Non-halogen active agent for scaling powder

A technology of activator and flux, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problem of not being able to use varieties with high performance requirements, achieve a wide range of applications, and overcome the effect of low activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

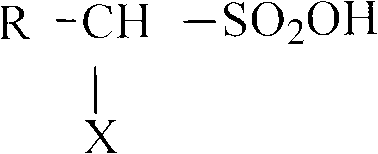

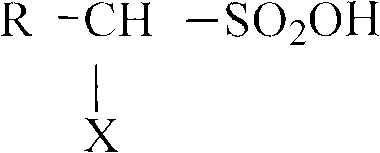

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: Application in no-cleaning liquid flux

[0024] The proportions by weight of the formula are as follows: 95% of isopropanol, 3% of diethylene glycol monomethyl ether, 1.5% of succinic acid, and 0.5% of diphenylguanidine methanedisulfonate. After stirring and dissolving completely, a colorless transparent liquid flux is obtained. At 250°C, it can quickly diffuse on the metal liquid surface of an alloy of 99.3% tin and 0.7% copper, react quickly with tin-copper oxide on the liquid surface, and has a good fluxing effect. At room temperature, the flux will not chemically corrode copper and tin substrates. In the wave soldering production line, after the soldering of electronic products, the insulation resistance of the PCB board surface reaches 1×10 13 More than Ω, it has good electrical properties.

Embodiment 2

[0025] Embodiment 2: Application in tin wire containing solid flux

[0026] The proportion by weight of the formula is as follows: 95% of rosin, 3% of ethylene glycol monophenyl ether, and 2% of imidazolium methanedisulfonate. After heating, roasting and dispersing completely, a transparent light yellow solid soldering flux is obtained. In the production of tin wires, the content of the flux extruded in the tin wires is controlled between 2.8% and 3.0%, and the tin wires are made of an alloy of Sn99.3% and Cu0.7%. The finished tin wire has good wettability on copper foil, bright solder joints and transparent residue. In the process of use, there is no odor, no rosin splash, good soldering effect, and the insulation resistance of tin wire residue reaches 1×10 13 Ω or more.

Embodiment 3

[0027] Embodiment 3: Application in flux paste

[0028] The proportions by weight of the formula are as follows: 50% of rosin, 40% of diethylene glycol monobutyl ether, 5% of stearic acid amide, and 5% of guanidine methanedisulfonate. After heating, melting and dispersing completely, a translucent light yellow paste soldering flux is obtained. Tin powder with metal components of Sn96.5%, Ag3.0%, and Cu0.5% is selected, and the diameter of the tin powder is between 25 microns and 45 microns. Solder paste is obtained by mixing 90% tin powder and 10% solder flux and stirring and miscible with each other. The solder paste has a good printing effect, and can be heated to obtain full and bright solder joints on the pads of copper, tin and nickel substrates. The insulation resistance of solder joint residue reaches 1×10 13 Ω, the solder joints will not be corroded and blackened after 6 months at room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impedance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com