Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Facilitate the positive reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

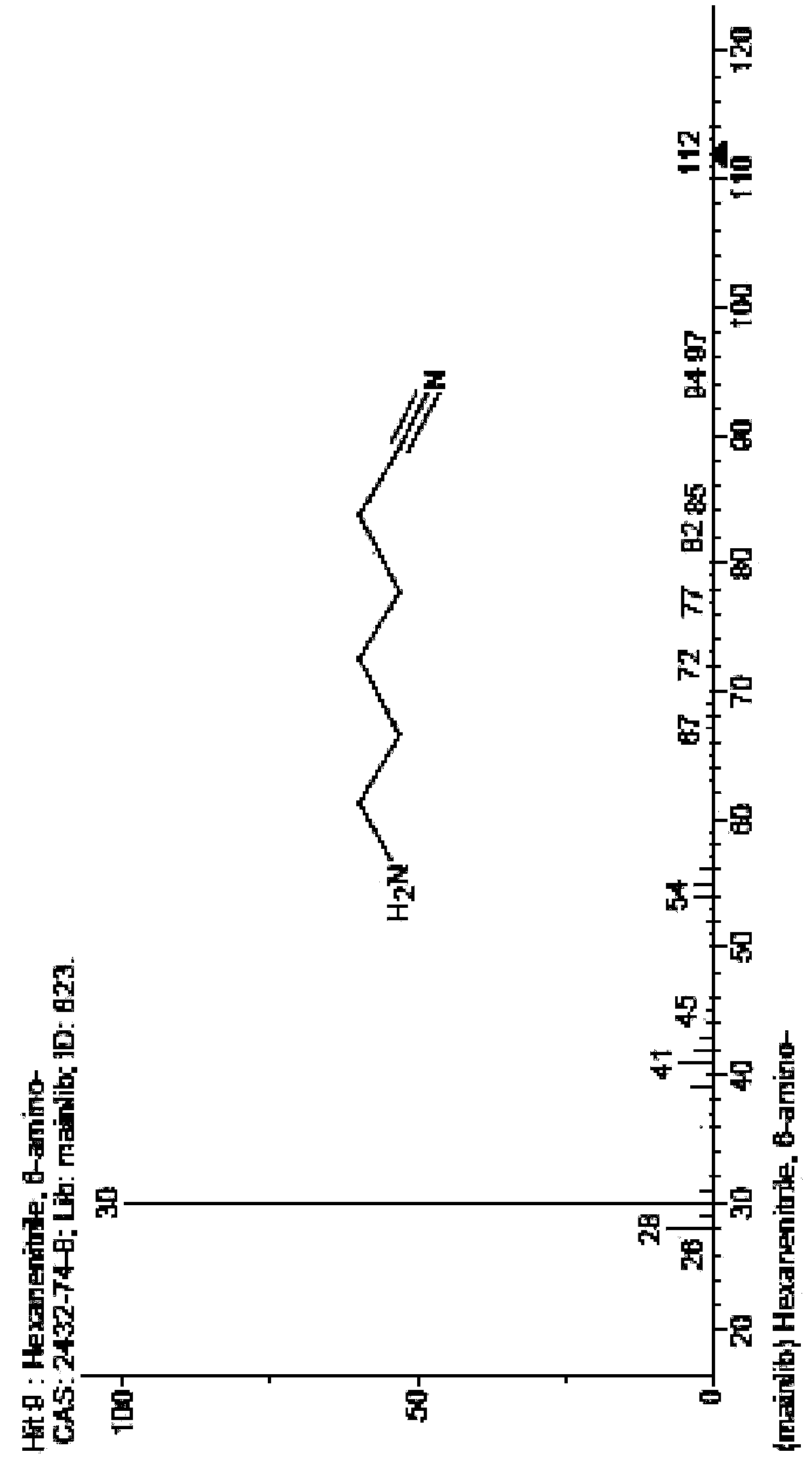

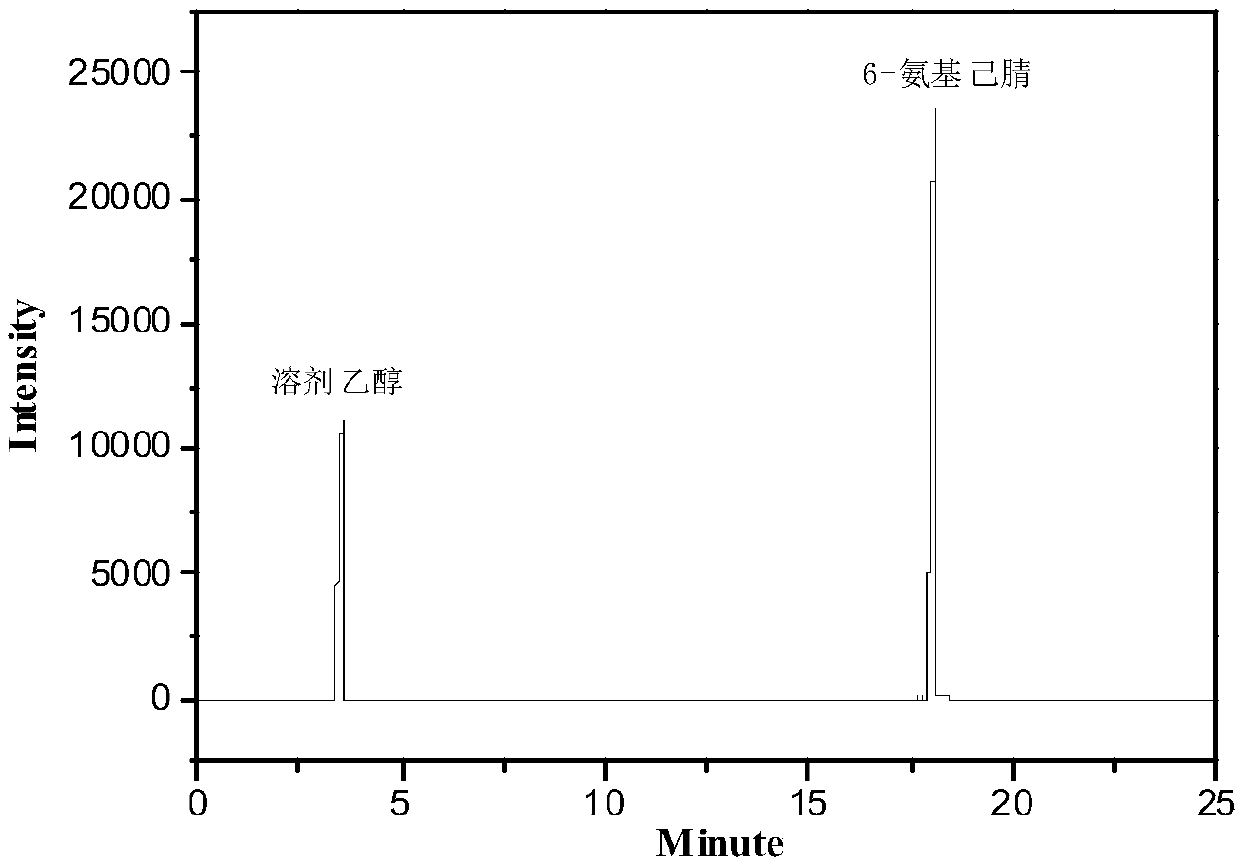

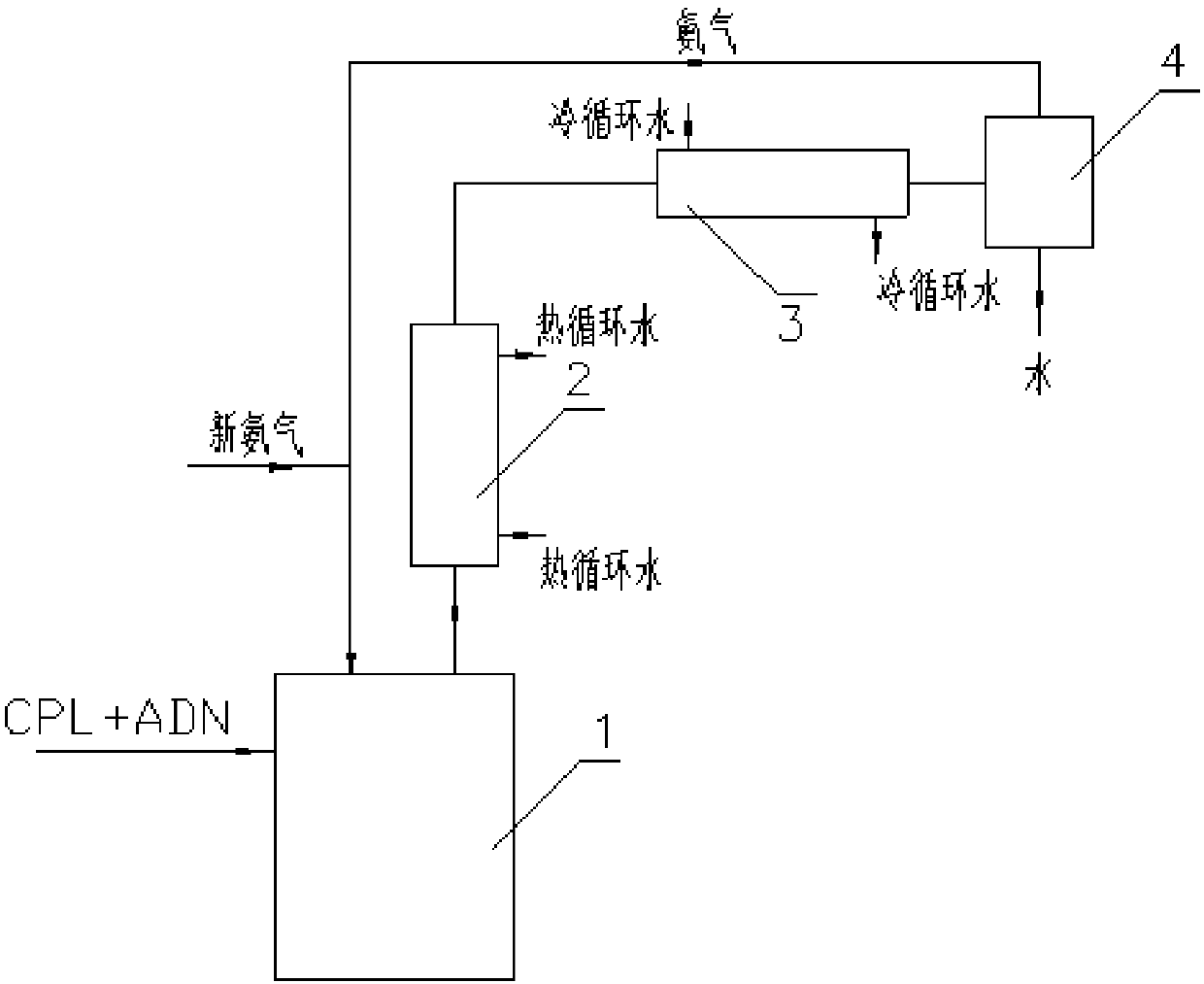

Method and device for preparing 6-amino-capronitrile with caprolactam liquid phase method

InactiveCN107739318AHigh reaction conversion rateGood choicePreparation by carboxylic acid amide dehydrationOrganic solventCaprolactam

The invention provides a method and device for preparing 6-amino-capronitrile from caprolactam by adopting a liquid phase method. In the method for preparing the 6-amino-capronitrile, the caprolactamis taken as a raw material; the method for preparing the 6-amino-capronitrile comprises the following step: S1: mixing the caprolactam, an organic solvent and a catalyst at a certain mass ratio, so asto obtain a mixed solution, adding the mixed solution into a reaction kettle and stirring and heating the mixed solution; S2: when the mixed solution in step S1 reaches certain temperature, introducing ammonia gas into the mixed solution for a reaction; S3, after the reaction in step S2 is ended, rectifying and purifying a reaction product, so as to obtain pure 6-amino-capronitrile. In the methodfor preparing the 6-amino-capronitrile, the caprolactam is taken as the raw material, the reaction conversion rate is comparatively high, and the preparation process is simple.

