Annular piston type pneumatic actuating mechanism

A pneumatic actuator, annular piston technology, applied in the direction of rotary piston engine, rotary or oscillating piston engine, engine components, etc., can solve the problems of increasing the cylinder volume, high energy consumption, and the length of the force arm cannot be effectively increased. , to achieve the effect of increasing the output torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

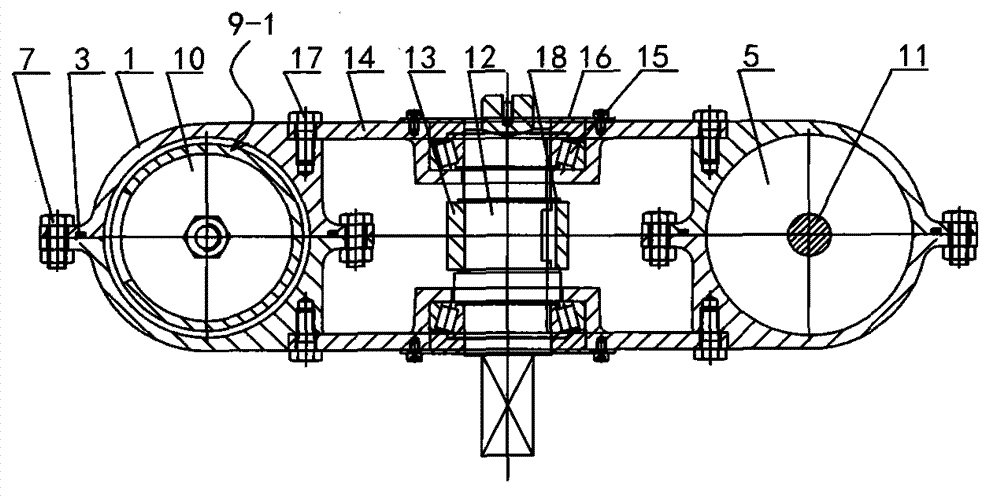

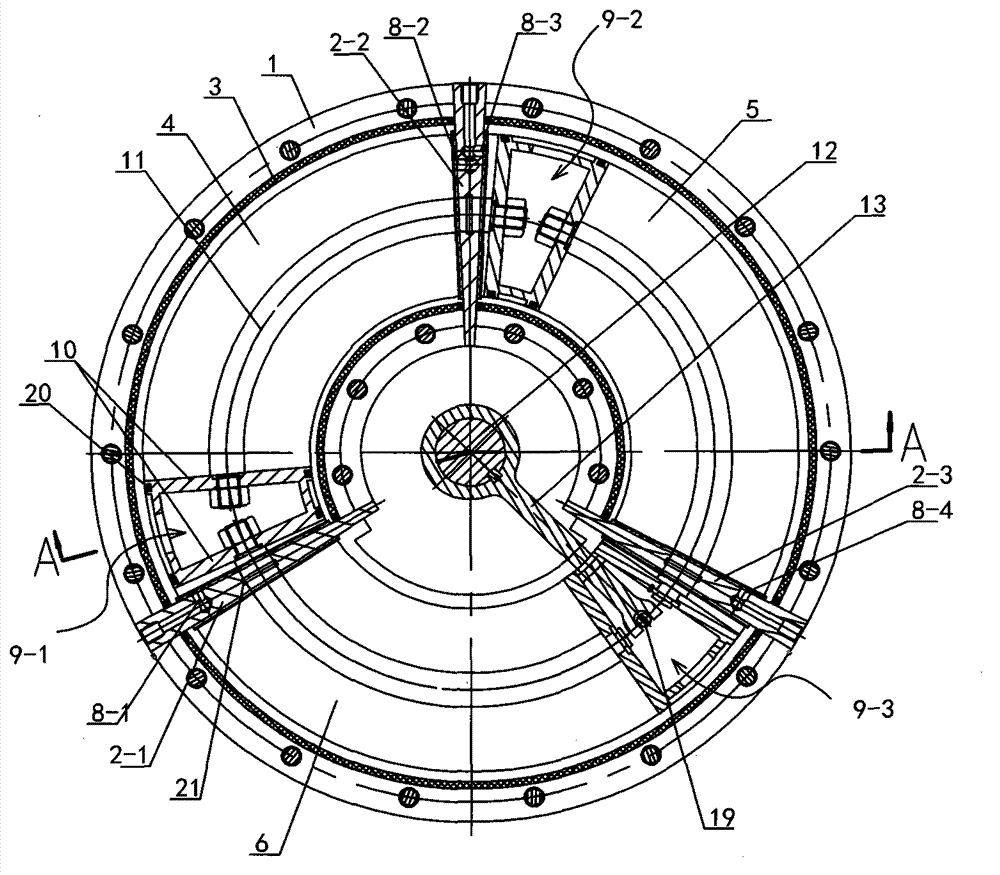

[0021] The annular piston type pneumatic actuator of the present invention is composed of a cylinder assembly, a piston assembly and a transmission output assembly.

[0022] The cylinder assembly includes six cylinder body mounting units 1, three baffles (baffle 2-1, baffle 2-2 and baffle 2-3) and special-shaped sealing ring 3.

[0023] The six-piece cylinders are installed in pairs 1 and form closed cylinders 4, 5 and open cylinders 6 with baffle plates. The closed cylinders 4, 5 and the open cylinder 6 are connected in series through flanges to form an annular cylinder. The cylinder installation units 1 are sealed by built-in special-shaped sealing rings 3 and connected and fixed by fastening bolts 7 .

[0024] The baffle plate 2-1 and the baffle plate 2-2 are respectively provided with an air nozzle 8-1 and an air nozzle 8-2 connected with the closed cylinder body 4; the baffle plate 2-2 and the baffle plate 2-3 are respectively provided with Gas nozzle 8-3 and gas nozzle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com