Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about How to "Eliminate residual internal stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

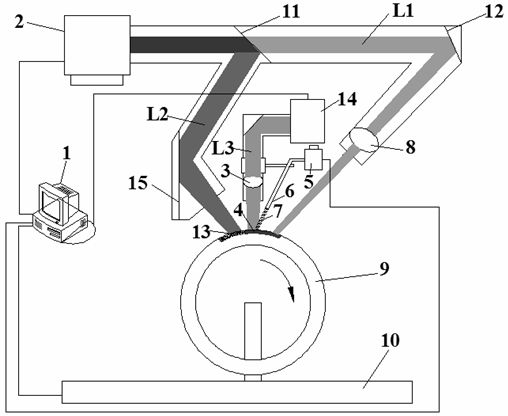

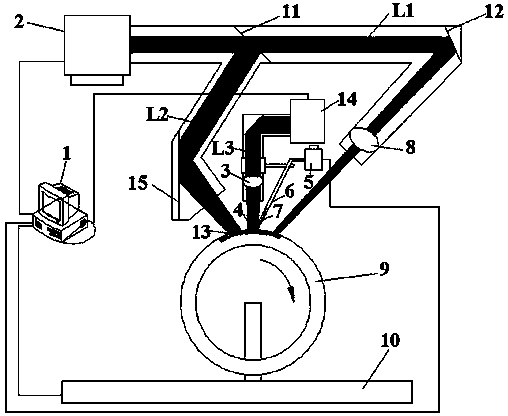

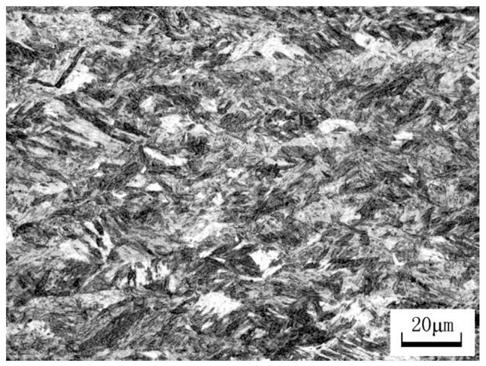

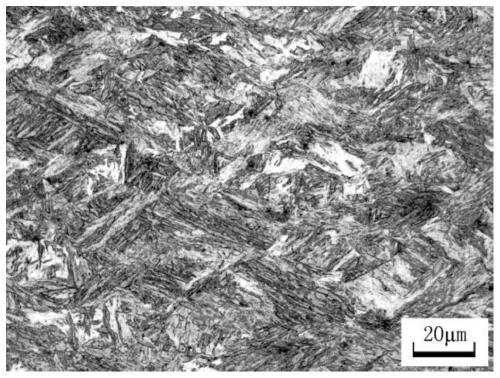

Method with functions of preheating and postheating for forming crack-free coating with high efficiency by three-light-beam laser-cladding technique

InactiveCN102383126ALow and adjustable dilution rateSmall heat affected zoneMetallic material coating processesLaser beam welding apparatusMelting tankHeat-affected zone

The invention discloses a method with functions of preheating and postheating for forming crack-free coating with high efficiency by a three-light-beam laser-cladding technique. The method comprises the following steps of: splitting a laser beam emitted by an Nd: YAG laser into two laser beams by using a laser beam splitter, namely a preheating laser beam for preheating the surface of a base material and a postheating laser beam for postheating the formed coating; then blowing alloy powder into a molten pool which is formed by focusing a laser beam emitted by a CO2 laser and acting the focused laser beam on the surface of the base material by using a powder nozzle, wherein after the CO2 laser beam moves away, a molten layer is cured and crystallized quickly to form the coating; and postheating the formed coating by adopting the postheating laser beam. The method has the advantages that: (1) the dilution rate of the coating is low and adjustable, and the coating is metallurgically combined with the base material, so the base material has a small thermal influence area and is deformation-free and crack-free; (2) residual inner stress in the coating can be eliminated effectively, a tissue can be improved, and the coating has high abrasion resistance, high corrosion resistance, high anti-cracking performance and high thermal shock resistance; and (3) relative to the processing efficiency in the conventional laser cladding technology, the processing efficiency in the method can be improved by 50 times to the maximum extent, so the processing cost is reduced greatly, and a large-scale industrialized application potential is realized.

Owner:NANCHANG HANGKONG UNIVERSITY

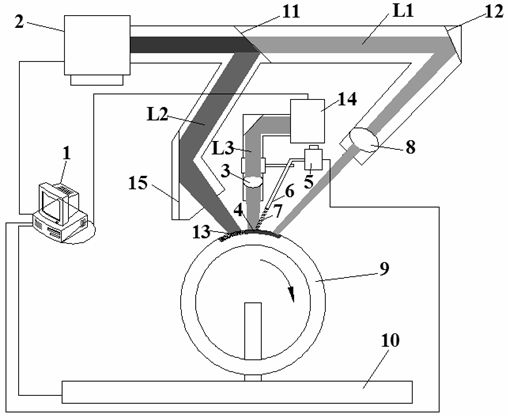

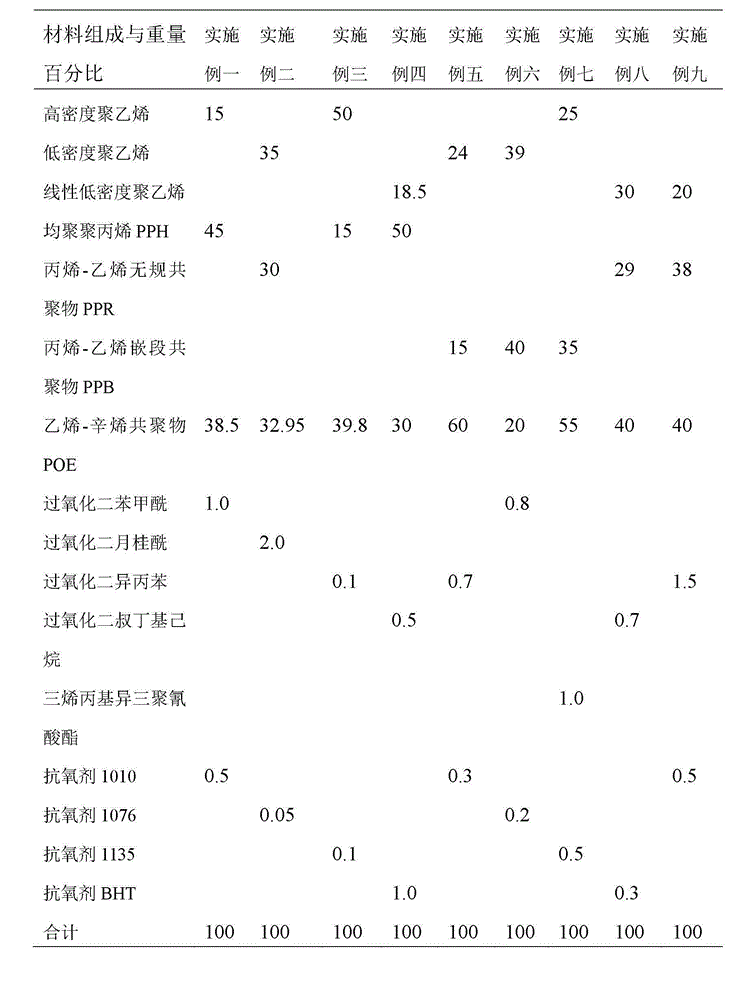

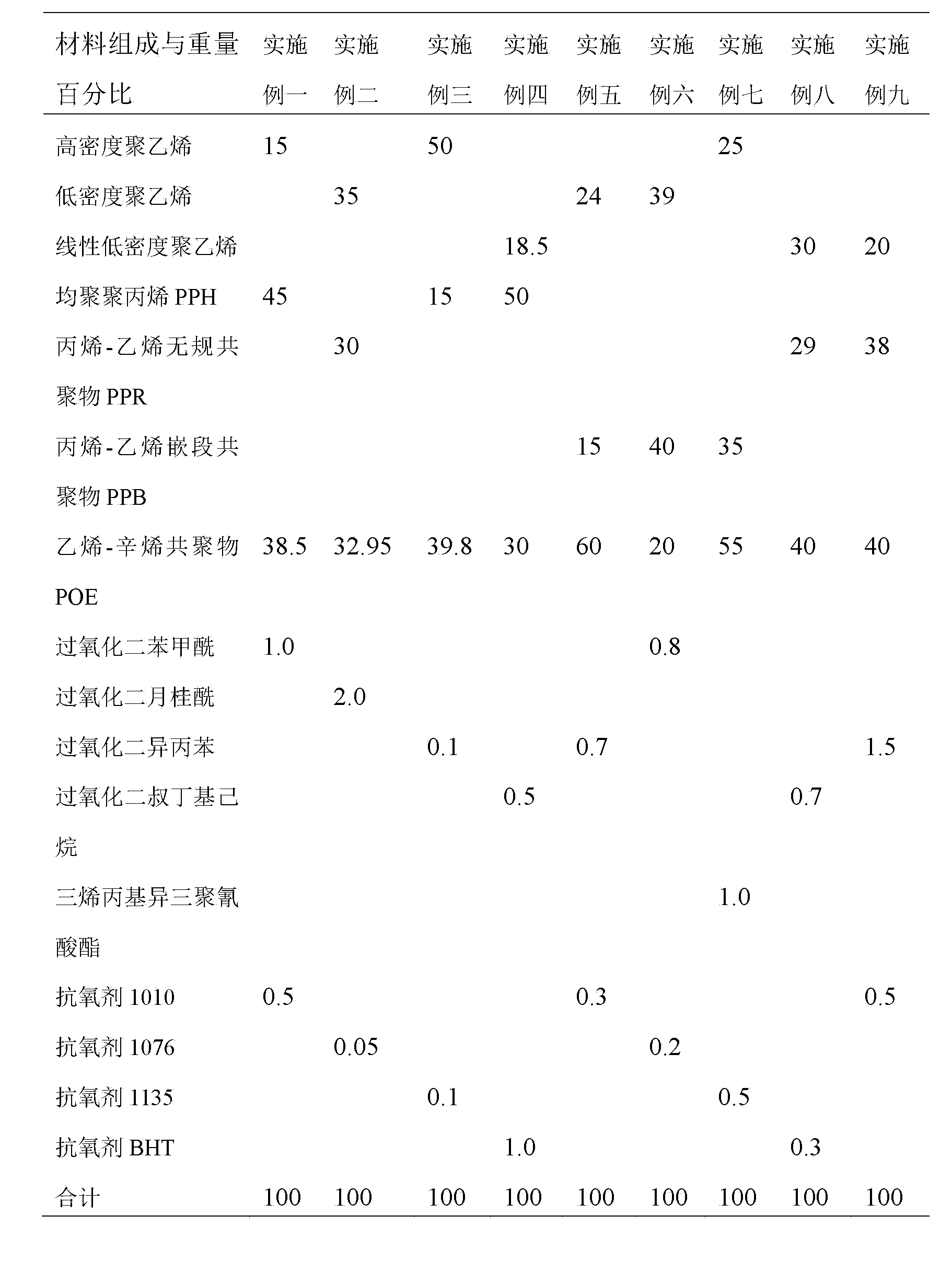

Polypropylene toughening modifying agent and polypropylene modified product thereof

