Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Avoid strong corrosive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for extracting aurum from difficult-to-handle sulphide ore aurum concentrate by two-segment pressurization leaching method

InactiveCN101876005ADoes not affect the leaching rateReduce consumptionProcess efficiency improvementIron sulfateSlag

The invention relates to a method for extracting aurum from difficult-to-handle sulphide ore aurum concentrate by two-segment pressurization leaching method comprising two segments of pressurization oxidation preprocessing and pressurization oxidation aurum leaching. The method comprises the steps of: firstly, pressurizing and oxidizing base metal sulfide such as iron sulfide with sulfuric acid-iron sulfate, wherein most S2- and S22- are oxidized into elemental sulfur; and secondly, pressurizing and leaching the preprocessed slag with thiocyanate so that aurum is selectively dissolved in the solution in the form of aurum-thiocyanic acid compound. Therefore, the pre-oxidation slag can be directly leached without neutralization, the technical process is short, the aurum recovery rate is high, the cost is low and pollution of low-concentration SO2 smoke gas, As2O3 smoke dust, and the like is avoided.

Owner:CENT SOUTH UNIV

Magnesium alloy chemical nickel plating solution and electroplating pretreatment method

ActiveCN101435077AImprove bindingWith metallic lusterLiquid/solution decomposition chemical coatingNickel saltCerium nitrate

The invention provides a magnesium alloy chemical nickel plating solution, which contains water, nickel salt, a reducing agent and a compounding agent; wherein, the nickel plating solution also contains cerium nitrate. The invention also provides a magnesium alloy electroplating pretreating method, which comprises the following steps: under the chemical nickel plating condition, the magnesium alloy and the chemical nickel plating solution are contacted; wherein, the chemical nickel plating solution is the one provided by the invention. In the chemical nickel plating solution provided by the invention, as the cerium nitrate is added, the binding force of a base material and a plating layer is obviously increased. The magnesium alloy electroplating pretreating method provided by the invention has simple technique, convenient operation, little pollution to the environment, high binding force of the base material and the plating layer, smooth and beautiful workpiece surfaces, low cost and high economic benefit.

Owner:BYD CO LTD

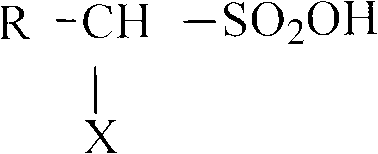

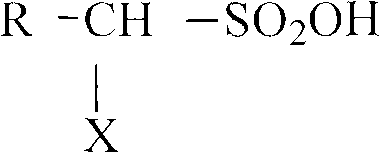

Non-halogen active agent for scaling powder

InactiveCN101758337AReduce corrosionNot corrosiveOrganic chemistryWelding/cutting media/materialsActive agentOrganic base

The invention relates to a non-halogen active agent for scaling powder, which is sulfonate generated by reacting sulfoacid and organic base. The sulfoacid can be alkyl sulfonic acid, alkyl disulfonic acid, isethionicacid, halogenation sulfoacid, such as methanesulfonic acid, ethanesulfonic acid, propanesulfonic acid, methionic acid, ethionic acid, malonic disulfonic acid ethylenehydrinsulfonic acid and the like. The sulfonate can be triethylamine methionic sulfonate, diphenyl guanidine methionic sulfonate and the like. The organic base can be organic amines, guanidines, imidazoles, phosphorus and the like. The invention has the advantages that firstly, the non-halogen active agent has high activity, belongs to a strong acid substance under active state and has the acidity strength similar to haloid acid; secondly, the non-halogen active agent has low corrosion, has no corrosion to a pad and a solder metal under the non-welding condition and has the advantage of low corrosion of organic acid active agent; and thirdly, the non-halogen active agent has wide application range and can be used as active components in multiple kinds of scaling powders.

Owner:HUNAN ASTAR BIO CHEM TECH

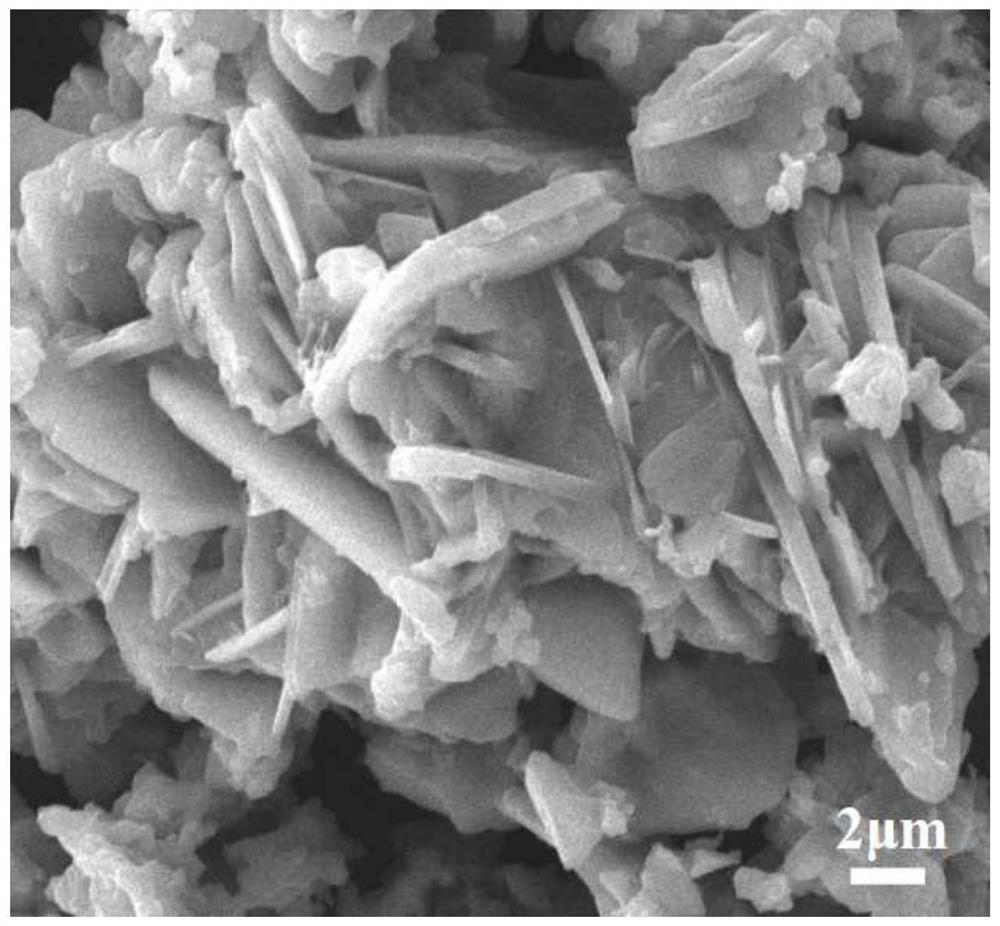

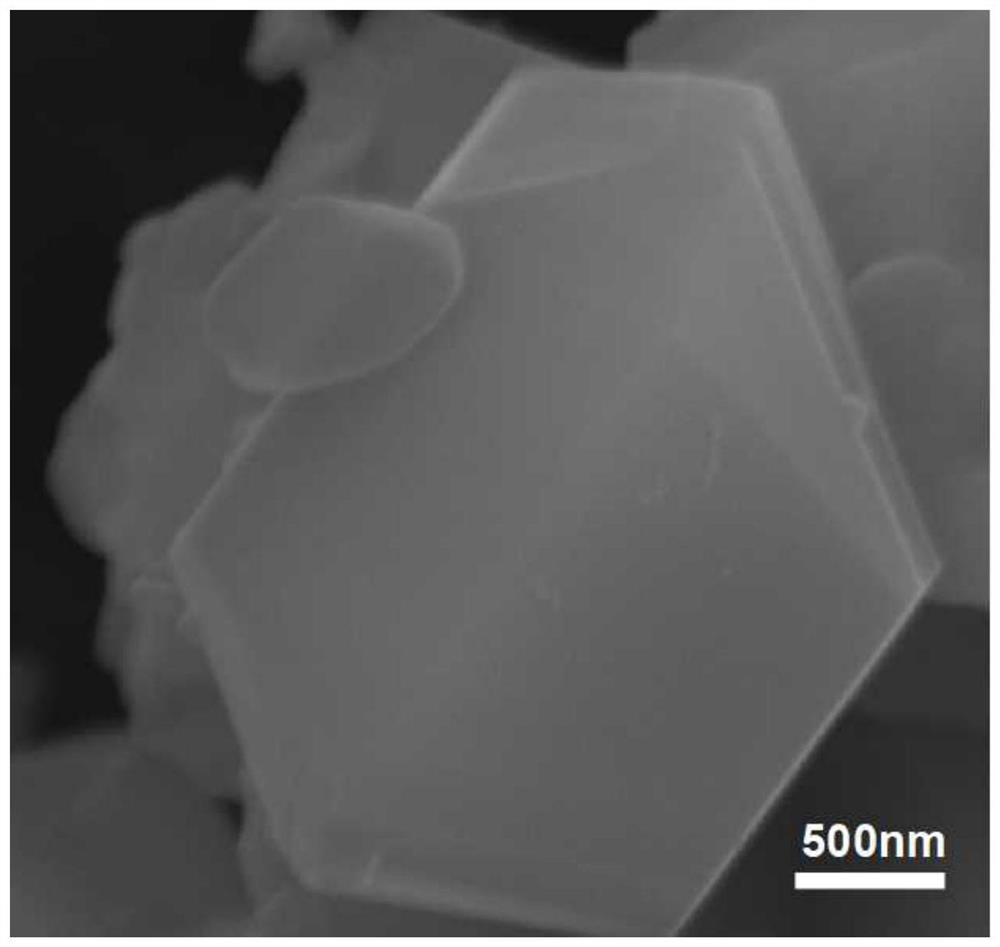

Aluminium chloride catalyst with high load capacity, preparation method and applications thereof

InactiveCN103706382AAvoid strong corrosiveImprove efficiencyCatalyst carriersOrganic compound preparationAluminium chlorideHigh load

The invention discloses an aluminium chloride catalyst with a high load capacity, a preparation method and applications thereof. The preparation method comprises the following steps: grinding ball-shaped active aluminium oxide, selecting aluminium oxide fine particle with a particle size of 60 to 100 meshes as the carrier of the supported aluminium chloride catalyst, subjecting dry CCl4 to carry out reactions with gamma-Al2O3 so as to obtain fresh AlCl3 steam, then using inert gas to carry the fresh AlCl3 steam, and making the fresh AlCl3 steam carry out immobilization reactions with hydroxyl groups on the surface of the aluminium oxide carrier so as to obtain the aluminium chloride catalyst with a high load capacity, wherein the AlClx content is 56 to 72 wt%, and the x is equal to 2.2 to 2.5. The supported aluminium chloride catalyst overcomes the strong corrosivity of aluminium chloride; the load capacity of the catalyst is increased, and the catalyzing efficiency of the catalyst is increased at the same time; and the problems of difficult stirring and material waste because of the large amount of reactants due to low catalyst active group concentration are solved. The catalyst can be used to catalyze the carboxylation reactions between toluene and CO2, the separation yield can reach 73.34% by taking AlClx as the baseline, and the catalyst has a high catalytic activity.

Owner:EAST CHINA UNIV OF SCI & TECH

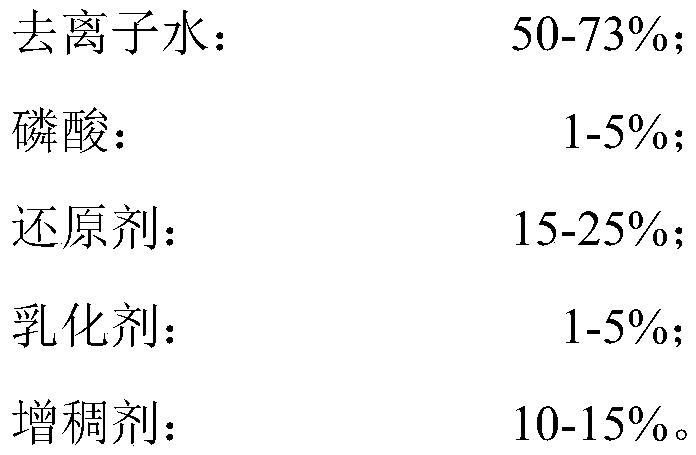

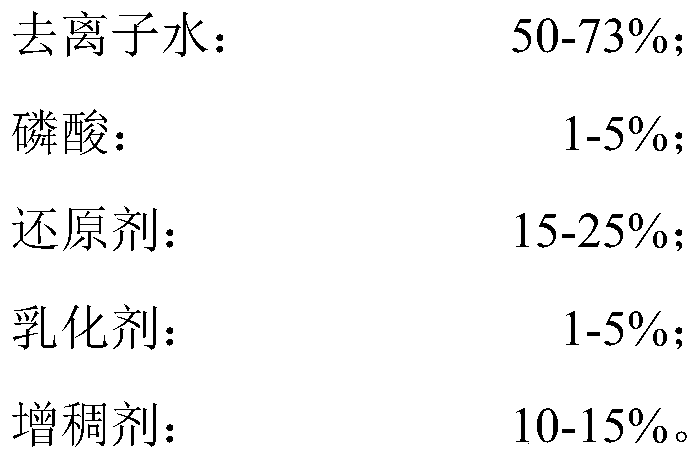

Discharge additive, printing paste and discharge printing method of polyester fabric

The invention provides a discharge additive of a polyester fabric. The discharge additive is prepared from, by weight, 50-73% of deionized water, 1-5% of phosphoric acid, 15-25% of a reducing agent, 1-5% of an emulsifier and 10-15% of a thickening agent. A printing paste of the polyester fabric comprises 94-100% of the discharge additive and 0-6% of a P type disperse dye. The invention also provides a discharge printing method of the polyester fabric. The method comprises the following steps of (1) printing by the printing paste, wherein the printing paste is applied on the surface of the colored polyester fabric for printing to form a pattern with colors; (2) aging, wherein the reducing agent performs reduction on the original disperse dye applied on the surface of the polyester fabric; (3) removal of paste through washing. The process is simple, saves the energy and reduces the consumption. The discharge additive has good stability, therefore, the effect can be achieved that the polyester fabric is subjected to printing after high-temperature dyeing by using the printing paste with the discharge additive, and the energy and the time are saved. The polyester fabric obtained by printing after high-temperature dyeing has excellent fastness in various aspects, uniform discharge printing and soft and full hand feeling.

Owner:GUANGZHOU SHENGQIN IND

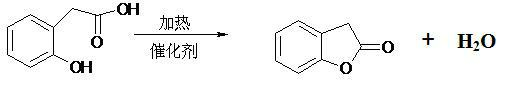

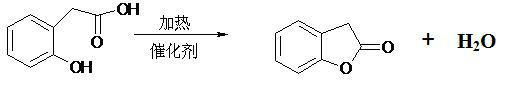

Production method of benzofuranone

ActiveCN102040572AAvoid strong corrosiveReduce investmentOrganic chemistryBenzeneReaction temperature

The invention provides a production method of benzofuranone, which is characterized in that o-Hydroxyphenylacetic acid is subject to azeotropic dehydration with a solvent only in the presence of commercial catalyst of cationic resins to generate benzofuranone, wherein the reaction temperature is 60-150 DEG C; the dosage of the catalyst is 0.1-20%; and the solvent accounts for 5-80% of the o-Hydroxyphenylacetic acid. The reacted solvent is no need of special treatment, and the filtered solvent is dehydrated to obtain the benzofuranone with concentration being above 96% in high yield.

