Novel air seal for combustion gas turbine tail barrel and manufacturing method for novel air seal

A technology for gas turbines and manufacturing methods, applied in the direction of gas turbine devices, mechanical equipment, jet propulsion devices, etc., can solve the problems of overall scrapping and large losses, and achieve the effects of simple processing, high yield, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

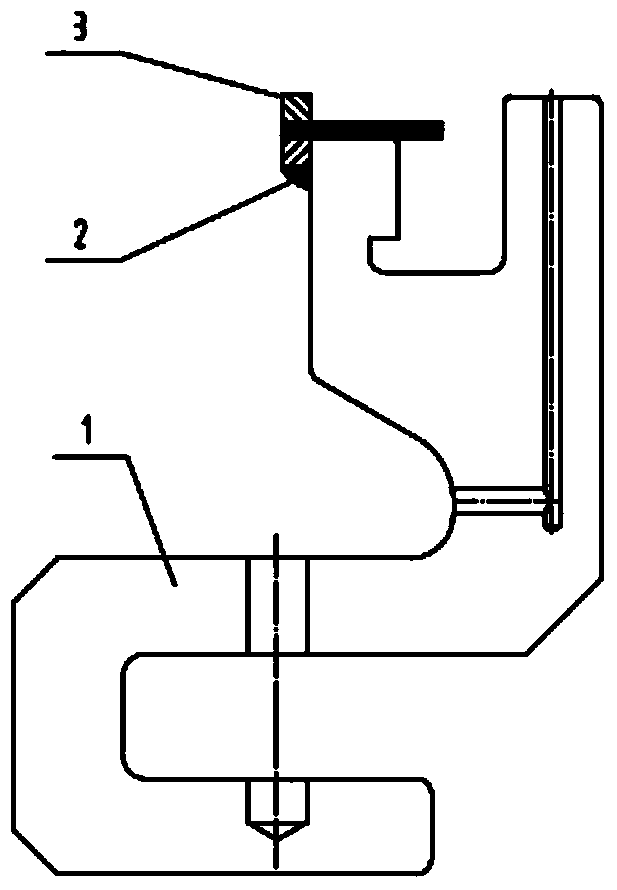

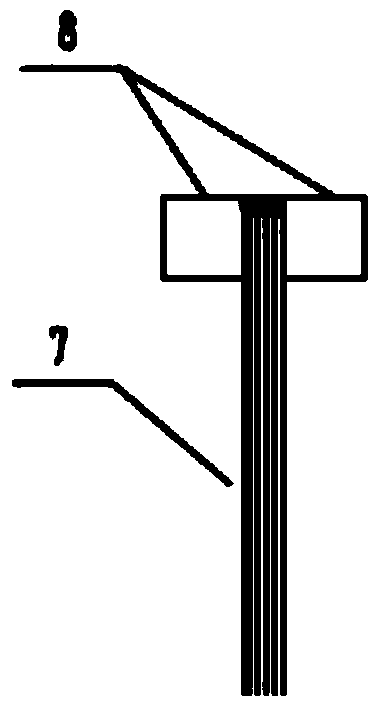

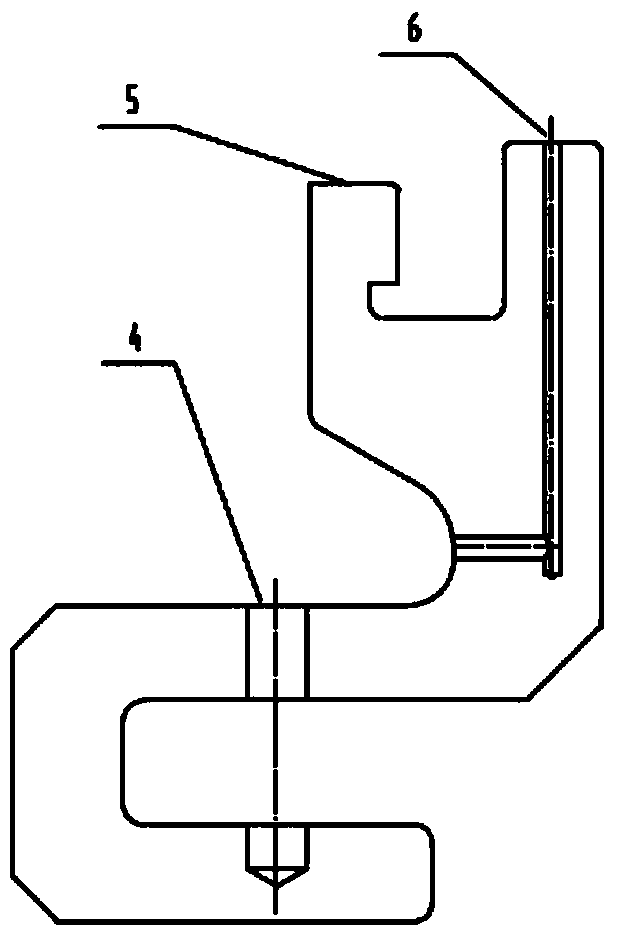

[0028] Such as figure 1 , figure 2 , image 3 As shown, a new type of gas turbine tailpipe air seal, the tailpiece air seal includes a brush 3 and a seal body 1, the brush 3 is composed of a brush tuft 7 and two metal strips 8, the brush tuft 7 is installed on the two metal strips 8 is in the shape of a "T" in the middle; the seal body 1 is provided with a brush mating surface 5, the brush cluster 7 of the brush 3 is fixed on the brush mating surface 5, and the metal strip 8 is close to the side of the brush mating surface 5, through Welded fixing points 2 secure the brush 3 to the seal body 1 .

[0029] The aforementioned metal strips 8 are of any geometric shape.

[0030] Cooling air hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com