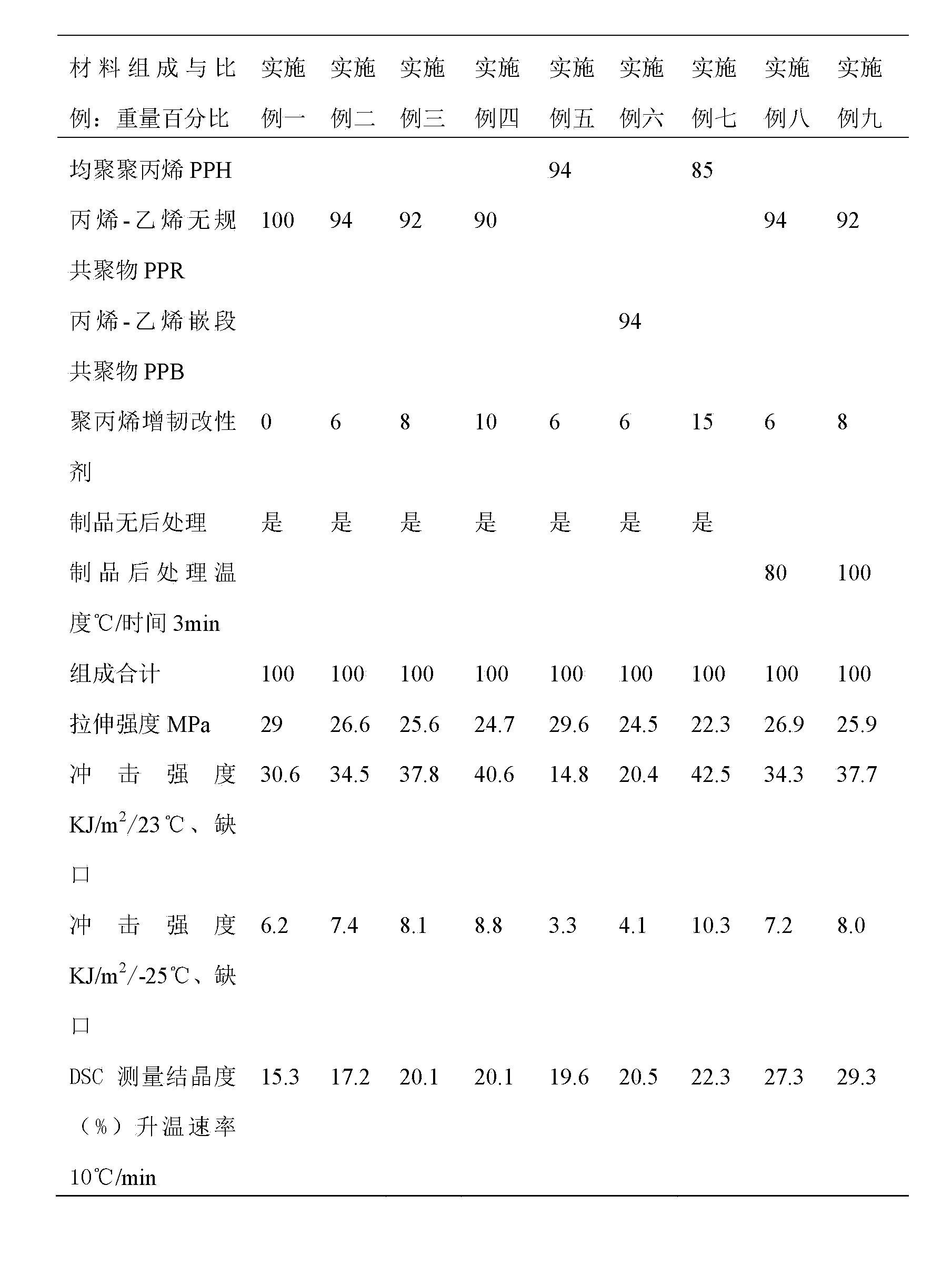

The invention discloses a polypropylene toughening modifying agent and a polypropylene modified product thereof. The polypropylene toughening modifying agent comprises the following components: 15-50 wt percent of polyethylene, 15-50 wt percent of polypropylene, 20-55 wt percent of ethylene / octene copolymer (POE), 0.1-2.0 wt percent of initiator and 0.05-1.0 wt percent of antioxidant. A polypropylene modified pipe and an injection molding product which are produced by adopting the polypropylene toughening modifying agent are produced by the steps as follows: 2-15 wt percent of the polypropylene toughening modifying agent and 85-98 wt percent of polypropylene resin are physically mixed, a proper amount of coloring agent is added, the polypropylene modified pipe is extruded on a single-screw pipe extruder, and the polypropylene modified product is injected-molded on an injection molding machine. The polypropylene modified product has an impact strength which is increased by 28-34.5 percent, the melting temperature which is raised by 1.5-1.8 DEG C, and the crystallinity which is increased by 26.7-35.2 percent. According to the invention, the slow secondary crystallization of the polypropylene modified product in a post-stage storage process can be effectively reduced, and the residual internal stress of the polypropylene modified product is greatly eliminated.

Owner:HUBEI UNIV OF TECH

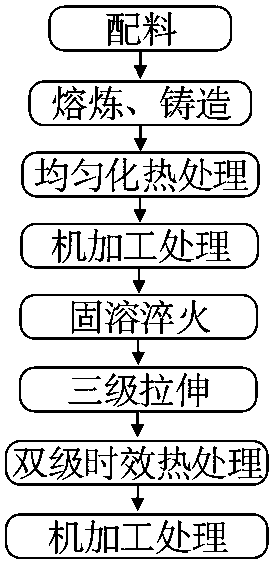

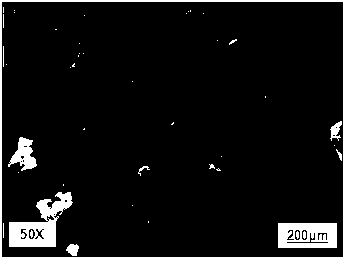

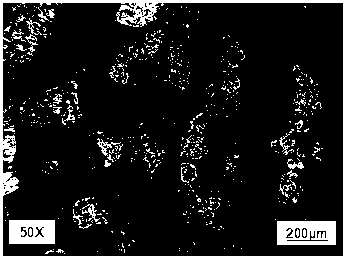

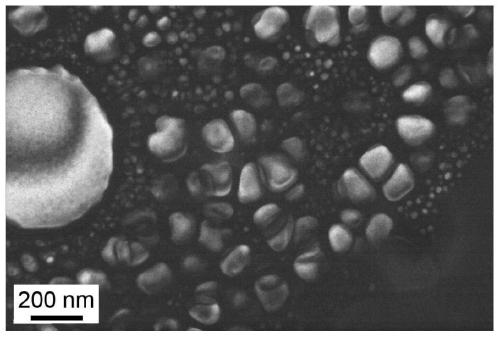

Preparation technology of high-strength aluminum alloy precision casting board

ActiveCN110699576AHigh strengthNot easy to process and deformMachining deformationUltimate tensile strength

The invention discloses a preparation technology of a high-strength aluminum alloy precision casting board and relates to the technical field of material machining. According to the technology, on thebasis of the original technology, the technology is optimized, the steps of solid-solution quenching, three-level stretching and double-stage aging heat treatment and reasonable step technology parameters are introduced, the new technology mainly comprising dosing, smelting, casting, homogenizing treatment, machining treatment, solid solution quenching, three-stage stretching, double-stage agingheat treatment and machining treatment is formed, the problem that when an existing technology is used, stress in the aluminum alloy precise casting board is released incompletely, machining deformation is generated, and the strength is insufficient, and by means of the technology, the high-strength aluminum alloy precision casting board which is not prone to machining deformation and high in strength can be obtained.

Owner:广西南南铝加工有限公司

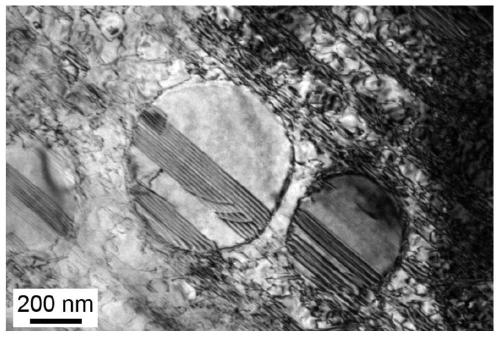

Nickle-cobalt based high temperature alloy turbine disk and preparation method thereof

ActiveCN111549259AHigh precisionHigh surface finishBlade accessoriesMachines/enginesSolution treatmentSurface preparation

The invention discloses a nickle-cobalt based high temperature alloy turbine disk and a preparation method thereof. According to the technical scheme, the surface layer of the nickle-cobalt based hightemperature alloy turbine disk is provided with microtwinning and is in the compressive stress state. The preparation method comprises carrying out surface treatment on a forged formed turbine disk billet to obtain the nickle-cobalt based high temperature alloy turbine disk; and surface treatment comprises the following steps: sequentially carrying out solution treatment, cutting rough machining,aging treatment, thermal shot blasting treatment and thermal mechanical surface treatment on the forged formed turbine disk billet to obtain the nickle-cobalt based high temperature alloy turbine disk. According to the invention, microtwinning is mainly introduced to the surface layer of the turbine disk to enhance the creep and fatigue resistance performance of the surface layer of the turbine disk to prolong the service life of the turbine disk.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

