Jacquard electromagnet assembly

A technology of magnet components and electromagnets, which is applied in the field of electromagnet components, can solve the problems of large power dissipation, small lever ratio, easy heating of coils, etc., and achieve the effects of improving utilization efficiency, reducing resistance arms, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

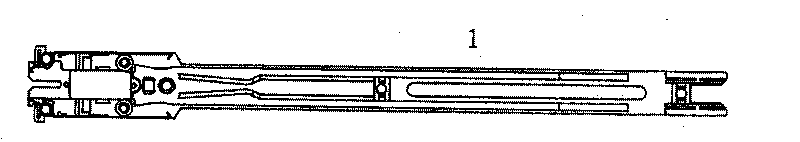

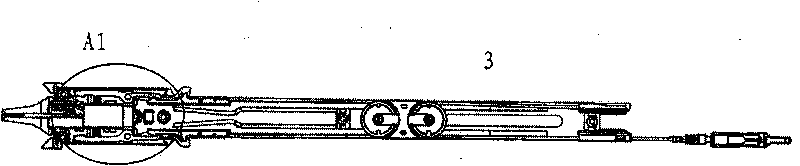

[0018] figure 1 It is a structural schematic diagram of the inner panel skeleton of the present invention, which is used to form the inner skeleton of the component and is prepared by injection molding process;

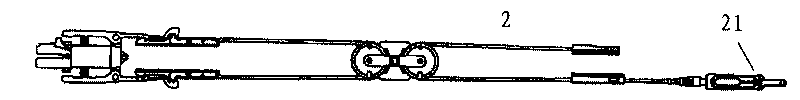

[0019] figure 2 The schematic diagram of the inner plate wire wheel assembly of the present invention is prepared by a plastic wear-resistant pulley and a wear-resistant wire rope. The two ends of the wire rope are respectively injected into the plastic hook 33 and the quick connector 21; the plastic hook 33 and the iron hook 32 are hooked. Hanging connection; the iron hook 32 is fixed by the fixed rotating shaft on the fixed bracket, and the spring 35 is placed in the central position of the power arm to support and help the iron hook 32 to reciprocate.

[0020] In this preferred solution, the iron hook 32 is designed such that the ratio of power arm: resistance arm is 2:1, increasing the power arm and reducing the resistance arm, so as to improve energy utilizatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com