Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Easy to calender" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

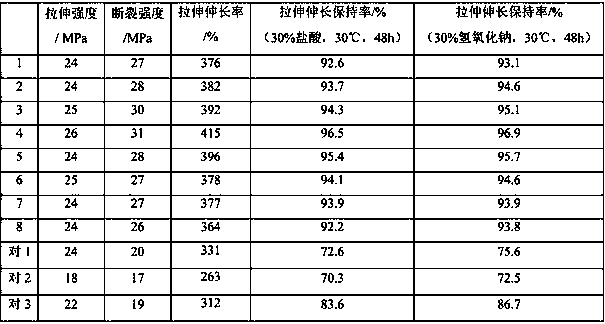

Corrosion-resistant cable material and preparation method thereof

InactiveCN109233295AExcellent radiation resistance and aging resistanceGood weather resistanceRubber insulatorsCross-linkAntioxidant

The invention discloses a corrosion-resistant cable material and a preparation method thereof. The corrosion-resistant cable material is prepared from the following raw materials in parts by weight: 30-45 parts of fluorinated silicone rubber, 15-25 parts of ethylene propylene diene monomer rubber, 18-30 parts of an ethylene-vinyl acetate copolymer, 6-12 parts of glass fiber, 10-20 parts of flame retardant, 4-10 parts of an anti-aging agent, 12-25 parts of a softening agent, 1-3 parts of an antioxidant, 3-8 parts of a plasticizer and 2-6 parts of a cross-linking agent. The corrosion-resistant cable material is high in toughness and high in corrosion resistance.

Owner:国网河南省电力公司方城县供电公司

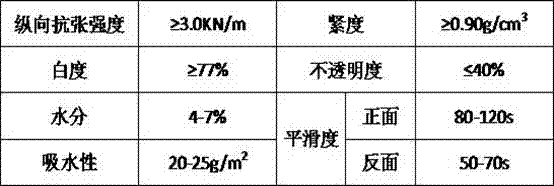

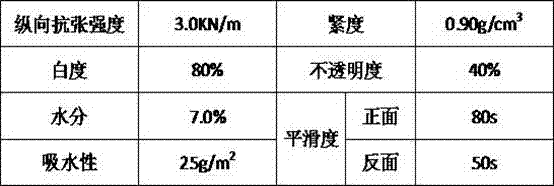

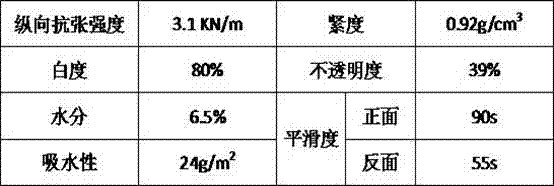

Production process of baking base paper

ActiveCN106868922AAffect surface strengthHigh strengthDefoamers additionWater-repelling agents additionCooking & bakingThree stage

The invention discloses a production process of baking base paper. The baking base paper is prepared by adopting 100% bleached softwood pulp through pulping, heavy residue removal, beating, adding of a wet strength agent, dilution, heavy residue removal, screening, adding of an internal sizing agent and a defoaming agent, dilution, net loading, formation, squeezing, first-stage drying, first-stage calendering, second-stage drying, surface sizing, third-stage drying, second-stage calendering and taking-up. Due to adoption of a preparation process of three stages of drying, two stages of calendering and one stage of impregnated surface sizing, generation of seersucker paper defects is reduced, the paper is good in flatness, high in smoothness and large in tightness, a use quantity of an oil-proofing agent is easy to control, and the use quantity of the oil-proofing agent is reduced; meanwhile, the oil-proofing agent is uniformly distributed, and the problem of food residues in the process of stripping foods is reduced.

Owner:XIANHE CO LTD

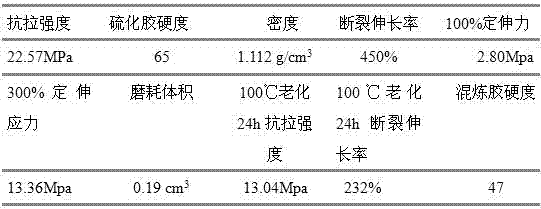

Rubber material for sealing ring of transformer and preparation method of rubber material

ActiveCN106883472AGood oil resistanceImprove wear resistanceBuilding insulationsRubber materialCross-link

The invention belongs to the technical field of sealing materials and particularly relates to a rubber material for a sealing ring of a transformer and a preparation method of the rubber material. The rubber material is prepared from the following raw material in parts by weight: 50-70 parts of nitrile rubber, 20-30 parts of acrylic rubber, 5-10 parts of epichlorohydrin rubber, 3-8 parts of wood fibers, 5-10 parts of nanometer titania, 15-25 parts of a fortifier, 1-5 parts of an anti-aging agent, 1-3 parts of an accelerate, 1-3 parts of sulfur, 3-6 parts of zinc oxide, 4-8 parts of stearic acid, 3-6 parts of asphalt, 1-3 parts of chlorinated paraffin, 10-15 parts of a plasticizer and 5-15 parts of a cross-linking agent. The rubber material for the sealing ring of the transformer is high in strength, small in compressive deformation and excellent in anti-aging performance.

