Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "For the purpose of saving energy and reducing consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Air cooling refrigerator and defrosting control method thereof

ActiveCN107120899AFor the purpose of saving energy and reducing consumptionLighting and heating apparatusDomestic refrigeratorsFlueFreezing chamber

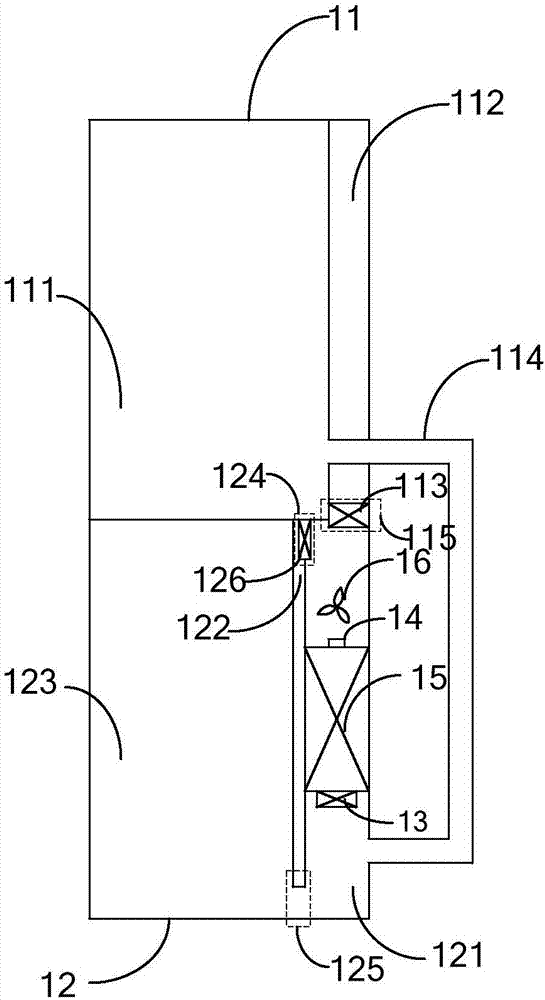

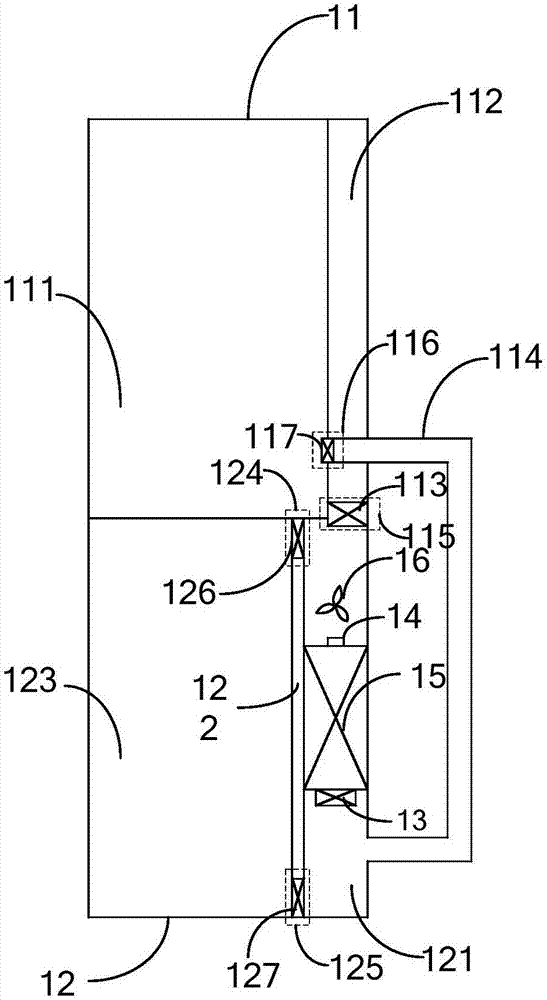

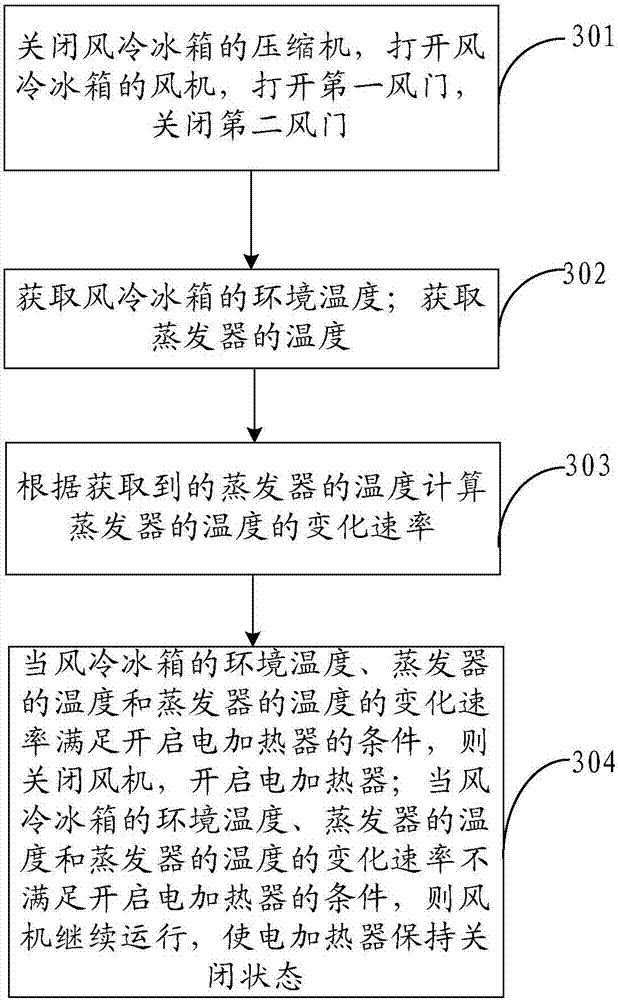

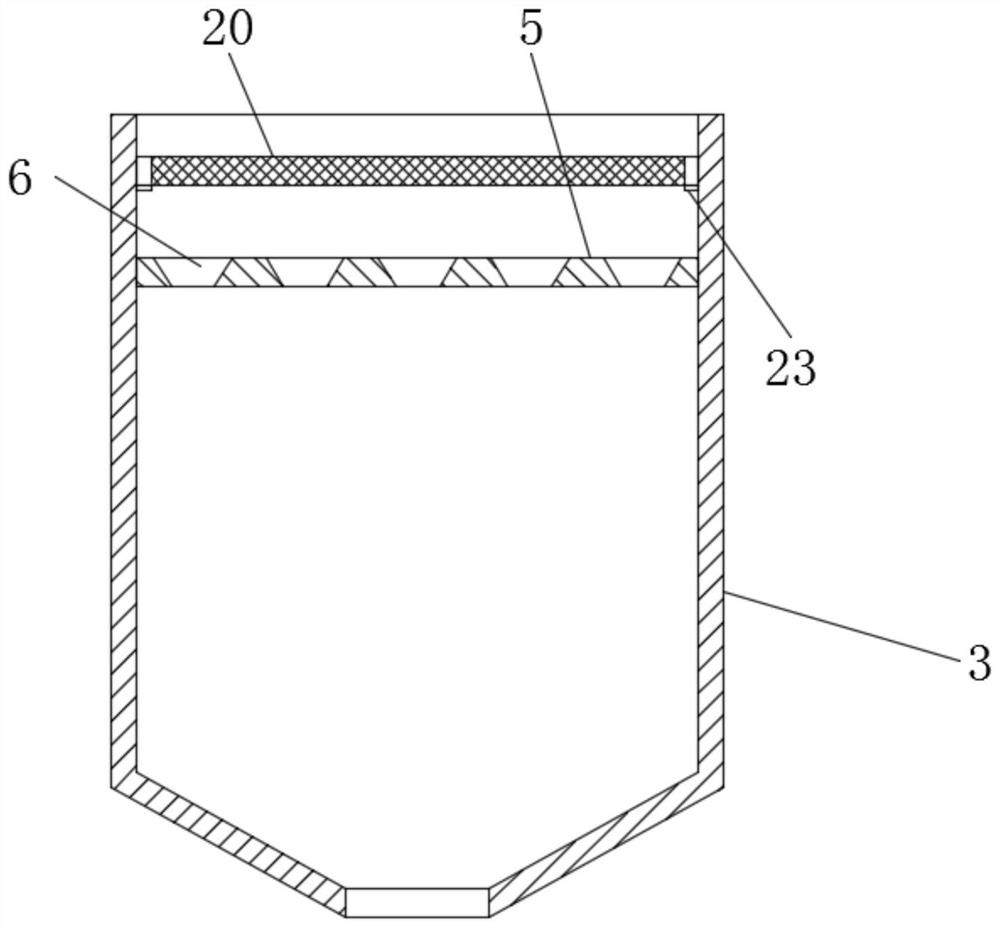

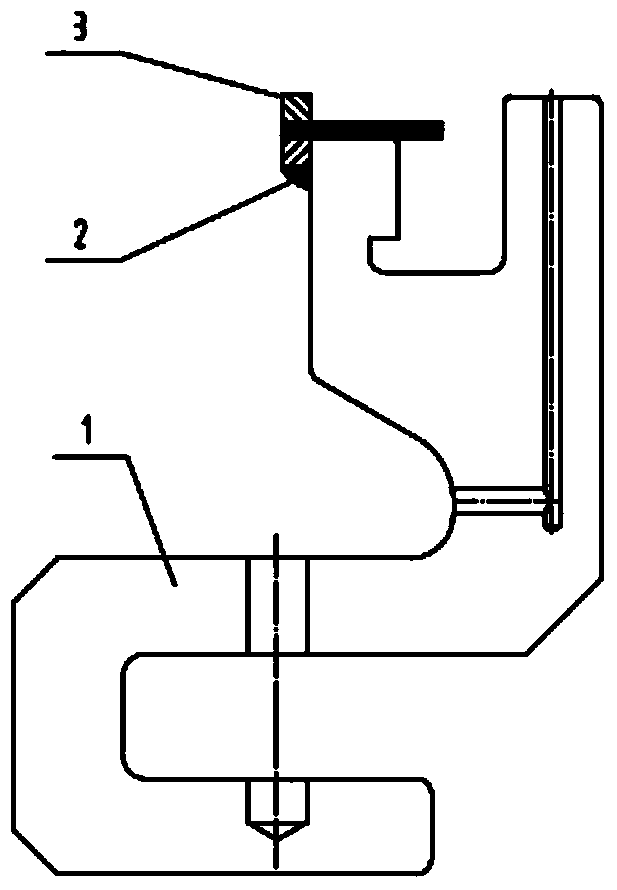

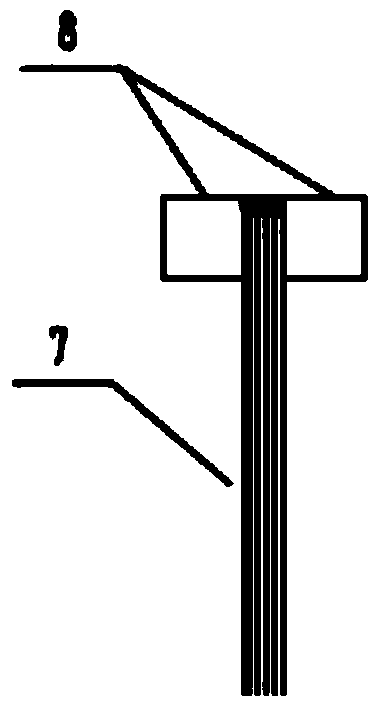

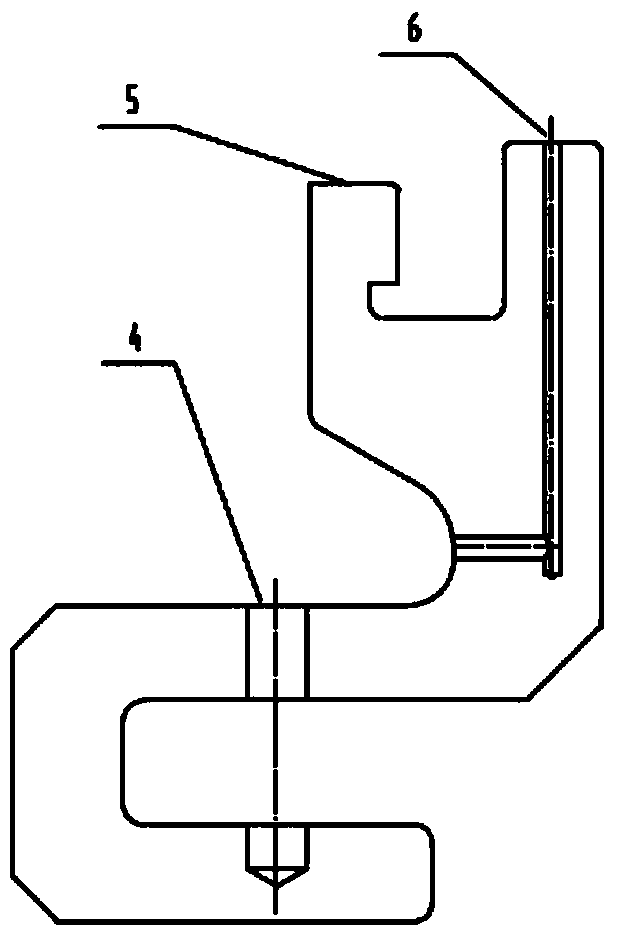

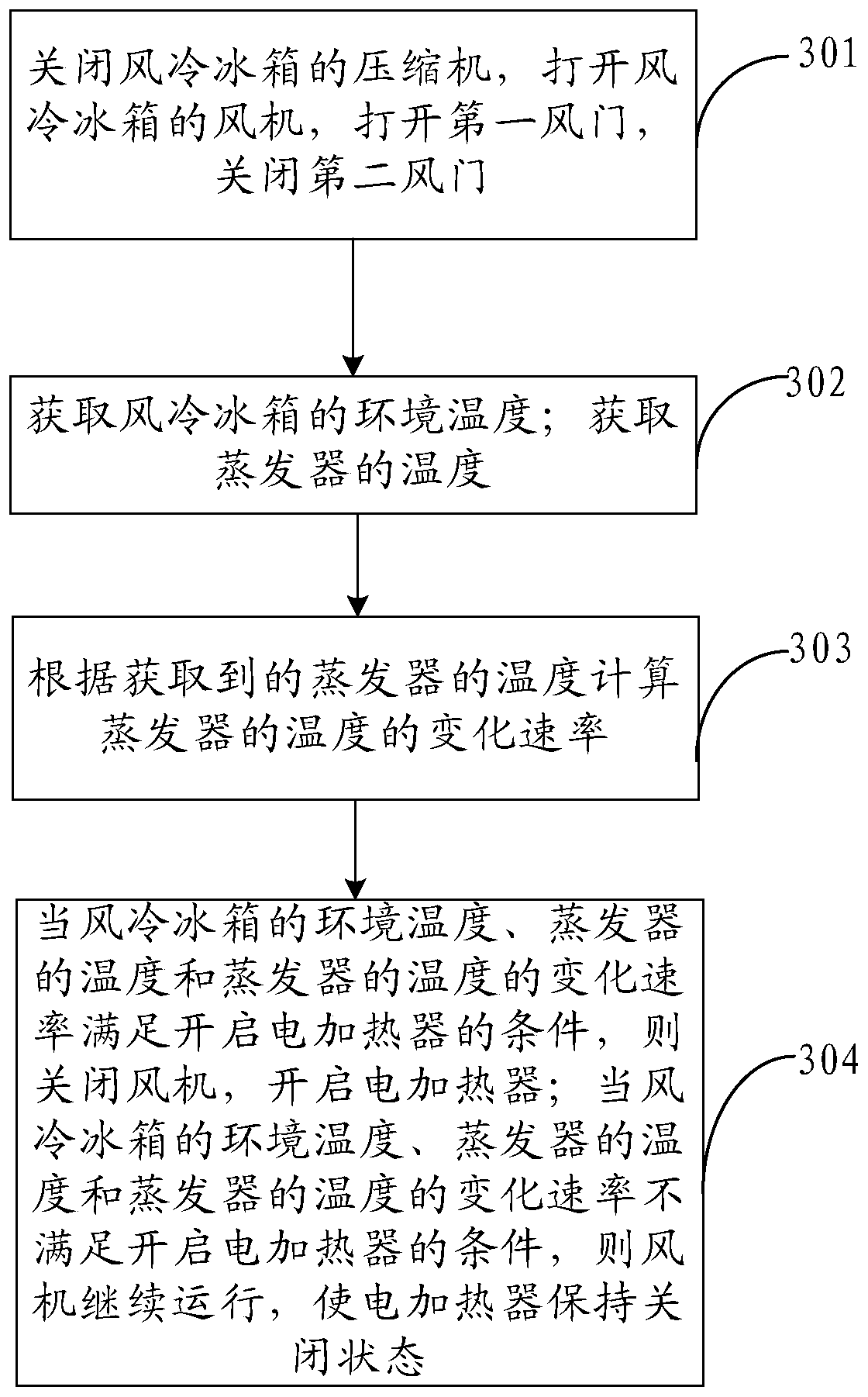

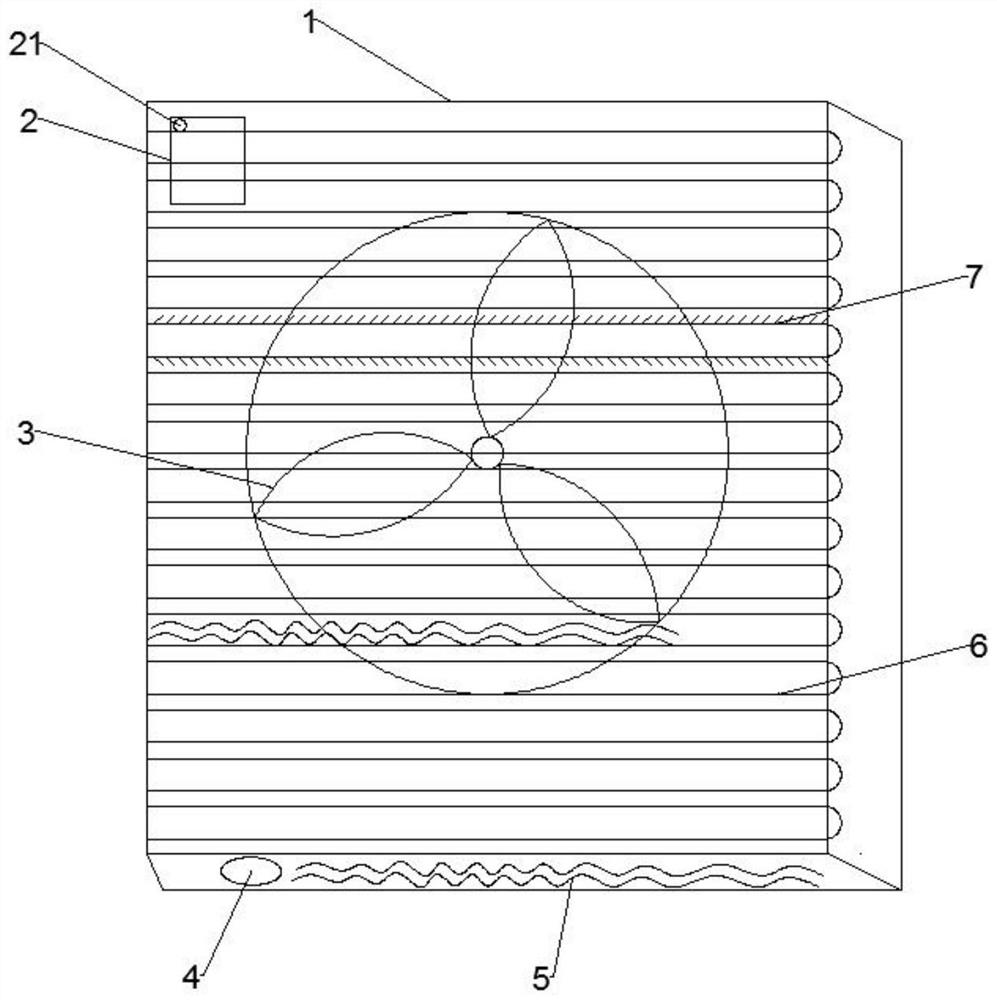

The embodiment of the invention provides an air cooling refrigerator and a defrosting control method thereof, and relates to the field of refrigerator control, wherein refrigerator defrosting can be achieved in a more labor-saving manner. The air cooling refrigerator comprises a freezing chamber and a cold storage chamber which achieve heat isolation through a heat insulation partition plate, an evaporator chamber used for providing the cooling capacity for the freezing chamber and the cold storage chamber, a freezing air flue and a cold storage air flue. The evaporator chamber is located in the freezing chamber and internally provided with an electric heater and a temperature sensor. The freezing air flue is used for transmitting the cooling capacity in the evaporator chamber to the freezing chamber, and the cold storage air flue is used for transmitting the cooling capacity in the evaporator chamber to the cold storage chamber. The evaporator chamber and the cold storage air flue are isolated or communicate with each other through a first air door. The freezing air flue and the evaporator chamber communicate with each other through a freezing air inlet, the storage space of the freezing chamber communicates with the evaporator chamber through a freezing air return port, and the freezing air inlet is provided with a second air door.

Owner:HISENSE(SHANDONG)REFRIGERATOR CO LTD

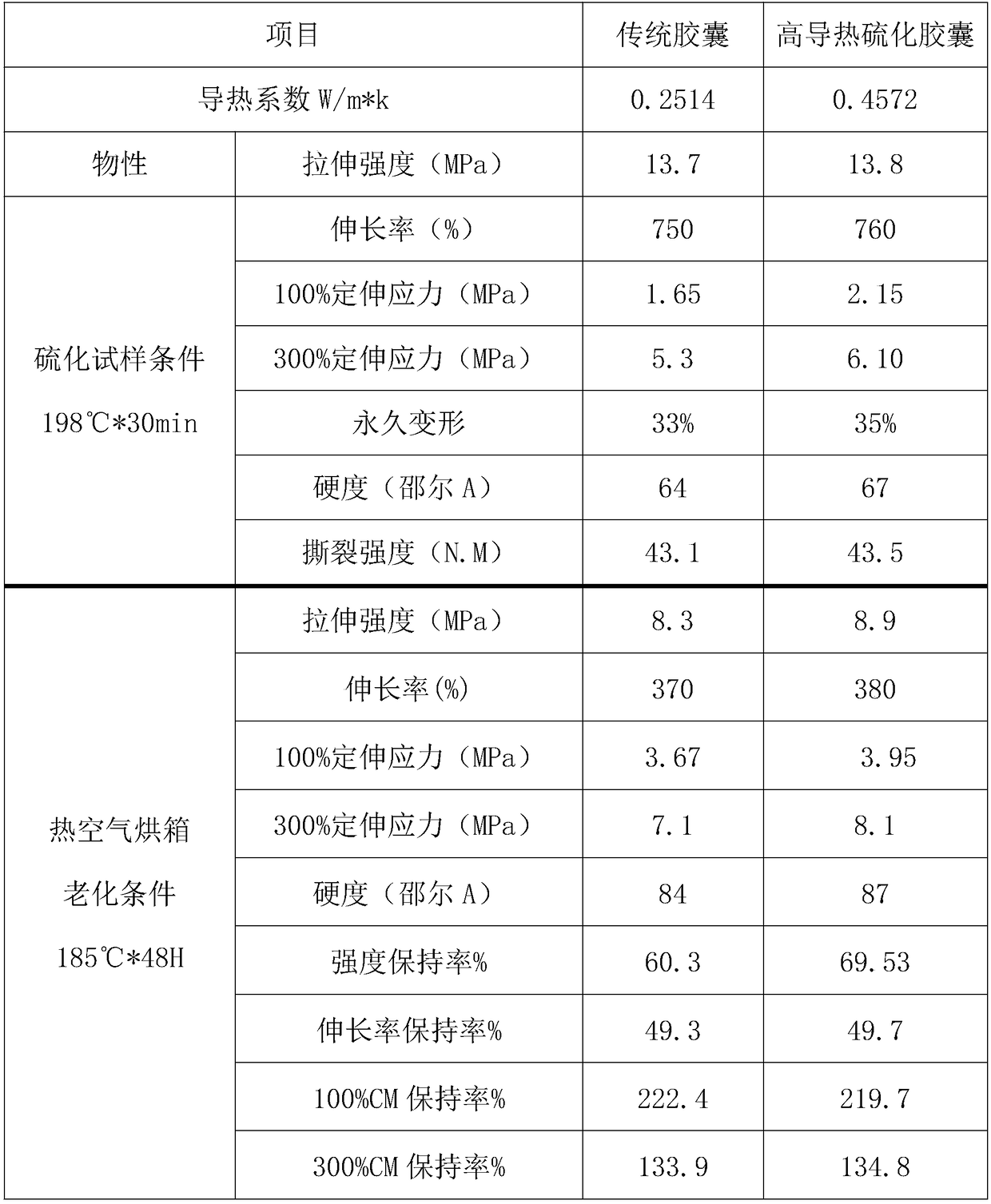

Preparation method of high-heat-conductivity type tire vulcanization capsule

The invention discloses a preparation method of a high-heat-conductivity type tire vulcanization capsule. The preparation method of the high-heat-conductivity type tire vulcanization capsule belongs to the technical field of tires, and comprises the following steps of (1) compounding the components according to the matching ratio: 95 parts of butyl rubber, 4 to 5 parts of chloroprene rubber, 15 to20 parts of N375 carbon black, 35 to 45 parts of acetylene black, 7 to 15 parts of graphene, 7 to 10 parts of alkane oil, 0.5 to 1.5 parts of stearic acid, 5 to 7 parts of zinc oxide, and 8 to 10 parts of resin; (2) primarily mixing; (3) filtering rubber; (4) secondarily mixing; (5) forming; (6) vulcanizing; (7) polishing; and (8) inspecting a finished product. According to the preparation methodof the high-heat-conductivity type tire vulcanization capsule provided by the invention, on the basis of ensuring the stability of various physical and mechanical properties, a heat conductivity coefficient is further improved, so that the aims of saving energy and reducing cost are achieved.

