Method for recovering reduction system tail gas in polycrystalline silicon production

A tail gas recovery and polysilicon technology, which is applied in the direction of halosilane, halide silicon compound, climate sustainability, etc., can solve the problems of increasing follow-up costs, increasing energy consumption in polysilicon production, and consuming large power, so as to save energy consumption and save Cost, shortening the effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, and the contents of the specific embodiments are not intended to limit the scope of protection of the present invention.

[0016] The invention relates to a tail gas recovery method of a reduction system in polysilicon production. In this method, the tail gas discharged from a reduction furnace is used as a raw material for hydrogenation reaction directly without cooling down, separating or analyzing. Therefore, the process flow can be shortened and energy saving can be achieved. purpose of reducing consumption.

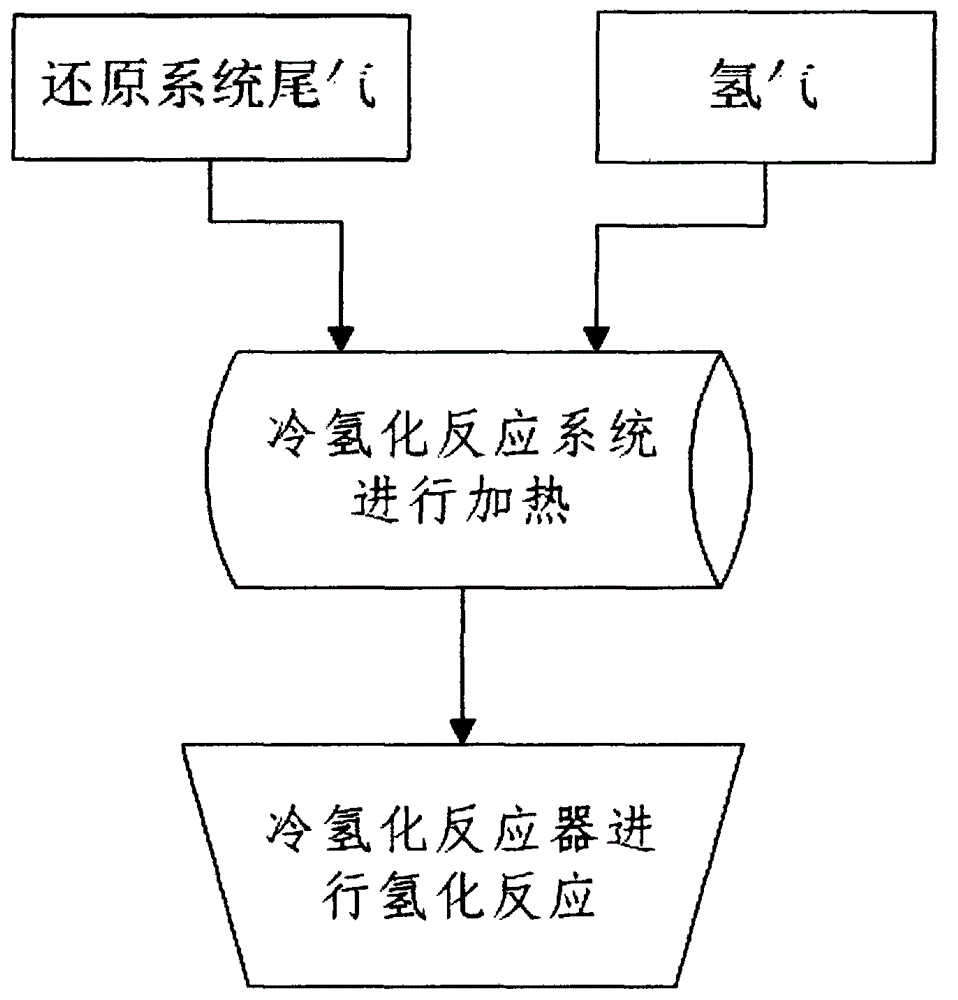

[0017] figure 1 A schematic flow chart of the method for recovering tail gas from a reduction system in polysilicon production according to the present invention is shown. like figure 1 As shown, the reduction system tail gas recovery method in polysilicon production of the present invention generally comprises the following three st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com