Antenna manufacturing process

A technology of manufacturing process and process method, which is applied in the field of communication antennas, can solve the problems of low work efficiency, high labor intensity, and high processing waste rate, and achieve the effects of increased production efficiency, simple manufacturing, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

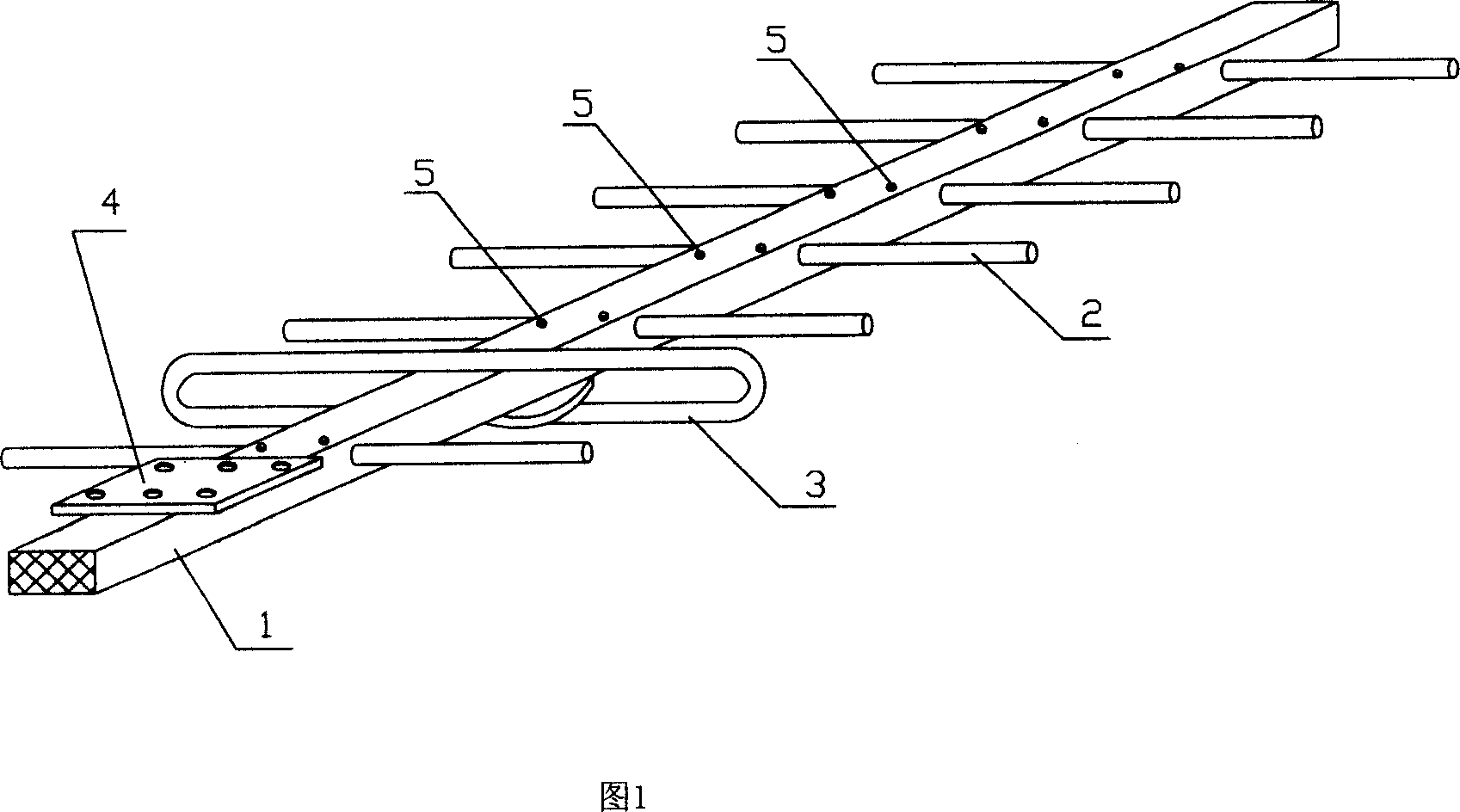

[0011] As shown in Figure 1, taking the Yagi antenna as an example, the antenna consists of a main square tube 1 and a circular tube 2 arranged on the square tube 1 to form a vibrator, and a ring tube 3 fixed on the square tube 1 to form a feed source. 1 is also provided with a mounting plate 4, and the antenna manufacturing process of the present invention includes the following steps: the manufacturing process method of the antenna is to change the traditional screw threading processing and riveting processing mode, directly adopts stamping and fixing, and it includes the following process steps:

[0012] (1), adopt the existing technology to process the round pipe 2 and the square pipe 1 with several holes, the end of the round pipe 2 is connected with a plastic sleeve, and the round pipe is inserted into the hole of the square pipe;

[0013] (2), punch the corresponding part of the square tube 1 with the round tube 2 (the punching point is 5), so that the round tube 2 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com