Automobile smart glass and manufacture method thereof

A technology for dimming glass and automobiles, applied in windshields, optics, vehicle parts, etc., can solve the problems of reducing sunlight transmittance, easy aging of automobile films, affecting normal use, etc., to shorten the response time, cut off Noise, the effect of increasing the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

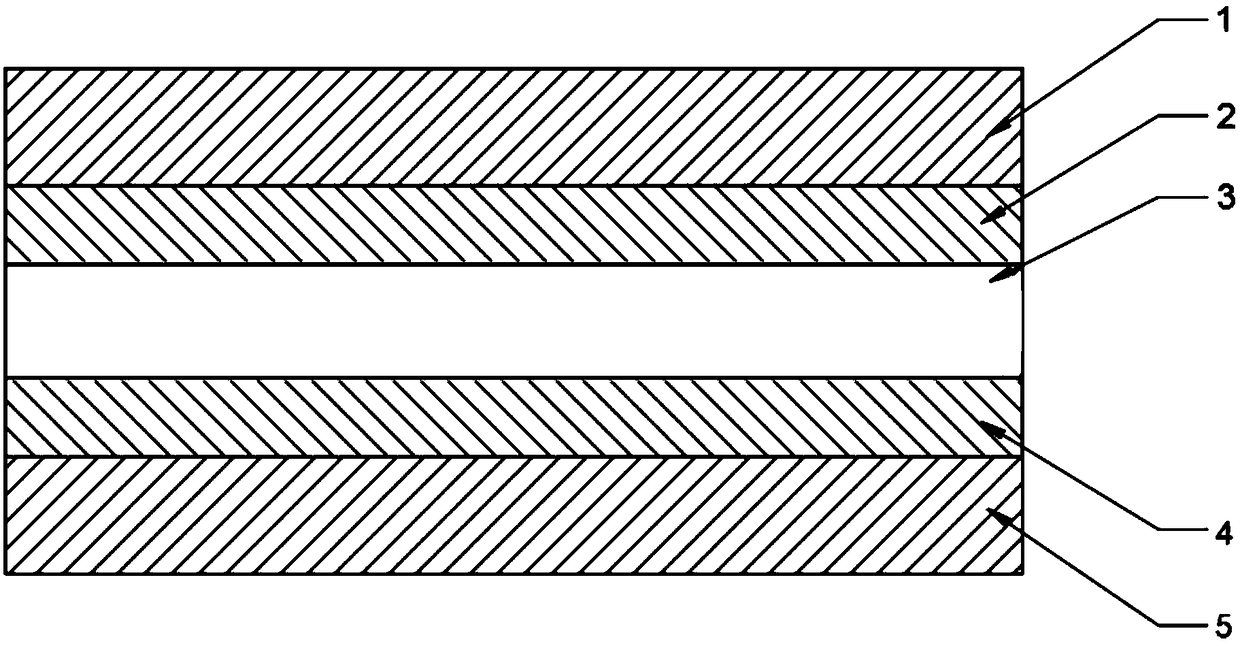

[0024] In order to facilitate the understanding of the present invention, the following will be described in conjunction with the accompanying drawings and embodiments.

[0025] refer to figure 1 It can be seen that the present invention discloses a method for preparing automotive dimming glass, comprising the following steps:

[0026] Step 101: preparing a conductive layer to provide a transparent organic film, the transparent organic film is less than 10 3 Under the ultra-low pressure environment of Pa and the carbon source fed in at a temperature greater than 600 ° C, a graphene layer with a thickness of 20nm-400nm is formed by chemical vapor deposition, and an electrode is arranged at the end of the graphene layer;

[0027] Step 102: Prepare the dimming film 3, prepare graphite nanoparticles through an ultrafine pulverizer, mix graphite nanoparticles, smectic liquid crystal materials, polymerizable monomers and initiators and stir to form a mixture, the mixture includes m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com