Owner:CHINA TIANCHEN ENG +1

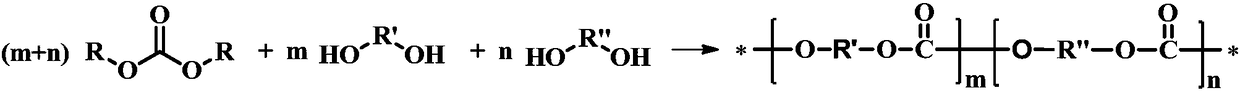

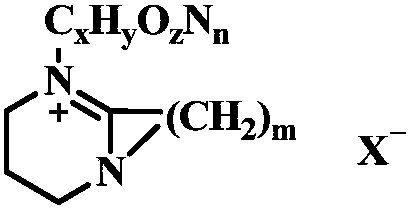

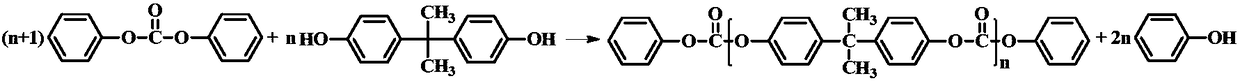

Method for preparing polycarbonate catalyzed by ionic liquid

The invention relates to a method for preparing polycarbonate catalyzed by ionic liquid. The method is characterized in that heterocyclic nitrogen-containing ionic liquid is used as a catalyst, the amount of the catalyst is 5*10<-3>-5% of the mass of a dihydroxy compound, the dihydroxy compound and bis(trichloromethyl) carbonate are taken as raw materials, a feeding mol ratio of the dihydroxy compound to the bis(trichloromethyl) carbonate is 1:0.8-1:10, and the corresponding polycarbonate is obtained by melt polymerization. A synthesis process of the polycarbonate includes two stages of transesterification and polycondensation. In the transesterification stage, a prepolymer is obtained under conditions of a reaction temperature of 90-180 DEG C, an atmospheric pressure and reaction time of0.05-6 h. In the polycondensation stage, the polycarbonate is obtained by synthesizing prepolymer at 200-270 DEG C, a vacuum degree of 4.0*10<-3> MPa-1.0*10<-5> MPa, and reaction time of 0.05-7 h. Thesynthetic method has the advantages of simple catalyst components and molecular structure that can be designed. Moreover, the catalyst is strong in alkalinity and high in activity. By-products can berecycled, which reduces the cost. The synthetic method does not use highly toxic phosgene, dose not require a solvent, is very little in three wastes generation, and conforms to the concept of cleanproduction.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

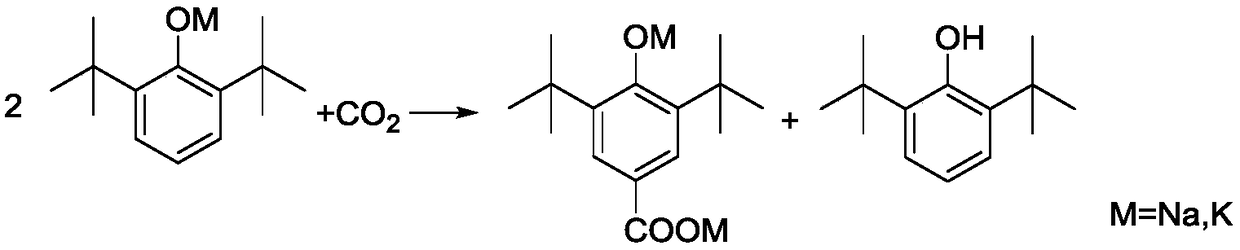

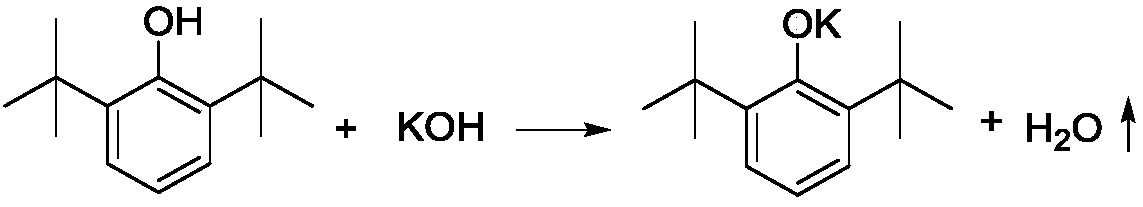

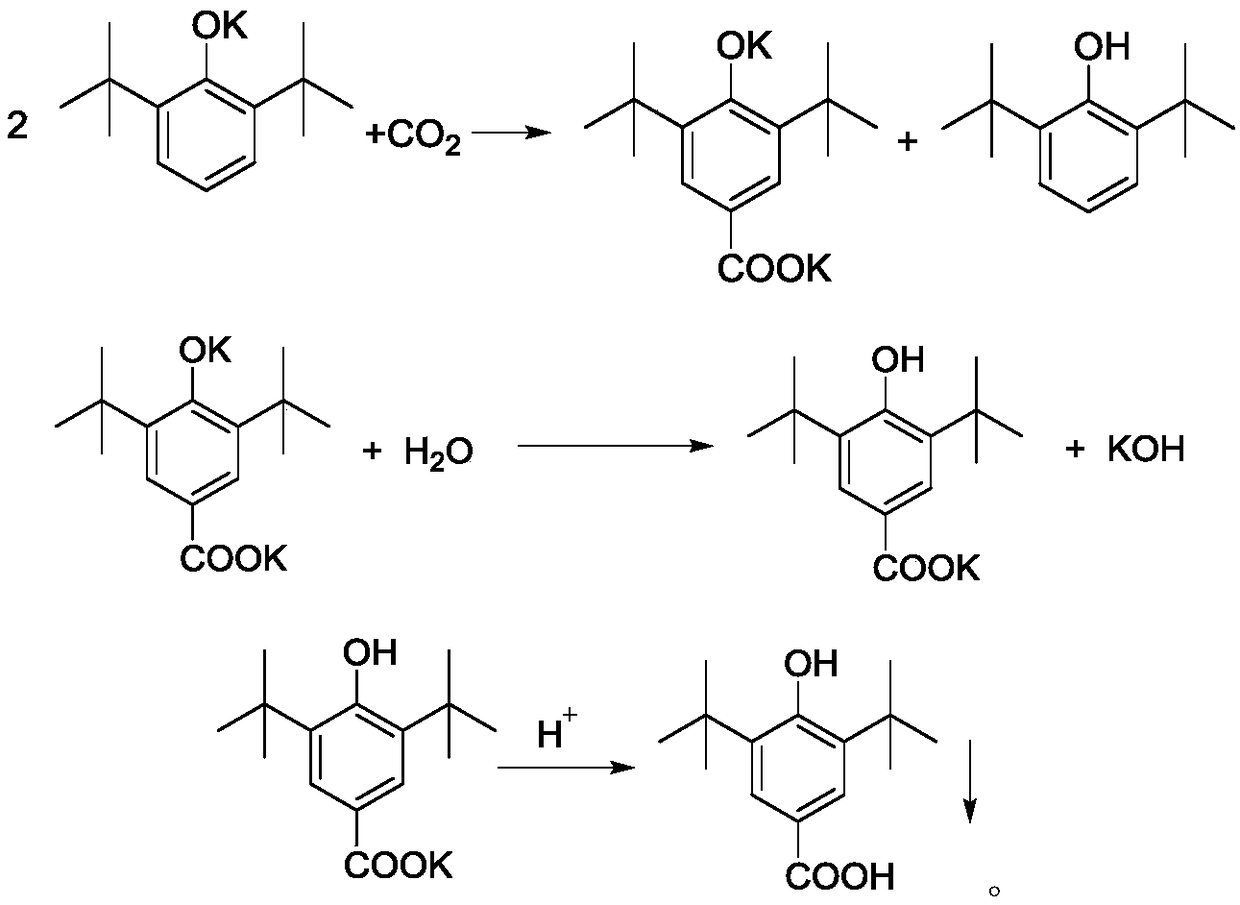

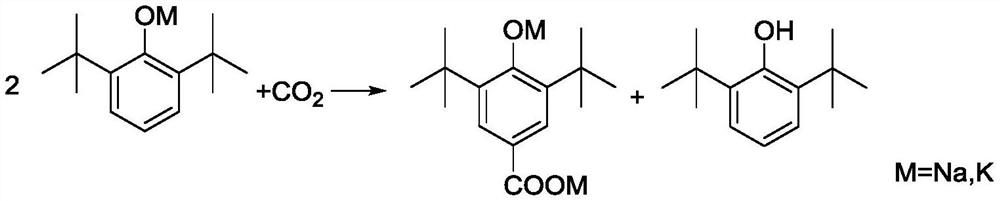

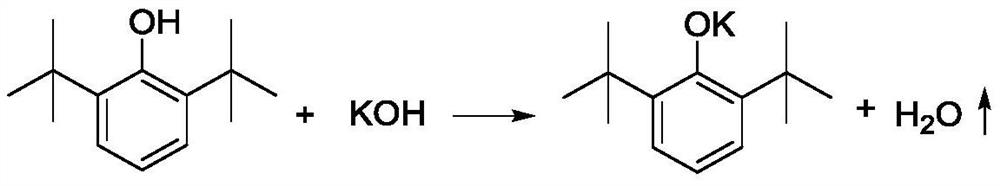

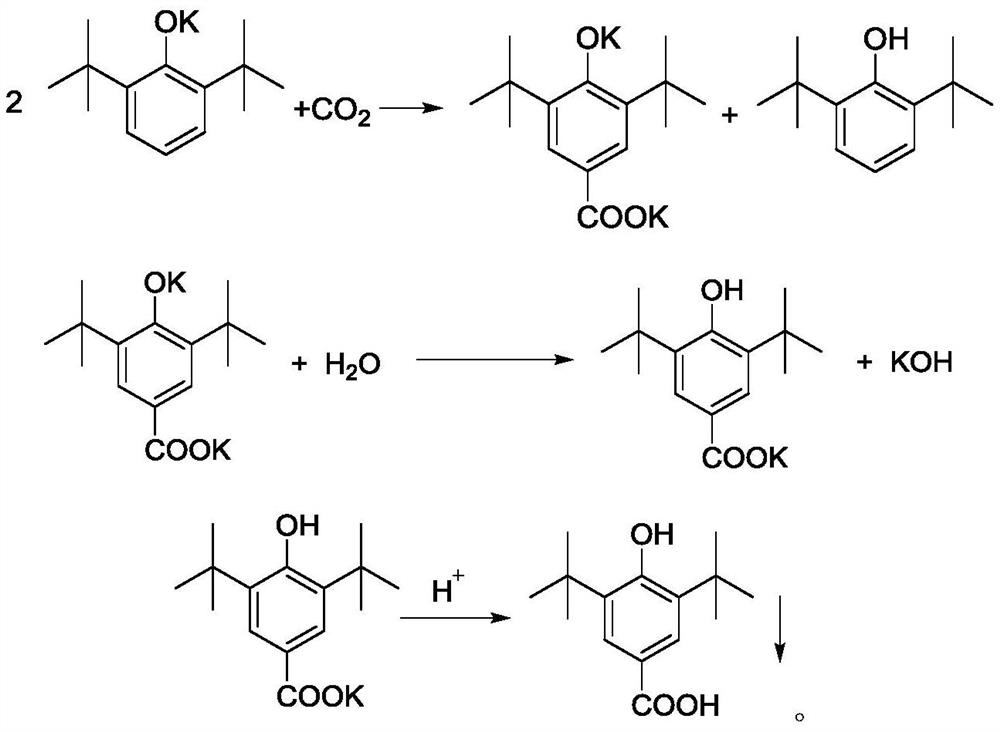

Production method of 3,5-di-tert-butyl-4-hydroxybenzoic acid

ActiveCN109096099APrevent spontaneous combustionAvoid problemsPreparation from carboxylic acid saltsOrganic compound preparationKolbe–Schmitt reactionSchmidt reaction

The invention discloses a production method of 3,5-di-tert-butyl-4-hydroxybenzoic acid. The production method sequentially comprises the steps as follows: 2,6-di-tert-butylphenol, a potassium hydroxide aqueous solution and toluene are added to a reactor under protection of nitrogen to be subjected to a reflux reaction under a water distribution condition; CO2 is introduced into the reactor until the pressure is 0.1-3.0 MPa, a Kolbe-Schmitt reaction is conducted under a pressure holding condition, after the reaction, corresponding aftertreatment is carried out, and a crude product of 3,5-di-tert-butyl-4-hydroxybenzoic acid is obtained. The method has short reaction time and high conversion rate, has obvious advantages as compared with traditional gas-solid processes and existing solvent-process synthesis processes and is suitable for further industrialization.