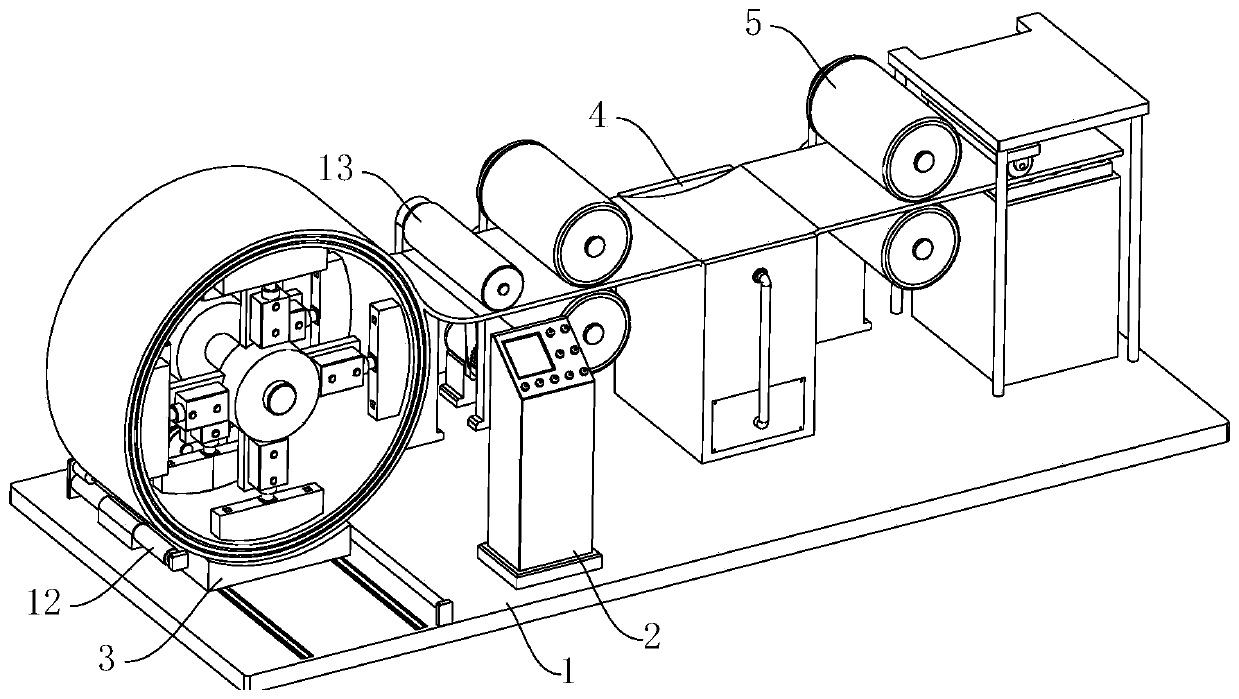

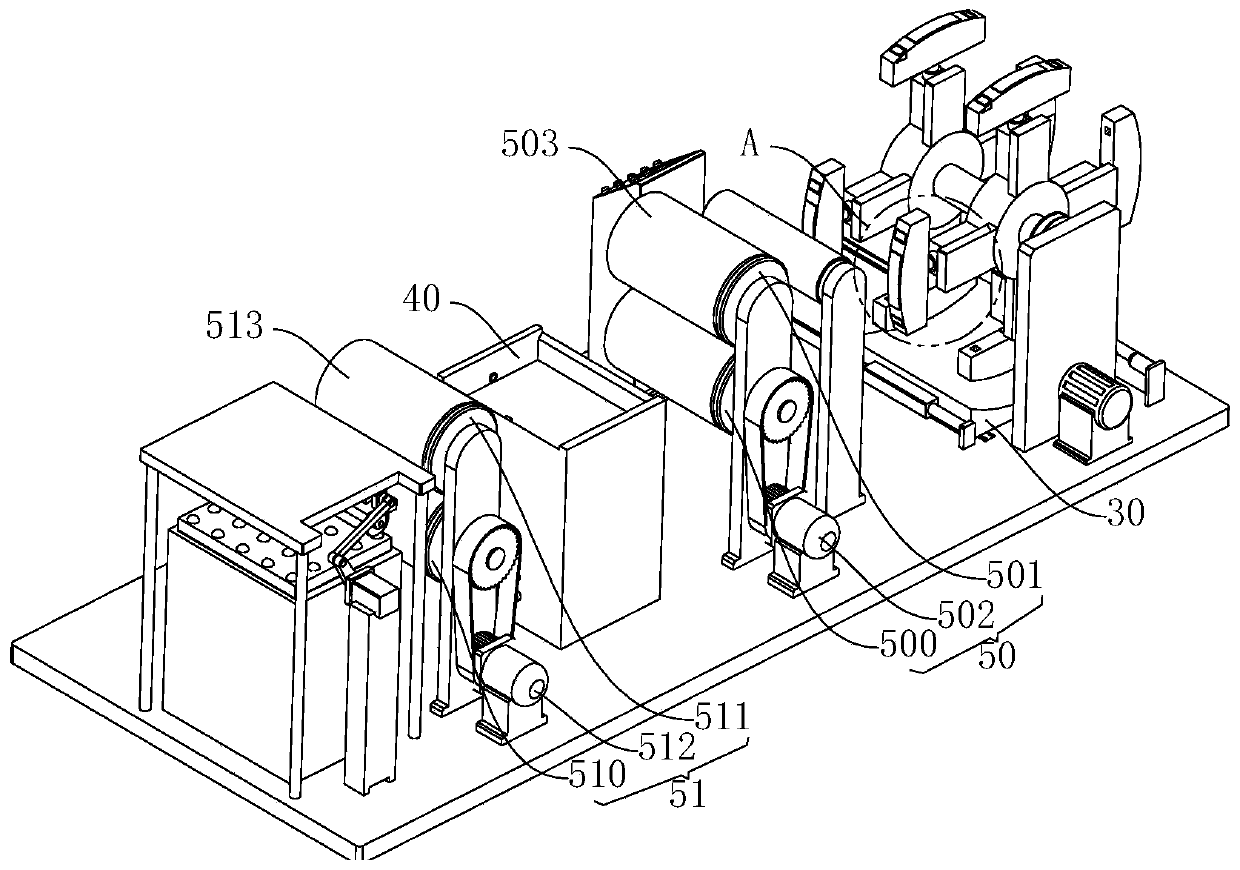

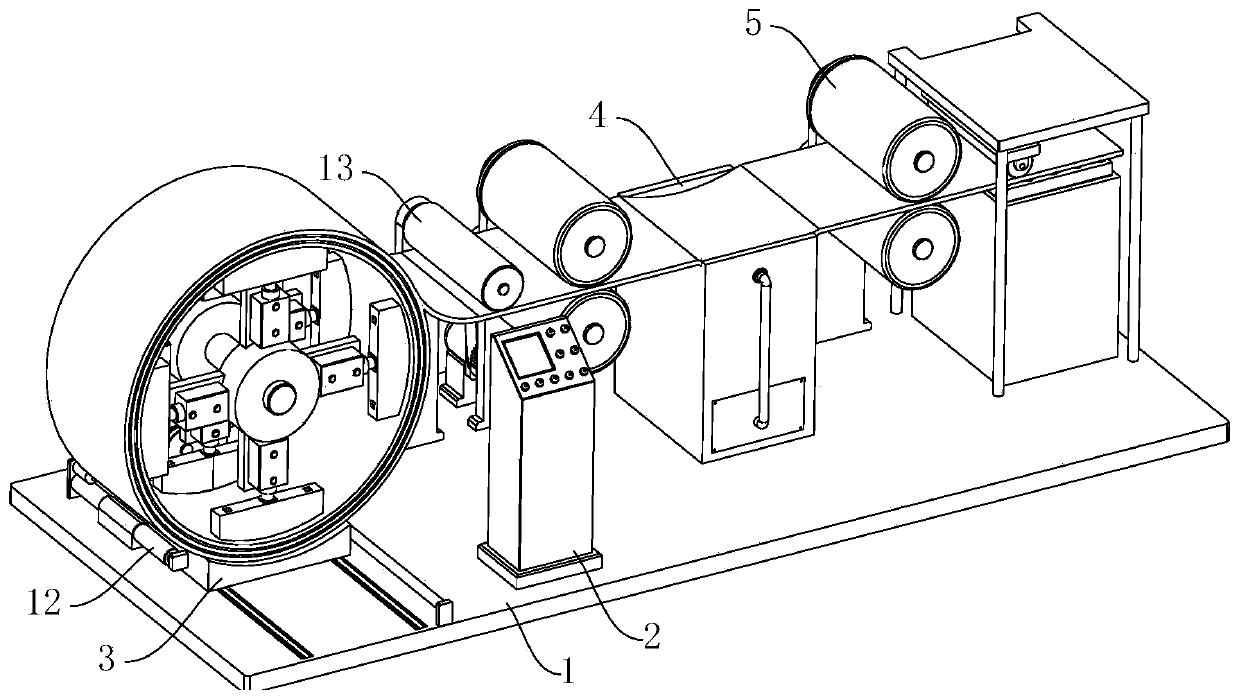

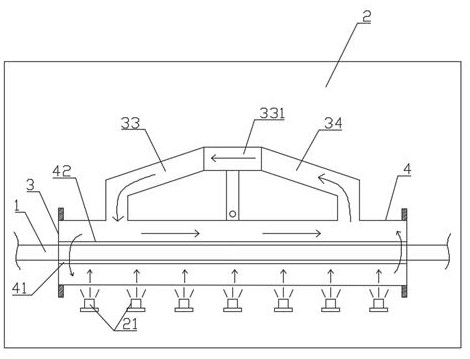

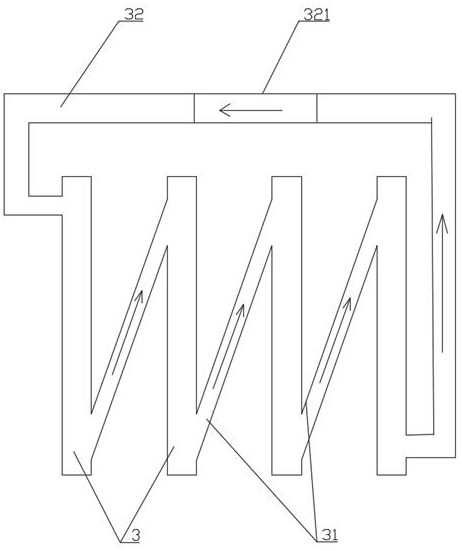

Automatic coil feeding device for uncoiling steel coil

ActiveCN111389955AReduce internal stressEasy to transportFurnace typesHeat treatment furnacesClassical mechanicsEngineering

The invention relates to the technical field of flattening equipment, in particular to an automatic coil feeding device for uncoiling a steel coil. The automatic coil feeding device comprises a base,a controller, a feeding mechanism, a heating mechanism and a conveying mechanism; and the feeding mechanism comprises a sliding table, a rotating assembly and a plurality of tightening assemblies, theheating mechanism comprises a heating table and a heat supply assembly, the conveying mechanism comprises a traction assembly, a flattening assembly and a compaction assembly, the traction assembly and the flattening assembly are symmetrically arranged at two ends of the heating table, the compaction assembly is arranged at the side of the flattening assembly, and the rotating assembly, the heatsupply assembly, the traction assembly, the flattening assembly, the compaction assembly and the plurality of tightening assemblies are all electrically connected with the controller. According to theautomatic coil feeding device for uncoiling the steel coil, the steel coil can be effectively and fixedly arranged, thereby preventing the steel coil from falling off and ensured not to be polluted when the internal stress of the steel coil is eliminated, thereby facilitating the subsequent production and use.

Owner:江苏南钢通恒新材料科技有限公司

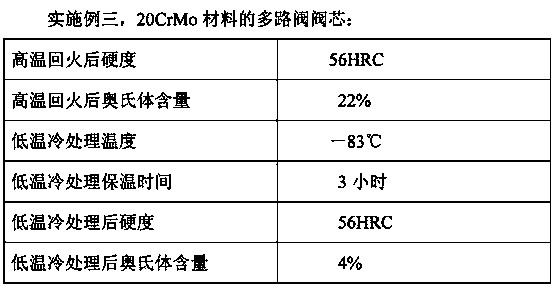

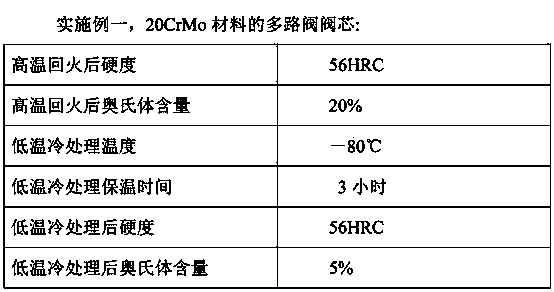

Processing method of valve core of multiway valve

InactiveCN103464968AEliminate residual internal stressImprove stabilityFurnace typesMetal working apparatusCold treatmentCore product

The invention discloses a processing method of a valve core of a multiway valve. The method mainly comprises the following steps including baiting, tempering treatment, coarse turning, carburization treatment, high-temperature tempering, low-temperature cold treatment, semi-finish machining, tempering and finish machining. The processing method has the advantages that semi-finished valve core products subjected to carburization, quenching and high-temperature tempering are placed into cold treatment media to be subjected to low-temperature cold treatment, residue austenite in internal tissues of the semi-finished valve core products can be eliminated through the low-temperature cold treatment, the tempering is carried out again after the semi-finish machining, the residue stress can be eliminated, and the stability is improved. The processing method is suitable for the processing of the valve core of the multiway valve.

