An electrochemical hydrogenation device and method

A hydrogenation device and electrochemical technology, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physicochemical processes, etc., can solve problems such as difficult product separation, excessive cathode water, and insufficient anode water. Achieve the effects of solving insufficient product yields, improving reaction efficiency, and solving product inhibition problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

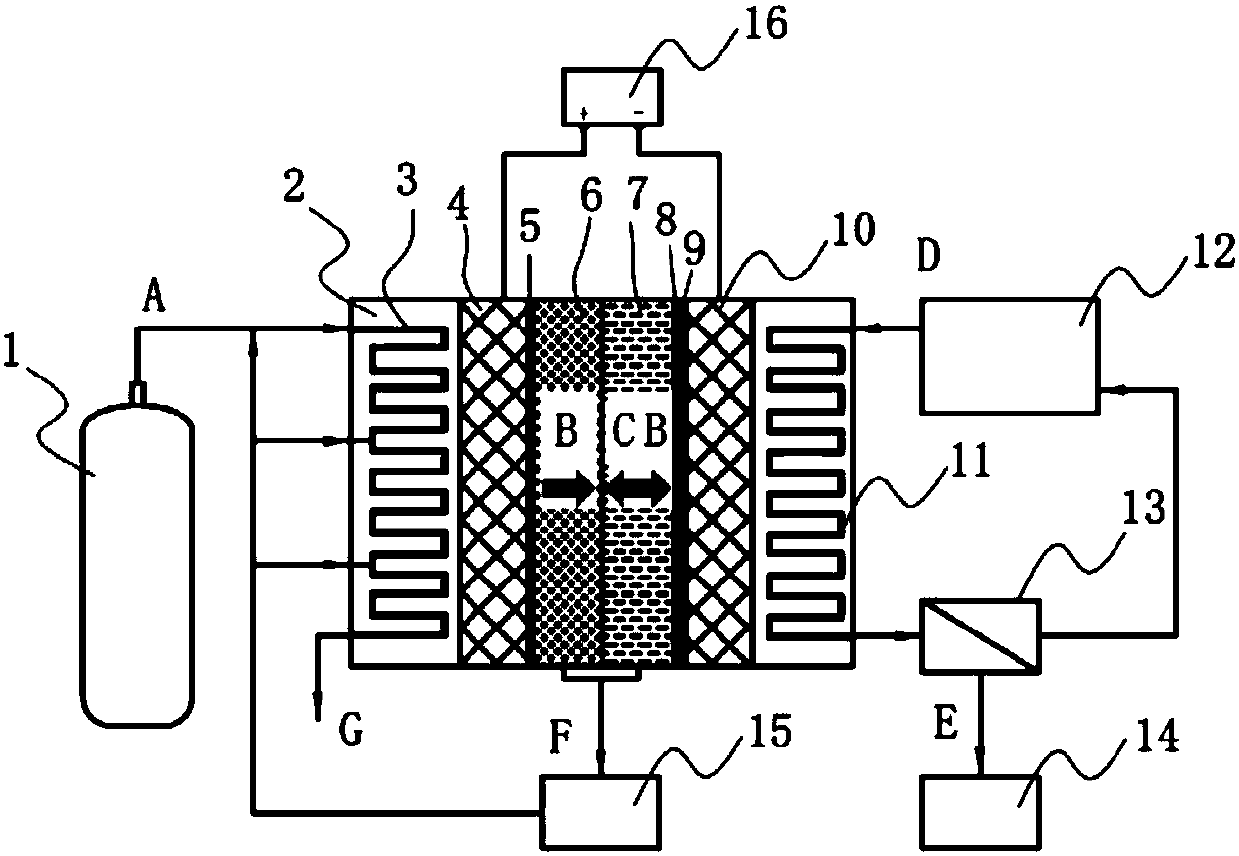

[0069] like figure 1 As shown, an electrochemical hydrogenation device, the device includes: a hydrogen storage tank 1, a reactor shell 2, a hydrogen flow channel 3, a hydrogen diffusion layer 4, a hydrogen dissociation catalytic layer 5, a cationic electrolyte membrane layer 6, an anion Electrolyte membrane layer 7, water dissociation catalytic layer 8, hydrogenation catalytic layer 9, hydrogenation diffusion layer 10, hydrogenation reactant flow channel 11, hydrogenation reactant storage tank 12, product separator 13, hydrogenation product storage tank 14, Ultrasonic humidifier 15, power supply 16,

[0070]The outlet of the hydrogen storage tank 1 is connected to the inlet of the hydrogen flow channel 3, one side of the hydrogen flow channel 3 is connected to one side of the hydrogen diffusion layer 4, the other side of the hydrogen diffusion layer 4 is connected to the hydrogen dissociation catalytic layer 5, and the hydrogen dissociation catalytic layer 5 The other side i...