Owner:安徽新秀化学股份有限公司 +1

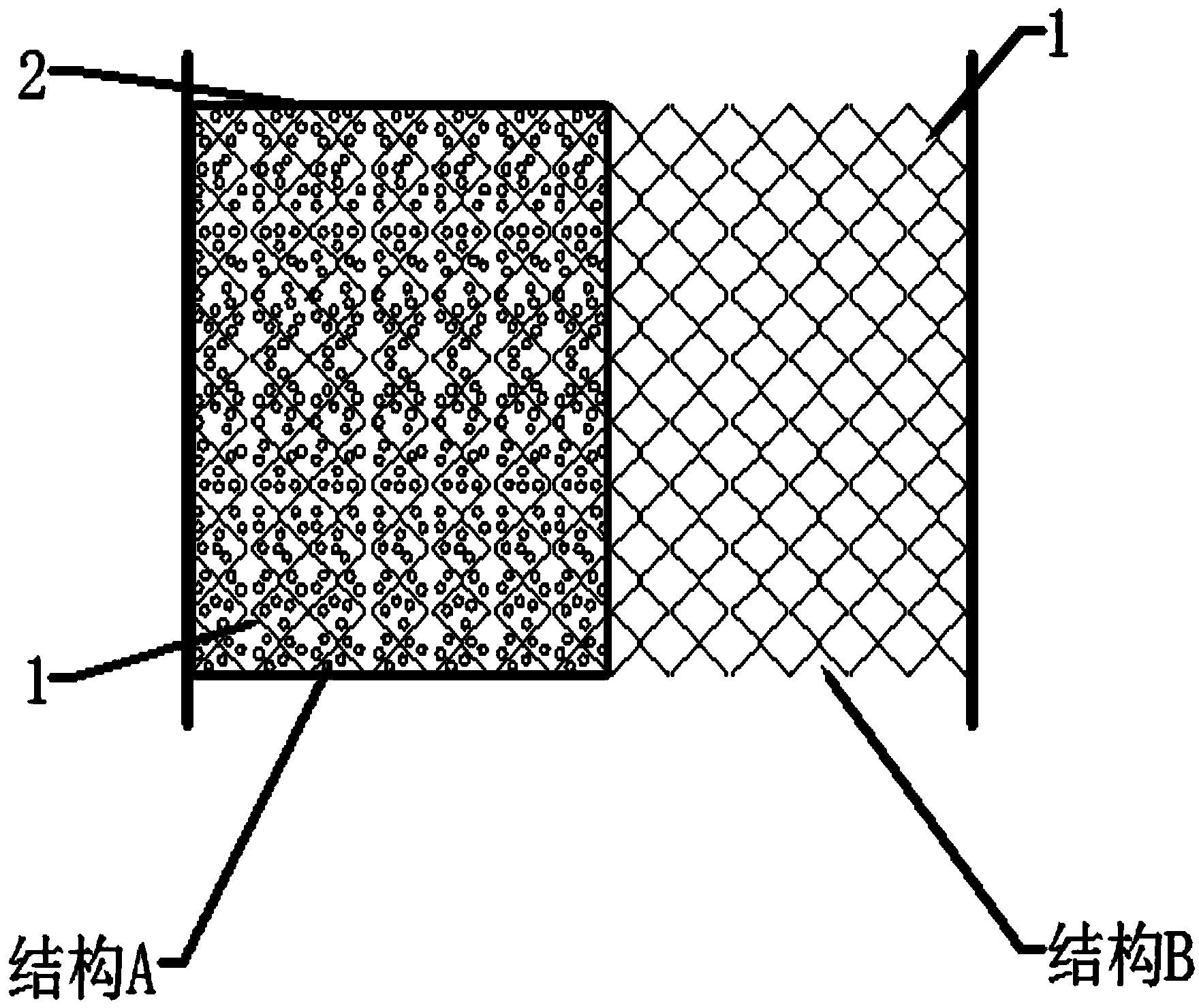

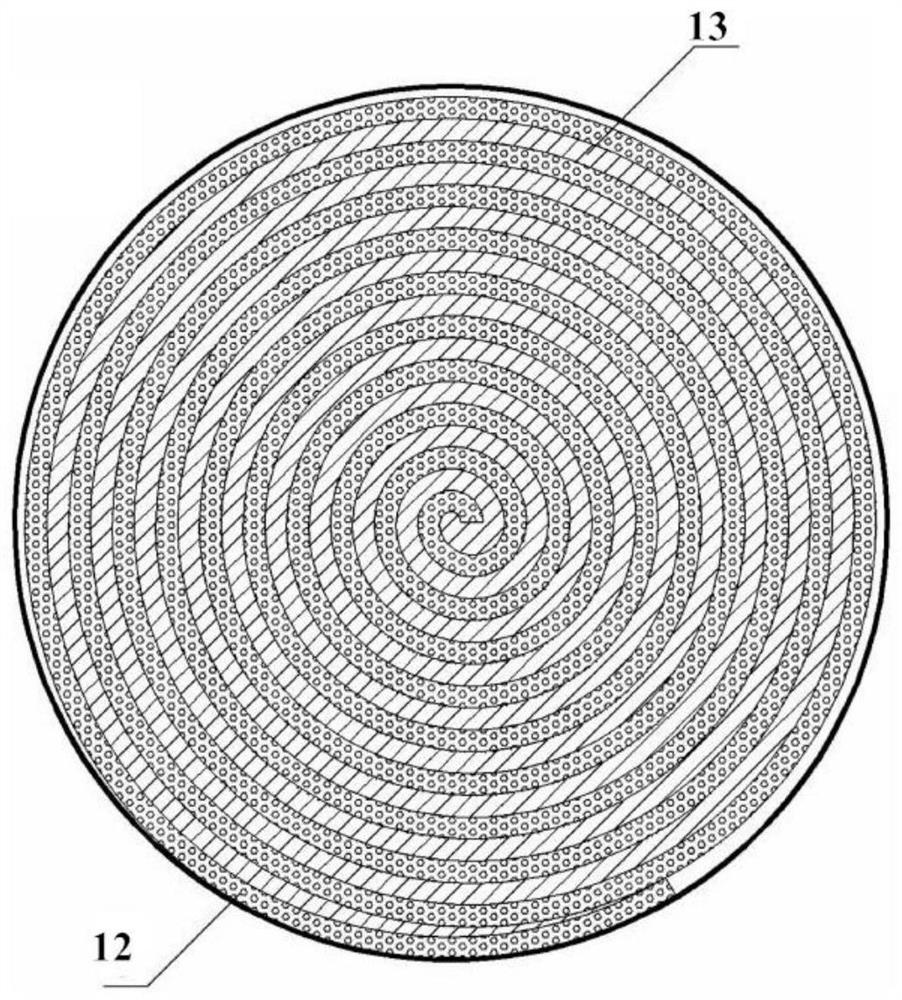

Catalytic rectification packing with radial distribution capacity

ActiveCN103752253AImprove Radial Distribution EffectImprove reaction efficiencyChemical/physical/physico-chemical processesFractional distillationVapor liquidEngineering

The invention relates to catalytic rectification packing with radial distribution capacity. The interior of a structure A consists of packing sheets; catalysts are filled in the packing, and the exterior is coated by a screen; a structure B refers to regular packing sheets and can be windowing guide packing, plate ripple packing, screen ripple packing, pore plate ripple packing, rolled pore plate ripple packing, cellular packing and other regular packing. The two structures are alternately and circumferentially distributed in a packing disc. The structure A and the structure B are circumferentially arranged in a staggered mode, so that the number of vapor-liquid multi-phase flow channels are increased, the mass transfer process of vapor-liquid multi-phase flow is facilitated, the phenomena of channeling and short circuit of vapor-liquid multi-phase flow are effectively avoided, small bed pressure drop is realized, a multi-phase flow radial diffusion effect is effectively enhanced, the reaction products are timely separated, and forward reaction is promoted, so that the amount of catalysts can be reduced.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD +1

Chlorination method for sucrose-6-ethyl ester

InactiveCN104774227AAvoid the disadvantagesFacilitate the positive reactionEsterified saccharide compoundsSugar derivativesSucroseDistillation

The invention relates to a chlorination method for sucrose-6-ethyl ester. The chlorination method comprises the following steps: (1) respectively preparing a chlorination reagent and a solution of sucrose-6-ethyl ester from a polar non-proton solvent; (2) chlorinating the sucrose-6-ethyl ester solution by a chlorination reagent solution; (3) refluxing under reduced pressure; and (4) evaporating the polar non-proton solvent by distilling, recycling, neutralizing the sucrose-6-ethyl ester solution in a distillation kettle, removing the solvent, adding water to dissolve, discoloring and crystallizing to obtain a sucrose-6-ethyl ester crude product, wherein the recycled a polar non-proton solvent is used for the chlorination reagent solution prepared in the step (1). According to the chlorination method, generated hydrogen chloride and sulfur dioxide are discharged by refluxing under reduced pressure to promote reaction to positively perform, and the final reaction temperature is reduced to 105 DEG C which is lower than the highest holding temperature in the existing chlorination technology by 10 DEG C, so that the defects generated by carbonization in the chlorination process are completely avoided; and the used polar non-proton solvent can be recycled for a next-batch chlorination reaction process, and therefore, the chlorination method is especially suitable for industrial production.

Owner:NANTONG CHANGHAI FOOD ADDITIVE

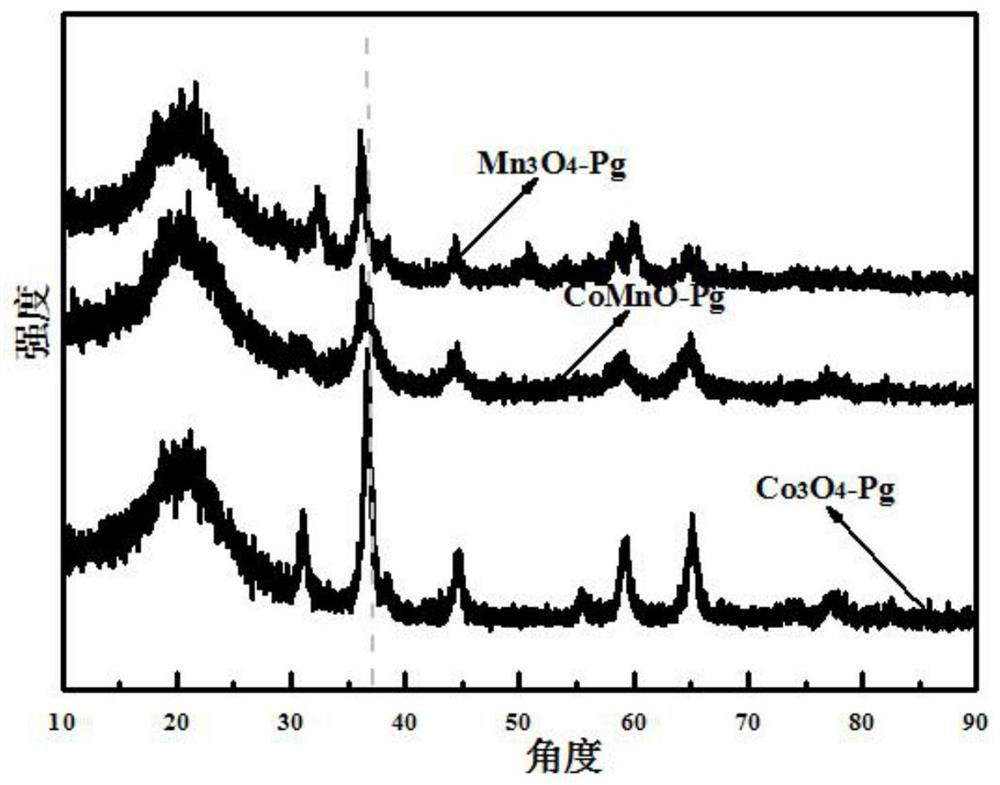

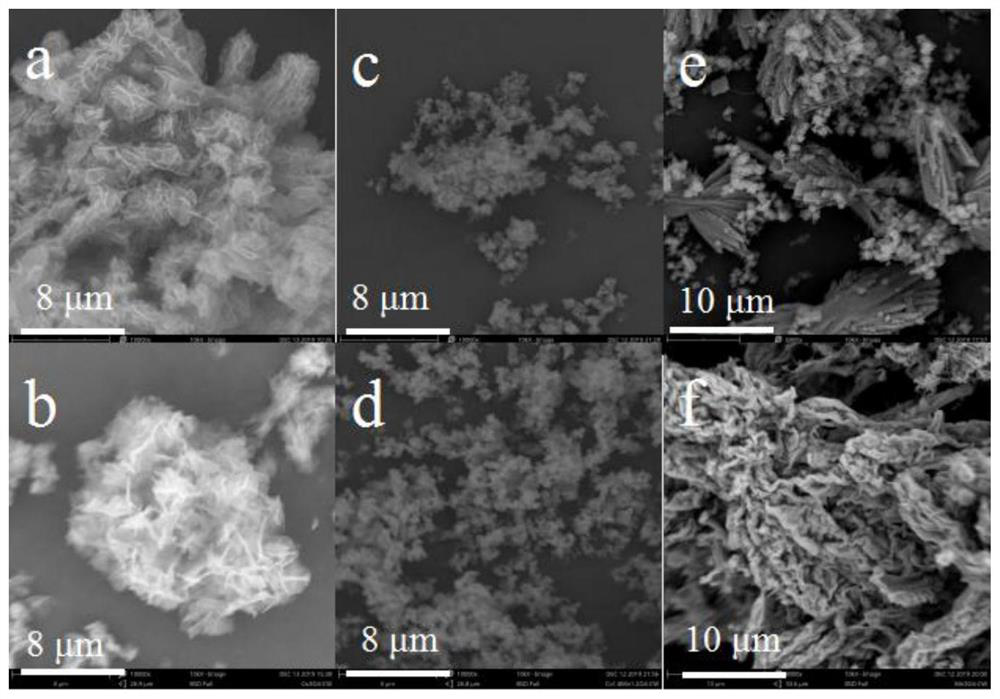

Bimetal cobalt oxide-based oxide as well as preparation method and application thereof

PendingCN111924891AImprove catalytic performanceHigh half-wave potentialCell electrodesManganese oxides/hydroxidesPtru catalystOxidation state

The invention discloses a bimetal cobalt oxide-based oxide as well as a preparation method and application thereof. The general formula of the bimetal cobalt oxide-based oxide is MaCobOn, a is 0-3, bis 0-3, a and b do not include 0, n is determined by the oxidation state of other elements, M is selected from one or more of iron, nickel, manganese, zinc or copper, and the surface of the bimetal cobalt oxide-based oxide has defects. The invention also discloses a preparation method and application of the catalyst. The structure of the precursor is controlled by regulating the optimal metal ionratio of the two transition metals and changing the mixed alcohol solvent in the solvothermal reaction, and finally the MaCobOn with different active site distributions can be obtained. As an oxygen reduction catalyst, the MaCobOn has the advantages of proper defects, high activity and stable performance, and meanwhile, the introduction of M metal greatly improves the electron transfer efficiencyand realizes an efficient oxygen reduction process. The preparation process of MaCobOn is simple, the process operability is high, and MaCobOn has good application prospects in the fields of metal-airbatteries, fuel cells, electrolytic cells, super capacitors and the like.

Owner:TIANJIN UNIV OF SCI & TECH

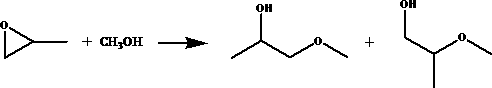

Efficient joint production method of propylene glycol monomethyl ether and propylene glycol monomethyl ether acetate

InactiveCN109796335AReduce energy consumptionLow toxicityPreparation by ester-hydroxy reactionEther preparation from oxiranesMonomethyl etherMethyl acetate

The invention discloses an efficient joint production method of propylene glycol monomethyl ether and propylene glycol monomethyl ether acetate. Propylene oxide, methanol and methyl acetate are takenas raw materials. The method comprises the steps of (1), the preparation of propylene glycol monomethyl ether raw esters: raw materials of the propylene oxide and the methanol are uniformly mixed andpass through a thermostatic reactor and a heat insulation reactor sequentially to generate the propylene glycol monomethyl ether raw esters under the catalytic condition of a medium and strong alkalisolid catalyst, flowing methyl acetate is adopted as a material for a thermal conductive oil pipe in a heat insulation reactor; (2), the preparation of propylene glycol monomethyl ether acetate: partof the propylene glycol monomethyl ether raw esters prepared in the step 1 and the methyl acetate which is preheated in the thermal conductive oil pipe are transferred to an esterification tower to bemixed, and the propylene glycol monomethyl ether acetate is generated by the interesterification reaction of the propylene glycol monomethyl ether raw esters and the methyl acetate which is preheatedin the thermal conductive oil pipe with the presence of acid positive ion resin. The method has the advantages of simple technology, high conversion efficiency and low energy consumption cost.