Owner:国网河南省电力公司方城县供电公司

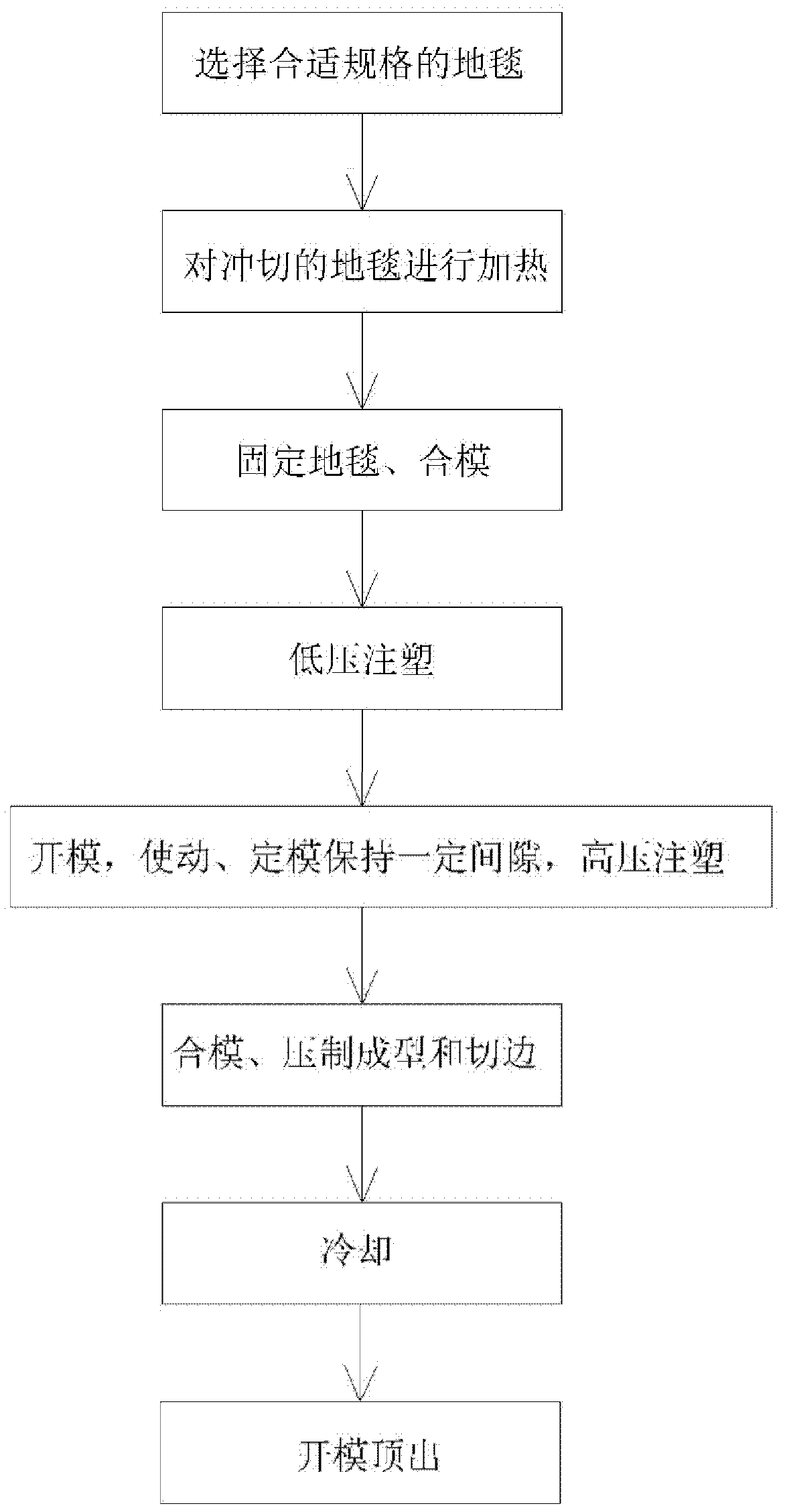

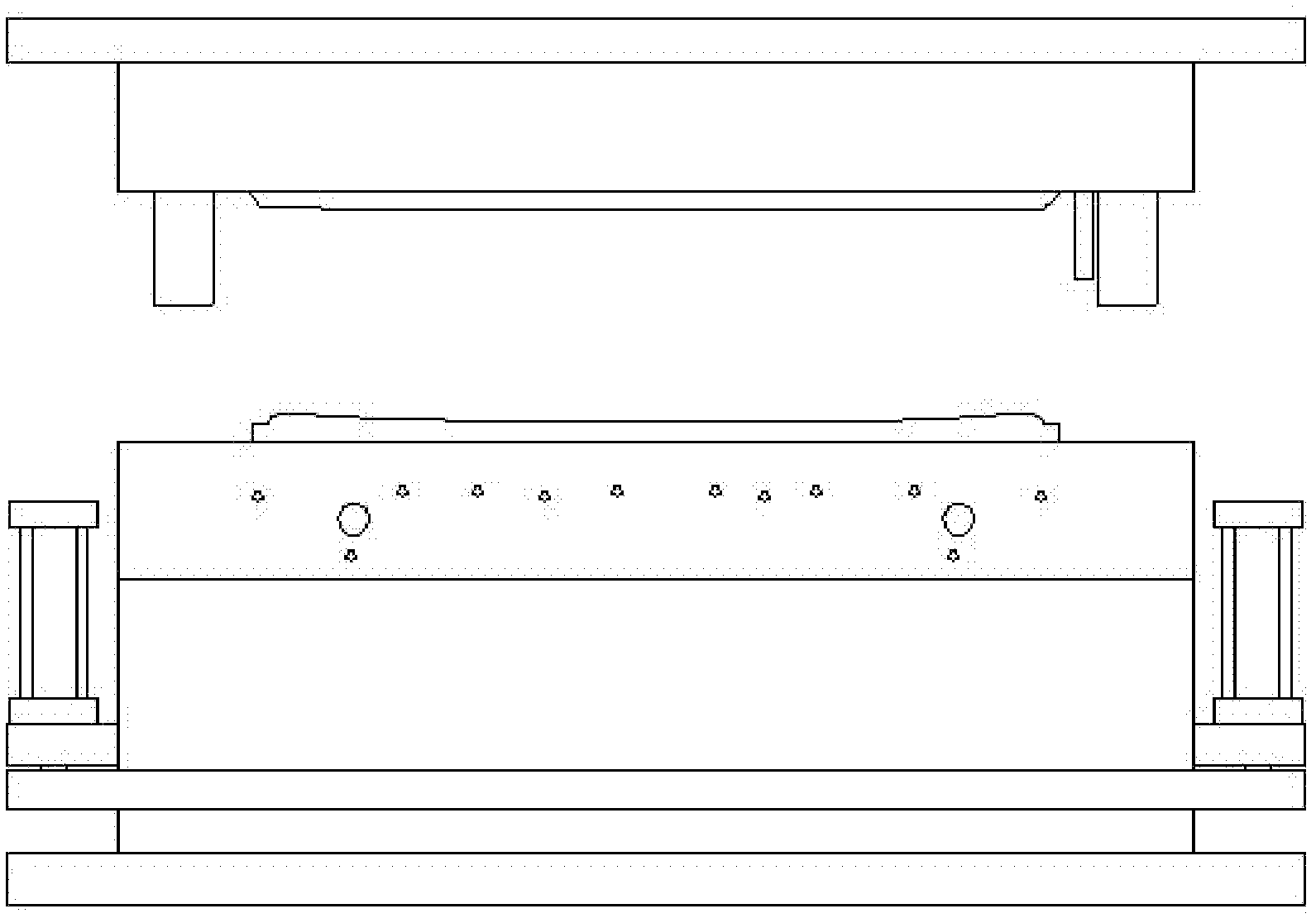

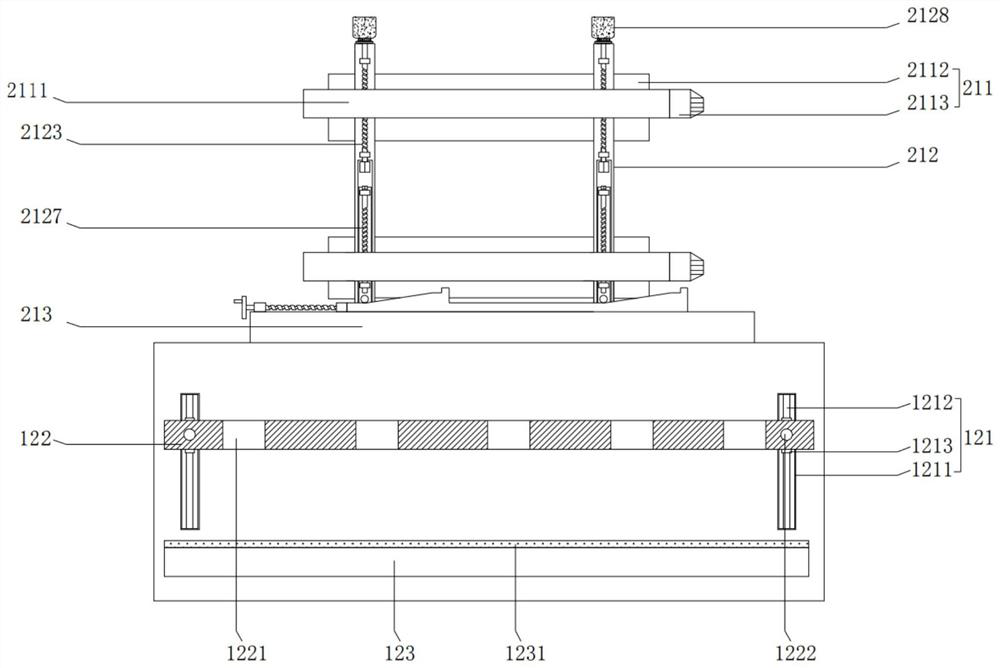

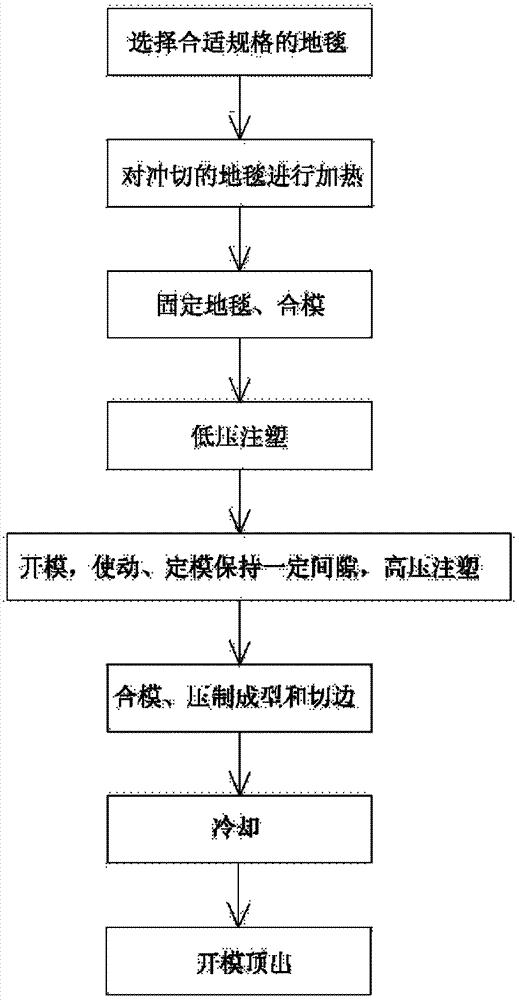

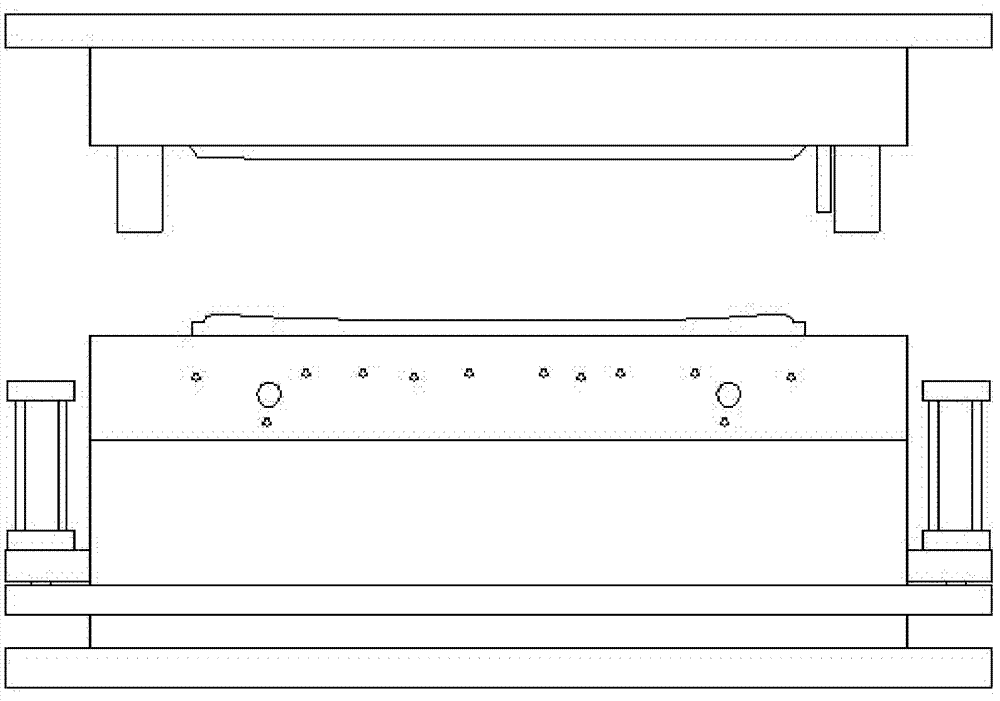

Injection molding and compression molding method of composite tufted carpet plastic interior ornament

The invention discloses an injection molding and compression molding method of a composite tufted carpet plastic interior ornament. The method comprises the following steps of: a, selecting a composite tufted carpet; b, heating the composite tufted carpet; c, opening a mold, fixing the composite tufted carpet in the injection mold, and then closing the mold; d, injecting plastic in an amount which is 10 to 20 percent of the required injection molding total amount under low pressure at a low speed by an injection molding machine through a plurality of hot runners; e, opening the injection moldto reserve certain clearance between a movable mold and a fixed mold, and starting the injection molding machine to inject the rest plastic of the required injection molding total amount under high pressure at a high speed; f, closing the mold, forming the composite tufted carpet plastic interior ornament by pressing, and simultaneously cutting the redundant edge and cooling; and g, opening the mold, and taking out the composite tufted carpet plastic interior ornament. The method is low in production condition requirement, good in product quality and high in production efficiency, the required equipment is cheap, and the produced product can be popularized in a large range.

Owner:NINGBO SUNLIGHT MOTOR PARTS

Preparation method of gutta-percha combined rubber compound for normal-temperature forming and processing

ActiveCN107415074AExcellent formabilityPhysical properties are not affectedGutta-perchaPolymer science

The invention discloses a preparation method of a gutta-percha combined rubber compound for normal-temperature forming and processing and relates to a rubber forming and processing method. Rubber is put in an internal mixer, a screw extruder or an open mill for plastifying, then stored natural rubber is mixed with 20-60 parts of carbon black, 30-80 parts of white carbon black and 2-10 parts of plasticizer in the equipment mentioned above, and rubber master batch is obtained and stored for 2-24 hours; gutta-percha is put in the internal mixer, the screw extruder or the open mill for plastifying, other accessory ingredients are added, gutta-percha rubber compound is obtained; and the gutta-percha rubber compound which is not stored and the rubber master batch are simultaneously added into the internal mixer or the open mill for uniform mixing (operation is performed at the low temperature between 25 DEG C and 35 DEG C), and then discharging is performed. By means of the preparation method of the gutta-percha combined rubber compound for normal-temperature forming and processing, the hardness of the gutta-percha and rubber compound combined with the gutta-percha is effectively lowered, the plasticity of the gutta-percha combined rubber compound is improved, the effect that the plasticity of a normal rubber compound is achieved is ensured, a series of operations such as rolling, extrusion and forming can be facilitated under the normal conditions, and the practical application value is good.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

High tear-resistant cable sheath material

The invention discloses a high tear-resistant cable sheath material. The high tear-resistant cable sheath material is prepared from the following raw materials in parts by weight: 53 to 69 parts of nitrile rubber, 18 to 32 parts of polypropylene, 10 to 18 parts of butadiene styrene rubber, 6 to 12 parts of polyurethane elastomer, 1 to 3 parts of black carbon N330, 18 to 27 parts of organophosphate ester modified nanometer clay, 2 to 5 parts of calcium carbonate, 4 to 10 parts of polyester fiber, 0.5 to 2 parts of sulfur powder, 2 to 4 parts of accelerant DM, 1 to 3 parts of accelerant TT, 1 to 5 parts of active zinc oxide, 1 to 3 parts of main antioxidant, 0.5 to 1 part of auxiliary antioxidant, 1 to 3 parts of main ultraviolet absorbing agent, 0.5 to 1 part of auxiliary ultraviolet absorbing agent, 5 to 12 parts of paraffin oil, 2 to 6 parts of trioctyl trimellitate, 3 to 5 parts of tributyl citrate, and 1 to 3 parts of lubricating agent. The high tear-resistant cable sheath material has the advantages that the tear-resistant property, tensile strength and other mechanical property are excellent, the flame-retardant property is good, and the anti-aging property is realized.

Owner:天长市康宁甘油科技有限公司

Method for producing low-iron high-pervious self-cleaning ultra-white rolling glass

The invention discloses a method for producing low-iron high-pervious self-cleaning ultra-white rolling glass. Prepared materials comprise components in parts by mass as follows: 68% to 75% of SiO2, 9% to 15% of Na2O, 8% to 12% of CaO, 1% to 3% of Al2O3 and 2% to 5% of MgO, a compound strong oxidant accounting for 0.1% to 1.0% of the prepared materials is added, iron contents of the materials are controlled to be within 50ppm, and the rolling glass is formed through mixing, melting, rolling, annealing, cut loading, coating, tempering and coating curing. According to the method, the iron contents of the materials and the mass ratio of the materials are controlled, the strong oxidant is added, glass sheets are manufactured by a natural gas total oxygen combustion technology, and photoelectric properties and physical properties of the rolling glass can be improved remarkably after two times of coating, tempering and curing, so that the sunlight transmittance is improved by 2.5% to reach more than 94.5%, the photoelectric conversion efficiency of the rolling glass can be improved, a self-cleaning function is provided, and industrial application of solar ultra-white rolling glass is facilitated.

Owner:江西省速睿科技有限责任公司

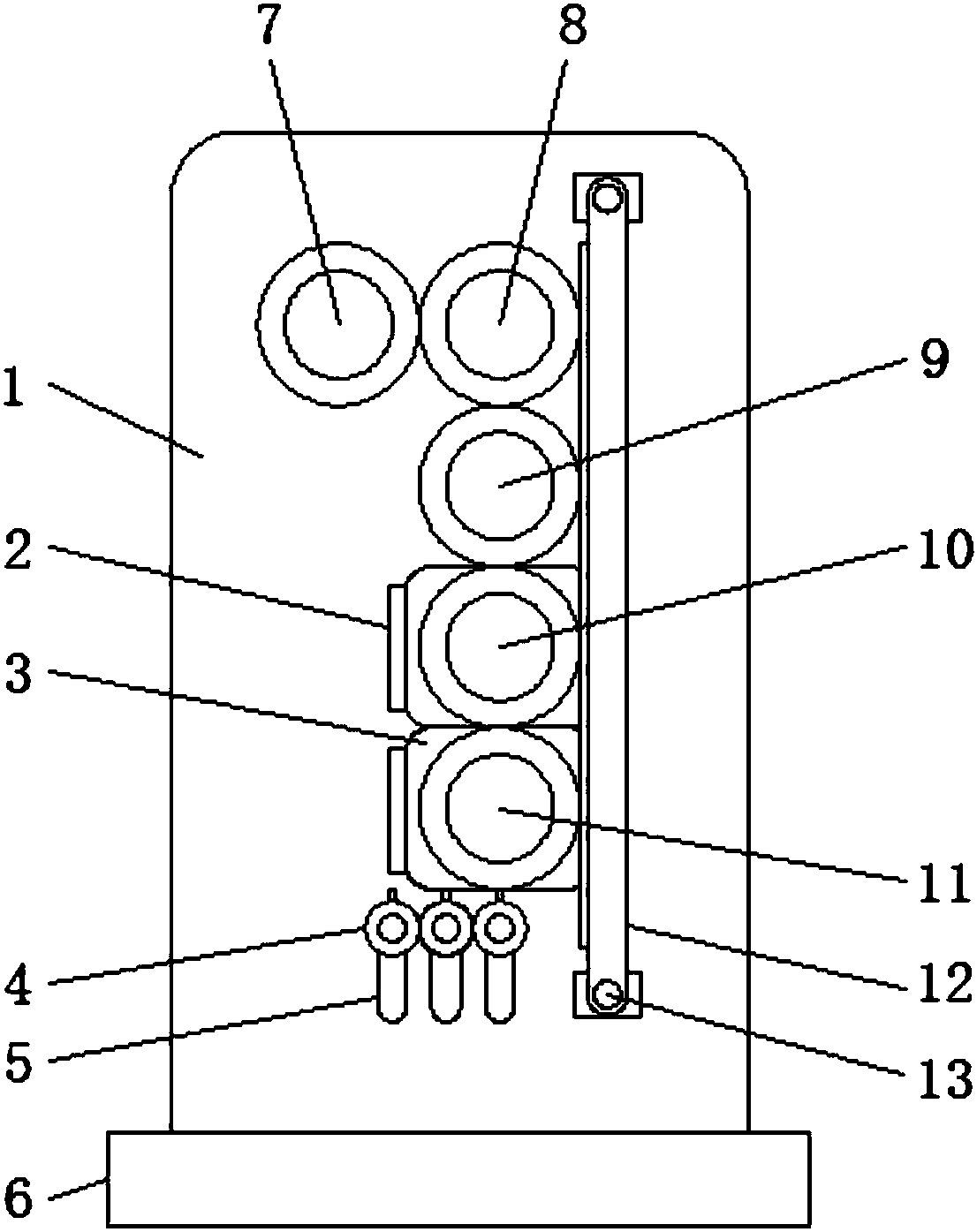

Five-roller calender for PVC film production

Owner:浙江康豪诺特装饰材料有限公司

Emergency efficient fireproof concrete pug agitating equipment and application method thereof

InactiveCN103862576APrevent splashPlay a protective effectCement mixing apparatusRefractoryMaterials science

The invention provides emergency efficient fireproof concrete pug agitating equipment and an application method thereof, belonging to the field of application of unshaped fireproof materials, and particularly relates to an emergency efficient fireproof concrete pug agitating method. The emergency efficient fireproof concrete pug agitating equipment is characterized by comprising a stainless steel boat, a pulling rope and an attaching type high-frequency vibrator, wherein the stainless steel boat is in a box shape with an opened upper end; the stainless steel boat is provided with a hanging ring; the hanging ring is connected with the pulling rope; the stainless steel boat is internally provided with the attaching type high-frequency vibrator. The agitating equipment provided by the invention is portable and practical; the equipment is combined with manual agitation so as to obtain high-quality mixed agitated fireproof concrete pug.

Owner:SHANDONG YAOHUA REFRACTORY MATERIAL SCI & TECH CO LTD

High-hardness plastic paving material

InactiveCN106810784AHigh hardnessImprove liquiditySynthetic resin layered productsFloor coveringsPlasticizerHardness

Owner:SHANGHAI JINKA FLOORING TECH

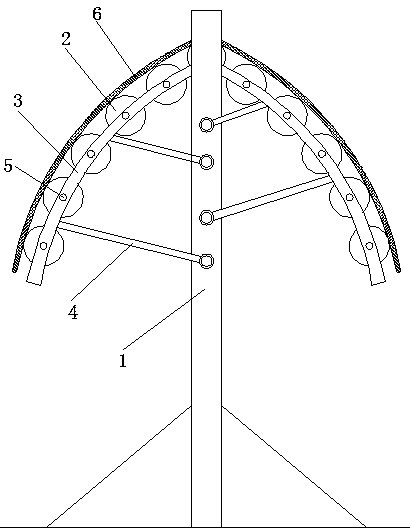

Flame-retardant high-temperature-resistant cable

ActiveCN105845246AGood weather resistanceGood oil resistanceInsulated cablesInsulated conductorsCopper conductorEpoxy

The invention discloses a flame-retardant high-temperature-resistant cable comprising a copper conductor, a fluoroplastic insulating layer wrapping the copper conductor, a silicone rubber inner sheath wrapping the fluoroplastic insulating layer, and an oversheath wrapping the silicone rubber inner sheath, wherein the oversheath is made of natural rubber composite material, and the raw materials of the natural rubber composite material include natural rubber, terpolymer EP rubber, butyl rubber, nylon 66, epoxy resin, eleaostearic acid, zinc oxide, sulphur, Bis(tert-butylperoxy), N,N'-m-phenylenedimaleimide, montmorillonite, kaolin, powdered steatile, zinc borate, aluminium hydroxide, promoter MBTS, promoter DPG, promoter CBS, antioxidant and phosphorus-containing fire retardant. The flame-retardant high-temperature-resistant cable is high in strength and has excellent high temperature resistant, aging resistant and flame retardant performances.