Owner:GUANGZHOU YUNTAI PRECISION MACHINERY

Preparation method of large-size 6061 aluminum alloy plate for semiconductor equipment

PendingCN112593100AImprove machining accuracyMeet the requirements of shape and position stabilityIngotStress relief

The invention discloses a preparation method of a large-size 6061 aluminum alloy plate for semiconductor equipment. The preparation method comprises the following steps of smelting and casting a proportioned aluminum alloy to obtain an aluminum alloy cast ingot; enabling the obtained aluminum alloy cast ingot to be subjected to homogenizing heat treatment, machining, preheating and hot rolling, and obtaining the large-specification aluminum alloy plate; and enabling the large-specification aluminum alloy plate obtained after the hot rolling to be pre-stretched, enabling the pre-stretched plateto be subjected to solution hardening, then conducting stretching and leveling, and conducting artificial aging. According to the preparation method, microstructure distortion energy segregation generated in the rolling process of the ultra-thick and ultra-wide 6061 plate can be eliminated or even, quenching internal stress generated by solid solution quenching is lower and more even, meanwhile,stress relief stretching after the quenching is combined, the residual internal stress is almost completely eliminated, the subsequent machining precision of the plate is remarkably improved, and therequirement of semiconductor equipment on high form and location stability of the aluminum plate is met.

Owner:广西南南铝加工有限公司

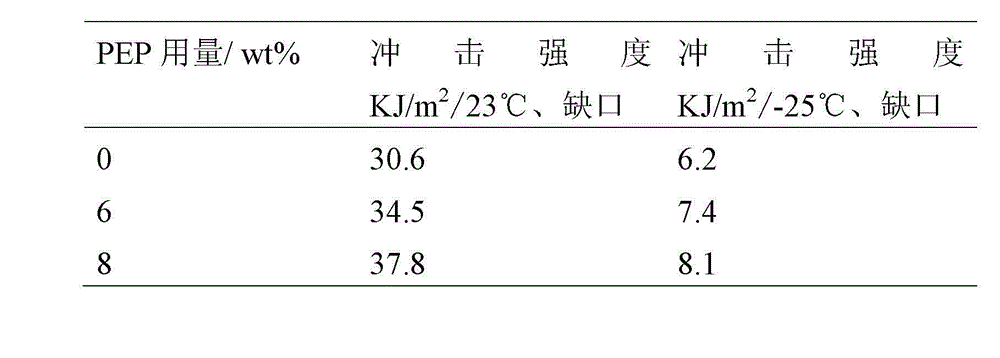

Method for preparing polypropylene toughening modifier by irradiation grafting

InactiveCN104877217ARaise room temperatureImprove low temperature impact strengthPolymer scienceAntioxidant

The invention discloses a method for preparing a polypropylene toughening modifier by irradiation grafting, which comprises the following steps: mixing polypropylene, polyethylene, ethylene-octylene copolymer (POE) and an antioxidant in percentage by weight, carrying out melt extrusion on a screw extruder, cooling, granulating, drying, adding the granules into a packaging bag, and carrying out gamma-ray irradiation to obtain the irradiation-grafted polypropylene toughening modifier. After the product is blended with an isotactic polypropylene resin, the normal-temperature / low-temperature impact strength of the isotactic polypropylene is obviously enhanced, the normal-temperature impact strength of the modified polypropylene is enhanced by 53.5-60%, the low-temperature impact strength is enhanced by 45.2-50%, the crystallization temperature of the polypropylene modified product is enhanced by 3.4-5.7 DEG C, and the crystallization rate is increased. The polypropylene toughening modifier can enhance the degree of crystallinity of the isotactic polypropylene, refine the crystal grains, reduce the phenomenon of secondary crystallization in the later storage process and eliminate the residual internal stress in the polypropylene modified product. The polypropylene toughening modifier is widely used for producing extrusion, injection molding and foaming products of polypropylene.

Owner:HUBEI UNIV OF TECH

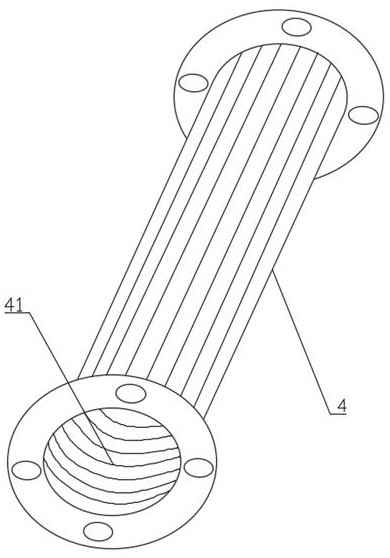

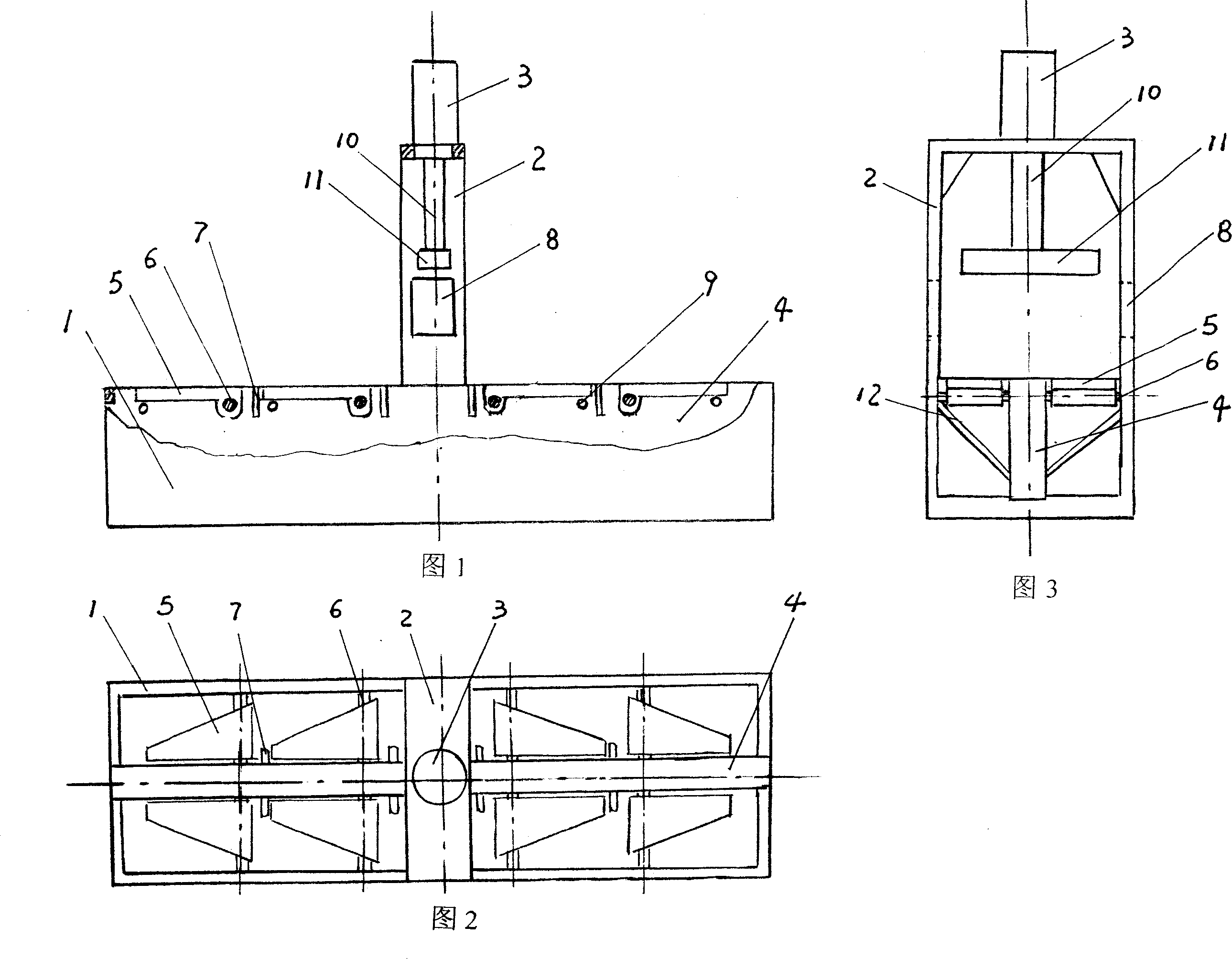

Method for straightening cross-beam of car and apparatus thereof

A method for straightening the deformed frame of car includes such steps as detaching, straightening the deformed parts, repairing the damaged parts by welding and redrilling, ageing, assembling with screw bolts and nuts, and cold rivetting by using rivets to replace the screw bolts and nuts. Its apparatus is also disclosed.

Owner:申勇

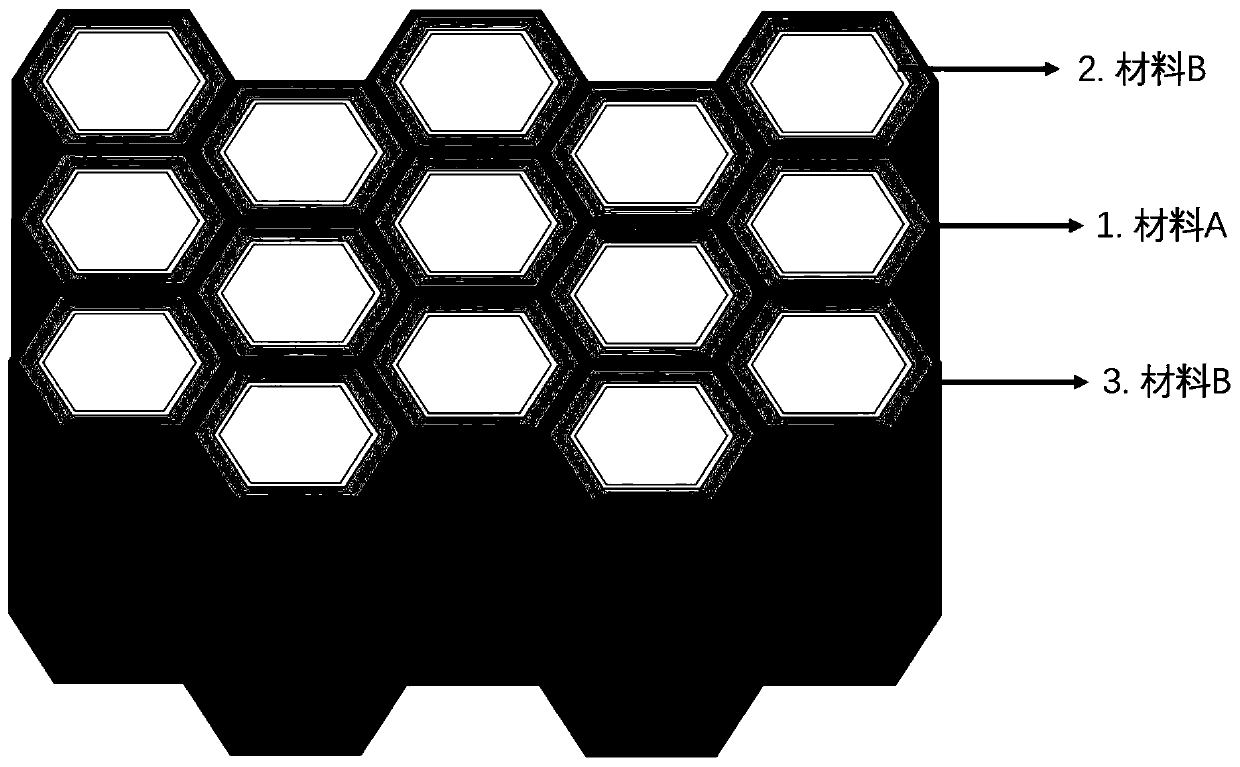

Additive manufacturing method of functional composite honeycomb material

ActiveCN110170656ATightly boundReduce defectsAdditive manufacturing apparatusFunctional compositeHoneycomb structure

The invention provides an additive manufacturing method of functional composite honeycomb material, and belongs to the technical field of additive manufacturing. In a printing process, two alloy powders with different materials are used for powder feeding and printing to prepare the functional composite honeycomb material, residual internal stress of the composite honeycomb material printing partis eliminated through a stress relief annealing heat treatment process, and the macroscopic mechanical property is improved. According to the three-layer functional composite honeycomb material prepared by the manufacturing method disclosed by the invention, original honeycomb material structure is improved, so that the structural performance of the honeycomb structure material is more stable, andthe three-layer functional composite honeycomb material is suitable for larger market demands.