Owner:谦信化工集团有限公司

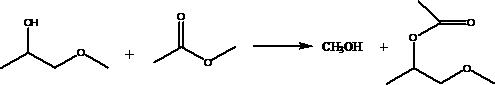

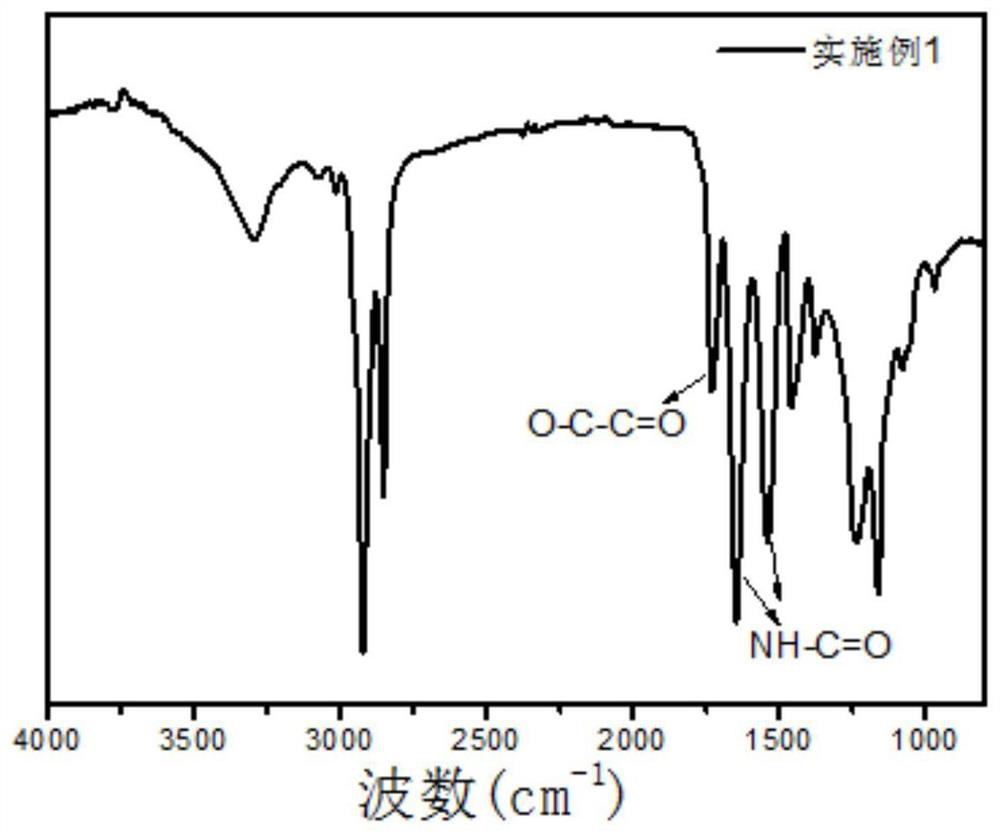

Application of polyester amide as high-temperature-resistant heat-shrinkable film

The invention discloses application of polyester amide as a heat shrinkage film, and relates to the technical field of high polymer materials. Polymer amide is subjected to tabletting and single-axis stretching. The preparation method of polyester amide comprises the following steps: (1) heating and dissolving 30-200 parts by weight of liquid dicarboxylic acid and 15-95 parts by weight of a diamine compound containing beta hydroxyl, and uniformly stirring to form a reaction solution; (2) adding 0.05-0.5 part by weight of a catalyst, heating to 65-100 DEG C in a nitrogen atmosphere, and reacting for 1-6 hours; (3) heating the reaction solution to 100-180 DEG C, and reacting for 3-18 hours; (4) heating the reaction system to 180-240 DEG C, and reacting for 0.5-4 hours; and (5) cooling the reaction system of the reaction solution to 100-180 DEG C to obtain the polyester amide. The polyester amide heat shrinkage film has the advantages that the polyester amide heat shrinkage film not only can replace a PET heat shrinkage film, but also does not melt even at the high temperature of 300 DEG C.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Method for synthesizing resorcinol by m-hydroxybenzoic acid

InactiveCN107881201AReduce usageReduce acid and alkali pollutionFermentationChemical reactionOrganic solvent

The invention relates to a method for synthesizing resorcinol by m-hydroxybenzoic acid. A one-step synthesis reaction is used, raw materials of m-hydroxybenzoic acid and a solvent are added in a high-pressure reaction vessel for being dissolved according to a mol ratio being 1-8:10-30, a catalyst is added for catalysis, the catalyst is a mixture of ethyl pyruvate and inulase, and m-hydroxybenzoicacid is obtained through steps of extraction and distillation. The reaction reduces soda acid pollution during a traditional technical production process and reduces the usage of a lot of organic solvents, which belongs to the environment friendly chemical reaction; waste water generated by post-treatment is less, and environment pollution is reduced.

Owner:JIAOCHENG XINYUANTAI BIOLOGICAL TECH CO LTD

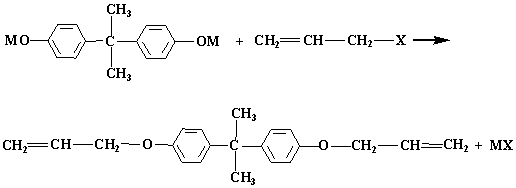

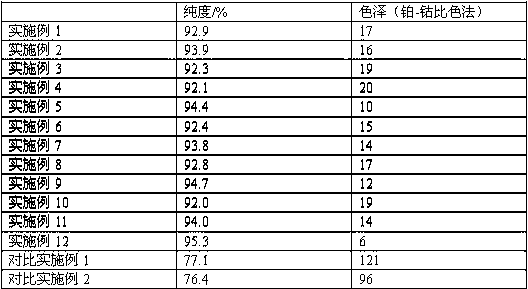

Preparation method of bisphenol A diallyl ether

ActiveCN108530274APromote generationEffective control of water contentOrganic compound preparationEther preparation by ester reactionsSimple Organic CompoundsEther

The invention belongs to the technical field of synthesis of organic compounds, and specifically relates to a preparation method of bisphenol A diallyl ether. The preparation method of bisphenol A diallyl ether comprises the following steps: (1) adding bisphenol A and a solvent into a reaction kettle, stirring for dissolving, and adding alkali and a water absorbent; (2) dropwise adding allyl halide at a certain temperature, and reacting for a certain time, thus obtaining a crude product; (3) filtering and desalting the crude product, carrying out vacuum distillation, and removing a low-boilingpoint substance, thus obtaining a finished product. The preparation method of bisphenol A diallyl ether, disclosed by the invention, is capable of effectively controlling the water content in a reaction system, reaction is facilitated to proceed forwards, steps for waste treatment in production are greatly reduced, the production cost is reduced, and the preparation method is suitable for large-scale production.

Owner:ZHEJIANG HUANGMA TECH +3

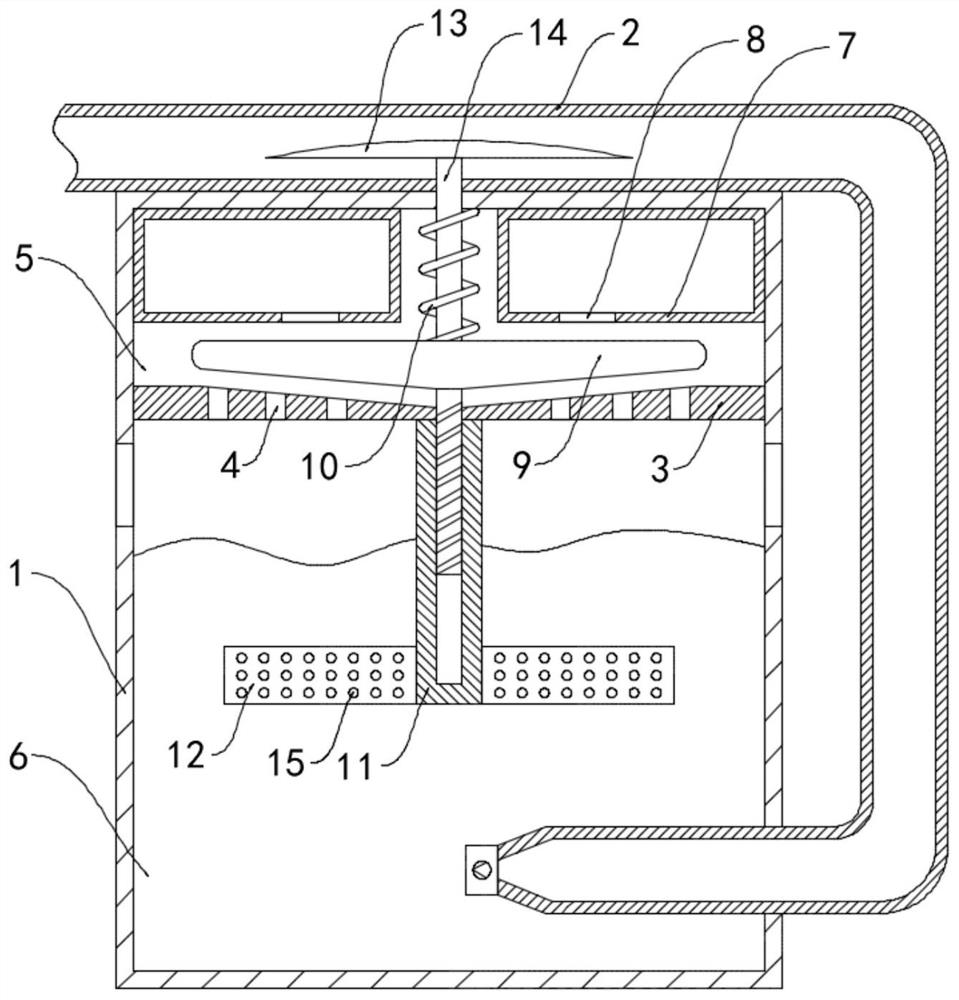

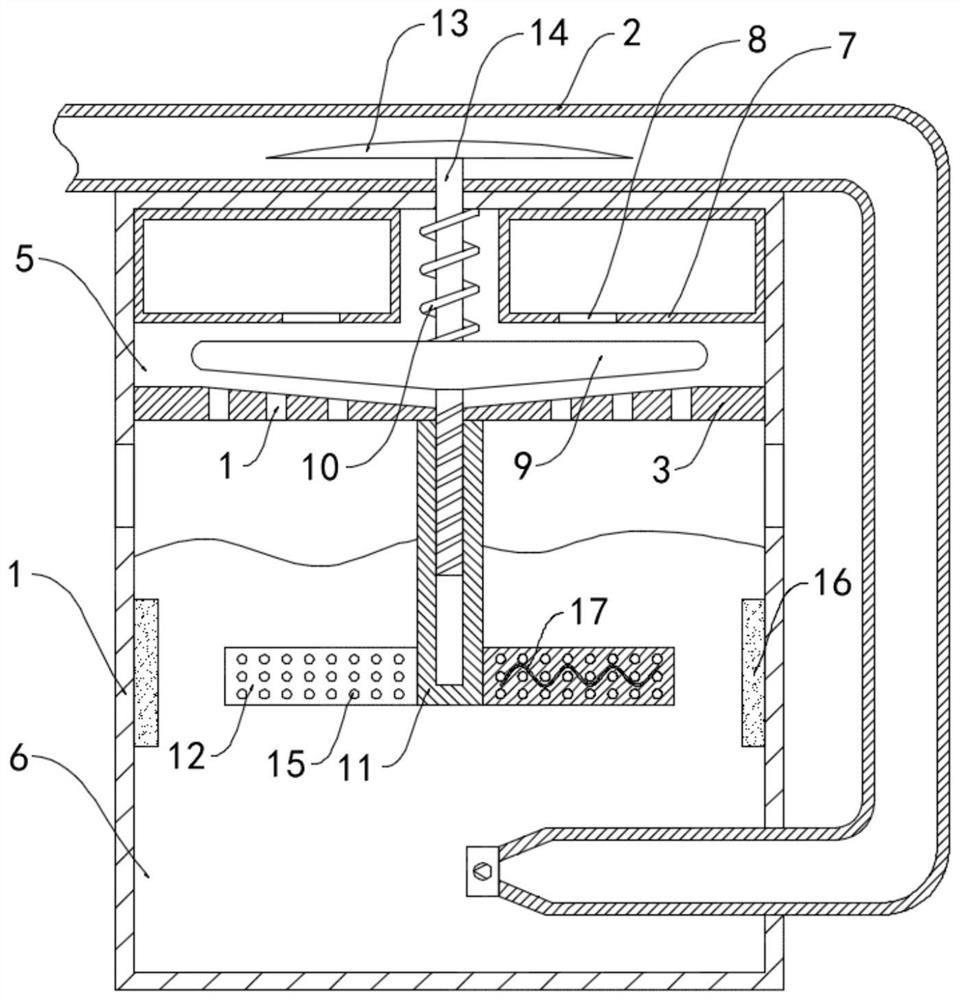

Tail gas treatment device for underground engineering construction machinery

PendingCN112807953AImprove purification effectAvoiding Difficult Wiring ProblemsExhaust apparatusTransportation and packagingEngineeringPipe

The invention belongs to the field of underground engineering construction, and particularly relates to a tail gas treatment device for underground engineering construction machinery, which comprises a shell and a gas inlet pipe fixedly communicated with the shell; the gas inlet pipe is communicated with the tail end of a tail gas discharge pipe of the underground engineering construction machinery; a horizontally-arranged sieve plate is fixedly connected to the inner side wall of the shell, a plurality of sieve holes are formed in the sieve plate at equal intervals, the interior of the shell is divided into a material storage cavity and a purification cavity through the sieve plate, an annular material storage box is fixedly connected to the top face of the material storage cavity, and purifying agent particles are contained in the annular material storage box. According to the tail gas purification device, an alkaline solution can absorb acid gas in tail gas to generate an acid-base neutralization reaction, and a good tail gas purification effect is achieved; by arranging the wing plates, a purifying agent can be continuously added into the purification cavity; meanwhile, the alkaline solution is stirred and disturbed, the contact area and probability of harmful tail gas and the alkaline solution are increased, and the purification effect of the tail gas purification device is further improved.