Owner:JIANGSU CHANGLONG AGROCHEM CO LTD

Method for synthesizing terpinum from turpentine oil and preparing terpineol and acetic ester

ActiveCN108752163ALess corrosiveHigh yieldOrganic compound preparationCarboxylic acid esters preparationAcetic anhydridePhosphoric acid

The invention discloses a method for synthesizing terpinum from turpentine oil and preparing terpineol and acetic ester. The method comprises the following steps: turpentine oil, water, phosphoric acid, alpha-hydroxy acid, a cocatalyst and an emulsifier are added into a reaction kettle, stirring is started, and a synthetic product is obtained after a reaction; the synthetic product is allowed to stand for crystallization, filtering is performed to obtain a hydrated terpinum crystal, a filter liquid is allowed to stand for delamination, and the upper layer is oil containing a hydrous product; the terpinum crystal is added into a dehydration reaction kettle and water is added thereto, stirring and heating are performed, and the reaction is allowed to obtain a crude terpineol product; the terpinum crystal is added into an esterification reaction kettle, acetic anhydride is added, stirring is performed, a temperature reaction is performed to obtain a crude acetic ester product; the crude terpineol product or the ethyl ester product is neutralized by lime water, water washing is performed, and a product after the water washing is subjected to vacuum fractionation to obtain a refined terpineol or acetic ester product. The method provided by the invention has the advantages of simple process, less discharge of three wastes, mild reaction conditions, high yield of terpineol, and relatively good social, ecological and economic benefits.

Owner:GUANGXI FORESTRY RES INST

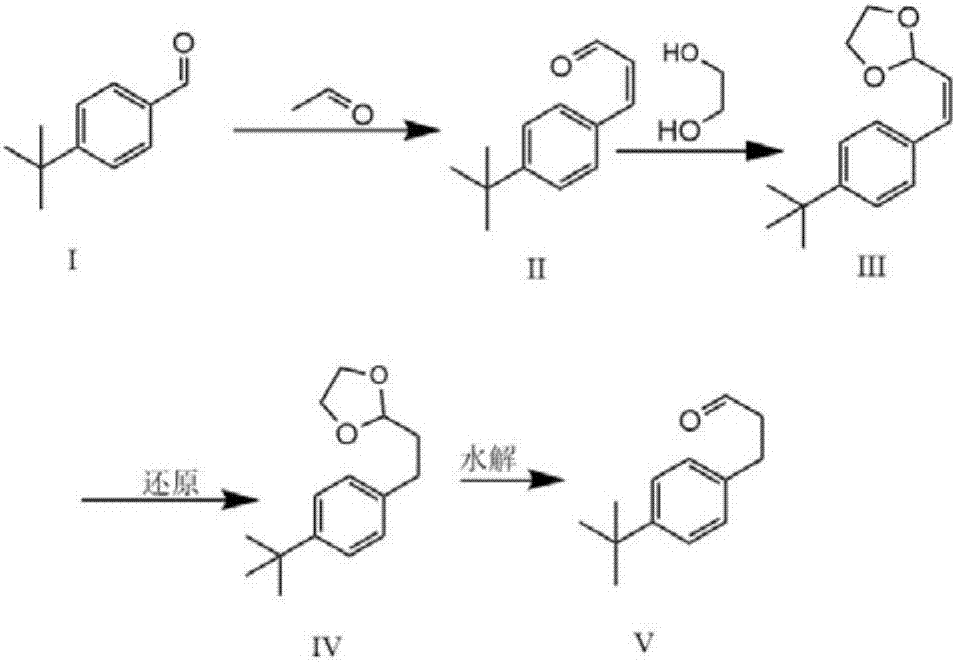

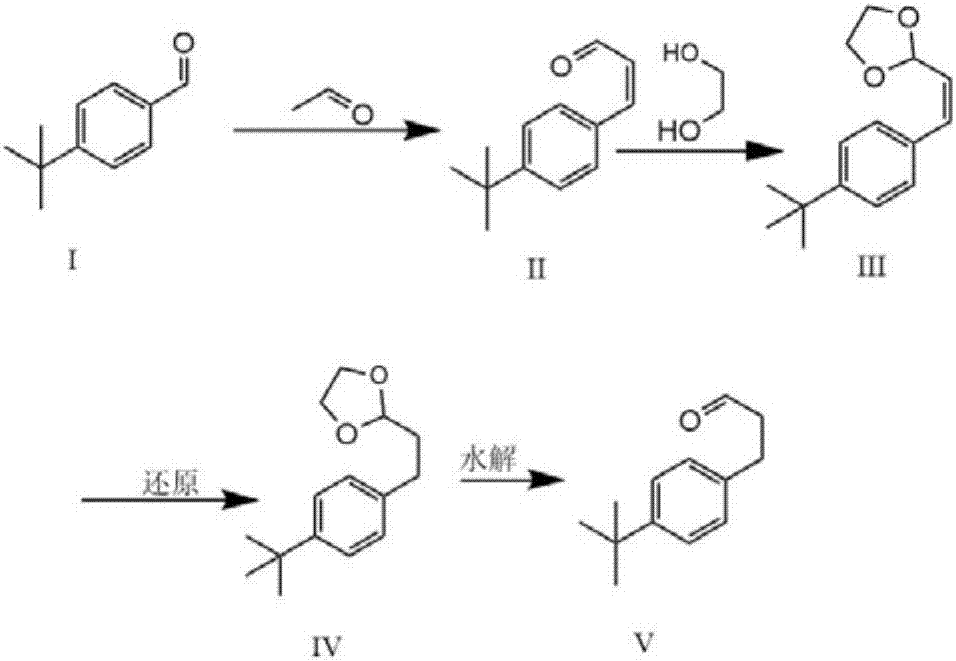

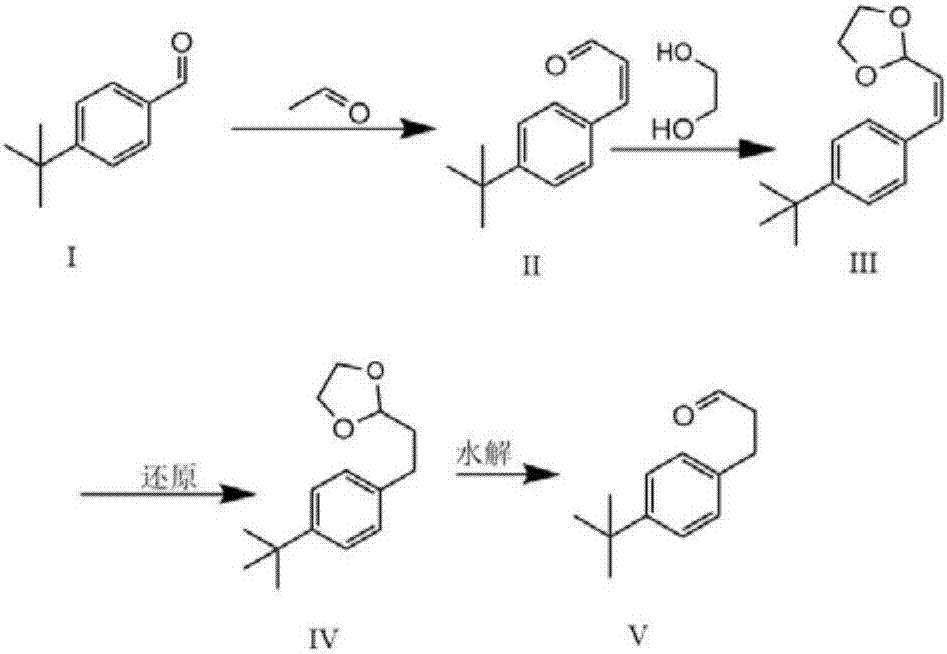

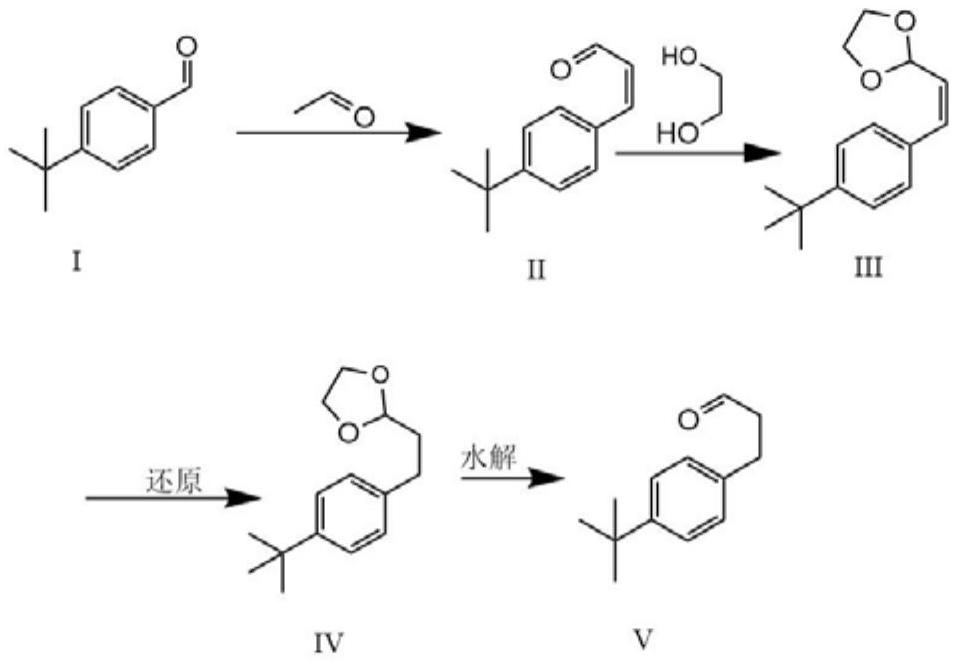

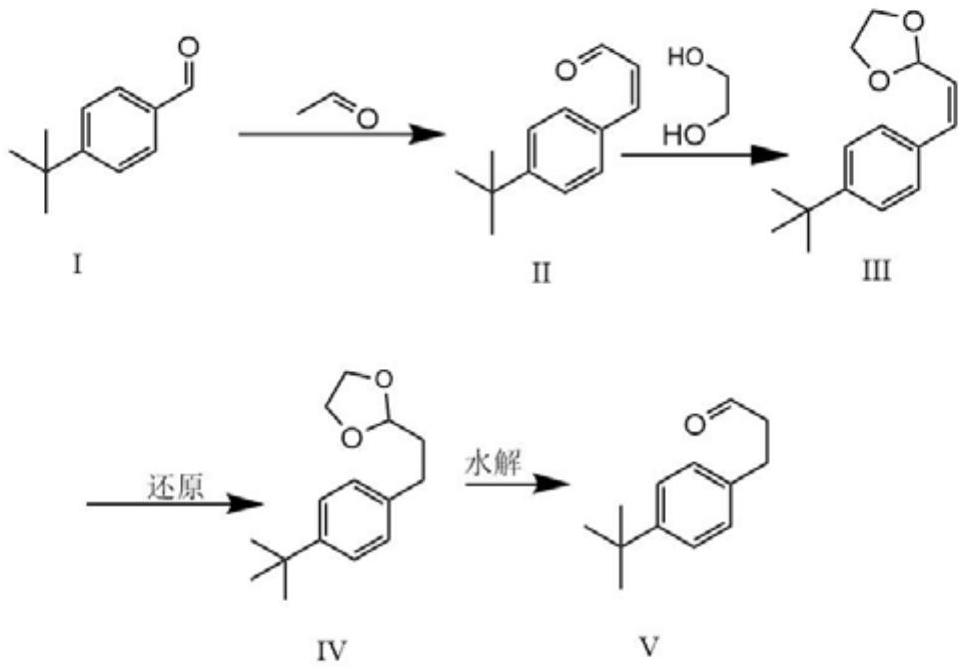

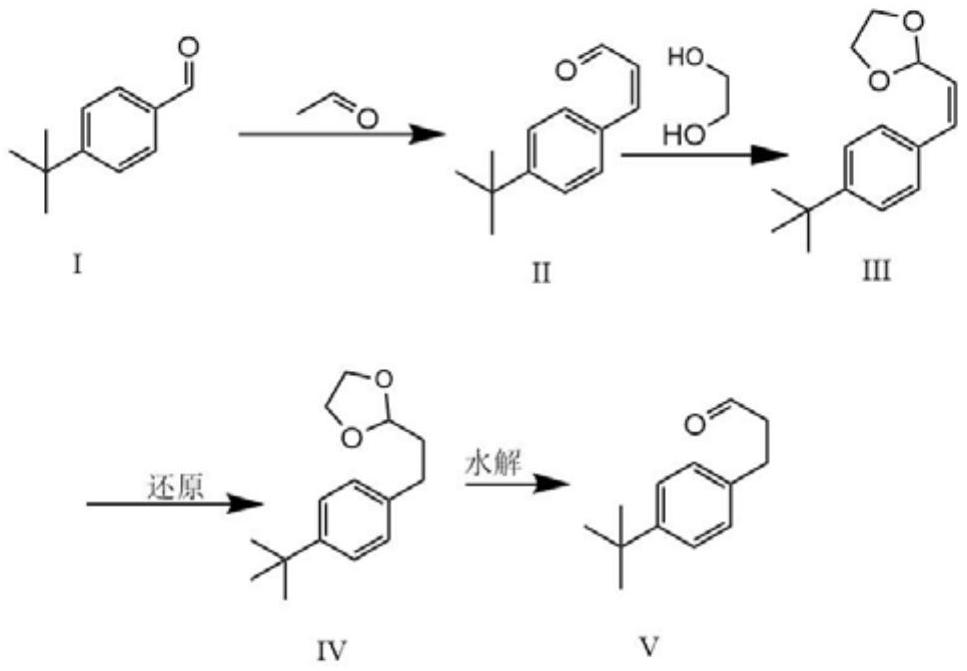

Method for synthesizing 3-(4-tert-butylphenyl)propionaldehyde

ActiveCN107954843AHigh selectivityAvoid strong corrosiveOrganic compound preparationPreparation from heterocyclic compoundsDouble bondSolvent

The invention discloses a method for synthesizing 3-(4-tert-butylphenyl)propionaldehyde. The method is executed according to reaction formulas as shown in the description and specifically comprises following steps: a compound shown as the formula I is subjected to Claisen-Schmidt condensation reaction, unsaturated aldehydes are produced, and a compound shown as the formula II is obtained; the compound shown as the formula II is dissolved in toluene and ethanediol and subjected to fractional distillation and water discharge under the action of a catalyst, and a compound shown as the formula IIIis produced through condensation; the compound shown as the formula III is dissolved in a solvent, then the catalyst is added, hydrogen is introduced under pressurizing action to reduce double bonds,and a compound shown as the formula IV is obtained; acetal shown as the formula IV is hydrolyzed under the acidic condition to form aldehyde, and 3-(4-tert-butylphenyl)propionaldehyde shown as the formula V is obtained. Compared with Friedel-Crafts acylation reaction in the prior art, the method for synthesizing 3-(4-tert-butylphenyl)propionaldehyde has the advantages as follows: conditions are mild, the Claisen-Schmidt condensation reaction is high in selectivity, unicity of condensation is high, and the problem of severe pollution caused by high consumption of strong-corrosion titanium tetrachloride is solved. The reaction synthesis is low-pollution, aftertreatment is simple, and the requirement of modern green production is met.