Owner:YONGYI RUBBER CO LTD

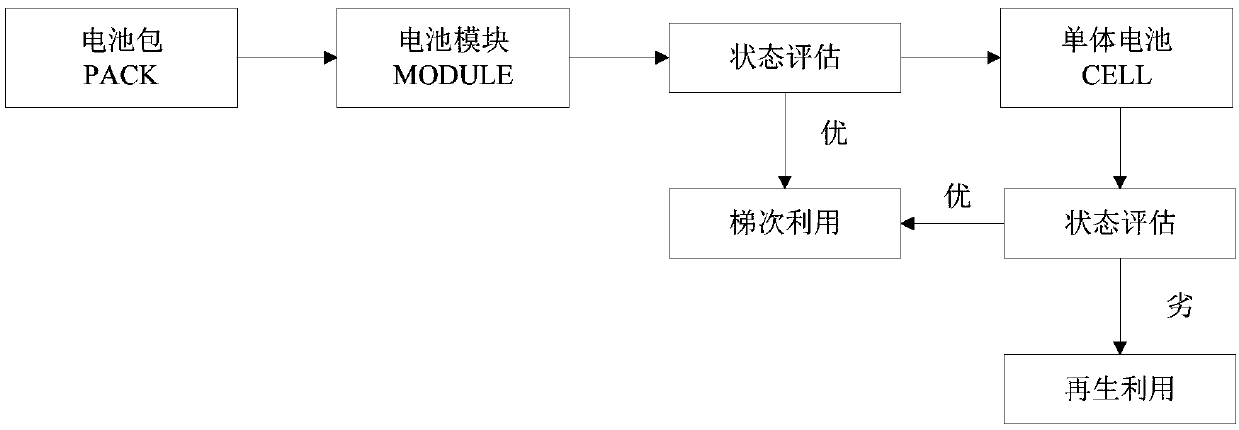

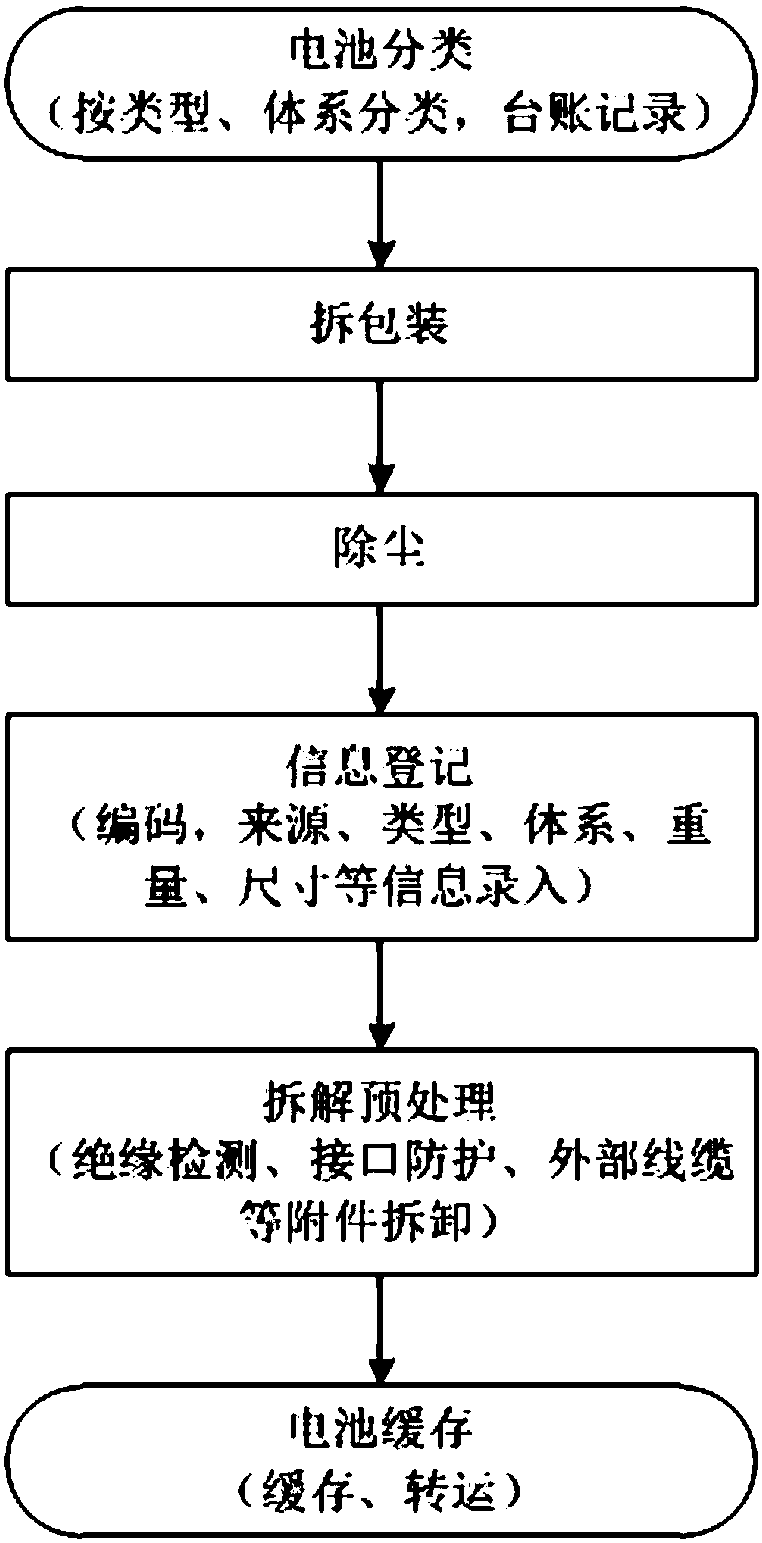

Ex-service battery sorting method

InactiveCN107645022AIncrease usageReduce shared costsWaste accumulators reclaimingSecondary cells servicing/maintenancePower batteryNew energy

The invention relates to an ex-service battery sorting method, and belongs to the technical field of battery ex-service treatment. Firstly, an ex-service battery pack is disassembled into battery modules, and the states of the battery modules are assessed. Secondly, the battery modules with the states conforming to a first set standard are sorted, and the battery modules not conforming to the first set standard are disassembled into single batteries again. Finally, the states of the single batteries are assessed, whether the states of the single batteries conform to a second set standard or not can be judged, the single batteries conforming to the second set standard are sorted, and the single batteries not conforming to the second set standard are recycled. By hierarchical graded cascadeutilization, the utilization rate of ex-service batteries is increased, the value of power batteries can be brought into full play, the apportioned cost of the batteries in cascade utilization fieldscan be reduced, energy is saved, consumption is reduced, and virtuous cycle of a new energy industry is promoted.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

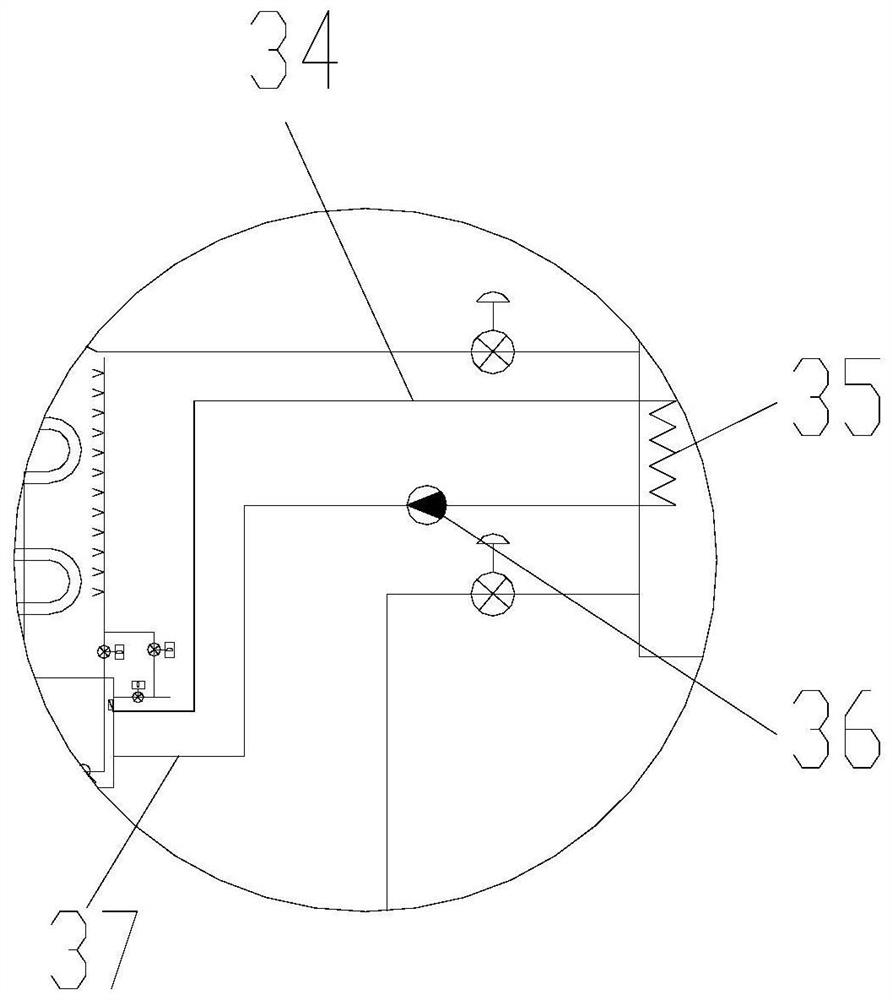

Jacquard electromagnet assembly

InactiveCN101718019AIncrease the lengthIncrease the number of turnsJacquardsEngineeringRegular Production

The invention discloses a jacquard electromagnet assembly which comprises a manual hole (31), an iron hook (32), a plastic hook (33), an electromagnet (34), a spring (35) and a dustproof shell (36) which is installed on the tail of the electromagnet assembly. The invention can effectively prevent dust from entering a transmission mechanism to form oil stains through the dustproof shell (36), and can carry out regular production without the cleaning operation; the iron hook (32) can be operated through the manual hole (31), thereby being convenient to dismount and maintain; the power arm of the iron hook (32) is extended, thereby enhancing the energy utilization efficiency; and the linear diameter of the electromagnet (34) is enlarged, thereby reducing the energy loss. The jacquard electromagnet assembly of the invention has the advantages of dust prevention, convenient demounting and maintenance, energy conservation and consumption reduction.

Owner:SHANGHAI CHAOCHENG ELECTRON SCI & TECH

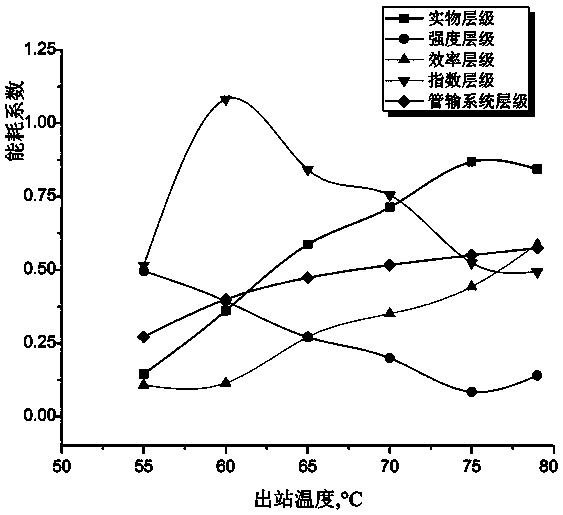

A crude oil pipeline transportation exergy consumption evaluation system analysis method based on analytic hierarchy process

ActiveCN109242267AImprove operational efficiencyFor the purpose of saving energy and reducing consumptionTechnology managementResourcesFeature vectorAnalysis method

The invention relates to a crude oil pipeline transportation exergy consumption evaluation system analysis method based on analytic hierarchy process. The analysis method comprises: first, exergy analysis of the process of crude oil pipeline transportation is carried out, crude oil pipeline exergy consumption evaluation system Hierarchical structure model is established according to the analysis index; according to crude oil pipeline exergy consumption evaluation system Hierarchical structure model, the judgment matrix of each index at different levels is constructed by 1 - 9 scale method, andthe weight of each index at different levels is calculated by root-square method according to the matrix of each level, and the eigenvector of the largest eigenvalue is normalized when being processed; consistency of judgment matrix is judged, if relevant indexes meet that requirement, the consistency of judgment matrix is accepted, and according to the index weight of each hierarchical structure, the influence degree of the low layer to the upper layer is obtained; 4. Combining the production data of the pipeline, the energy efficiency of the crude oil pipeline transportation process is evaluated; the energy consumption coefficient of pipeline crude oil is Calculated. The system of the invention judges the energy-saving potential and the improvement direction of the energy consumption.

