Organic waste gas treatment integrated equipment

A technology of organic waste gas and equipment, applied in the field of organic waste gas treatment integrated equipment, can solve the problems of large concentration fluctuations, energy waste, and single function, and achieve the effects of avoiding damage, avoiding splashing, and enhancing safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

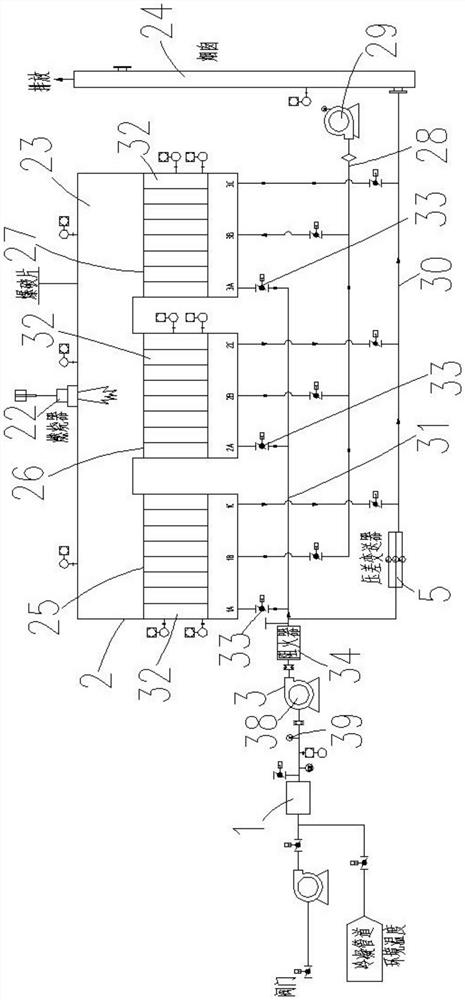

[0056] In this embodiment, when treating organic waste gas with small and medium air volumes, the organic waste gas is first filtered through a pre-treatment filter. The way to deal with the filter, the activated carbon filter can adsorb most of the particulate matter and organic substances (VOCs), but the directivity is not strong, and the molecular sieve filter can be used for particulate matter and organic substances with a specified diameter ( VOCs) for adsorption, strong directivity.

[0057] When the organic waste gas is filtered by the pre-treatment filter, particulate matter and organic substances (VOCs) are adsorbed on the pre-treatment filter. The particulate matter and organic substances (VOCs) are desorbed, and the desorbed gas is sent to the RTO regenerative combustion furnace under the control of the main control fan.

[0058] Stage 1: The desorbed organic waste gas passes through the first regenerator and is preheated by the ceramic regenerator in the first reg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com