Owner:查昀

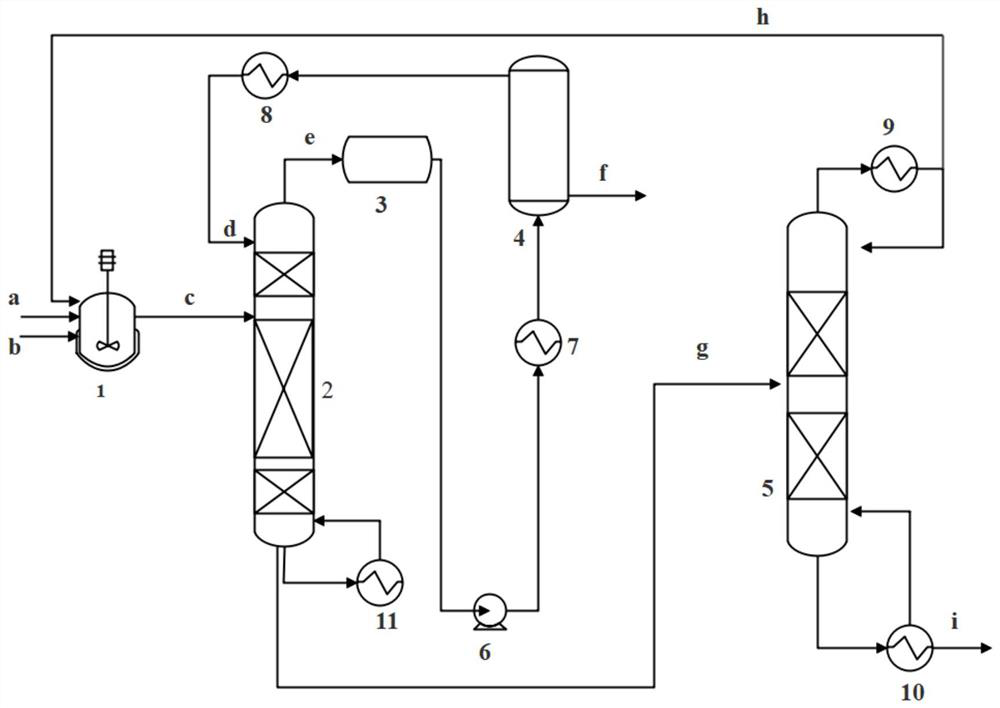

Device and process for producing propylene glycol monomethyl ether acetate by reactive distillation coupled pervaporation

ActiveCN112194580ALarge mass transfer areaIncrease mass transfer rateOrganic compound preparationChemical industryMonomethyl etherReactive distillation

The invention discloses a device for producing propylene glycol monomethyl ether acetate by coupling reactive distillation with pervaporation. The device comprises a pre-reactor, a catalytic reactivedistillation tower, a pervaporation feeding buffer tank, a pervaporation membrane assembly and a product refining tower. The invention also discloses a process for producing propylene glycol monomethyl ether acetate by reactive distillation coupled pervaporation. The method disclosed by the invention is simple, good in effect, strong in operability and remarkable in energy-saving effect, and the propylene glycol monomethyl ether acetate can be applied to large-scale industrial production.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD

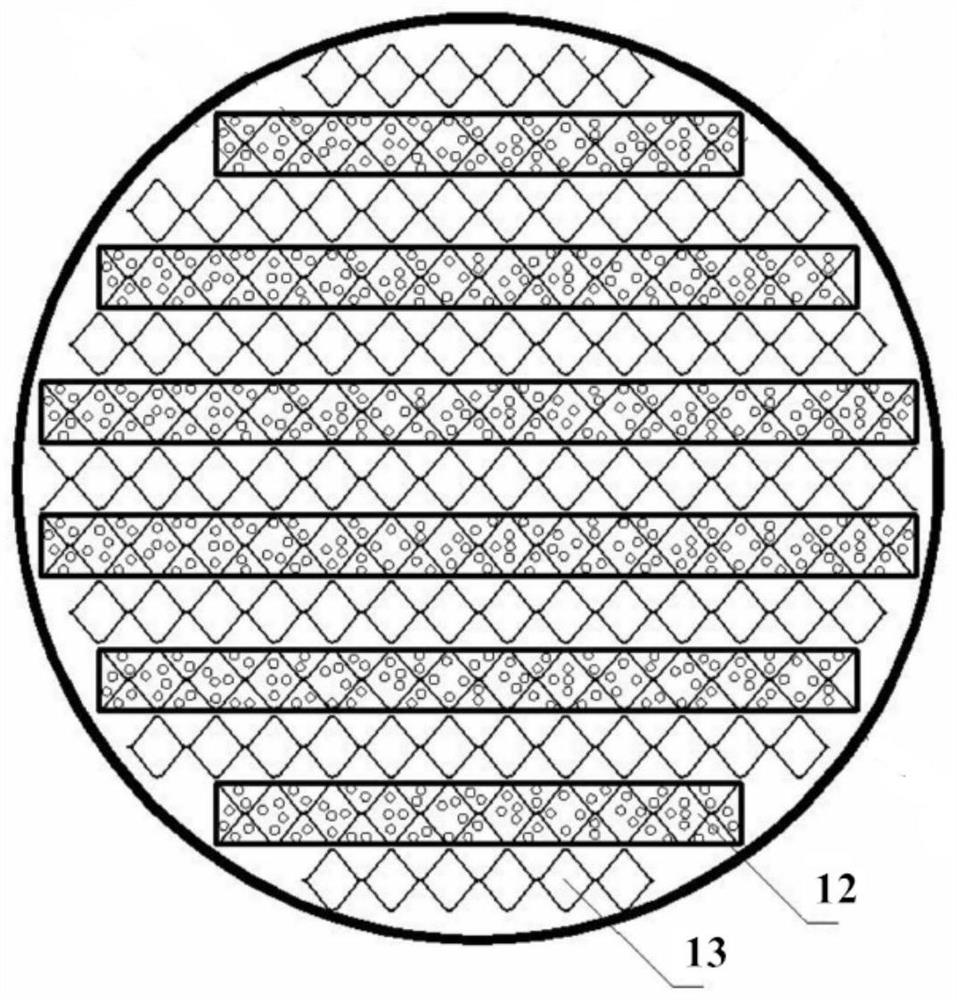

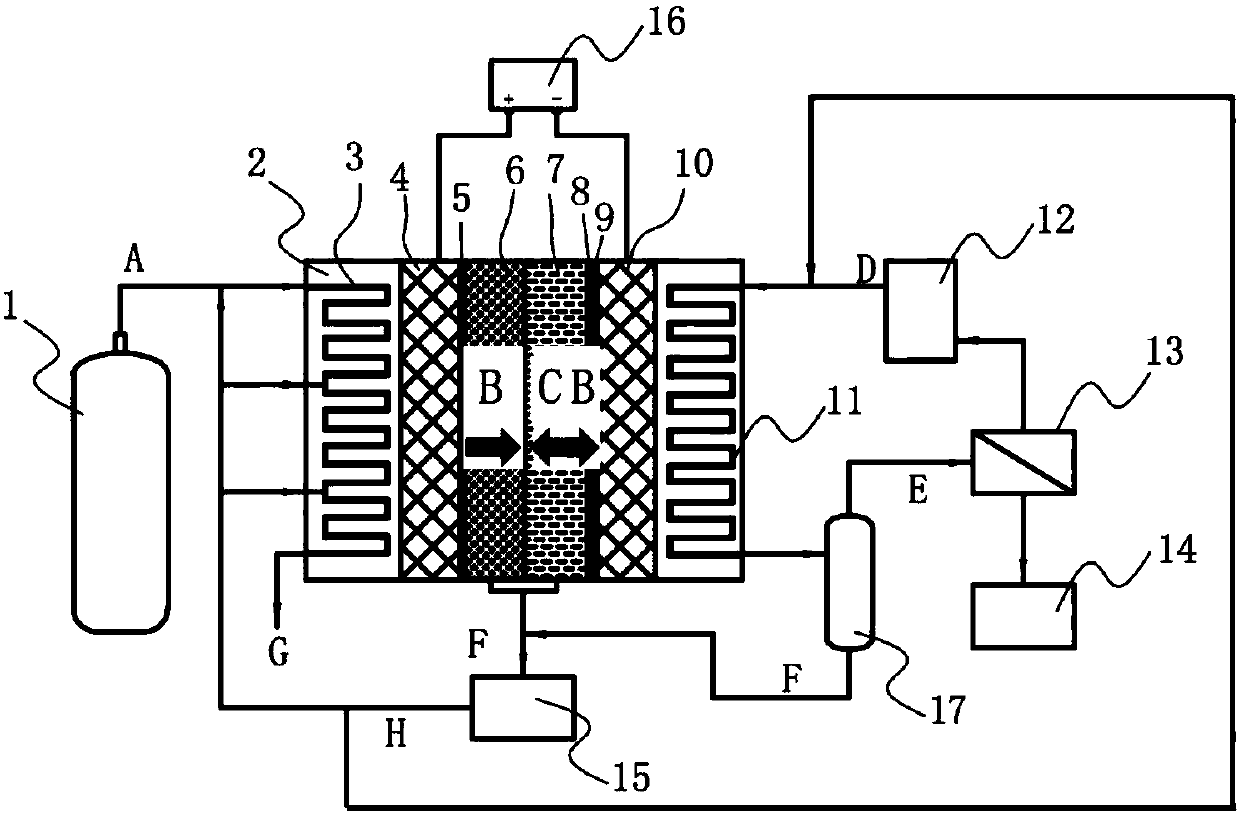

An electrochemical hydrogenation device and method

PendingCN107913653ASettlement yieldResolve inhibitionProcess control/regulationEnergy based chemical/physical/physico-chemical processesElectric energyElectrochemistry

The invention relates to an electrochemical hydrogenation device and method and belongs to the technical field of chemical engineering. The device includes a planar laminated assembly. The planar laminated assembly is formed by laminating a hydrogen dissociation catalytic layer, a cation electrolyte membrane layer, an anion electrolyte membrane layer, a water dissociation catalytic layer and a hydrogenation catalytic layer which are planar layers in order. When the device is utilized to perform hydrogenation, the reaction process is stable and controllable, the reaction yield is high, a reactor is self-humidifying, and water management is easy to perform. The device and the method allow a hydrogenation process to be efficient, rapid and stable, do not need high temperature or high pressure, only consume a small amount of electricity, and can perform a catalytic hydrogenation reaction on organic matters at room temperature under atmospheric pressure. A reaction process is economical andenvironmentally friendly.

Owner:DALIAN UNIV OF TECH PANJIN INST OF IND TECH

Synthesizing method of O,O-dimethyl phosphorodithioate

ActiveCN108864181AIncrease contentHigh yieldGroup 5/15 element organic compoundsChemical synthesisMethanol

The invention belongs to the technical field of chemical synthesis, and particularly relates to a synthesizing method of O,O-dimethyl phosphorodithioate. The synthesizing method of the O,O-dimethyl phosphorodithioate has the advantages that on the basis of existing technical method, a proper catalyst is further screened, added into a methanol solution and dripped into a sulfide mother liquid, so that the content and yield of the target product are further increased; the whole methanol dripping process is performed under the micro-negative pressure condition, so that the step of dripping the methanol to react can be performed at lower temperature of 25 to 35 DEG C, and the reaction product of hydrogen sulfide can escape out at micro-negative pressure of 30 to 50mmHg, so as to effectively accelerate the reaction to perform along the positive direction.

