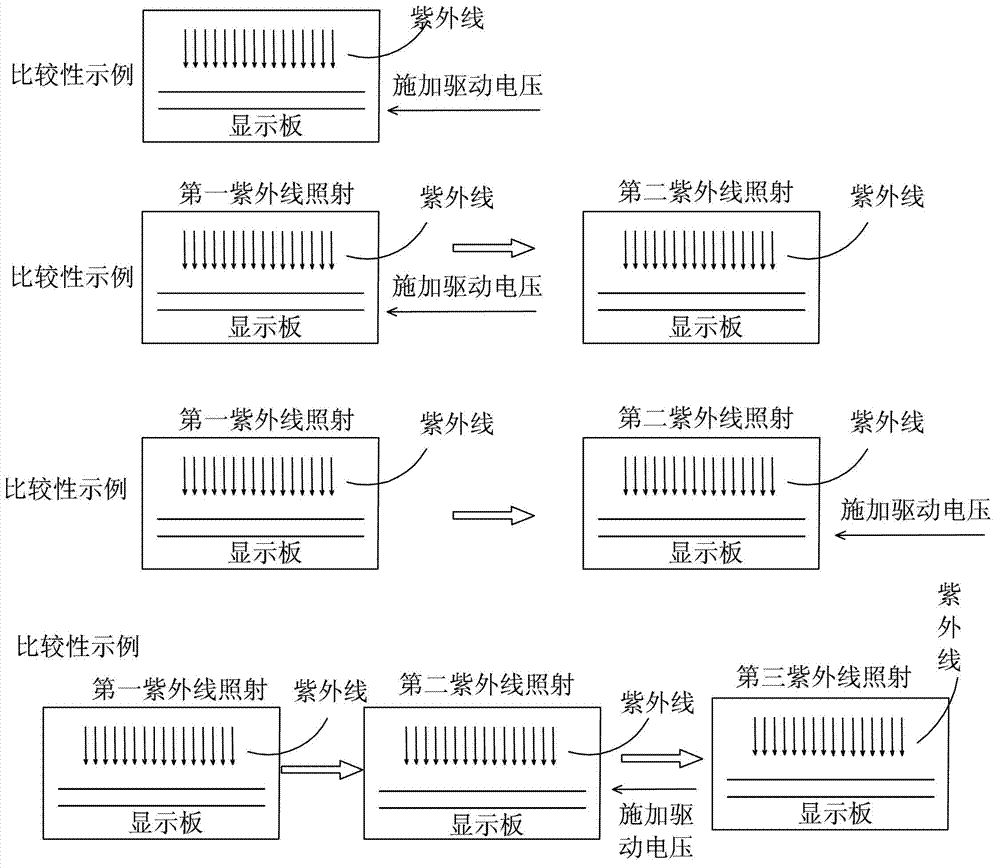

Method for manufacturing liquid crystal display element

The present invention addresses the problem of providing a method for manufacturing a liquid crystal display element capable of sufficiently aligning liquid crystal molecules at an appropriate pre-tilt angle in a short time. This method for manufacturing a liquid crystal display element is a method for manufacturing a liquid crystal display element provided with a pair of substrates each providedwith an electrode, and a vertically oriented liquid crystal layer disposed between the substrates. This method for manufacturing a liquid crystal display element is characterized by comprising: a stepfor arranging a pair of substrates so that electrodes face each other with a liquid crystal composition containing liquid crystal molecules and a polymerizable monomer interposed therebetween; a stepfor maintaining the voltage applied to the liquid crystal composition at a first voltage higher than the threshold voltage of the liquid crystal molecules; and a step for obtaining a liquid crystal layer by polymerizing the polymerizable monomer by irradiating the liquid crystal composition with an active energy ray while maintaining the liquid crystal composition at a second voltage after reducing the voltage to a second voltage that is higher than the threshold voltage but lower than the first voltage.

Owner:DIC CORP

Technology for preparing hybrid flocculant by gangue base raw material and hybrid flocculant prepared by the same

InactiveCN102730807BAchieve secondary useTake advantage ofWater/sewage treatment by flocculation/precipitationTurbidityVacuum pump

The present invention discloses a technology for preparing hybrid flocculant by gangue base raw material and a hybrid flocculant prepared by the same. The steps of the technology are as follows: preparing the hybrid flocculant by the gangue base waste residue; during the process of synthesis, preparing the gangue base raw material and stirring together the modified gauge base filter residue and acrylamide after alkali and acid extraction; performing vacuum-pumping to pass nitrogen; and adding an initiator to perform polymerization, so as to obtain the gray viscous hybrid flocculant in a gel state. Compare with the prior art, the gangue waste residue of the technology can be fully used, and thus the waste control by waste is realized. The obtained hybrid flocculant has advantages of a strong flocculation ability, high sedimentation speed and high compactness. COD and BOD removal rate of the technology is much higher than that of a single polyacrylamide system and a simple mixture of modified gauge base filter residue and polyacrylamide. The technology also has advantages of less quantity of reagent, relatively higher processing efficiency of waste water of drilling well and coalification, and obviously higher removal efficiency of water turbidity and chroma.

Owner:JINING MEDICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Preparation method of poly[2, 5-dyhydroxy-1, 4-phenylene pyridine diimidazole] polymer Preparation method of poly[2, 5-dyhydroxy-1, 4-phenylene pyridine diimidazole] polymer](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/d0f58cdd-7ce6-4dd0-8c91-b0f4bbca9a4a/2013106175895100002DEST_PATH_IMAGE001.PNG)

![Preparation method of poly[2, 5-dyhydroxy-1, 4-phenylene pyridine diimidazole] polymer Preparation method of poly[2, 5-dyhydroxy-1, 4-phenylene pyridine diimidazole] polymer](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/d0f58cdd-7ce6-4dd0-8c91-b0f4bbca9a4a/2013106175895100002DEST_PATH_IMAGE002.PNG)