Heat treatment method of additive manufacturing high-temperature alloy working in low-temperature environment

A heat treatment method and additive manufacturing technology, applied in the direction of additive processing, etc., to achieve excellent low-temperature performance, improve uneven structure, and eliminate residual internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

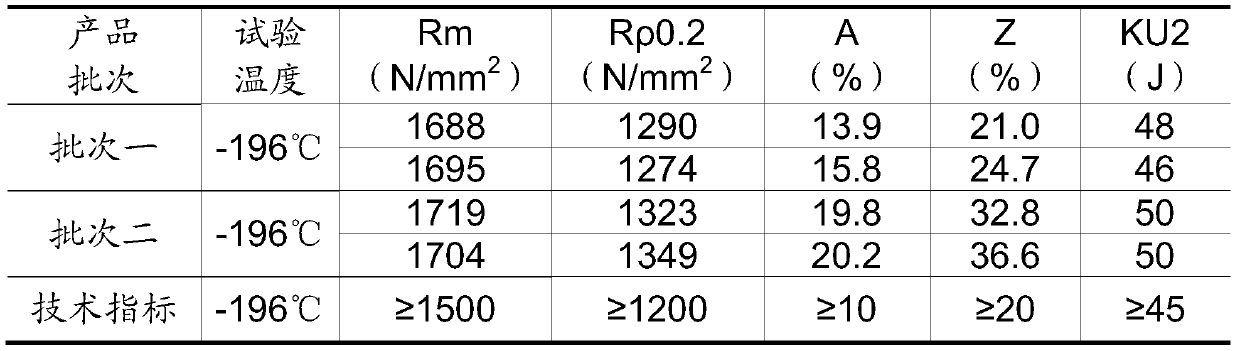

Embodiment 1

[0022] Take a certain type of engine turbo pump centrifugal wheel as an example.

[0023] (1) The workpiece is manufactured by laser selective melting and forming additive manufacturing superalloy.

[0024] (2) Heat treatment: The centrifugal wheel after separating the substrate is heat treated in a vacuum heat treatment furnace, and the pressure in the furnace is not greater than 10 -3 Pa, after the environment in the furnace meets the requirements, heat up to 1100°C for 4 hours. After the heat preservation is completed, backfill with argon to cool, and the pressure of backfill with argon is 3.03×10 5 Pa, cooled to below 80°C and air-cooled; then heat treated in a vacuum heat treatment furnace, the pressure in the furnace is not greater than 10 -3 Pa, after the environment in the furnace meets the requirements, heat it up to 730°C for 8 hours, then cool it to 630°C at a cooling rate of 50°C / h and keep it for 8 hours. After the heat preservation is over, backfill with argon t...

Embodiment 2

[0029] Take the high-pressure housing of a certain type of engine turbo pump oxygen pump as an example.

[0030] (1) The workpiece is manufactured by laser selective melting and forming additive manufacturing superalloy.

[0031] (2) Heat treatment: The centrifugal wheel after separating the substrate is heat treated in a vacuum heat treatment furnace, and the pressure in the furnace is not greater than 10 -3 Pa, after the environment in the furnace meets the requirements, heat up to 1080°C for 4 hours. After the heat preservation is completed, backfill with argon to cool, and the pressure of backfill with argon is 2.02×10 5 Pa, cooled to below 80°C and air-cooled; then heat treated in a vacuum heat treatment furnace, the pressure in the furnace is not greater than 10 -3 Pa, after the environment in the furnace meets the requirements, heat it up to 730°C for 8 hours, then cool it to 630°C at a cooling rate of 50°C / h and keep it for 8 hours. After the heat preservation is over...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com