Owner:德州绿霸精细化工有限公司

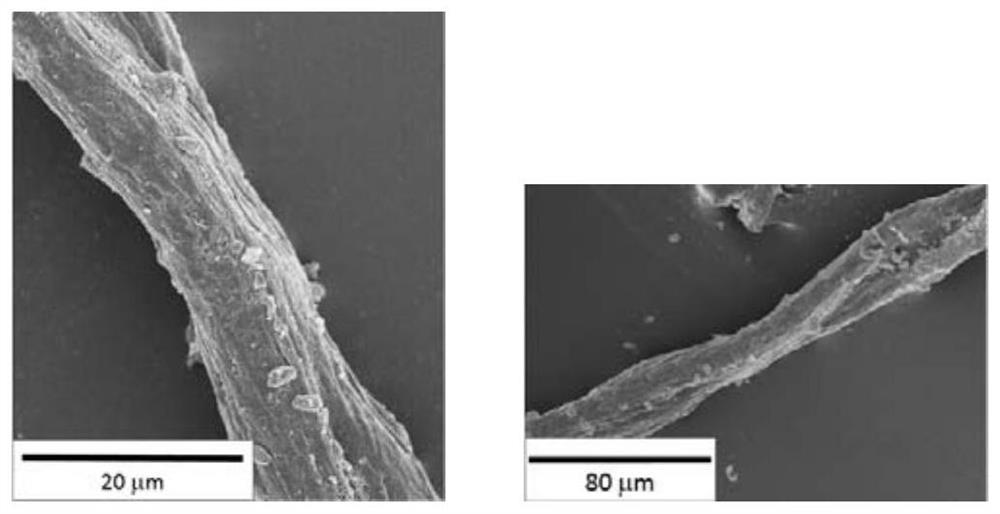

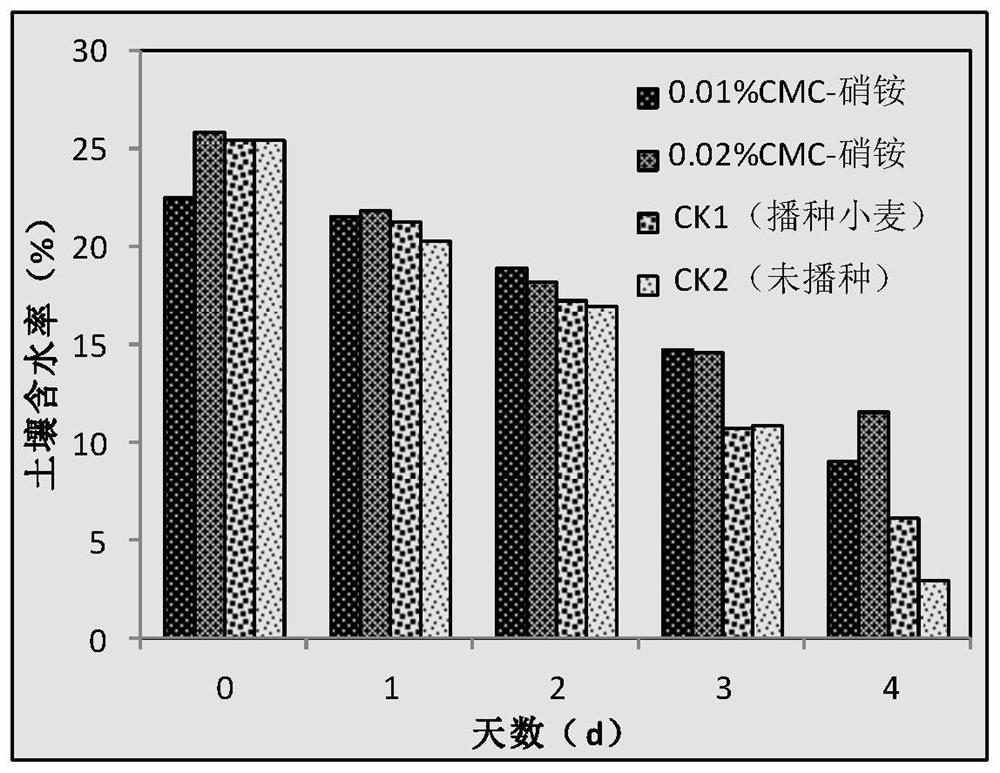

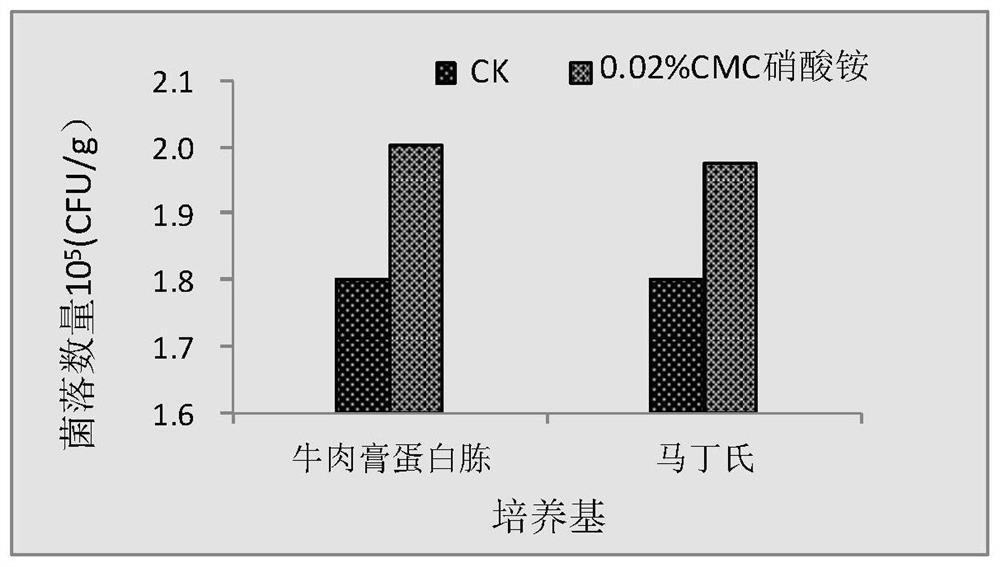

A kind of cellulose derivative and its preparation method and application

ActiveCN110467682BTo achieve the purpose of nitrogen supplyImprove water retentionBiocidePlant growth regulatorsCarboxymethyl celluloseGrowth plant

The invention discloses a cellulose derivative. A preparation method for the cellulose derivative comprises the following steps: subjecting cellulose to alkalization and etherification to obtain a carboxymethyl cellulose intermediate; subjecting the carboxymethyl cellulose intermediate to nitration in a nitrification system, and then carrying out washing, drying, stoving and crushing successivelyto obtain carboxymethyl cellulose carboxylate; and subjecting the carboxymethyl cellulose carboxylate to amination in an ammonium system, and then carrying out neutralization, precipitation and dryingsuccessively to obtain the target cellulose derivative. The cellulose derivative of the invention contains three groups, i.e., a nitrate group, a carboxymethyl group and an ammonium ion, has slow release and water retention performance, can increase soil strength, is applicable to arid regions, and provides favorable conditions for plant growth.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +2

Synthesis method of ethyl tetrazole-5-carboxylate

The invention relates to a method for synthesizing ethyl tetrazole-5-carboxylate, which belongs to the field of organic synthesis and comprises the following steps of: (1) heating and refluxing by taking ethyl cyanoformate and sodium azide as raw materials and a mixed solution of methylbenzene and water as a solvent to generate ethyl tetrazole-5-carboxylate sodium salt; (2) heating and distillingthe reflux liquid obtained in the step (1) to remove methylbenzene; (3) neutralizing the distillate obtained in the step (2) with an acidic solution, and conducting separating to obtain a crude product of ethyl tetrazole-5-carboxylate; and (4) recrystallizing the crude product of ethyl tetrazole-5-carboxylate through a mixed solvent of low-carbon hydrocarbon and water, and conducting separating toobtain ethyl tetrazole-5-carboxylate. The synthesis method disclosed by the invention is simple to operate and high in yield, and the purity of the prepared ethyl tetrazole-5-carboxylate is high.

Owner:河北凯诺中星科技有限公司 +1

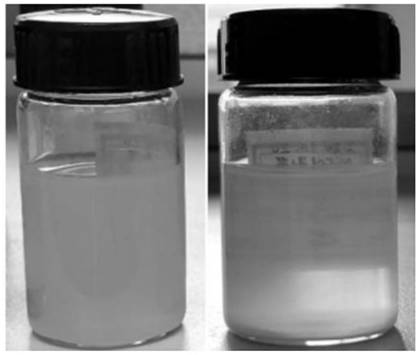

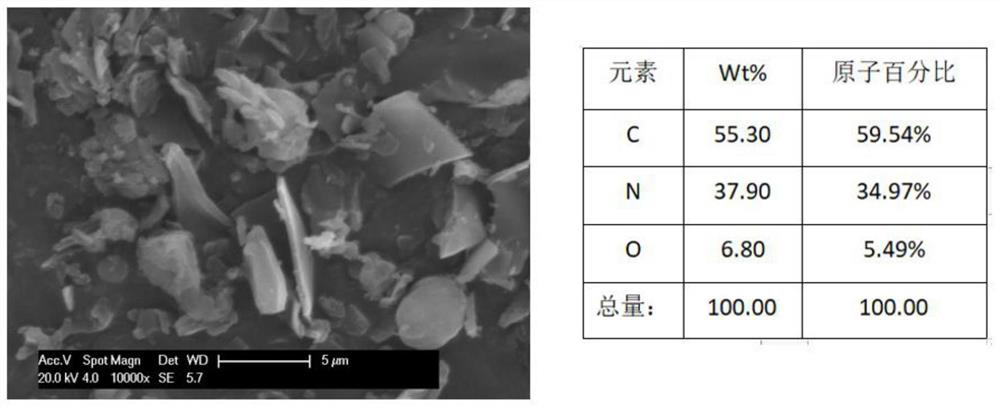

Organic modification method for improving dispersity of graphite phase carbon nitride in lubricating oil

The invention relates to the technical field of lubricating oil preparation, in particular, relates to an organic modification method for improving dispersity of graphite phase carbon nitride in lubricating oil, and solves the problem of low compatibility of modified graphite phase carbon nitride and lubricating oil in the prior art. The organic modification method for improving the dispersity of the graphite phase carbon nitride in the lubricating oil comprises the steps: firstly, mixing a certain amount of long carbon chain organic carboxylic acid, triethylamine, 1-ethyl-(3-dimethylaminopropyl)carbodiimide hydrochloride (EDC.HCL) and 1-hydroxybenzotriazole (HOBT), and adding the mixture into a certain amount of organic solvent. According to the preparation method, an organic long carbon chain is introduced into the surface of graphite phase carbon nitride by utilizing amidation reaction, so that the problem that the graphite phase carbon nitride is difficult to be compatible with an organic matrix is solved, and the compatibility of the graphite phase carbon nitride with oils and lipids is greatly improved. The organically modified graphite phase carbon nitride can be stably dispersed in base oil for a long time, and can be used as a lubricating additive to be applied to the field of lubrication.

Owner:无锡烯创科技有限公司

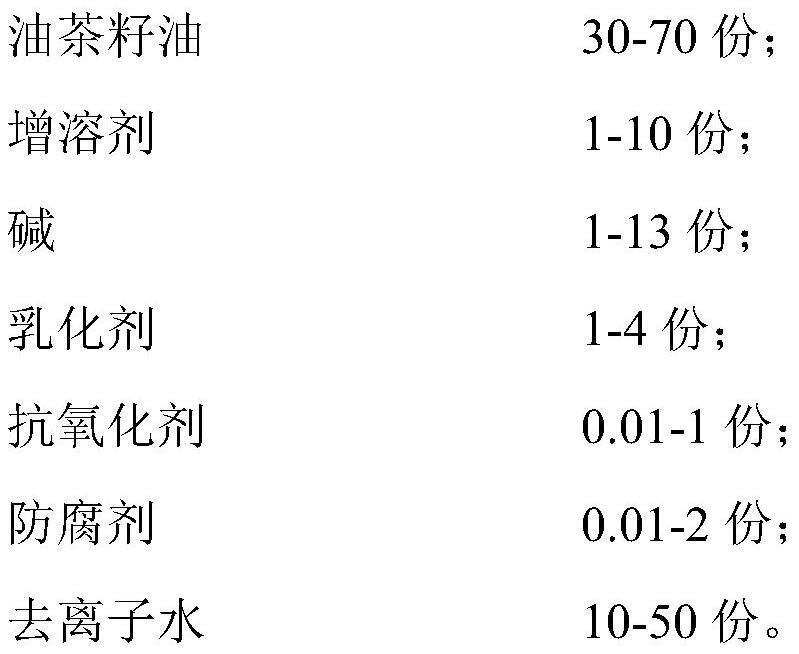

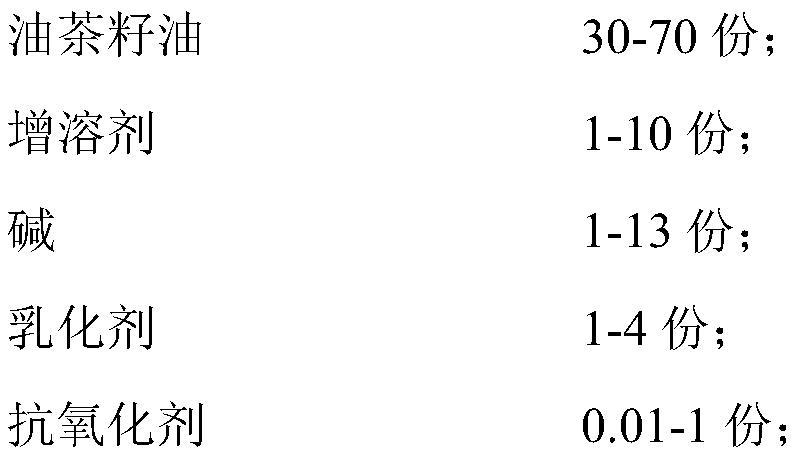

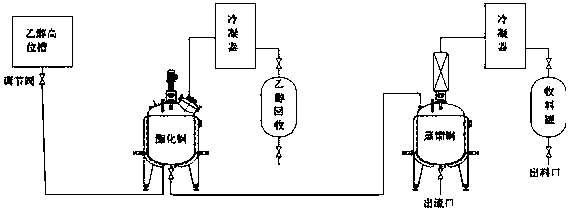

Camellia oleosa seed oil soap base material and preparation method thereof

PendingCN112226304ASimple preparation processShort reaction timeSoap detergents with organic compounding agentsSkin careHuman skinPreservative

The invention provides a camellia oleosa seed oil soap base material and a preparation method thereof. The soap base material comprises the following components in parts by weight: 30-70 parts of camellia oleosa seed oil, 1-10 parts of a solubilizer, 1-13 parts of alkali, 1-4 parts of an emulsifier, 0.01-1 part of an antioxidant, 0.01-2 parts of a preservative and 10-50 parts of deionized water. The preparation method comprises the following steps of: (1) adding alkali into deionized water to prepare alkali liquor; (2) adding a solubilizer into the camellia oleosa seed oil, uniformly stirring,adding the alkali liquor prepared in the step (1), heating to 30-60 DEG C, and quickly stirring and saponifying for 30-90 minutes while keeping the temperature; (3) adding an antioxidant into the saponification liquid obtained in the step (2), and stirring for 5-10 minutes while keeping the temperature; and (4) adding an emulsifier and a preservative, continuing to stir for 5-15 minutes to obtaina soap base material, then stopping heating and stirring, and cooling. The camellia oleosa seed oil soap base material can react in a low temperature range within a short time, active ingredients incamellia oleosa seed oil are effectively reserved, the pH value of the soap base material is close to that of human skin, and the soap base material can be conveniently added into other systems to prepare different types of washing products.