Owner:广州粤道智能科技发展有限公司

Polymer alloy for rubber ducts and preparation method thereof

ActiveCN102838791AGood weather resistanceImprove flame retardant performanceRigid pipesPolymer alloyAlloy

The invention discloses polymer alloy for rubber ducts. The alloy comprises the following raw materials in part by weight: 20 to 30 parts of CM135B, 70 to 80 parts of NBR3305, 4 to 6 parts of magnesium oxide, 4 to 6 parts of coumarone resin, 25 to 35 parts of high abrasion carbon black, 60 to 80 parts of general purpose carbon black, 5 to 15 parts of white carbon black, 6 to 12 parts of dibutyl ester, 1.2 to 2.5 parts of sulphur, 0.5 to 1.5 parts of accelerating agents CZ, 3 to 8 parts of composite curing agents EataMixTCHC, 10 to 20 parts of distilled aromatic extracts(DAE), 0.5 to 1.5 parts of anti-aging agents RD, 0.3 to 0.8 part of antiscorching agents CTP and 15 to 25 parts of white bole. According to the invention, the alloy improves the abrasion resistance, the ozone aging resistance, the weathering ageing resistance and the fire resistance of acrylonitrile-butadiene rubber, improves the rolling and the extruding of rubber stocks, improves the fineness of the rubber stocks, reduces shrinking percentage, improves the tensile strength and the tearing resistance of the rubber stocks, has small permanent deformation, improves the oil resistance and the corrosion resistance of the rubber stocks, prolongs the service life, effectively reduces production costs and further increases the quality of products.

Owner:河南亿博科技股份有限公司

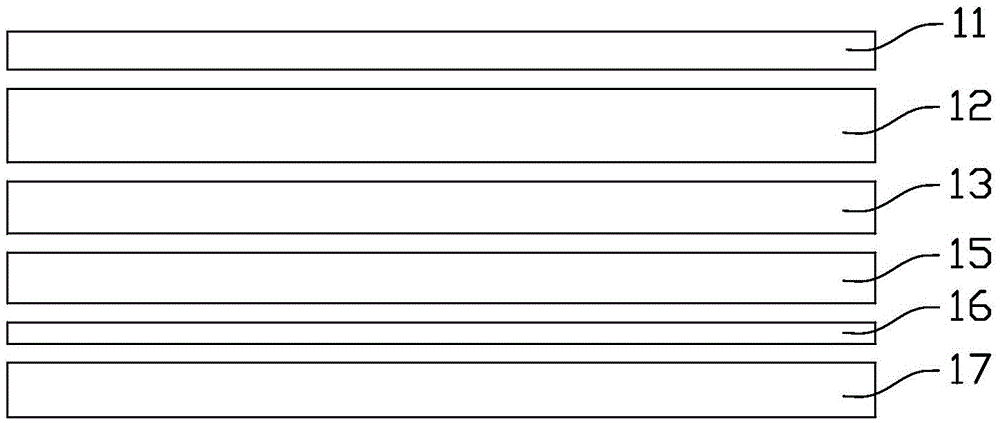

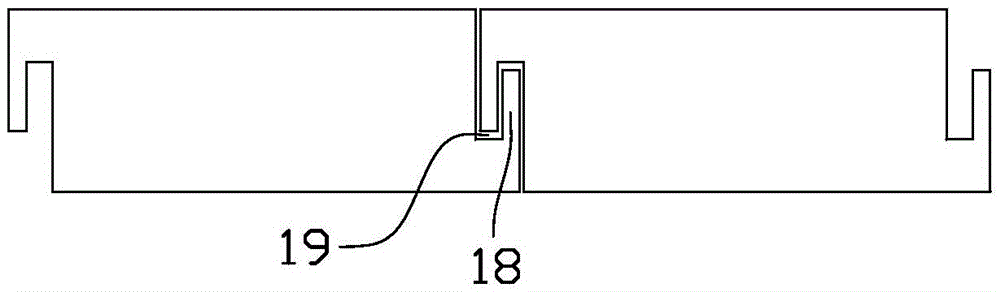

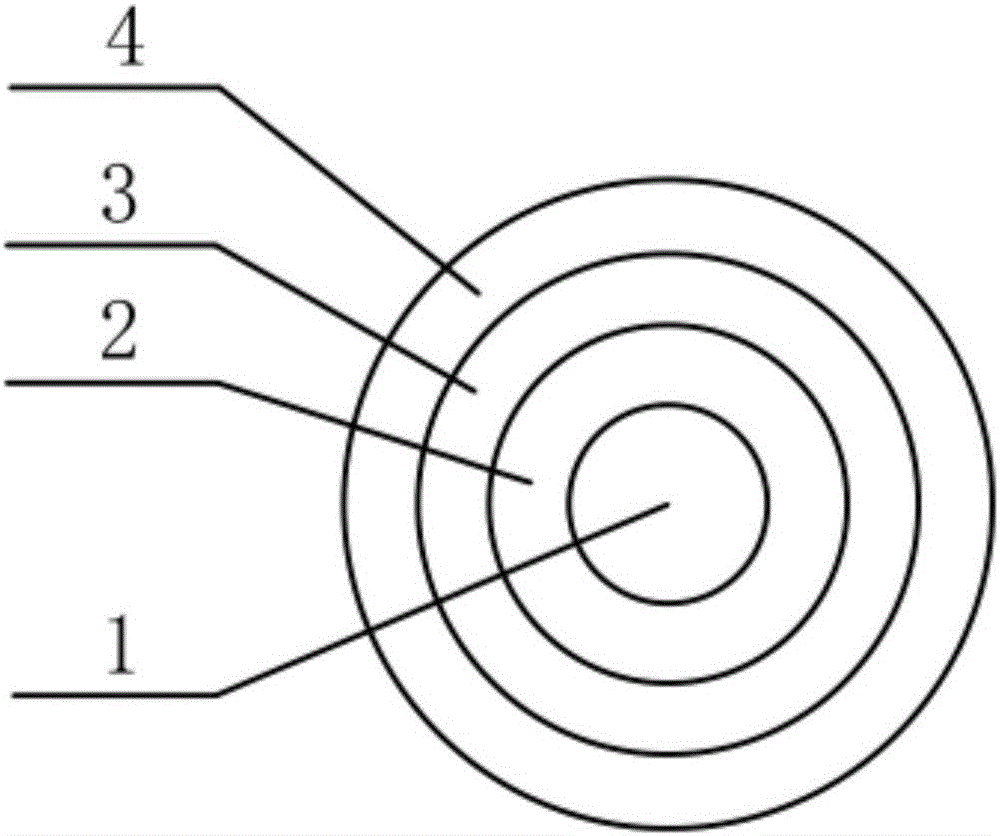

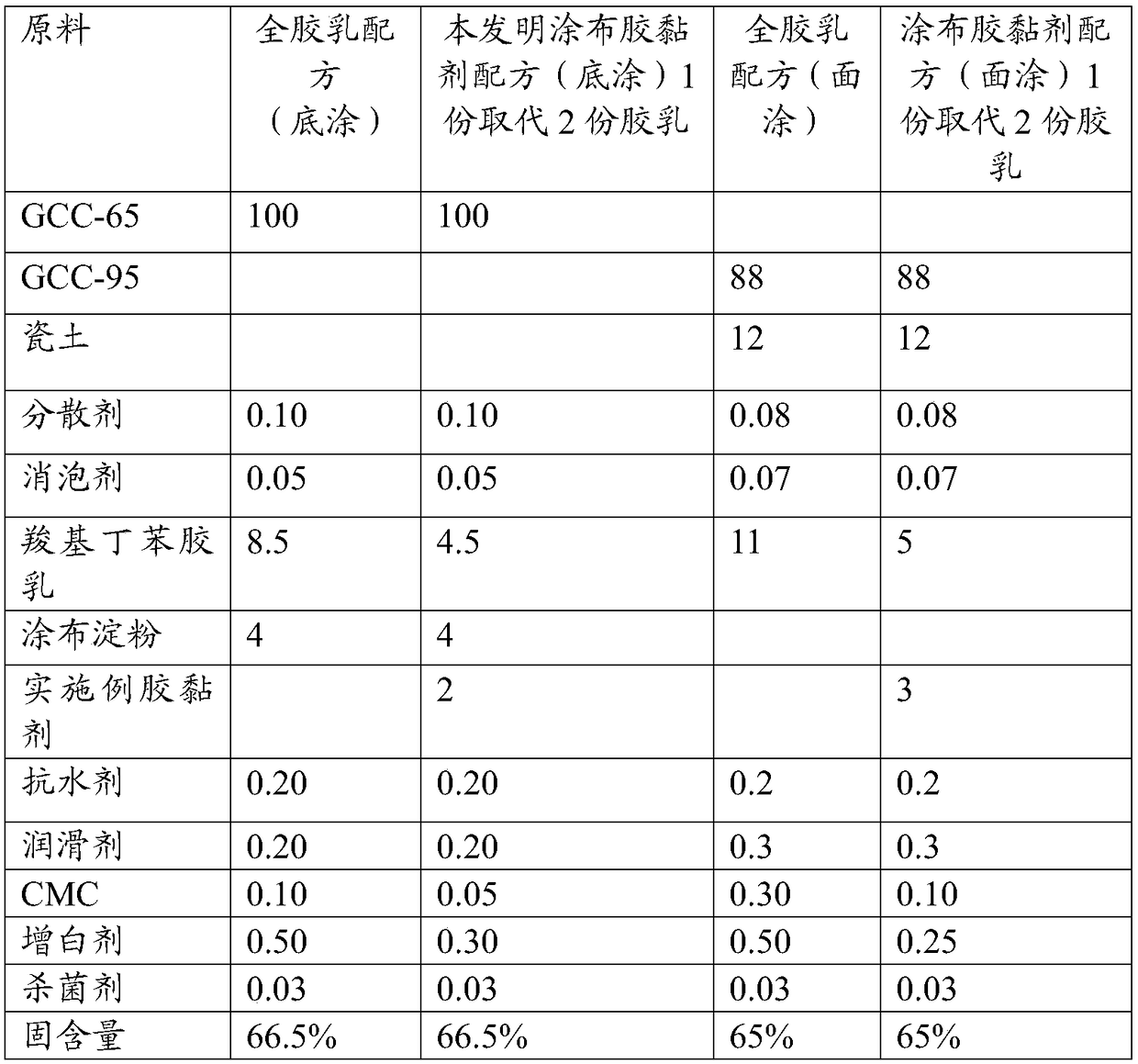

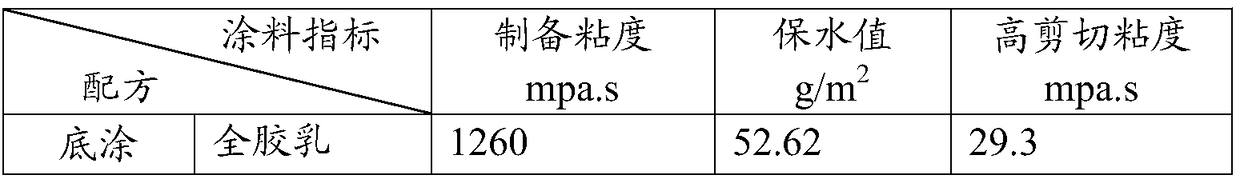

Environmental-friendly coating adhesive and preparation method thereof

ActiveCN108867167AReduce dosageReduce manufacturing costNon-fibrous pulp additionPaper coatingEmulsionPetroleum

The invention discloses an environmental-friendly coating adhesive and a preparation method thereof. The environmental-friendly coating adhesive is prepared from the following components: a starch emulsion with the mass concentration being 30 percent to 60 percent, a plasticizer, a polyvinyl acetate (PVA) solution with the mass concentration being 20 percent to 30 percent, a cross-linking agent, an initiator and a modified monomer. According to the coating adhesive provided by the invention, the adhesive property of the coating adhesive is better than the adhesive property of carboxylic butadiene-styrene latex, the coating adhesive can partially and even fully replace the carboxylic butadiene-styrene latex, and the dosage of the overall adhesive is reduced, so that the production cost of coating paper is reduced, and the non-renewable petroleum resource can be saved.

Owner:QUFU NORMAL UNIV +1

Preparing process for microporous teflon membran

InactiveCN1195008CImprove plasticityEasy to calenderSemi-permeable membranesPolytetrafluoroethyleneHigh productivity

A microporous teflon film is prepared from the dispersed teflon resin and the arylhydrocarbon-removel isoparaffin in weight ratio of 100:(20-40) through heating to 100-200 deg.c for removing lubricating assistance, longitudinal stretching and transverse stretching under control of computer, and fixing shape at 250-400 deg.C. Its advantages are no harmful gas releasing in its production, high productivity, and high quality.

Owner:宁波登天氟材有限公司

Four-roller plastic calender with wider application range

The invention relates to the field of plastic processing, and discloses a four-roller plastic calender with a wider application range. The four-roller plastic calender comprises a calender shell, wherein a first sliding rod is arranged inside the calender shell, and the surface of the first sliding rod is slidably connected with sliding blocks; the surfaces of the sliding blocks are sleeved with moving plates, rotating discs are rotationally connected to the ends, away from the first sliding rod, of the sliding blocks, and rolling rollers are rotationally connected to the other ends of the rotating discs; and a rotating handle is connected to the right side of the calender shell in an inserted mode, a gear is fixedly connected to the surface of the left end of the rotating handle, and a bearing is fixedly connected to the surface of the rotating handle; and second connecting rods are fixedly connected to one sides of the sliding blocks. The moving plates, the gear, the rotating handle,the bearing and the sliding blocks are arranged to form the device capable of being lifted manually, and synchronous lifting of the rolling rollers can be guaranteed, so that deviation, caused by lifting, of calendered plastic is avoided, and the practicability and functionality of the device are improved.

Owner:张怀文

Production technology for coarse double-grain rubber slab

The invention discloses a production technology for a coarse double-grain rubber slab. The production technology comprises the following steps: 1) raw material pretreatment; 2) weighing preparation; 3) mixing; 4) calendering; 5) cooling; 6) grain cloth pretreatment; 7) vulcanization; 8) inspection; and 9) trimming, inspection and packaging. The production technology improves the pretreatment of arubber compound, and correspondingly refines latex reclaimed rubber and natural rubber, so the plasticity of the latex reclaimed rubber is improved, subsequent calendering, extrusion and molding are facilitated, and the obtained coarse double-grain rubber slab has a stable shape and a clear pattern.