Owner:NORTHEAST GASOLINEEUM UNIV

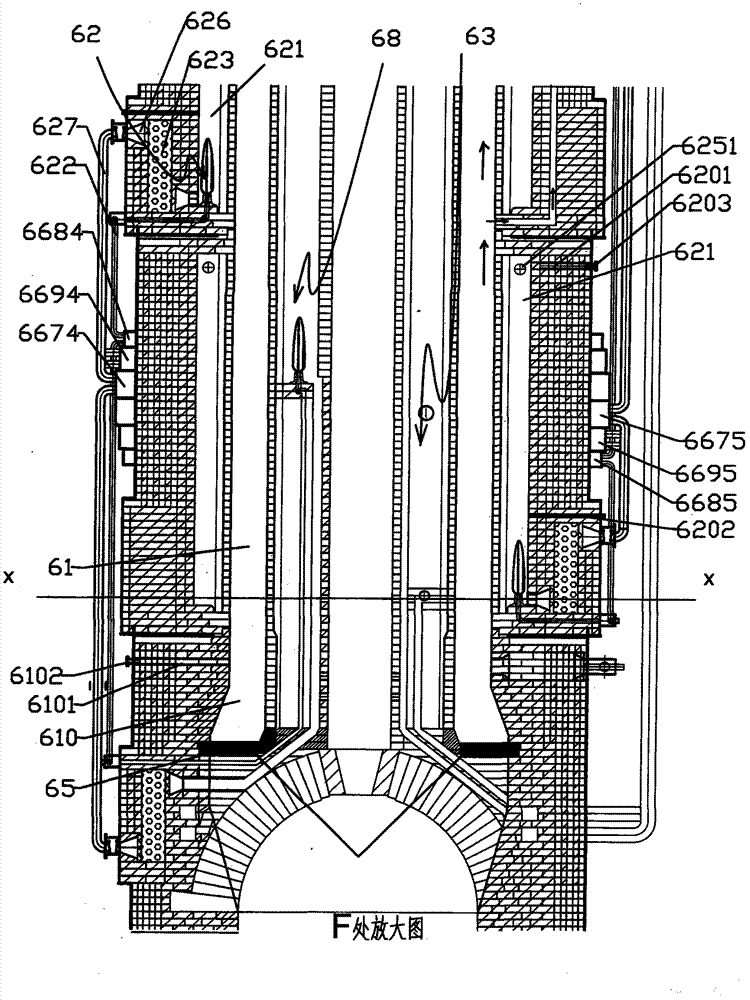

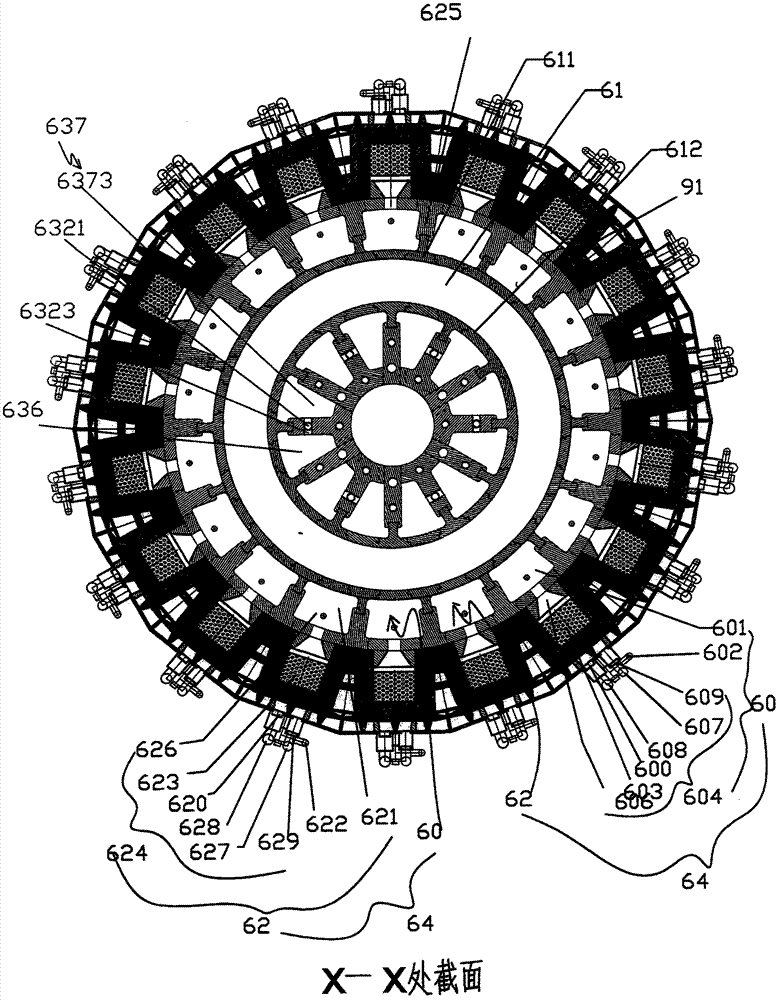

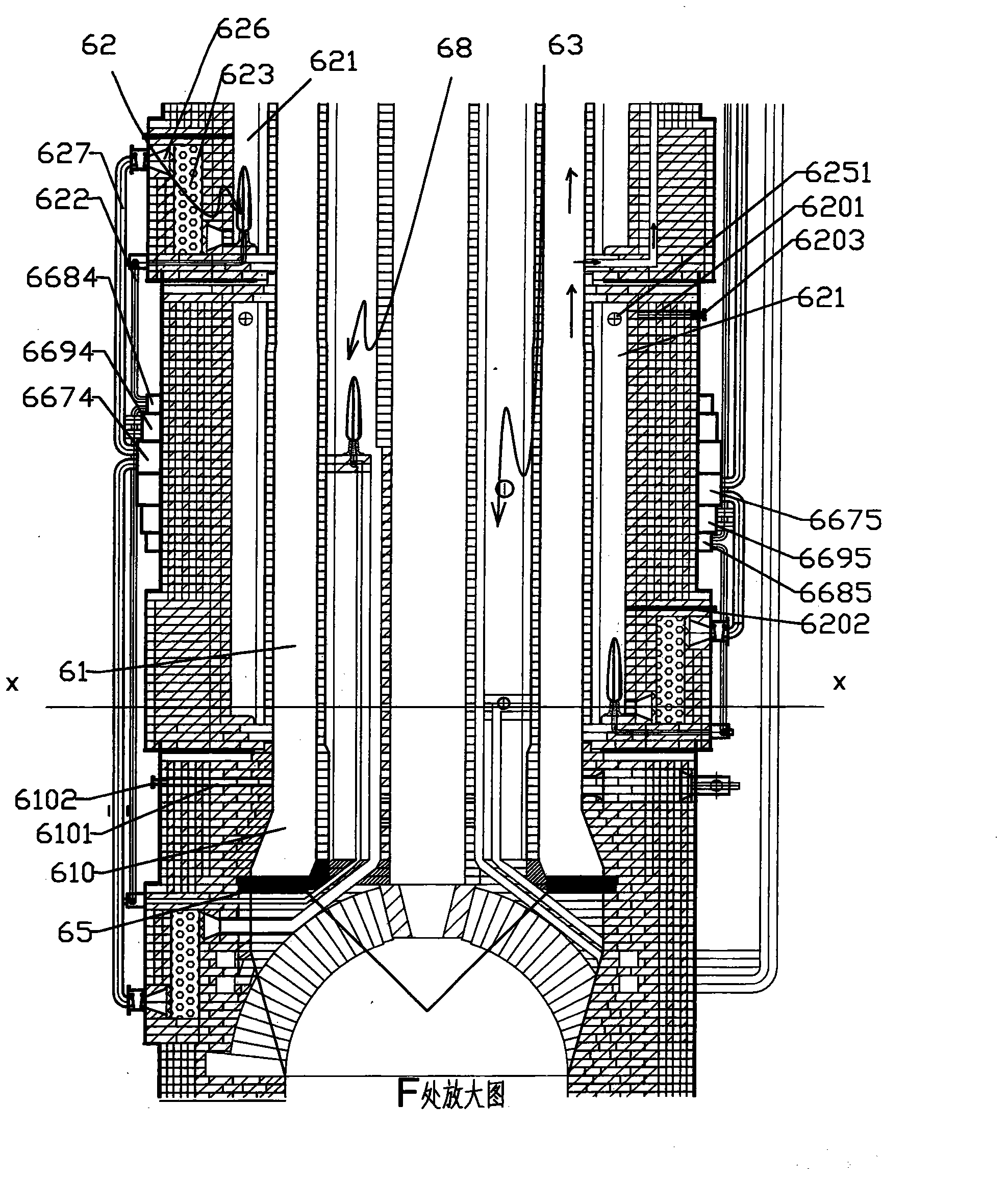

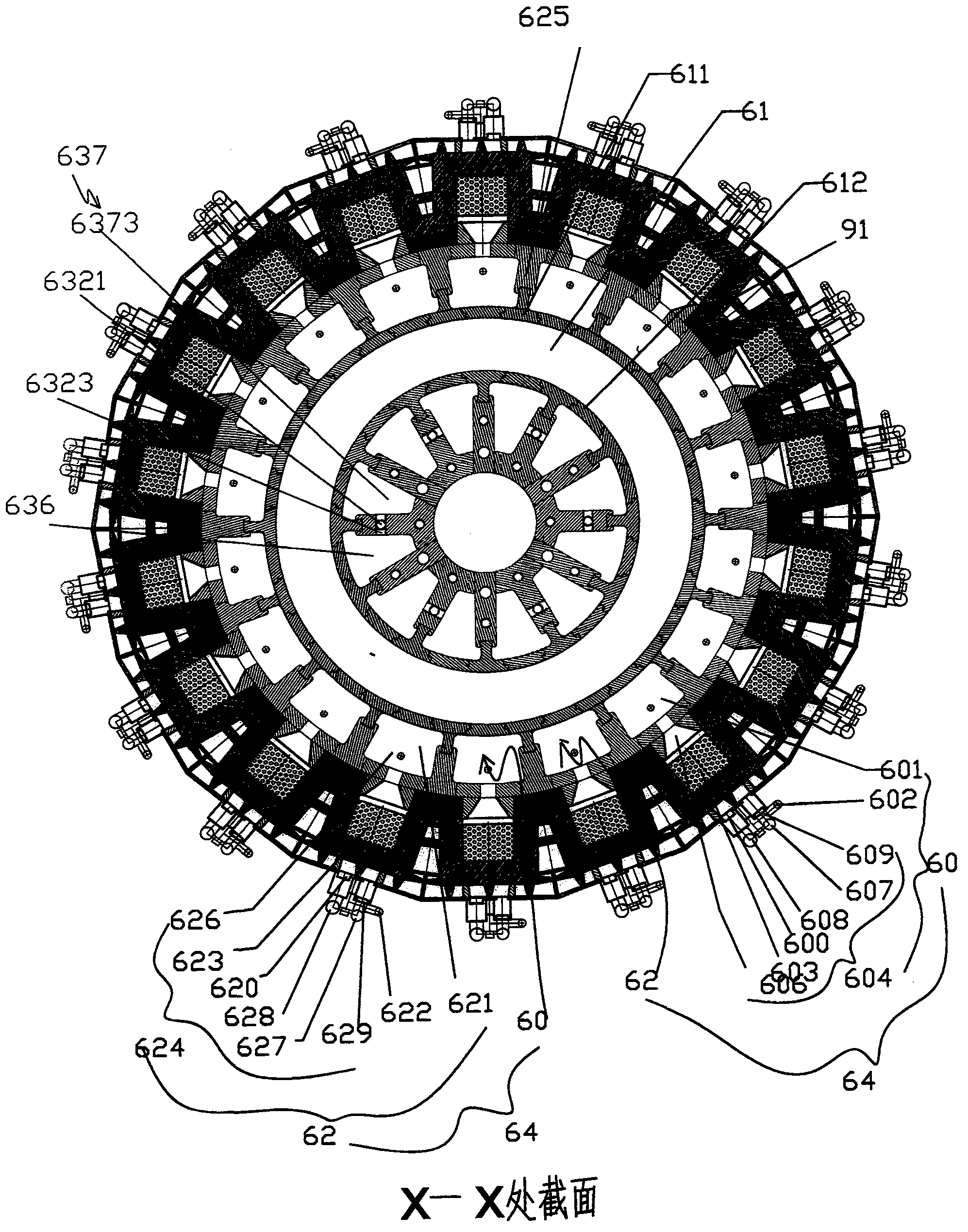

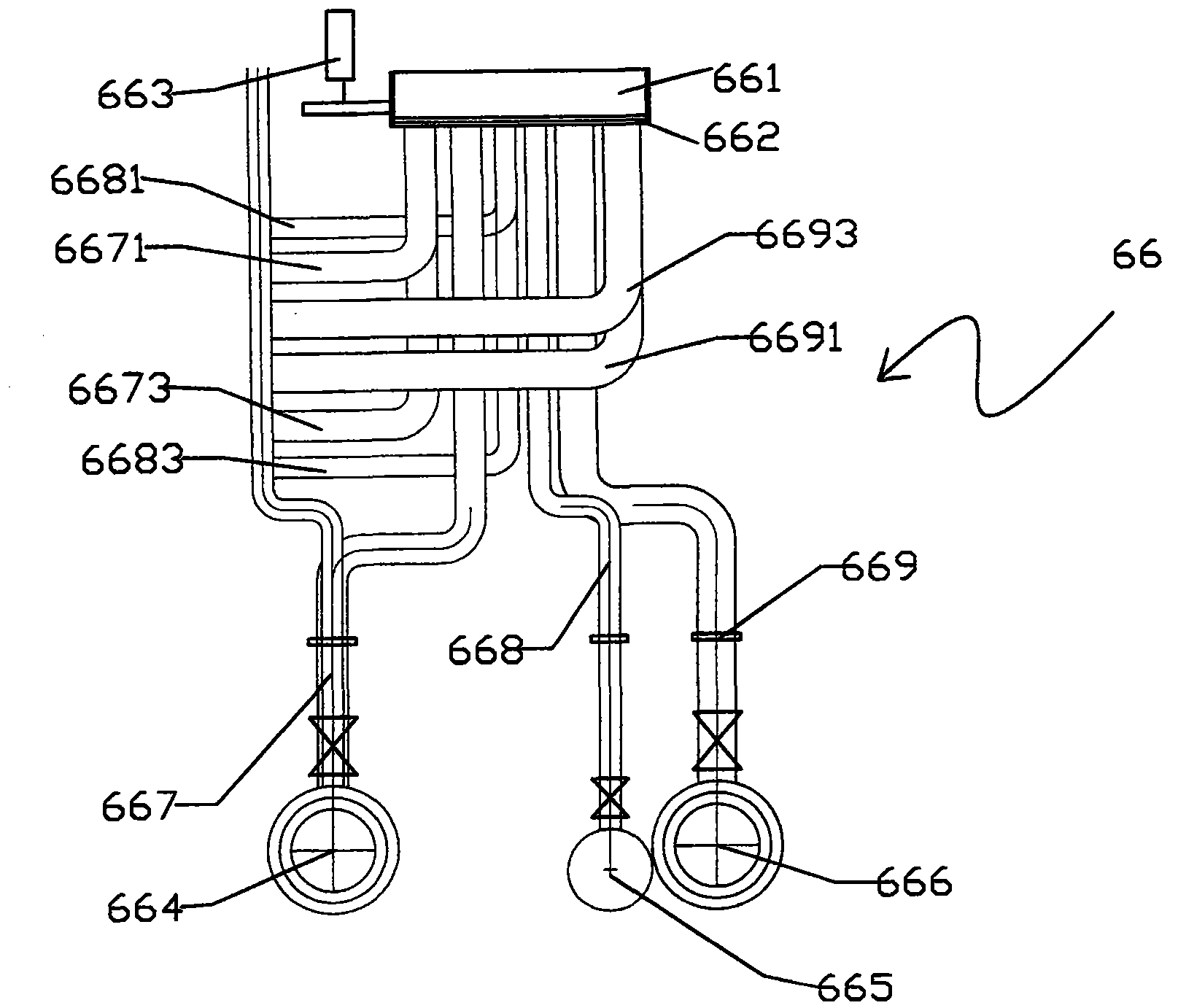

Heat storage and exchange device for gas heater of coal pyrolyzing furnace

InactiveCN102766473AImprove combustion efficiencyReduce coking costCombustible gas coke oven heatingProcess engineeringCombustion chamber

The invention discloses a heat storage and exchange device for a gas heater of a coal pyrolyzing furnace. The heat storage and exchange device comprises two sets of heat storage chambers, two sets of heat storage members, two sets of air inlet branch pipes and two sets of combustion waste gas discharging branch pipes; a first heat storage chamber is arranged in a furnace body outer wall, a first heat storage member is arranged in the first heat storage chamber, one end of the first heat storage chamber leads to the bottom of a first combustion chamber, and the other end of the first heat storage chamber is respectively connected with a first air inlet branch pipe and a first combustion waste gas discharging branch pipe; a second heat storage chamber is arranged in the furnace body outer wall, a second heat storage member is arranged in the second heat storage chamber, one end of the second heat storage chamber leads to the bottom of a second combustion chamber, and the other end of the second heat storage chamber is respectively connected with a second air inlet branch pipe and a second combustion waste gas discharging branch pipe; and combustion chamber through holes are arranged between the first combustion chamber and the second combustion chamber. According to the heat storage and exchange device for the gas heater of the coal pyrolyzing furnace, air entering the combustion chambers of the gas heater can be heated, the combustion efficiency of gases in the combustion chambers is improved, hot waste gases obtained after gas combustion in the combustion chambers can be used for heat storage, additional heat sources are not required, and coking costs are saved.

Owner:SHANXI XINLI ENERGY TECH

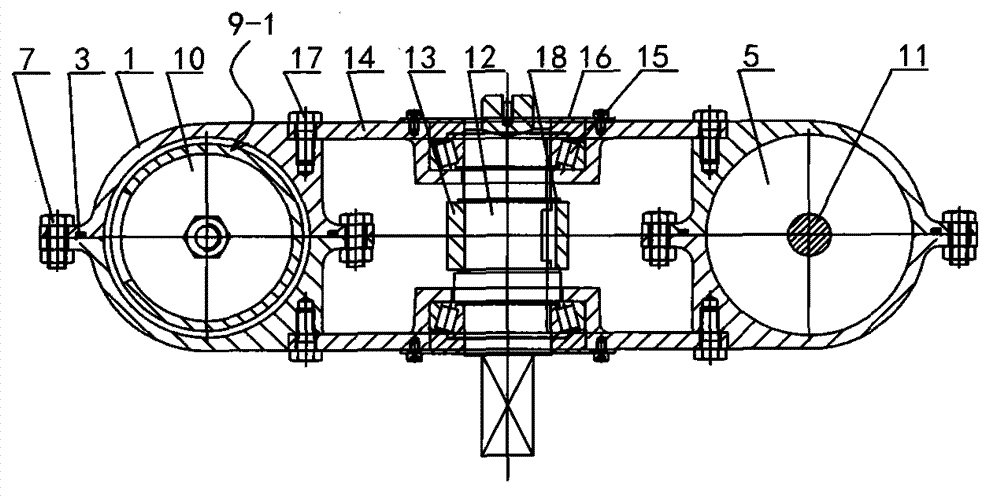

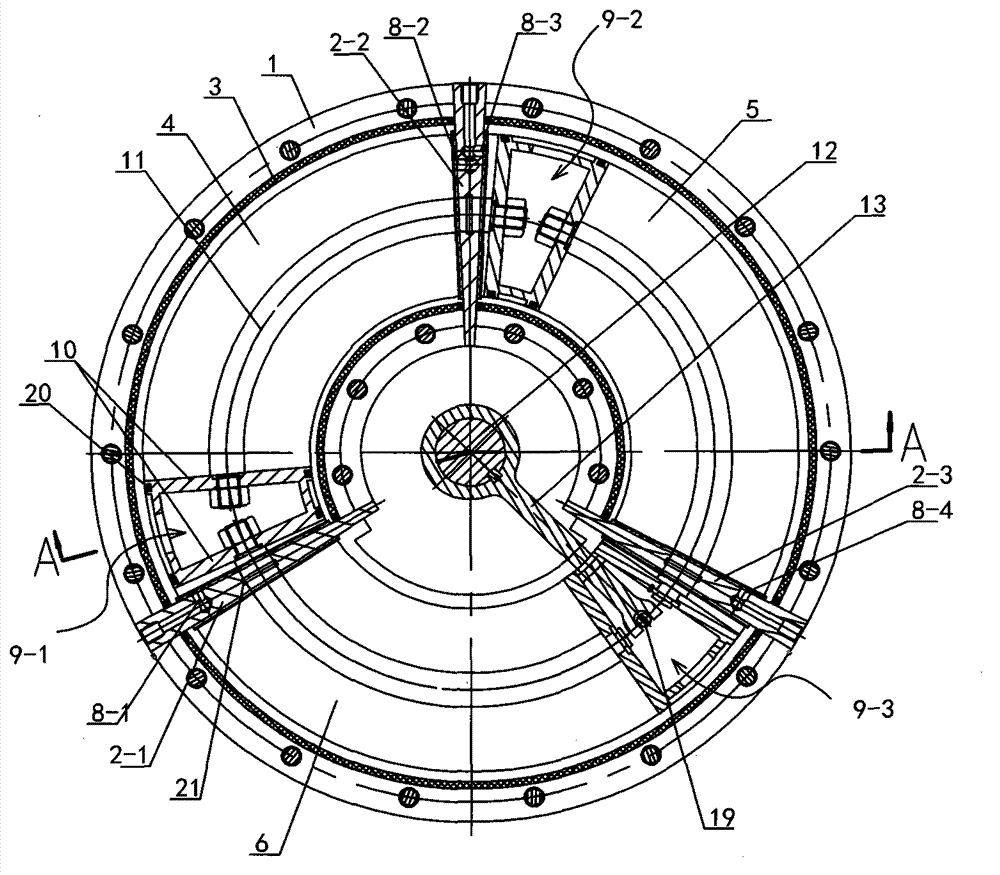

Annular piston type pneumatic actuating mechanism

InactiveCN102926813AIncrease output torqueReduce areaEngine componentsRotary piston enginesDrive shaftEngineering

The invention discloses an annular piston type pneumatic actuating mechanism, which belongs to the field of pneumatic actuating mechanism production. The annular piston type pneumatic actuating mechanism mainly comprises an air cylinder assembly, a piston assembly and a transmission output assembly, wherein the air cylinder assembly is used for being assembled into a plurality of isometric cylinder bodies, an annular air cylinder is formed by connecting the isometric cylinder bodies in series, and the isometric cylinder bodies at least comprise one open cylinder body and one sealed cylinder body; the piston assembly comprises a pneumatic piston, a driven piston and an annular push rod, the pneumatic piston is arranged in the sealed cylinder body, the driven piston is arranged in the open cylinder body, and adjacent pneumatic pistons and / or driven pistons are respectively in transmission connection through isometric annular push rods; and the transmission output assembly comprises a driving shaft and a connecting crank, and the driving shaft is coaxially arranged at the position of an axis of the annular air cylinder and is in transmission connection with the piston assembly arranged at the position of the open cylinder body through the connecting crank. Compared with the prior art, the annular piston type pneumatic actuating mechanism disclosed by the invention has the characteristics of convenience for large-torque output, energy saving, consumption reducing, and the like.