Owner:江西联锴科技有限公司

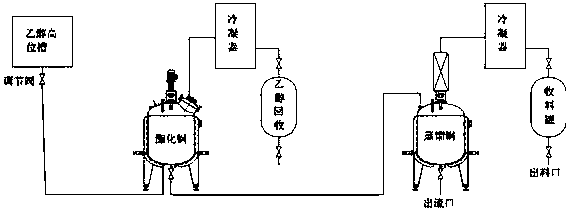

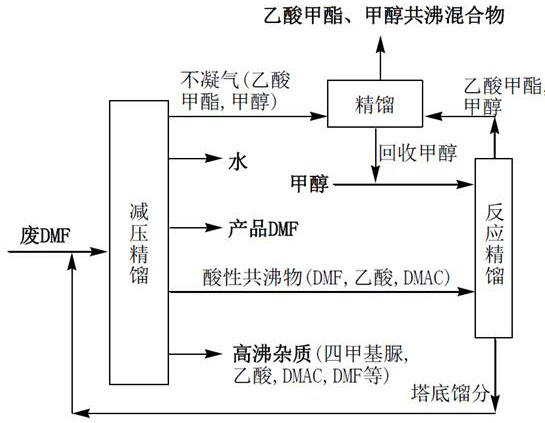

A kind of synthetic method of ethyl salicylate

ActiveCN110283072BHigh yieldFully contactedOrganic compound preparationCarboxylic acid esters preparationEthyl salicylateHigh concentration

The invention belongs to the field of chemical engineering, and particularly discloses a synthetic method of ethyl salicylate with high purity and conforming to drug use. The method comprises the steps of using sulfuric acid for catalytic synthesis of the ethyl salicylate, washing a product and purifying the product; a mixture of ethanol and water is collected while ethanol with high concentration is added to a reaction system in the synthesis process, forward esterification reaction can be effectively promoted, and the improvement of the reaction yield is facilitated; the obtained ethyl salicylate product is high in purity, no unknown impurities are introduced, the requirements of the drug use are met, the quality is guaranteed from raw materials, and the unknown risk of the product during clinical use is reduced.

Owner:GUANGZHOU XINGQUN PHARMA

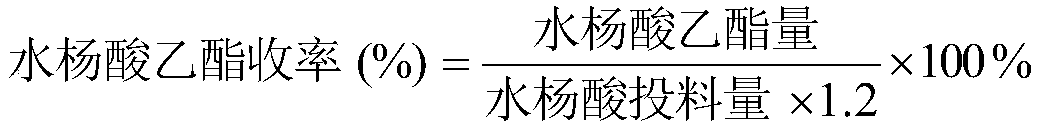

Preparation method of 3-methyl-1, 5-pentanediol

ActiveCN113880689ANovel synthetic routeHigh yieldOrganic compound preparationPreparation by hydrogenationPyridiniumPtru catalyst

The invention provides a preparation method of 3-methyl-1, 5-pentanediol, which comprises the following steps of: (1) carrying out a condensation reaction on isobutene and formaldehyde as raw materials under the action of an acid catalyst and an auxiliary agent to generate 3-methylene pentane-1, 5-diol and 3-methyl pentyl-2-ene-1, 5-pentanediol; and (2) carrying out a hydrogenation reaction by taking the 3-methylene pentane-1, 5-diol and the 3-methyl pentyl-2-ene-1, 5-pentanediol as raw materials to obtain 3-methyl-1, 5-pentanediol. A sulfoacid pyridinium salt is used as a catalyst and phosphate is used as an auxiliary agent in the condensation reaction of isobutene and formaldehyde, so that the product yield can be obviously improved. The method has the advantages of short process steps, high yield and low cost, and is suitable for industrial amplification.

Owner:WANHUA CHEM GRP CO LTD

A catalytic rectification packing with radial distribution capability

ActiveCN103752253BIncrease the flow channelEnhanced mass transferChemical/physical/physico-chemical processesFractional distillationVapor liquidCatalytic distillation

The invention relates to catalytic rectification packing with radial distribution capacity. The interior of a structure A consists of packing sheets; catalysts are filled in the packing, and the exterior is coated by a screen; a structure B refers to regular packing sheets and can be windowing guide packing, plate ripple packing, screen ripple packing, pore plate ripple packing, rolled pore plate ripple packing, cellular packing and other regular packing. The two structures are alternately and circumferentially distributed in a packing disc. The structure A and the structure B are circumferentially arranged in a staggered mode, so that the number of vapor-liquid multi-phase flow channels are increased, the mass transfer process of vapor-liquid multi-phase flow is facilitated, the phenomena of channeling and short circuit of vapor-liquid multi-phase flow are effectively avoided, small bed pressure drop is realized, a multi-phase flow radial diffusion effect is effectively enhanced, the reaction products are timely separated, and forward reaction is promoted, so that the amount of catalysts can be reduced.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD +1

Synthesis method of cyanoacetamide

ActiveCN113292452AEnhance heat and mass transferLower activation energyOrganic compound preparationPreparation by carboxylic acid amide dehydrationOrganic synthesisPhosgene

The invention relates to a synthesis method of cyanoacetamide, and belongs to the technical field of organic synthesis. According to the method, a tubular reactor is used as reaction equipment, malonamide is used as a raw material, and cyanoacetamide is generated under the action of triphosgene. The triphosgene with relatively high reaction activity is used, so that the activation energy of the reaction can be reduced, and the forward proceeding of the reaction is promoted; a pipeline reactor is used as reaction equipment, so that the mass and heat transfer effect of a reaction system can be improved, the reaction time and the retention time of a product in the reaction system are further shortened, and the product purity and yield are effectively improved. The atom utilization rate is high, the by-product ammonium chloride can be sold as a product or used for other reactions, and the recovered solvent and the treated rectification base solution can be used for reactions; and only a small amount of activated carbon waste residues are generated, so that the environment-friendly benefit is high.

Owner:山东京博生物科技有限公司

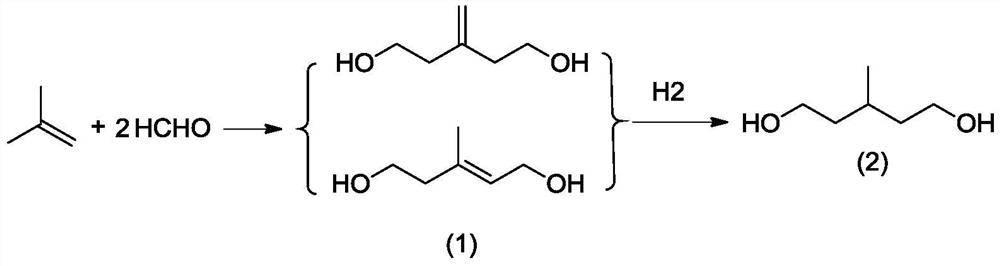

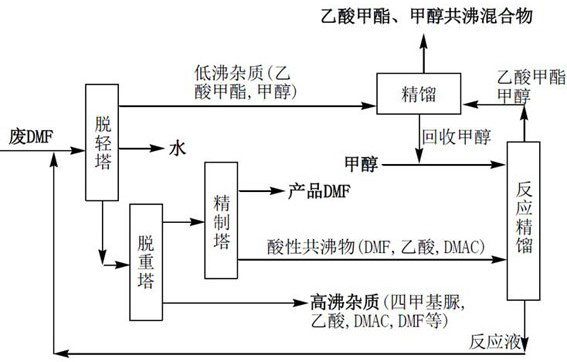

Method for treating waste DMF in sucralose production

ActiveCN113636951AEasy to remove and recycleAvoid concentrationOrganic compound preparationChemical industrySucrosePtru catalyst

The invention relates to a method for treating waste DMF in sucralose production, and the method is characterized by comprising the following steps: (1) feeding waste DMF discharged from the bottom of a deacidification tower into a vacuum rectification tower for vacuum rectification, feeding non-condensable gas extracted from the top of the rectification tower into a methanol rectification tower for rectification again, and feeding methanol recovered by rectification into a reaction rectification tower for reaction; (2) feeding an acidic azeotrope extracted from the lower part of the reduced-pressure rectifying tower into a reactive rectifying tower; controlling the volume ratio of the acidic azeotrope to methanol to be 1: (0.9-1.5), returning reaction liquid at the bottom of the reactive distillation tower to the vacuum distillation tower, and returning a mixture of methanol and methyl acetate distilled from the top of the reactive distillation tower to the methanol distillation tower. The method has the advantages that the generated methyl acetate is removed through reactive distillation, the reaction is promoted to proceed forwards, and the yield is increased; acetic acid contained in the raw materials is used as a catalyst, so that the problem of inactivation does not need to be worried about, and excessive decomposition of DMF is avoided; the prepared methyl acetate is high in purity, the product DMF is high in purity, and the production cost of sucralose is reduced.

Owner:ANHUI JINGHE IND

The production method of 3,5-di-tert-butyl-4-hydroxybenzoic acid

ActiveCN109096099BPrevent spontaneous combustionAvoid problemsPreparation from carboxylic acid saltsOrganic compound preparationBenzoic acidTert butyl phenol

The invention discloses a production method of 3,5-di-tert-butyl-4-hydroxybenzoic acid. The production method sequentially comprises the steps as follows: 2,6-di-tert-butylphenol, a potassium hydroxide aqueous solution and toluene are added to a reactor under protection of nitrogen to be subjected to a reflux reaction under a water distribution condition; CO2 is introduced into the reactor until the pressure is 0.1-3.0 MPa, a Kolbe-Schmitt reaction is conducted under a pressure holding condition, after the reaction, corresponding aftertreatment is carried out, and a crude product of 3,5-di-tert-butyl-4-hydroxybenzoic acid is obtained. The method has short reaction time and high conversion rate, has obvious advantages as compared with traditional gas-solid processes and existing solvent-process synthesis processes and is suitable for further industrialization.

Owner:安徽新秀化学股份有限公司 +1

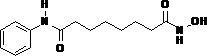

A kind of method utilizing modified mesoporous material to catalyze preparation vorinostat

ActiveCN109134313BHigh yieldHigh purityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsHydroxylamineMesoporous silica

The invention provides a method for preparing vorinostat under the mesoporous silica coupling / catalysis system modified by suberic anhydride and coupling agent, the method comprises the following steps: preparing suberic anhydride and coupling agent Modified mesoporous silica; pretreat the suberic acid reactant with the hydrophilic modified mesoporous silica for 1-2 h, and then react with aniline or its salt to form the intermediate octanoylanilide acid; in the presence of modified mesoporous silica, the obtained caprylanilic acid is reacted with hydroxylamine or its salt to prepare vorinostat. The method of the invention has high selectivity and yield, short amidation reaction time, and the obtained vorinostat has a purity of over 99%.

Owner:新昌县勤勉生物医药科技有限公司

A method for preparing cellulose acetate butyrate with high butyryl content

ActiveCN106632697BAvoid strong corrosiveOvercome the problem that hydrolysis into butyric acid cannot be recycledAcetic acidCellulose

The invention discloses a method for preparing cellulose acetate butyrate with high butyryl group content, which comprises the following steps: After the crushed cellulose is activated with acetic acid, under the catalysis of sulfuric acid, transesterification occurs with alkyl butyrate to generate high butyrate For cellulose acetate butyrate with acyl group content, the alcohol produced by rectification during the transesterification reaction promotes the positive reaction. In the cellulose acetate butyrate prepared by the method, the acetyl group content is 1-2 wt%, and the butyryl group content is 50-53 wt%. The invention adopts a non-corrosive esterification agent, the excess esterification agent can be recycled, greatly reduces the production cost, and is suitable for industrial production.