Owner:宣城新润发高分子科技有限公司

A flame retardant and high temperature resistant cable

ActiveCN105845246BGood weather resistanceGood oil resistanceInsulated cablesInsulated conductorsCopper conductorEpoxy

The invention discloses a flame-retardant high-temperature-resistant cable comprising a copper conductor, a fluoroplastic insulating layer wrapping the copper conductor, a silicone rubber inner sheath wrapping the fluoroplastic insulating layer, and an oversheath wrapping the silicone rubber inner sheath, wherein the oversheath is made of natural rubber composite material, and the raw materials of the natural rubber composite material include natural rubber, terpolymer EP rubber, butyl rubber, nylon 66, epoxy resin, eleaostearic acid, zinc oxide, sulphur, Bis(tert-butylperoxy), N,N'-m-phenylenedimaleimide, montmorillonite, kaolin, powdered steatile, zinc borate, aluminium hydroxide, promoter MBTS, promoter DPG, promoter CBS, antioxidant and phosphorus-containing fire retardant. The flame-retardant high-temperature-resistant cable is high in strength and has excellent high temperature resistant, aging resistant and flame retardant performances.

Owner:广州粤道智能科技发展有限公司

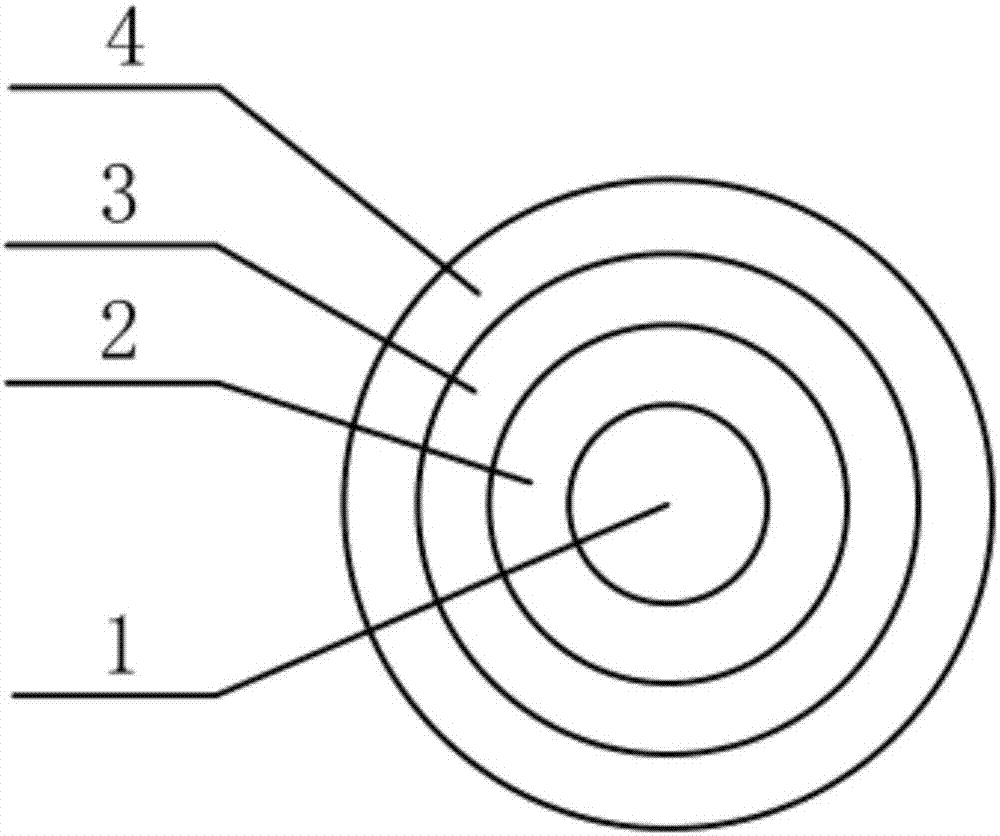

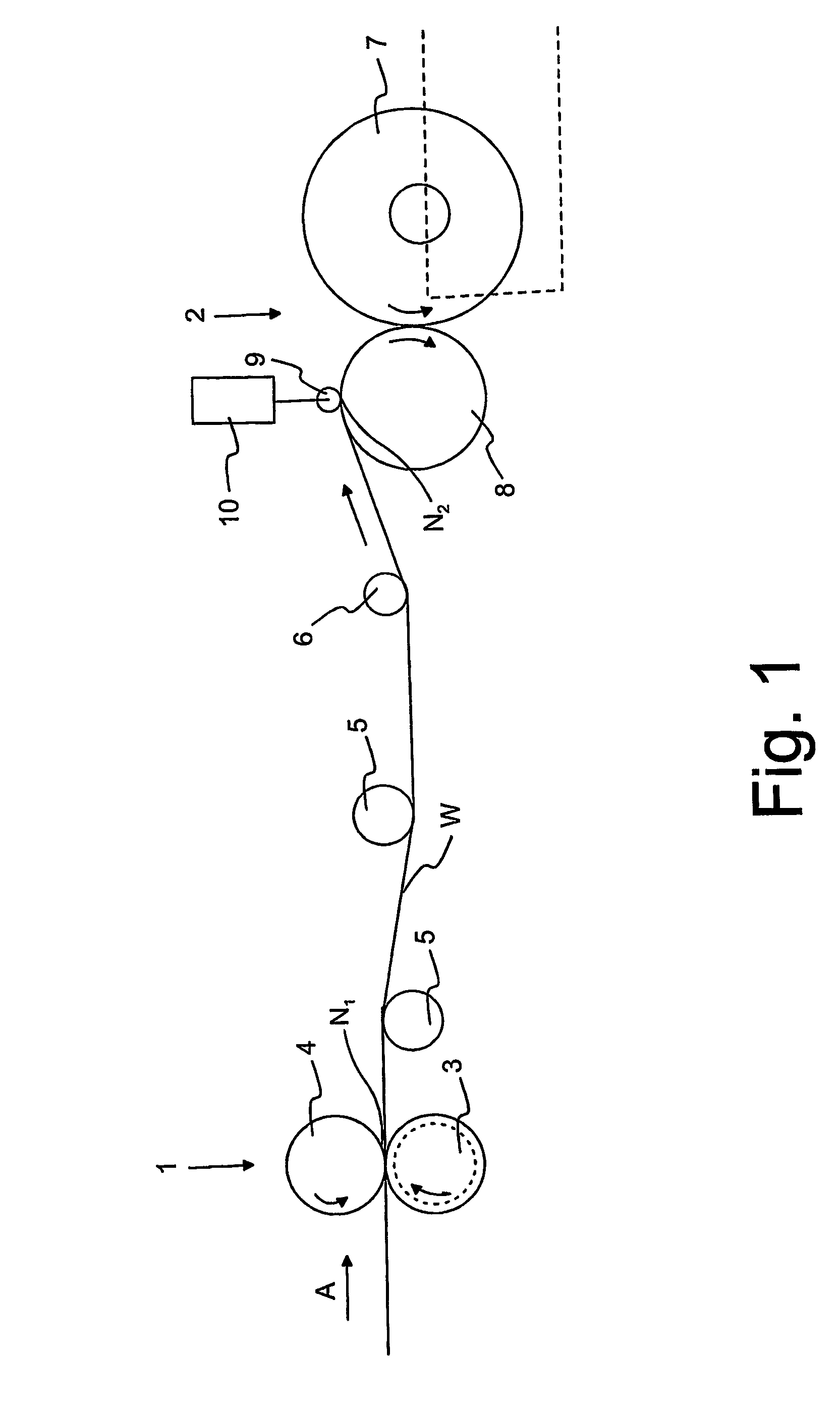

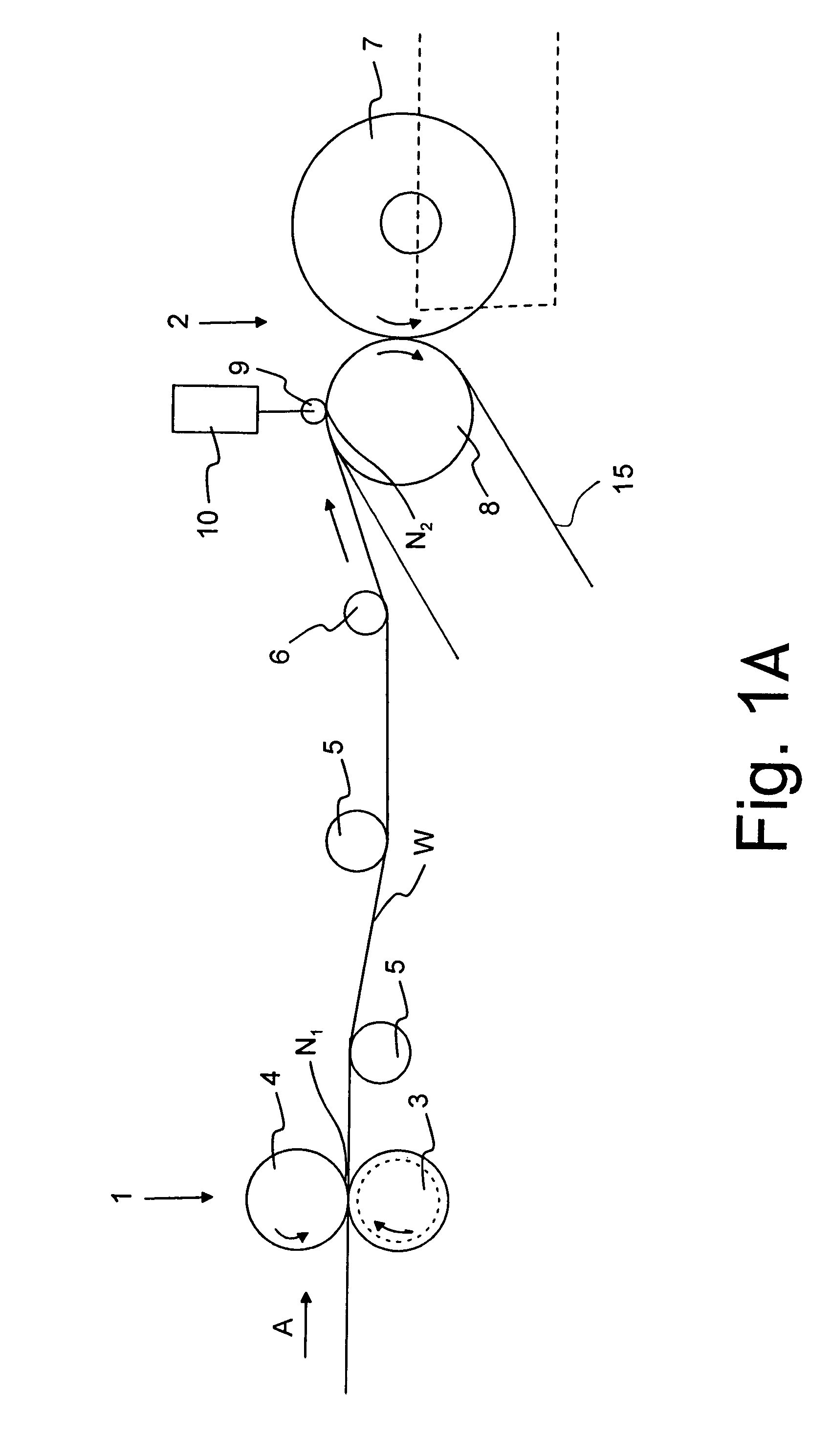

Method and apparatus for calendering a paper or paperboard web

InactiveUS7438784B2Easy to calenderNon-fibrous pulp additionNatural cellulose pulp/paperPaperboardPulp and paper industry

A method and a device for calendering a paper or paperboard web, in which the web is led first into a calendering step and then into a reeling step. At least one edge area of the web is calendered separately in the reeling step.

Owner:VALMET TECH INC

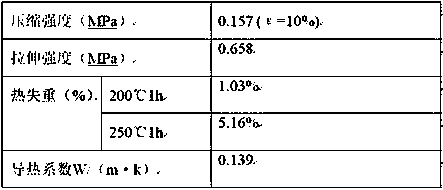

Insulation sealing rubber strip for switch cabinets, and production method thereof

The invention belongs to the field of rubbers, and concretely relates to an insulation sealing rubber strip for switch cabinets, and a production method thereof. The insulation sealing rubber strip comprises an inner layer and an outer layer; the inner layer is made from nitrocellulose resin, n-butyl methacrylate, cis-polybutadiene rubber, ethylene-propylene-diene monomer, bromobutyl rubber, reticular polyimide, calcium carbonate, paraffin oil, attapulgite, carbon nanofibers, stearic amide, zinc oxide, N-cyclohexyl-2-benzothiazole sulfenamide, sulfur, carbon black, white carbon black, tackifying resin, titanate, phenyl silicone oil, a plasticizer, an antioxidant and assistants; and the outer layer is made from polyimide, calcium carbonate, microcrystalline wax, the antioxidant and the assistants. The insulation sealing rubber strip has the advantages of good insulation property, good ozone resistance, good thermal ageing resistance, good low temperature resistance, good chemical corrosion resistance, good impact and water resistance, and high toughness, strength and wear resistance. The invention also provides the production method of the insulation sealing rubber strip.