Owner:NANJING UNIV OF TECH

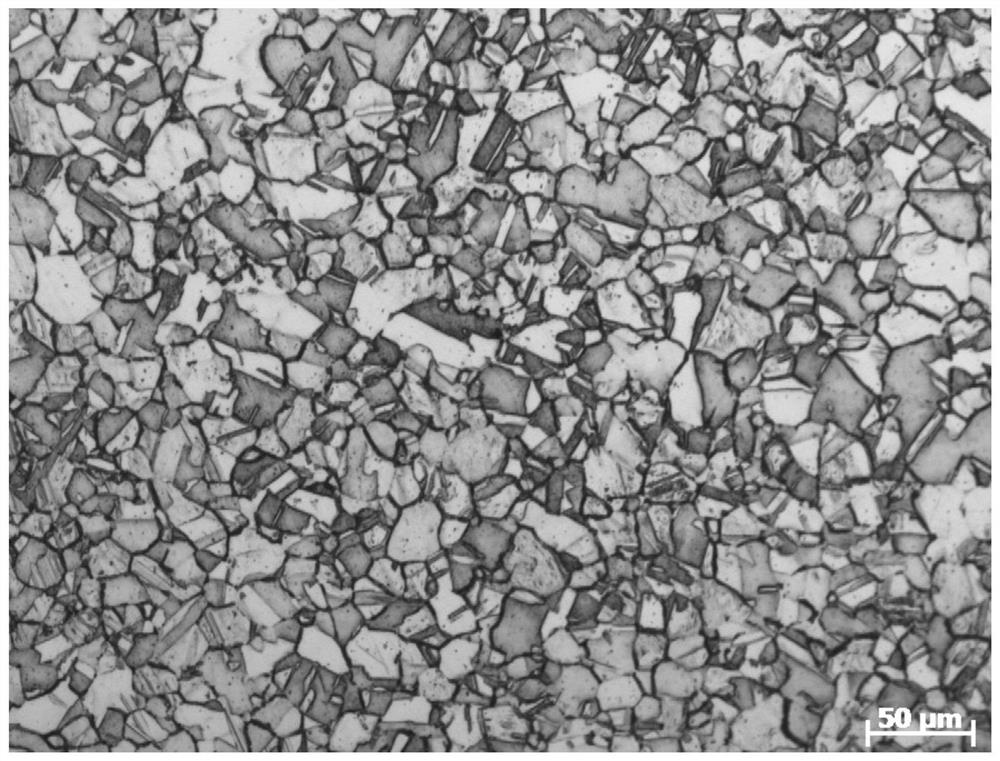

Low-expansion alloy and preparation method thereof

ActiveCN111809120AImprove the strengthening effectDoes not affect linear expansion coefficientFurnace typesHeat treatment furnacesSolution treatmentMetallurgy

The invention relates to a low-expansion alloy and a preparation method thereof, and relates to the technical field of low-expansion alloys. According to the mainly adopted technical scheme, the volume fraction of annealing twin crystals in the low-expansion alloy is larger than or equal to 20%, and the linear expansion coefficient of the low-expansion alloy within the temperature range of -160 DEG C to 25 DEG C is 0.8*10<-6> / DEG C to 1.5*10<-6> / DEG C. The preparation method of the low-expansion alloy comprises the step of sequentially carrying out solution treatment, cold rolling deformationtreatment and annealing treatment on a low-expansion alloy body so as to obtain the low-expansion alloy, wherein in the cold rolling deformation treatment step, the total deformation of the alloy is 65-99%, and in the annealing step, the annealing temperature ranges from 800 DEG C to 900 DEG C, and the annealing time ranges from 5 min to 30 min. According to the low-expansion alloy, annealing twincrystals can be effectively introduced into the low-expansion alloy, so that the low-expansion alloy is strengthened on the premise that the linear expansion coefficient of the alloy is hardly influenced. The contradictory relation between the expansion performance and the strength of the alloy is fundamentally solved, and application of the low-expansion alloy in precise structural parts is facilitated.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Technology for machining positioning rings

InactiveCN105983818AHigh surface hardnessExtended service lifeSolid state diffusion coatingFurnace typesEngineeringMachining

The invention discloses a technology for machining positioning rings. The technology is characterized by comprising steps of carrying out technological processes of discharging, forging, annealing, machining, tempering, machining, ion nitriding, inspecting and finished product acquiring and the like. The technology for machining the positioning rings has the advantages that the comprehensive performance of the positioning rings can be improved, and the service lives of the positioning rings can be prolonged.

Owner:重庆沁煌实业有限公司

Working method of automatic coil feeding device for steel coil rolling

ActiveCN111530966AReduce internal stressEasy to transportWire straightening devicesHeat treatment process controlSteel beltPhysics

The invention relates to the technical field of leveling equipment, in particular to an automatic coil feeding device for steel coil rolling and an application method of the automatic coil feeding device. The automatic coil feeding device comprises a base, a controller, a feeding mechanism, a heating mechanism and a conveying mechanism, wherein the feeding mechanism comprises a slipway, a rotatingassembly and a plurality of tight supporting assemblies; the heating mechanism comprises a heating platform and a heat supplying assembly; the conveying mechanism comprises a traction assembly, a leveling assembly and a compacting assembly; the traction assembly and the leveling assembly are symmetrically arranged at two ends of the heating platform; the compacting assembly is arranged beside theleveling assembly; and the rotating assembly, the heat supplying assembly, the traction assembly, the leveling assembly, the compacting assembly and the tight supporting assemblies are electrically connected with the controller. Through the adoption of the automatic coil feeding device for steel coil rolling and the application method of the automatic coil feeding device disclosed by the invention, steel coils can be effectively fixed, and falling of the steel coils is avoided; and besides, when the internal stress of steel belts is eliminated, the steel coils can be guaranteed to be free from pollution, and subsequent production and usage are convenient.

Owner:内蒙古包钢同业金属新材料有限公司

Forging and thermal treatment technique for Cr12MoV steel

InactiveCN106319178AImprove solubilityMitigate and alleviate the adverse effects that easily cause stress concentrationTemperature controlThree stage

The invention discloses a forging and thermal treatment technique for Cr12MoV steel. The forging and thermal treatment technique specific for Cr12MoV steel comprises the following working procedures that a PLC four-point temperature-controlled regenerative heating furnace is selected and applied, and the heating process is divided into three stages, specifically, heating is carried out till the temperature is 550 DEG C firstly, the temperature is increased from 550 DEG C to 850 DEG C at a uniform speed, the temperature increasing speed is kept to be 80-90 DEG C per hour, the temperature is kept at 850 DEG C for eight hours, and then the temperature is increased to 1100-1150 DEG C; the initial forging temperature is 1100-1150 DEG C, and the final forging temperature is 850-880 DEG C; oil or salt bath quenching is carried out till the temperature is 1100-1150 DEG C, and the temperature is preserved for 15 min; cooling is carried out; three sections of isothermal spheroidizing at the temperatures of 720 DEG C, 740 DEG C and 720 DEG C separately are carried out, and each section lasts for two hours; tempering is carried out at the temperature of 220 DEG C; and the steel is discharged out of a furnace and placed in air for natural cooling. Processing molds for the technique can make carbide refined, edges and corners round and Austenite matrixes superfine, and high hardness and compressive strength are achieved.

