Method for treating waste DMF in sucralose production

A technology of sucralose and a treatment method, which is applied in chemical instruments and methods, preparation of organic compounds, chemical industry and other directions, can solve the problems of reduced DMF recovery, accelerated DMF decomposition, and high catalyst consumption, and achieves the promotion of positive progress, The effect of improving yield and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

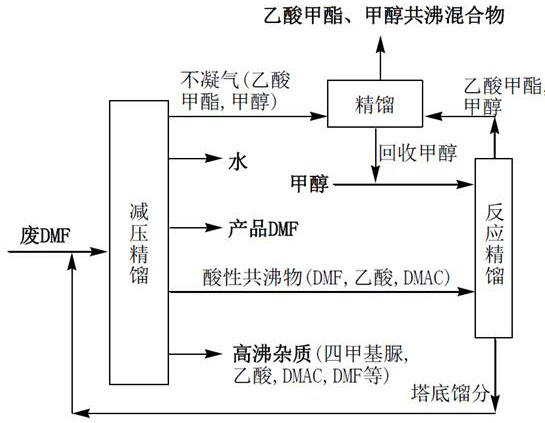

Image

Examples

Embodiment 1

[0022] In this embodiment, the vacuum rectification tower, the methanol rectification tower, and the reactive rectification tower all use single-column batch rectification, and the packing is 50 cm high, 4 cm in diameter, and filled with glass springs;

[0023] (1) Send 2500 mL of waste DMF (10% acetic acid, no more than 1% water, DMAC, and tetramethylurea, and the rest is DMF) discharged from the bottom of the deacidification tower in the sucralose DMF recovery section to vacuum distillation The tower is subjected to vacuum rectification, and the low-boiling impurities (methyl acetate, methanol) are distilled out under normal pressure. The temperature of the kettle remains unchanged, the pressure in the tower drops to 30 kPa, and the water is distilled out. The volume of low-boiling impurities and water is 21mL; Reduce the pressure to 7-9 kPa, control the top temperature of the vacuum distillation tower at 75-80°C to distill out a total of 1700 mL of product DMF (purity 99.8%)...

Embodiment 2

[0027] The bottoms of the reactive distillation tower in Example 1 are returned to the system to carry out rectification under reduced pressure again, and the specific operation steps are as follows:

[0028] Mix 1600mL of the bottom fraction of the reactive distillation tower and 1000mL of waste DMF discharged from the bottom of the deacidification tower and put it into the vacuum rectification tower, repeat the operation steps of Example 1 to obtain 130 mL of low-boiling impurities, which are combined into methanol and acetic acid Non-azeotropic mixture of methyl esters; distilled water 170 mL, product DMF 1750 mL (purity 99.72%), acidic azeotrope 650 mL, bottom liquid 70 mL.

[0029] The content (GC) of each step product of embodiment 2 is as follows:

[0030] Element Methyl acetate Methanol DMF DMAC Tetramethylurea Acetic acid retention time (min) 2.8 3.4 9.8 11.9 13.8 14.4 Waste DMF(%) 84.3 4.1 1.86 8.7 Reactive distillat...

Embodiment 3

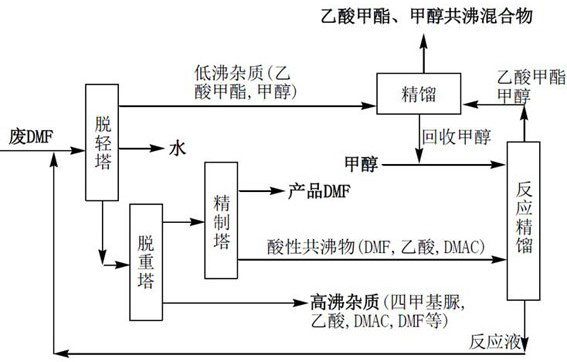

[0032] In this embodiment, the vacuum rectification tower, the methanol rectification tower, and the reactive distillation tower all adopt continuous rectification, and the vacuum rectification tower is replaced by a light removal tower, a weight removal tower and a refining tower connected in sequence. The specific process see process figure 2 :

[0033] (1) The waste DMF discharged from the bottom of the deacidification tower in the sucralose DMF recovery section (9% acetic acid, water, DMAC, and tetramethylurea do not exceed 1%, and the rest is DMF) is mixed with the bottom fraction of the reactive distillation tower after 0.9 m 3 The amount per hour is pumped into the middle of the light removal tower (the theoretical plate number of the light removal tower is 25, and the feed position is the 18th plate), and the top temperature of the light removal tower is controlled at 85°C, the pressure inside the tower is 30 kPa, and the top temperature is 85°C. The reflux ratio is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com