Owner:吴江兴业橡胶有限公司

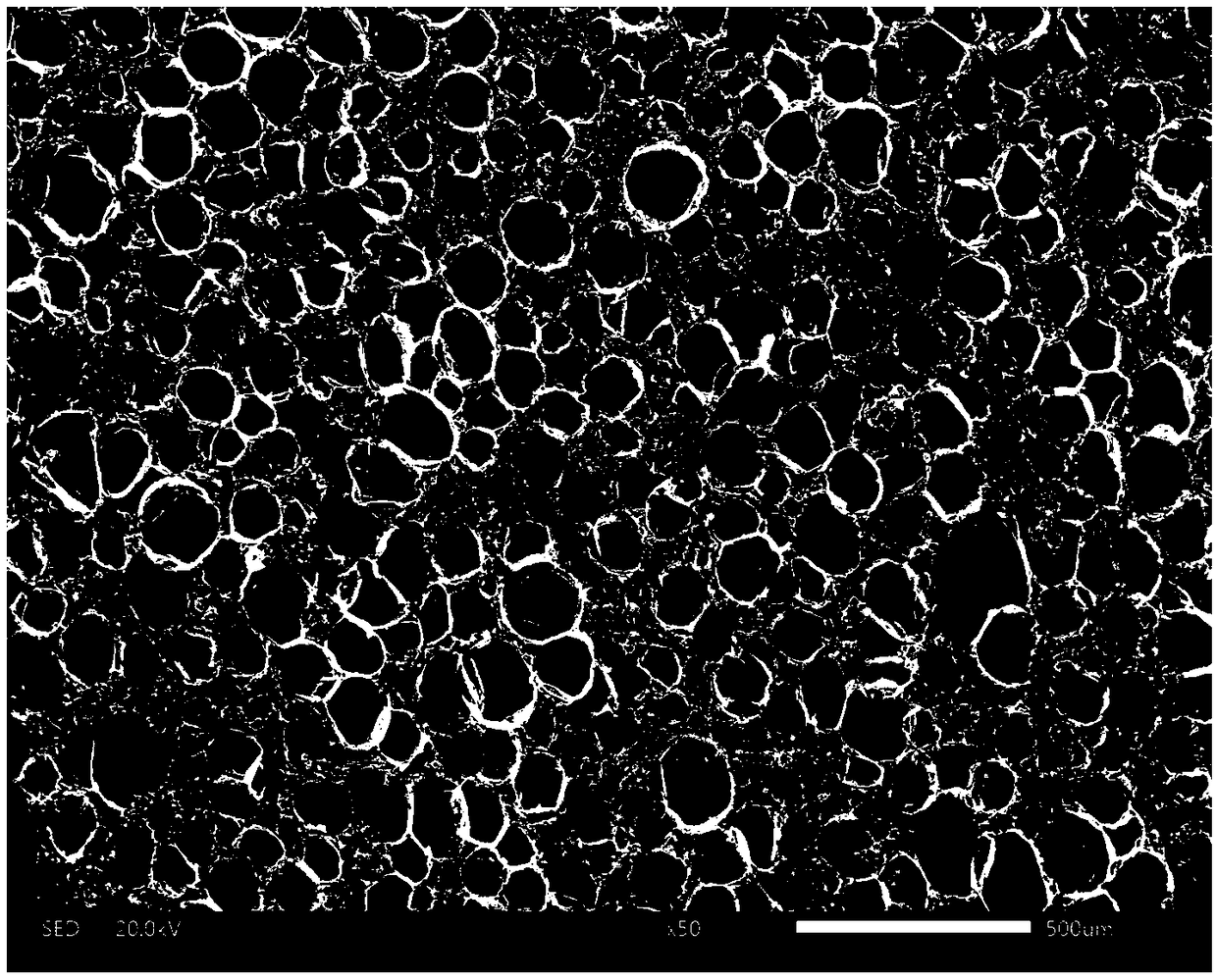

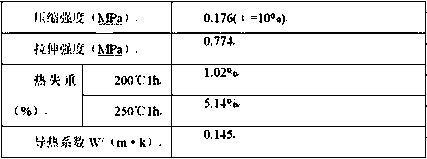

Expandable silicone rubber sheet and preparation method thereof

The invention discloses an expandable silicone rubber sheet and a preparation method thereof. The expandable silicone rubber sheet is prepared from the following components in parts by weight: 100 parts of silicone rubber, 10 to 30 parts of white carbon black, 100 to 150 parts of filler, 3 to 5 parts of vulcanizing agent, 6 to 10 parts of foaming agent and 3 to 8 parts of hydrogenated silicone oil. The preparation method of the expandable silicone rubber sheet comprises the following steps: putting and mixing the silicone rubber and the white carbon black in proportion in an open mill, then sequentially adding the filler, the vulcanizing agent, the foaming agent and the hydrogenated silicone oil, and mixing, thus preparing the expandable silicone rubber sheet. The expandable silicone rubber sheet disclosed by the invention can be used as a filling material for filling a gap of a structural member, and the gap of the structural member can be spontaneously filled during a temperature rising process through foaming; compared with a foamed silicone rubber filling material prepared by a traditional method, the preparation method has the advantages that advanced foaming is not required,the expandable silicone rubber sheet and the structural member are integrally formed, filling is compact, the foaming is uniform, and the like.

Owner:WUHAN UNIV OF TECH

High-efficiency and environmental protection cleaning agent special for aluminum pot

The invention provides a high-efficiency and environmental protection cleaning agent special for an aluminum pot. Production equipment, a heat-resistant and alkali-resistant stainless steel reactor and an acid and alkali-resistant mixer are prepared. The preparation process of the cleaning agent comprises the steps: first, starting production, and adding tap water of general water level to the reactor; second, adding 10-40% of caustic soda to the reactor in turn, turning on the mixer for mixing to dissolve completely, letting the mixture stand and cooled to the room temperature; third, turning on the mixer, and adding 0.5-3% of molybdate dissolving completely; forth, adding 0.5-5% of sodium gluconate, and mixing to dissolve completely; fifth, adding 0.5-5% of sodium polyacrylate with low molecular weight, and mixing to dissolve completely; sixth, adding 0.1-0.5% of sodium chloride, and mixing to dissolve completely; seventh, adding 0.1-0.5% of corrosion inhibitor, and mixing to dissolve completely; eighth, adding the surplus water, and mixing for half an hour till the solution concentration is uniform; ninth, filling after passing inspection. In the invention, the cleaning efficiency and the environmental protection performance are improved greatly.

Owner:佛山市海明威生态科技股份有限公司

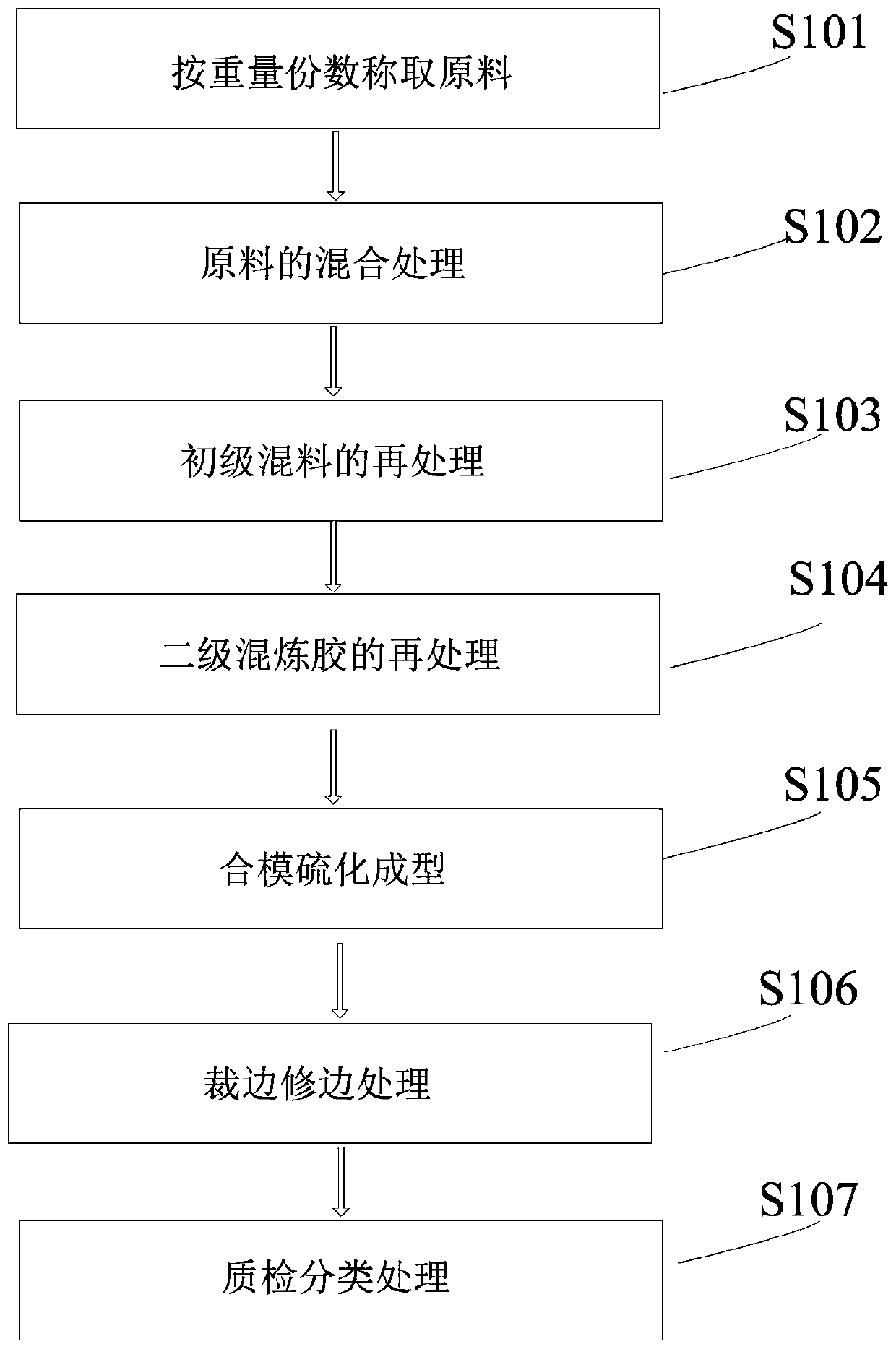

Anti-aging rubber sealing ring material and preparation method thereof

The invention provides an anti-aging rubber sealing ring material and a preparation method thereof, and belongs to the technical field of rubber sealing materials. The preparation method of the anti-aging rubber sealing ring material comprises the following steps of weighing of raw materials by weight, raw material mixing, primary mixed material re-treatment, secondary rubber compound re-treatment, die assembly and vulcanization molding, edge cutting and trimming, and quality inspection and classification. The anti-aging rubber sealing ring material and the preparation method thereof have theadvantages that bauxite powder is dispersed in a raw material network structure, so that the wear resistance of a rubber gasket is improved; due to the use of a plasticizer, the vitrification temperature of rubber is reduced, the plasticity and fluidity of the rubber are enhanced, and the hardness and tensile stress of the rubber are reduced; nano silicon dioxide and quartz fiber are added, so that the pressure resistance, anti-aging performance and corrosion resistance of the sealing ring material are enhanced, and the phenomena of overflow and leakage are effectively prevented; the preparation process is simple, and the cost is low.

Owner:杭州泰妍流体科技有限公司

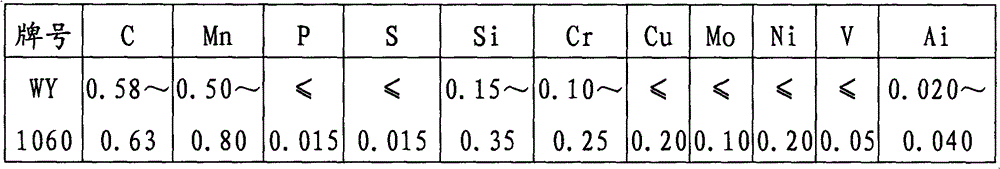

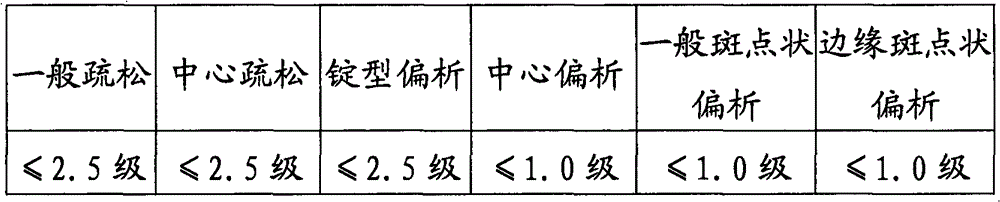

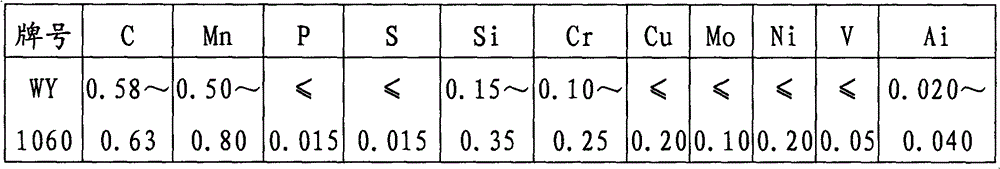

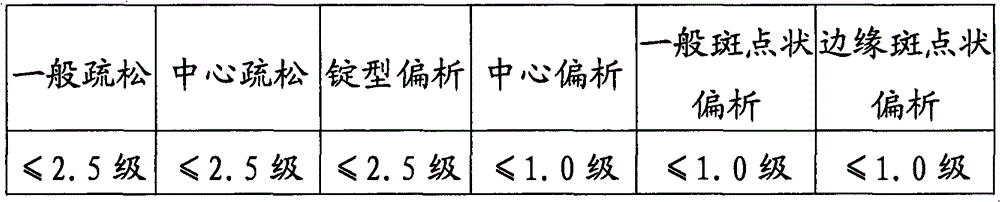

Material used in ballscrew

ActiveCN102719765AOvercome weaknessImprove internal organizational structureGearingWeaknessQuenching

The invention provides a material used in a ballscrew. The material comprises the following components in percentage by weight: 0.58-0.63% of carbon element, 0.5-0.80% of manganese element, less than or equal to 0.015% of phosphorus element, less than or equal to 0.015% of sulfur element, 0.15-0.35% of silicon element, 0.10-0.25% of chromium element, less than or equal to 0.20% of copper element, less than or equal to 0.10% of molybdenum element, less than or equal to 0.20% of nickel element, less than or equal to 0.05% of vanadium element, 0.020-0.040% of aluminum element, and the balance iron element. Steel smelted by adopting the alloy-elements-containing material of the invention overcomes weaknesses of GCr15 steel completely, improves internal organizational structure of the steel, reserves the original advantages of the GCr15 steel, is easy-cutting and easy-calendering, and improves the quenching brittleness and deformation ability; in addition, the material of the invention is particularly suitable for production adopting a cold-rolling technology; therefore, the traditional productive technology of the ballscrew is completely changed, and excellent social and economic effects are created.