Owner:KUNSHAN YAXIANG SPICEL CO LTD

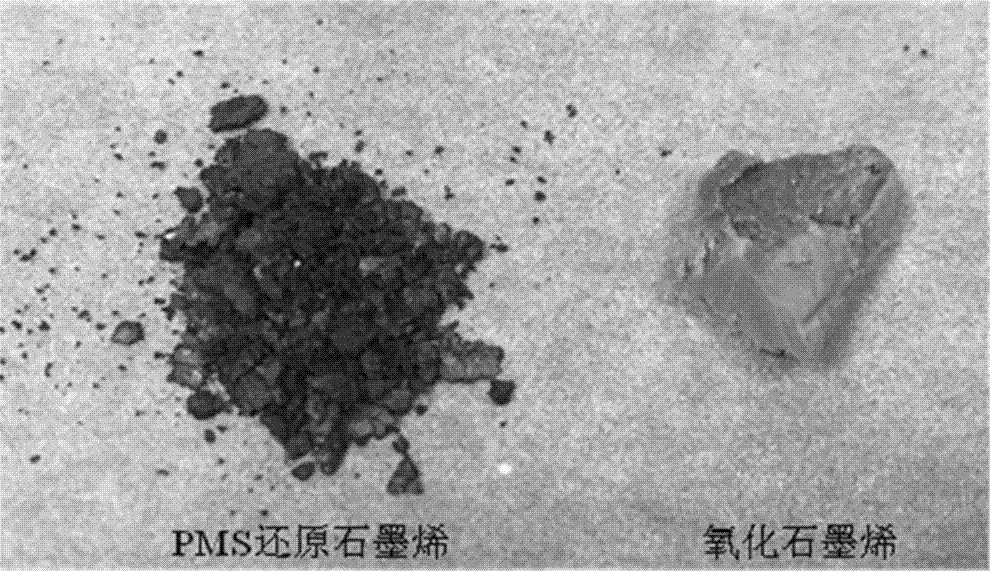

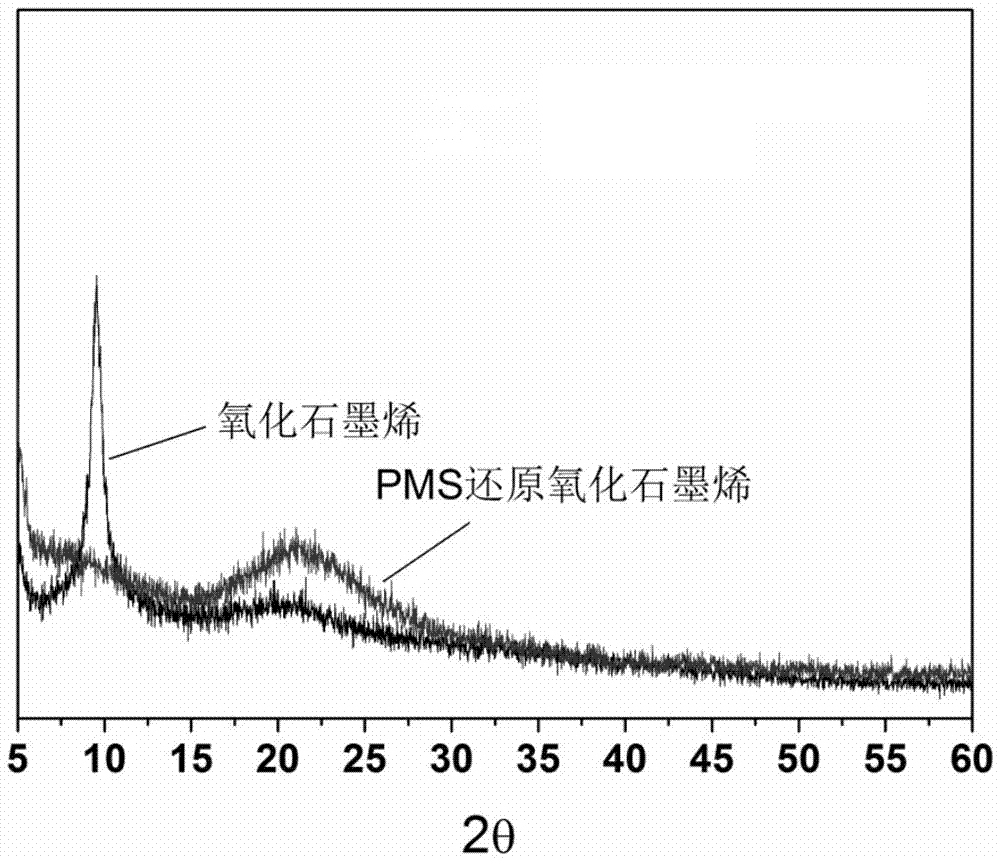

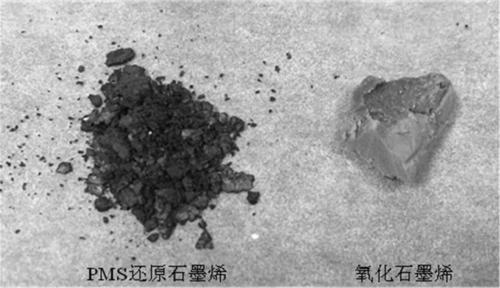

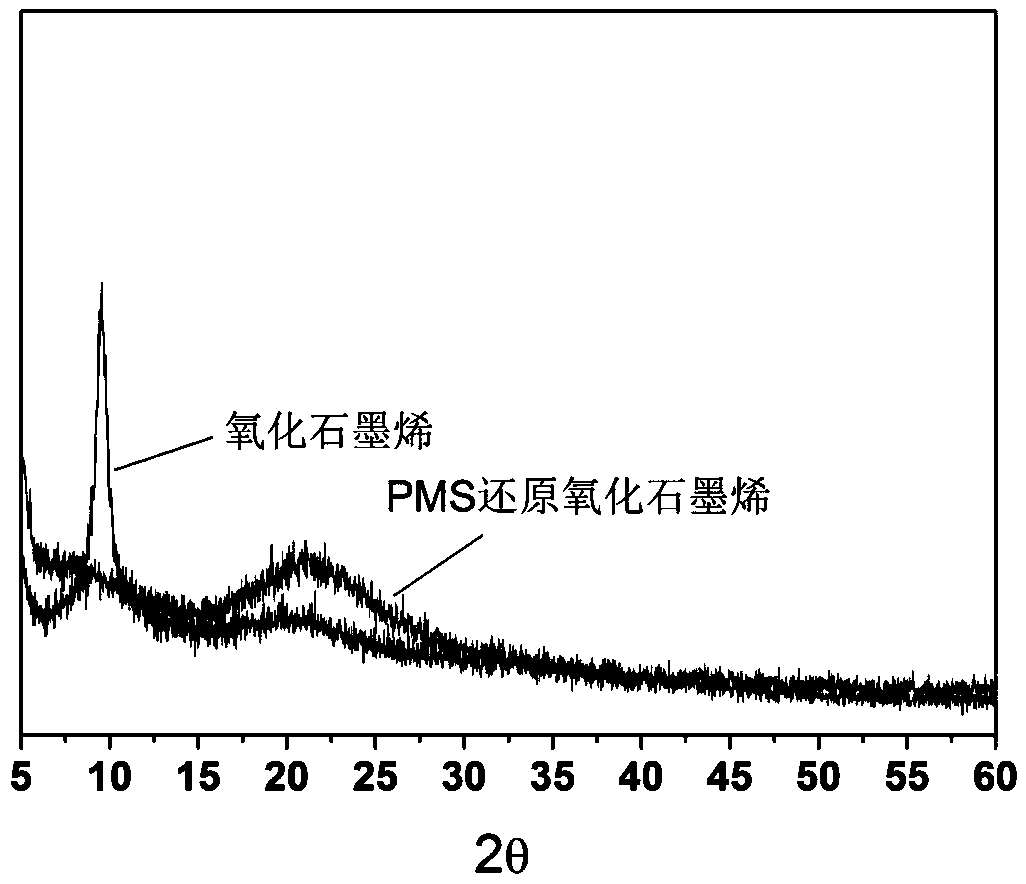

Preparation method of graphene and graphene

The invention discloses a preparation method of graphene and the graphene. According to the preparation method of the graphene, graphene oxide is reduced by hydrogen-containing polysilane serving as a reducer, and the graphene is obtained. According to the preparation method, hydrazine hydrate, a derivative of hydrazine hydrate, hydrogen iodide, sodium borohydride and other substances with strong toxicity, high volatility and strong corrosion are avoided, and the method is safe and environment-friendly, requires mild conditions and can be used for batch production.

Owner:NAT UNIV OF DEFENSE TECH

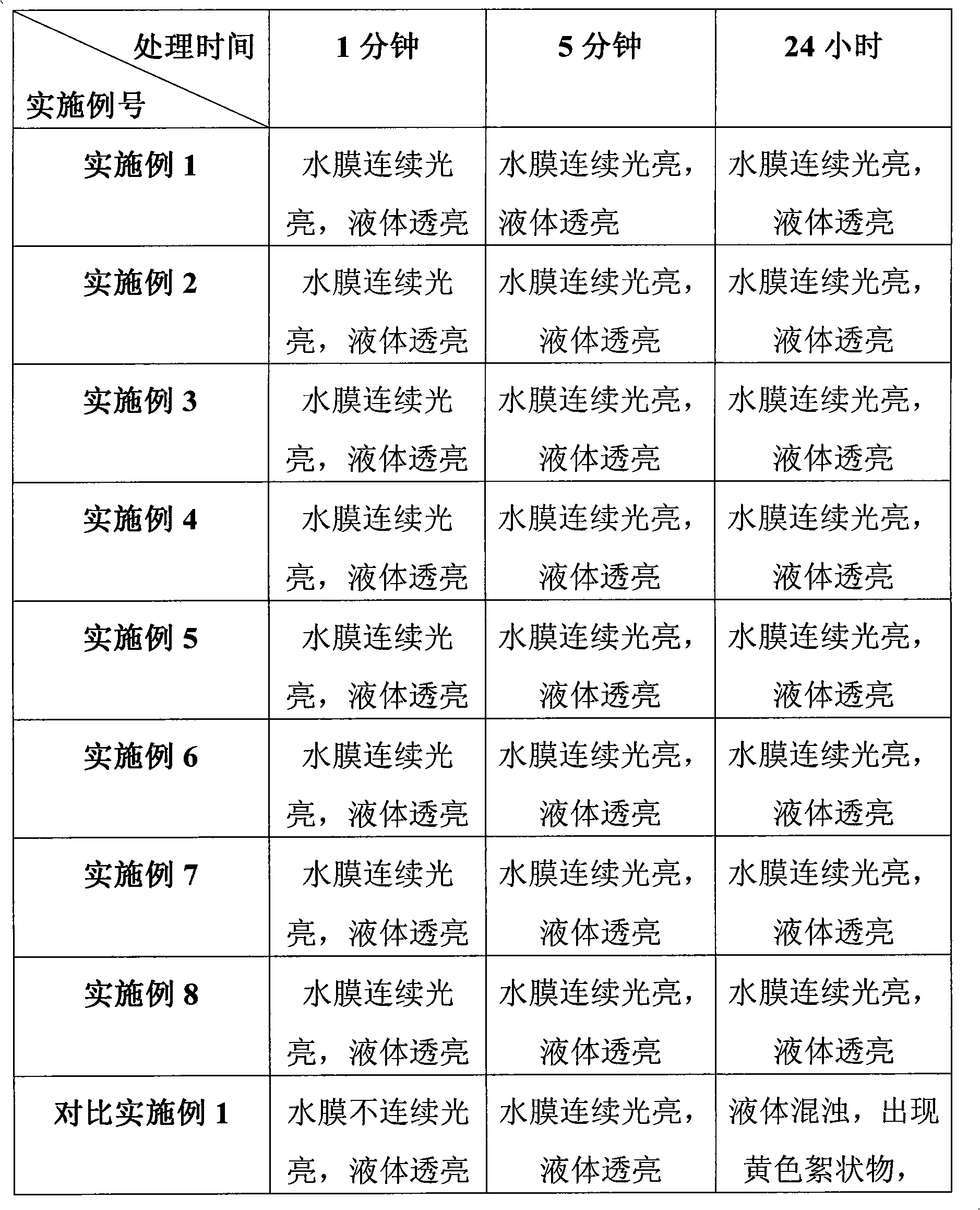

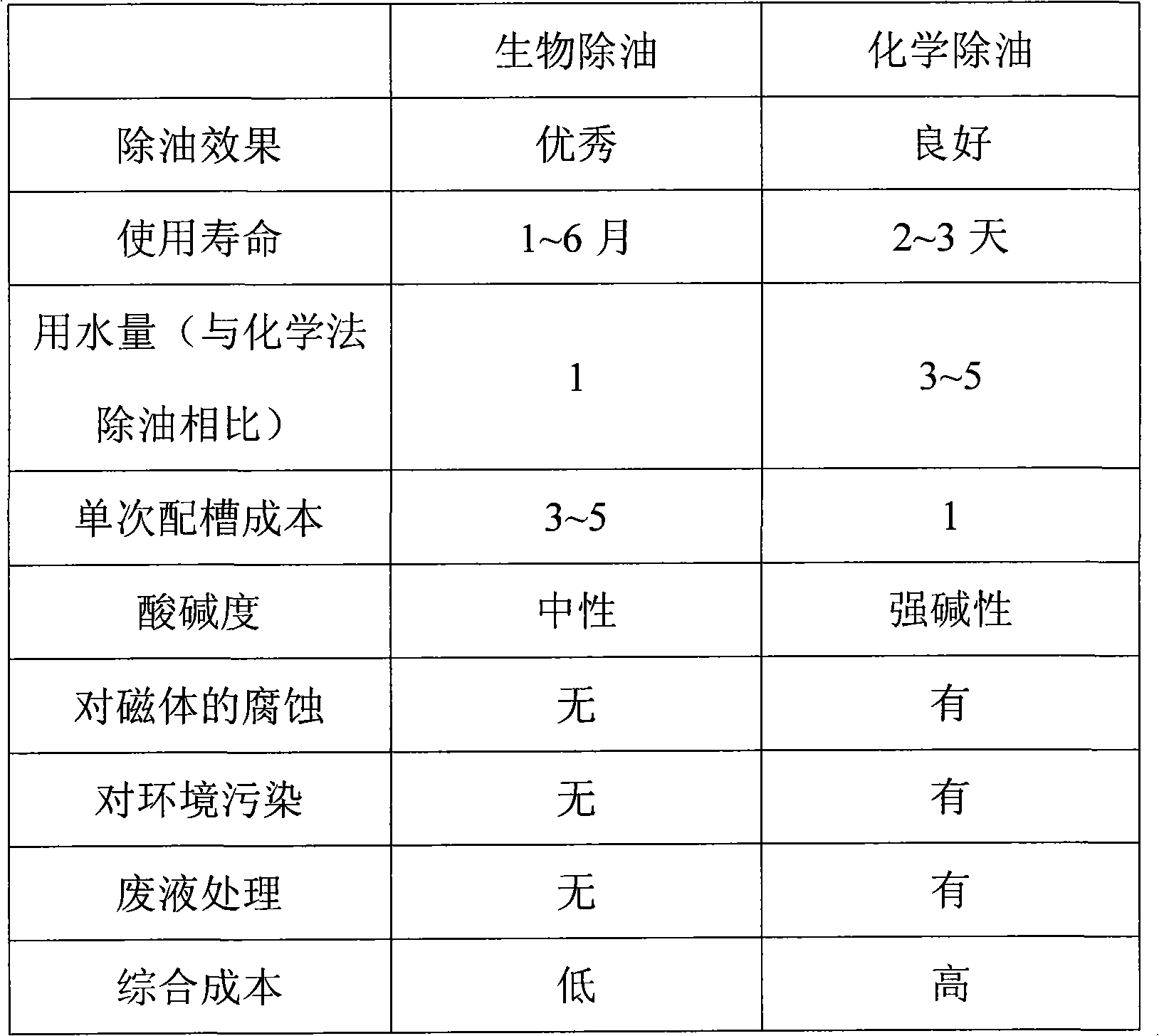

Biological oil removing agent for permanent-magnet materials

ActiveCN102040947AAvoid strong corrosiveAvoid the defect of not being able to completely degrease and degreaseOther chemical processesMagnetic materialsEnvironmental resistancePhosphoric acid