Owner:山东益龙阀门有限责任公司

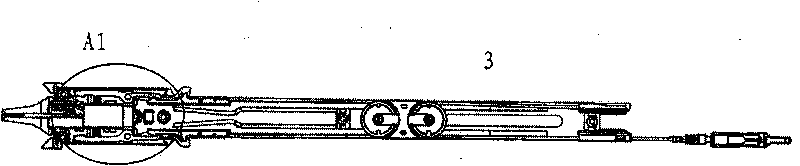

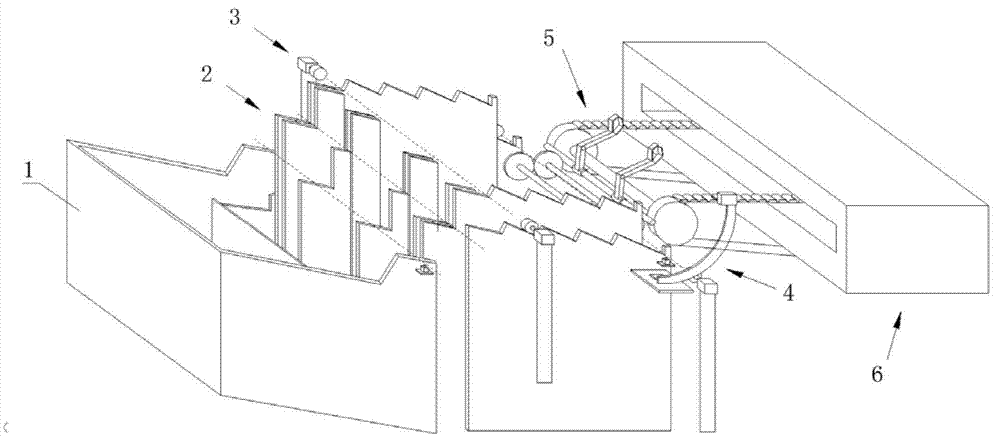

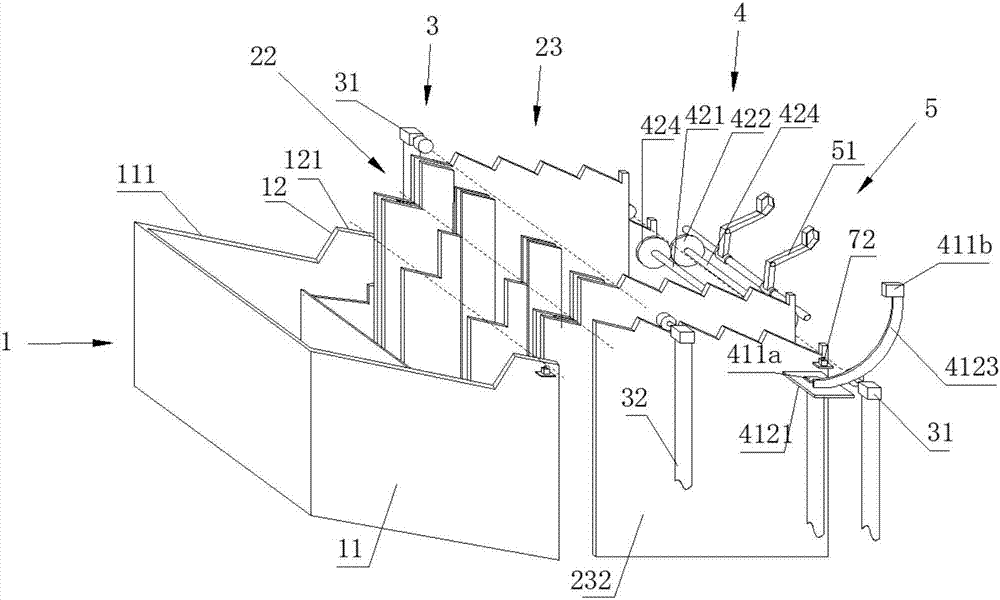

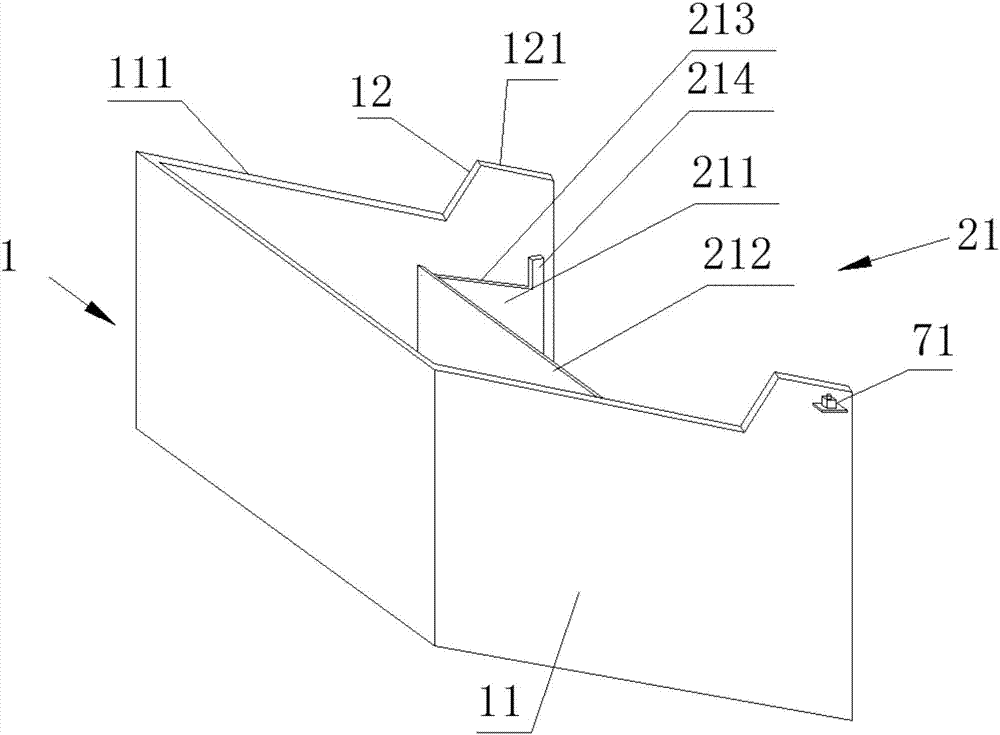

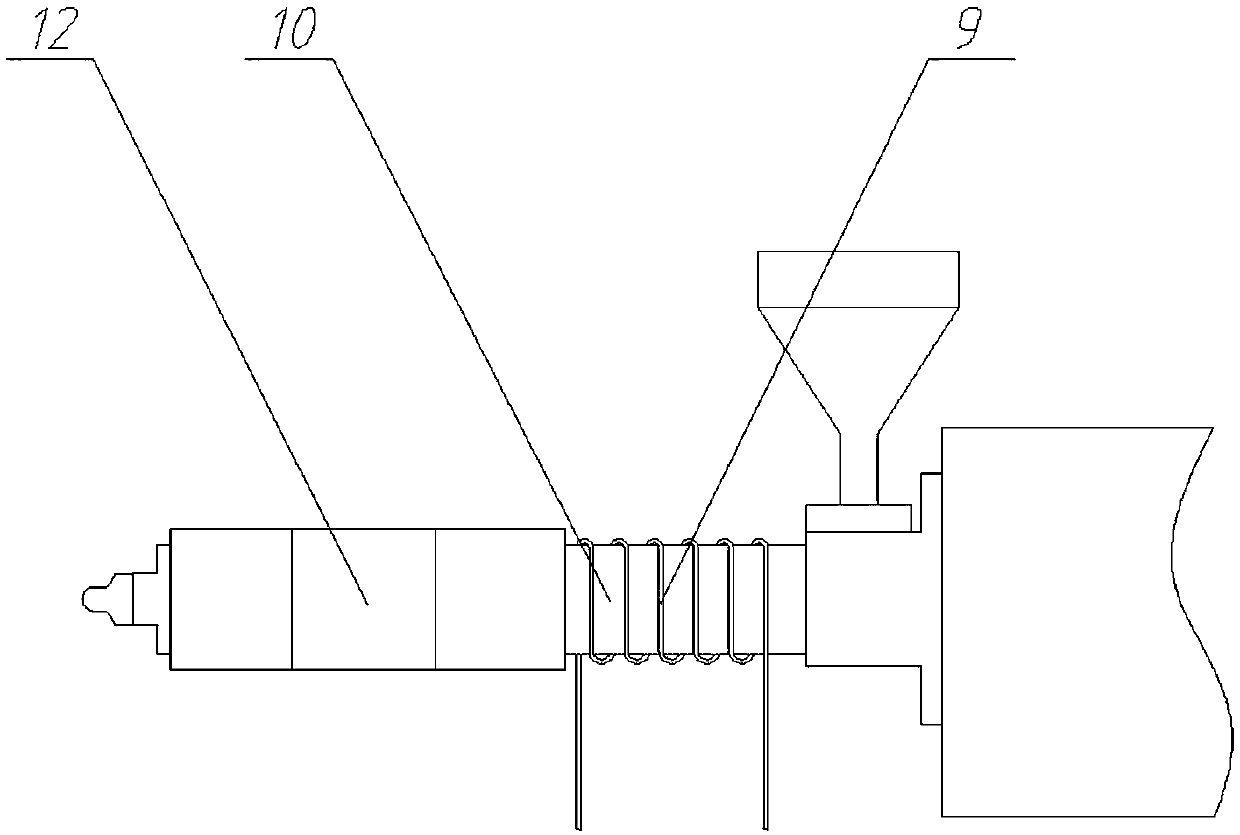

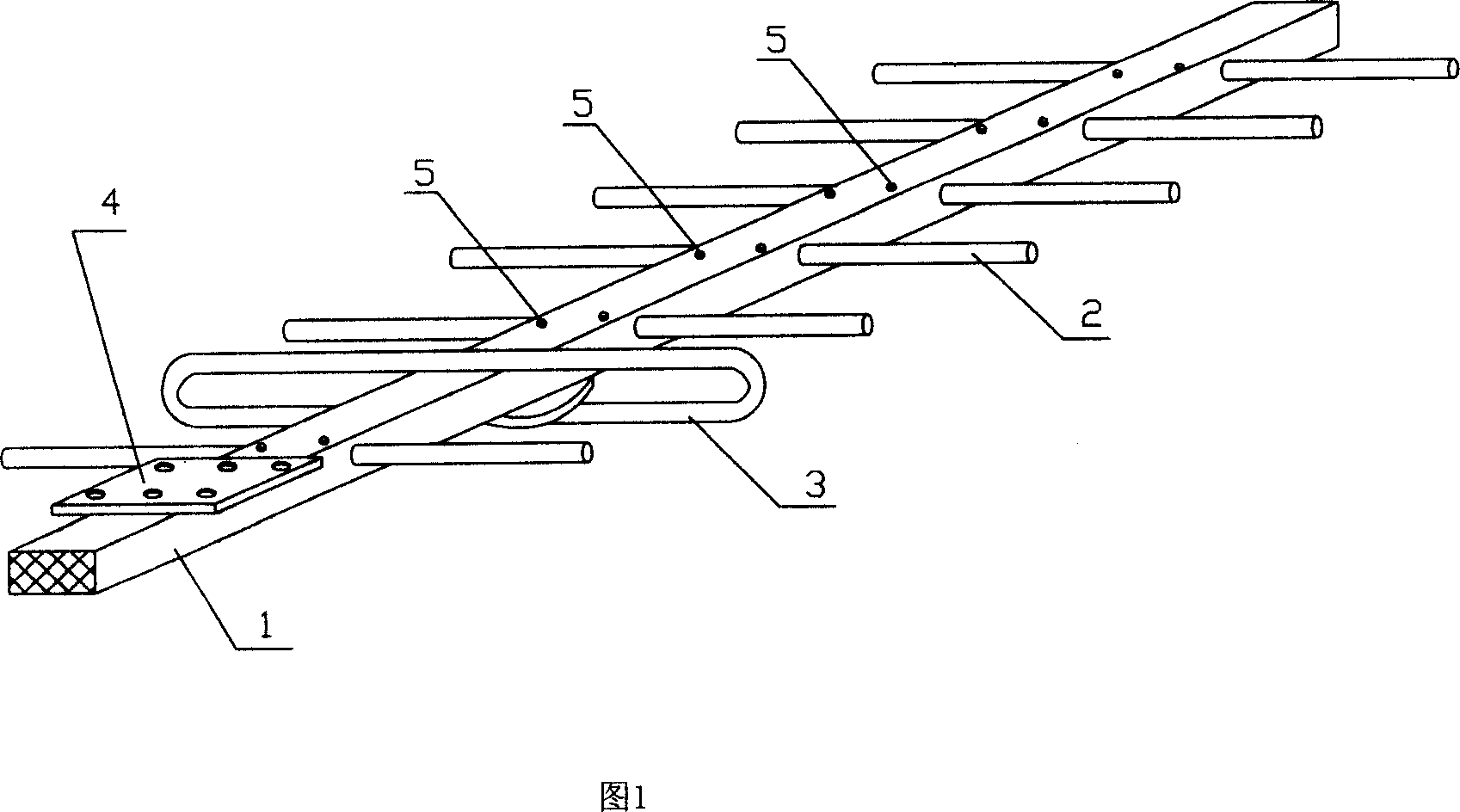

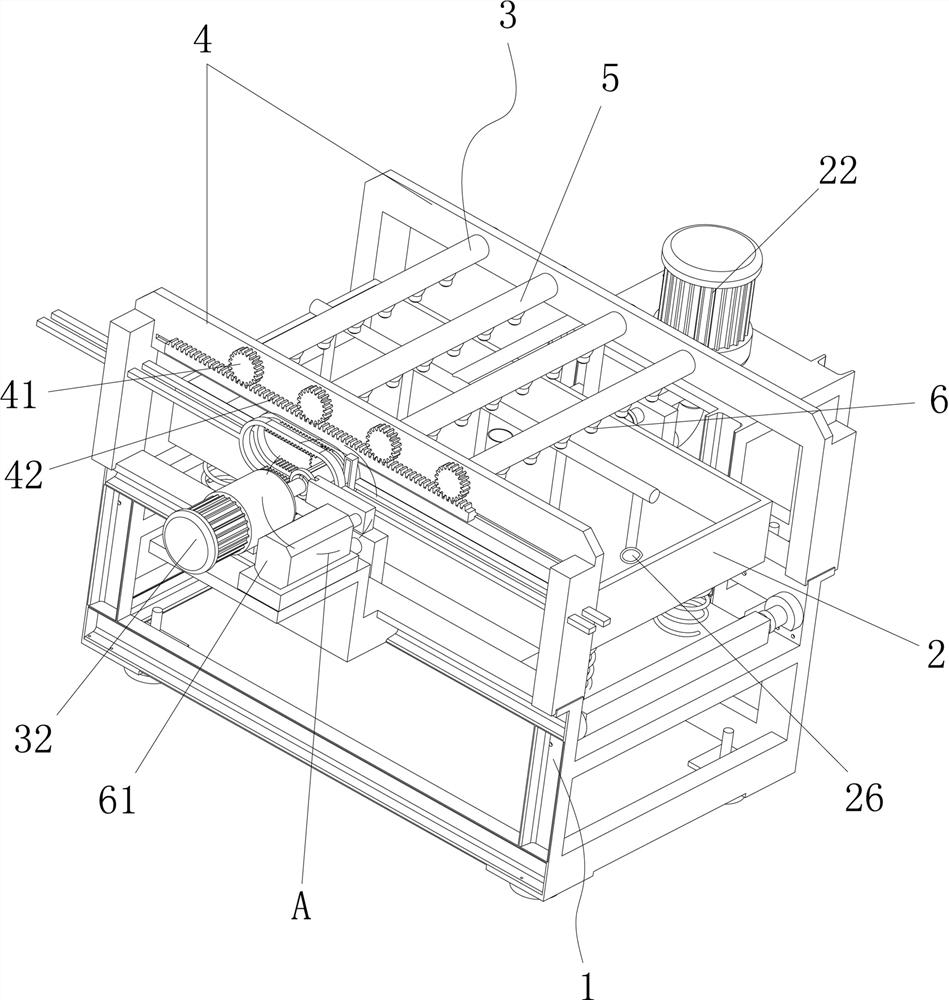

Intermediate frequency heating device for thin rod piece

InactiveCN107236848AHigh degree of automationSlide in timeFurnace typesIncreasing energy efficiencyControl systemIntermediate frequency

The invention provides an intermediate frequency heating device for a thin rod piece. The intermediate frequency heating device for the thin rod piece comprises a material storage rack, a grading feeding device, a thin rod piece angle adjustment device, a thin rod piece feeding device and a heating device; the thin rod piece which is stored on the material storage rack is conveyed to the thin rod piece angle adjustment device for performing angle adjustment through the grading feeding device, and then is fed into the heating device through the thin rod piece feeding device. Compared with the prior art, the heating device provided by the invention is high in automation degree. Through unified regulation and control of a control system, the processes of automatically feeding the thin rod piece and automatically adjusting an angle are completed.

Owner:安庆市恒瑞达汽车零部件制造有限公司

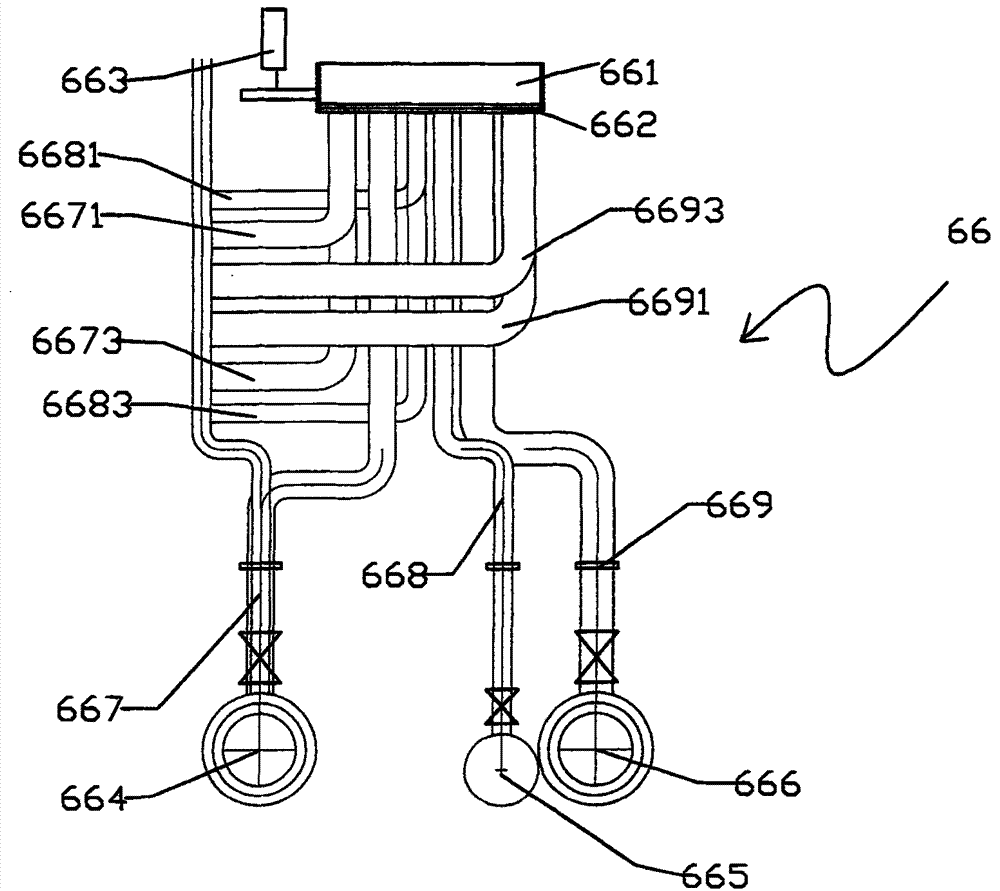

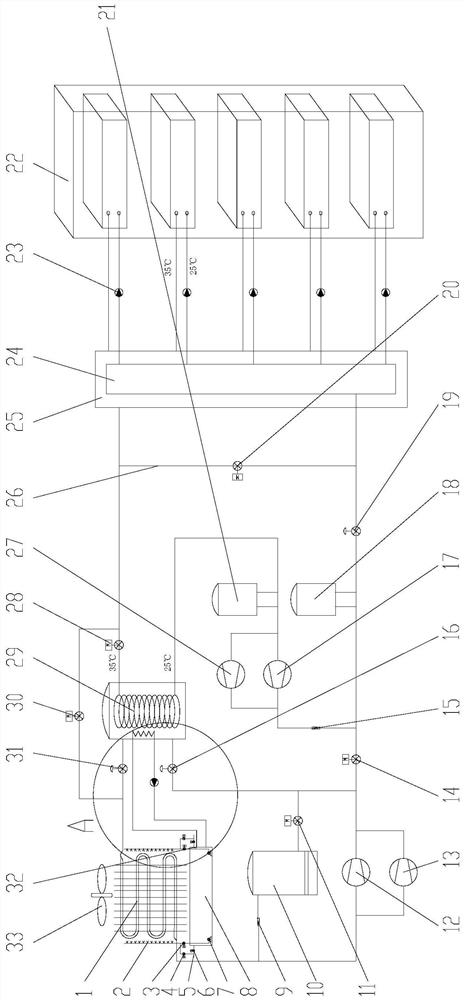

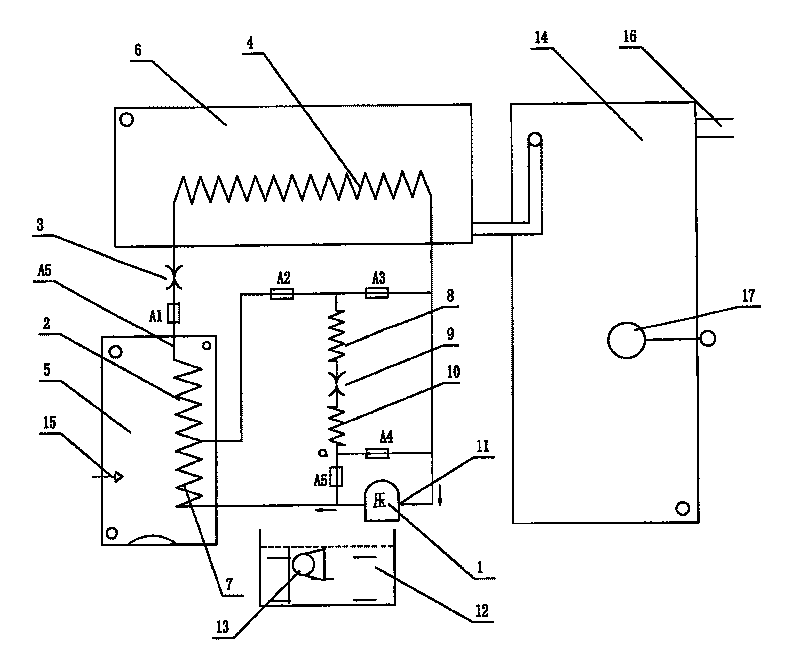

Cooling system of cold plate type server and control method

ActiveCN113473802AGood cooling effectImprove cooling efficiencyCooling/ventilation/heating modificationsEnergy efficient computingProcess engineeringEnergy consumption

The invention discloses a cooling system of a cold plate type server and a control method. The cooling system comprises a compressor refrigeration cycle, a fluorine pump refrigeration cycle and an emergency refrigeration cycle, wherein the compressor refrigeration cycle, the fluorine pump refrigeration cycle and the emergency refrigeration cycle are communicated with one another, and one refrigeration mode in the three refrigeration cycle modes is selected and used according to the external temperature. According to the invention, the cold storage spray cooling and intermediate cooling technology is adopted, so that the heat dissipation effect of the cold plate type server is greatly improved, and the purposes of saving energy and reducing consumption are achieved; the compressor refrigeration cycle and the fluorine pump refrigeration cycle are independently used at different temperatures, so that the maximum heat dissipation purpose can be achieved with the minimum energy consumption, and the purposes of saving energy and reducing consumption are achieved; and by arranging the emergency refrigeration cycle, when the compressor breaks down, heat dissipation can be continuously conducted on the cold plate type server, so that normal operation of the server is guaranteed, and the reliability of the device is greatly improved.

Owner:SUZHOU LANGCHAO INTELLIGENT TECH CO LTD

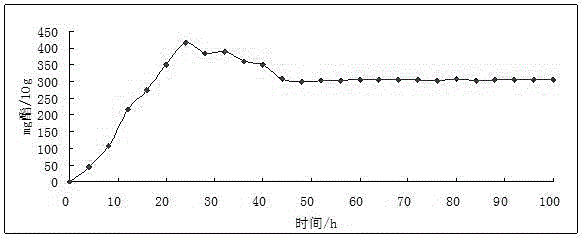

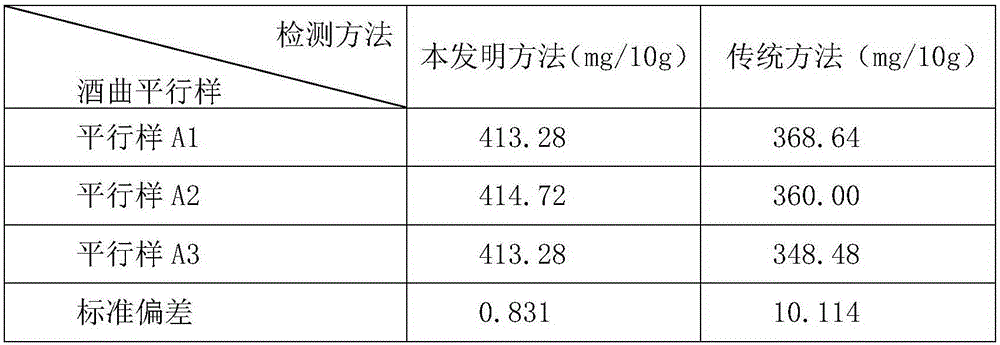

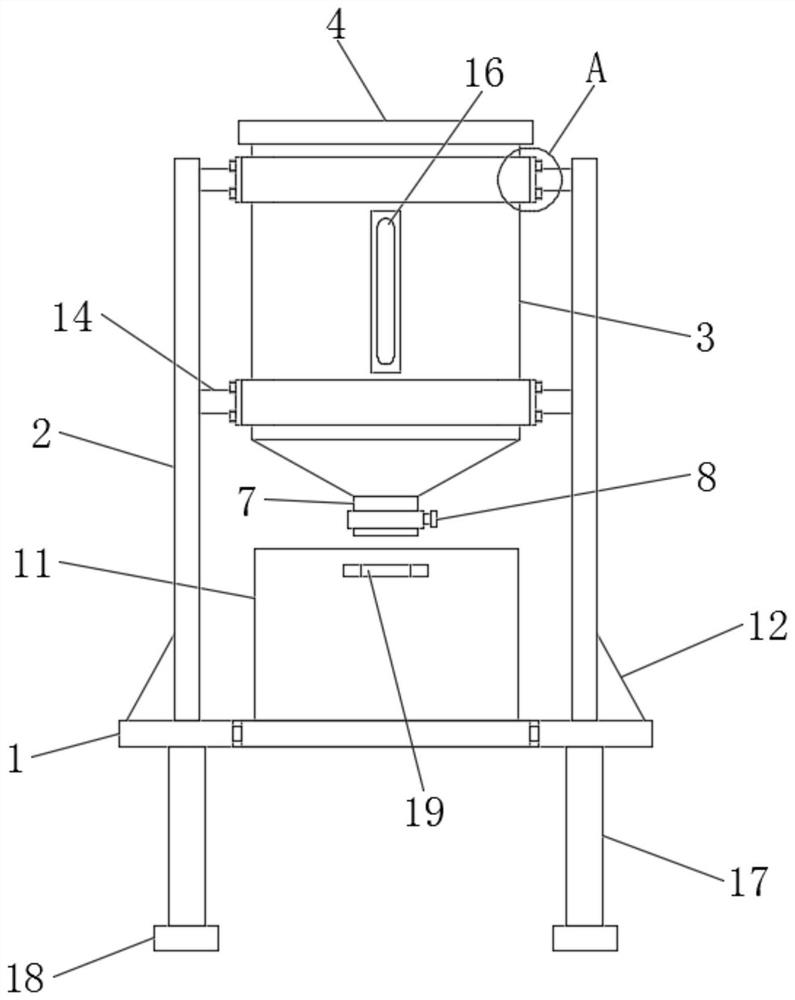

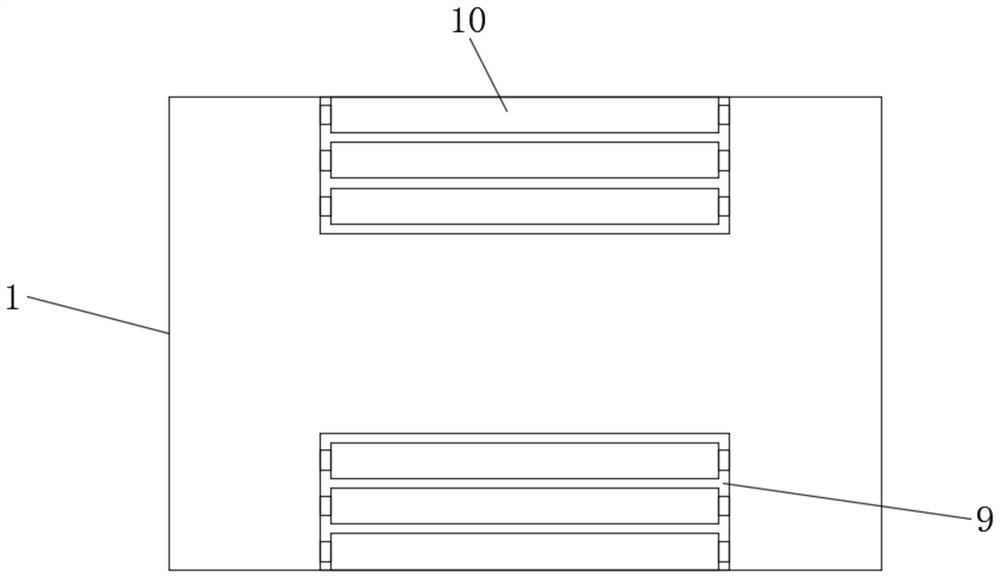

Detection method for esterifying power of distillers yeast

ActiveCN106226460ATruly reflect the ability of esterification to generate aromaGood reproducibilityChemical analysis using titrationAcetic acidYeast

The invention discloses a detection method for an esterifying power of distillers yeast. The detection method comprises sample pretreatment, titration and calculation. According to the invention, a mixed acid of caproic acid, acetic acid and lactic acid is used as an esterifying substrate to detect the esterifying power, and the caproic acid, acetic acid and lactic acid are directly prepared in absolute ethanol to prepare a caproic acid-acetic acid-lactic acid ethanol solution of which the concentration is 5%, so that acids which are insoluble in water are fully dissolved, detection results of the method are good in reproducibility and experimental data of the method are reliable, and the detection results can more truly reflect the esterifying and aroma producing abilities of a starter; according to the method, saponification is directly performed on an esterifying liquid to avoid loss of produced ester matters and make the detection results more accurate, and further save energy and lower consumption, simplify detection procedures and improve work efficiency; the method disclosed by the invention shortens the detection time, and is more conducive to rapid detection principles and suitable for industrialized large-scale detection.

Owner:SICHUAN JIANNANCHUN GRP CO LTD

Components of high-performance getter alloy and processing method of high-performance getter alloy

The invention discloses components of a high-performance getter alloy. The high-performance getter alloy comprises the following components of, in parts by mass, 40-80 parts of zircon, 12-18 parts ofa material A and 0-6 parts of a material B; the material A comprises the following components of, in percentage by weight, 20%-30% of graphite, 5%-15% of vanadium, 1%-8% of niobium and the balance iron; and the material B comprises the following components of, in percentage by weight, 10%-20% of nickel, 6%-14% of chromium, 3%-12% of aluminum, 5%-15% of cobalt and the balance iron. The invention further discloses a processing method of the high-performance getter alloy. The air suction rate and the air suction capacity of the machined getter alloy are greatly improved, the air suction performance of the getter alloy is greatly improved, meanwhile, the activation temperature of the getter alloy is reduced, the cost is saved, and the purposes of energy conservation and consumption reduction are achieved.

Owner:安徽有研吸气材料有限公司

Novel air seal for combustion gas turbine tail barrel and manufacturing method for novel air seal

InactiveCN104196637AImprove sealingImprove yieldGas turbine plantsJet propulsion plantsMetal stripsEngineering

The invention discloses a novel air seal for a combustion gas turbine tail barrel and a manufacturing method for the novel air seal. The air seal comprises a brush and a sealing piece body, wherein the brush comprises a brush wire cluster and two metal strips; the brush wire cluster is arranged between the two metal strips, so as to form a T shape; the sealing piece body is provided with a brush wire matching surface; the brush wire cluster of the brush is fixed on the brush wire matching surface; the metal strips are clung to the side surfaces of the brush wire matching surface; the brush and the sealing piece body are fixed by welding fixing points. According to the novel air seal, high-temperature gas at an outlet part of the combustion gas turbine tail barrel can be effectively sealed, the problem of sealing failure caused by severe factors such as high-temperature fuel gas can be well controlled by reasonably selecting a material and a processing process. The novel air seal comprises the brush and the sealing piece body, and can resist the oxidation and corrosion caused by the high-temperature gas of a combustion gas turbine. According to the novel air seal and the manufacturing method of the novel air seal, the processing is easy, the control is easy to implement, the rate of finished products is high, and the aims of saving energy and reducing the consumption can be realized.