Owner:安徽省威远精密工业科技有限公司

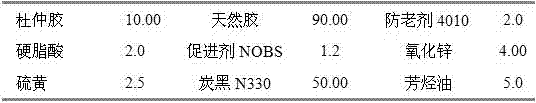

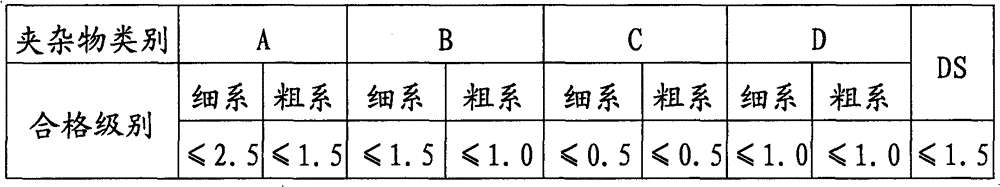

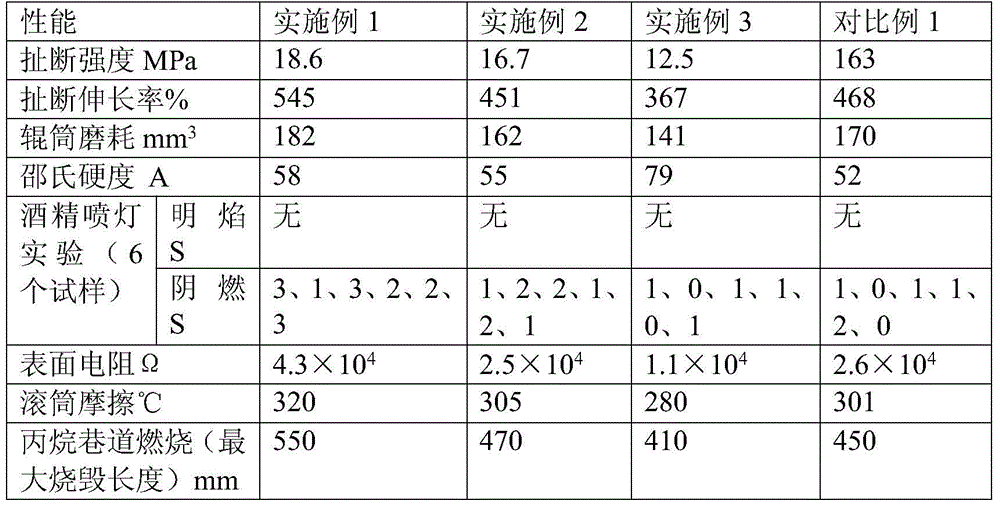

Fabric core laminated flame retardant conveyor belt cover layer rubber and preparation method thereof

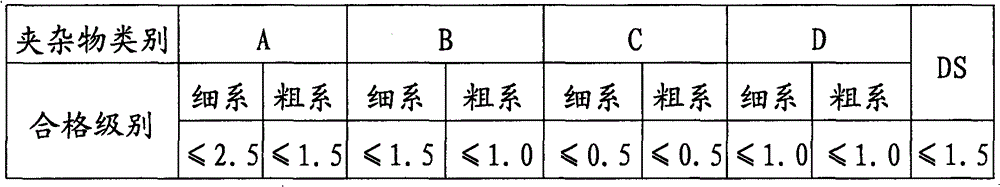

The invention relates to rubber for a fabric core laminated flame-retardant conveyor belt covering layer and a preparation method thereof, belonging to the technical field of flame-retardant covering. The preparation method comprises the following steps: adding chlorinated polyethylene, butadiene styrene rubber and natural rubber into an internal mixer or an open mill; sequentially adding a flame retardant, metal oxides, stearic acid, an anti-aging agent, a reinforcing agent and a plasticizer; and finally, adding a vulcanizing agent and a vulcanizing accelerator, uniformly mixing to obtain covering layer rubber, and vulcanizing on a flat vulcanizing plate, thereby obtaining the product. The chlorinated polyethylene, butadiene styrene rubber and natural rubber serve as a matrix, a high-efficiency flame retardant is filled, and an excellent flame-retardant effect is achieved. Meanwhile, by filling carbon black and silica filler, the mechanical property is greatly improved, and high mechanical property and good flame-retardant effect can be considered simultaneously. The various performances of the covering layer rubber composite material can meet the MT830 standard.