The invention relates to a biological oil removing agent for permanent-magnet materials. The biological oil removing agent is prepared according to the following steps: diluting the biological oil removing agent with water in the volume ratio of 1:(19-99) to obtain a diluent; and regulating the pH value of the diluent to 6.0-9.0 by using two of phosphoric acid, citric acid, sodium citrate and trisodium phosphate, and keeping the temperature of the diluent at 10-40 DEG C for later use. The biological oil removing agent can be used for thoroughly removing oil stains in the permanent-magnet material under the condition of mild pH value without generating substances harmful to the environment. The biological oil removing agent is environment-friendly. Meanwhile, microbes in the biological oil removing agent are cheap and are easy to obtain, and the biological oil removing agent has strong continuous oil removal capability, therefore, the oil removal cost can be greatly lowered by using the biological oil removing agent.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

A kind of non-halogen active agent for soldering flux

InactiveCN101758337BReduce corrosionNot corrosiveSulfonic acids salts preparationWelding/cutting media/materialsActive agentOrganic base

A non-halogen active agent for a flux is a sulfonate formed by a sulfonic acid reacting with an organic base. The sulfonic acid can be an alkyl sulfonic acid, alkyl disulfonic acid, hydroxyl sulfonic acid or halogenated sulfonic acid. The organic base can be an organic amine, carbamidine, imidazole, phosphorus. The non-halogen active agent for a flux has the advantage of high activity and low corrosion.

Owner:HUNAN ASTAR BIO CHEM TECH

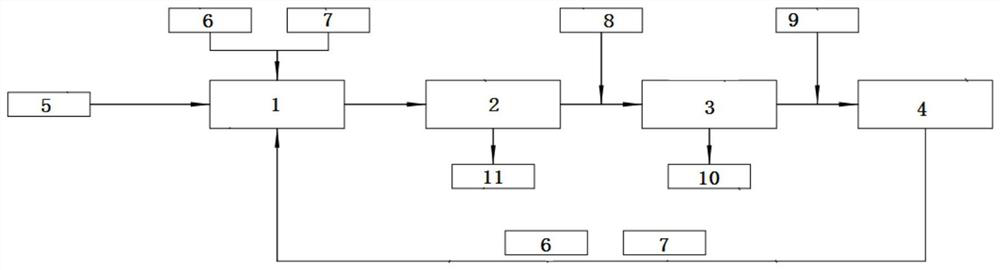

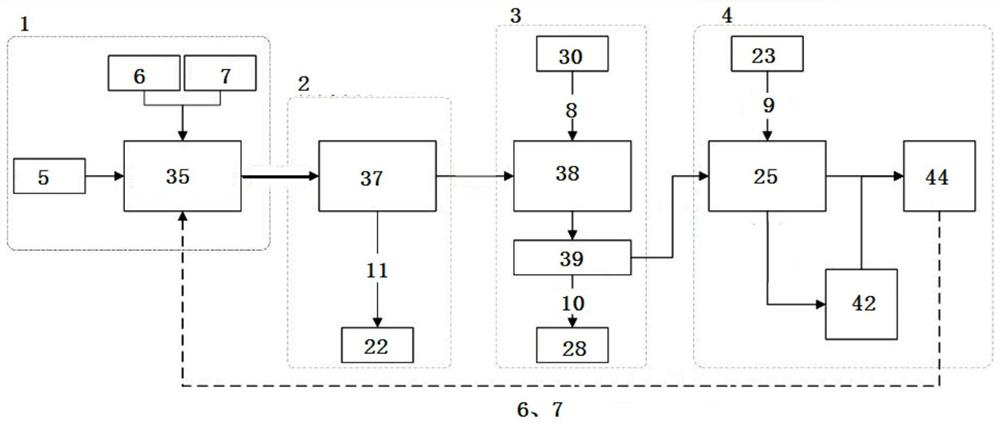

Oil removal treatment device and method for oil-based drill cuttings

ActiveCN111636833ARealize resourcesRealize resource processingConstructionsFluid phaseLiquid storage tank

The invention discloses an oil removal treatment device and method for oil-based drill cuttings. The device is arranged in an upper treatment chamber and a lower treatment chamber and comprises an extraction unit, a solid-liquid separation unit, an extraction oil separation unit and an extraction agent recovery unit. Main equipment of the device is divided into the two treatment chambers, integrated design is adopted, major equipment is placed in the upper treatment chamber, and the lower treatment chamber is mainly used for containing liquid storage tanks of all the units. Through the design,all treated liquid phases can flow into the liquid storage tanks through self weight, a large amount of power is saved, the two treatment chambers are stacked up and down, the occupied area can be reduced, and the equipment can be operated more conveniently.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Method for preparing cellulose acetate butyrate

The invention discloses a method for preparing cellulose acetate butyrate, which comprises the following steps: dissolving crushed cellulose in a solvent, and carrying out alcoholysis reaction with acetonitrile and butyronitrile under the catalysis of concentrated sulfuric acid to generate cellulose acetate butyrate. In the cellulose acetate butyrate prepared by the method, the content of acetyl is 1-15wt%, and the content of butyryl is 35-53wt%. According to the invention, a non-corrosive esterifying agent and a solvent are adopted, and a solvent NMMO aqueous solution can be recycled after being concentrated, so that the production cost is greatly reduced, and the method is suitable for industrial production.

Owner:WANHUA CHEM GRP CO LTD

Preparation method of mesoporous cellulose fiber material

ActiveCN113755964AAvoid strong corrosiveCreate pollutionArtificial filaments from cellulose solutionsPulp properties modificationFreeze-dryingCellulose fiber

The invention discloses a preparation method of a mesoporous cellulose fiber material. The preparation method of the mesoporous cellulose fiber material comprises the following steps of carrying out acidolysis, centrifugation, dialysis, ultrasonic treatment and evaporation on microcrystalline cellulose to prepare a cellulose nanocrystalline material; pre-hydrolyzing tetraethoxysilane and hydrochloric acid under a water bath condition to obtain a SiO2 precursor solution; adding the SiO2 precursor solution into the cellulose nanocrystalline material, stirring at 60 DEG C for 3 hours, and evaporating at room temperature to induce self-assembly so as to obtain a mixed solution; extruding the mixed solution into a coagulating bath through an extrusion pump, soaking, washing with water, and airing to obtain a composite fiber material; and removing SiO2 from the composite fiber material with a hydrofluoric acid solution, washing with ethanol, and performing vacuum freeze drying to obtain the mesoporous cellulose fiber material. The process is simple, environment-friendly, wide in raw material source and easy to obtain oriented fibers; and the obtained mesoporous cellulose fiber material has an excellent mesoporous structure and a high specific surface area, and has a wide application prospect when being used as a functional carrier material.

Owner:XIAN UNIV OF TECH

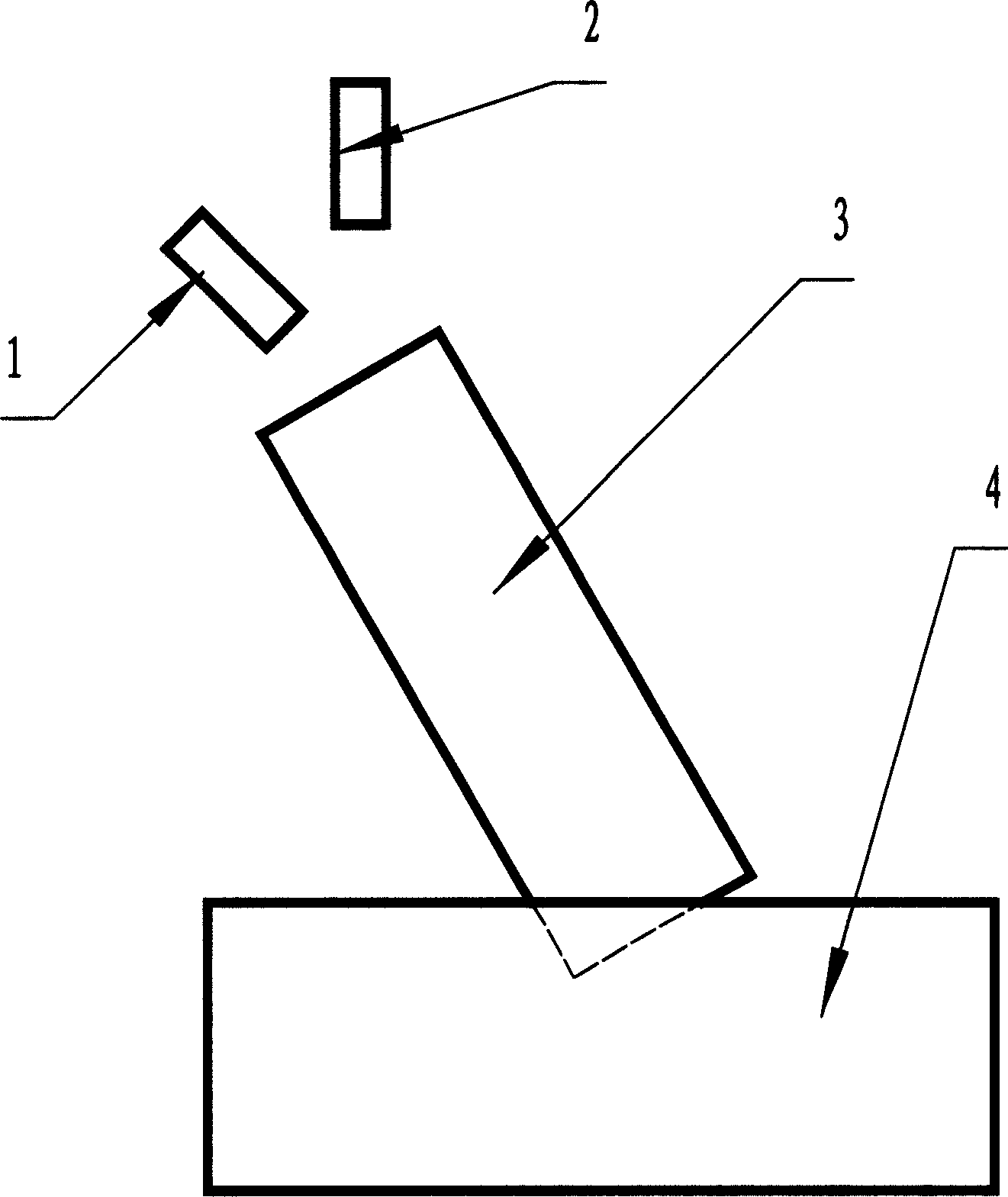

Method and apparatus for reclaiming water soluble fusing waste

InactiveCN1621168AAvoid strong corrosiveSolid waste disposalIncinerator apparatusReclaimed waterWater soluble

Below outflow opening of molten waste, high pressure air-water mixture spray gun is installed to smash the effluent, the smashed particles perform heat exchange with water to cool, the cooled particles are fed via the guide barrel to solid-liquid separator for separation, and separated solid matter is dried and packed to obtain final recovered particle matter.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI +1

Waste Reduction Methods

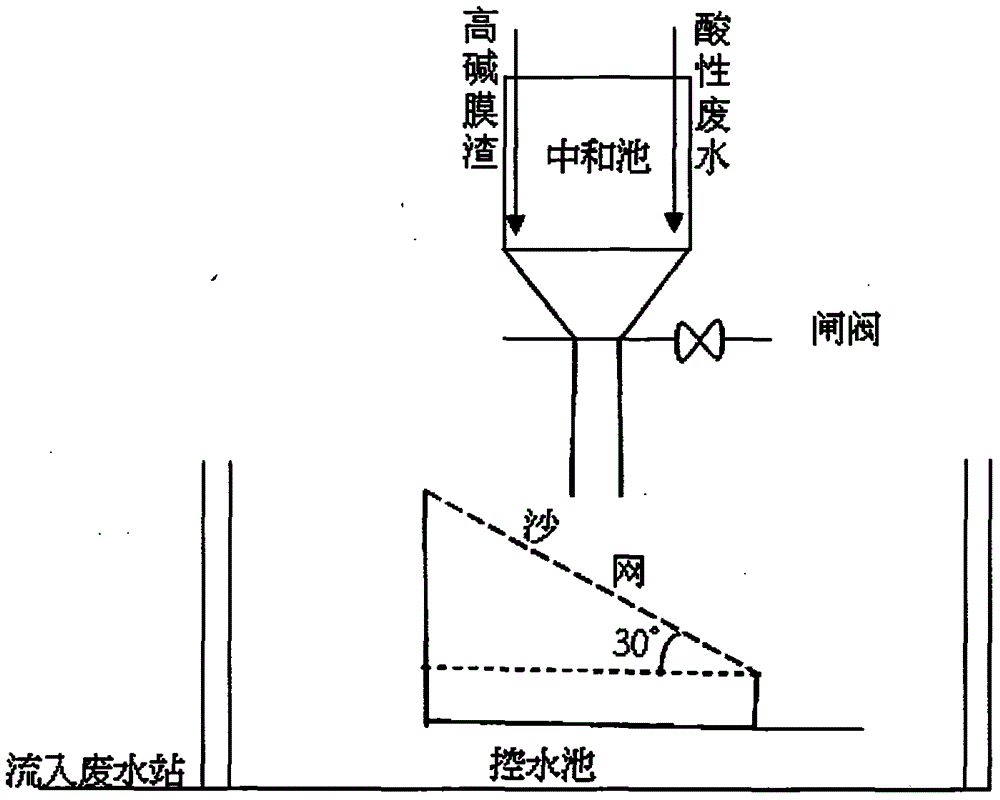

ActiveCN104028536BAvoid strong corrosiveIncrease moisture contentSolid waste disposalWater/sewage treatment by neutralisationAlkalinityControl system

The invention relates to a waste reducing system and a method in the field of electronic information printed circuit boards. The invention solves the problems of strong corrosivity, high water content and difficult incineration in existing high-alkalinity water membrane slag, and provides a system and a method convenient for incineration after neutralizing and reducing water content. The technical scheme is as follows: acidic wastewater and high-alkalinity membrane slag are dehydrated by adopting a water control system after being neutralized. The system and the method have the following benefits: the high-alkalinity membrane slag can be neutralized, the water content is reduced, the reduction of membrane slag wastes is realized, and the wastes are conveniently incinerated, so that the treatment cost of the wastes is decreased.