Owner:瑞安市劲力机械制造有限公司

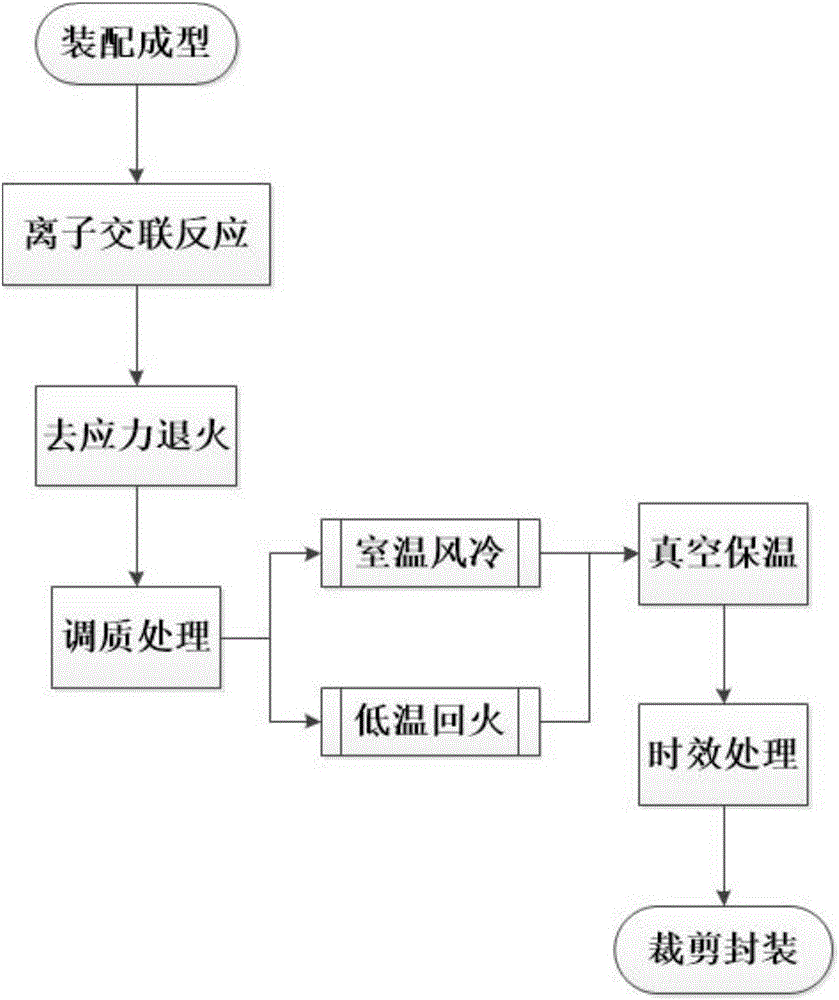

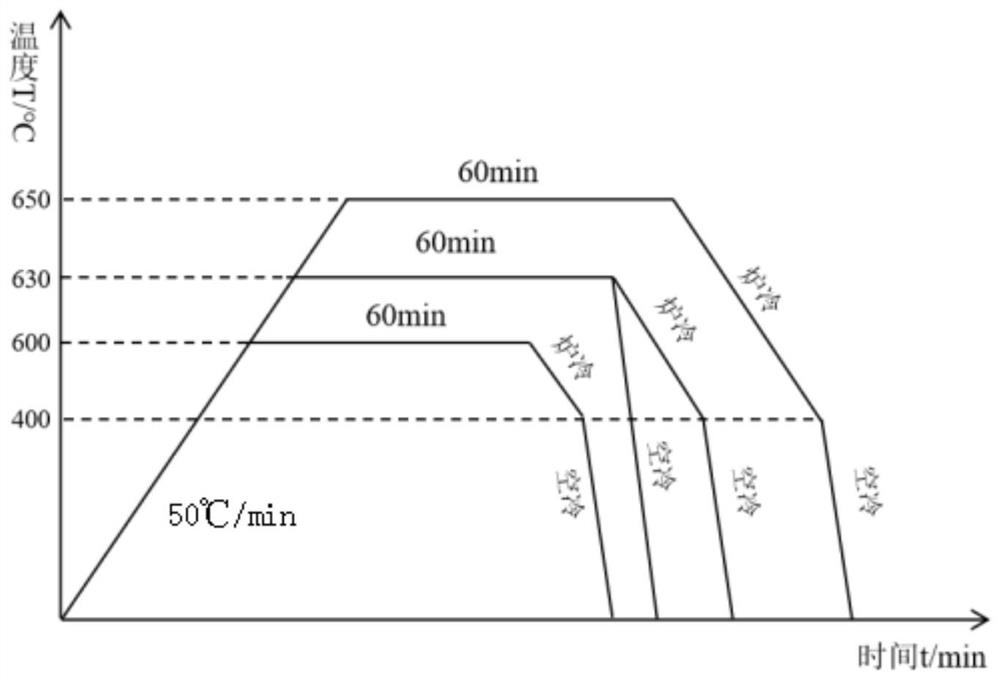

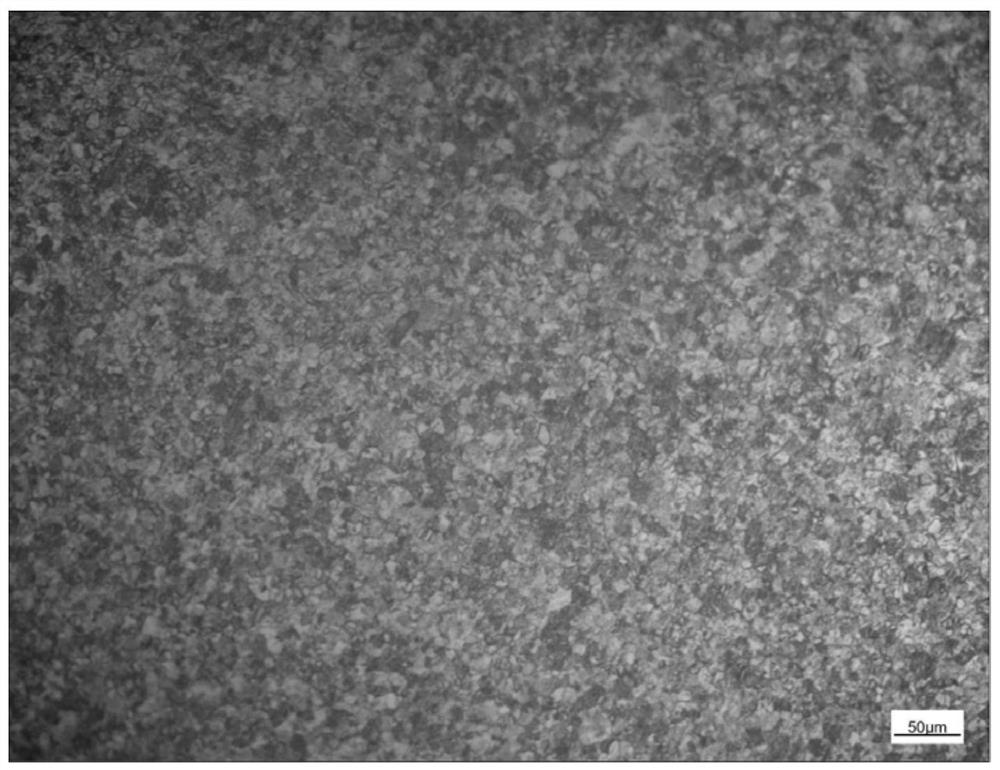

Heat treatment process method for processing CAH (Calcium Alginate Hydrogel) artificial muscles

The invention provides a heat treatment process method for processing CAH (Calcium Alginate Hydrogel) artificial muscles. The heat treatment process method adopts a vacuum and whole heating manner and comprises four phases of cross-linking, heating, keeping heat and cooling. The heat treatment process method comprises the main method steps: immersing the artificial muscles into a CaCl2 solution and carrying out an ion cross-linking reaction for 20min at a water bath temperature of 30 DEG C; then carrying out stress relieving annealing and putting the artificial muscles into a drying box for heating; setting corresponding parameters; taking out the artificial muscles and cooling with air at an indoor ventilation part; keeping for 30min and putting the artificial muscles into a vacuum drying box for 0.5h; adjusting the set parameters, and slowly cooling to 50 DEG C along a vacuum box and keeping the temperature constant for 1.5h until tempering treatment is finished; finally, standing in air for 3h, and gradually cooling to a room temperature to finish an ageing process; and cutting, packaging and storing. The heat treatment process method provided by the invention has a clear principle and a remarkable effect, and can be commonly applied; and comprehensive mechanical properties including a responding speed, a service life, output power and the like of the CAH artificial muscles can be effectively improved.

Owner:HARBIN ENG UNIV

Method for eliminating residual stress of titanium part subjected to powerful spinning deformation

PendingCN112921259AEliminate residual internal stressReduced risk of deformationSpinningHeat conservation

A method for eliminating residual stress of a titanium part subjected to powerful spinning deformation comprises the following steps that 1, the titanium part subjected to spinning is placed in a heat treatment furnace, the temperature is increased to the target temperature of 530-560 DEG C at the heating speed of 10-52 DEG C / min, and the heat preservation time is 60-100 min; and 2, after heat preservation is conducted, cooling is conducted to 380-410 DEG C in a furnace cooling manner, and then discharging and air cooling are conducted to the room temperature. According to the process, the residual internal stress of the TA1 part after the powerful spinning deformation can be eliminated, so that the risk of deformation of a thin-walled cylinder part due to the release of the residual stress in the subsequent machining process is reduced, and the microstructure excellence and the use performance of the material are improved.

Owner:XIAN TAIJIN INDAL ELECTROCHEM TECH

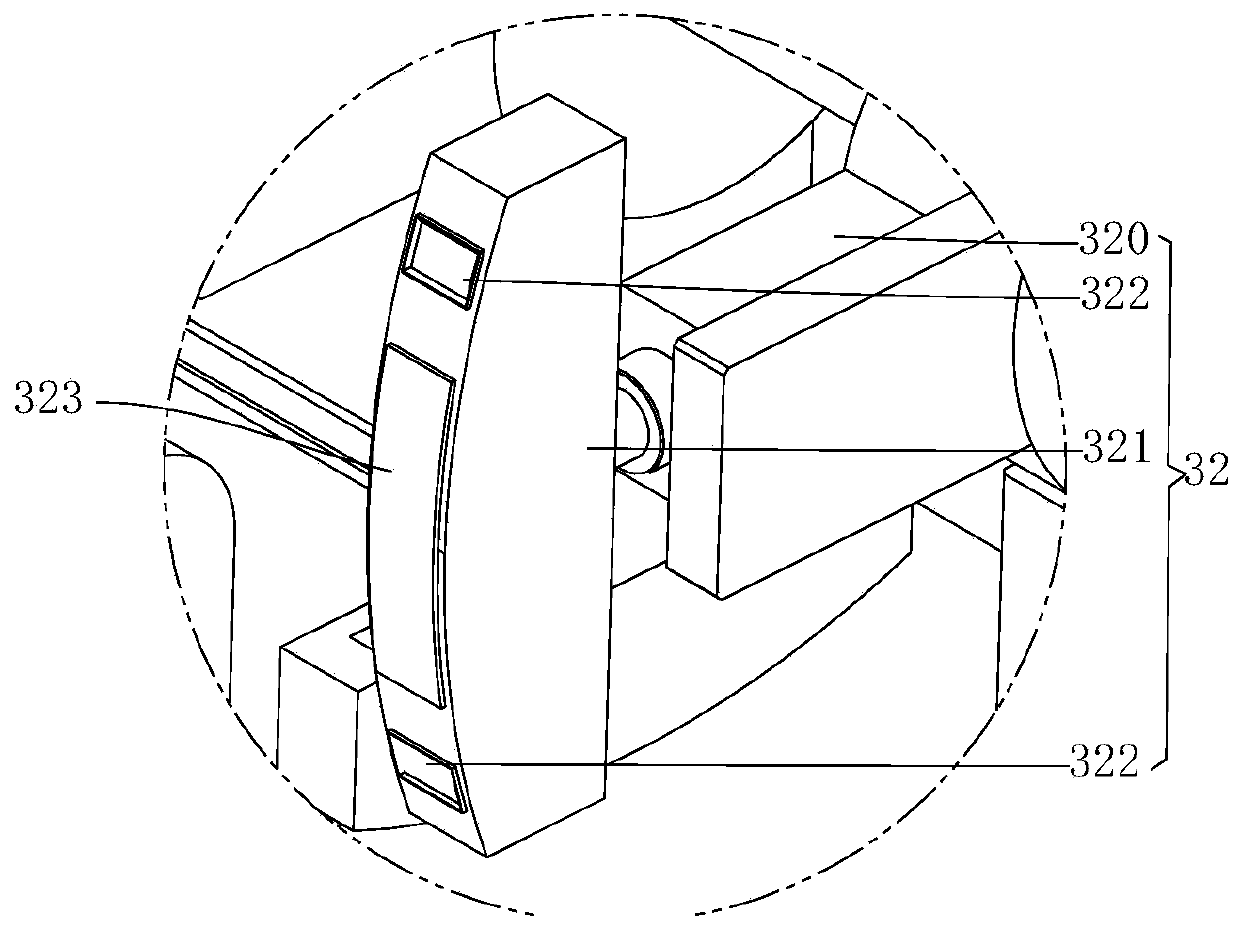

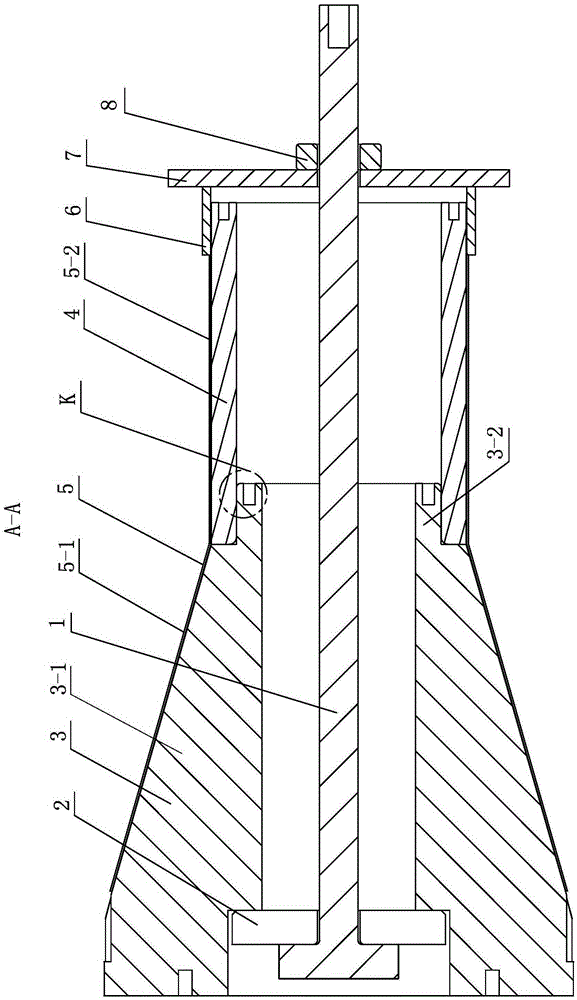

Accurate control device and method for inner diameter size of titanium alloy barrel cone composite component