Owner:WUXI BOTON CONVEYOR SOLUTION CO LTD

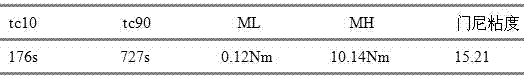

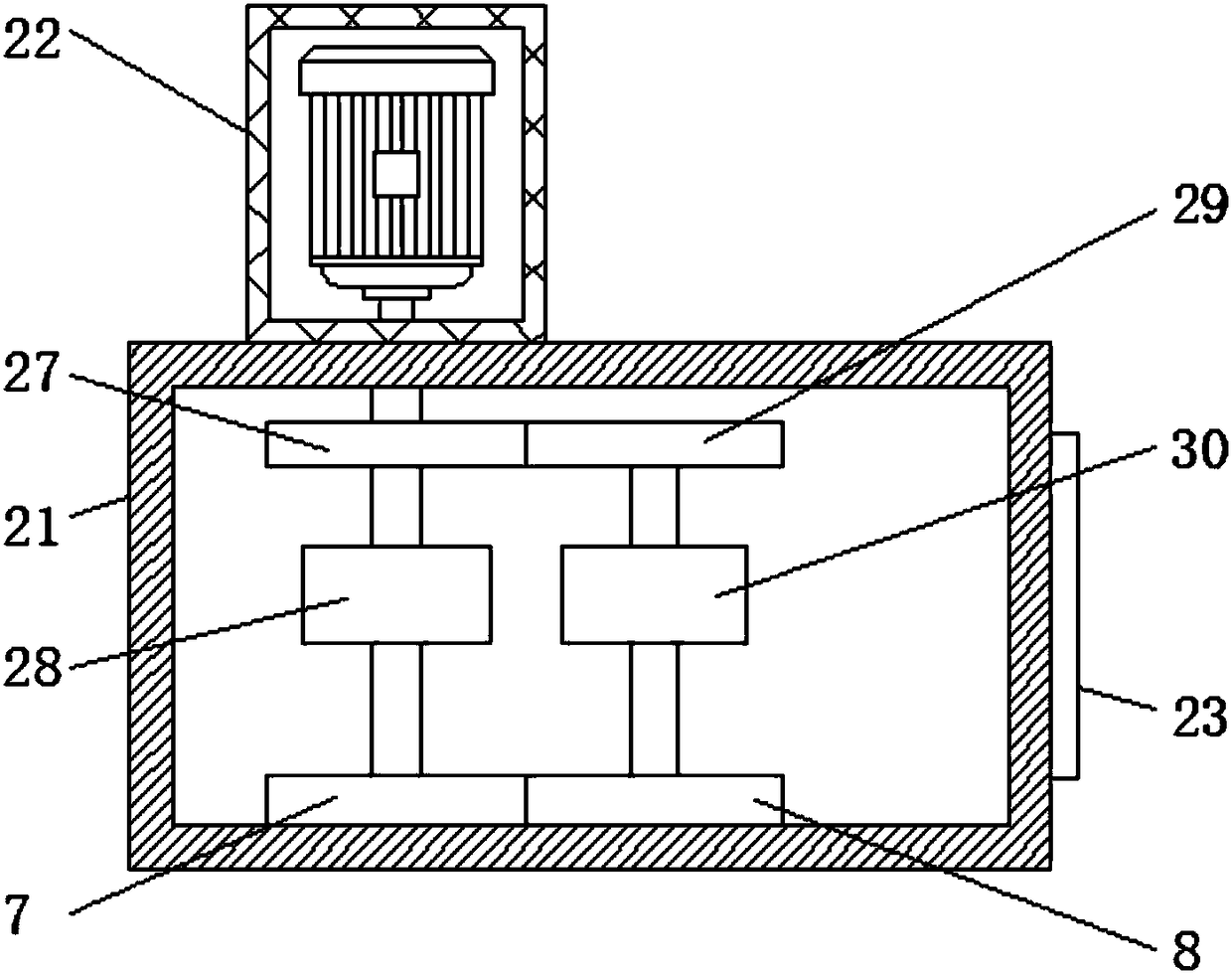

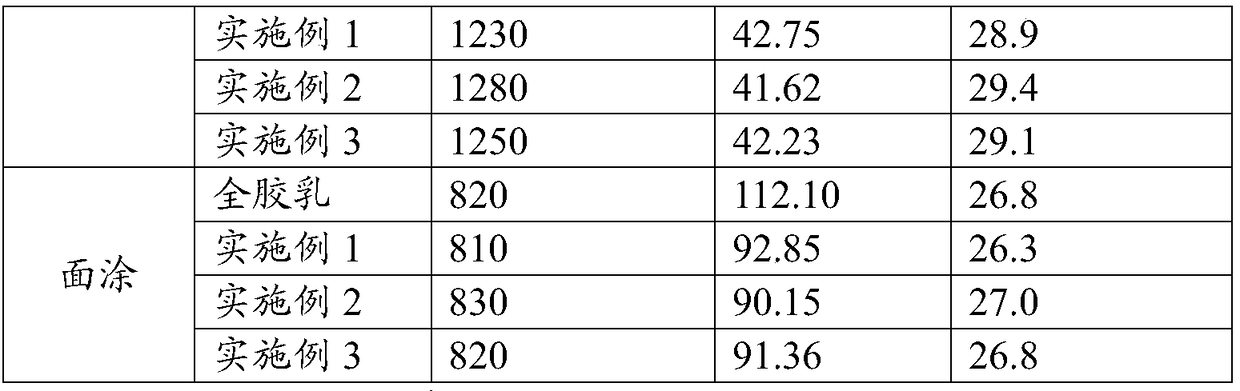

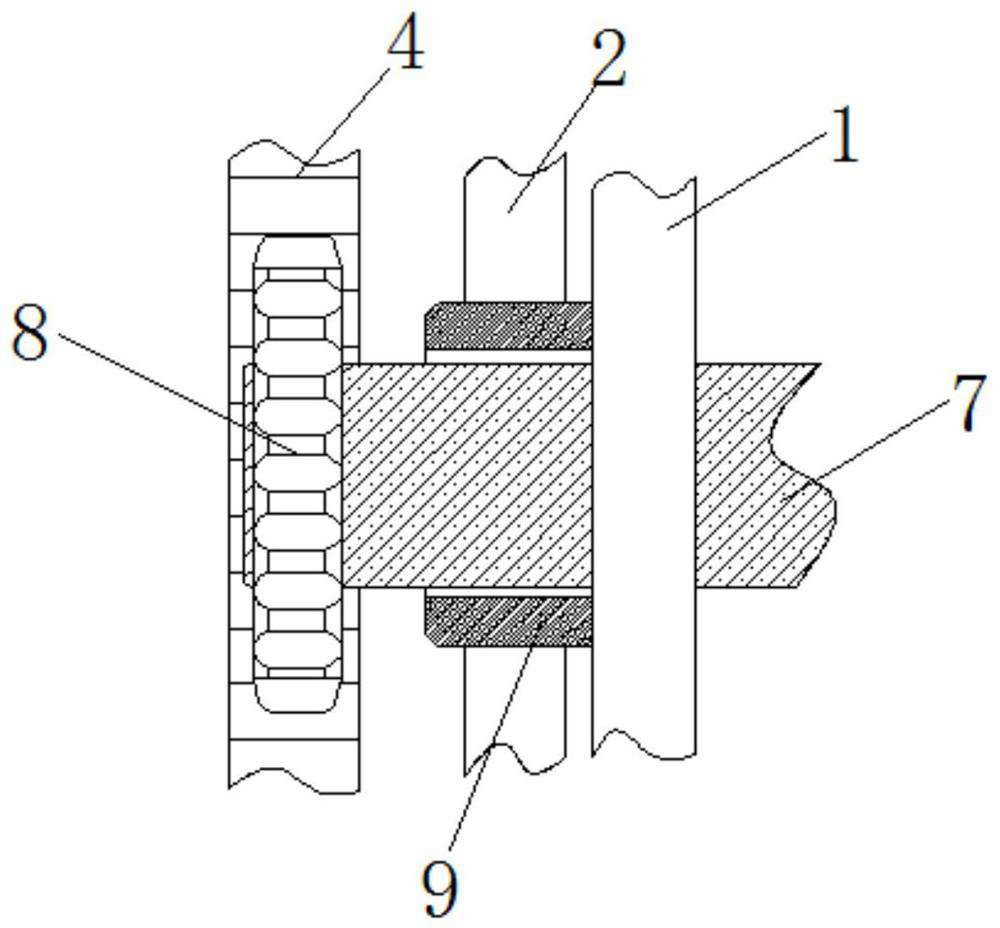

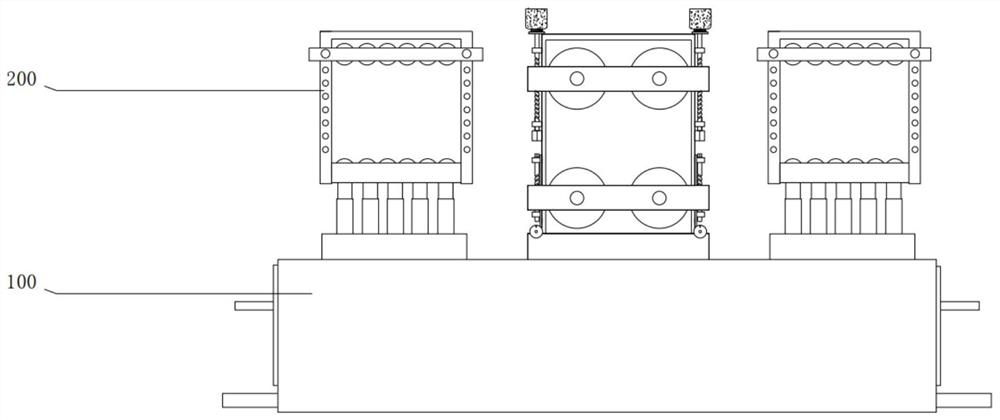

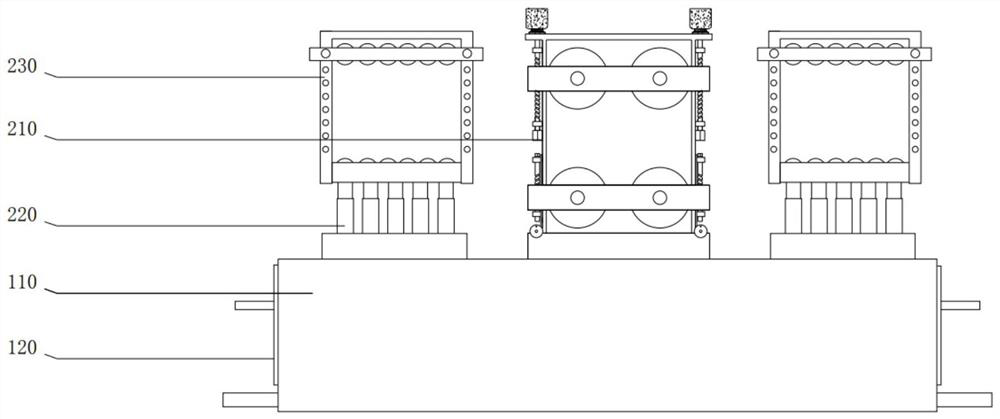

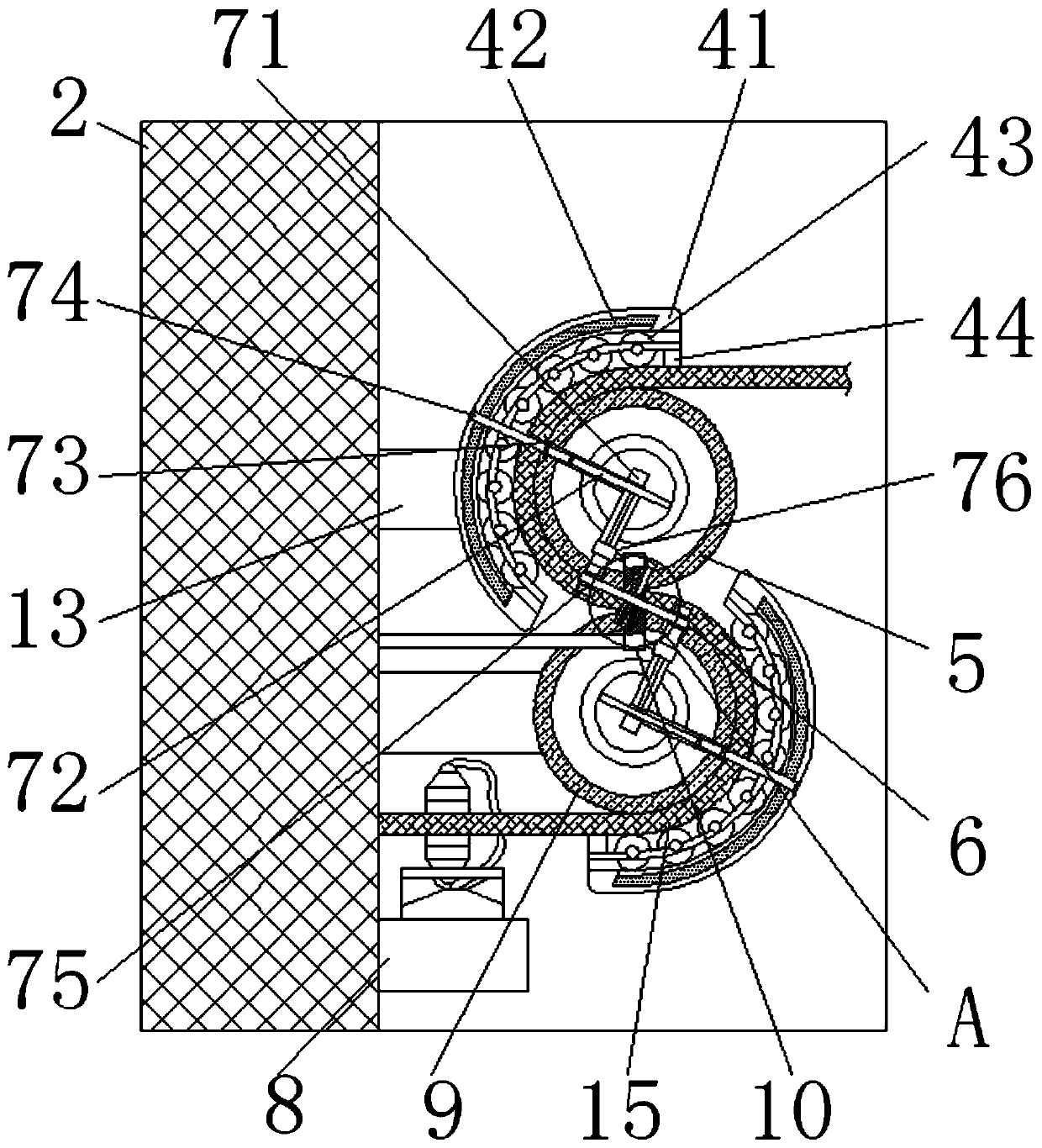

Calender with integrated adjusting mechanism

ActiveCN113231470AImprove processing efficiencyEasy to placeMetal rolling stand detailsGuiding/positioning/aligning arrangementsMechanical engineeringIndustrial engineering

The invention provides a calender with an integrated adjusting mechanism, and belongs to the technical field of steel calendering production. The calender comprises a base and calendering assemblies; the base comprises a table body and a placing frame; each calendering assembly comprises a calendering piece, a telescopic piece and a pressing piece; each calendering piece comprises a base, a calendering part and first supports; the bases are fixed on the table body; the first supports are fixed to two sides of the tops of the bases; each calendering part comprises a first groove body and a calendering roller; the rolling rollers are rotationally arranged on the inner walls of the first groove bodies; and one end of each calendering roller rotationally penetrates through one side of the corresponding first groove body. By adjusting the distance between every two adjacent first groove bodies, adjustment and use can be conveniently achieved according to the specification of a calendering material, the application range of existing steel calendering production equipment is conveniently widened, and therefore the machining efficiency of the steel calendering production equipment is improved.

Owner:福建大东海实业集团有限公司

Injection molding and compression molding method of composite tufted carpet plastic interior ornament

The invention discloses an injection molding and compression molding method of a composite tufted carpet plastic interior ornament. The method comprises the following steps of: a, selecting a composite tufted carpet; b, heating the composite tufted carpet; c, opening a mold, fixing the composite tufted carpet in the injection mold, and then closing the mold; d, injecting plastic in an amount which is 10 to 20 percent of the required injection molding total amount under low pressure at a low speed by an injection molding machine through a plurality of hot runners; e, opening the injection moldto reserve certain clearance between a movable mold and a fixed mold, and starting the injection molding machine to inject the rest plastic of the required injection molding total amount under high pressure at a high speed; f, closing the mold, forming the composite tufted carpet plastic interior ornament by pressing, and simultaneously cutting the redundant edge and cooling; and g, opening the mold, and taking out the composite tufted carpet plastic interior ornament. The method is low in production condition requirement, good in product quality and high in production efficiency, the required equipment is cheap, and the produced product can be popularized in a large range.