Owner:上海展华电子(南通)有限公司

Preparation method of graphene and graphene

The invention discloses a preparation method of graphene and the graphene. According to the preparation method of the graphene, graphene oxide is reduced by hydrogen-containing polysilane serving as a reducer, and the graphene is obtained. According to the preparation method, hydrazine hydrate, a derivative of hydrazine hydrate, hydrogen iodide, sodium borohydride and other substances with strong toxicity, high volatility and strong corrosion are avoided, and the method is safe and environment-friendly, requires mild conditions and can be used for batch production.

Owner:NAT UNIV OF DEFENSE TECH

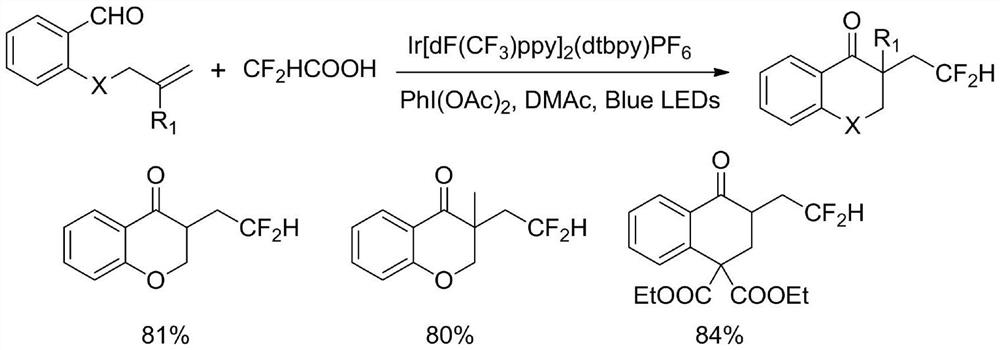

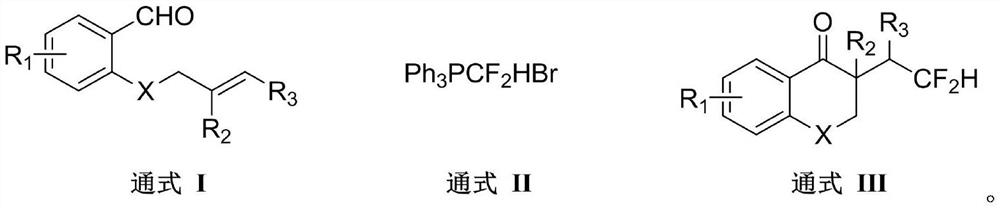

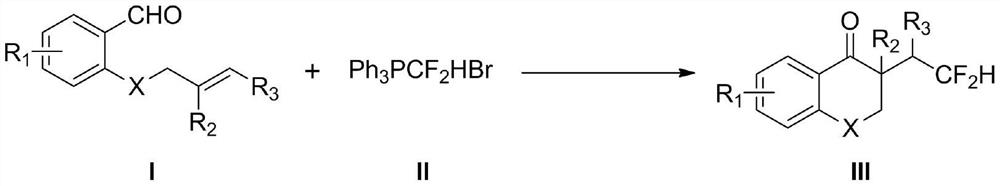

Method for synthesizing difluorohydromethylated 2, 3-dihydrobenzopyran-4-one derivative

PendingCN114853707AAvoid strong corrosiveAvoid cumbersome synthesisOrganic compound preparationCarboxylic acid esters preparationFluoroacetic acidEngineering

According to the method for synthesizing the difluorohydromethylated 2, 3-dihydrobenzopyran-4-one derivative, difluorohydromethyl triphenylphosphonium bromide is adopted as a difluorohydromethylation reagent, tris (2-phenylpyridine) iridium is adopted as a photocatalyst, and the difluorohydromethylated 2, 3-dihydrobenzopyran-4-one derivative is synthesized under the conditions of alkali and illumination. According to the invention, difluoromethyl triphenylphosphonium bromide which is stable and easy to obtain is used as a difluoromethylation reagent, so that the defects of strong corrosivity, irritation and toxicity of difluoroacetic acid are overcome. The stable, easily available and commercialized tris (2-phenylpyridine) iridium is used for replacing (Ir [dF (CF3) ppy] 2 (dtbpy) PF6) as a photocatalyst, so that the tedious synthesis of a complex photocatalyst is avoided. The method has the advantages of simple process flow, easily available raw materials, mild reaction conditions, simple and efficient operation, wide substrate application range, stable and easily controllable process, safety and environmental friendliness, and is suitable for industrial production.

Owner:SHANGRAO NORMAL UNIV

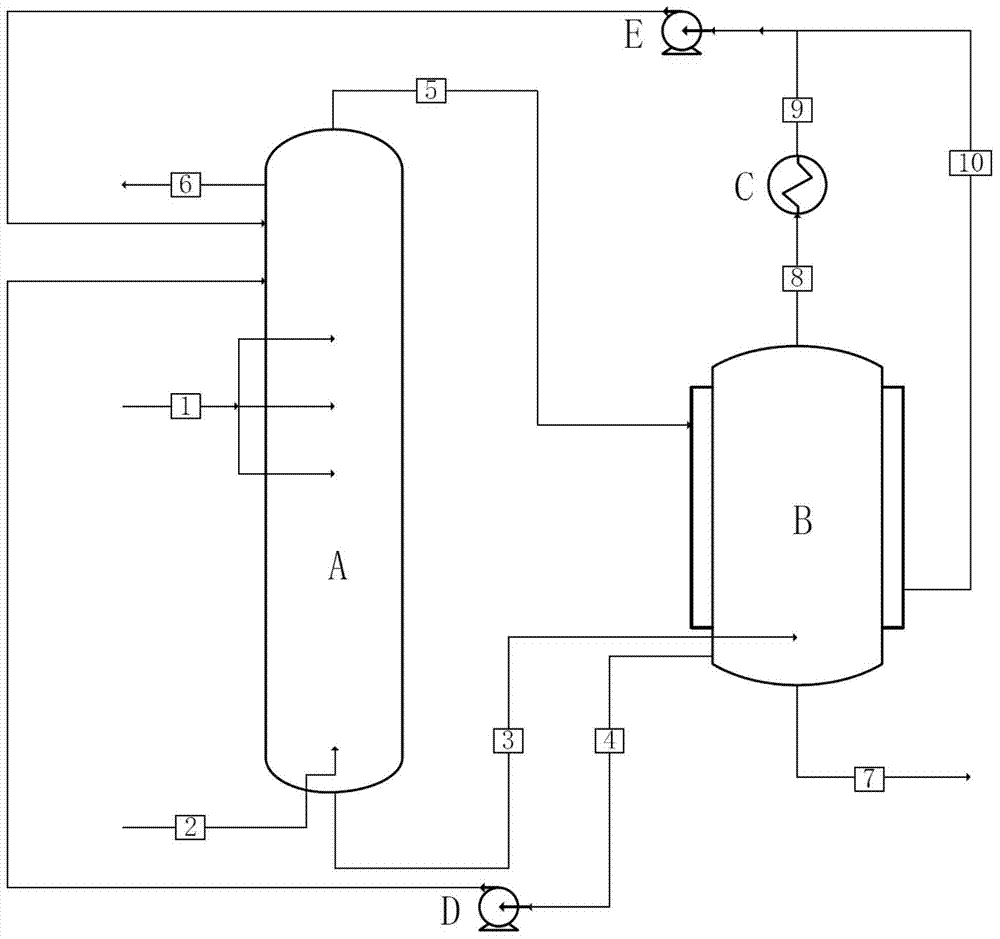

A device and method for recycling waste sulfuric acid from alkylation

ActiveCN105217654BSave operating timeAvoid strong corrosiveChemical industryAmmonia compoundsCondensate pumpAmmonia gas

The invention relates to an alkylate waste sulfuric acid resourceful treatment device and method. The device is composed of a reaction flotation tower, a crystallizer, a heat exchanger, a mother solution circulation pump, a condensate pump and connecting pipelines between the components. Alkylate waste sulfuric acid and ammonia gas serve as inlet materials of the reaction flotation tower, and a high-temperature and high-pressure ammonium sulfate mother solution generated at the bottom of the tower enters a crystallizer; low-pressure steam generated by the reaction flotation tower is extracted from the top of the tower and enters an outer jacket of the crystallizer; polymerization oil in the alkylate waste sulfuric acid is subjected to floatation and extraction in reaction and floatation integrated equipment to obtain polymerization oil; the normal-pressure saturated ammonium sulfate mother solution crystallized in the crystallizer returns the reaction flotation tower through the mother solution circulation pump; generated crystals are extracted to serve as ammonium sulfate crystals; the normal-pressure steam generated in the crystallizer is condensed through the heat exchanger and then returns to the reaction flotation tower through the condensate pump; condensation water generated in the outer jacket of the crystallizer returns to the reaction flotation tower through the condensate pump. The method process is simplified, the operation time is shortened, and the method is environmentally friendly.

Owner:TIANJIN RUYOU TECH CO LTD

Magnesium alloy chemical nickel plating solution and electroplating pretreatment method

InactiveCN101435077BImprove bindingWith metallic lusterLiquid/solution decomposition chemical coatingNickel saltPretreatment method

The invention provides a magnesium alloy chemical nickel plating solution, which contains water, nickel salt, a reducing agent and a compounding agent; wherein, the nickel plating solution also contains cerium nitrate. The invention also provides a magnesium alloy electroplating pretreating method, which comprises the following steps: under the chemical nickel plating condition, the magnesium alloy and the chemical nickel plating solution are contacted; wherein, the chemical nickel plating solution is the one provided by the invention. In the chemical nickel plating solution provided by the invention, as the cerium nitrate is added, the binding force of a base material and a plating layer is obviously increased. The magnesium alloy electroplating pretreating method provided by the invention has simple technique, convenient operation, little pollution to the environment, high binding force of the base material and the plating layer, smooth and beautiful workpiece surfaces, low cost andhigh economic benefit.

Owner:BYD CO LTD

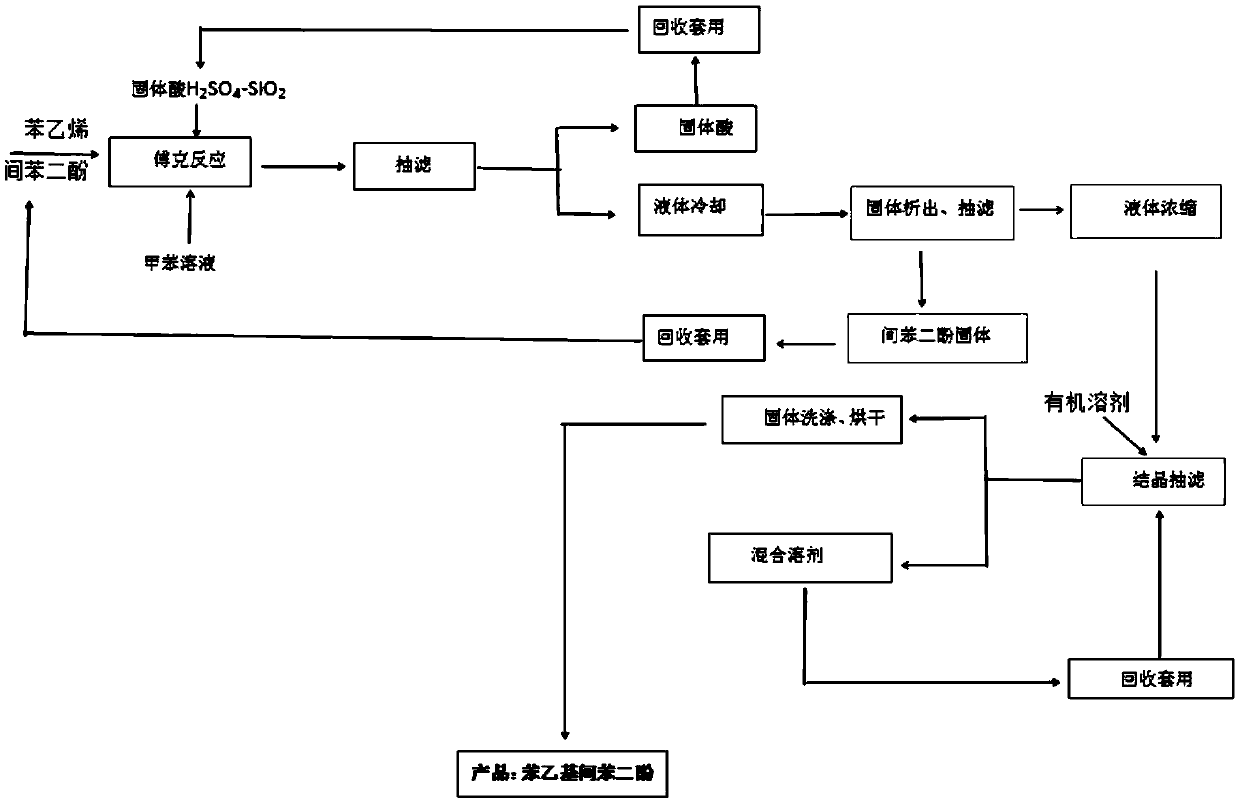

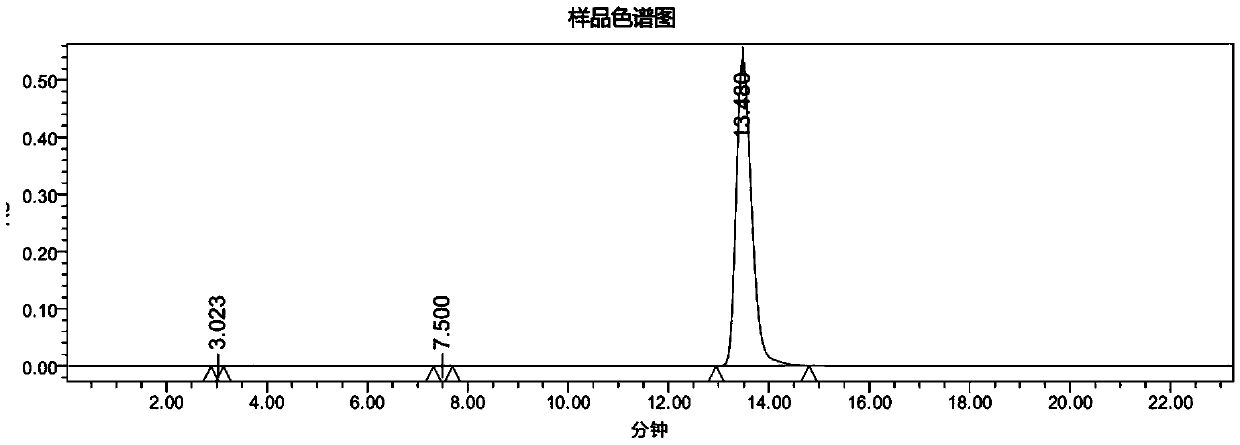

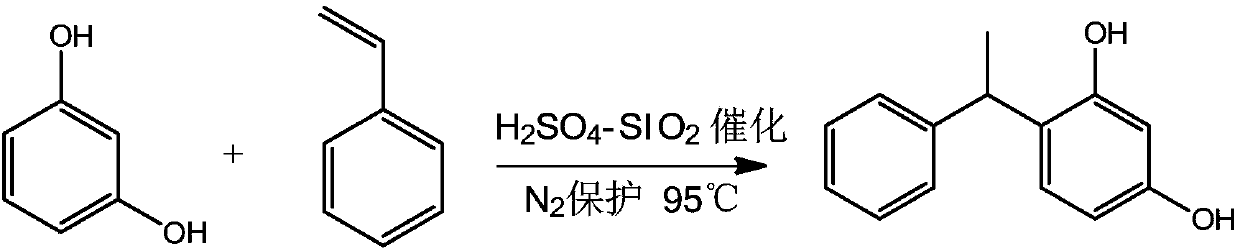

Method for industrially preparing phenethyl resorcinol based on H2SO4-SiO2 solid acid catalyst