Owner:JIANGSU TURBINE SEAL HIGH TECH

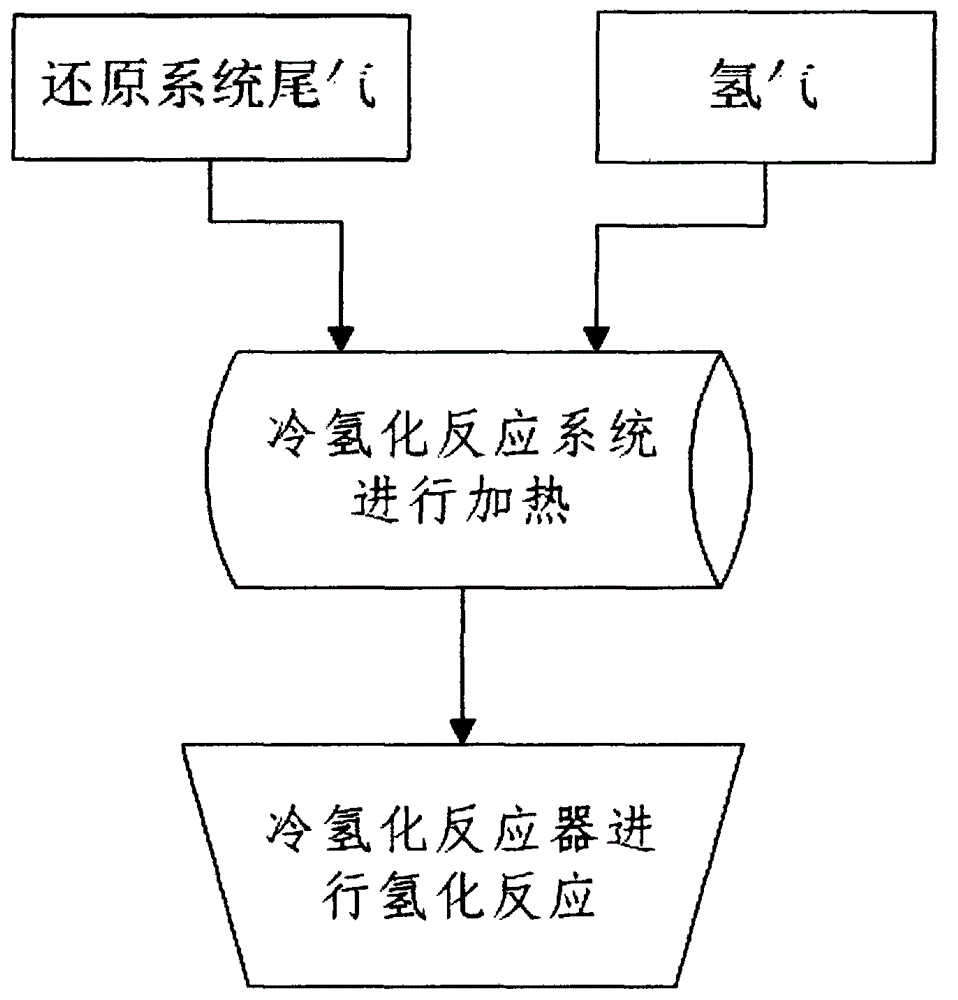

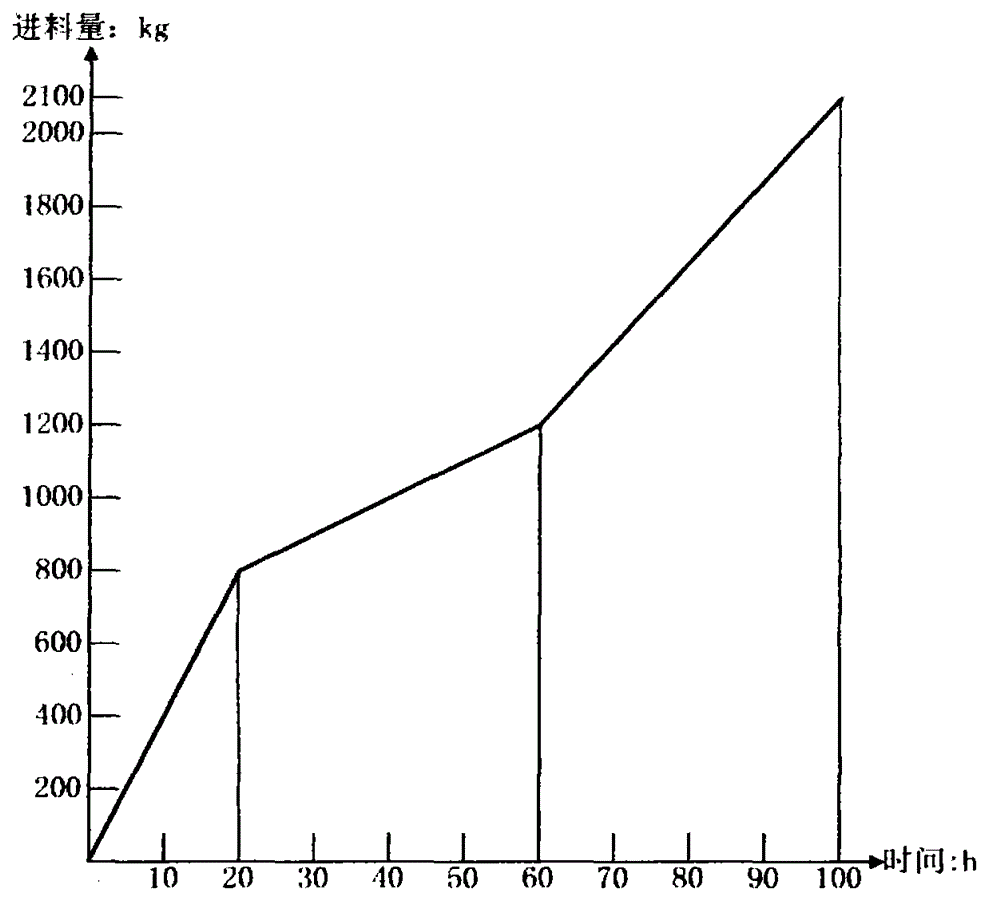

Method for recovering reduction system tail gas in polycrystalline silicon production

ActiveCN106145120AReduce energy consumptionLow costChemical industryHalogenated silanesRecovery methodHydrogen

The invention relates to a method for recovering reduction system tail gas in polycrystalline silicon production. The method comprises the following steps: reduction system tail gas is directly fed into a cold hydrogenation system, hydrogen is injected into the cold hydrogenation system, and the volume of injected hydrogen is 15%-21% of the total gas volume of the cold hydrogenation system; the reduction system tail gas and hydrogen are heated by the cold hydrogenation system at the temperature of 540-560 DEG C; the heated reduction system tail gas and hydrogen are input into a cold hydrogenation reactor for hydrogenation, silicon tetrachloride in the reduction system tail gas is enabled to have a reaction with hydrogen and is directly converted into trichlorosilane, and dichlorosilane in the reduction system tail gas is converted into trichlorosilane through a purifying device in the cold hydrogenation reactor. According to the method, the tail gas exhausted from a reduction furnace is directly subjected to hydrogenation as a raw material without cooling, separation or desorption, so that the process can be shortened, and the purposes of energy saving and consumption reduction can be achieved.

Owner:周正平 +1

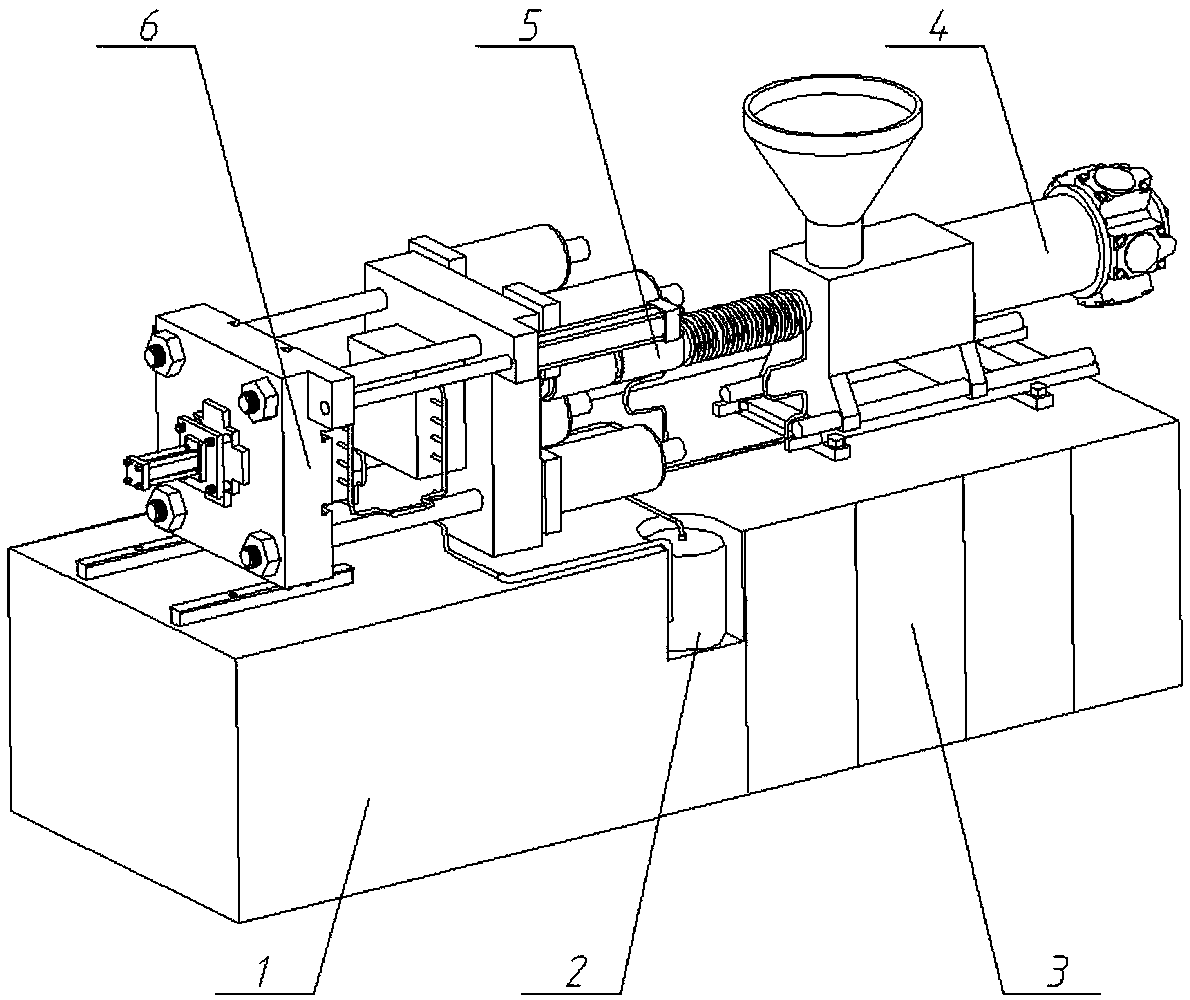

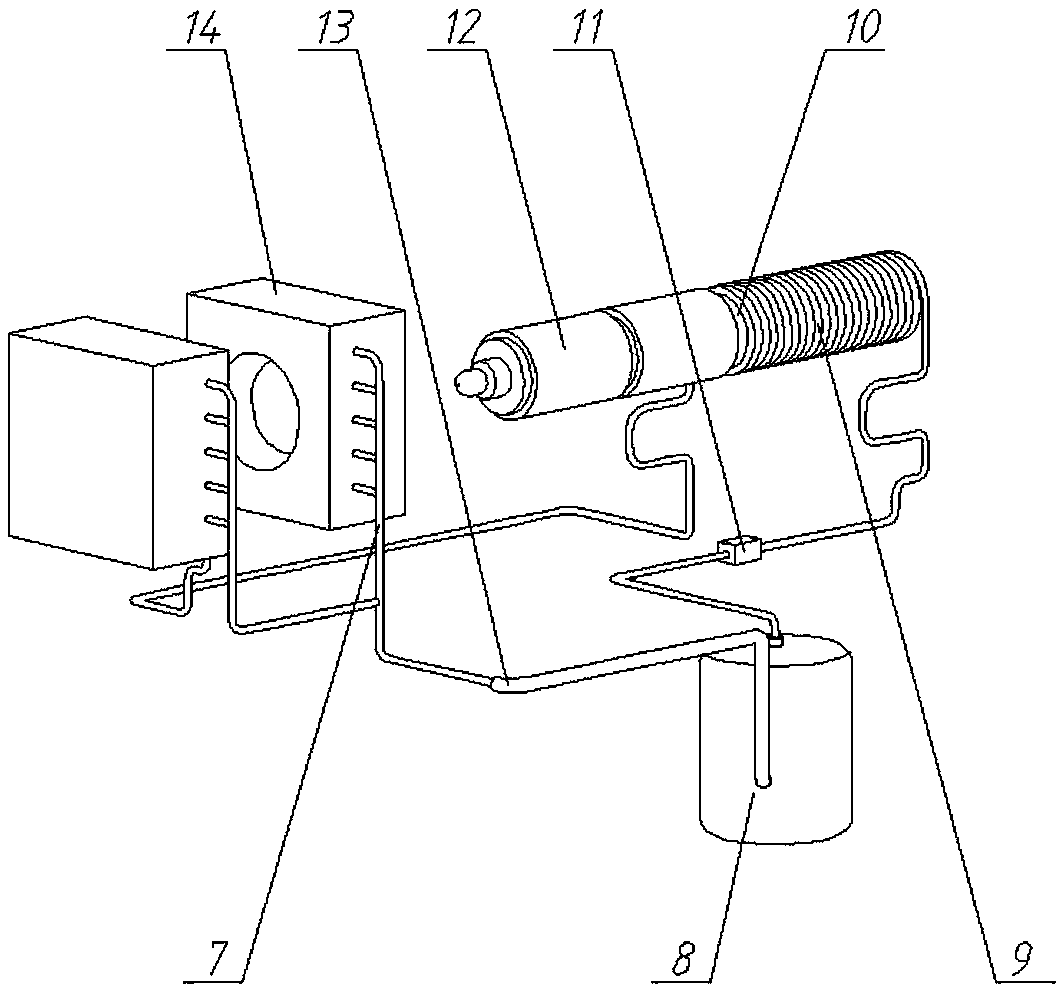

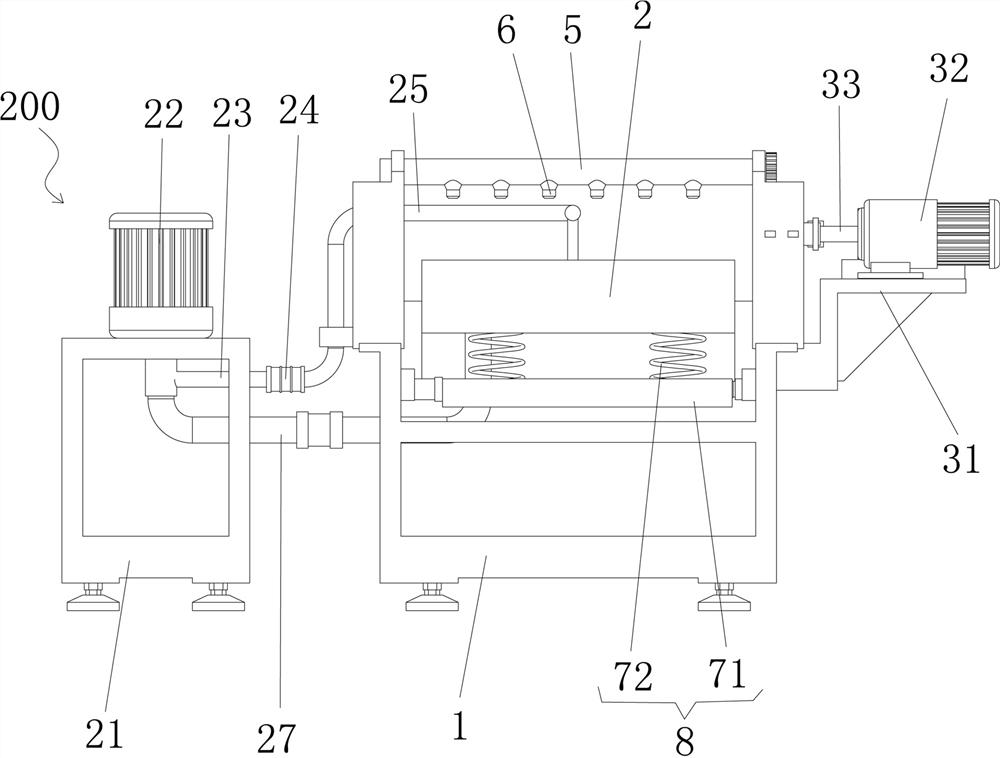

Thermal cycle energy-saving injection molding machine

The invention discloses a thermal cycle energy-saving injection molding machine. The thermal cycle energy-saving injection molding machine mainly comprises a machine frame, a thermal cycle system, a control system, an injection system, a plasticizing system, a mold closing system and the like, wherein the thermal cycle system is mainly composed of an evaporator, a compressor, a condenser, an expansion valve, a connecting pipe, refrigerants and the like, the evaporator is arranged in a mold, the compressor is arranged at the position, between an injection molding machine front mold plate and aninjection seat, of a lower machine body, the condenser is arranged on a machine barrel, the expansion valve is arranged between the compressor and the condenser, and the devices are connected throughthe connecting pipe. According to the thermal cycle energy-saving injection molding machine, by means of the reverse Carnot cycle principle, the liquid-state refrigerant in the evaporator is vaporized to absorb heat so as to cool the mold; and the refrigerant is pressurized by using the compressor, and the gas-state refrigerant in the condenser is liquefied to discharge heat so as to heat the machine barrel. Compared with an existing cooling device, a thermal cycle energy-saving heating and cooling device has the advantages that energy of the cooling end of the mold is utilized, and energy circulation between the cooling end of the mold and the heating end of the machine barrel or a feeding hopper is achieved.

