Method and apparatus for reclaiming water soluble fusing waste

A molten and water-soluble technology, which is applied in the field of effective recovery of water-soluble molten waste, can solve the problem of environmental pollution caused by discharged waste liquid, and achieve the effect of avoiding strong corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

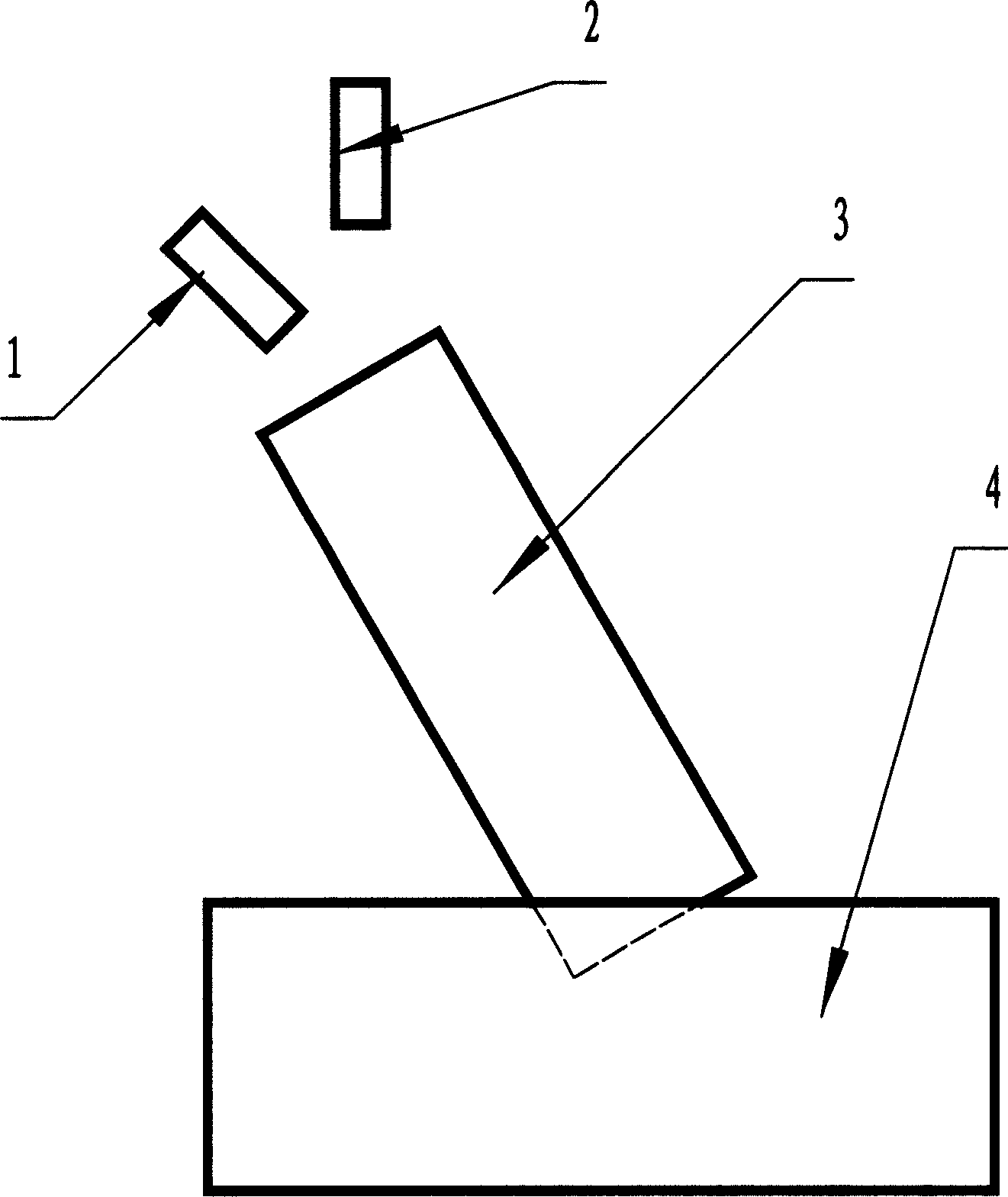

Image

Examples

Embodiment 1

[0014] Recovery of sodium carbonate: the by-product of the production of cyclohexanone - the sodium salt of organic acid is incinerated and the molten sodium carbonate waste falls into the bottom of the furnace. When the molten sodium carbonate waste flows downward from the inlet of the water tank to the diversion barrel, the molten sodium carbonate waste is crushed by a high-pressure air-water combined jet, and the crushed molten waste alkali falls into the water in the lower part of the diversion barrel It is sent to solid-liquid separation equipment (such as scraper conveyor) through the diversion barrel. When the solution reaches saturation, the crushed sodium carbonate is no longer soluble in water and settles to the bottom of the solid-liquid separation equipment. Sodium carbonate granules are fished out through this equipment, and recovered granules of sodium carbonate can be obtained after drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com