InactiveCN109534960AReduce manufacturing costShort reaction timeOrganic chemistryOrganic compound preparationOrganic solventSolid acid

The invention discloses a method for industrially preparing phenethyl resorcinol based on an H2SO4-SiO2 solid acid catalyst. The phenylethyl resorcinol is synthesized in one step under the catalysis of the high-efficiency solid acid H2SO4-SiO2. The method can be applied to industrial production to achieve high-efficiency production of the phenethyl resorcinol, and can recycle and reuse a resorcinol raw material and an organic solvent under the condition of meeting the advantages of the high-efficiency catalyst in order to achieve the purposes of simplifying the process route and reducing the environmental protection pressure.

Owner:LIAONING UNIVERSITY

Method for extracting gold from refractory sulfide ore gold concentrate by two-stage pressurized oxygen leaching

InactiveCN101876005BDoes not affect the leaching rateReduce consumptionProcess efficiency improvementIron sulfateSlag

The invention relates to a method for extracting aurum from difficult-to-handle sulphide ore aurum concentrate by two-segment pressurization leaching method comprising two segments of pressurization oxidation preprocessing and pressurization oxidation aurum leaching. The method comprises the steps of: firstly, pressurizing and oxidizing base metal sulfide such as iron sulfide with sulfuric acid-iron sulfate, wherein most S2- and S22- are oxidized into elemental sulfur; and secondly, pressurizing and leaching the preprocessed slag with thiocyanate so that aurum is selectively dissolved in the solution in the form of aurum-thiocyanic acid compound. Therefore, the pre-oxidation slag can be directly leached without neutralization, the technical process is short, the aurum recovery rate is high, the cost is low and pollution of low-concentration SO2 smoke gas, As2O3 smoke dust, and the like is avoided.

Owner:CENT SOUTH UNIV

A method for preparing cellulose acetate butyrate with high butyryl content

ActiveCN106632697BAvoid strong corrosiveOvercome the problem that hydrolysis into butyric acid cannot be recycledAcetic acidCellulose

The invention discloses a method for preparing cellulose acetate butyrate with high butyryl group content, which comprises the following steps: After the crushed cellulose is activated with acetic acid, under the catalysis of sulfuric acid, transesterification occurs with alkyl butyrate to generate high butyrate For cellulose acetate butyrate with acyl group content, the alcohol produced by rectification during the transesterification reaction promotes the positive reaction. In the cellulose acetate butyrate prepared by the method, the acetyl group content is 1-2 wt%, and the butyryl group content is 50-53 wt%. The invention adopts a non-corrosive esterification agent, the excess esterification agent can be recycled, greatly reduces the production cost, and is suitable for industrial production.

Owner:WANHUA CHEM GRP CO LTD

A kind of method of synthesizing p-tert-butylphenylpropionaldehyde

ActiveCN107954843BHigh selectivityAvoid strong corrosiveOrganic compound preparationPreparation from heterocyclic compoundsPtru catalystAcyl group

The invention discloses a method for synthesizing p-tert-butylphenylpropionaldehyde, which is carried out according to the following reaction formula: specifically, the steps are as follows: the unsaturated aldehyde is generated by the Claisen-Schmidt condensation reaction of formula I under alkaline conditions And the step of obtaining formula II; dissolving formula II in toluene and ethylene glycol under the action of a catalyst, fractionating water, and condensing to generate the step of formula III; dissolving formula III in a solvent, adding a catalyst, and feeding hydrogen under pressure Reducing the double bond to obtain the step of formula IV; hydrolyzing the acetal of formula IV into aldehyde under acidic conditions to obtain the step of formula V of p-tert-butylphenylpropionaldehyde. The method for synthesizing p-tert-butyl propionaldehyde of the present invention, compared with the prior art using Krafts acylation reaction, has mild conditions, strong selectivity of Claisen-Schmidt condensation reaction, high condensation unity, and avoids A large amount of highly corrosive titanium tetrachloride is used, causing serious pollution problems. The reaction synthesis of the invention has little pollution, simple aftertreatment, and meets the requirements of modern green production.

Owner:KUNSHAN YAXIANG SPICEL CO LTD

A kind of method for preparing cellulose acetate butyrate

The invention discloses a method for preparing cellulose acetate butyrate, which comprises the following steps: after dissolving pulverized cellulose in a solvent, alcoholysis reacts with acetonitrile and butyronitrile under the catalysis of concentrated sulfuric acid to generate cellulose acetate butyrate . In the cellulose acetate butyrate prepared by the method, the content of acetyl groups is 1-15wt%, and the content of butyryl groups is 35-53wt%. The invention adopts non-corrosive esterification agent and solvent, and the solvent NMMO aqueous solution can be recycled and reused after being concentrated, which greatly reduces the production cost and is suitable for industrial production.