Owner:TEDERIC MACHINERY

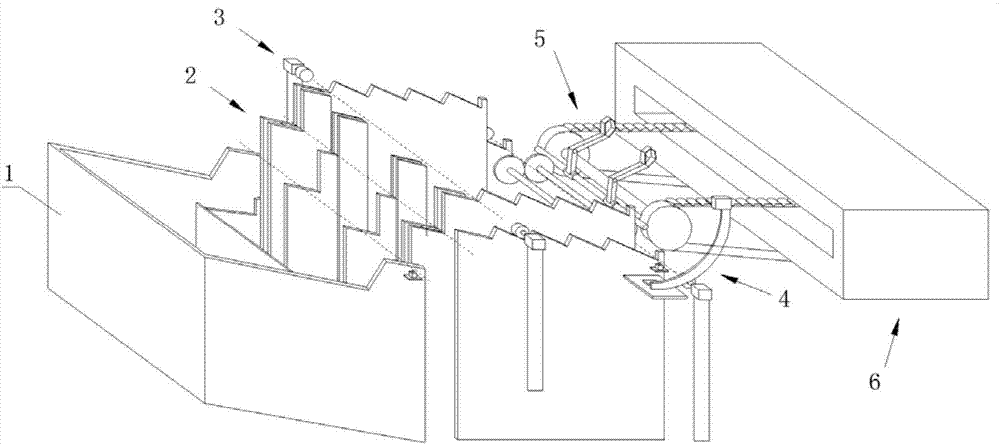

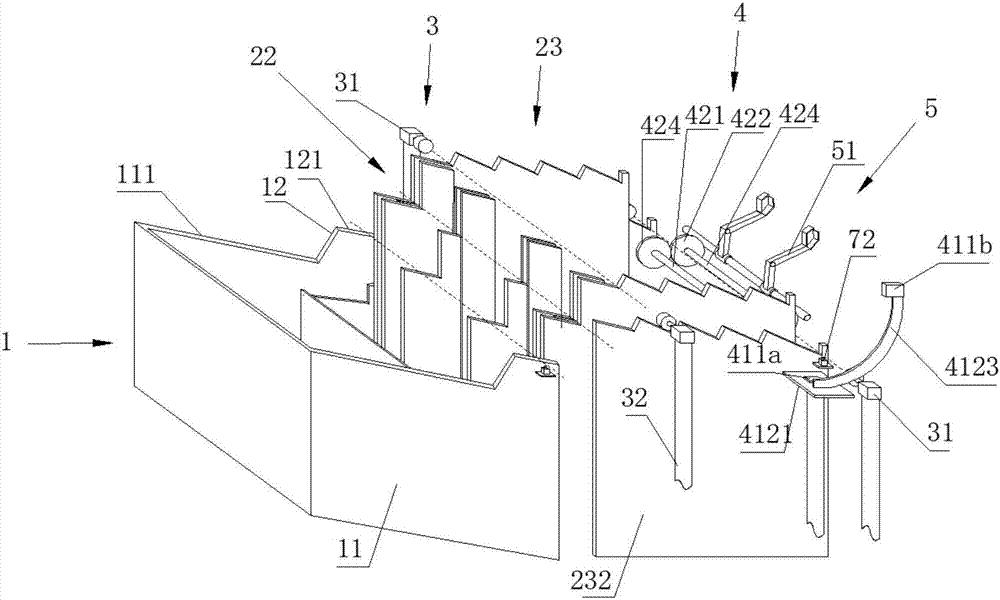

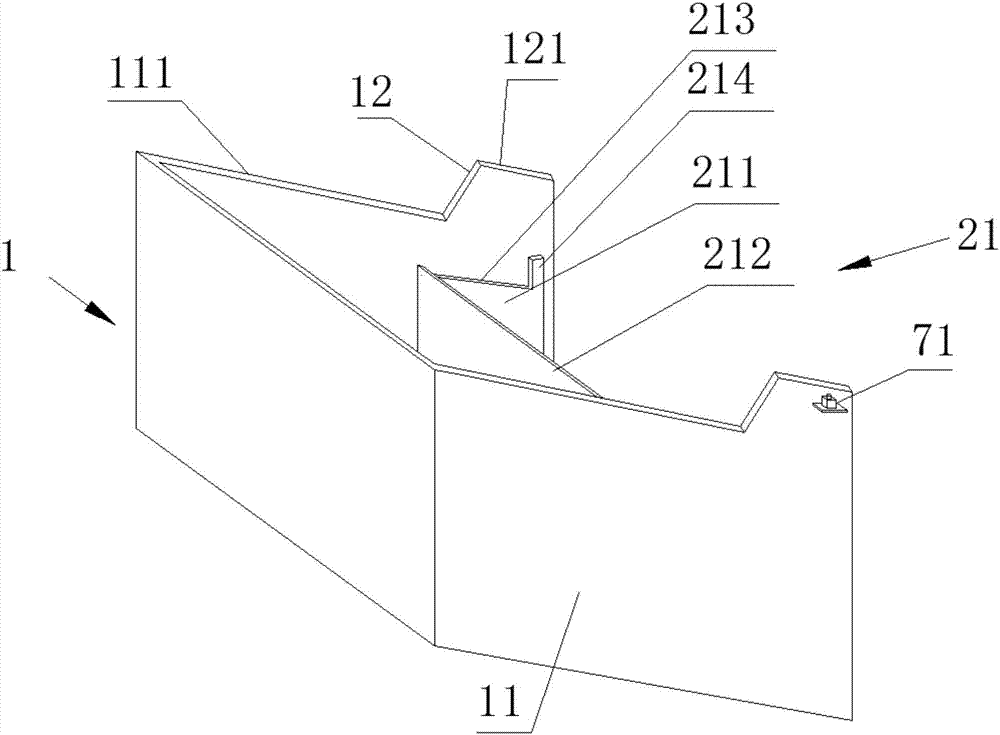

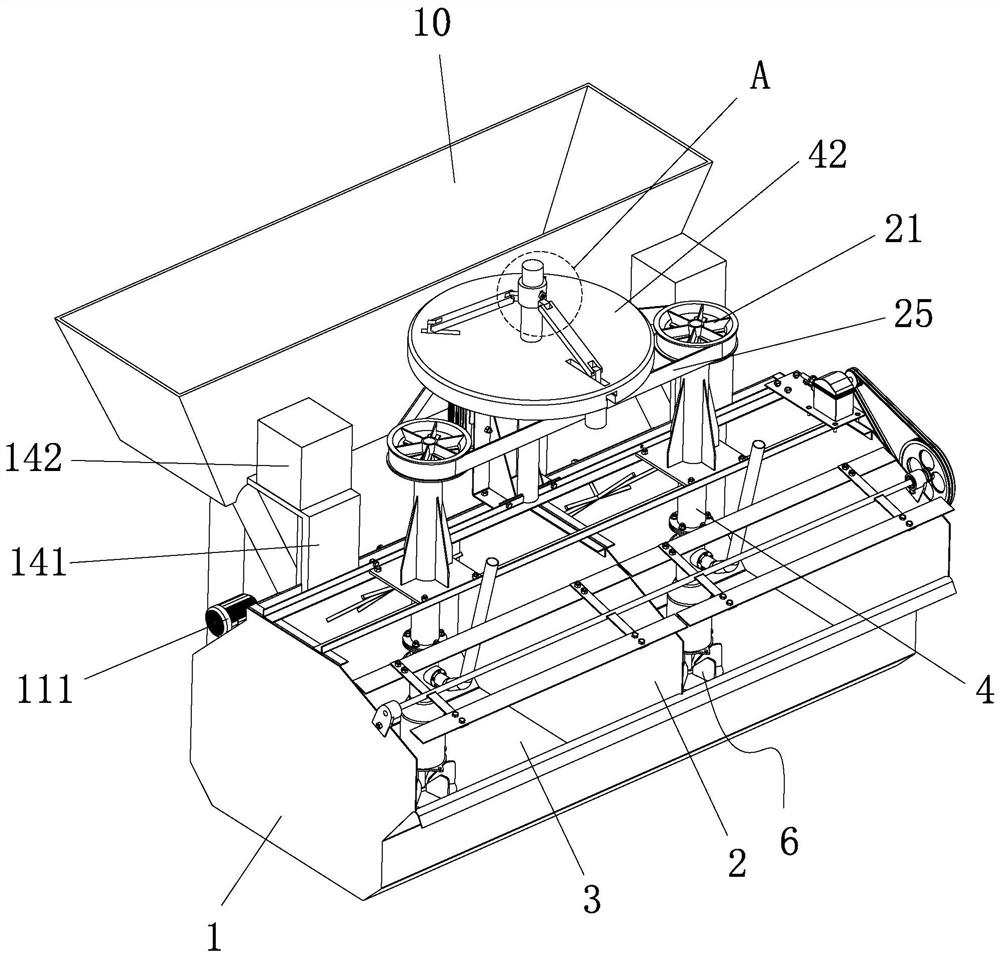

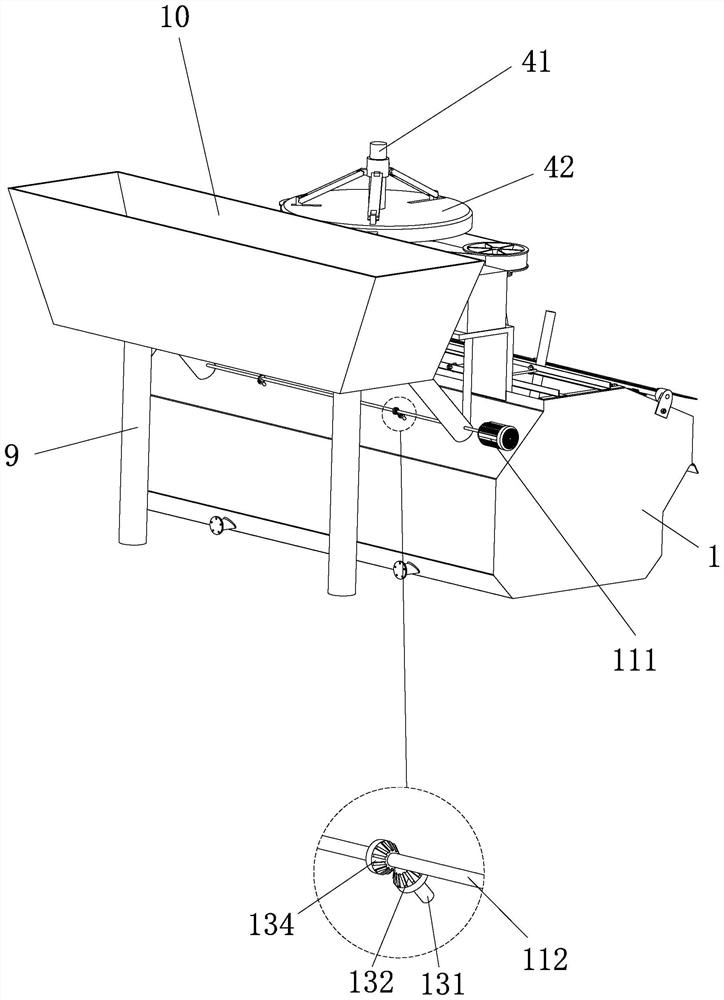

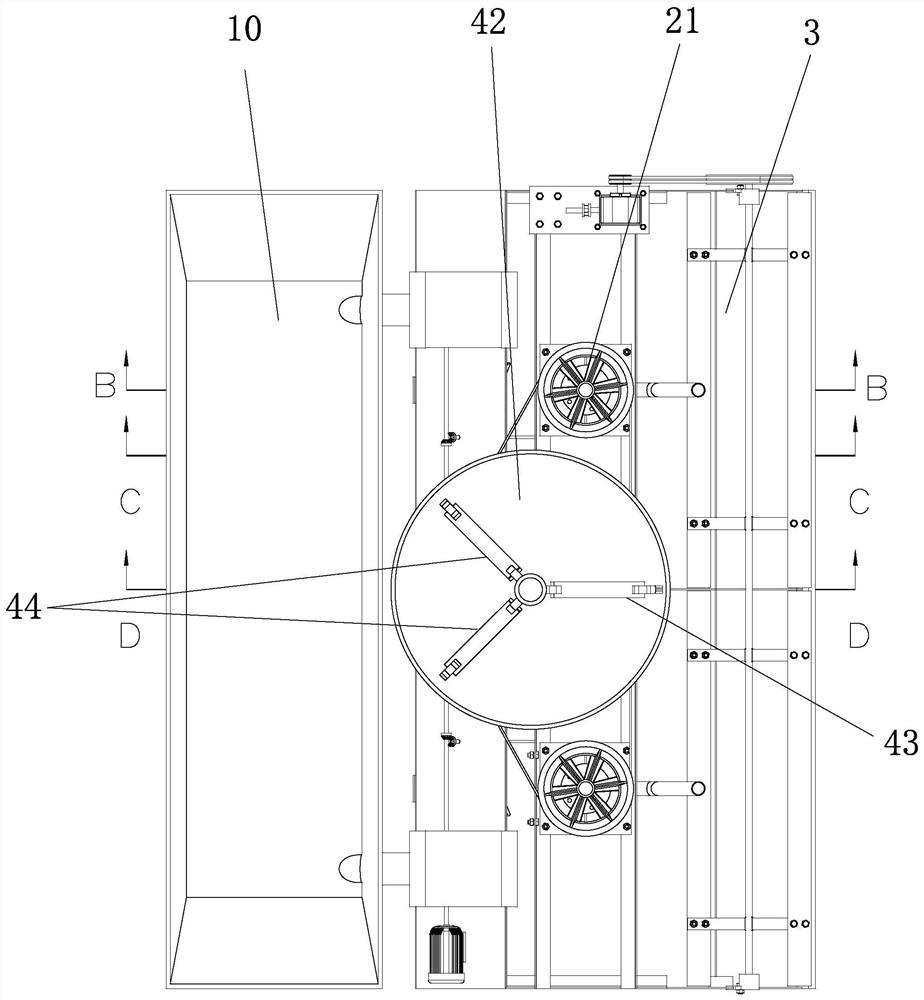

Automatic feeding device for rod tie members

InactiveCN107217126AHigh degree of automationSlide in timeIncreasing energy efficiencyFurnace typesThree stageEngineering

The invention provides an automatic feeding device for rod tie members. The automatic feeding device comprises a storage rack, a first-stage feeding mechanism, a second-stage feeding mechanism and a third-stage feeding mechanism; the rod tie members are stored on the storage rack; the first-stage feeding mechanism picks up a plurality of rod tie members from the storage rack; the second-stage feeding mechanism picks up one rod tie member from the first-stage feeding mechanism and feeds the rod tie member to the third-stage feeding mechanism; and the three-stage feeding mechanism feeds the rod tie member to a rod tie member machining station. Compared with the prior art, the automatic feeding device has the advantages that the automation degree is high, and the automatic feeding process of the rod tie members can be completed.

Owner:安庆市恒瑞达汽车零部件制造有限公司

Antenna manufacturing process

InactiveCN101026258AIncrease productivityReduce labor intensityAntenna detailsEngineeringCurrent technology

This invention discloses a manufacturing technology and a method for antennas, which applies a present technology to process round tubes and square tubes with several holes, in which, the round end is sleeved with plastic cover and plugged into the square tube characterizing in applying a punch method to fix it including the following steps: punching the square tube with the round tube to fix the two tubes to constitute a vibrator, then setting two fixing bolts on the square tube to be jacketed with an installing plate then to fix the plate on the square tube by punch finally applying the current technology to fix the feed unit on the tube to make up of a whole antenna.

Owner:GUANGDONG SHENGLU TELECOMM TECH

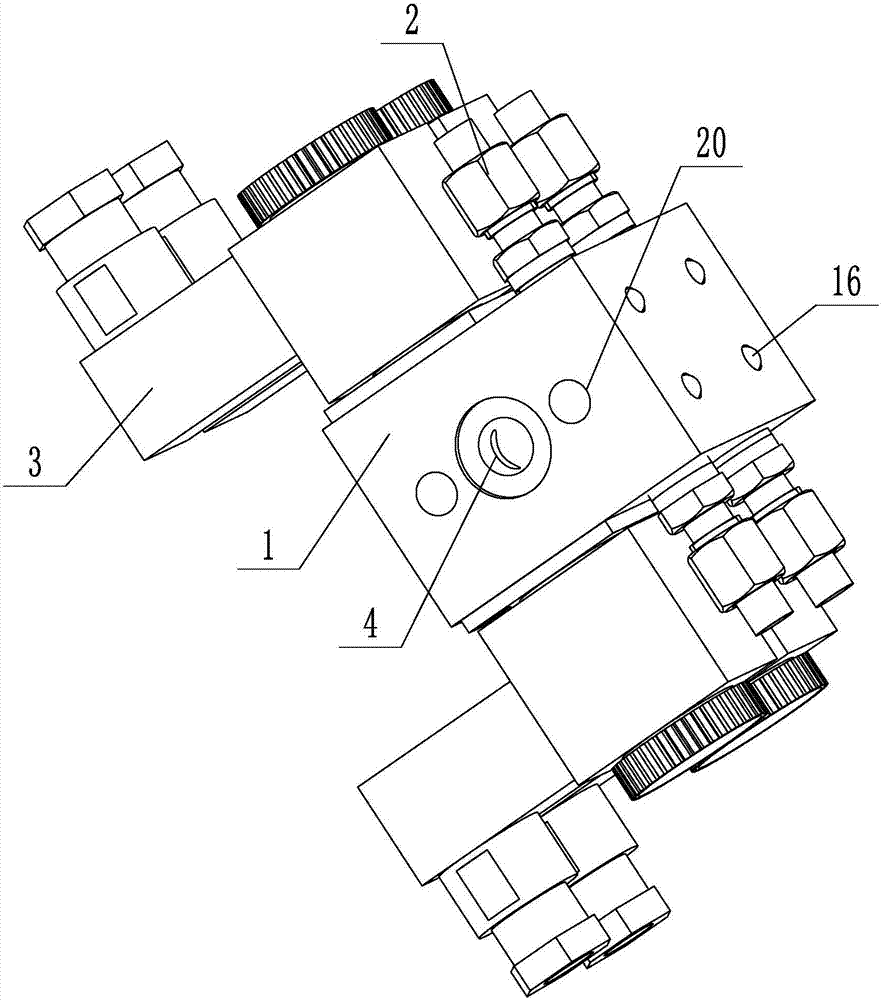

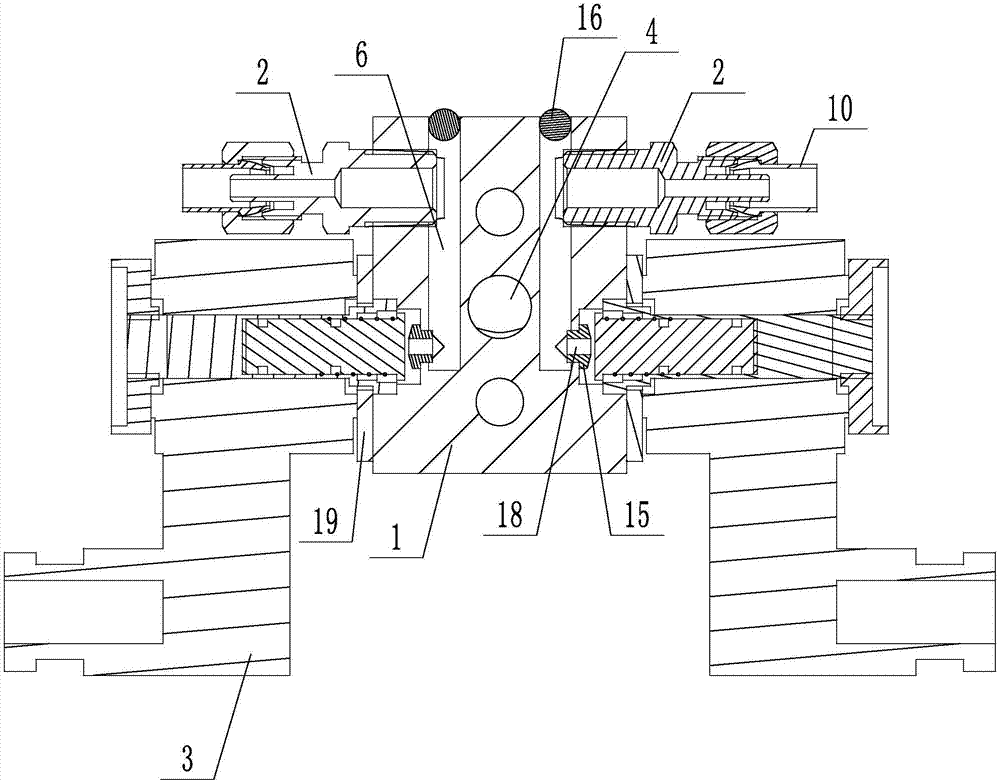

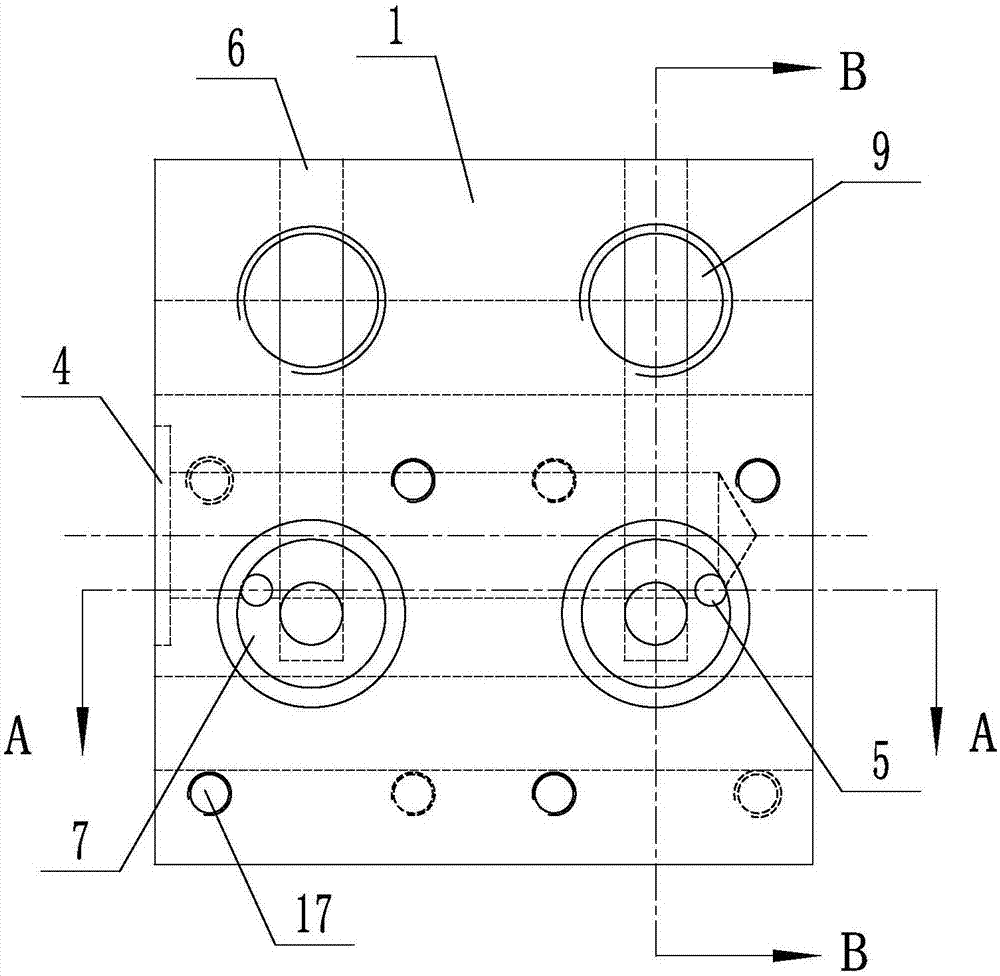

Auxiliary-jet integrated solenoid valve group for air jet loom

The invention discloses an auxiliary-jet integrated solenoid valve group for an air jet loom. The auxiliary-jet integrated solenoid valve group comprises a valve base, air outlet pipe joints, solenoidvalves and an air jet loom auxiliary air bag, wherein the air outlet pipe joints and the solenoid valves are installed on the valve base, and the air jet loom auxiliary air bag is used for installingthe valve base. An air pipeline is arranged in the valve base, one end of the air pipeline is communicated with the air jet loom auxiliary air bag, the other end of the air pipeline is communicated with the air outlet pipe joints, the solenoid valves correspond to the air outlet pipe joints one to one, and the solenoid valves are located on the air pipeline. One solenoid valve controls opening and closing of one air outlet pipe joint, precise control over air jet of a single auxiliary nozzle is achieved, and the air flow is saved, so that the aim of saving energy and reducing consumption is achieved; meanwhile, enough solenoid valves can be installed in a limited space without mutual interference.

Owner:SHANDONG RIFA TEXTILE MACHINERY

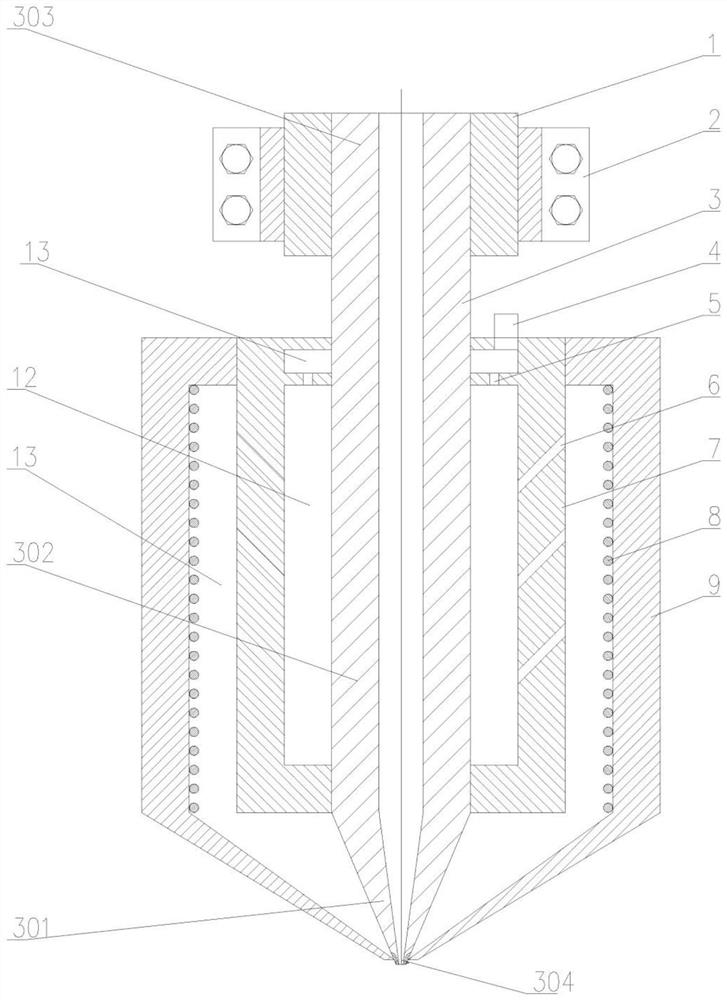

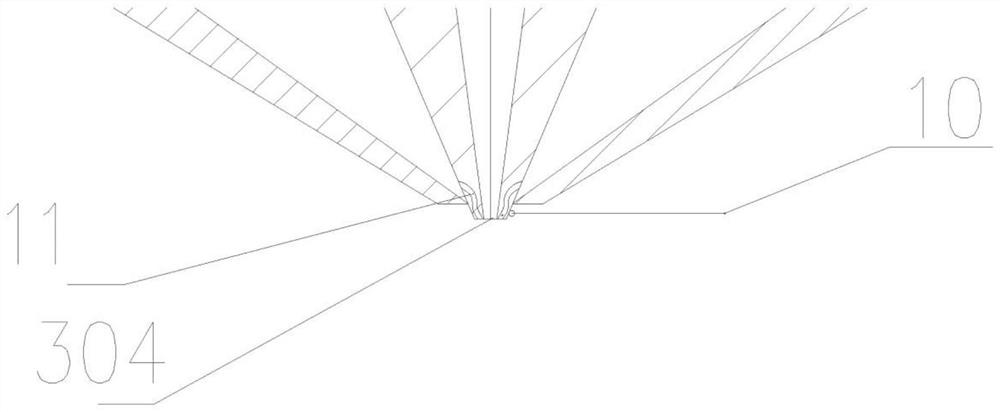

Heating protection suction nozzle for wafer repair machine

The invention provides a heating protection suction nozzle for a wafer repair machine, the heating protection suction nozzle comprises a micropore suction nozzle with a flow guide groove, a temperature sensor, a heating device and a protective gas circulation device, and the temperature sensor, the heating device and the protective gas circulation device are respectively fixed on the micropore suction nozzle with the flow guide groove. The micropore suction nozzle with the flow guide groove is divided into a head part, a body part and a tail part from bottom to top, and adsorption holes for adsorbing wafers are formed in the head part of the micropore suction nozzle with the flow guide groove. The heating protection suction nozzle has the beneficial effects that the micropore suction nozzle with the flow guide groove can be heated through the heating device, then soldering tin is heated and melted, and therefore damaged wafers are removed. The real-time temperature of the head part ofthe micropore suction nozzle with the flow guide groove can be detected through the temperature sensor, so that constant-temperature control is achieved, and damage to the wafers caused by excess temperature can be avoided. Heated protective gas can be guided to the periphery of the wafers to be welded through the flow guide groove in the micropore suction nozzle, and anti-oxidation protection isconducted on the wafers in the welding process.

Owner:深圳市金翰半导体技术有限公司

A kind of air-cooled refrigerator and defrosting control method thereof

ActiveCN107120899BFor the purpose of saving energy and reducing consumptionLighting and heating apparatusDomestic refrigeratorsCold storeCooling capacity

The embodiment of the invention provides an air cooling refrigerator and a defrosting control method thereof, and relates to the field of refrigerator control, wherein refrigerator defrosting can be achieved in a more labor-saving manner. The air cooling refrigerator comprises a freezing chamber and a cold storage chamber which achieve heat isolation through a heat insulation partition plate, an evaporator chamber used for providing the cooling capacity for the freezing chamber and the cold storage chamber, a freezing air flue and a cold storage air flue. The evaporator chamber is located in the freezing chamber and internally provided with an electric heater and a temperature sensor. The freezing air flue is used for transmitting the cooling capacity in the evaporator chamber to the freezing chamber, and the cold storage air flue is used for transmitting the cooling capacity in the evaporator chamber to the cold storage chamber. The evaporator chamber and the cold storage air flue are isolated or communicate with each other through a first air door. The freezing air flue and the evaporator chamber communicate with each other through a freezing air inlet, the storage space of the freezing chamber communicates with the evaporator chamber through a freezing air return port, and the freezing air inlet is provided with a second air door.