Owner:NINGBO SUNLIGHT MOTOR PARTS

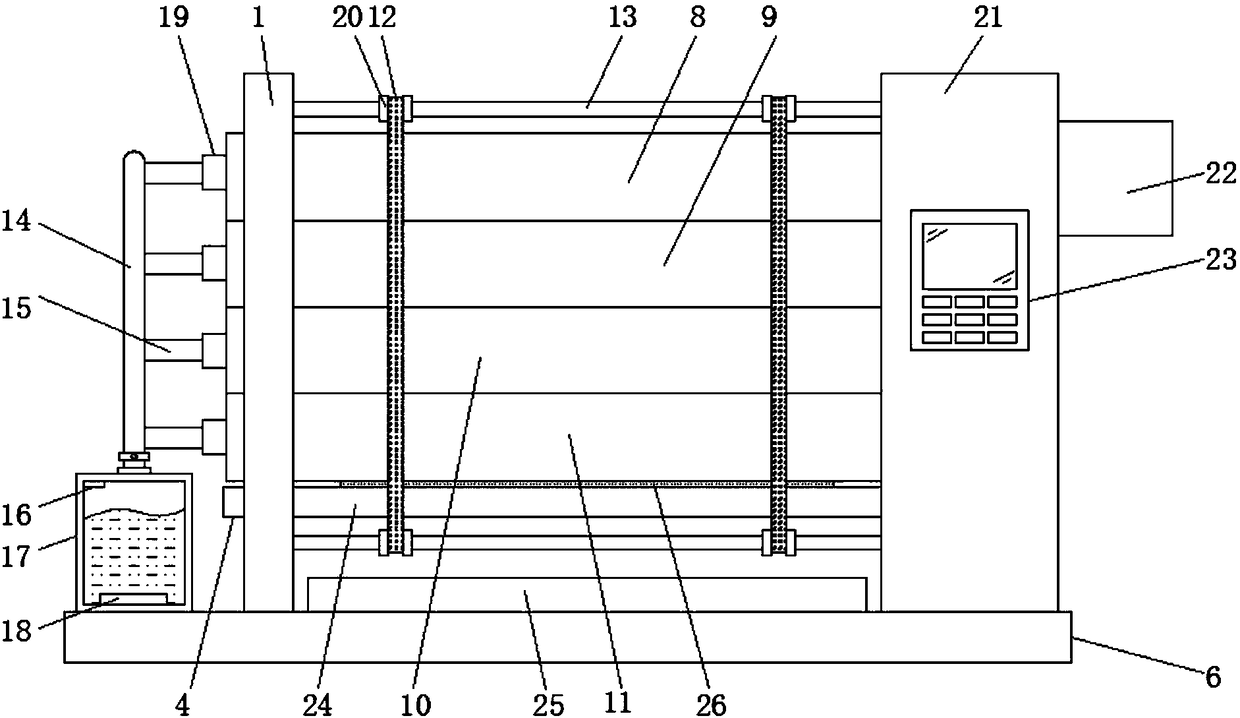

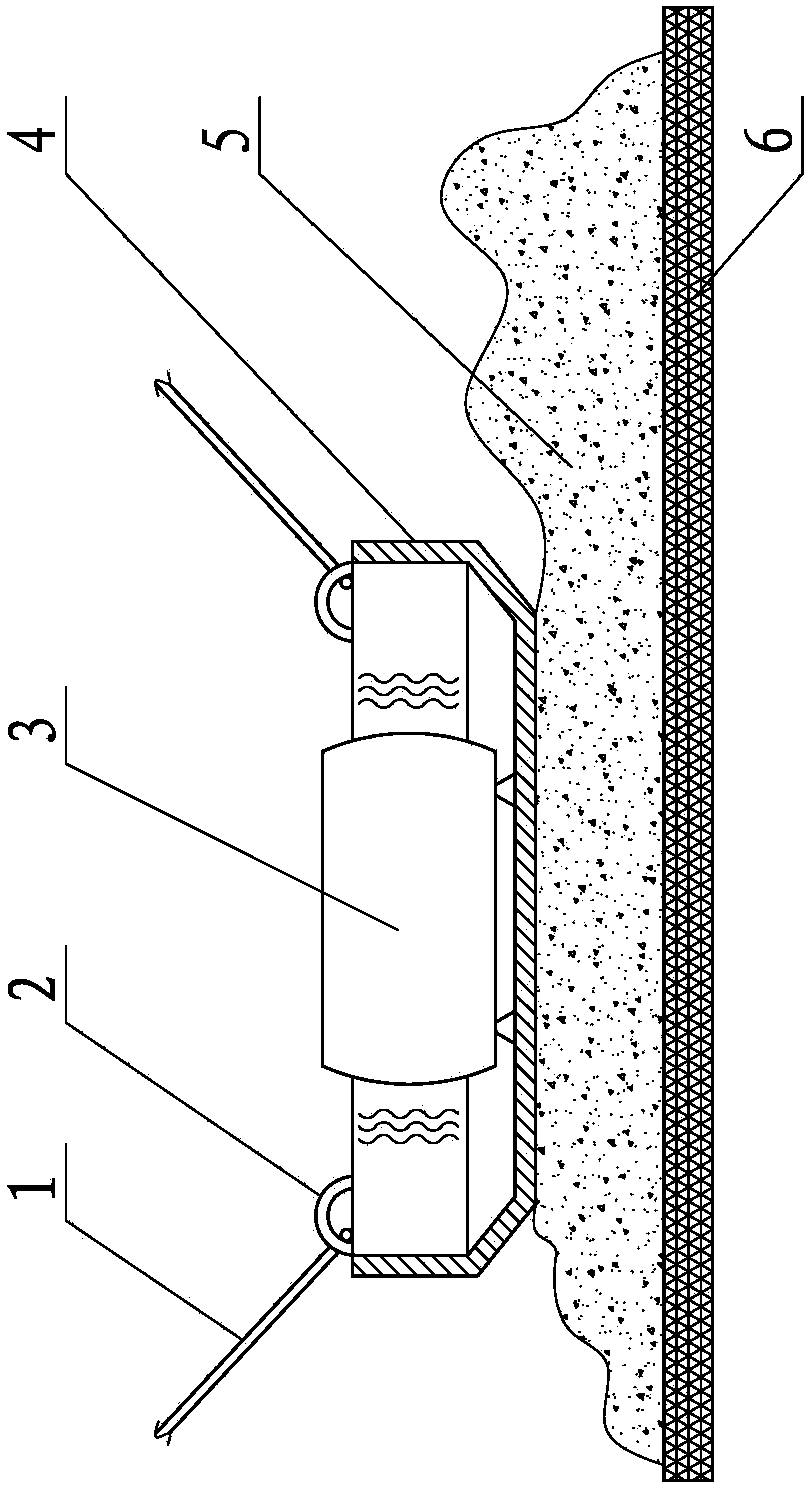

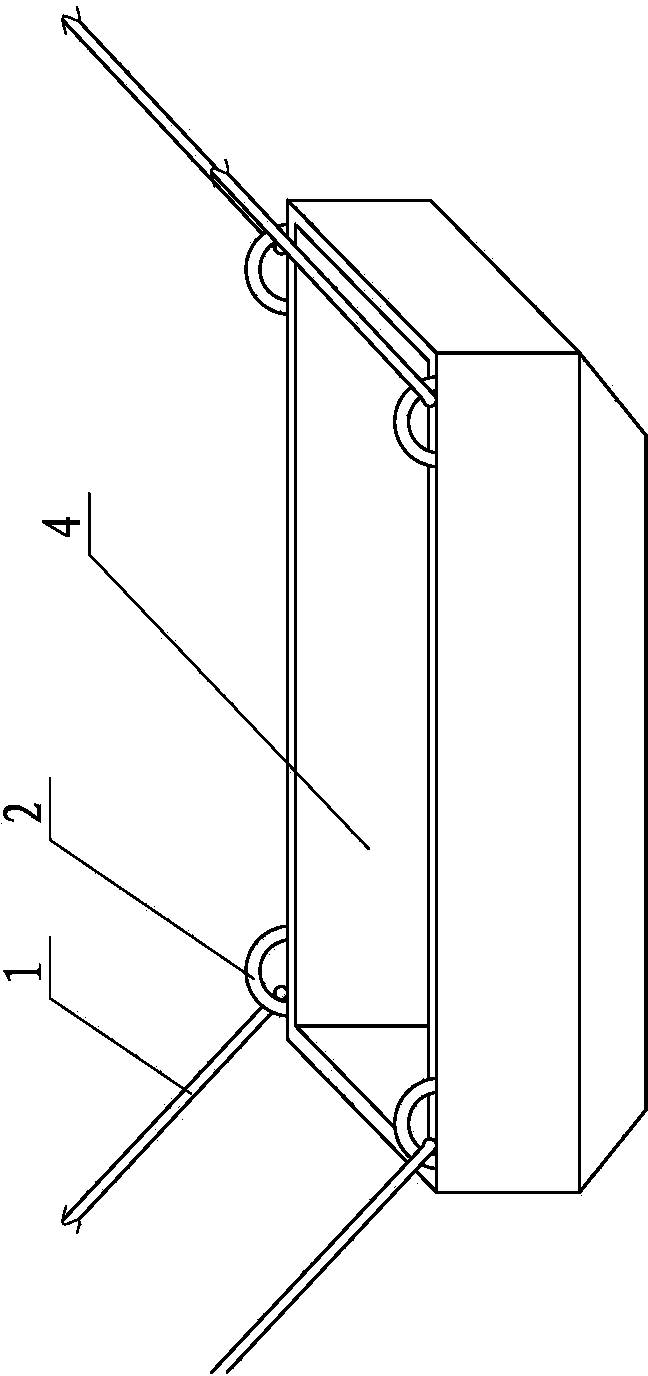

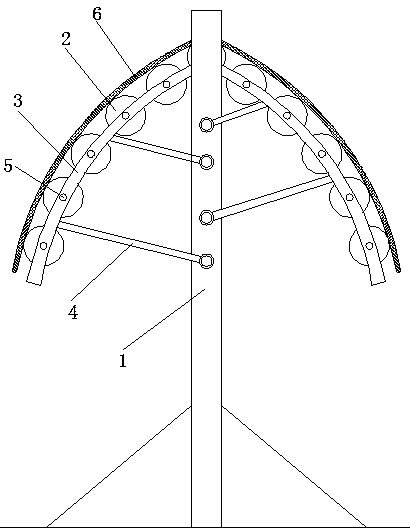

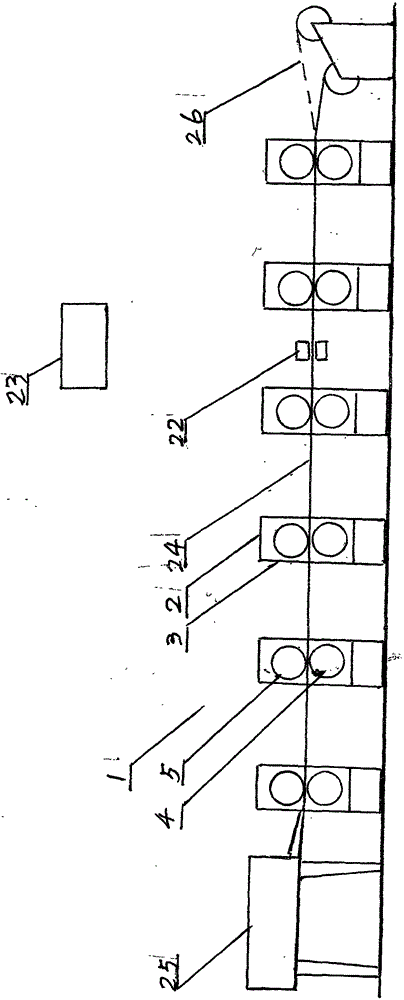

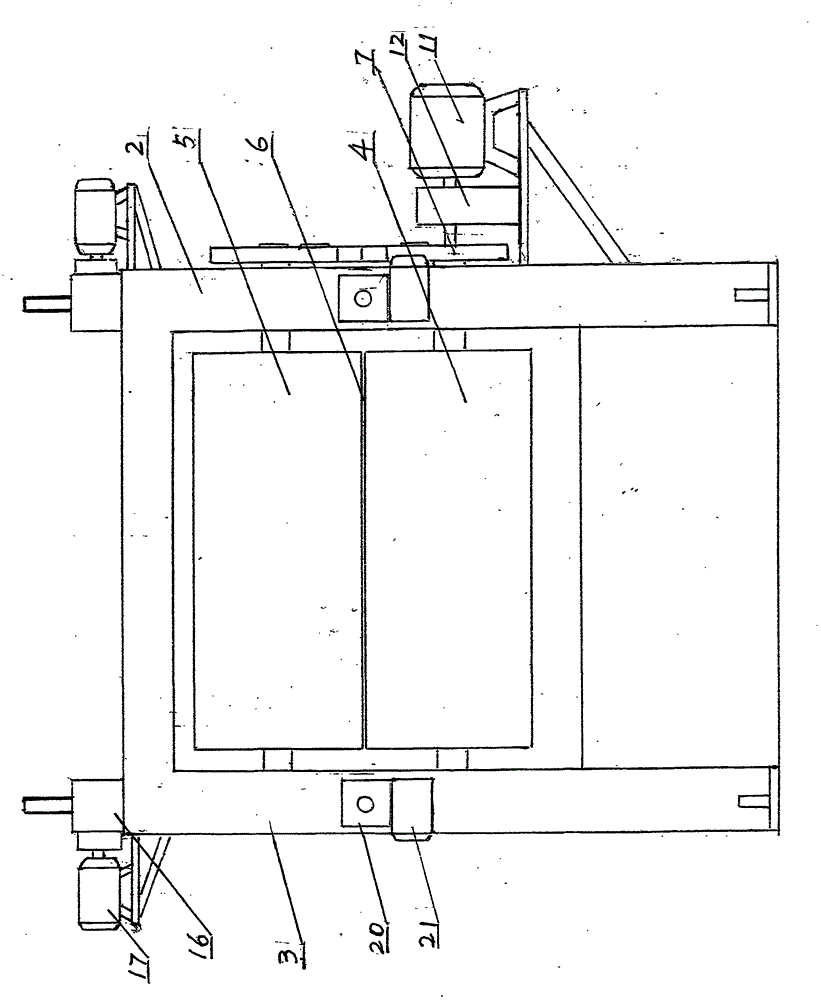

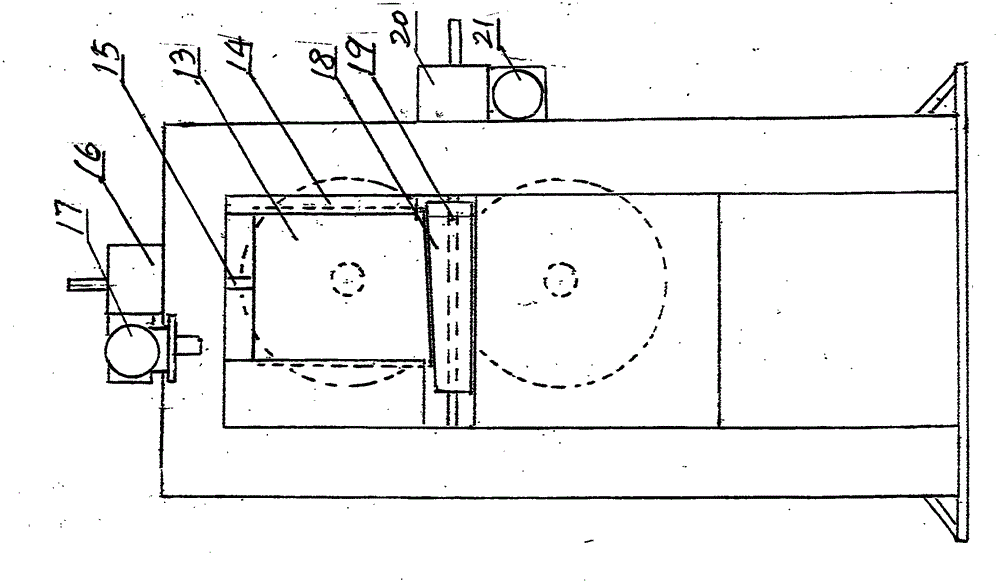

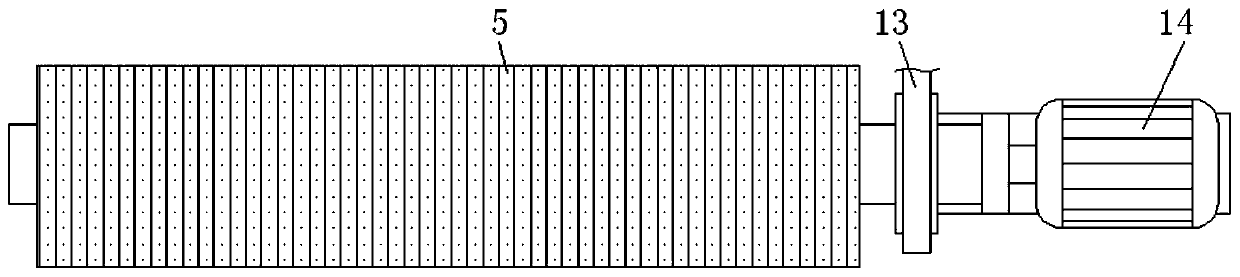

A kind of flexible graphite paper calendering device

The invention relates to the production technology of flexible graphite paper, in particular to a flexible graphite paper calendering device. The flexible graphite paper calendering device is composed of a plurality of sequentially-arranged calenders 2. Each calender is composed of a rack 3, a driving compression roller 4, a driven compression roller 5, a compression roller transmission mechanism and an adjusting mechanism for adjusting a calendering gap formed between the two compression rollers, wherein the adjusting mechanism comprises bearing boxes arranged inside the two sides of the rack, and further comprises a wedge-shaped sliding block and an electric control device of the calendering gap adjusting mechanism, the bearing boxes are in threaded connection with a screw rod of a first worm and gear mechanism, the wedge-shaped sliding block is in sliding fit with the inclined lower bottom edges of the bearing boxes and provided with the inclined upper surface, and the wedge-shaped sliding block is in threaded connection with a screw rod of a second worm and gear mechanism installed on one side of the rack. The flexible graphite paper calendering device has the advantages that independent transmission mechanisms of the calenders are arranged, the device is compact, the using effect is good, and maintenance and disassembly are convenient; the calenders with the same size and diameter are arranged at intervals, loosening and tensioning pressure is applied to graphite paper, and calendering and extending are facilitated; intelligent closed-loop control is adopted, precision of graphite paper calendering thickness is controlled to be high, and control is flexible and reliable.

Owner:黑龙江东方聚能石墨科技有限公司

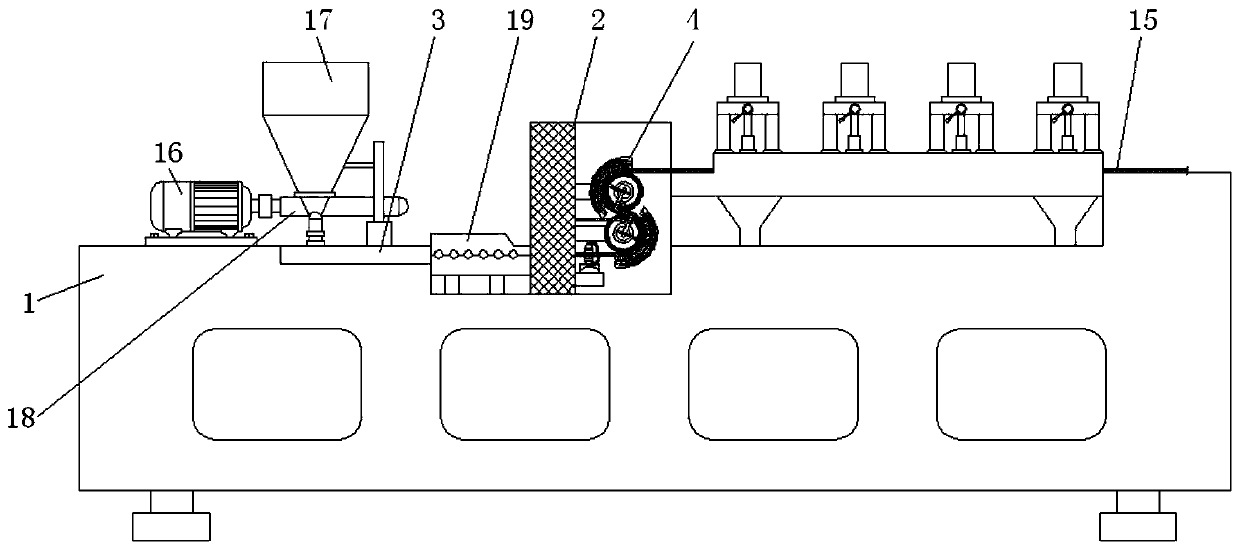

PVC free foaming plate production equipment

ActiveCN111267329AImprove smoothnessImprove straightnessSpraying apparatusFlat articlesProcess engineeringMachine

The invention relates to the technical field of plastic processing, and discloses PVC free foaming plate production equipment. The equipment comprises a machine body, wherein a calendaring mechanism is fixedly connected to the middle of the upper surface of the machine body; a material conveying cavity is fixedly connected to the left side of the upper surface of the machine body; a feed hopper isfixedly connected to the top of the material conveying cavity; and a servo motor is fixedly connected to the portion, on the left side of the feed hopper, at the top of the machine body. According tothe PVC free foaming plate production equipment, the sides, opposite to each other, of an upper rotating roller and a lower rotating roller are each uniformly and fixedly connected with eight rotating rods; when foaming material moves, the foaming material moves in the same direction with the rotating rods in contact with the foaming material correspondingly, so that the sticking situation amongthe rotating rods and the foaming material is avoided, and the smoothness of a foaming plate produced by the PVC free foaming plate production equipment is improved; meanwhile, the original sliding friction contact mode is replaced by the sliding connection, so that the heating uniformity of the foaming material is improved; and an adjustable smoothing plate is parallel to the tangent plane at thetop of the corresponding upper rotating roller, so that the flattening effect of the foaming plate is improved.

Owner:ZHEJIANG YONGYU FURNITURE CO LTD

Material used in ballscrew

ActiveCN102719765BOvercome weaknessImprove internal organizational structureGearingWeaknessQuenching

The invention provides a material used in a ballscrew. The material comprises the following components in percentage by weight: 0.58-0.63% of carbon element, 0.5-0.80% of manganese element, less than or equal to 0.015% of phosphorus element, less than or equal to 0.015% of sulfur element, 0.15-0.35% of silicon element, 0.10-0.25% of chromium element, less than or equal to 0.20% of copper element, less than or equal to 0.10% of molybdenum element, less than or equal to 0.20% of nickel element, less than or equal to 0.05% of vanadium element, 0.020-0.040% of aluminum element, and the balance iron element. Steel smelted by adopting the alloy-elements-containing material of the invention overcomes weaknesses of GCr15 steel completely, improves internal organizational structure of the steel, reserves the original advantages of the GCr15 steel, is easy-cutting and easy-calendering, and improves the quenching brittleness and deformation ability; in addition, the material of the invention is particularly suitable for production adopting a cold-rolling technology; therefore, the traditional productive technology of the ballscrew is completely changed, and excellent social and economic effects are created.

Owner:安徽省威远精密工业科技有限公司

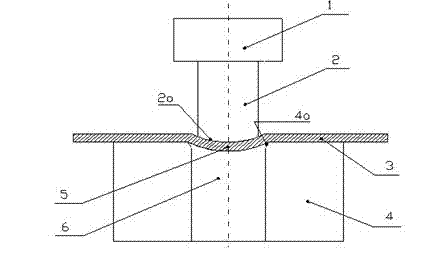

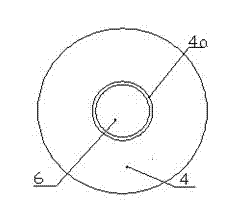

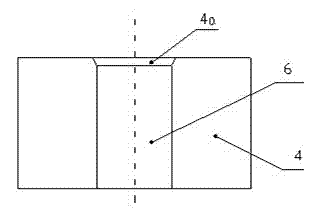

Steel plate surface blind hole punching die

The invention discloses a steel plate surface blind hole punching die. The steel plate surface blind hole punching die comprises a convex die installed on a plunger chip of a punch, and a concave die arranged on a punch base, wherein a through hole is formed in the centre of the concave die; the diameter of a column of the convex die is less than that of the hole in the centre of the concave die; and the impacting surface of an impacting head of the convex die is arc shaped. According to the steel plate surface blind hole punching die, the freedom degree on the direct contact between a lower stopping point of the convex die and a lower forming part of a blind hole of the concave die is released, and therefore, the surface of a steel plate is stretched to be formed within an elastic range through a material, so that the wear of the die is reduced, the work hardening is achieved, the mechanical performance of a product is improved, the rigid contact of the convex die and the concave die is avoided, punching equipment is avoided being damaged, the feasibility and the reliability in the rigid punching production are achieved, and the service life of the die is prolonged; after the improvement on the die, the arc-shaped concave pit type blind hole processed by the concave die can be formed relatively precisely, and has low deformation, and the cost of processing is relatively low.

Owner:CHENGDU ZHONGHONG RAIL TRANSIT ENVIRONMENTAL PROTECTION IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com