Owner:WANHUA CHEM GRP CO LTD

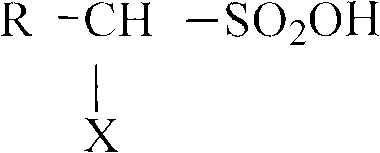

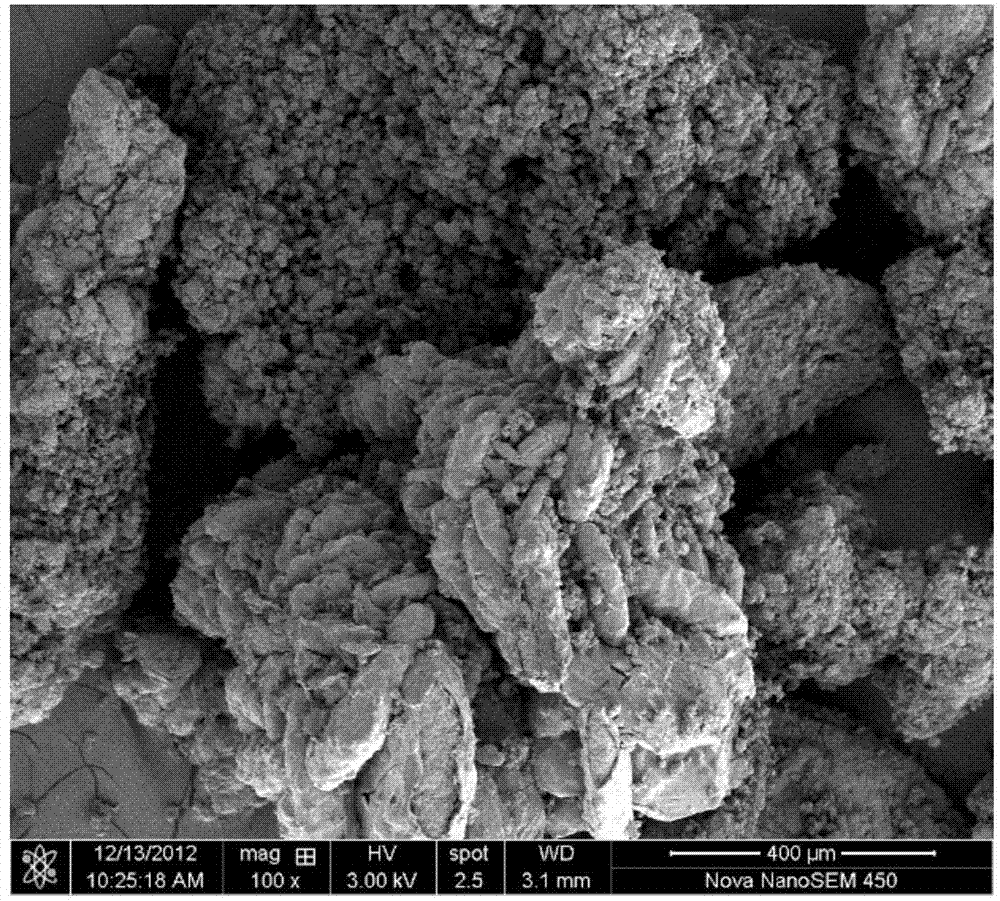

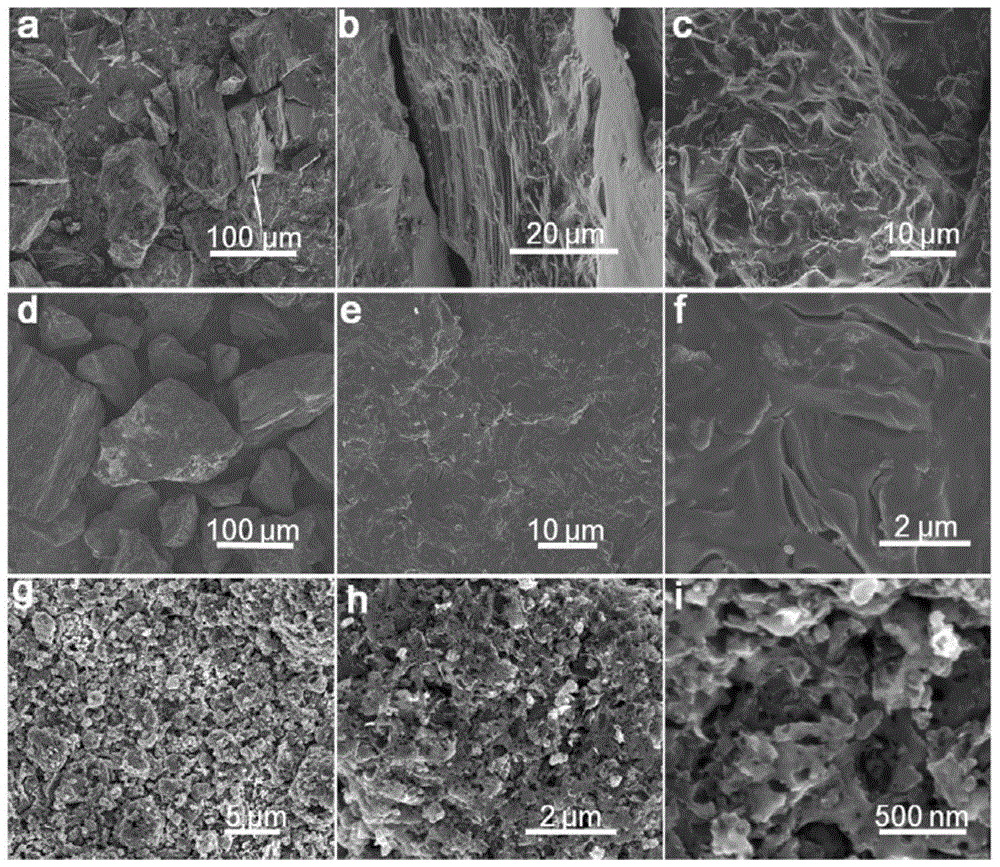

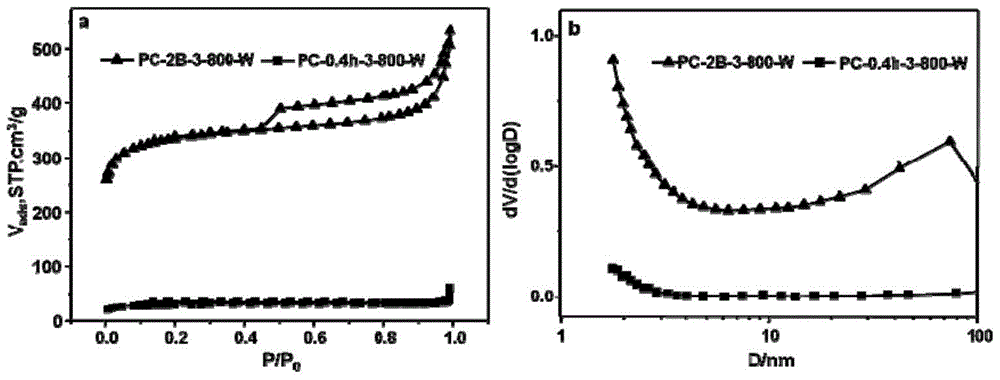

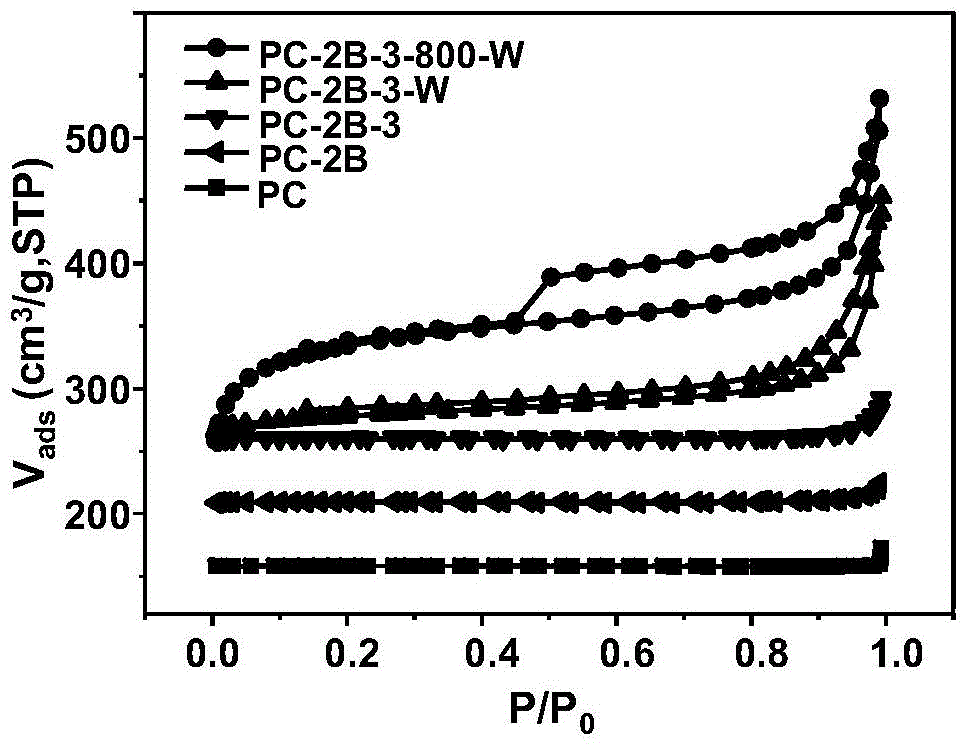

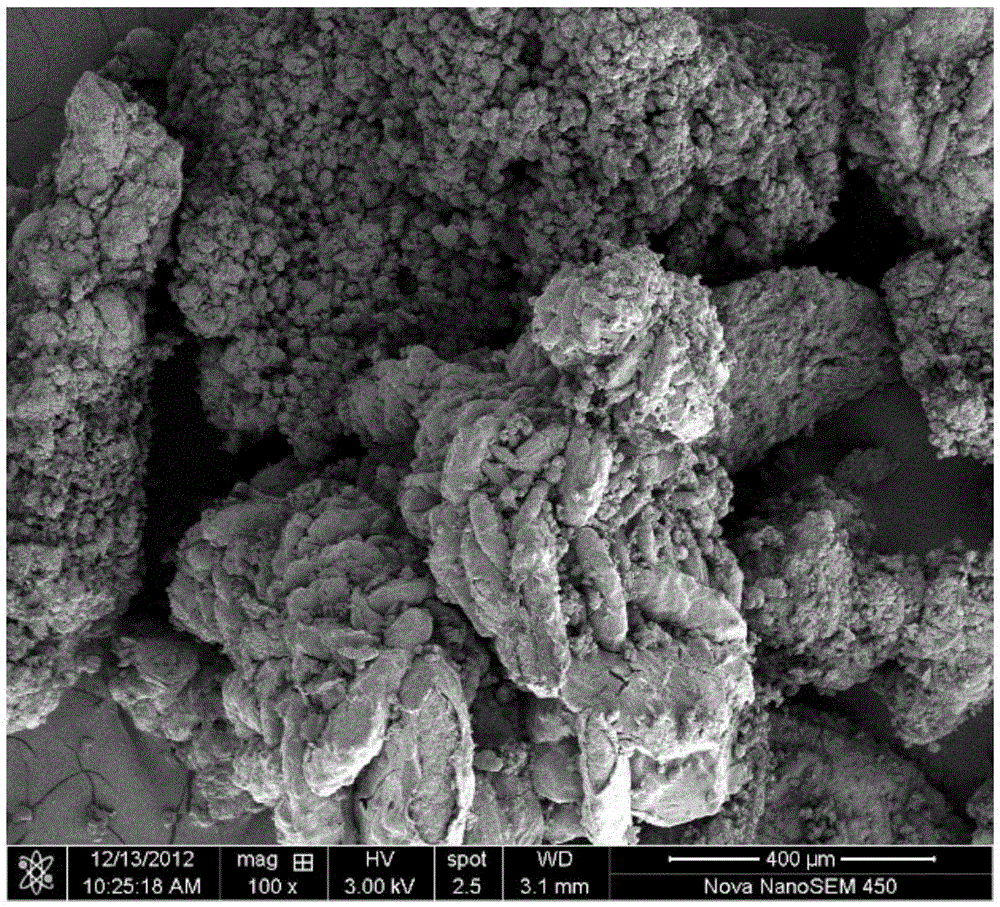

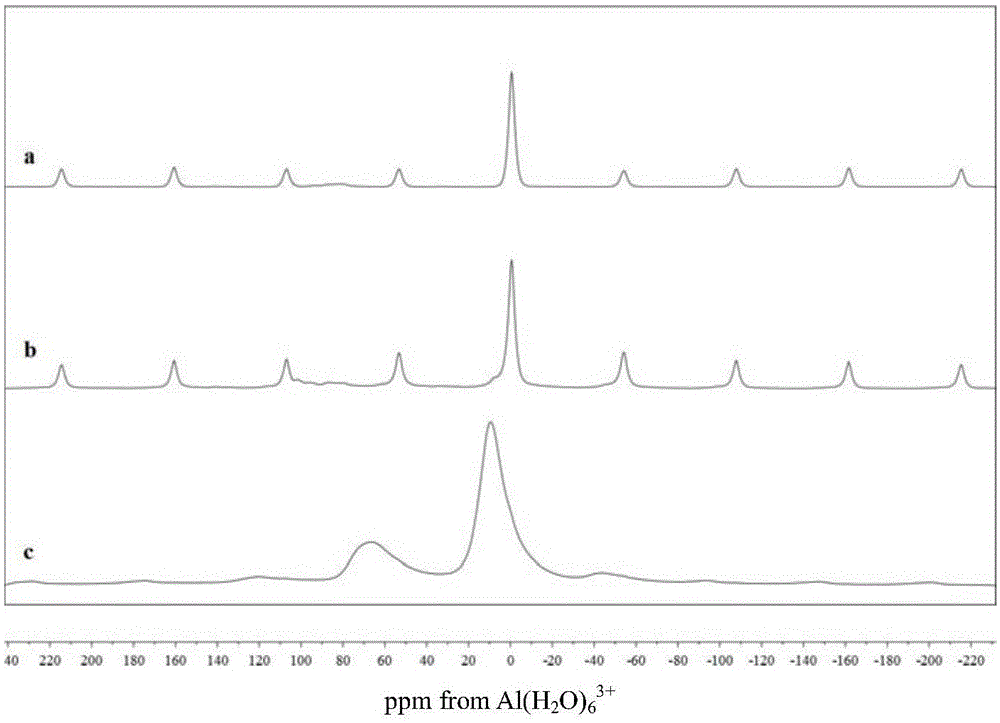

A kind of activated carbon with graded pores and preparation method thereof

ActiveCN104843704BHigh specific capacityImprove power characteristicsCarbon compoundsActivation methodPotassium hydroxide

The invention relates to an activated carbon comprising a hierarchical hole channel structure and a production method thereof and belongs to the novel carbon material production field. The production method is based on the activation of the mechanical force auxiliary potassium carbonate on heavy carbon sources such as petroleum coke, coal, or phenolic resin. The production method comprises the specific steps of mixing the screened heavy carbon source powder with the potassium carbonate and obtaining the activated carbon for a super capacitor through the ball-milling, activation, washing and drying process. According to the activated carbon comprising the hierarchical hole channel structure and the production method thereof, the activated carbon is large in specific surface area, is of a hierarchical hole channel structure, and the like; the technical route that the potassium carbonate serves as a pore forming agent to produce the activated carbon is implemented and the problem that raw materials such as the petroleum coke and the coal cannot be activated by the potassium carbonate is solved; compared with potassium hydroxide and other activation methods, the corrosion is low, the adaptability to the raw materials is high, the specific surface area is large, the mesoporous pore capacity is large, the enlargement is easy, and the like; the novel activated carbon can be widely applied to the adsorption, catalysis, electrochemical energy storage and other fields and accordingly the application prospect is wide.

Owner:DALIAN UNIV OF TECH

Biological oil removing agent for permanent-magnet materials

ActiveCN102040947BAvoid strong corrosiveAvoid the defect of not being able to completely degrease and degreaseOther chemical processesMagnetic materialsDiluentPhosphoric acid

The invention relates to a biological oil removing agent for permanent-magnet materials. The biological oil removing agent is prepared according to the following steps: diluting the biological oil removing agent with water in the volume ratio of 1:(19-99) to obtain a diluent; and regulating the pH value of the diluent to 6.0-9.0 by using two of phosphoric acid, citric acid, sodium citrate and trisodium phosphate, and keeping the temperature of the diluent at 10-40 DEG C for later use. The biological oil removing agent can be used for thoroughly removing oil stains in the permanent-magnet material under the condition of mild pH value without generating substances harmful to the environment. The biological oil removing agent is environment-friendly. Meanwhile, microbes in the biological oil removing agent are cheap and are easy to obtain, and the biological oil removing agent has strong continuous oil removal capability, therefore, the oil removal cost can be greatly lowered by using the biological oil removing agent.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

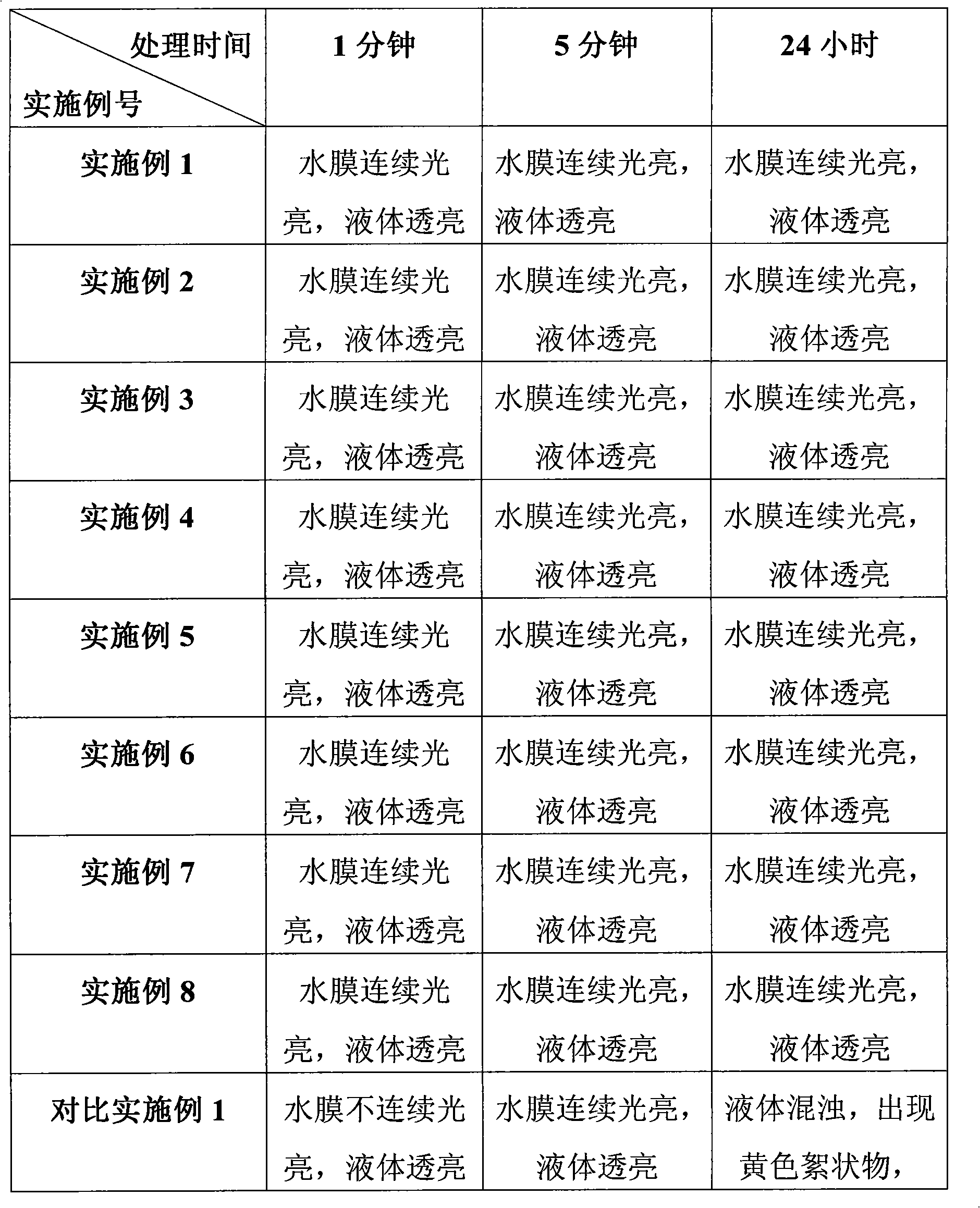

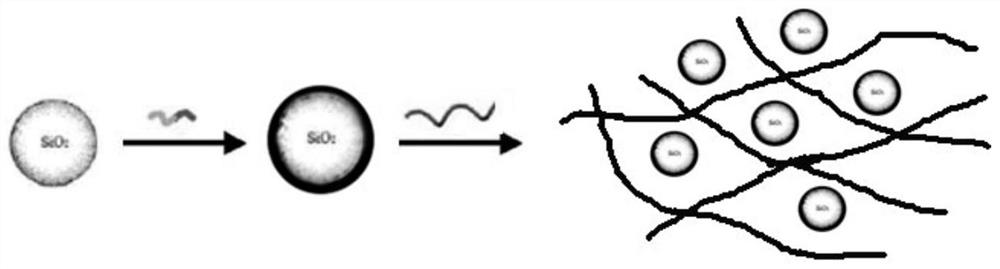

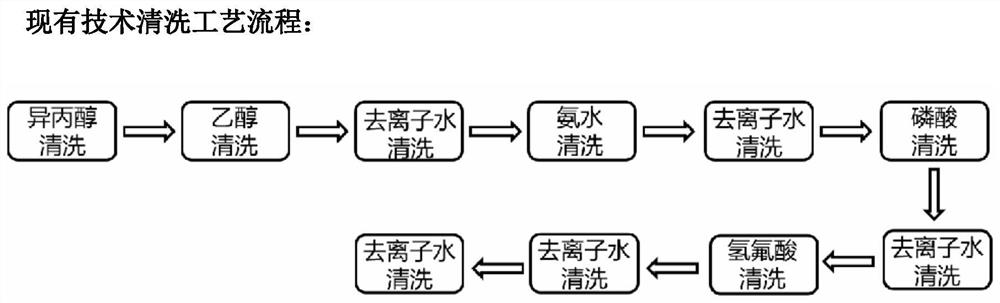

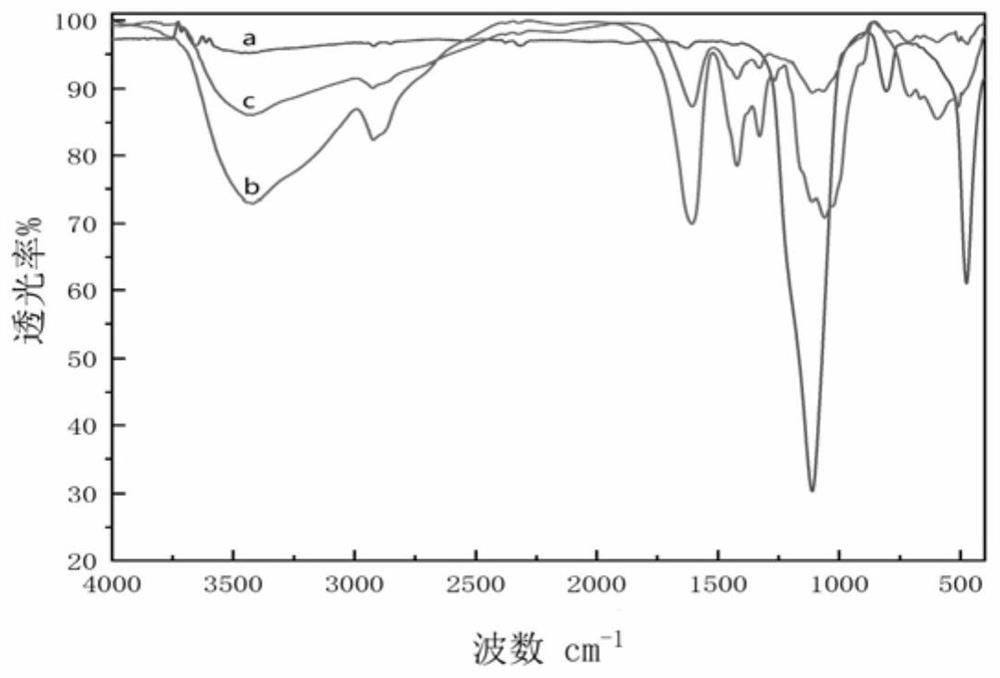

Nanometer colloid particle, preparation method, cleaning agent containing nanometer colloid particle and cleaning method

ActiveCN114292707AUnique structureImprove stabilityInorganic/elemental detergent compounding agentsMaterial nanotechnologyActive agentSurface-active agents

The invention provides a nanometer colloid particle, a preparation method and application thereof, a cleaning agent containing the nanometer colloid particle, a preparation method of the cleaning agent, a cleaning method of the cleaning agent and the like, and the nanometer colloid particle comprises nanometer silicon dioxide, a colloid stabilizer and a silicon dioxide adsorbent. The cleaning agent comprises the nano colloid particles, a pH regulator, a surfactant, a wetting agent and ultrapure water. The nano colloid particle has excellent stability and cleaning effect, is especially suitable for cleaning hard and brittle material surfaces such as silicon wafers, sapphire substrates, optical glass, gallium arsenide substrates, precision ceramics and the like, and has wide application prospects and substitution potential.