Owner:HISENSE(SHANDONG)REFRIGERATOR CO LTD

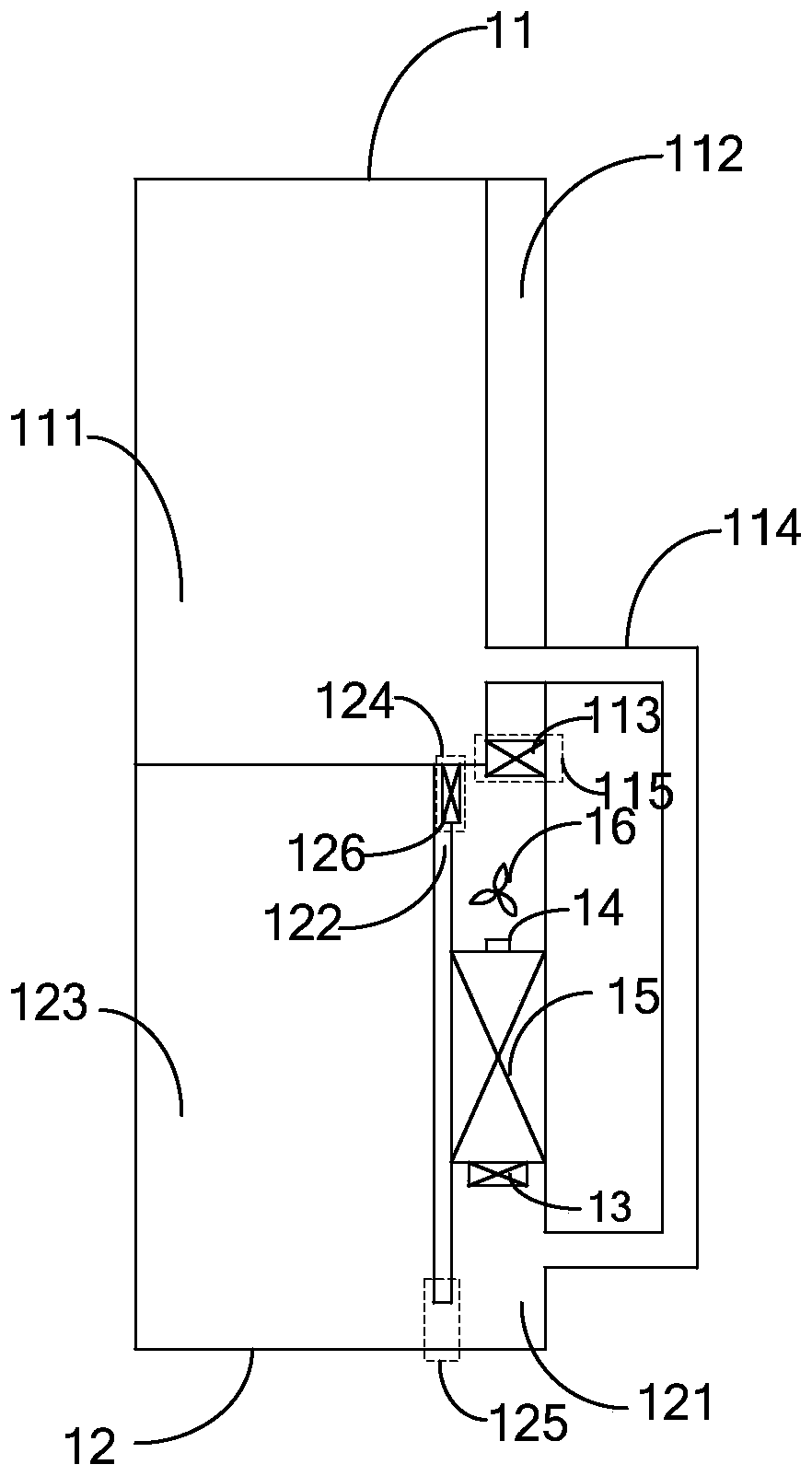

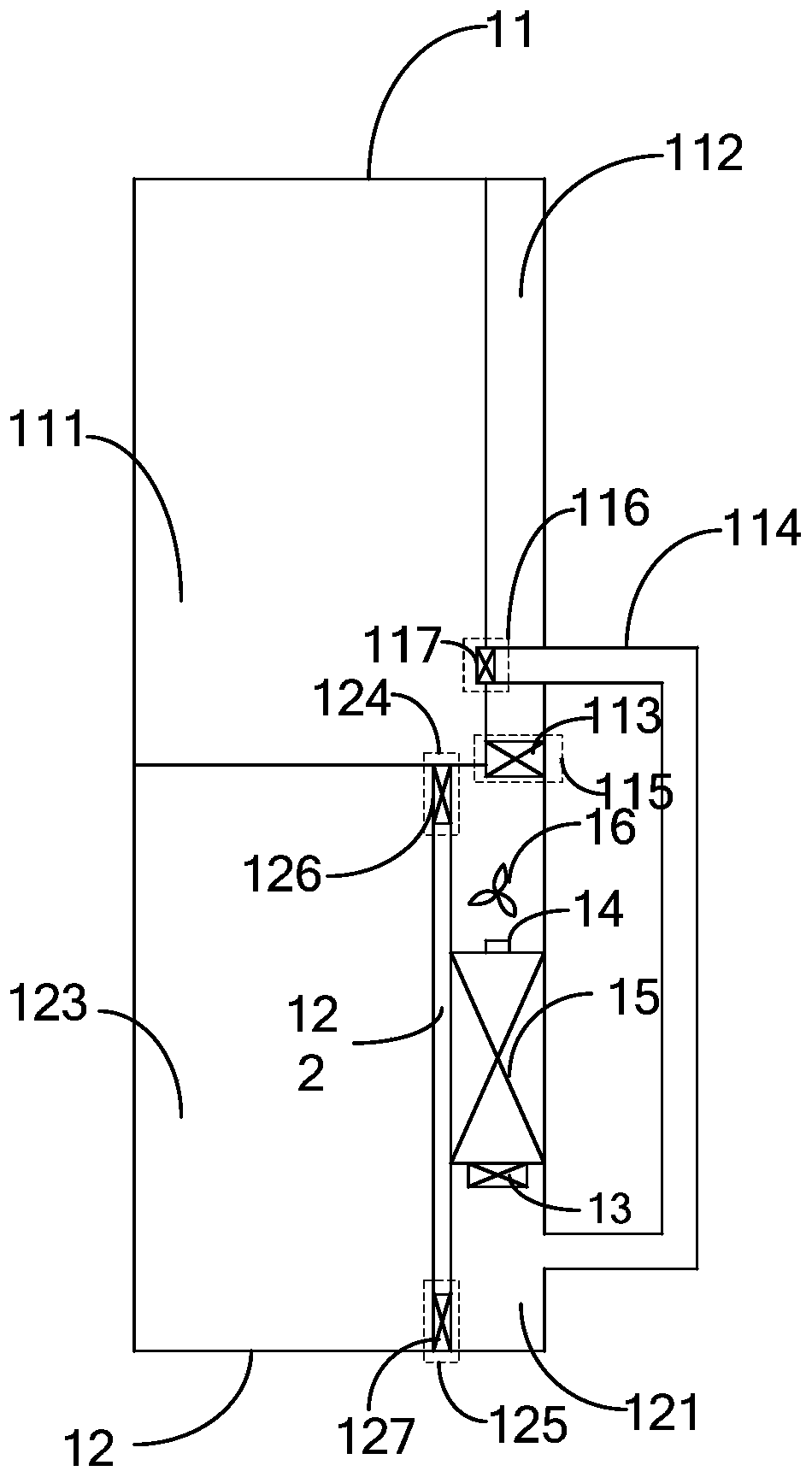

Household heating device capable of realizing efficient heat exchange

PendingCN112113265AImprove cooling efficiencyHigh degree of intelligenceHeating fuelElectric heating systemTemperature controlRoom temperature

The invention relates to a household heating device capable of realizing efficient heat exchange. The heating device comprises a device body and a display screen thereof and is characterized in that aplurality of three-dimensional ribbed tubes are arranged in the device body; heat-conducting media are arranged in the three-dimensional ribbed tubes; a fan is arranged on the front side wall of thedevice body; a circulating pump and a heating device body are arranged at the bottom below the device body; and the three-dimensional ribbed tubes are welded on the heating device and a U-shaped tubeof the circulating pump. According to the heating device, an intelligent control system is adopted to integrally control the device, and the intelligent control system is connected with the three-dimensional ribbed tubes and the heating device body; and the heating device achieves temperature control in different environments according to the number of the three-dimensional ribbed tubes and the power of the heating device body. The heating device has the advantages that the three-dimensional ribbed tubes are used as heat dissipation devices, the heat exchange area of each three-dimensional ribbed tube is 3-4 times that of a common light tube, and the three-dimensional ribbed tubes are not only high in heat dissipation efficiency, but also safe and reliable when being used indoors. According to the device, the intelligent control system is used, when the room temperature reaches the set temperature, the device can automatically enter a sleep mode, and thus the purposes of energy savingand consumption reduction are achieved.

Owner:陕西就掌核科技发展有限公司

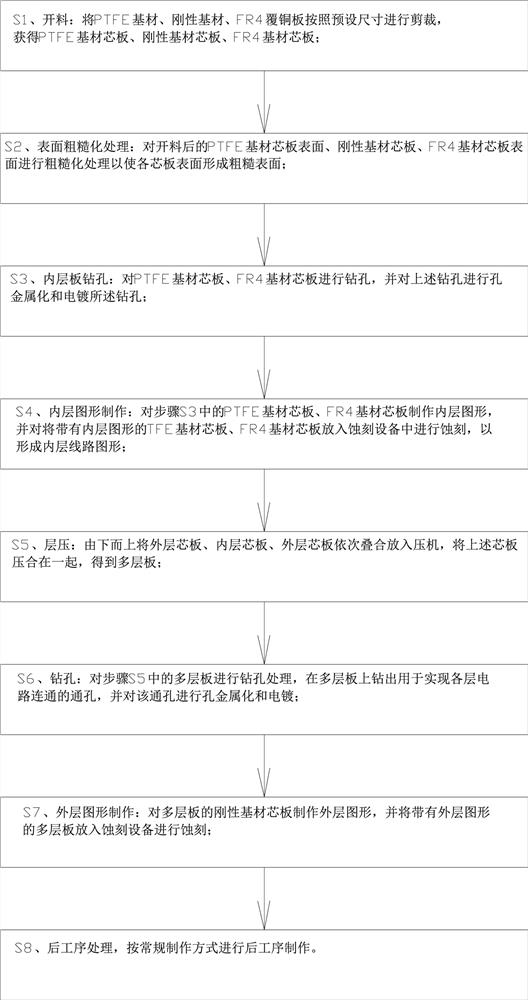

A high-frequency and high-speed pcb board for macro and micro base stations for 5g communication and its preparation process

ActiveCN112867267BSimple processEasy to manufactureConductive material chemical/electrolytical removalDielectric lossEngineering

The invention discloses a macro / micro base station high-frequency high-speed PCB board for 5G communication and its preparation process, wherein the preparation process includes the following steps: S1, material cutting, S2, surface roughening treatment, S3, inner layer board drilling, S4, inner graphics production, S5, lamination, S6, drilling, S7, outer graphics production and S8, post-processing. The purpose of the present invention is to overcome the deficiencies in the prior art and provide a preparation of high-frequency and high-speed PCB boards for 5G communication macro / micro base stations with simple process, good etching uniformity, high production efficiency, and can effectively reduce the scrap rate craft. Another object of the present invention is to provide a high-frequency and high-speed PCB board for macro / micro base stations for 5G communication using the above preparation method. The macro / micro base station high-frequency and high-speed PCB board for 5G communication of the present invention has the advantages of excellent high-speed / high-frequency transmission characteristics, small dielectric loss, and the like.

Owner:广东兴达鸿业电子有限公司

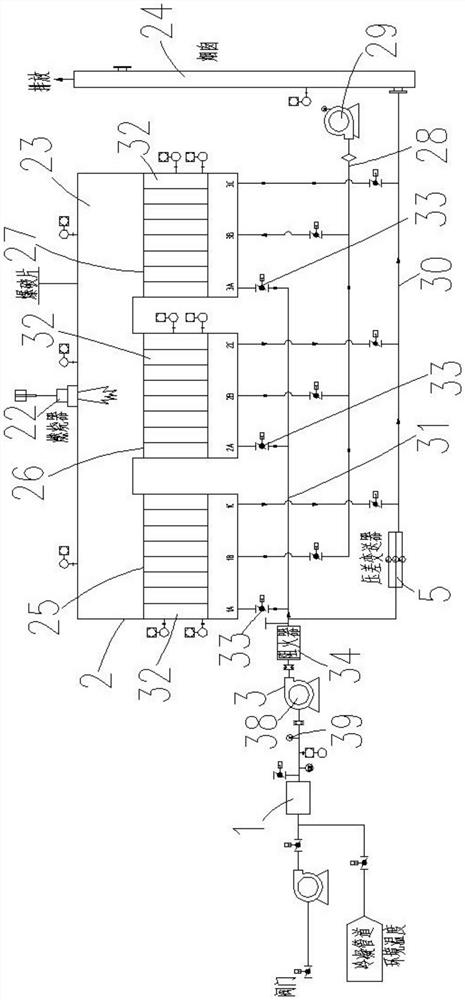

Organic waste gas treatment integrated equipment

PendingCN111964078AAvoid damageAvoid injuryDispersed particle filtrationIncinerator apparatusThermodynamicsAir volume

The invention relates to the field of waste gas treatment, in particular to organic waste gas treatment integrated equipment which comprises a pretreatment filter, an RTO thermal storage and burning furnace body, and an air volume control system for controlling the discharging amount of organic waste gas, and further comprises a pressure release safety device arranged on the RTO thermal storage and burning furnace body; after passing the pretreatment filter, organic waste gas enters the RTO thermal storage and burning furnace body under control of the air volume control system; and a pressuredifference transmitter for monitoring the pressure difference of the two sides of the RTO thermal storage and burning furnace body is arranged on the RTO thermal storage and burning furnace body and is connected with the air volume control system. According to the organic waste gas treatment integrated equipment, the pressure difference transmitter can compare the pressure difference between an air intake pipeline and an air discharging pipeline to control the blast amount of the air volume control system and realize the purposes of energy conservation and consumption reduction; and after reaching the set pressure value, the pressure release safety device blasts for decompression, the RTO thermal storage and burning furnace body is prevented from being damaged due to excessively large pressure during the operating process.

Owner:GUANGZHOU HUAKE ENVIRONMENTAL PROTECTION ENG

Heat storage and heat exchange method for coal pyrolysis furnace combustion heater

InactiveCN102796534AImprove combustion efficiencyFor the purpose of saving energy and reducing consumptionCombustible gas coke oven heatingCombustion chamberExhaust fumes

The invention discloses a heat storage and heat exchange method for a coal pyrolysis furnace combustion heater. The method comprises the following steps that: firstly, after hot waste gas in a first combustion chamber enters a second combustion chamber, the hot waste gas is discharged out from a second burnt waste gas exhaust branch pipe through the heat absorbing and temperature decreasing of a second heat accumulator in a second heat accumulation cavity; secondly, when the coal gas in the second combustion chamber is burnt, air enters the second combustion chamber through the second heat accumulation cavity and is heated by the second heat accumulator to become hot air for the combustion supporting of the coal gas in the second combustion chamber; and simultaneously, the hot waste gas after combustion in the second combustion chamber enters the first combustion chamber and is discharged out from a first burnt waste gas exhaust branch pipe through the heat absorbing and temperature decreasing of a first heat accumulator in a first heat accumulation cavity; and thirdly, the first step and the second step are carried out alternately and circularly. The method can heat air entering a gas chamber and also can carry out heat storage by using the hot waste gas after the combustion of the coal gas so that the coking cost is saved without extra heat source.

Owner:SHANXI XINLI ENERGY TECH

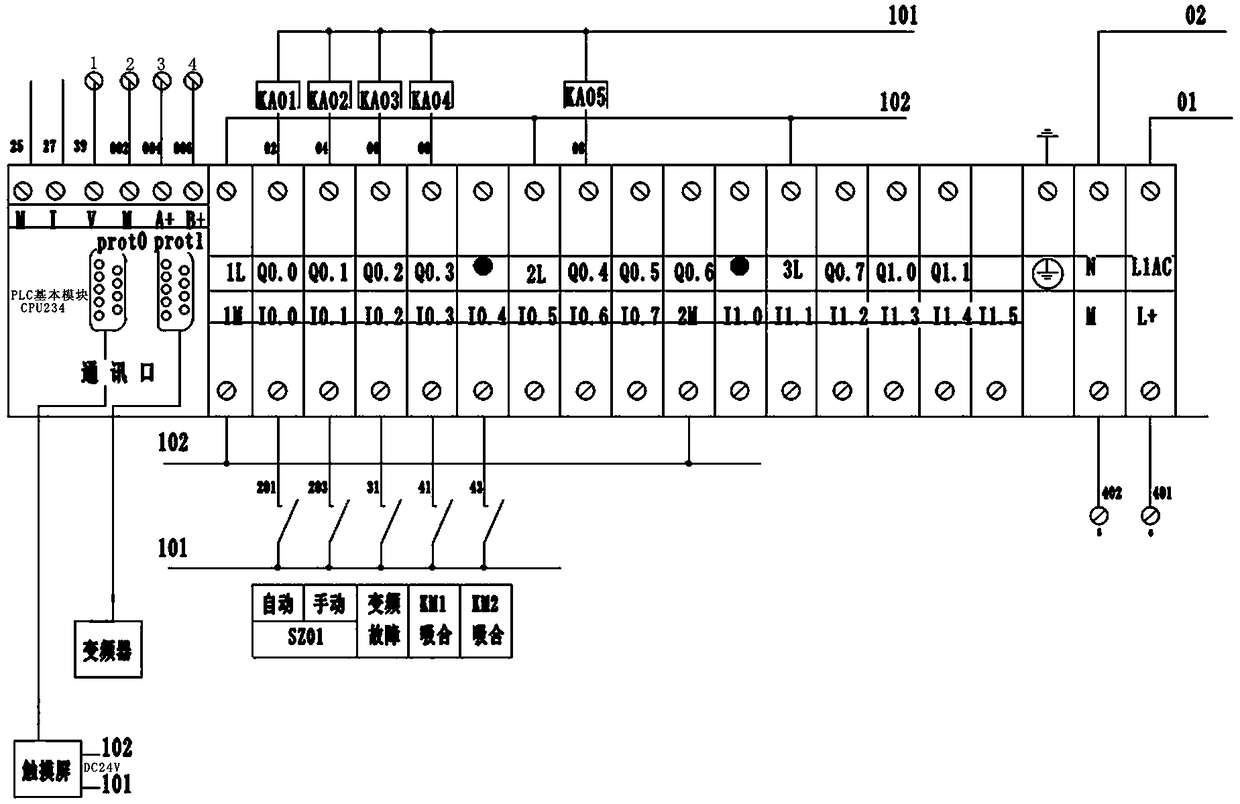

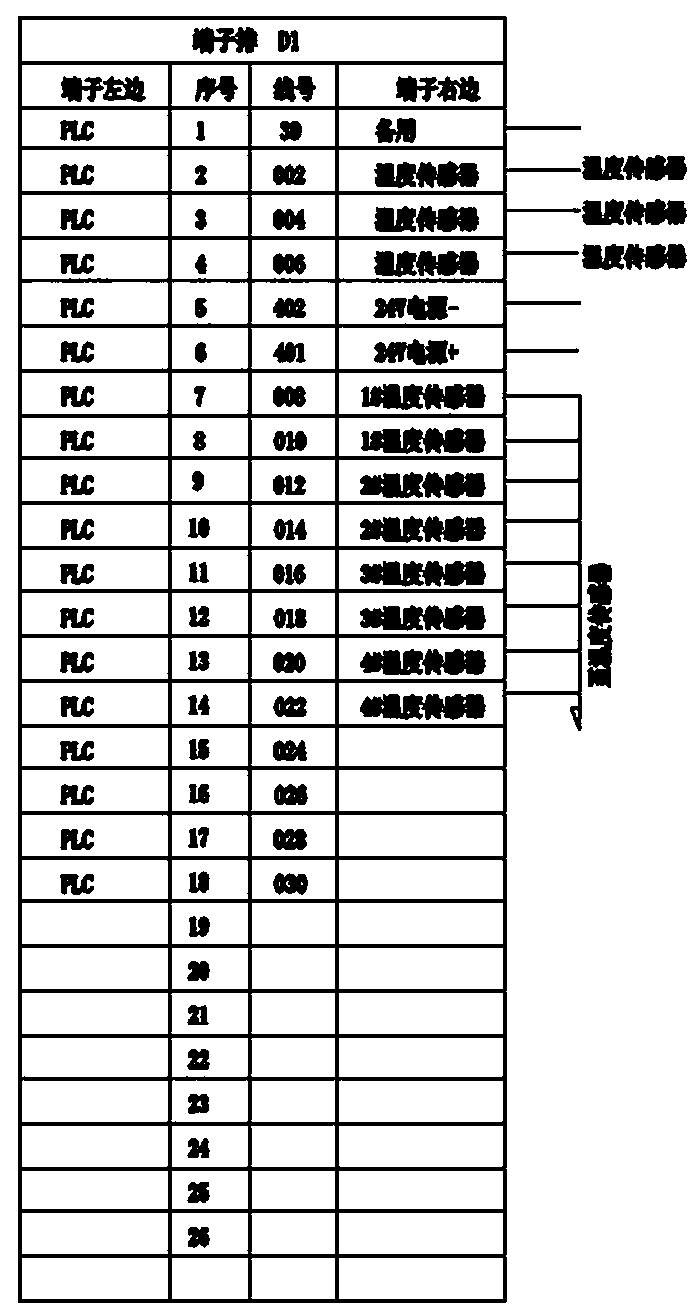

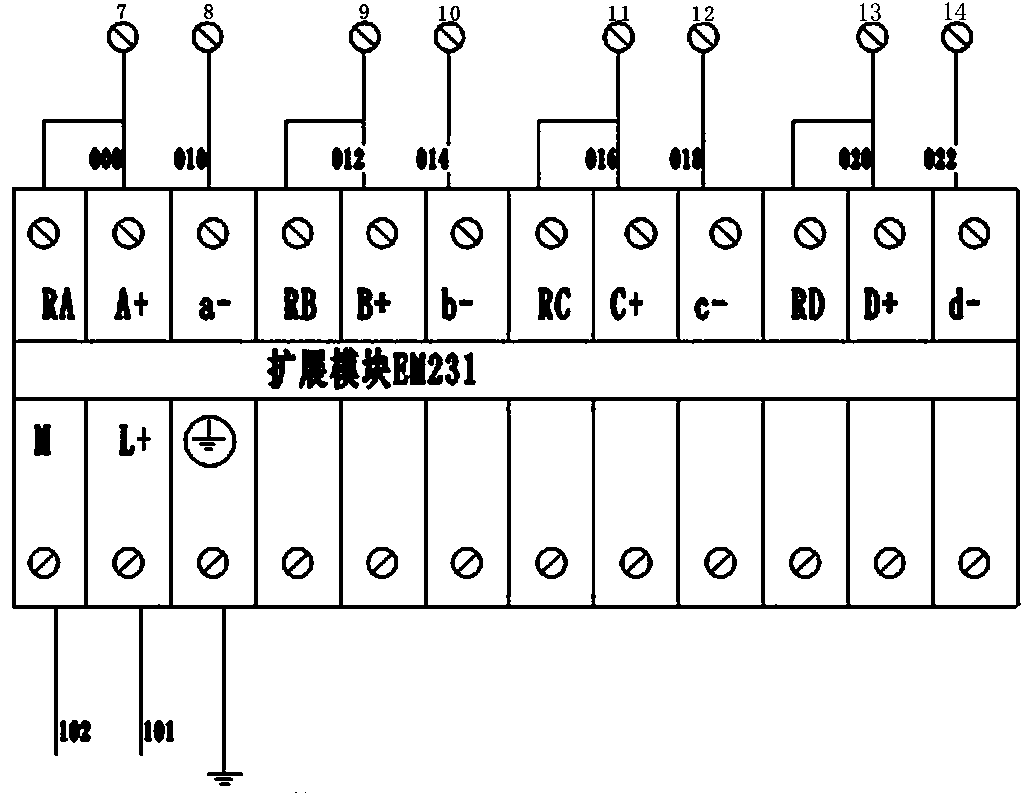

Temperature automatic control device for main motor of auxiliary shaft hoist

PendingCN109343599AEnsure safe and efficient operationChange the working environmentTemperature control using plurality of sensorsEarth drilling and miningAutomatic controlElectric machinery

The invention discloses a temperature automatic control device for a main motor of an auxiliary shaft hoist, comprising a shell provided with a touch screen and operation buttons. The shell is internally provided with an auxiliary shaft hoisting main motor temperature automatic control system and a power supply which are connected with the touch screen and the operation buttons. The auxiliary shaft hoisting main motor temperature automatic control system includes a PLC. The 485 interface of the PLC is connected with a first end of a frequency converter and the HIM of the touch screen. The input interface of the PLC is connected with temperature sensors for detecting the winding temperature of a main motor, the indoor temperature of the main motor and the outdoor temperature of the main motor through an analog input module EM232. The output interface of the PLC is connected with a second end of the frequency converter through an analog output interface. A third end of the frequency converter is connected with a fan through a contactor. The PLC is further connected with the operation buttons and a relay. The power connection end of the PLC is connected with a 24V switching power supply. The PLC is further provided with a sensor for detecting the temperature of the PLC. The problem that a hoist cannot start or stop normally in summer, in winter and in a hot standby state in the prior art is solved.