Embodiment 2

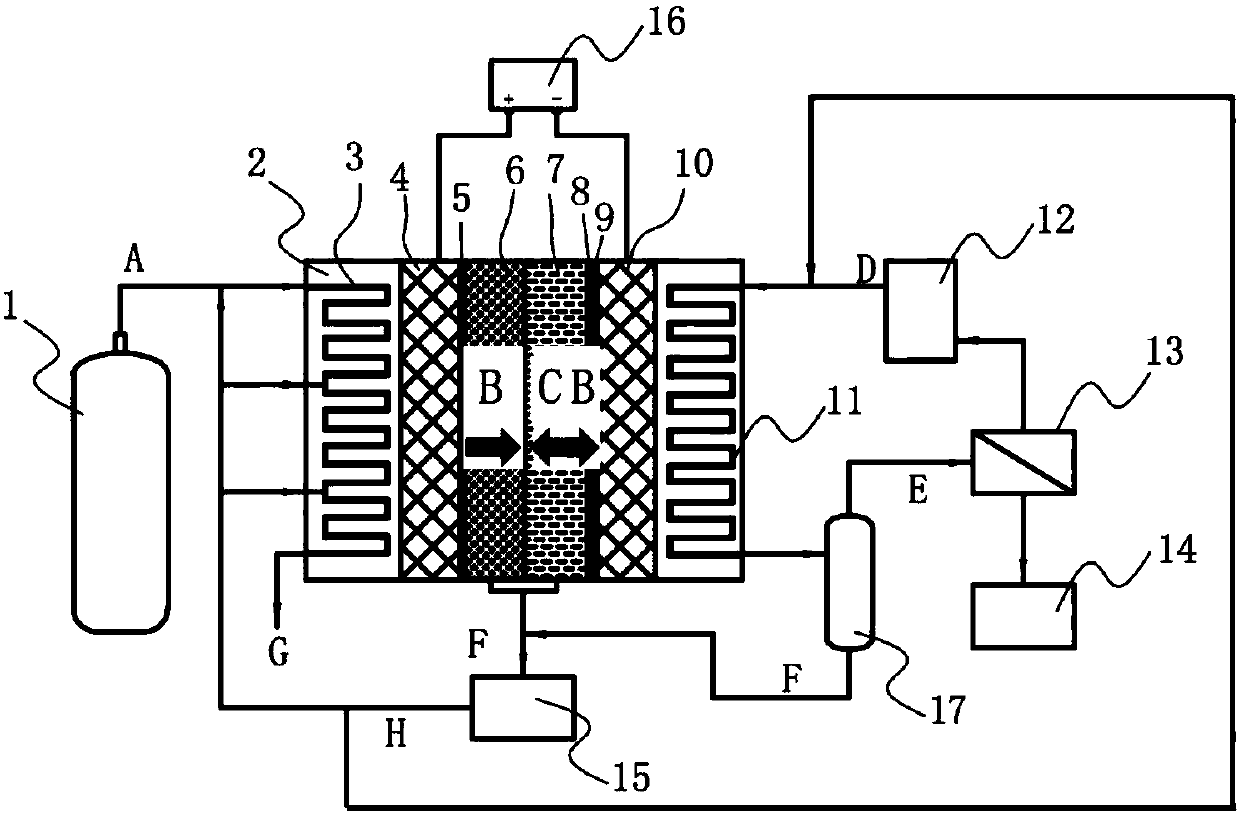

[0075] Such as figure 2 As shown, an electrochemical hydrogenation device, the device includes: a hydrogen storage tank 1, a reactor shell 2, a hydrogen flow channel 3, a hydrogen diffusion layer 4, a hydrogen dissociation catalytic layer 5, a cationic electrolyte membrane layer 6, an anion Electrolyte membrane layer 7, water dissociation catalytic layer 8, hydrogenation catalytic layer 9, hydrogenation diffusion layer 10, hydrogenation reactant flow channel 11, hydrogenation reactant storage tank 12, product separator 13, hydrogenation product storage tank 14, Ultrasonic humidifier 15, power supply 16, hydrogenation product separatory tank 17,

[0076] The outlet of the hydrogen storage tank 1 is connected to the inlet of the hydrogen flow channel 3, one side of the hydrogen flow channel 3 is connected to one side of the hydrogen diffusion layer 4, the other side of the hydrogen diffusion layer 4 is connected to the hydrogen dissociation catalytic layer 5, and the hydrogen d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com