Owner:ZHEJIANG AUFIRST MATERIAL TECH CO LTD

A kind of high loading capacity aluminum chloride catalyst and its preparation method and application

InactiveCN103706382BAvoid strong corrosiveImprove efficiencyCatalyst carriersOrganic compound preparationAluminium chlorideCCL4

The invention discloses an aluminium chloride catalyst with a high load capacity, a preparation method and applications thereof. The preparation method comprises the following steps: grinding ball-shaped active aluminium oxide, selecting aluminium oxide fine particle with a particle size of 60 to 100 meshes as the carrier of the supported aluminium chloride catalyst, subjecting dry CCl4 to carry out reactions with gamma-Al2O3 so as to obtain fresh AlCl3 steam, then using inert gas to carry the fresh AlCl3 steam, and making the fresh AlCl3 steam carry out immobilization reactions with hydroxyl groups on the surface of the aluminium oxide carrier so as to obtain the aluminium chloride catalyst with a high load capacity, wherein the AlClx content is 56 to 72 wt%, and the x is equal to 2.2 to 2.5. The supported aluminium chloride catalyst overcomes the strong corrosivity of aluminium chloride; the load capacity of the catalyst is increased, and the catalyzing efficiency of the catalyst is increased at the same time; and the problems of difficult stirring and material waste because of the large amount of reactants due to low catalyst active group concentration are solved. The catalyst can be used to catalyze the carboxylation reactions between toluene and CO2, the separation yield can reach 73.34% by taking AlClx as the baseline, and the catalyst has a high catalytic activity.

Owner:EAST CHINA UNIV OF SCI & TECH

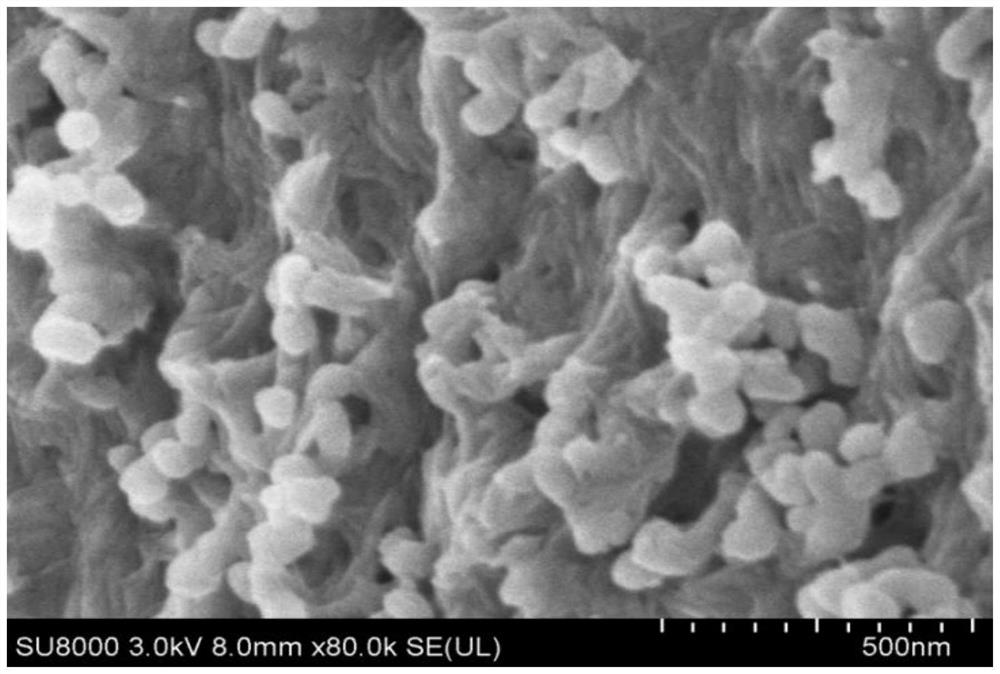

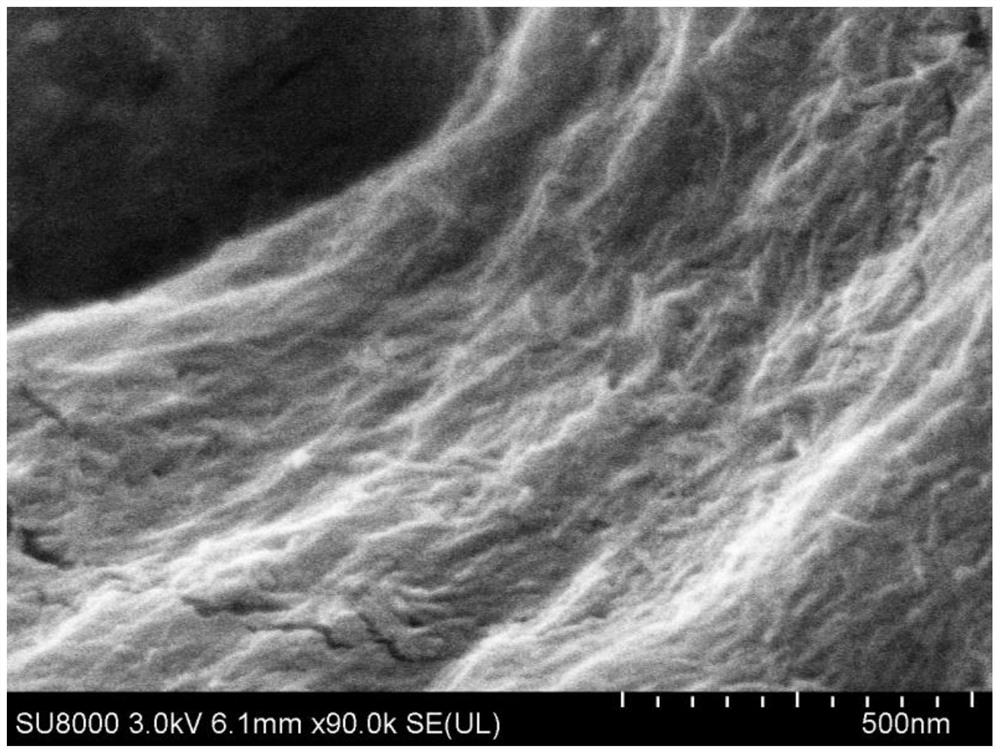

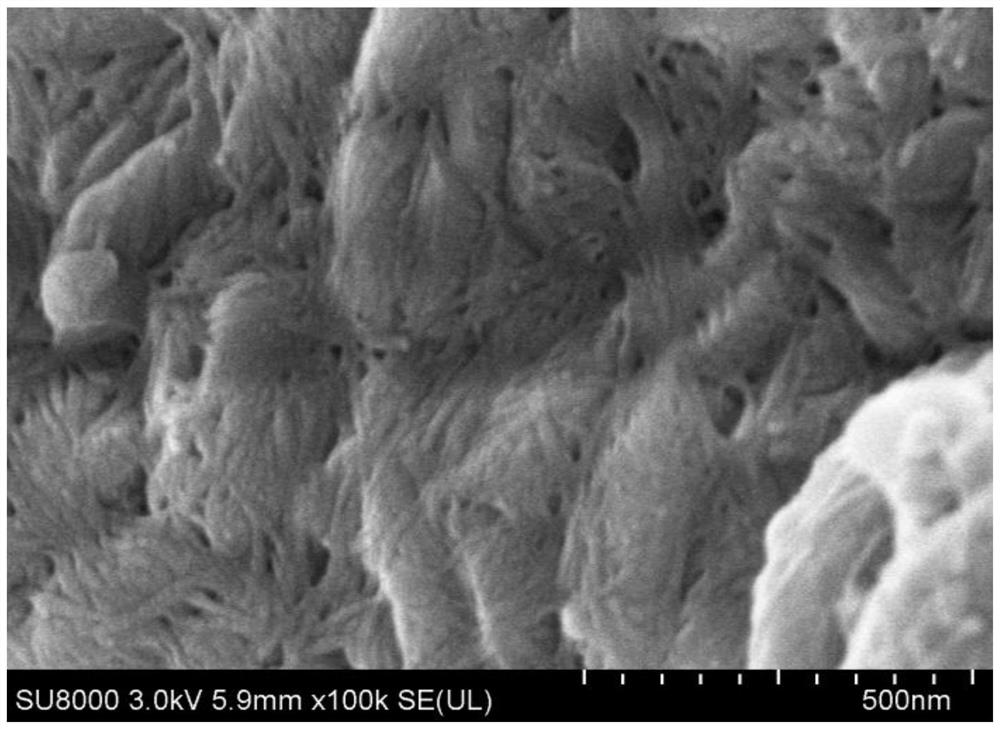

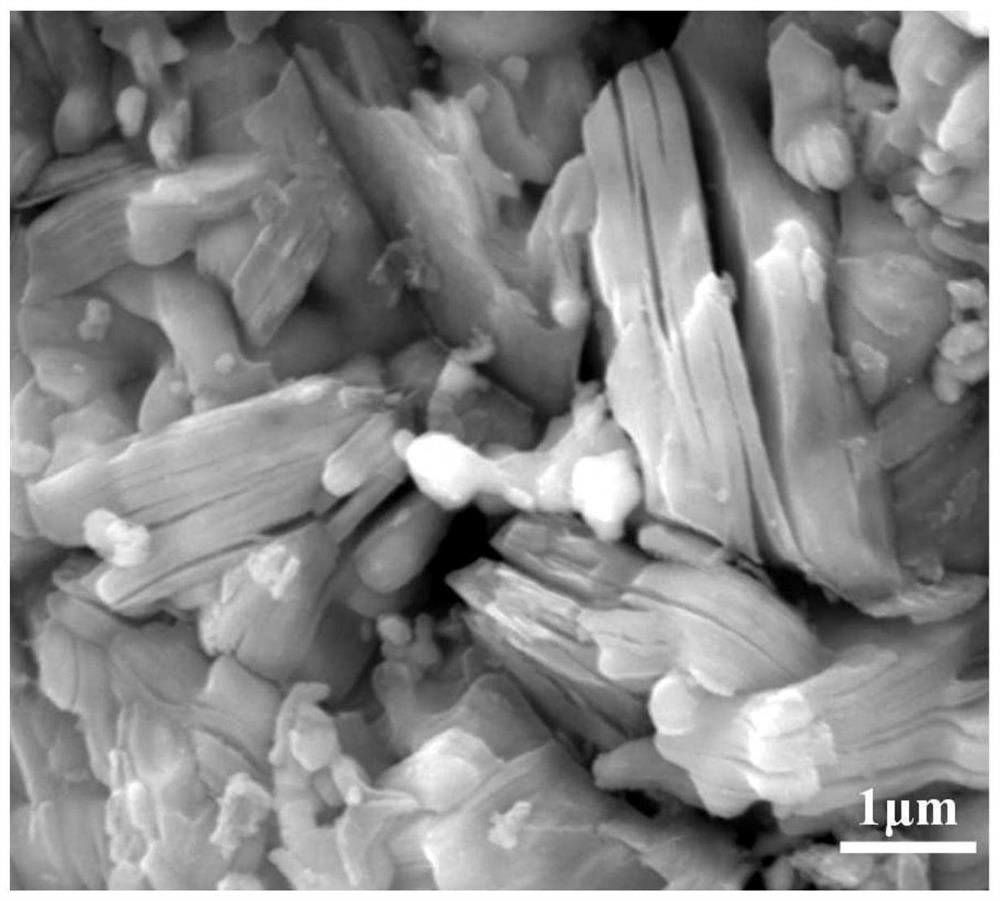

Green and efficient preparation method of titanium carbide Mxene nanosheet

ActiveCN113620294AIncrease productivityThe preparation process is green and controllableMaterial nanotechnologyTitanium carbideFreeze-dryingPhysical chemistry

The invention discloses a green and efficient preparation method of a titanium carbide Mxene nanosheet, and belongs to the technical field of preparation of inorganic nano materials. The invention aims to solve the problem that the existing Ti < 3 > C < 2 > T < x > Mxene material has extremely strong corrosivity and toxicity in the preparation process. The method comprises the following steps: 1, preparing powder A; 2, preparing powder B; 3, preparing powder C; 4, transferring the powder C, an intercalator and deionized water into an electrolytic tank, preheating, and stripping intercalation; and 5, washing the product, and carrying out vacuum freeze drying to obtain the Ti < 3 > C < 2 > T < x > Mxene nanosheet. According to the method, NiCl2. 6H2O is used for removing an Al atomic layer of a Ti3AlC2 phase, ferric chloride is used for removing the generated nickel elementary substance, a green and environment-friendly intercalation agent is used for further stripping the Ti3C2Tx Mxene material, the material is successfully constructed, the preparation process is green and controllable, and the production efficiency is high. The Ti < 3 > C < 2 > T < x > Mxene nanosheet prepared by the preparation method disclosed by the invention is used as a non-metal nano material.

Owner:HARBIN INST OF TECH AT WEIHAI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com