ActiveCN105268779APrecise control of inner diameter sizeEliminate residual internal stressStress distributionThermal contraction

The invention relates to an accurate shape correction control device and method for a thin-wall barrel conical part, in particular to an accurate control device and method for the inner diameter size of a titanium alloy barrel cone composite component. The problems that as the thermal contraction of all parts is not consistent after hot spinning forming of the titanium alloy thin-wall component is finished, deviation of the coaxiality, roundness and shape accuracy is caused, the geometric accuracy of a workpiece is lowered, the stress distribution is not uniform when the titanium alloy thin-wall component serves as a force bearing component, and the use intensity is lowered are solved. The accurate control device comprises a thrust augmentation rod, a conical mould, a cylinder, a thrust augmentation ring, a thrust augmentation plate and a nut, wherein the thrust augmentation rod is sequentially sleeved with the conical mould, the cylinder, the thrust augmentation ring and the thrust augmentation plate from a stop end to a threaded end, one end of the cylinder is arranged on a straight barrel section in a sleeving mode, the other end of the cylinder is tightly attached to the inner wall of the thrust augmentation ring, the thrust augmentation plate abuts against the thrust augmentation ring, and the nut is screwed to the threaded end of the thrust augmentation rod. The accurate control device and method are used for accurate control over the inner diameter size of the titanium alloy barrel cone composite component.

Owner:HARBIN INST OF TECH

Method with functions of preheating and postheating for forming crack-free coating with high efficiency by three-light-beam laser-cladding technique

InactiveCN102383126BLow and adjustable dilution rateSmall heat affected zoneMetallic material coating processesLaser beam welding apparatusMelting tankHeat-affected zone

The invention discloses a method with functions of preheating and postheating for forming crack-free coating with high efficiency by a three-light-beam laser-cladding technique. The method comprises the following steps of: splitting a laser beam emitted by an Nd: YAG laser into two laser beams by using a laser beam splitter, namely a preheating laser beam for preheating the surface of a base material and a postheating laser beam for postheating the formed coating; then blowing alloy powder into a molten pool which is formed by focusing a laser beam emitted by a CO2 laser and acting the focused laser beam on the surface of the base material by using a powder nozzle, wherein after the CO2 laser beam moves away, a molten layer is cured and crystallized quickly to form the coating; and postheating the formed coating by adopting the postheating laser beam. The method has the advantages that: (1) the dilution rate of the coating is low and adjustable, and the coating is metallurgically combined with the base material, so the base material has a small thermal influence area and is deformation-free and crack-free; (2) residual inner stress in the coating can be eliminated effectively, a tissue can be improved, and the coating has high abrasion resistance, high corrosion resistance, high anti-cracking performance and high thermal shock resistance; and (3) relative to the processing efficiency in the conventional laser cladding technology, the processing efficiency in the method can be improved by 50 times to the maximum extent, so the processing cost is reduced greatly, and a large-scale industrialized application potential is realized.

Owner:NANCHANG HANGKONG UNIVERSITY

Low-temperature stress relieving and tension straightening process of copper alloy plate and strip foils

InactiveCN107988570AEliminate residual internal stressMeet the requirements of deep processingFurnace typesHeat treatment furnacesEtchingStress relieving

The invention relates to a low-temperature stress relieving and tension straightening process of copper alloy plate and strip foils. The process comprises the steps of uncoiling, degreasing, scrubbingfor the first time, drying for the first time, performing low-temperature stress relief and tension straightening, pickling, scrubbing for the second time, passivating, drying for the second time andcoiling. According to the low-temperature stress relieving and tension straightening process, expanded stress relief annealing is adopted, so that partial residual internal stress of materials is eliminated, the deep processing requirements of copper alloy materials are satisfied, and especially, the requirements of etching and half etching of high-end frame materials are preferably satisfied; high-tension straightening is adopted at low temperature, so that the plate shapes of the copper plate and strip foils are improved, and slight bad plate shapes such as edge waves and the like before annealing are eliminated; the materials are still kept at an original state after stress relief annealing, and additionally, the plasticity and the electrical performance of the materials are improved;copper strip expanded through type annealing is adopted, so that the phenomenon of nonuniformity in annealing is avoided; and the requirement on the internal stress of deep processing of the domesticcopper alloy plate and strip foils is satisfied at present, and especially for the requirement of half etching of the high-end frame materials, copper plates after etching do not warp or distort.

Owner:中铝洛阳铜加工有限公司

Method for producing thin abrasion-resistant steel through DQ technology

ActiveCN111349759ACurl shape controllableEasy to shapeFurnace typesHeat treatment furnacesHeat conservationAustenite

The invention discloses a method for producing thin abrasion-resistant steel through a DQ technology. The method comprises the following steps of smelting, rough rolling, finish rolling and DQ which are conducted in sequence; during smelting, a cast blank is heated to 1220-1280 DEG C, and heat preservation is conducted for 2-4 h for sufficient austenitizing; the rough rolling temperature is 1050+ / -30 DEG C; the initial temperature of finish rolling is 1020+ / -20 DEG C, the final temperature is 860+ / -20 DEG C, the passing speed of a steel plate is 1.8-3.5 m / s, and the thickness is 4-12 mm; and during DQ, after finish rolling is completed, direct quenching is conducted in a single phase cooling mode, the rate of cooling upper water to cooling lower water is 60-80 / 65-85, the cooling rate is 40-80 DEG C / s, the cooling time is 4-8 s, and then, cooling of the encryption section is conducted for 3-6 s. The production technology is simple, the efficiency is high, the cost is low, the comprehensive performance of the type of steel is excellent, the tensile strength of the steel is higher than or equal to 1200 MPa, and the impact energy is larger than or equal to 50 J at the temperature of -40 DEG C.

Owner:武汉钢铁有限公司

Low-loss single-mode optical fiber and wiredrawing process thereof

ActiveCN108919415AAvoid churnEliminate residual internal stressGlass optical fibreGlass making apparatusSingle-mode optical fiberOptoelectronics

The invention discloses a low-loss single-mode optical fiber and a wiredrawing process thereof, and mainly solves a technical problem that in the prior art, a single-mode optical fiber is low in intensity and large in internal stress. The invention well solves the problem and can be used for an optical fiber by the technical scheme that the low-loss single-mode optical fiber is characterized by comprising a core layer, an inner coating layer and an outer coating layer which are sequentially arranged from inside to outside, wherein the core layer adopts germanium-doped silicon dioxide; the inner coating layer adopts fluorine-doped silicon dioxide; the outer coating layer adopts silicon dioxide; and the inner coating layer is of a sunk profile structure.

Owner:江苏南方光纤科技有限公司

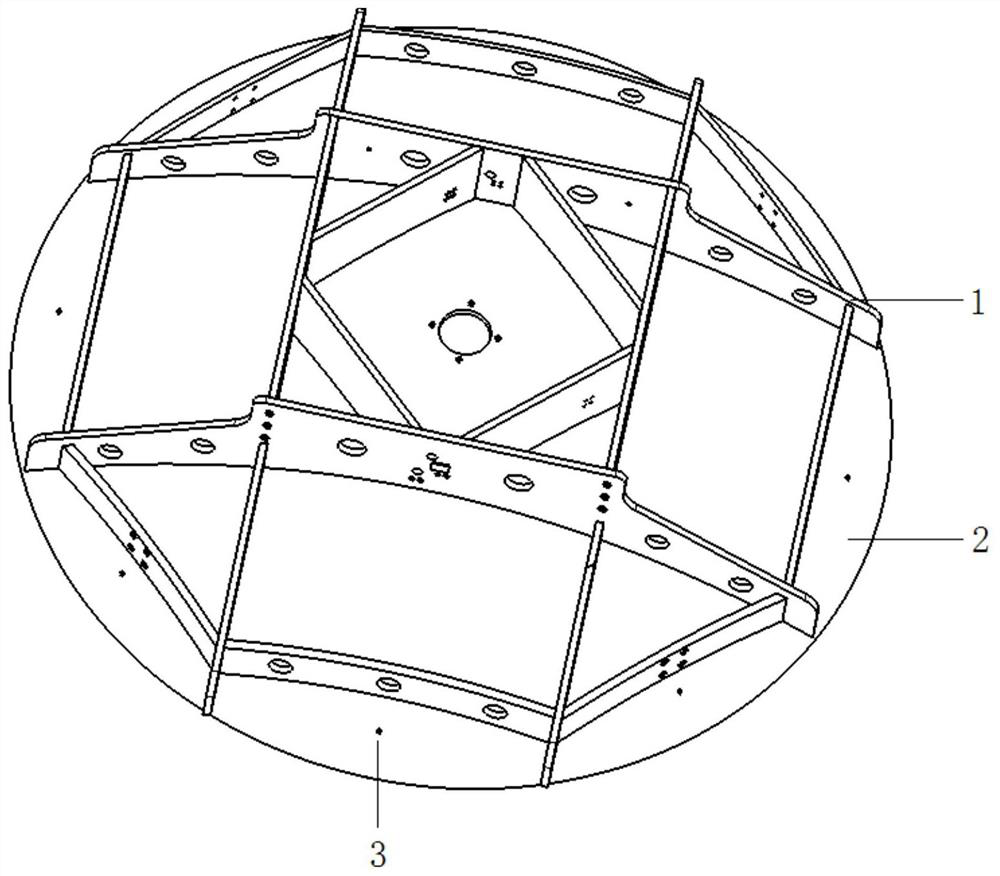

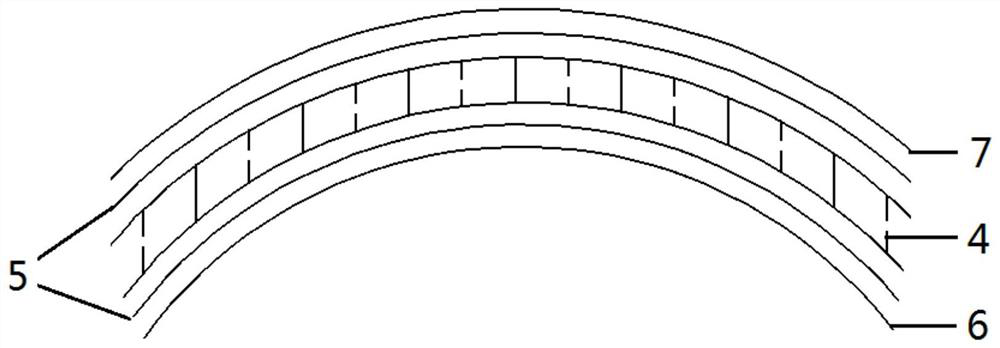

Composite material reflector forming and assembling method

ActiveCN112537047AAvoid deformationReduce the problem of uncoordinated assembly positioningDomestic articlesAdhesiveAluminum honeycomb

The invention provides a composite material reflector forming and assembling method. Both the lower skin and the upper skin of the reflecting surface of a reflector are formed by narrow-band laying, the preforming of a porous aluminum honeycomb core is conducted before cementing and then the porous aluminum honeycomb core is subjected to secondary cementing with the upper skin and the lower skin,the cured reflecting surface is subjected to aging treatment, the reflecting surface and back ribs are assembled by adopting a forming and cementing integrated tool, the reflecting surface is uniformly pressurized by a method of calibrating embedded part positioning and manufacturing a vacuum bag in an edge margin area, the reflecting surface and the back ribs as well as the back ribs are bonded by using a room-temperature curing structural adhesive, and glass cloth reinforcing angle sheets are laid at adhesive joints by a wet method. According to the composite material reflector forming and assembling method provided by the invention, the molded surface precision control problem of the composite material reflector is solved, and the structural stability of the reflector is ensured.