Owner:山西潞安环保能源开发股份有限公司常村煤矿

Chloroprene concentration system

ActiveCN113121305AReduce dosageAvoid icy conditionsChemical industryHalogenated hydrocarbon separation/purificationSaline waterThermodynamics

The invention relates to the technical field of concentration, in particular to a chloroprene concentration system which comprises a reaction concentration device and a condensing device, the condensing device comprises an initial condenser and a fractional condenser, gas passages of the reaction concentration device, the initial condenser and the fractional condenser sequentially communicate with one another, and a refrigerant inlet of the initial condenser communicates with a refrigerant outlet of the fractional condenser. Refrigerant passages of the initial condenser and the fractional condenser are connected in series to replace independent cooling, the problem that freezing is prone to occurring due to the fact that the temperature difference between frozen saline water and system heat exchange material flow is large when the initial condenser adopts the frozen saline water as refrigerant for independent cooling is solved, frequent deicing is avoided, efficient and stable production is guaranteed, the refrigerant consumption is reduced, and the purposes of saving energy and reducing consumption are achieved. The interior of the initial condenser can be prevented from being iced, the initial condenser does not need to be subjected to deicing treatment, the operation stability of the concentration system is guaranteed, the production efficiency is further improved, when the interior of the initial condenser is iced, online deicing is achieved, and the problem that a material system is polluted by CaCl2 saline water introduced into an original deicing process is solved.

Owner:BLUESTAR BEIJING TECH CENT

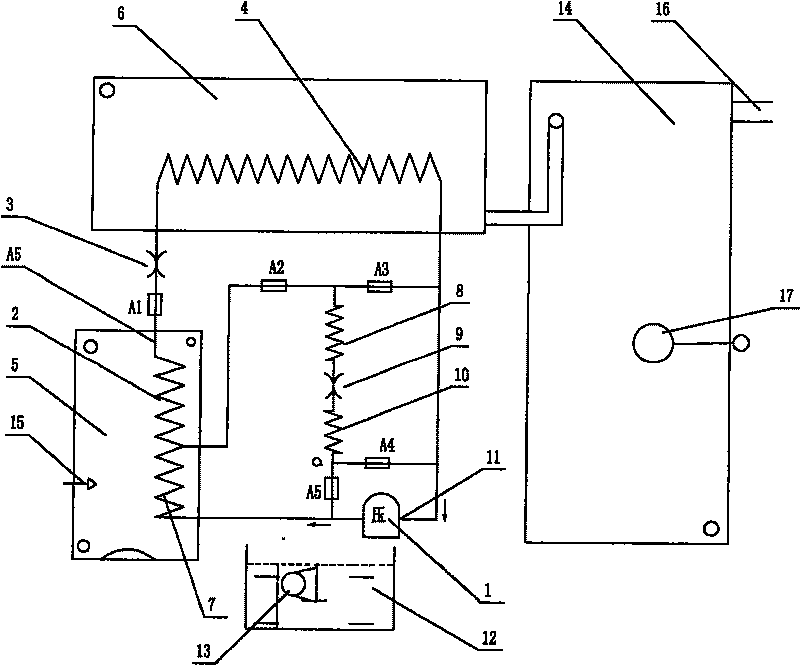

Multifunctional waterhead air-conditioner water heater

InactiveCN101225997BReduce consumptionWith air temperature adjustment functionFluid heatersEnergy efficient heating/coolingWarm waterWater source

The invention relates to a multifunctional water source air-conditioning water heater, comprising a compressor, a condenser, a throttling device and a cooling circulating pipeline of an evaporator. The multifunctional water source air-conditioning water heater is characterized in that a hot collecting heat insulated water tank is positioned on the external periphery of the condenser; a residual heat water tank is positioned on the external periphery of the evaporator; the front end section of the condensation pipe of the condenser is connected with one end of an air conditioning circulating pipeline; the other end of the air-conditioning circulating pipeline is connected with the input end of the compressor; the air-conditioning circulating pipeline comprises an outdoor cooled heat exchanger, a throttling and an indoor cooled heat exchanger connected in sequence; switch valves A1 and A2, used for controlling the switching of the pipeline, are positioned are positioned respectively on the cooling circulating pipeline and the air-conditioning circulating pipeline. The multifunctional water source air-conditioning water heater has the advantages of having the function of air conditioner to regulate air temperature, reusing the heat produced in the cooling circulating pipeline and simultaneously absorbing the heat from the cleaning warm water discharged by the household.

Owner:康景安

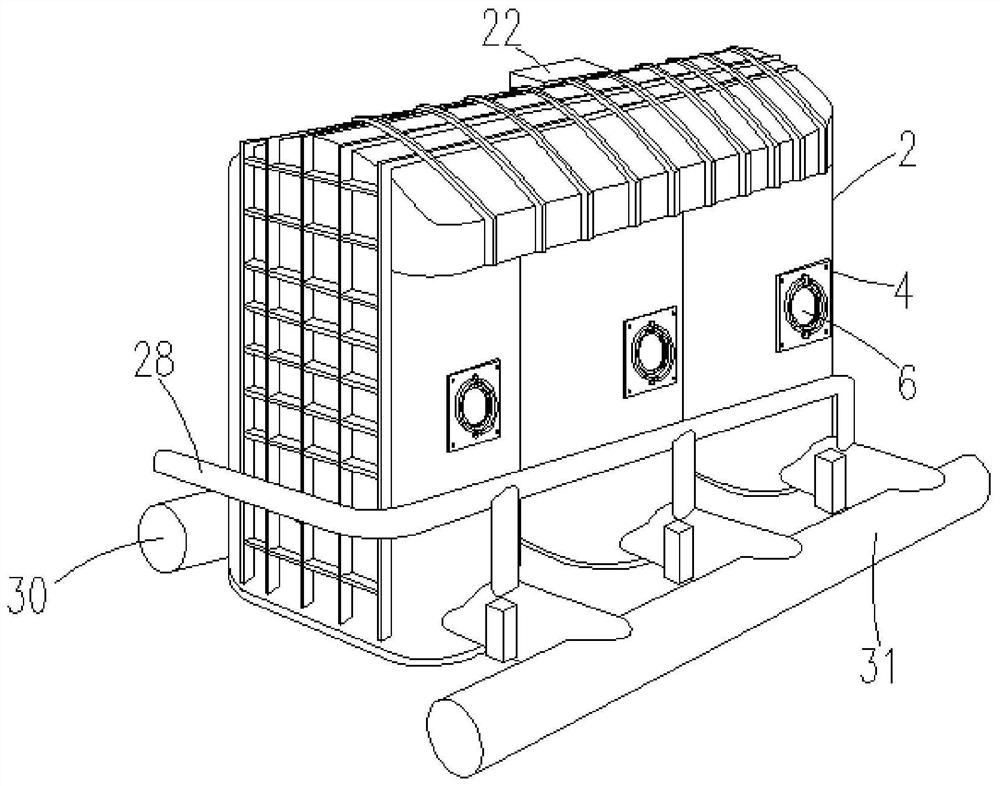

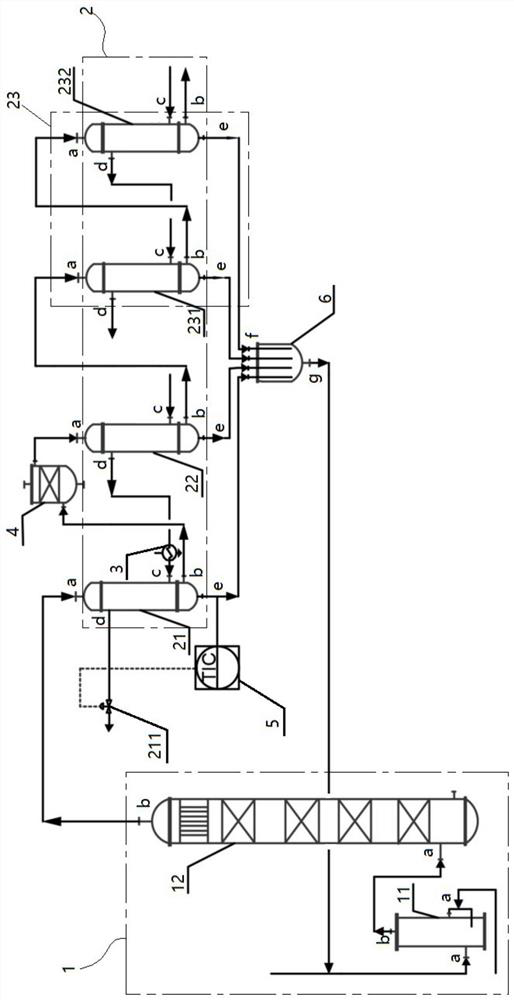

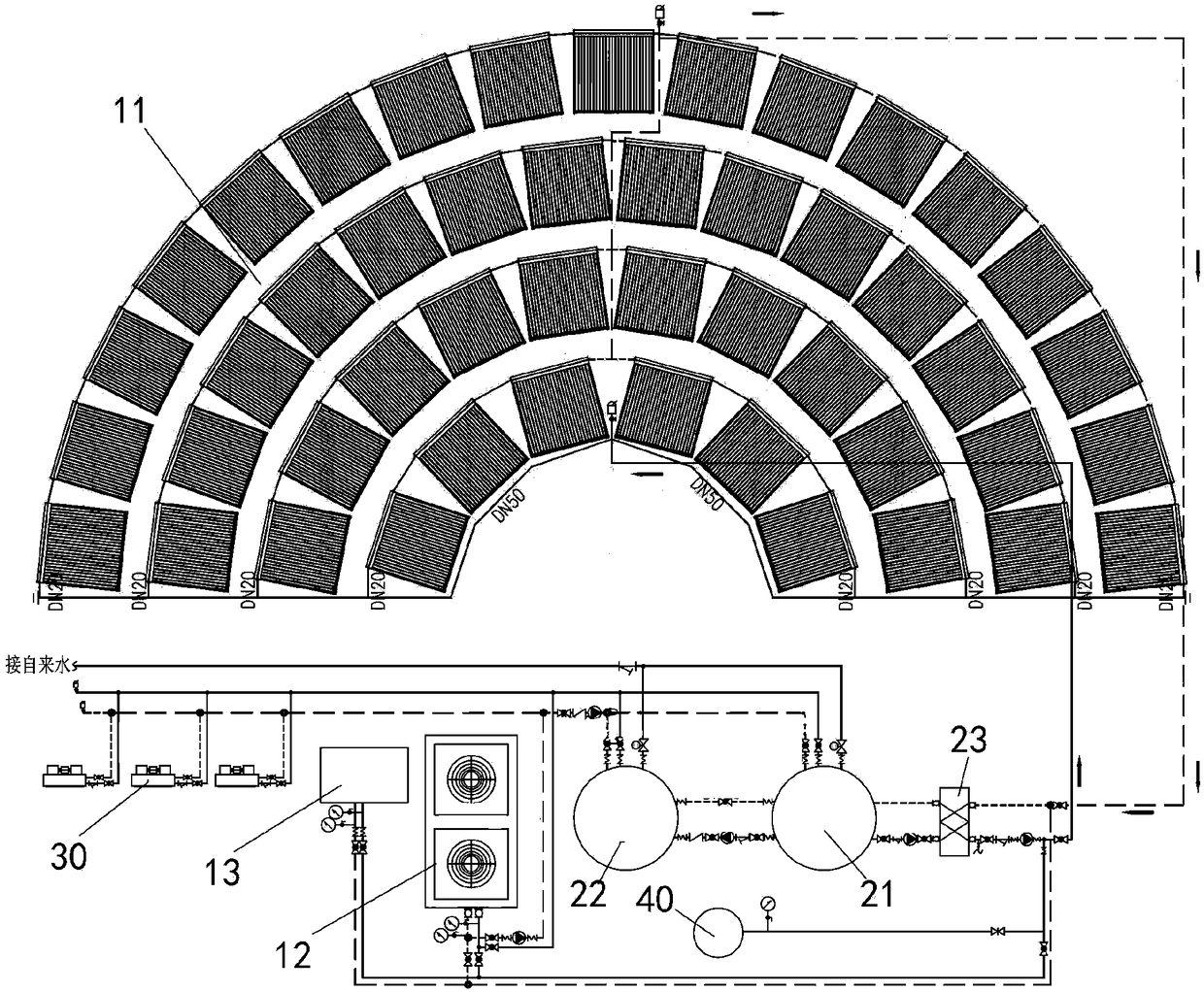

Energy-saving and environment-friendly three-energy new energy heat supply system

PendingCN108167918AAvoid disadvantagesFor the purpose of saving energy and reducing consumptionSolar heating energyLighting and heating apparatusThermal energyNew energy

The invention relates to the technical field of heat supply equipment, and discloses an energy-saving and environment-friendly three-energy new energy heat supply system. The energy-saving and environment-friendly three-energy new energy heat supply system comprises a heat supply device generating heat energy, a heat storage device storing heat energy, a heat dissipation device outputting heat toa user, and a control unit controlling running of the heat supply device. The heat supply device comprises solar heat supply equipment, electromagnetic heat supply equipment and air source heat supplyequipment. A heat supply pipeline of the solar heat supply equipment, a heat supply pipeline of the electromagnetic heat supply equipment and a heat supply pipeline of the air source heat supply equipment are connected in parallel one by one to form the heat energy output end. The heat dissipation device and the heat storage device obtain heat from the heat energy output end and are connected inparallel. The control unit is used for controlling the work state of the three pieces of heat supply equipment; and due to a heat supply manner that the three pieces of heat supply equipment jointly cooperate to work, the advantages of every kind of heat supply equipment can be well utilized, the disadvantages of every kind of heat supply equipment are avoided, and the purposes of energy saving and consumption reducing are achieved; and compared with coal heat supply, the energy-saving and environment-friendly three-energy new energy heat supply system is relatively environment-friendly.

Owner:山西悦凌空调有限公司

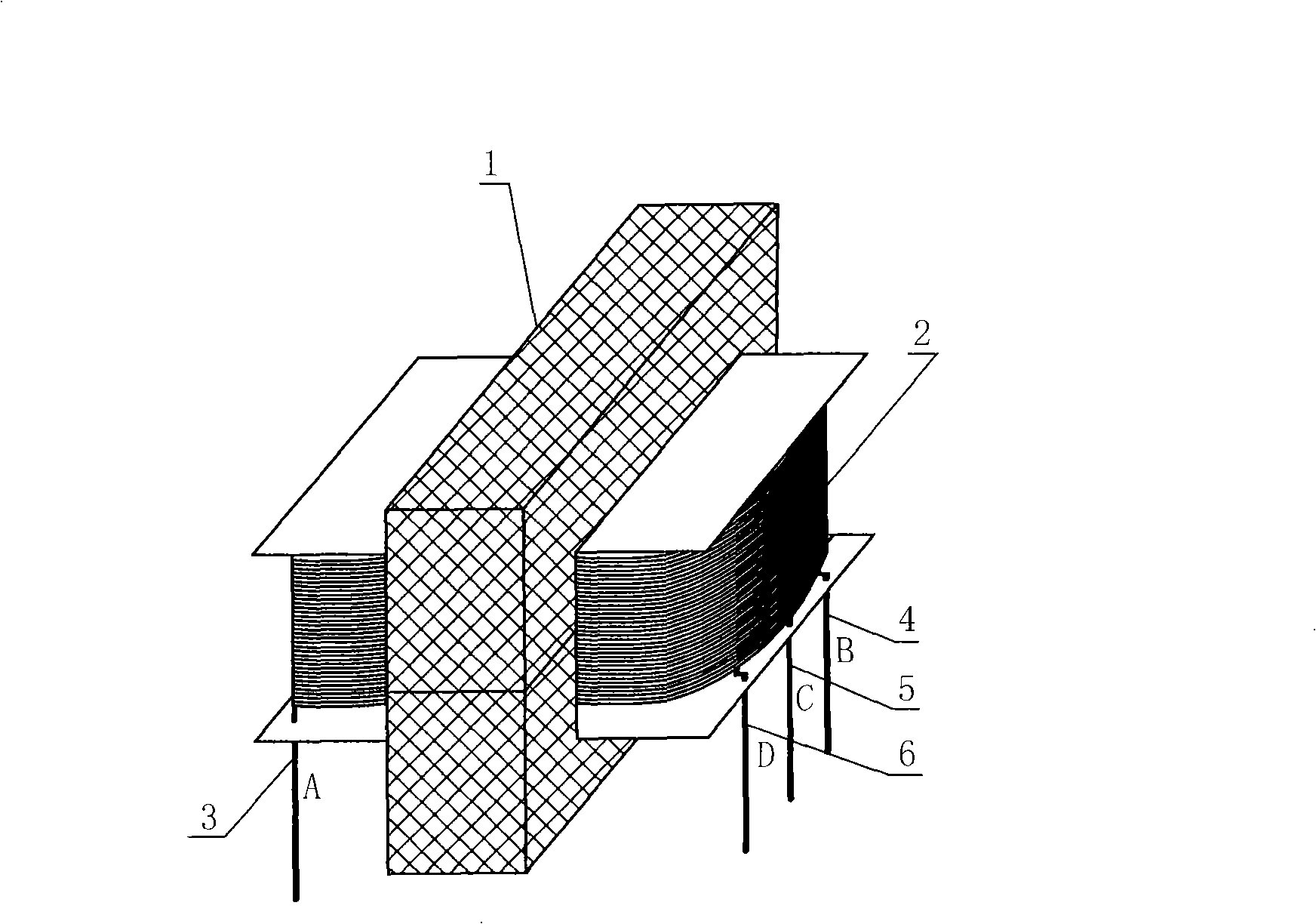

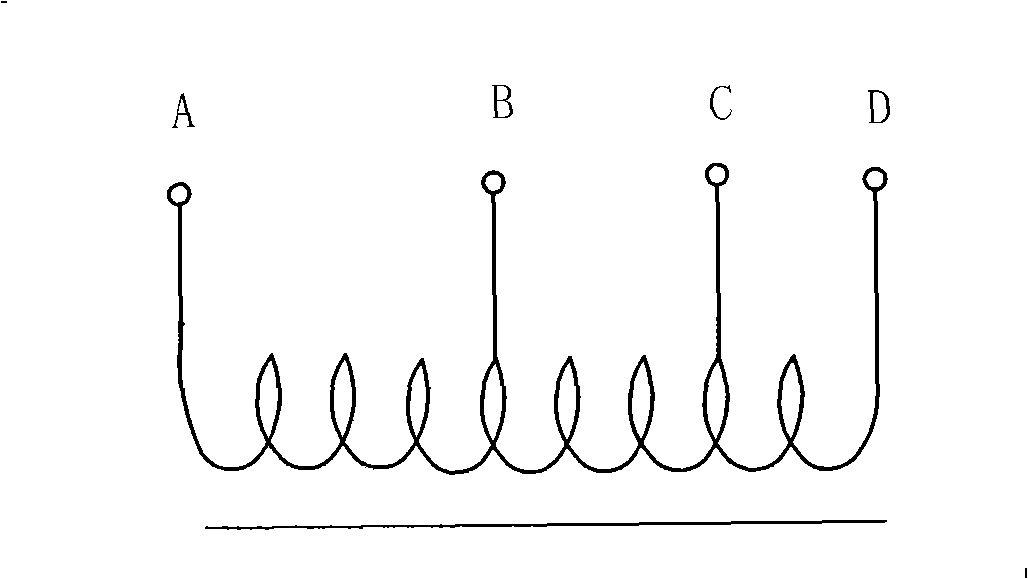

Universal inductor of electric ballast

InactiveCN101320622AExtended service lifeExtend the lifespanTransformersTransformers/inductances coils/windings/connectionsEngineeringInductor

A general inductor of electronic ballast, belonging to an electron component, especially an inductor applied to the electronic ballast, capable of adjusting the inductance and being applied to fluorescent lamps with each power. The general inductor of electronic ballast of this invention is composed of a magnetic core and a coil surrounded on the magnetic core, wherein more than two of tapping points are on the coil, different tapping points generate different inductances which are matched with the corresponding feature of the fluorescent lamp. Due to the commonality, the general inductor of electronic ballast of this invention is able to enable the single one electronic ballast to generate plural features which are satisfied to match with the fluorescent lamps with each feature, and the service life of the fluorescent lamp is enlarged and the best light efficiency can be developed, at the same time the target of saving energy can be achieved, and the waste caused by unmatched features can be avoided; at the same time, the service life of the electronic ballast can be correspondingly enlarged and the back repair rate is reduced.

Owner:杨韶军

A device for improving sncr denitrification efficiency of circulating fluidized bed boiler

ActiveCN110975581BIncreased chance of collisionImprove completenessGas treatmentEmission preventionIon clustersElectromagnetic generator

Owner:HUNAN UNIV OF HUMANITIES SCI & TECH

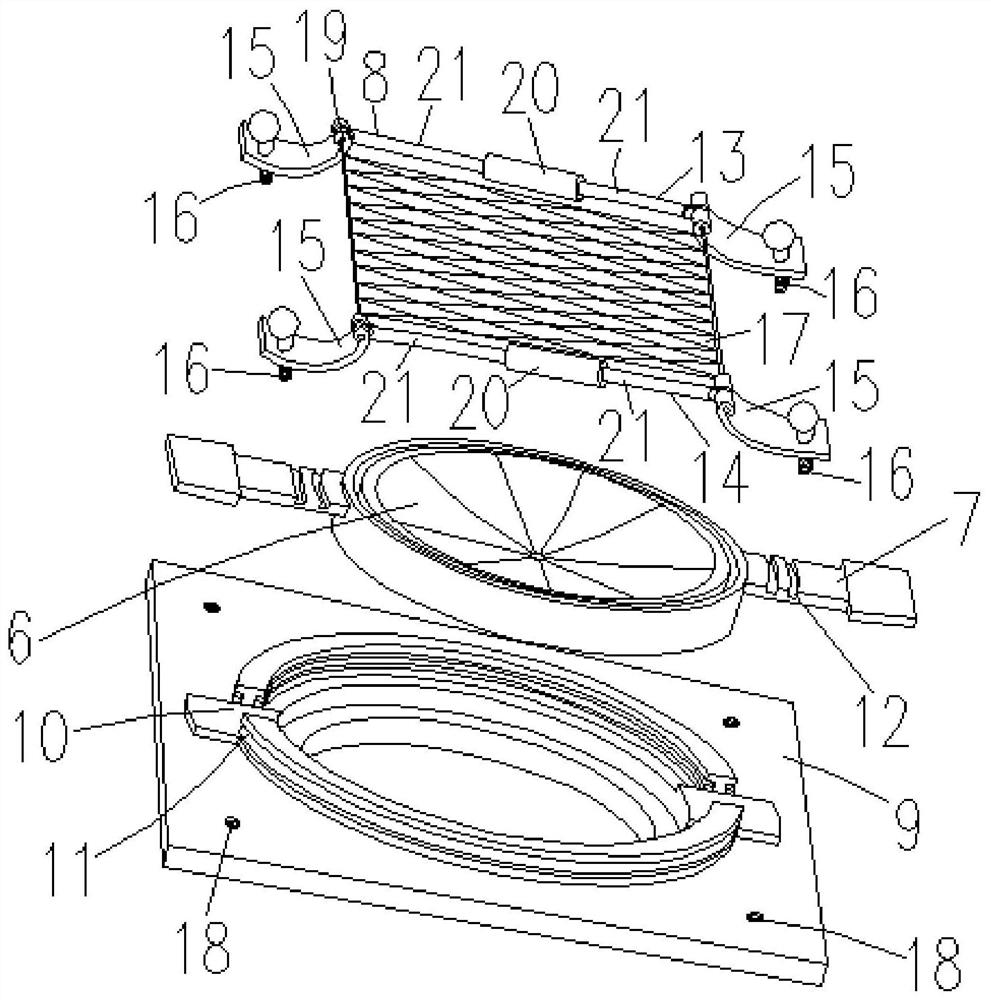

Novel flotation machine

ActiveCN113000228ALow probability of collision attachmentIncreased probability of collision attachmentFlotationElectric machineProcess engineering

The invention discloses a novel flotation machine, wherein firstly, an air guide fan blade is arranged on a main shaft, the air guide fan blade can actively drain air in an air guide pipe downwards while rotating and working through the main shaft, and then through double inflation of an air inlet pipe and the air guide fan blade, the inflation amount can be increased, and the probability that ore grains collide with bubbles and adhere to the air can be increased; in addition, through the arrangement of a driving device, two main shafts can be driven to rotate simultaneously, a single motor does not need to drive a single main shaft, and therefore energy consumption is reduced to the minimum. In addition, a plurality of flotation areas share one raw ore pulp tank for feeding, so that the purposes of saving energy and reducing consumption can be achieved; meanwhile, a rotary sealing part is arranged on a feeding pipe connected with the raw ore pulp tank, the feeding pipe is opened when the rotary sealing part rotates, meanwhile, ore pulp can be stirred, then chemicals are added from a chemical feeding pipe, and the chemicals are stirred with the ore pulp while being added, so that the ore pulp and the chemicals are fully mixed; and the mineral separation time and efficiency can be improved.

Owner:GUANGDONG PROVINCE DABAOSHAN MINING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com