Owner:WANHUA CHEM GRP CO LTD

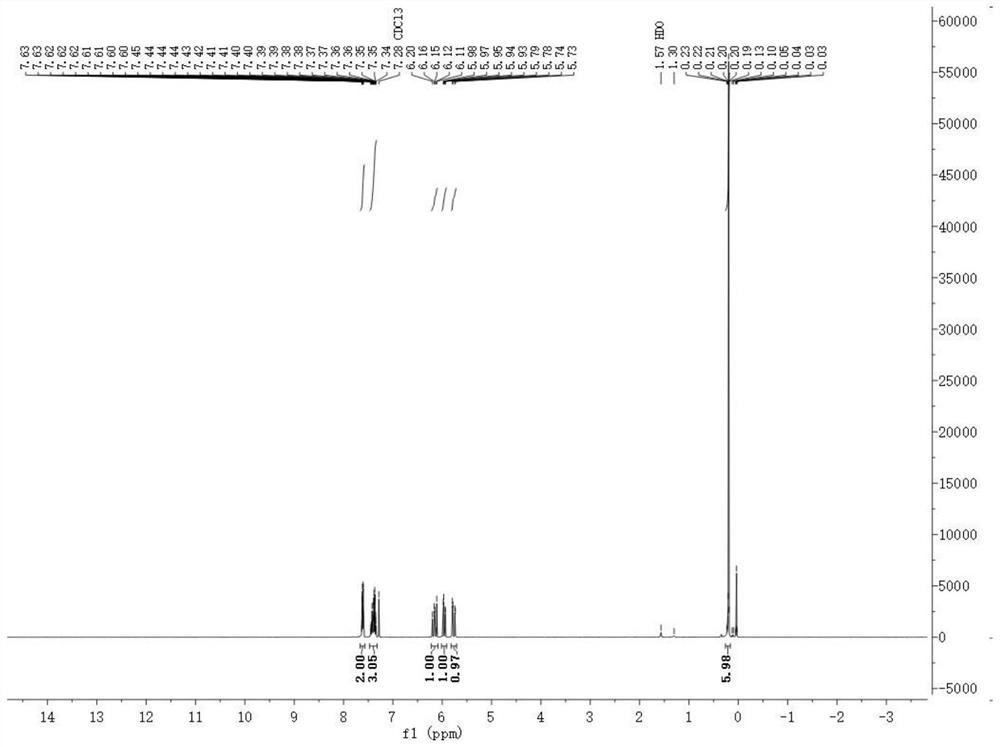

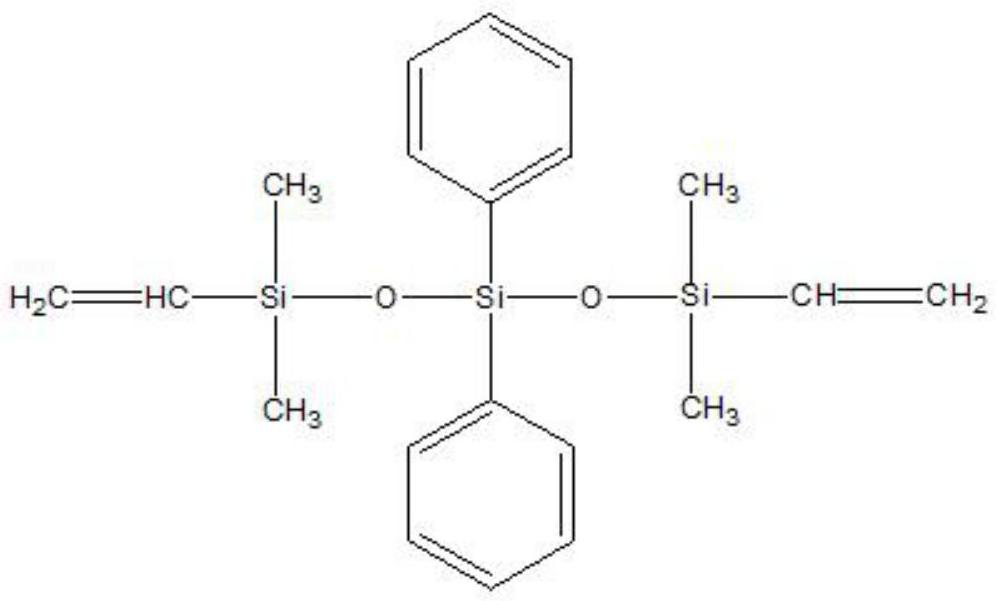

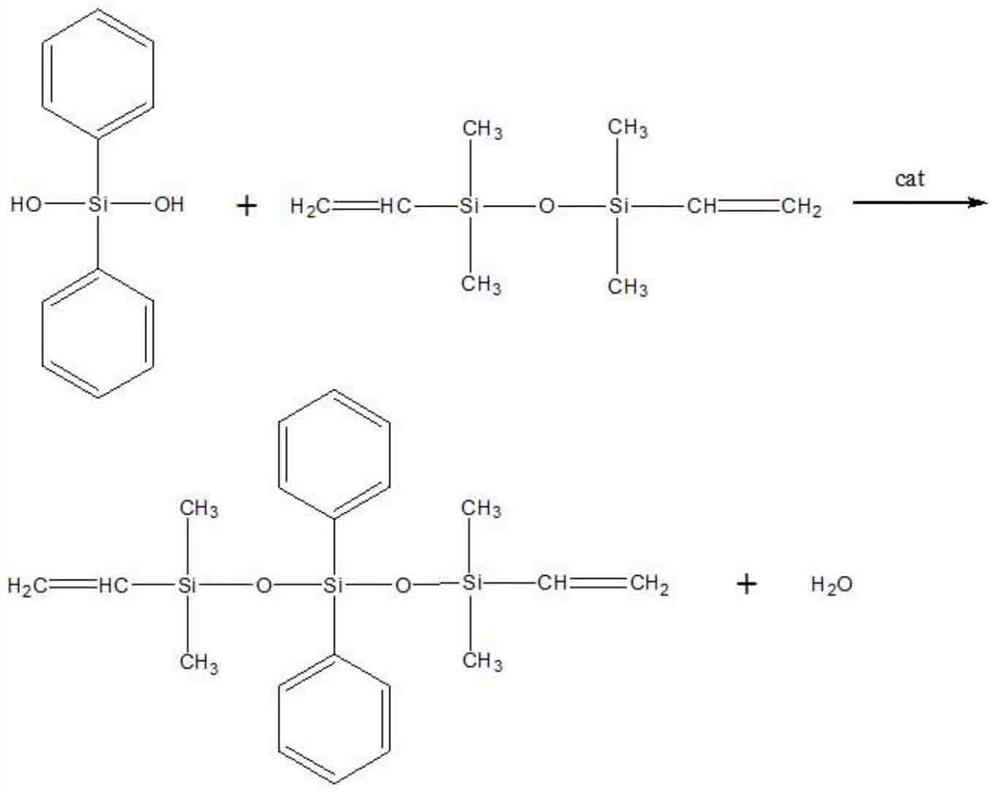

A kind of preparation method of 1,5-divinyl-3,3-diphenyl-1,1,5,5-tetramethyltrisiloxane

ActiveCN110156825BSolve environmental problemsSolve the problem of selectivitySilicon organic compoundsPtru catalystMeth-

The invention relates to a preparation method of 1,5-divinyl-3,3-diphenyl-1,1,5,5-tetramethyltrisiloxane, which comprises: under the protection of protective gas, the The organic solvent, diphenylsilanediol, divinyltetramethyldisiloxane and catalyst are mixed in proportion, the temperature is raised for reflux reaction, and the water generated by the reaction is separated by reflux with a water separator. After the reaction is completed, the temperature is lowered, Neutralize and wash with water to obtain the organic phase, and rectify under negative pressure to obtain the product. The invention avoids the problems of environmental protection and low selectivity caused by using chlorosilane as a reaction raw material, and has the advantages of simple and convenient operation, high catalytic efficiency, high yield, good safety and the like.

Owner:新元化学(山东)股份有限公司

A kind of sulfonated polyvinyl alcohol catalytic composite membrane and its preparation method

ActiveCN110354698BReduce corrosionFacilitate a positive responseMembranesSemi-permeable membranesPolymer sciencePtru catalyst

The invention relates to a catalytic composite membrane of sulfonated polyvinyl alcohol and a preparation method thereof. It is characterized in that the catalytic composite membrane has a "sandwich" structure, that is, it includes a support layer, a separation layer and a catalytic layer. The support layer adopts a hydrophilic support body; the separation layer is made of MoS 2 The separation layer is prepared by adding sodium alginate (SA); the catalytic layer is prepared by cross-linking polyvinyl alcohol (PVA) with an acidic catalyst. Specific preparation method: soak the support with deionized water for pretreatment; dissolve SA in MoS 2 The separation layer casting liquid is prepared in the dispersion liquid, and the film is scraped to dry; the PVA solution, the acidic catalyst and the crosslinking agent are added together, stirred, and then coated on the dried separation layer, and the film is dried to prepare the catalytic layer. The invention adopts the chemical grafting method to graft the acidic catalyst on the PVA chain, so that the polymer chain can have more acid sites; at the same time, the chemical grafting method can minimize the loss of the catalyst.

Owner:NANJING TECH UNIV

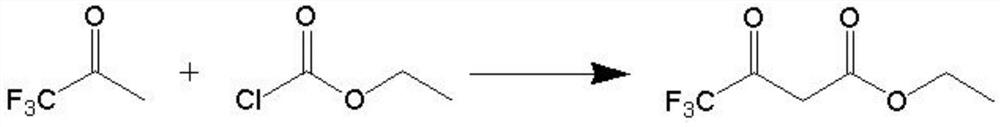

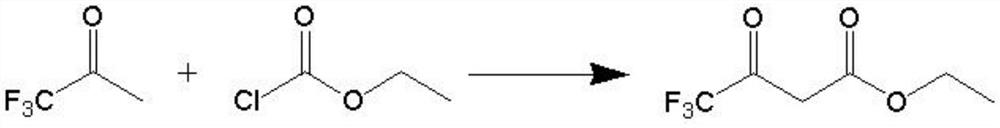

A kind of synthetic method of 4,4,4-trifluoroethyl acetoacetate

ActiveCN113072449BAvoid accumulationLower the activation energy of the reactionOrganic compound preparationCarboxylic acid esters preparationEthyl chloroformateChemical synthesis

The invention relates to a method for synthesizing ethyl 4,4,4-trifluoroacetoacetate, and belongs to the field of chemical synthesis. The invention adopts trifluoroacetone and ethyl chloroformate as raw materials, and uses hydrogen chloride as a catalyst to carry out the reaction in a pipeline reactor. The invention provides a new method for synthesizing ethyl 4,4,4-trifluoroacetoacetate, which adopts ethyl chloroformate with higher reactivity, and uses hydrogen chloride to catalyze the reaction, shortens the reaction time, and avoids 4,4,4 ‑The self-condensation reaction of ethyl trifluoroacetoacetate in the strong acid and strong base system improves the yield of the reaction and the purity of the product.

Owner:山东京博生物科技有限公司

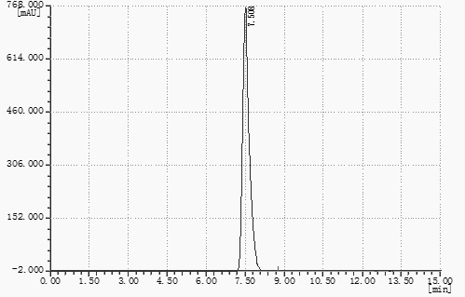

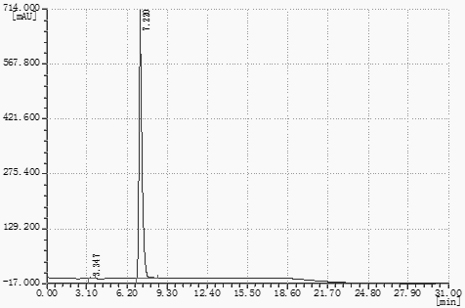

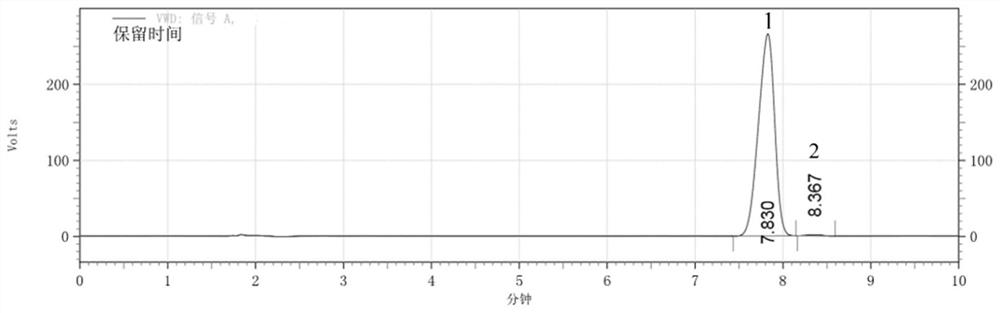

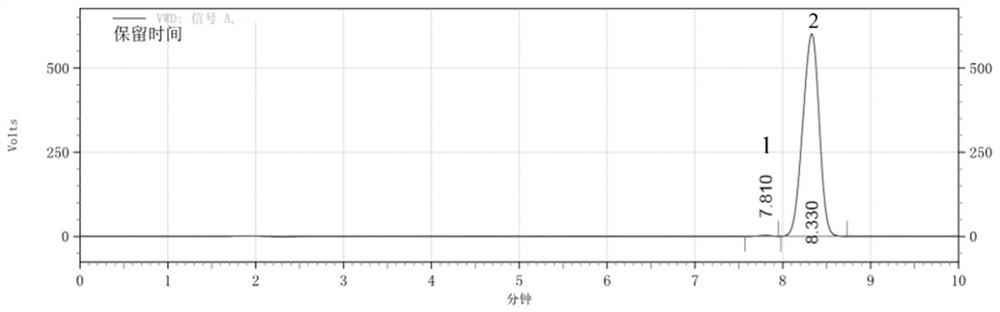

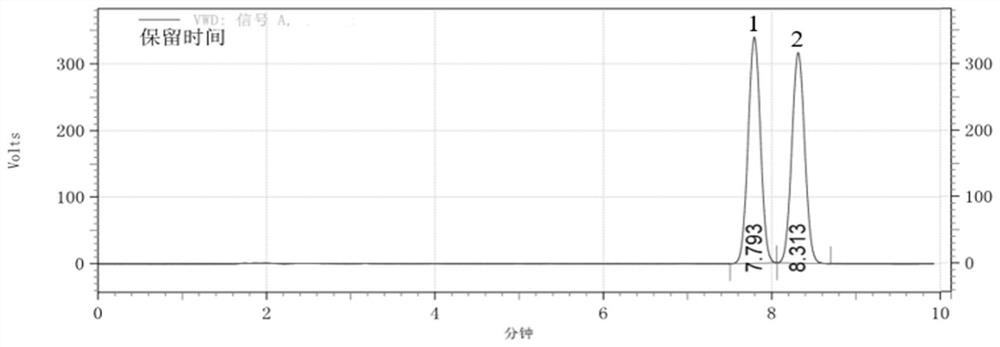

Analysis method for chiral purity of 1-naphthylethylamine

PendingCN113341053ARapid determination of chiral purityFacilitate the positive reactionComponent separationSulfonyl chlorideUltraviolet detectors

The invention relates to analysis method for the chiral purity of 1-naphthylethylamine. The analysis method comprises the following two steps of (1) derivatization and (2) separation and detection. The method is mild in condition, convenient and low in price. According to the analysis method, (D)-camphor sulfonyl chloride is taken as a derivatization reagent to carry out derivatization reaction with 1-NEA, the chiral purity of the D-camphor sulfonyl chloride and the derivative of the 1-NEA is analyzed through the combination of reversed-phase high performance liquid chromatography and an ultraviolet detector, so that the chiral purity of the 1-NEA is analyzed.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com