Owner:XIAN AIRCRAFT IND GROUP

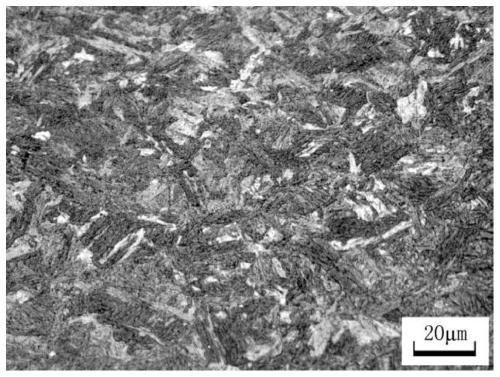

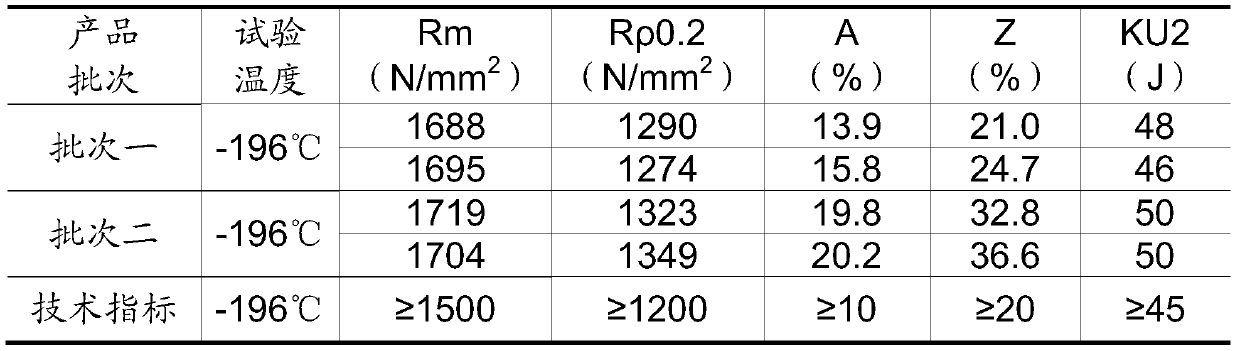

Heat treatment method of additive manufacturing high-temperature alloy working in low-temperature environment

ActiveCN110964992AGood low temperature ductilityEliminate residual internal stressAdditive manufacturing apparatusPhysicsHeat conservation

The invention discloses a heat treatment method of an additive manufacturing high-temperature alloy working in a low-temperature environment. A heat treatment technology comprises the steps of carrying out heat preservation on the additive manufacturing high-temperature alloy for 1 h to 4 h under a condition of a vacuum environment where a pressure intensity is not greater than 10 <-3 > Pa and under the condition that a temperature is 1080 DEG C to 1150 DEG C, recharging argon and cooling; and then carrying out heat preservation for 8 h + / -0.5 h under the condition of the vacuum environment where the pressure intensity is not greater than 10 <-3> Pa and under the condition that the temperature is 730 DEG C + / -10 DEG C, then carrying out furnace cooling at a cooling speed of 50 DEG C / h tillthat the temperature is 630 DEG C + / -10 DEG C, carrying out heat preservation for 8 h+ / -0.5 h, recharging argon and cooling. After heat treatment, a reinforced precipitated phase of a material is well matched with an austenitic matrix, good low temperature performance is obtained, and working requirements in the low temperature environment can be satisfied, wherein the working requirements include that at-196 DEG C, Rm is not less than 1500 N / mm <2>, Rp0.2 is not less than 1200 N / mm <2>, A is not less than 10%, Z is not less than 20%, and KU2 is not less than 45 J.

Owner:XIAN SPACE ENGINE CO LTD

Polypropylene toughening modifying agent and polypropylene modified product thereof

Owner:HUBEI UNIV OF TECH

Material of high speed train brake disc for low temperature environment

ActiveCN108707826AMeet operational requirementsImprove impact absorption performanceManganeseAbsorbed energy

The invention discloses a material of a high speed train brake disc for low temperature environment. The material of the high speed train brake disc is characterized by comprising the composition of,by mass, 0.15-0.27% of carbon, 0.3-0.6% of silicon, 0.6-1.0% of manganese, 0.5-0.9% of chromium, 0.3-0.7% of molybdenum, 1.5-2.0% of nickel, 0.01-0.03% of aluminum, 0.05-0.09% of copper, 0.03-0.06% ofstibium, less than 0.005% of phosphorus, less than 0.01% of sulfur and the balance iron. The material combines the influence of different elements on the toughness of alloy steel, reasonably adjuststhe proportion of the alloy elements and produces the material of the brake disc. The impact absorbing energy of a brake disc at low temperature is obviously improved casting through the combination of reasonable heat treatment and cold treatment process, and the operation requirements of the brake disc under low temperature conditions are met.

Owner:WENSHANG HAIWEI MOTORCYCLE ACCESSORIES CO LTD

Forming and assembling method of a composite material reflector

ActiveCN112537047BAvoid deformationReduce the problem of uncoordinated assembly positioningDomestic articlesAdhesiveAluminum honeycomb

The invention provides a molding and assembling method of a composite material reflector. The lower and upper skins of the reflecting surface of the reflector are formed by narrow-band paving. Aging treatment, the assembly of the reflective surface and the back rib adopts the integrated tooling of molding and bonding, the reflective surface is uniformly pressurized by calibrating the positioning of the embedded parts and making a vacuum bag in the edge margin area, and the reflective surface and the back rib as well as the back rib and the back rib are used at room temperature Curing the structural adhesive for bonding, and laying the glass cloth reinforcement corner piece in the glue joint position by wet method. The forming and assembling method provided by the invention solves the problem of surface precision control of the composite material reflector and ensures the structural stability of the reflector.

Owner:XIAN AIRCRAFT IND GROUP

Production method of non-loose steel wire rope

ActiveCN111621635AUniform internal organizationHigh tensile strengthRope making machinesFurnace typesWire rodMegasonic cleaning

The invention provides a production method of a non-loose steel wire rope. The production method comprises the steps of wire rod forming: selecting 304 stainless steel wires with diameter of 5.5mm; surface treatment: soaking the wires in dilute hydrochloric acid to remove an oxide film; wire drawing: drawing the wires with the diameter of 5.5mm into 1.5mm steel wires; stranding: stranding a plurality of layers of steel wires into rope strands; rope laying up: stranding the rope strands around the center line of a rope core on a laying-up machine into a steel wire rope; heat treatment: puttingthe laid-up steel wire rope strand in a heat treatment furnace for heat treatment, and carrying out ultrasonic cleaning and cooling after heat treatment; and inspection: calculating the safety factorof the steel wire rope. The production method provided by the invention is not used in the steel wire rope at present, and the produced steel wire rope has the advantages that all layers of steel wires inside the steel wire rope are in close contact with each other, the non-looseness performance is excellent, the fatigue resistance is good, the stability is good, and the service life is long.

Owner:江苏亚盛金属制品有限公司

Method for straightening cross-beam of car and apparatus thereof

A method for straightening the deformed frame of car includes such steps as detaching, straightening the deformed parts, repairing the damaged parts by welding and redrilling, ageing, assembling with screw bolts and nuts, and cold rivetting by using rivets to replace the screw bolts and nuts. Its apparatus is also disclosed.

Owner:申勇

Hyperspectral display frame hyperspectral traceless injection molding technique

InactiveCN108407246AHigh glossImproved surface hardness and qualityInjection molding processEnvironmental resistance

The invention belongs to the technical field of injection molding, and relates to a hyperspectral display frame hyperspectral traceless injection molding technique. A prepared display frame is high insurface glossiness and free of defects such as melted marks, flow marks, bubbles and shrink marks, the product surface hardness and quality are greatly improved, and the product percent of pass is improved by 20-30%; before injection molding, condensation is conducted at first, then drying treatment and microwave treatment are conducted, and residual internal stress in raw materials can be effectively and completely eliminated; pressure adjusting in the injection molding process is conducted in three stages, shrinkage cavities and recesses are avoided, the flow marks, seam lines and the layering phenomenon are eliminated, the internal stress produced in the product injection molding process and various defects caused in the injection molding process are reduced, and the product percent ofpass, quality and strength are improved; rapid temperature increase and rapid temperature decrease during application are achieved, the speed tends to be uniform, heat energy is fully utilized, heatenergy losses and production cost are reduced, and the product percent of pass is increased; and the spraying procedure is not needed, pollution to the environment is greatly reduced, and the requirements of environment protection and energy conservation are met.

Owner:太仓市天丝利塑化有限公司

Method for improving hardness of inner gear

InactiveCN110241291AEliminate residual internal stressOrganizational stabilityFurnace typesIncreasing energy efficiencyHeating timeFree cooling

A method for improving hardness of an inner gear comprises the following steps that firstly, the integral inner gear is subjected to solid solution treatment, the solid solution treatment temperature is 400-450 DEG C, and the heat preservation time is 4 h; secondly, after solid solution treatment is finished, quenching treatment is conducted on the outer circle face, the upper end face and the lower end face of the inner gear, and the quenching temperature is 50-60 DEG C; thirdly, after the second step is finished, the gear face of the inner gear is subjected to quenching treatment, and the quenching temperature is 70-70 DEG C; fourthly, after the third step is finished, the inner gear is subjected to aging treatment, the aging temperature is 250-280 DEG C, and the heat preservation time is 3 h; fifthly, natural cooling is conducted for 2 h; and sixthly, an induction heater is utilized for conducting heating treatment on the outer circle face, the upper end face and the lower end face of the inner gear, the heating temperature is 200-220 DEG C, and the heating time is 1 h; and sixthly, natural cooling is conducted to the room temperature. By means of the method, the hardness of the inner gear can be effectively improved, the inner gear can better resist impacts, and the service life of the inner gear can be better prolonged.

Owner:XUZHOU XIANGQIAO MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com